A centering device for verifying or calibrating the installation of the flow meter to be tested

A centering device and flowmeter technology, applied in the field of measurement, can solve the problems of affecting the accuracy of verification or calibration, low efficiency, and inaccurate installation and alignment, and achieve the goal of eliminating potential safety hazards, accurate alignment, and ensuring accuracy of verification or calibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

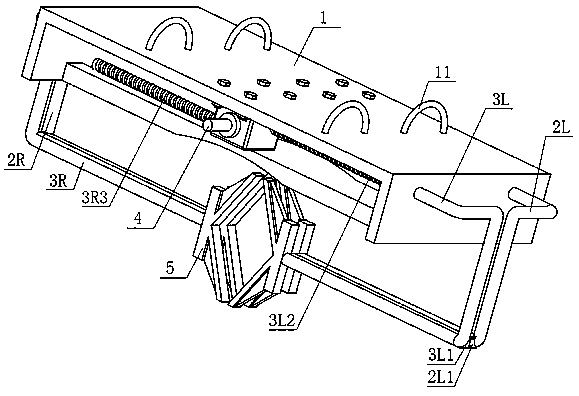

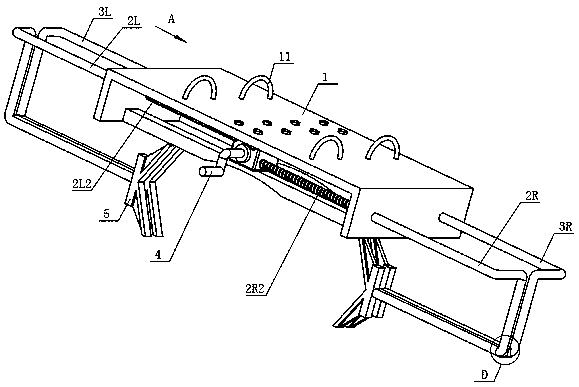

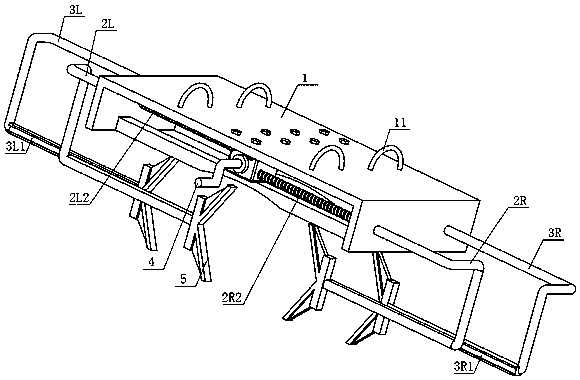

[0021] Such as figure 1 As shown in -8, a centering device for verifying or calibrating the flowmeter to be tested includes a frame body 1 and a rotating shaft 4 . The frame body 1 is U-shaped. The bottom of the frame body 1 faces upwards, the left and right sides are perpendicular to the bottom, and the frame body opening faces downwards. Hanging lugs 11 are connected to the outer surface of the bottom of the frame body 1 to facilitate the movement of the frame body 1 . A turbine case 12 is fixedly connected to the inner surface of the bottom of the frame body 1 .

[0022] The rotating shaft 4 is a cylinder, and the central axis is parallel to the left and right sides of the frame body 1 . The two ends of the rotating shaft 4 extend out of the turbine case 12 . Stretch out the rotating shaft 4 of worm case 12 front ends to be fixedly connected with rotating shaft handle.

[0023] figure 2 , 3 Among them, the end of the frame body 1 with the shaft handle on the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com