Automatic mold drawing machine for wheel casting mold

A technology for casting molds and ejectors, applied in the field of automatic ejectors, can solve problems such as ejector sticking, affecting production efficiency, mold damage, etc., so as to increase the contact area, improve production efficiency, and facilitate removal and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

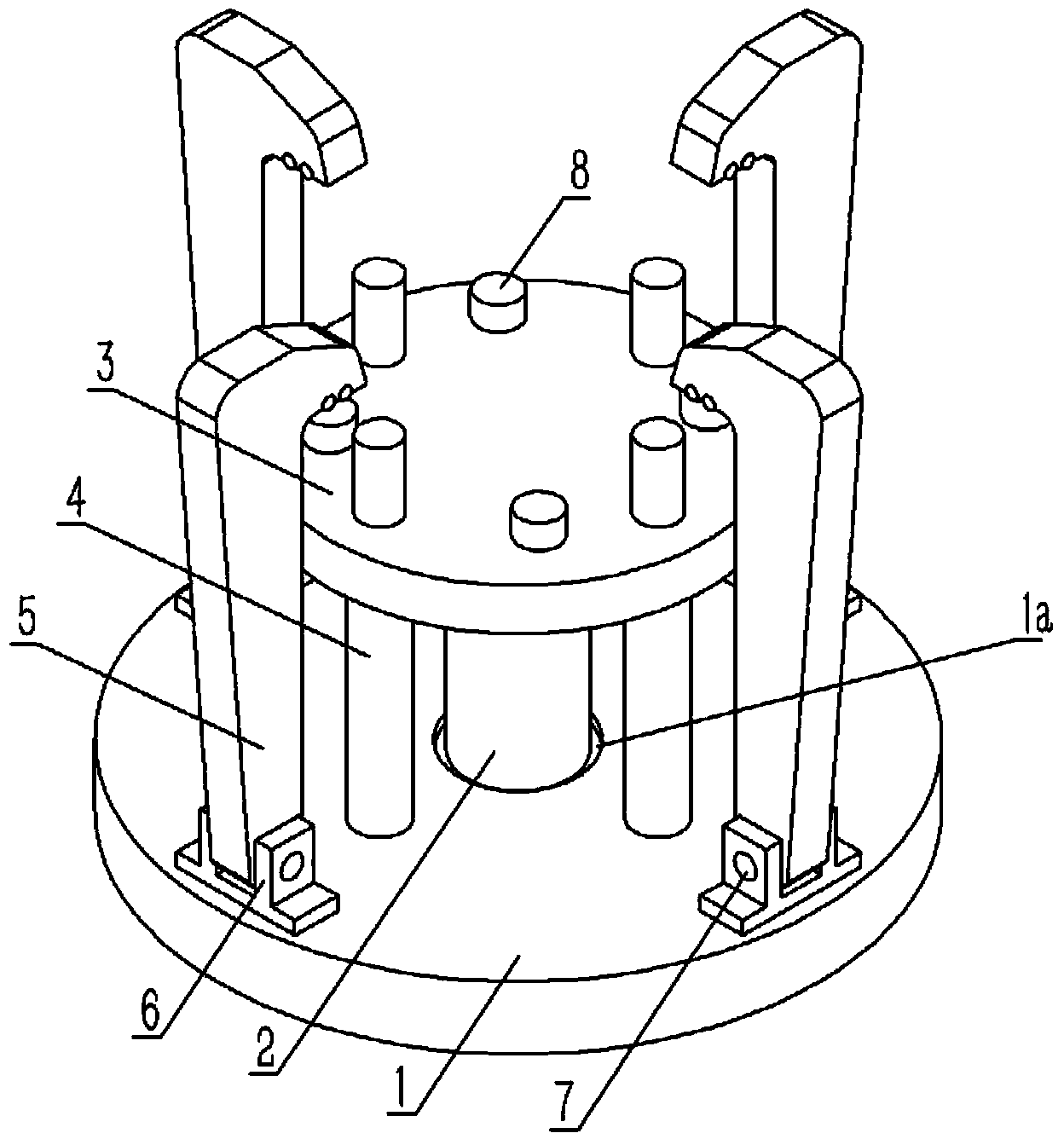

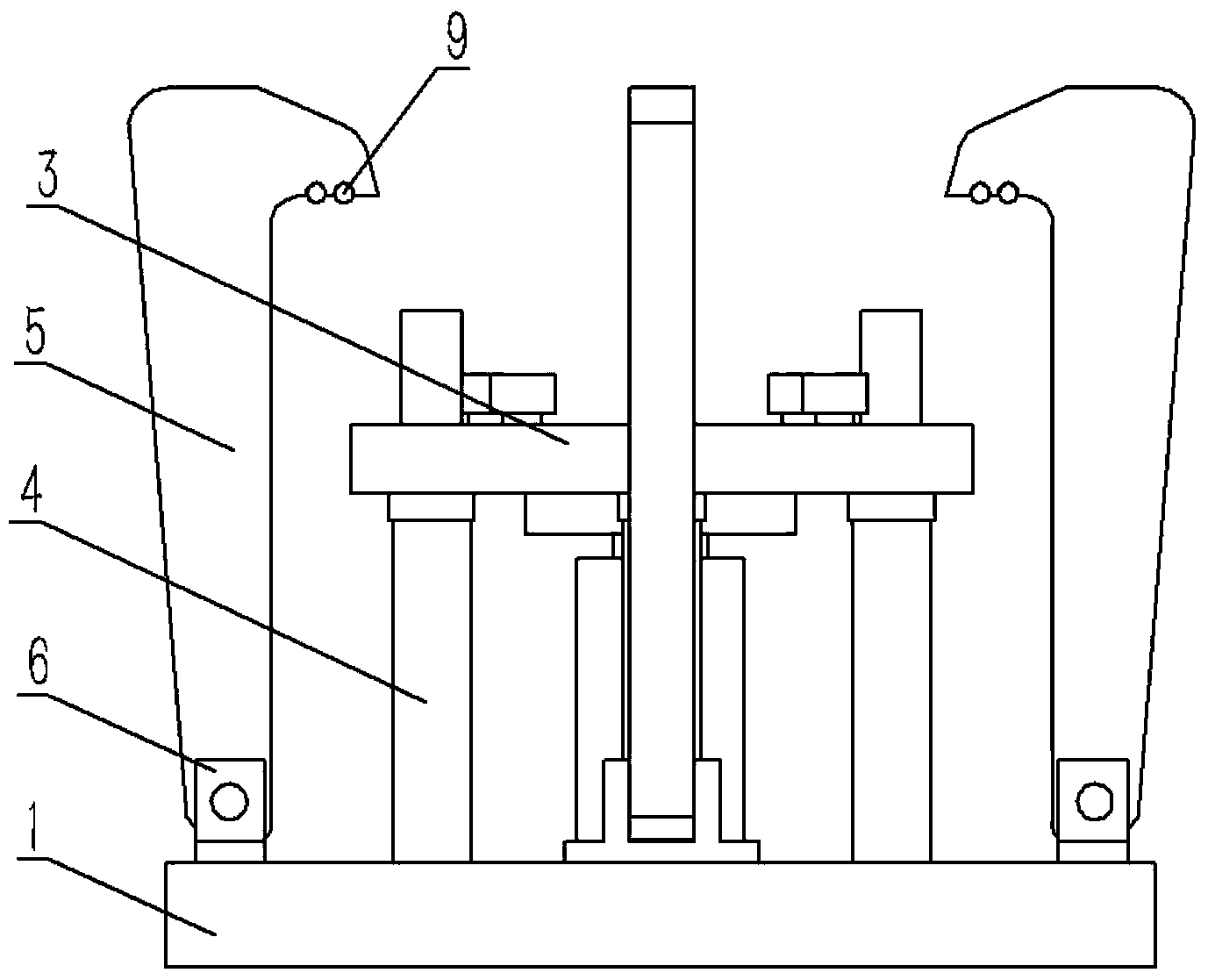

[0023] Example: see Figures 2 to 8 As shown, an automatic mold-drawing machine for a wheel casting mold includes a mold-pulling mechanism 10 and a mold mounting seat 20. The mold-pulling mechanism 10 includes a base 1, and the center of the base 1 is formed with a concave platform 1a, and the concave platform 1a of the base 1 An oil cylinder 2 is installed, and the piston rod of the oil cylinder 2 is fixed with an adjustment plate 11, the top plate 3 is pressed against the adjustment plate 11, and a number of adjustment bolts 8 are fixed on the upper end surface of the top plate 3, and the top plate 3 is plugged with A plurality of guide columns 4, the guide columns 4 are fixed on the base 1, and the outer side of the top plate 3 is provided with a plurality of drag hooks 5, and the drag hooks 5 are hinged on the base 1 through the hinge seat 6 and the hinge shaft 7;

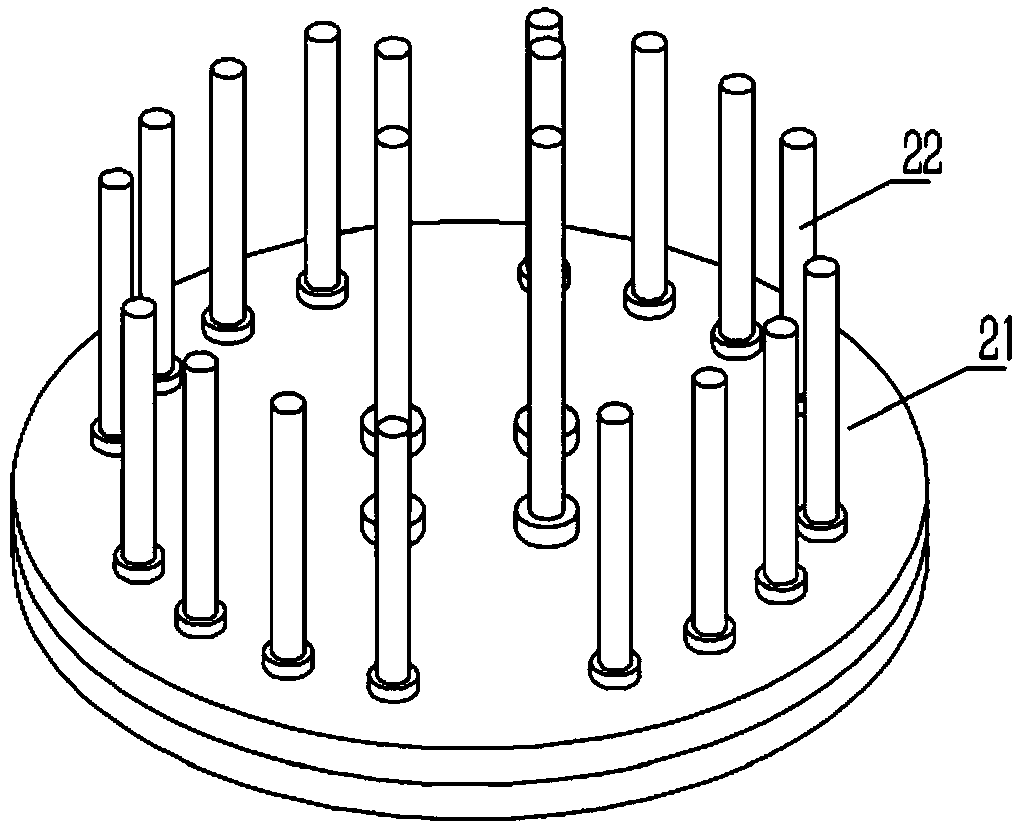

[0024] The mold mounting seat 20 includes a bottom plate 21, a screw rod 22 is fixed on the bottom plate 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com