Large drawing and overturning molding box closer

A box closing machine, a large-scale technology, applied in the parts of the molding machine, casting and molding equipment, and equipment for loosening the model, etc. The process is simplified, the degree of automation is high, and the labor intensity is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

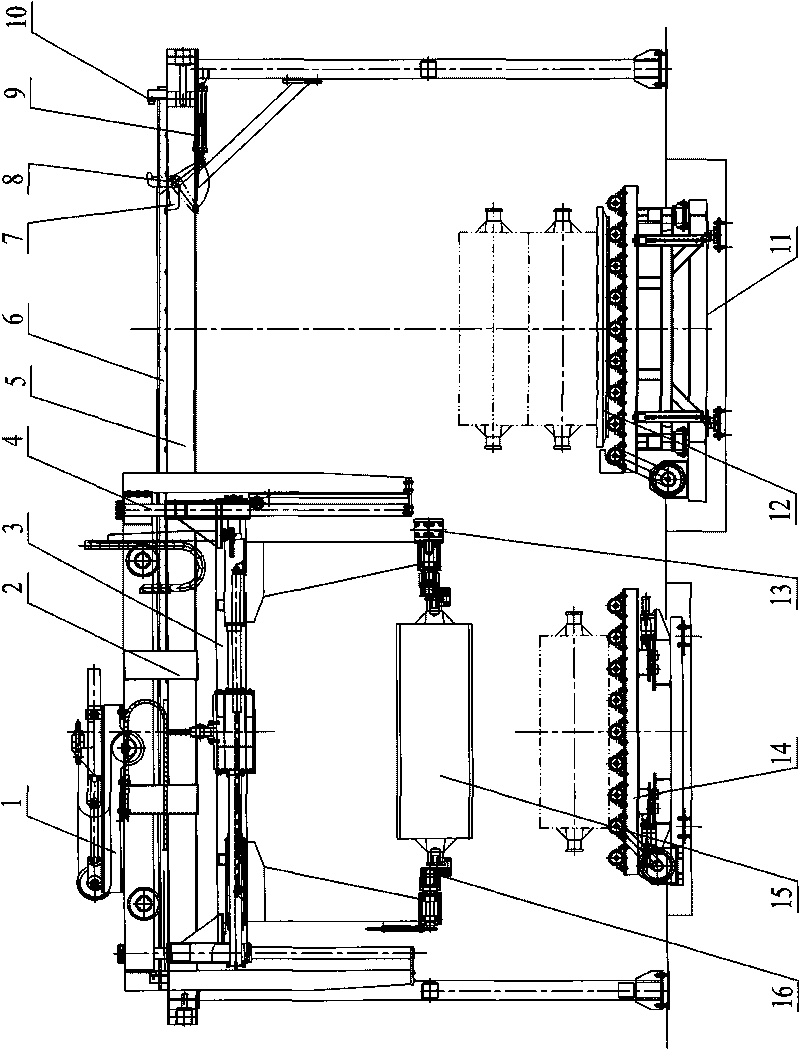

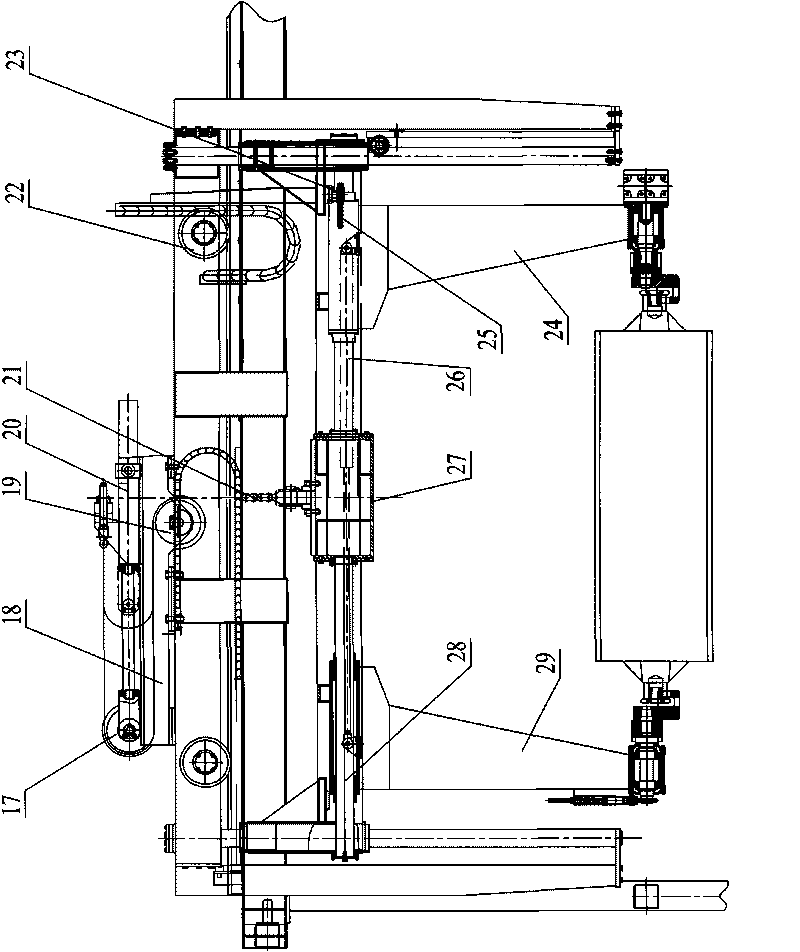

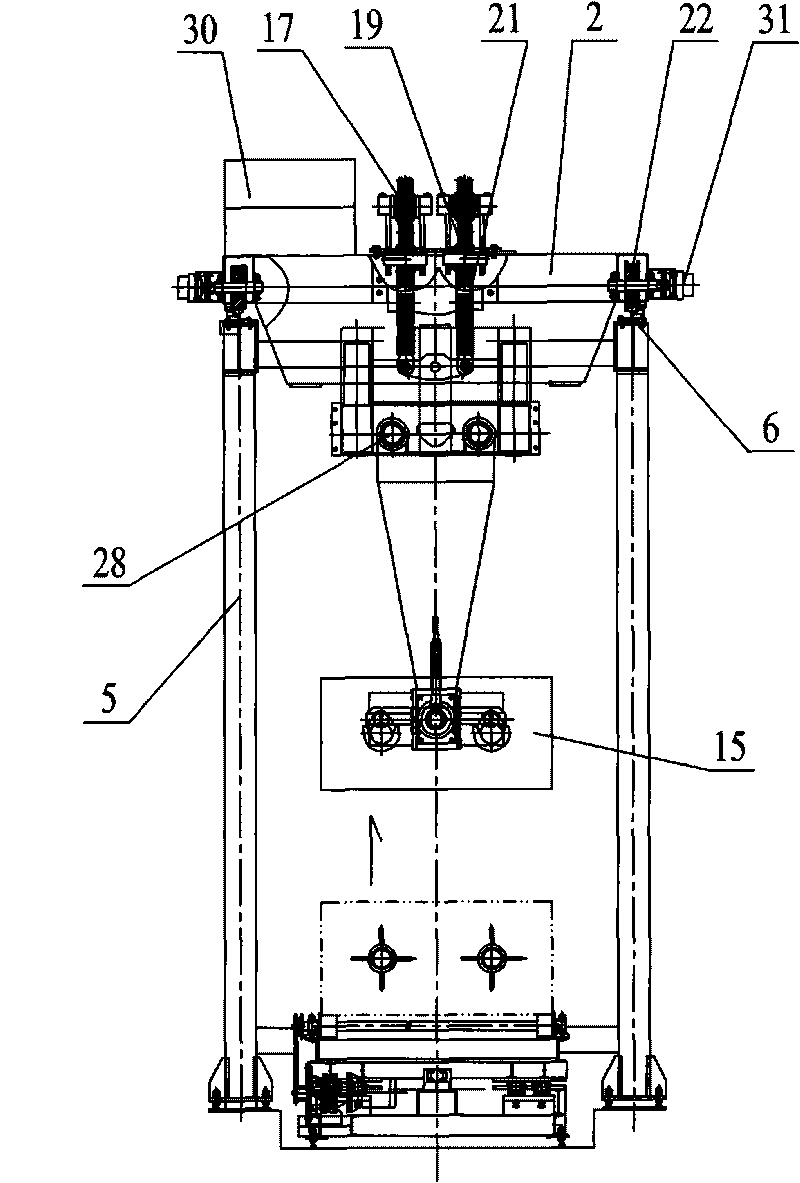

[0023] Such as figure 1 As shown, the present invention is mainly composed of a hydraulic lifting mechanism 1, a mobile frame 2, a hydraulic telescopic mechanism 3, a fixed frame 5, a pneumatic locking device, a limit baffle 10, a rotary motor 13 and a manipulator 16; The guide rail 6 is installed through bolts, and the mobile frame 2 is placed on the guide rail 6 and can slide horizontally; the right side of the fixed frame 5 is equipped with a limit baffle 10, and the limit baffle 10 is used to limit the sliding of the mobile frame 2 position; a hydraulic lifting mechanism 1 is installed on the mobile frame 2, and the hydraulic lifting mechanism 1 is connected with the hydraulic telescopic mechanism 3, and the hydraulic telescopic mechanism 3 can be lifted and dropped; a manipulator 16 is installed on the hydraulic telescopic mechanism 3, and the manipulator 16 is used for lifting and Release the sand box 15; a rotary motor 13 is installed on the manipulator 16, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com