Automatic demolding device

An automatic demoulding and separation device technology, applied in the field of mold casting, can solve problems such as easy misoperation, deformation of sand mold, uneven force on sand mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

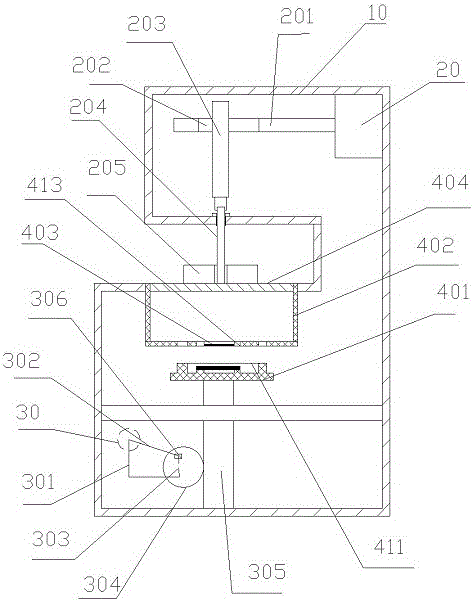

[0016] Embodiment 1 is basically as attached figure 1 Shown: an automatic demoulding device, including a frame 10, a mold body, a first separating device and a second separating device. The mold body includes an upper mold 404, a lower mold 403, a mold body 401 and a mold frame 402. The mold frame 402 is detachably installed in the middle of the frame 10. The shape and size of the upper mold 404 are slightly smaller than the mold frame 402. The upper mold 404 can Slide in the mold frame 402, the lower mold 403 is fixedly connected on the bottom surface of the mold frame 402, the lower mold 403 is provided with a mold groove 413 that runs through the lower mold 403, the mold body 401 is separated from the lower surface of the lower mold 403, and the mold body 401 There is a protrusion 411 opposite to the mold groove 413. The shape of the protrusion 411 is the external shape of the part. Lifting the mold body 401 can make the material in the mold body form the external shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com