Patents

Literature

48results about How to "Smooth exit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

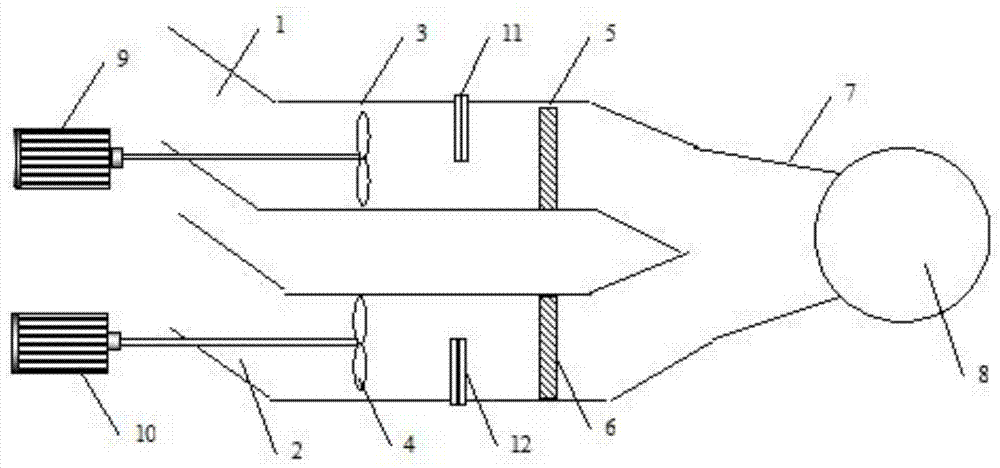

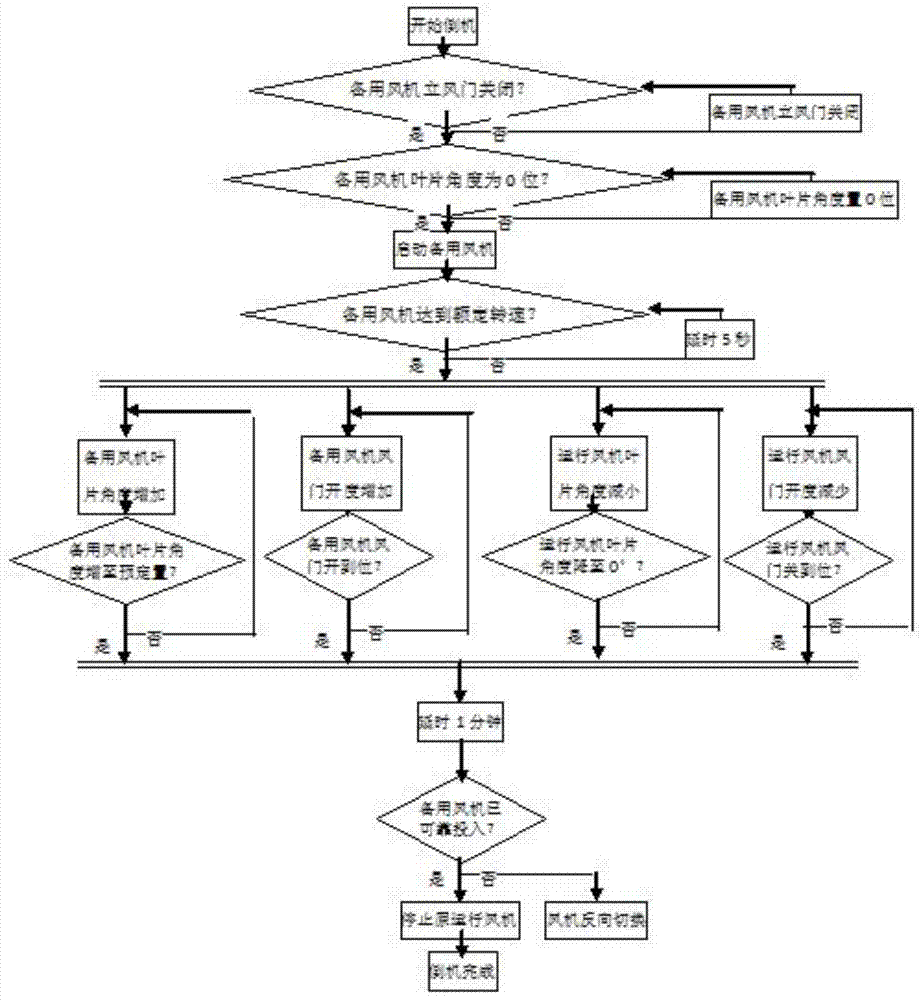

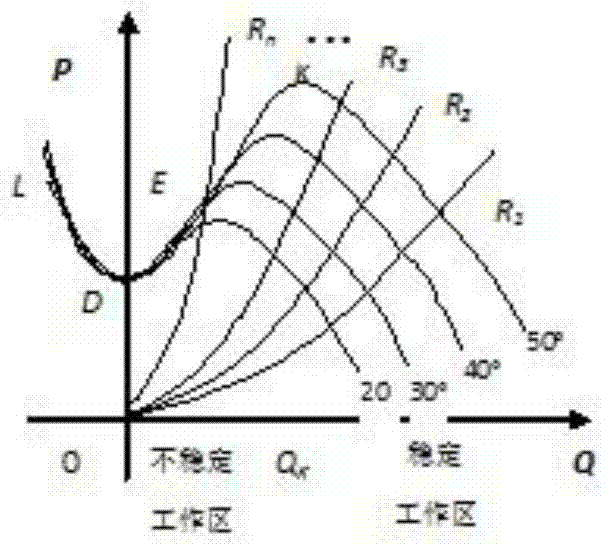

Method for replacing coal mine main fan without blowing-down on basis of adjustable moving blades

InactiveCN103883343APrevent failoverImprove the success rate of reverse machineTunnel/mines ventillationCoalAir volume

The invention provides a method for replacing a coal mine main fan without blowing-down on the basis of adjustable moving blades, and belongs to switching methods for coal mine main fans and standby fans. According to the method, in the normal fan-replacement process, two fans keep operating all the time, so that it is guaranteed that ventilation power is continuously provided; parallel connection is adopted for wind separation, the air volume is stable in the fan-replacement process, and fan replacement without blowing-down is achieved; when the fan operating normally breaks down, a synthetic judgment is given through a vibrating sensor, an air volume negative-pressure sensor, a temperature sensor and a motor electrical parameter sensor, according to abnormal degrees of the faulted fan, and early warning, placement of fault symbols and fault mode starting are sequentially carried out until fan replacement without blowing-down is achieved. The method has the advantages that fan replacement without blowing-down is achieved by means of adjustable moving blade capacity of the fans; in the whole fan-replacement process, adjustment of blade angles is combined adjustment of opening degrees of air doors, so that the air volume is adjusted; the possibility that unsmooth clamping occurs and the air doors do not reach fault points in place during opening and closing is reduced, meanwhile, the fan-replacement speed is quicken, and fan-replacement time is shortened.

Owner:CHINA UNIV OF MINING & TECH

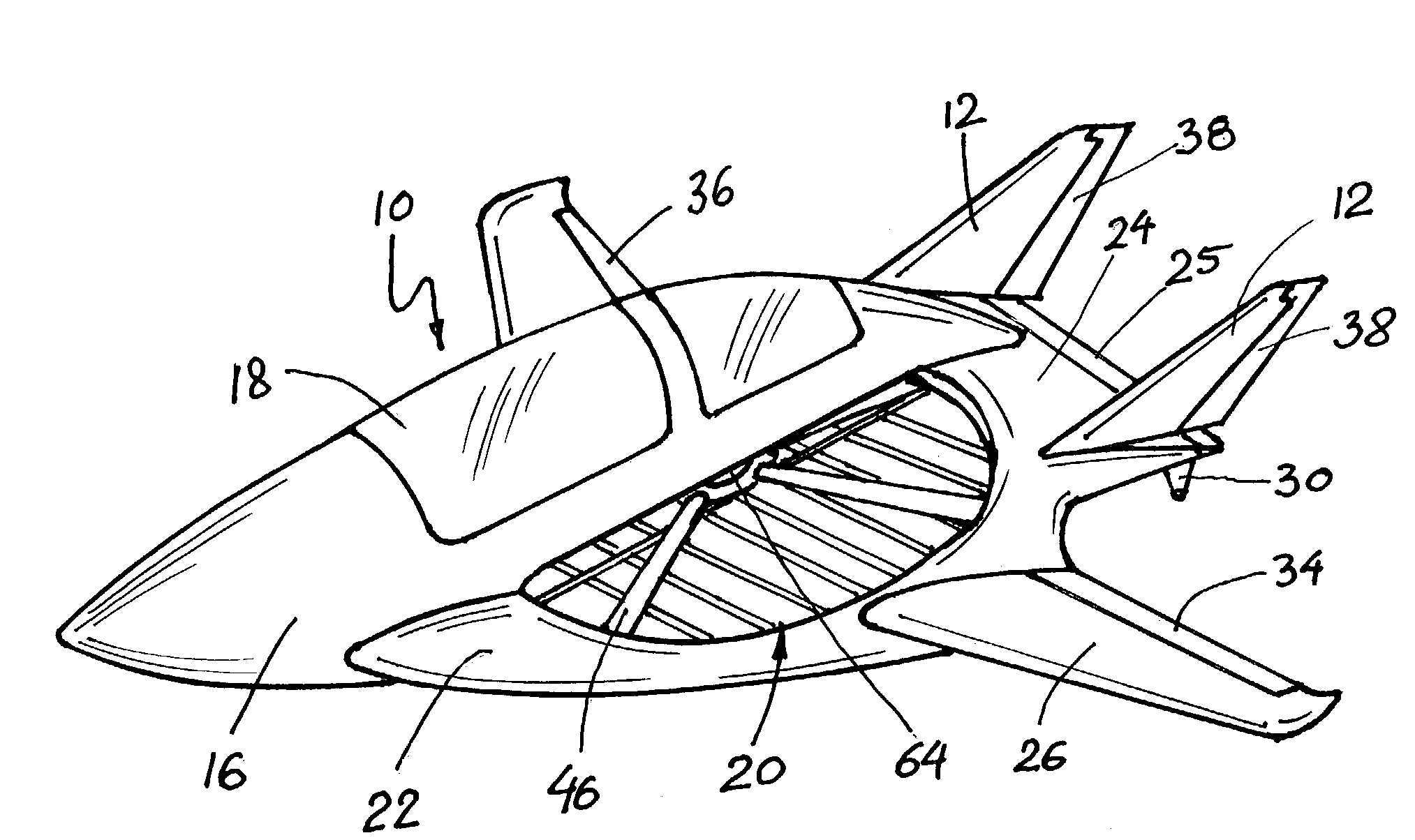

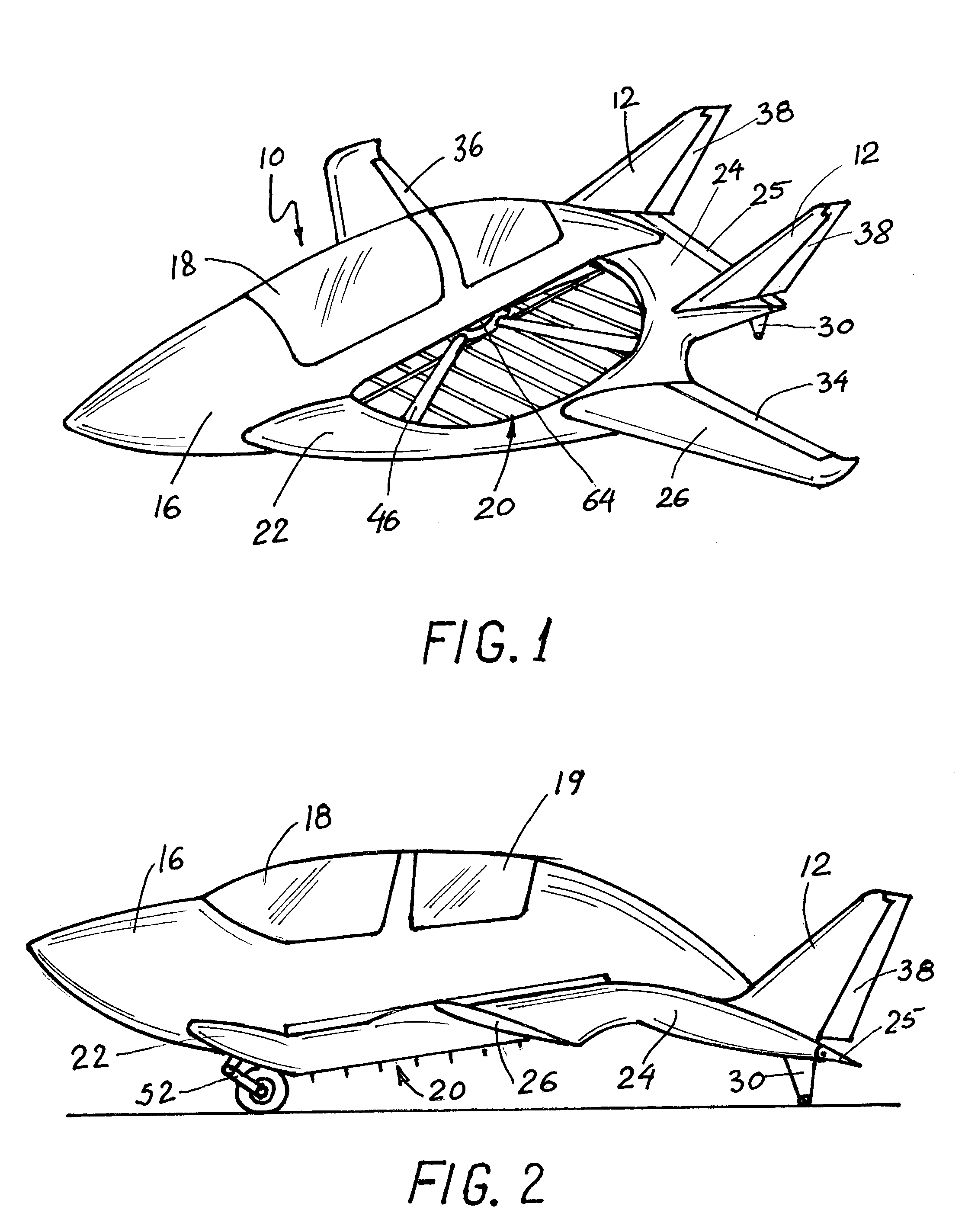

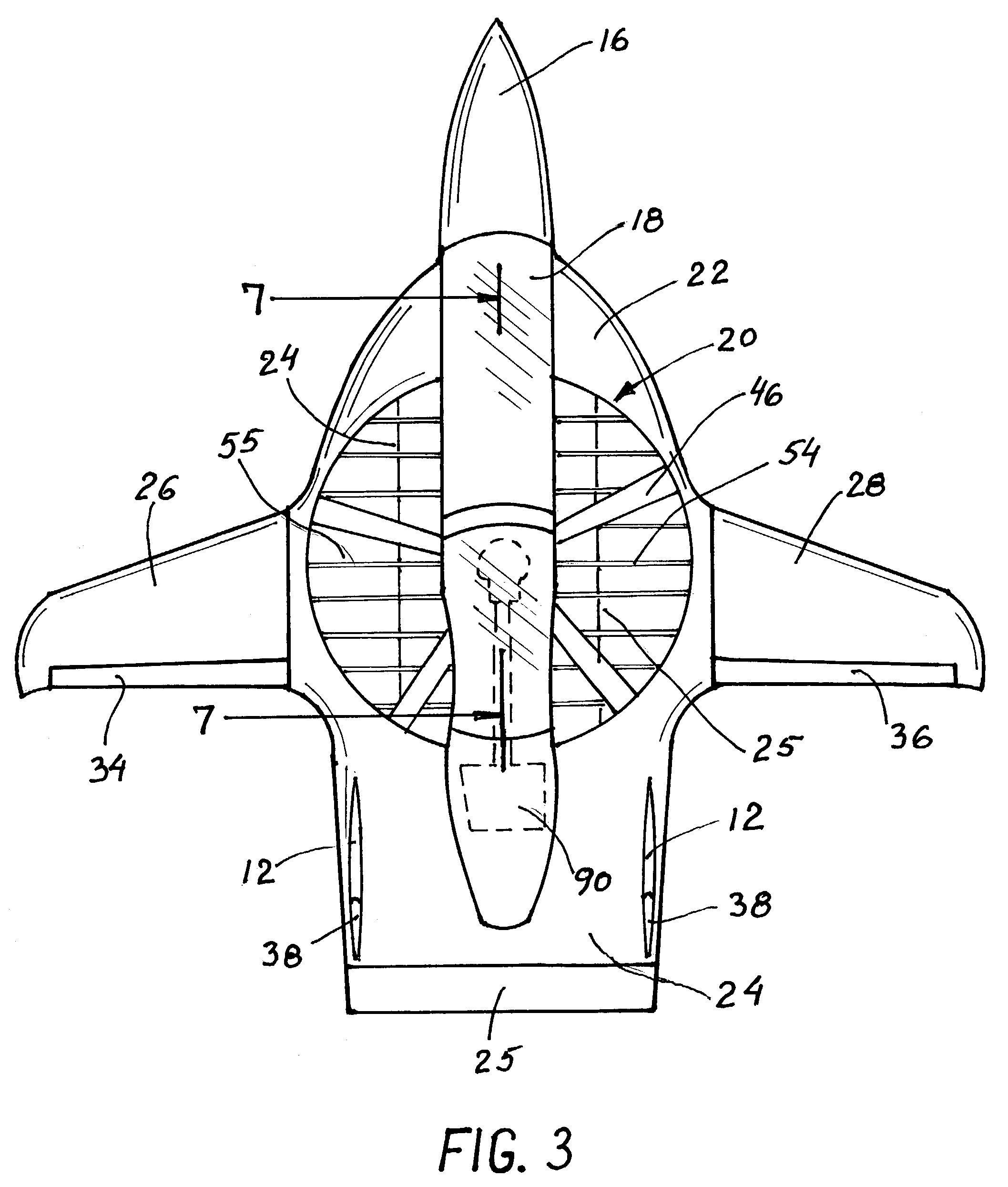

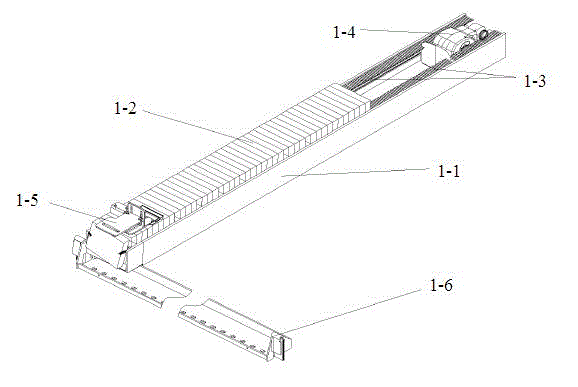

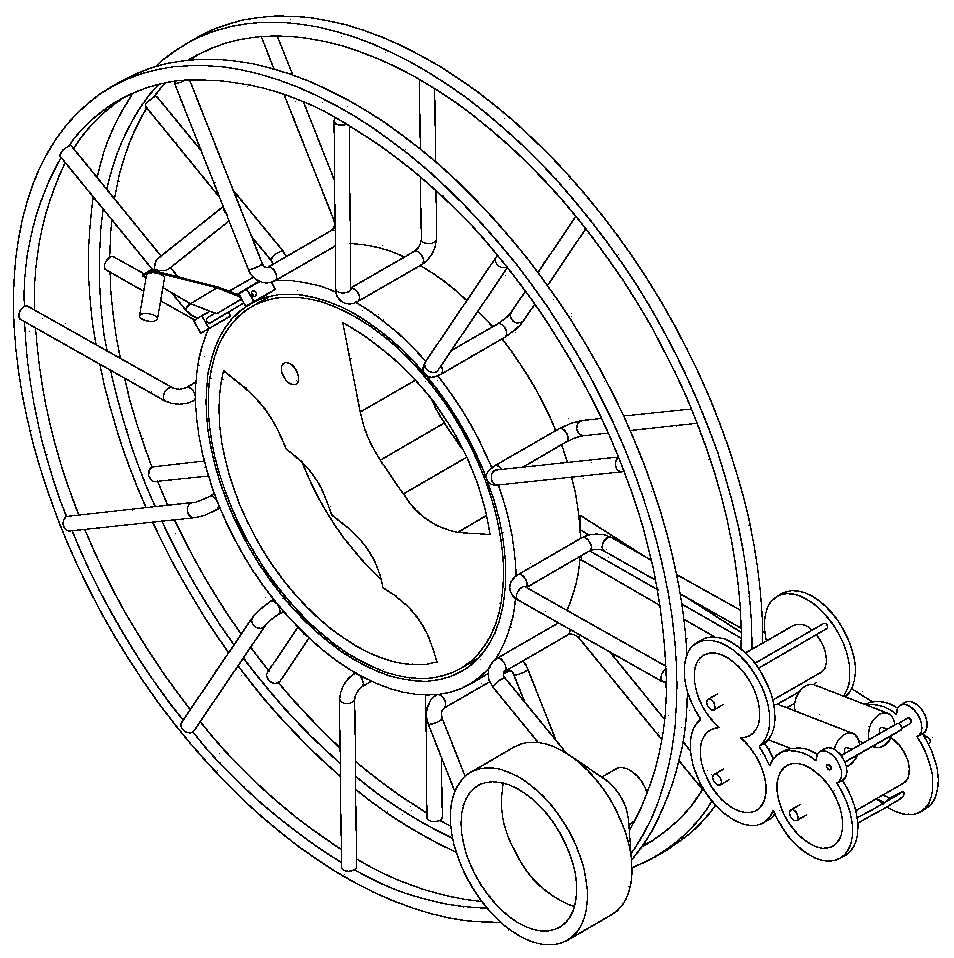

VTOL/STOL ducted propeller aircraft

InactiveUS7281680B2Avoid vibrationPrevent flutteringAircraft navigation controlVertical landing/take-off aircraftsLouverDucted propeller

The aircraft incorporates a single ducted propeller. The fuselage Bridges over the ducted propeller assembly, and is shaped in a way that the incoming air can smoothly flow into the propeller area. The duct has an aerodynamically shaped frontal area, and an aft extension, which forms the tail section. The wings are attached to the side of the duct. The ducted propeller assembly also contains louvers, which run span wise, to redirect the outgoing air in horizontal direction. During vertical take-off or landing, the propeller has a horizontal plane of rotation, after take-off the whole craft entirely tilts forward approximately 26 degrees to transition into horizontal wing born flight. During vertical flight, the aircraft is controlled by control louvers installed inside the ducted propeller assembly in the propeller slipstream.

Owner:MELKUTI ATTILA

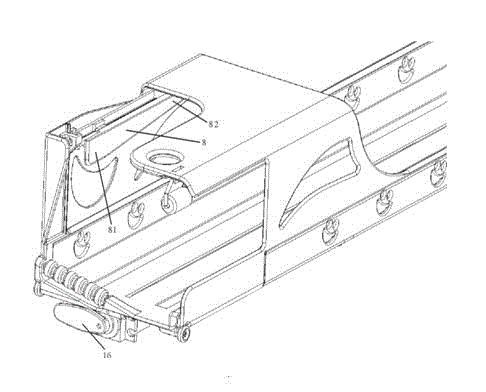

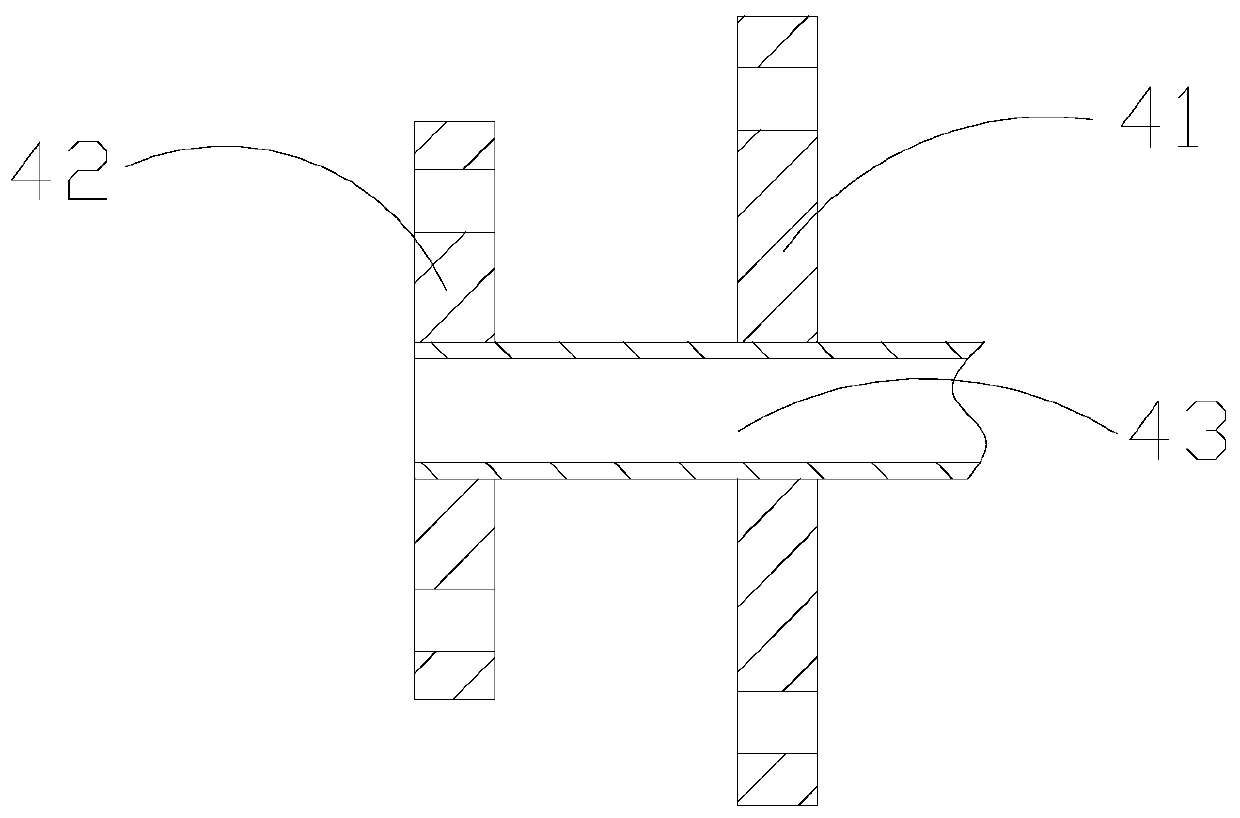

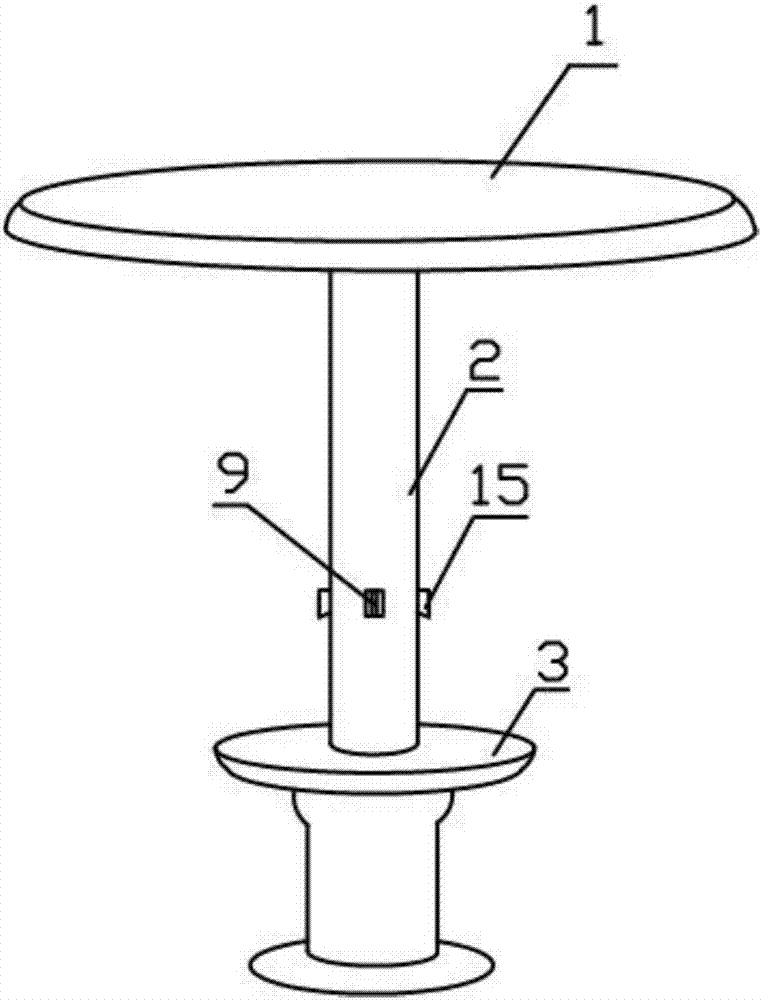

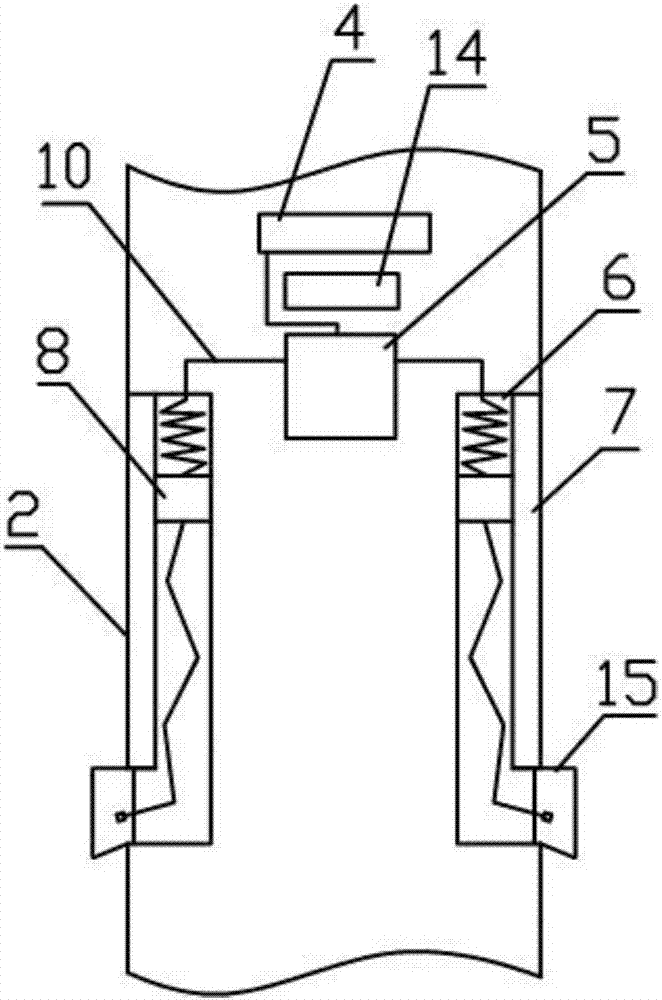

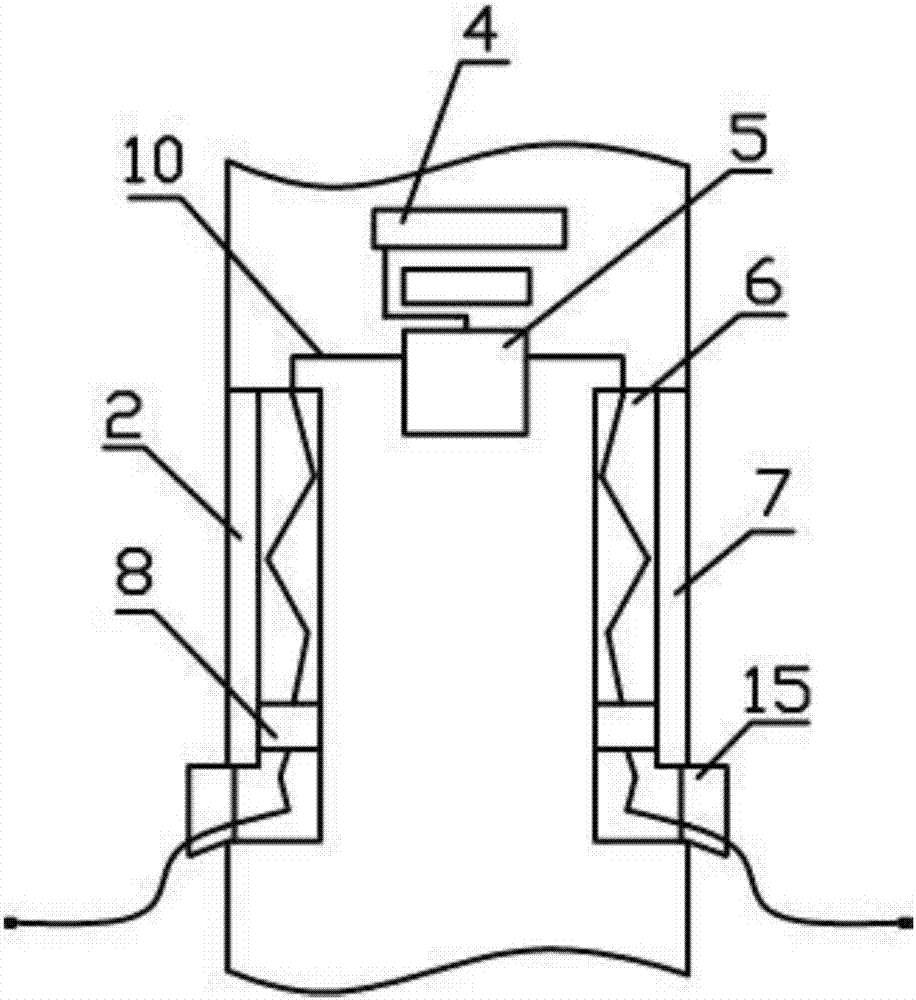

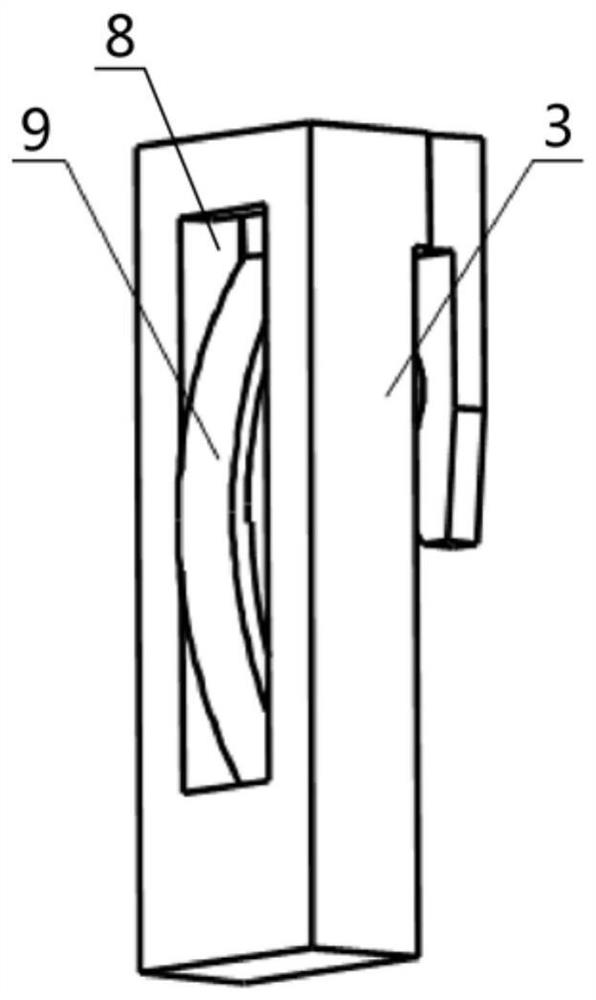

Drawer type boxed article distributing device

ActiveCN102874535ASimple processSimple structureCoin-freed apparatus detailsStorage devicesCamElectrical and Electronics engineering

The invention discloses a drawer type boxed article distributing device. The device comprises an article storage channel, an article inlet and an article outlet, wherein a bottom plate is arranged in the article storage channel; two sides of the bottom plate are connected with a first partition board and a second partition board; the first partition board and the second partition board extend upwards at the front end of the article storage channel close to the article outlet and are connected with a device for preventing articles from being gathered; and a lower baffle plate for preventing the articles from sliding downwards and a cam for uplifting one end of a first box of articles first are arranged at the article outlet. The drawer type boxed article distributing device has the advantages of simple structure and convenience for operation; and by the drawer type boxed article distributing device, boxed articles can be smoothly taken out of warehouses through the outlet, and the working efficiency is improved. Preferably, a first guide plate and a second guide plate are arranged on the drawer type boxed article distributing device, so that the boxed articles are prevented from being uplifted or sliding towards side wings when sliding in the article storage channel, and can be stacked neatly and taken out of the warehouses uniformly.

Owner:JIANGSU XUNJIE HARNESS TECH

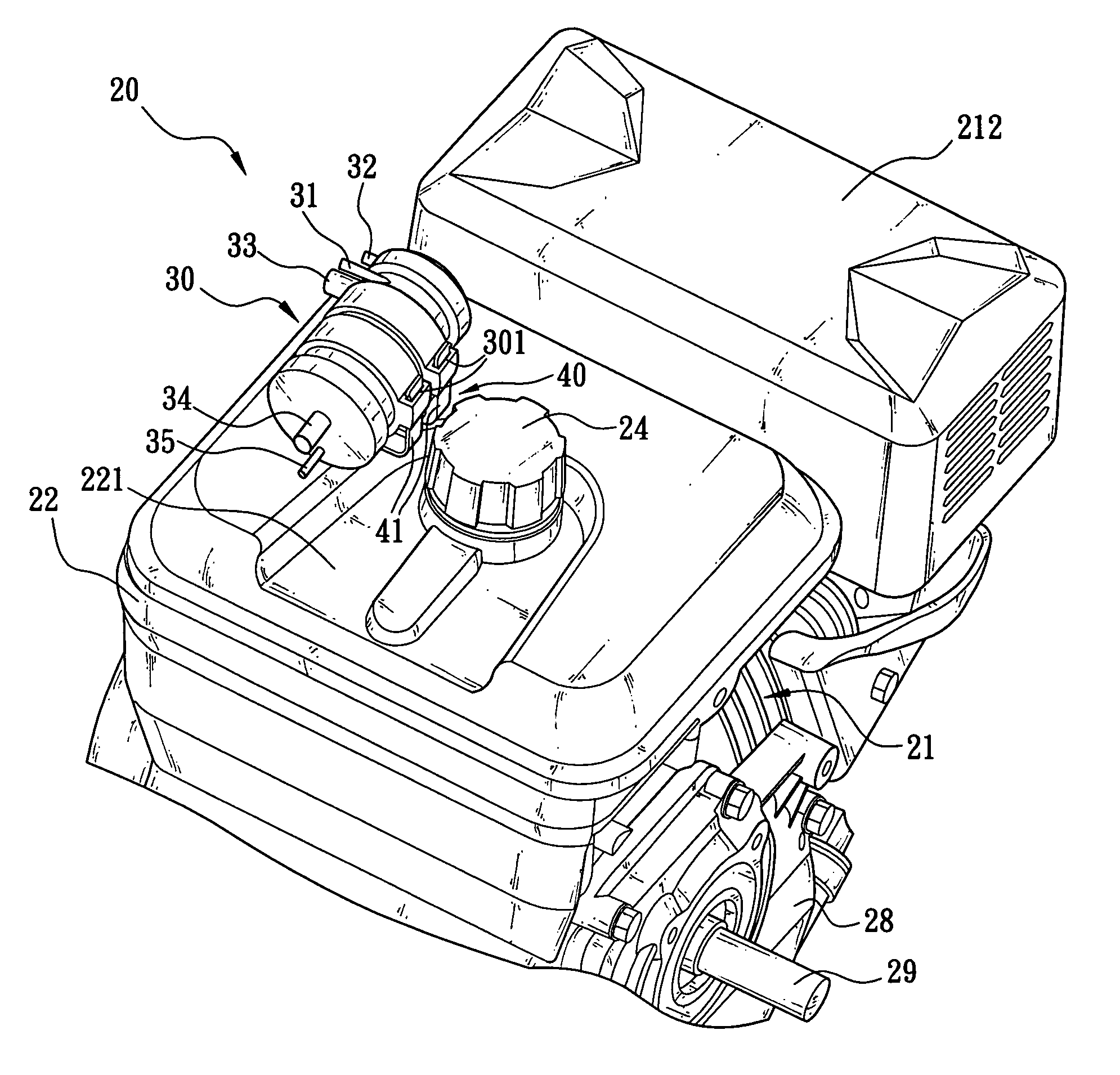

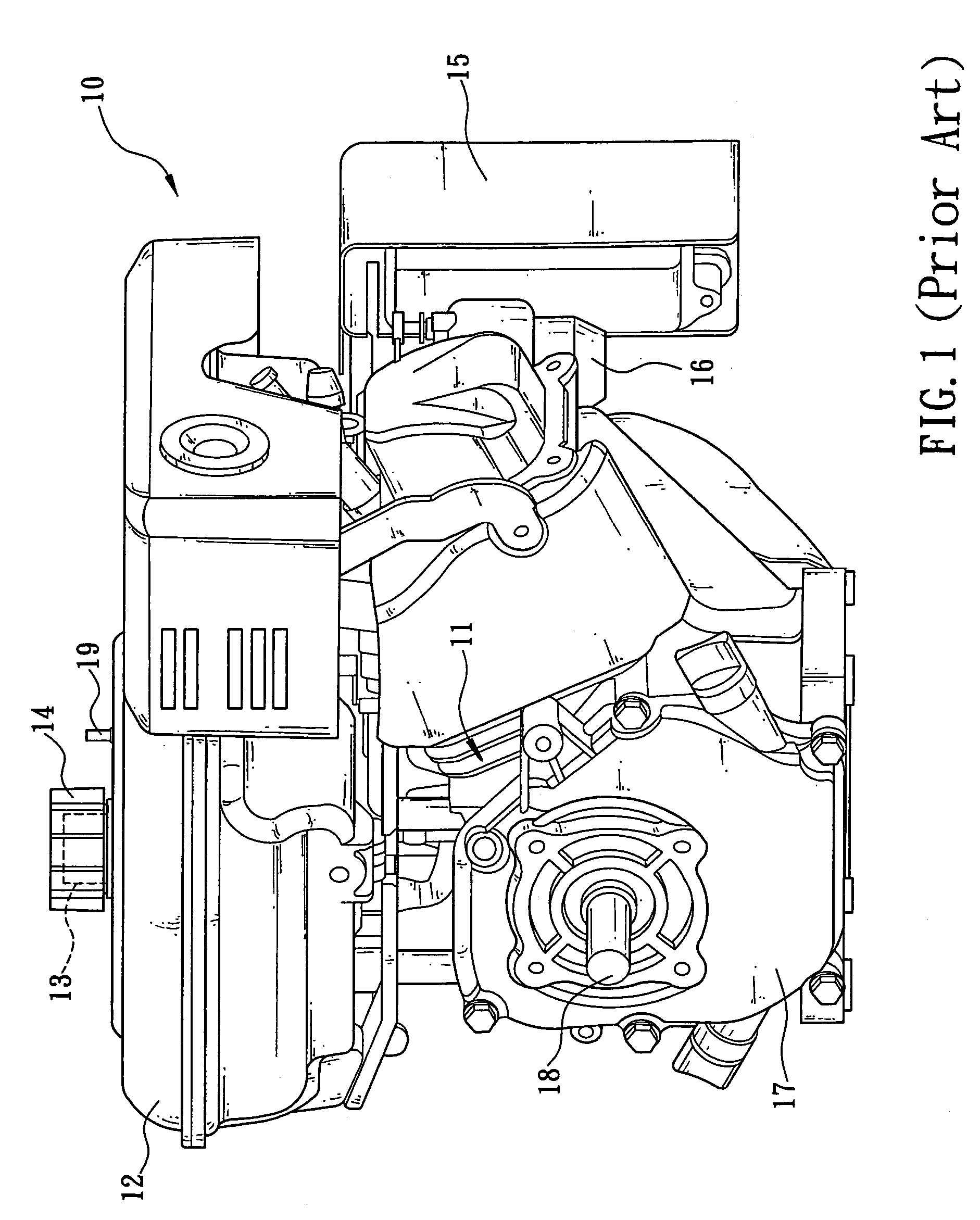

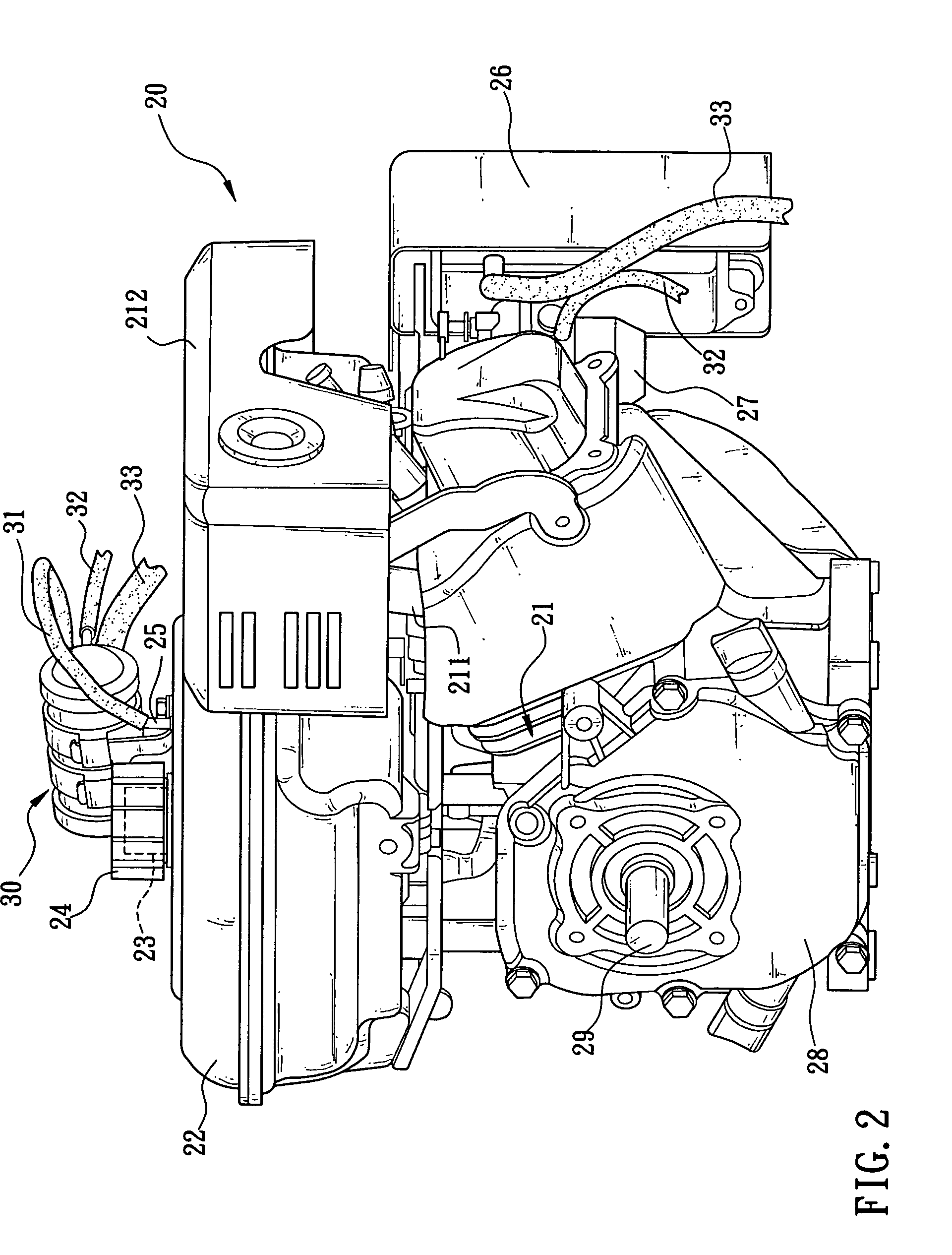

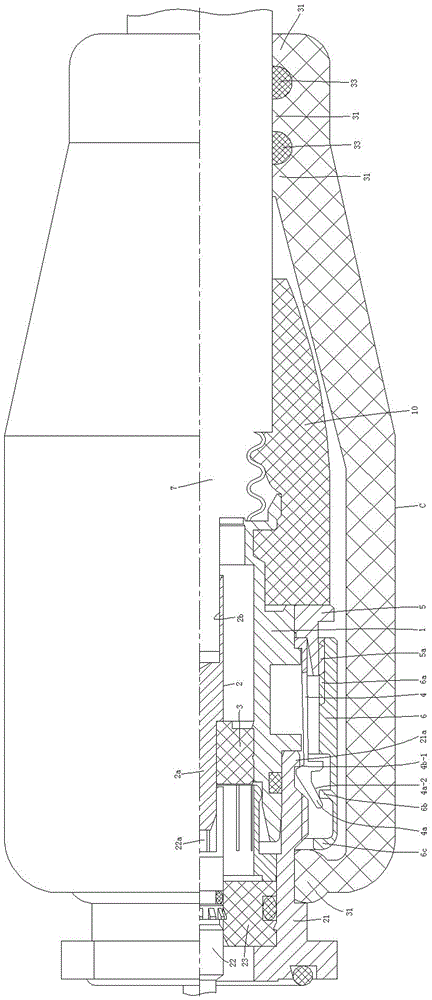

Gas filtering and recirculating device for general machine

InactiveUS7100580B2Smooth exitCompromise functionNon-fuel substance addition to fuelMachines/enginesAtmospheric airFuel tank

The present invention relates to a gas filtering and recirculating device for a general machine having an engine and a fuel tank provided above the engine, which is mountable above the fuel tank and comprises at its one end an air outlet in fluid communication with atmosphere and an oil drain below the air outlet and above the fuel tank such that the oil drain is proximate the fuel tank, enabling the gas filtering and recirculating device to completely filter and absorb gas generated by fuel in the fuel tank and prevent the gas from discharging into the atmosphere via an air outlet in the fuel tank and causing air pollution.

Owner:KYMCO

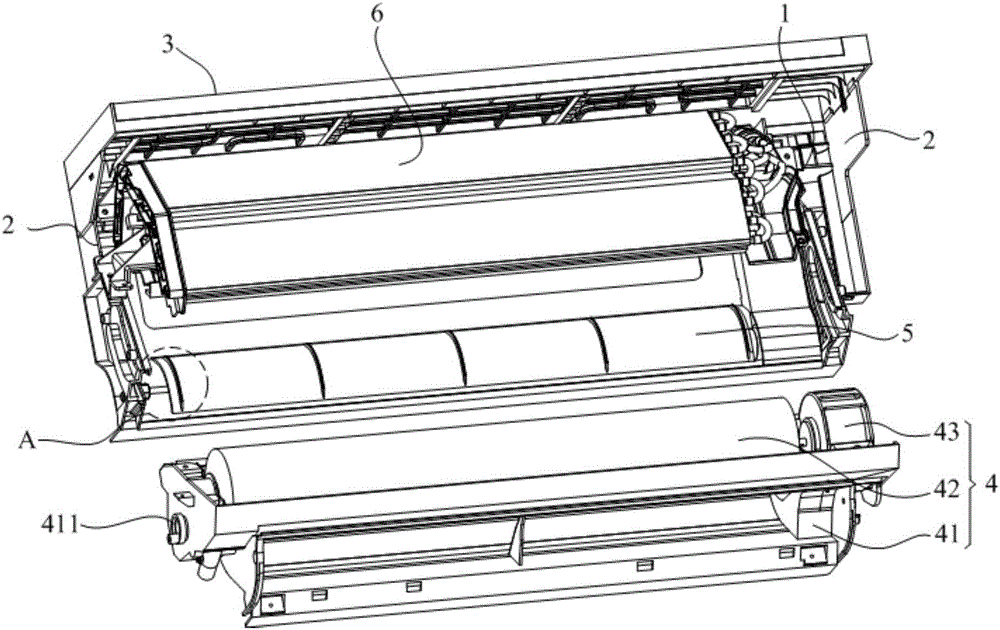

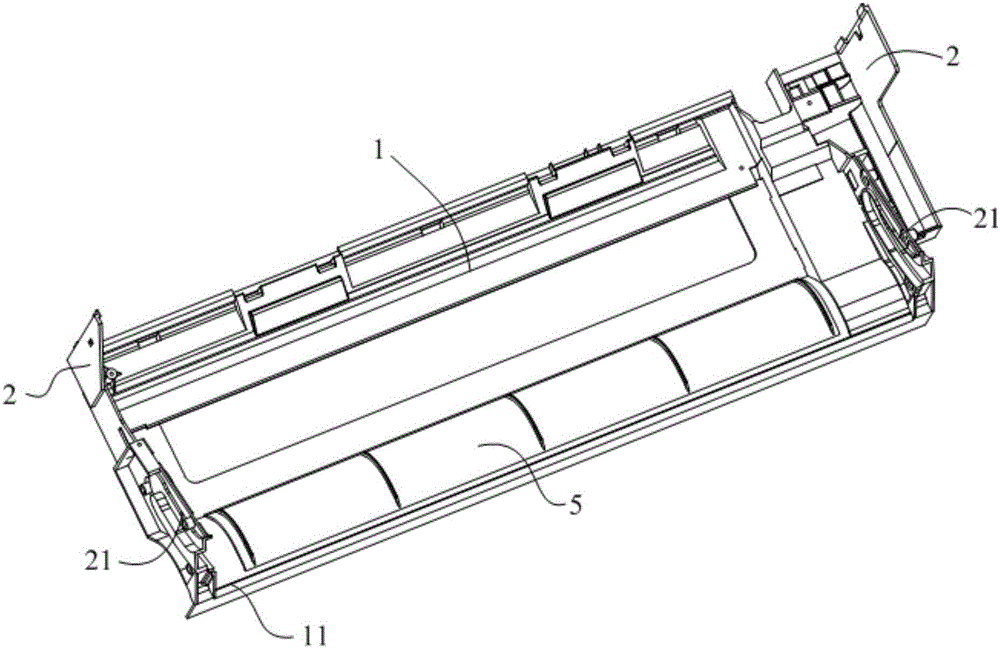

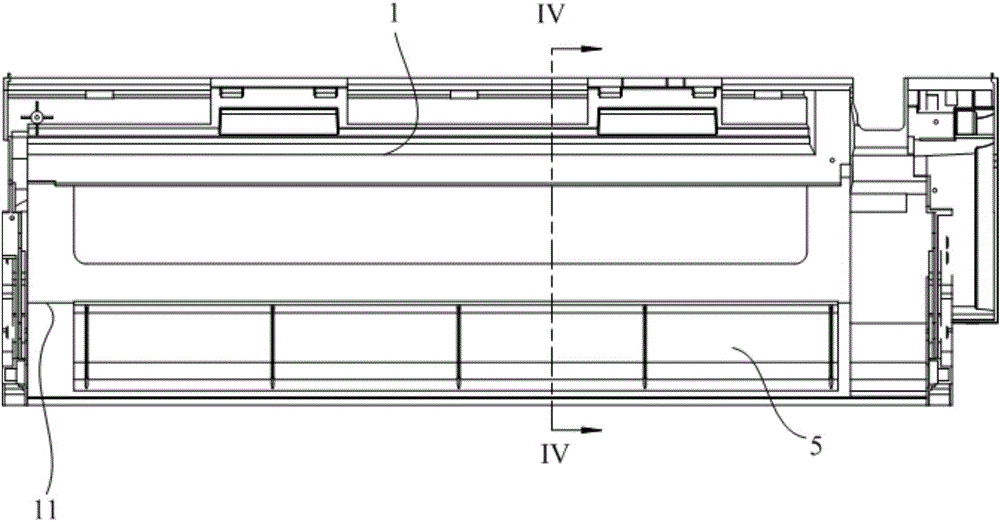

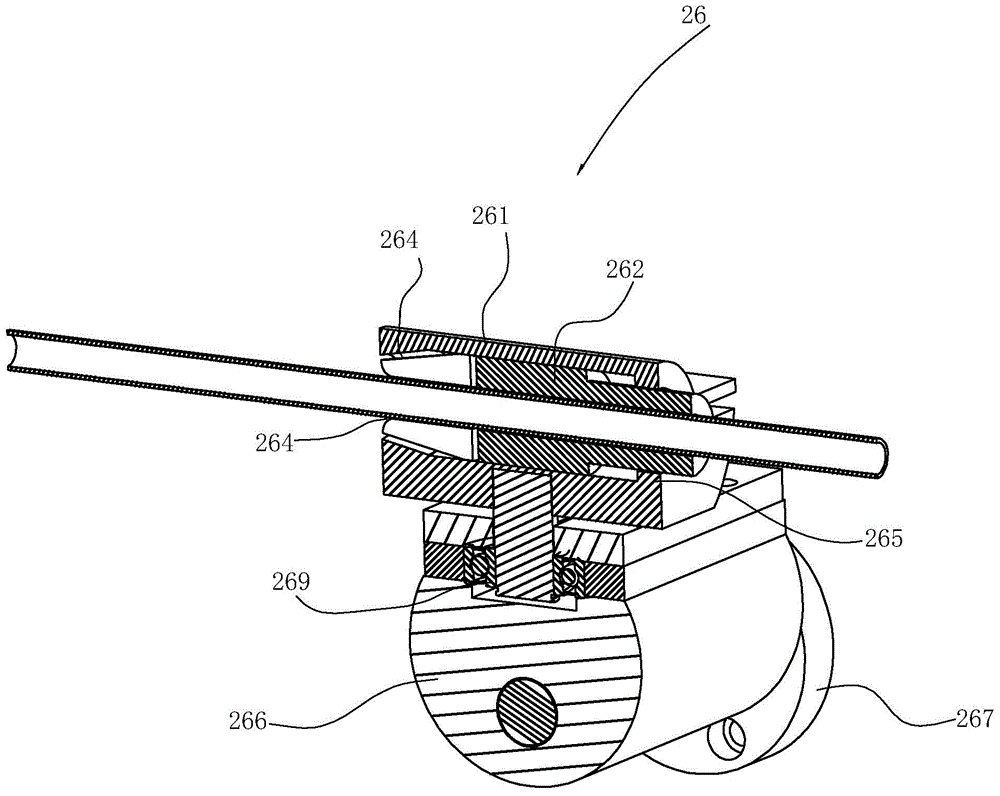

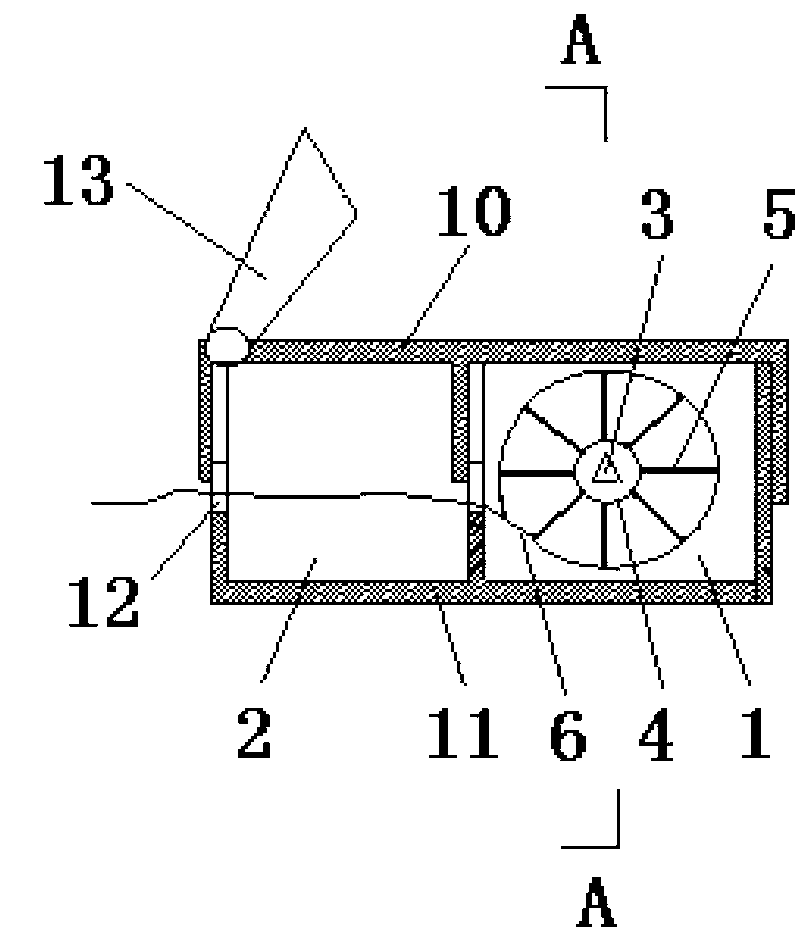

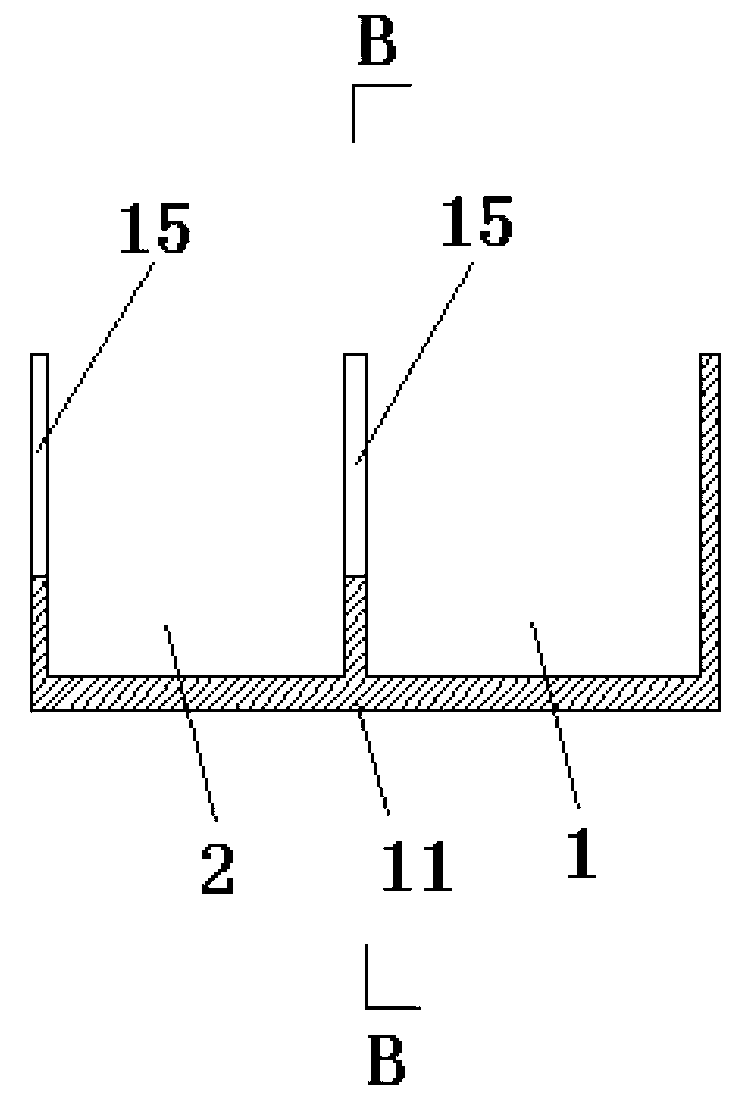

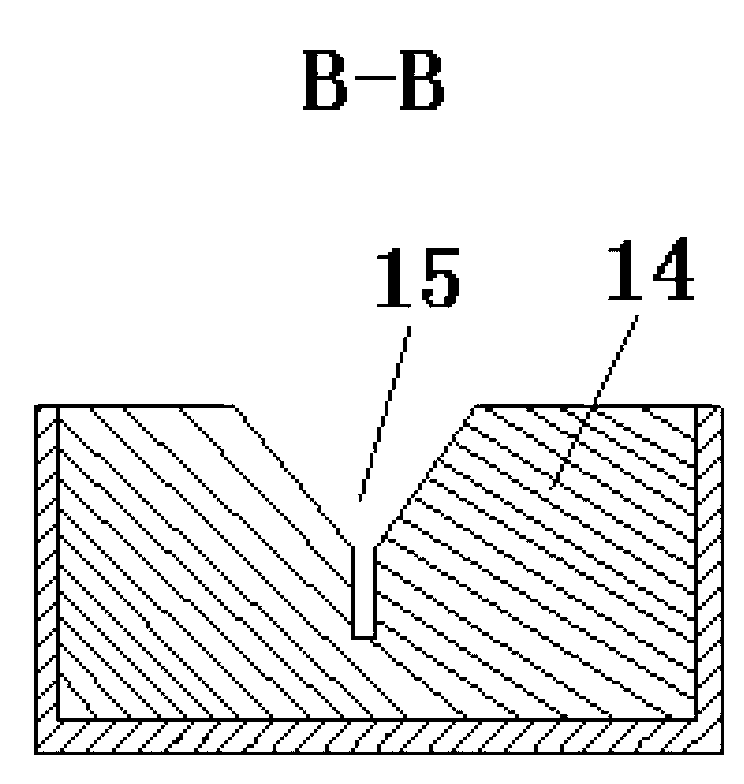

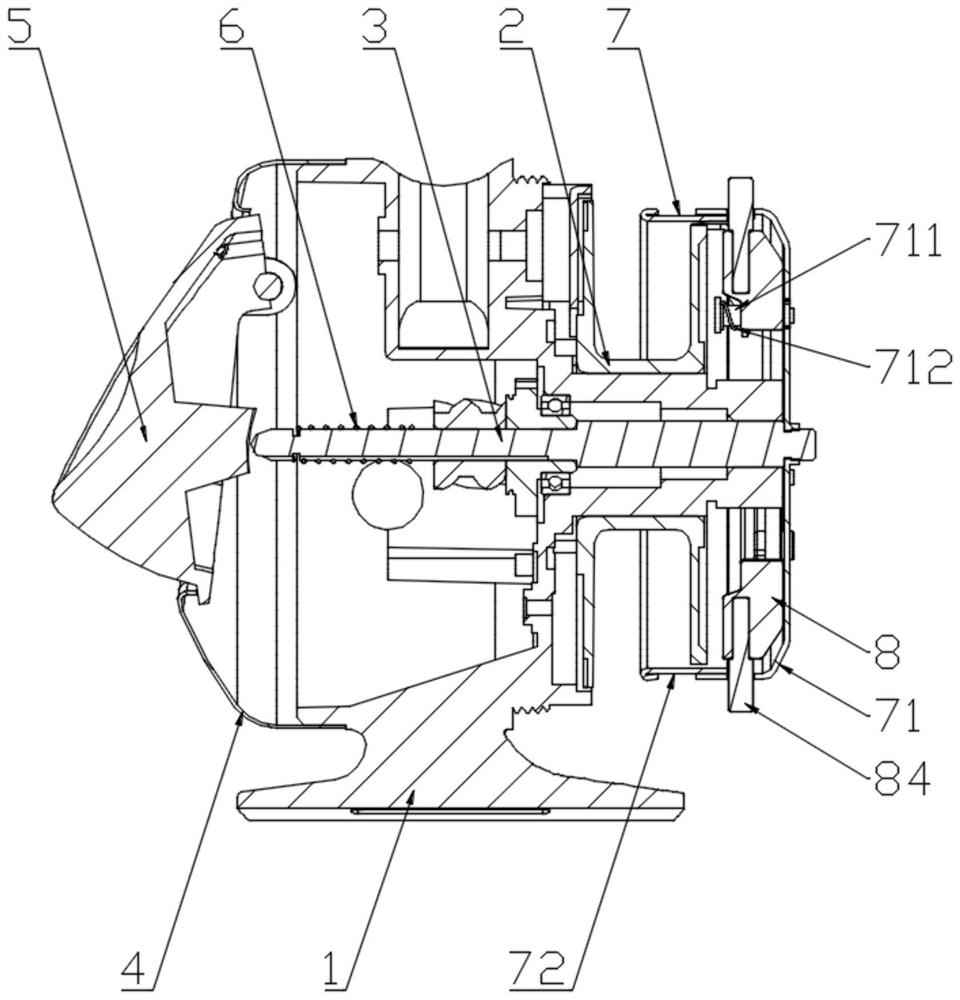

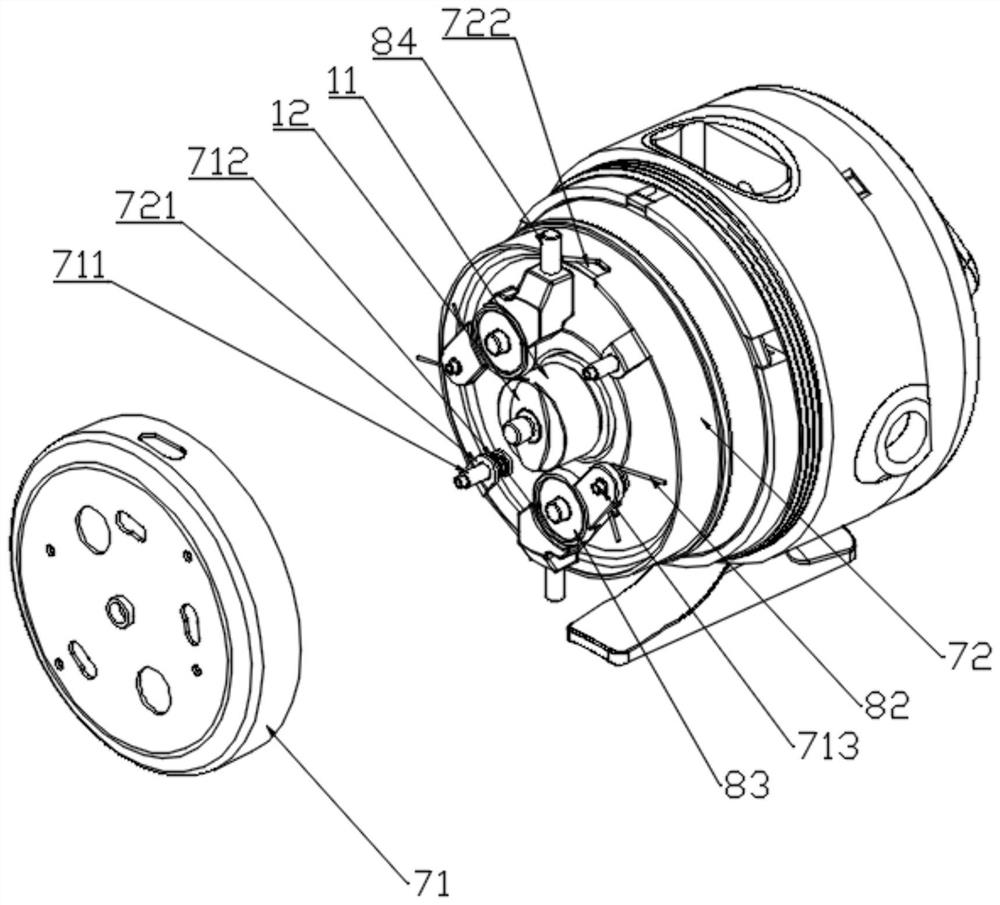

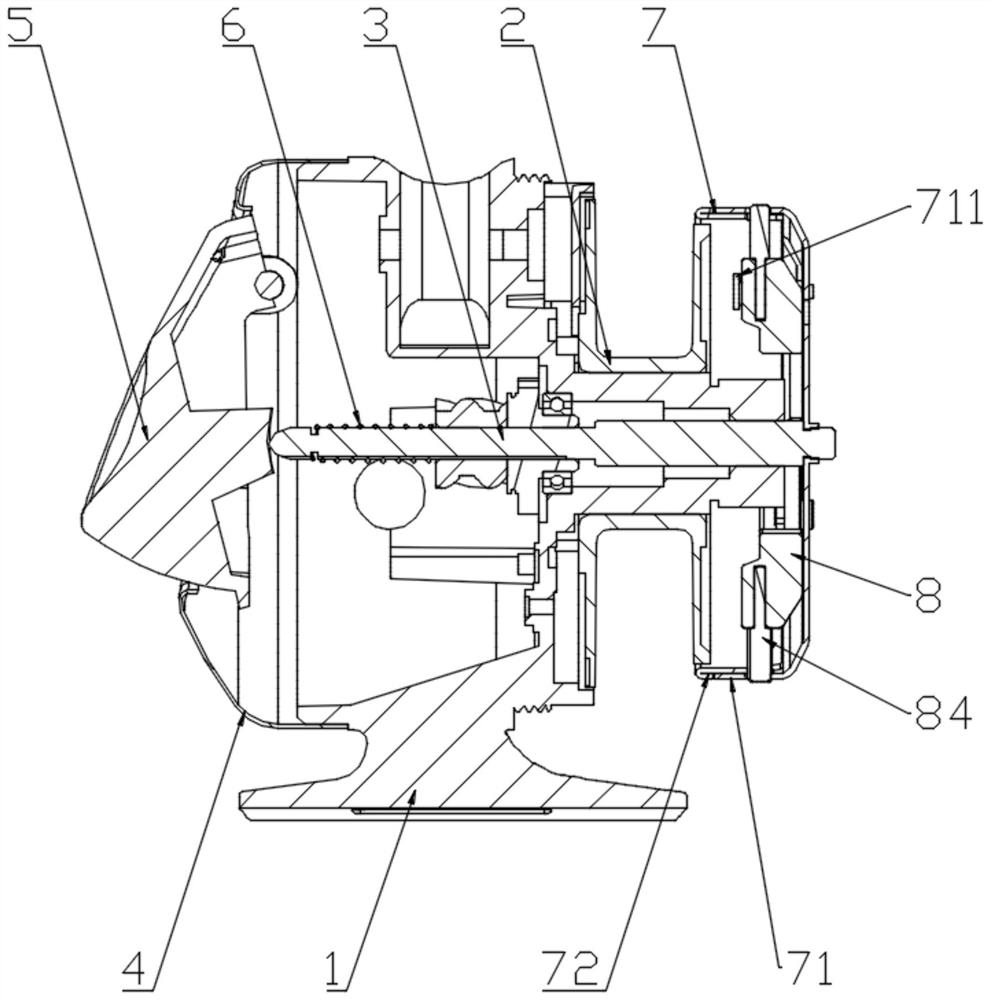

Air conditioner indoor unit and air conditioner

ActiveCN106705236AImprove convenienceSmooth exitDucting arrangementsLighting and heating apparatusPlate heat exchangerEngineering

The invention discloses an air conditioner indoor unit and an air conditioner. The air conditioner indoor unit comprises a shell, a heat exchanger, a refrigerant input and output pipe, a drain pipe and an air channel structure; the air channel structure can be pulled out or put into relative to the shell; and a protective plate for guiding movement of the air channel structure is arranged at the refrigerant input and output pipe and the drain pipe in an enclosing mode. According to the technical scheme, the situation that the refrigerant input and output pipe and the drain pipe are damaged due to putting into or pulling out of the air channel structure can be effectively avoided, so that the maintenance or cleaning safety of the air channel structure of the air conditioner indoor unit is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

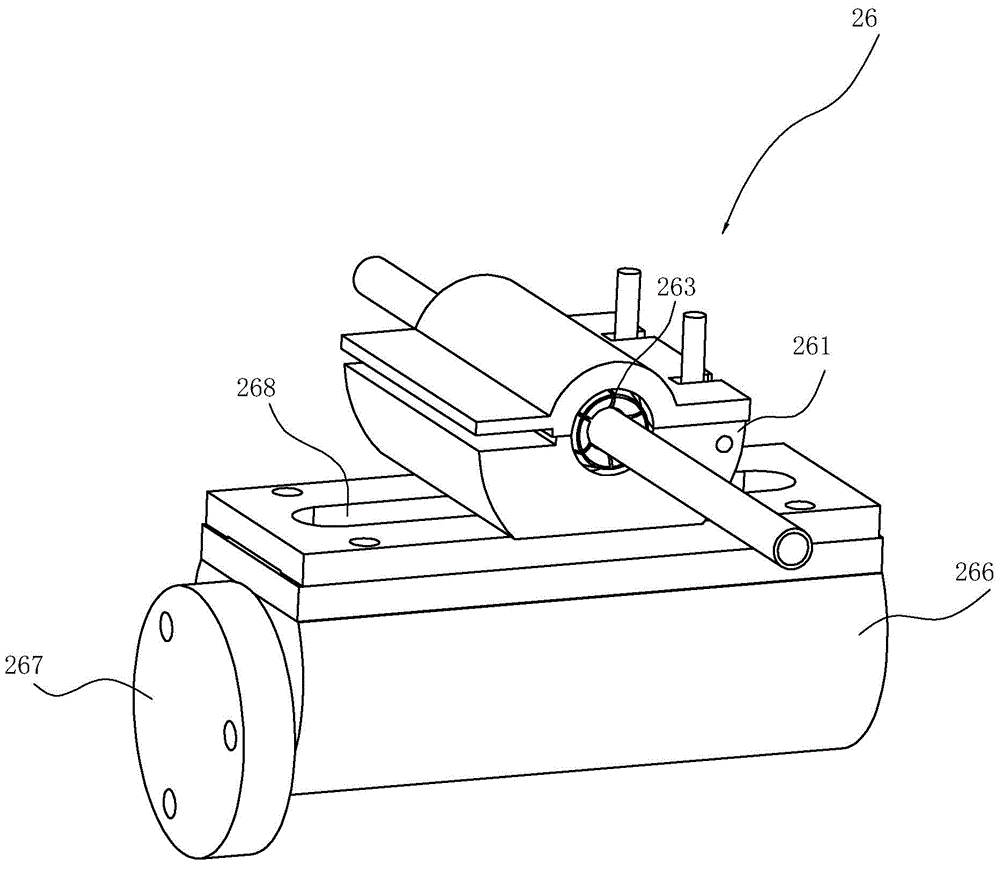

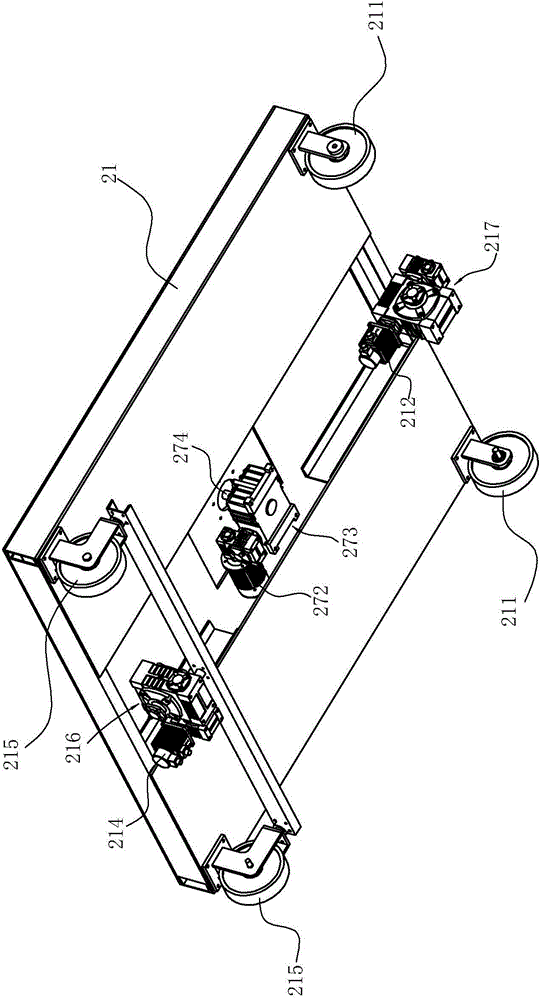

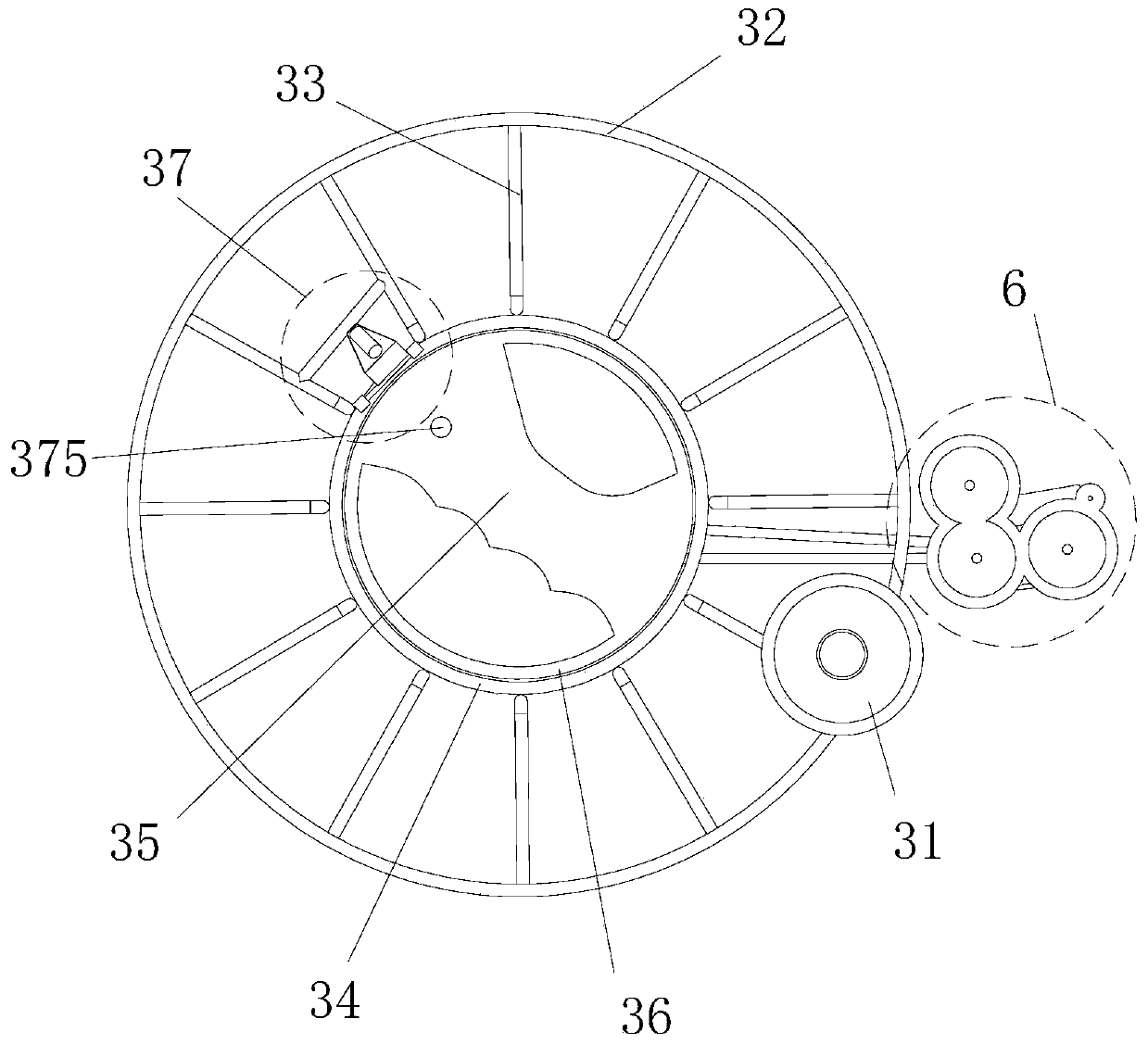

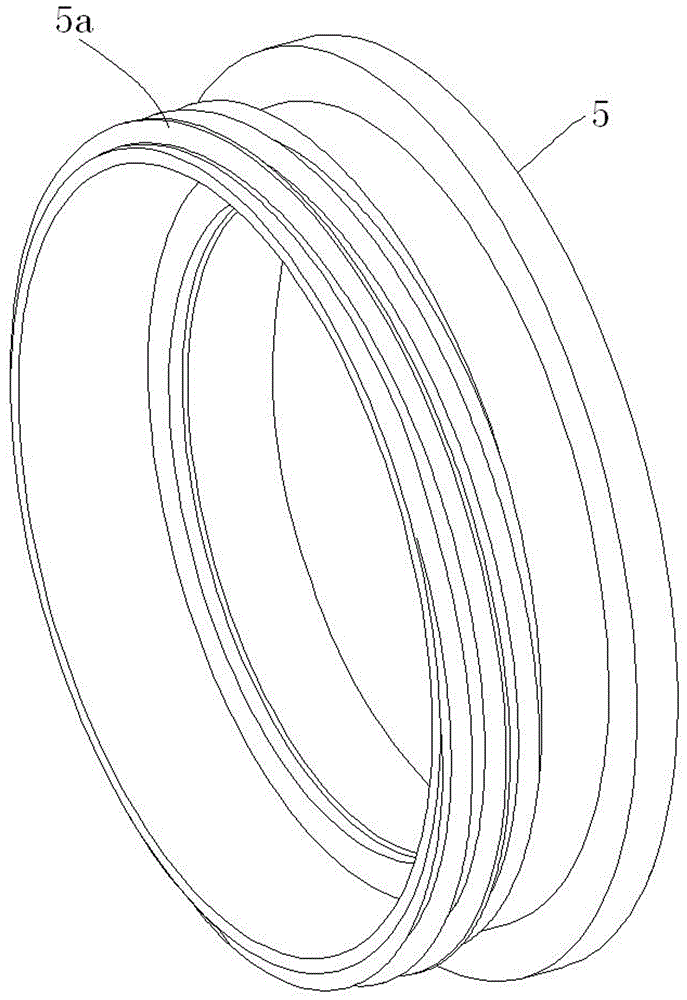

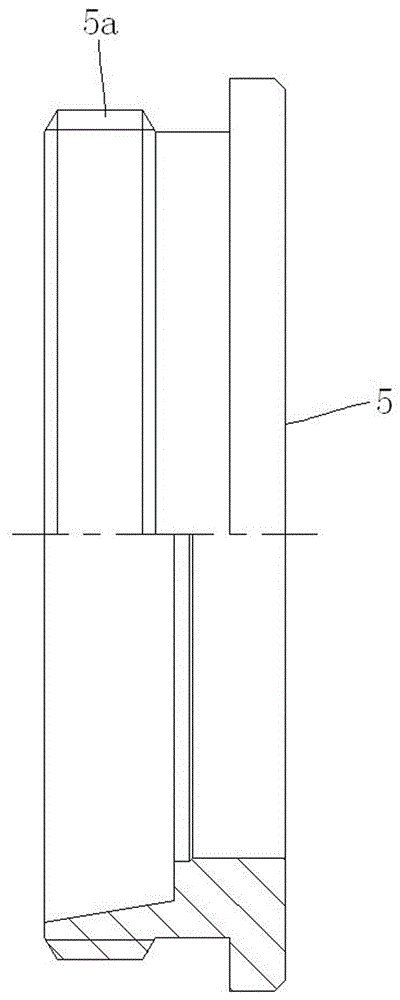

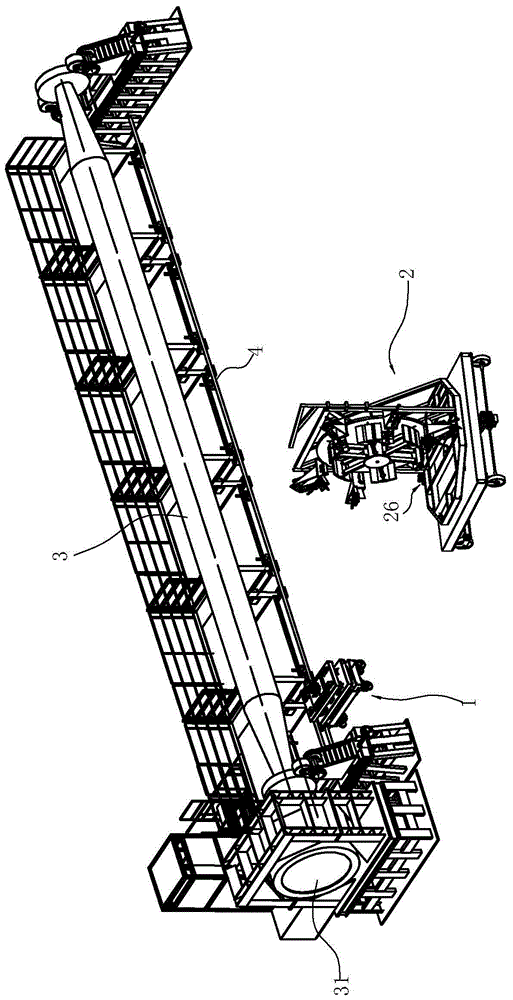

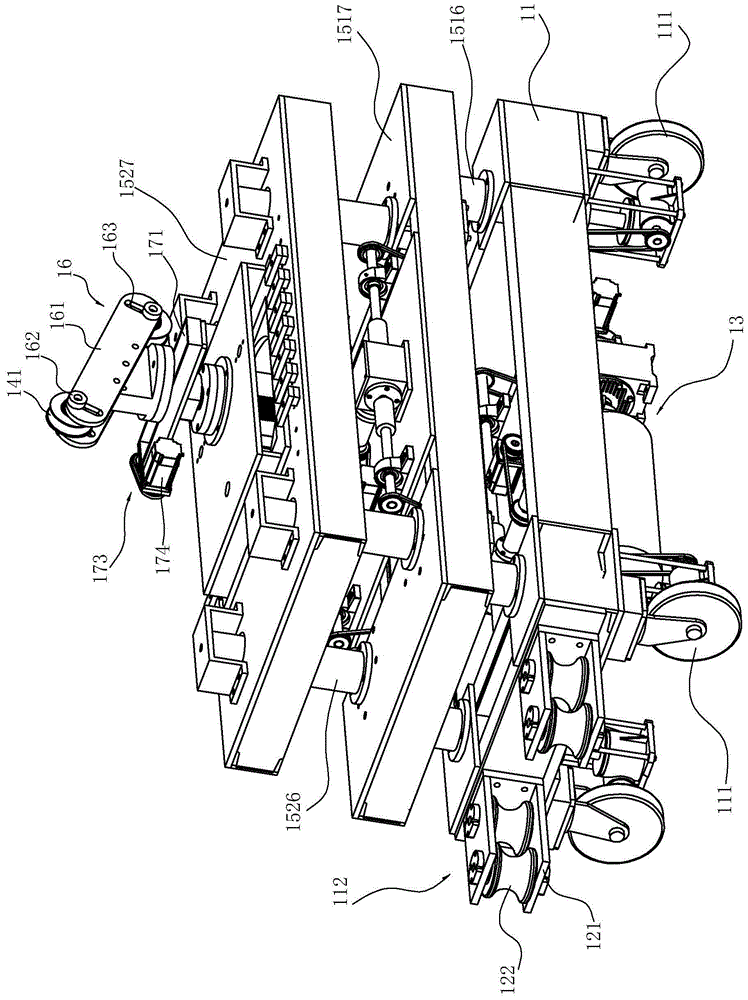

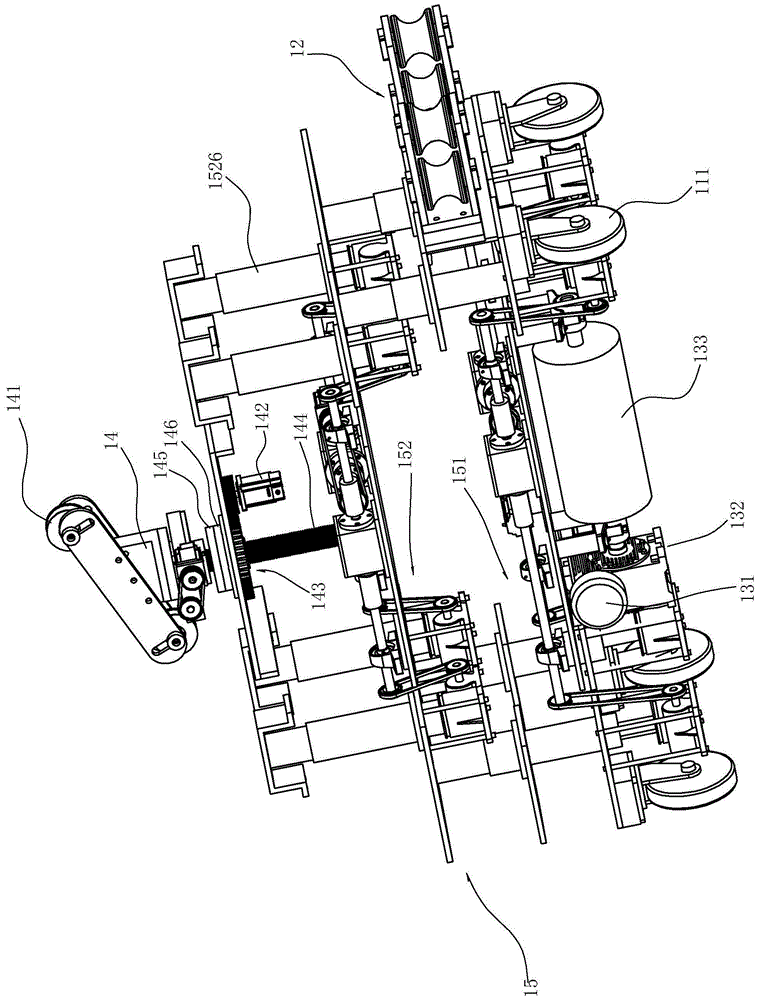

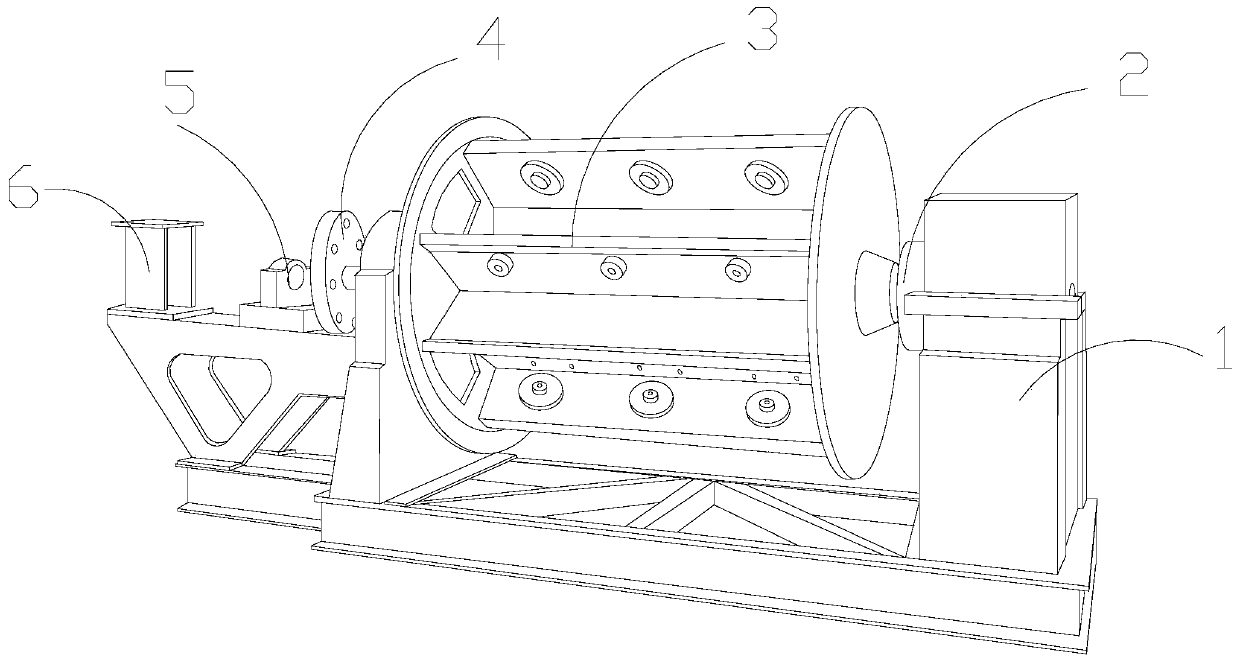

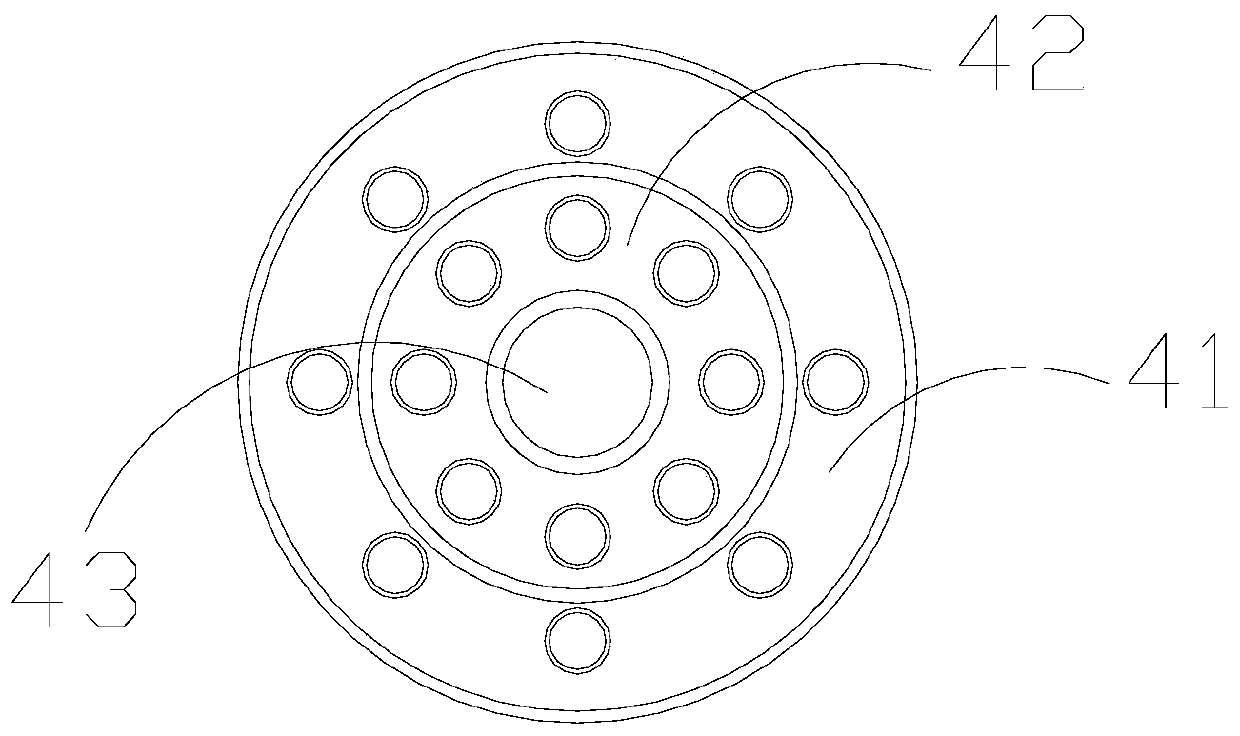

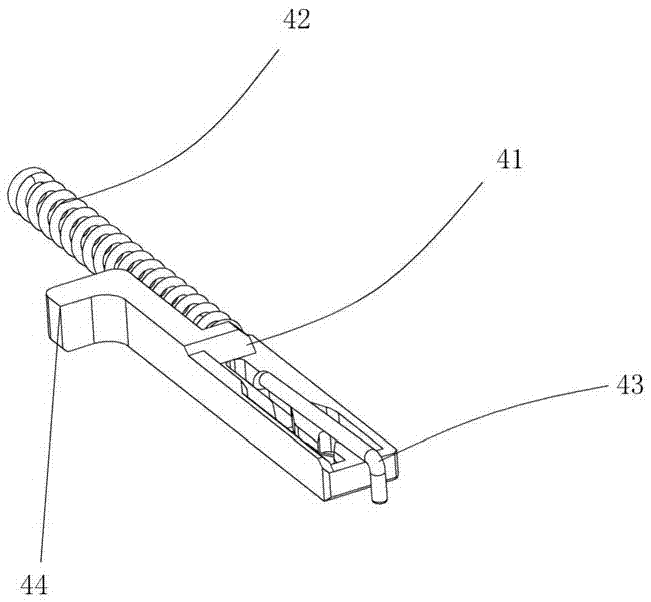

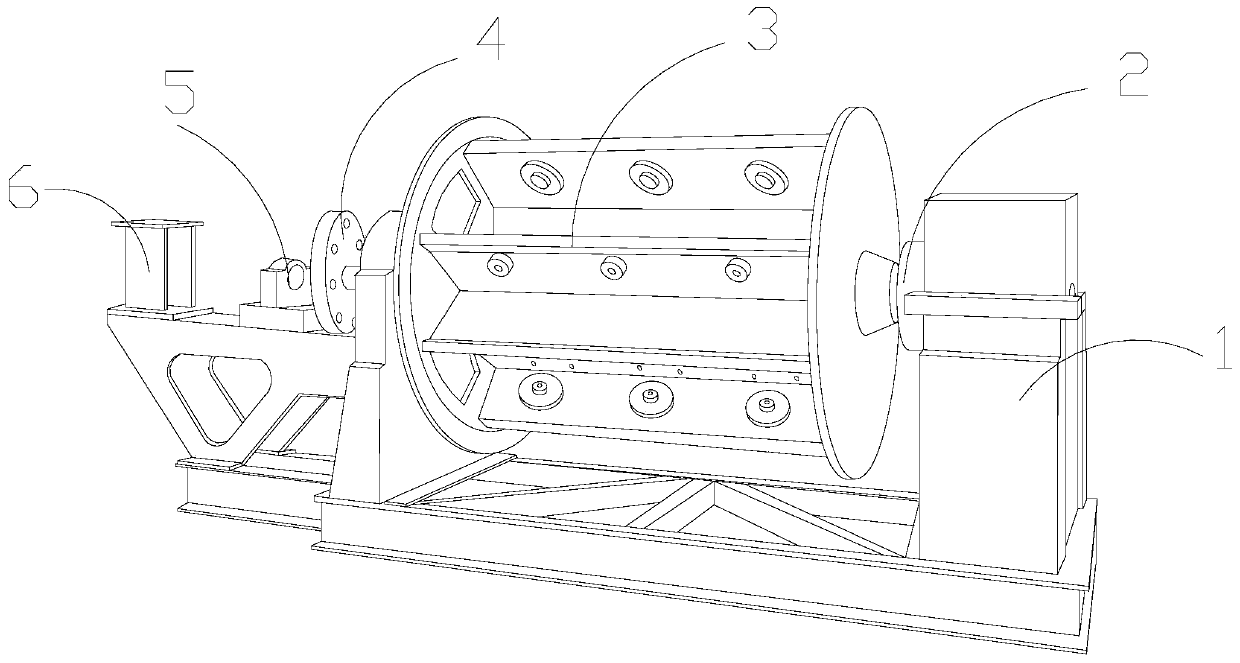

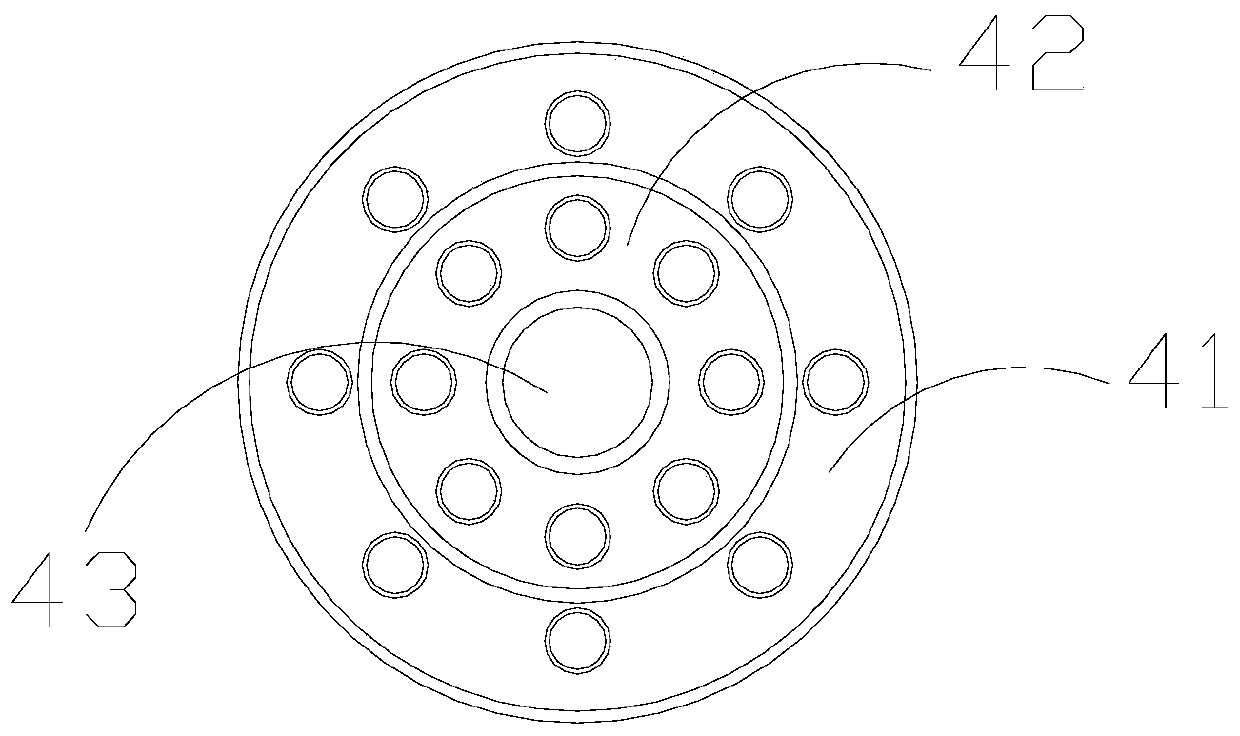

Pipe coiler

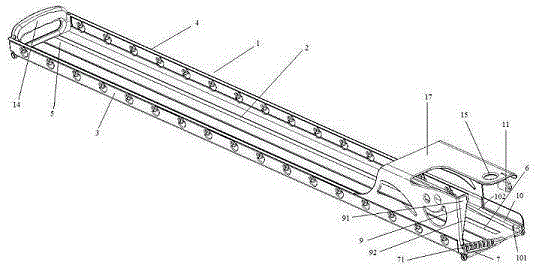

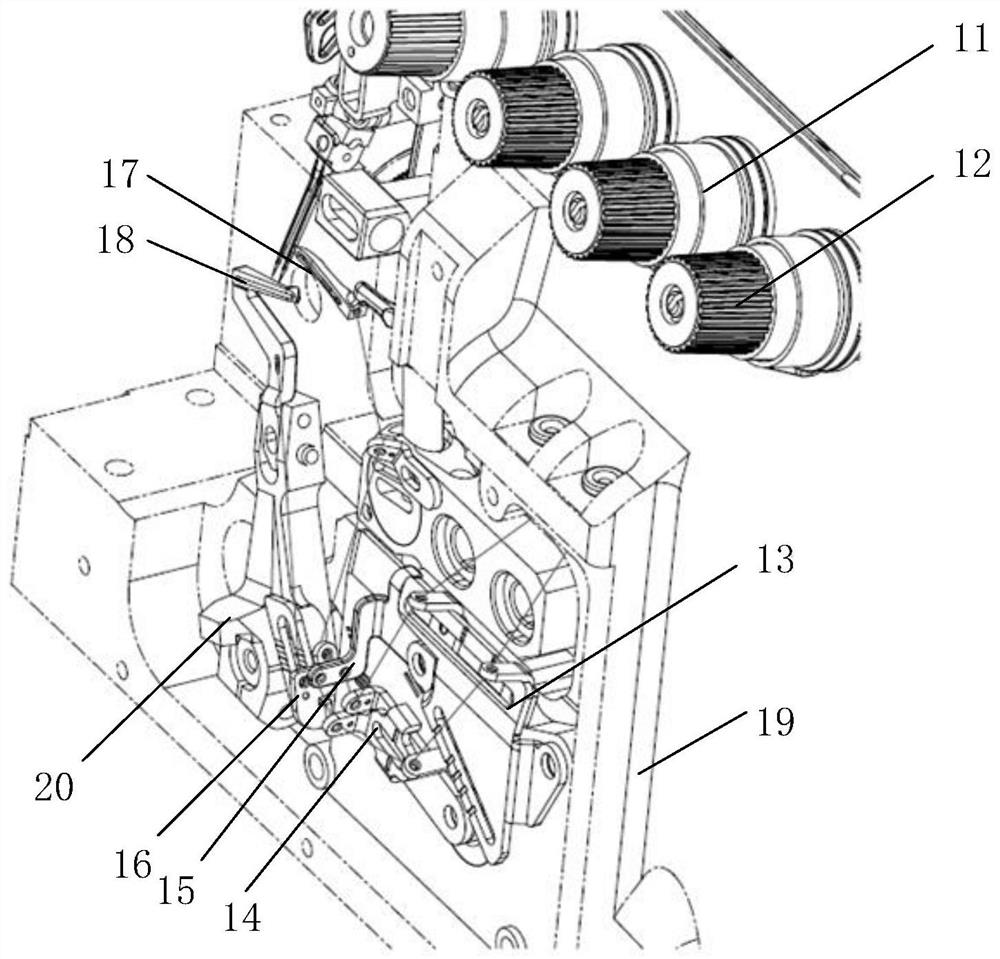

ActiveCN104444563ASimple structureGood anti-shrink functionFilament handlingControl systemEngineering

The invention relates to a pipe coiler. The pipe coiler comprises a riding wheel used for bearing a pipe to be coiled and is characterized by further comprising a pipe conveying device and a pipe uncoiling device, wherein the pipe conveying device sequentially comprises a pipe conveying base, a lifting mechanism, a fine adjustment mechanism, a supporting base, a radial adjusting mechanism and a riding wheel from bottom to top, the pipe uncoiling device comprises a pipe uncoiling base, a base plate is arranged on the pipe uncoiling base and provided with a support, and the support is provided with a rotating disk which is provided with an axial clamping mechanism, a radial clamping mechanism, a telescopic sleeve, an anti-shrinking mechanism, sensors and a control system. Through the pipe coiler, the pipe feeding position can be tracked in real time, the pipe conveying height, the pipe conveying angle and the pipe conveying speed can be adjusted in real time, the pipe coiling quality is guaranteed, the scrap risk is reduced, the labor intensity of workers is relieved, and manual cost is saved; due to the design of the pipe uncoiling device, it is effectively prevented that in the pipe distributing process, a coiled pipe bundle loosens, the loosened pipe bundle overlaps and is knotted, the pipe can go out smoothly, pipe distribution quality is guaranteed, and product quality is good.

Owner:ZHENHAI PETROCHEM JIANAN ENG

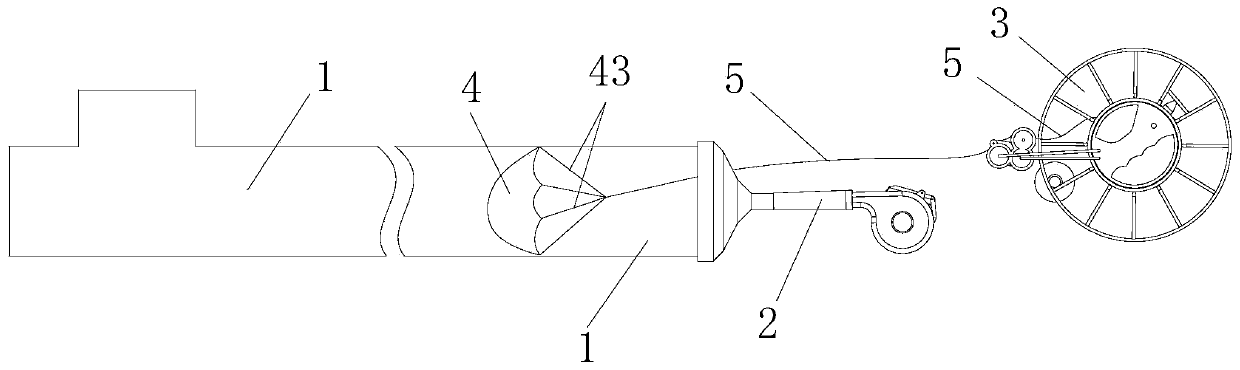

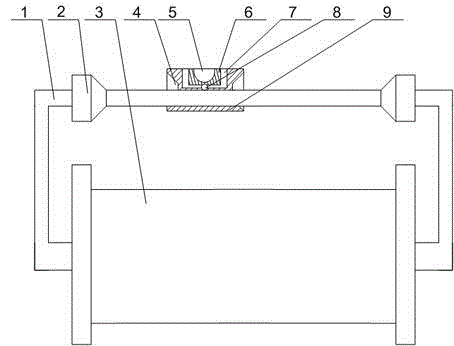

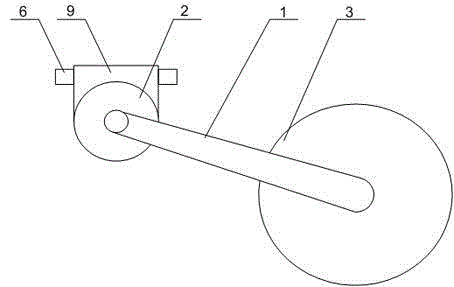

Threading device for measuring three-dimensional coordinates of pipe

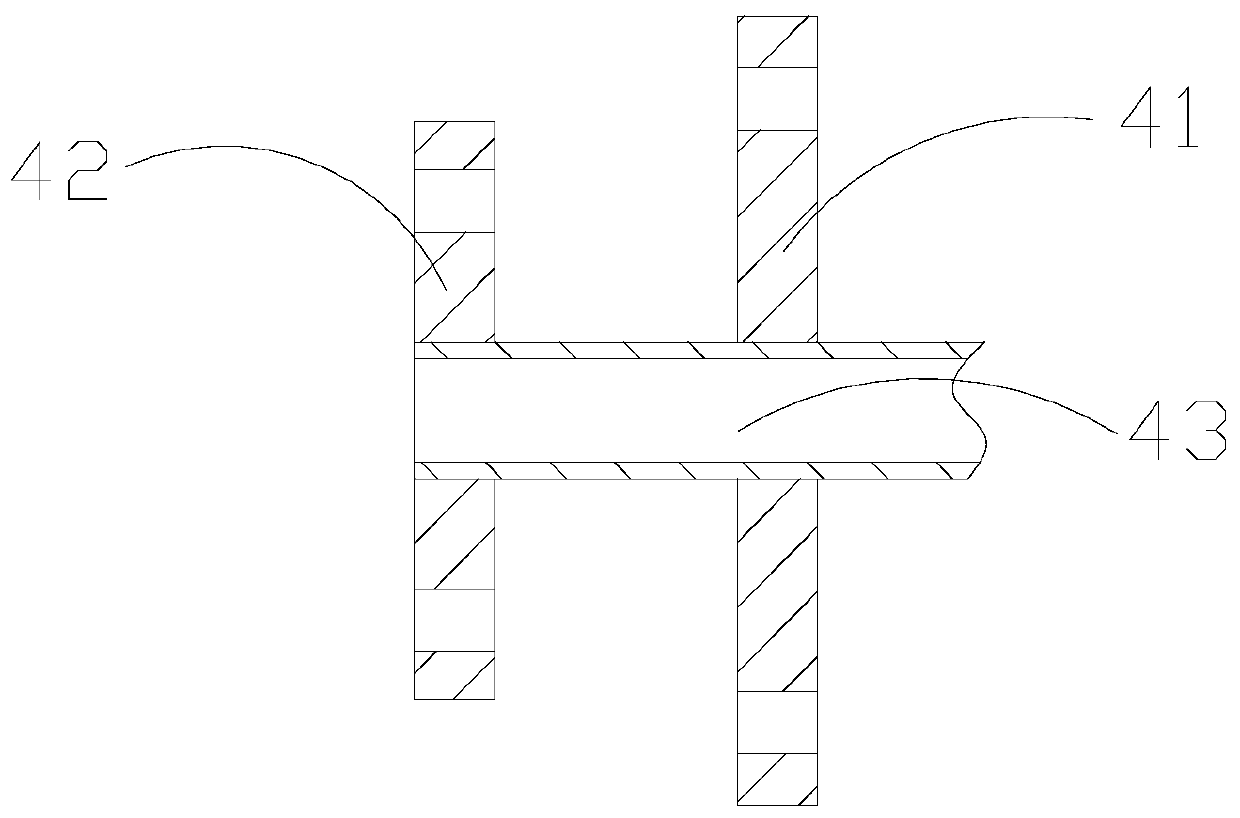

PendingCN110116932ASimple structureEasy to operateMeasurement devicesFilament handlingEngineeringSteel rope

The invention discloses a threading device for measuring three-dimensional coordinates of a pipe. The threading device mainly comprises an air blowing device, a lead wire, a traction device and a take-up reel; one end of the lead wire passes through the air blowing device to be fixedly connected with the traction device, and the other end of the lead wire is spirally wound in the take-up reel; andthe traction device is placed at one end of the pipe to be tested, and the head of the air blowing device is arranged at the end of the pipe to be tested in a sleeving manner. In the using process, aKevlar line is tied to a special U-shaped lightweight plastic bag to be placed into one end of the pipe, a sleeve head is arranged on a pipe opening in a sleeving manner, an air blower connected to abattery is aligned with a large hole of the sleeve head to blow air into the U-shaped bag at the pipe opening until the U-shaped bag is blown to the other end of the pipe, and threading is finished.After the Kevlar line threaded into the pipe is connected to a traction steel rope, the traction steel rope is replaced in the pipe, then the traction steel rope is connected to a measuring host, themeasuring host is pulled to slide from one end of the pipe to the other end of the pipe, and data collection is finished after dragging by the traction steel rope and running in the pipe by one roundtrip.

Owner:佛山市华禅能燃气设计有限公司

Waterproof self-locking radio-frequency coaxial connector assembly

InactiveCN106654700ASmooth transmissionImprove locking forceEngagement/disengagement of coupling partsCouplings bases/casesElectrical conductorRadio frequency signal

The invention discloses a waterproof self-locking radio-frequency coaxial connector assembly. The assembly comprises male and female radio-frequency coaxial connectors; the male connector comprises a cylindrical clamping jaw, a bush and a thread sleeve; a conical hole and a clamping jaw annular bulge are arranged at the front end of a cylindrical body of the clamping jaw; the clamping jaw annular bulge is provided with an outwards tilted radial conical surface which is tilted outwards and radially; an outer threaded section is arranged on the outer wall surface of the bush; the thread sleeve is provided with an inner threaded section and a first thread sleeve annular bulge which is bulged inwards; the thread sleeve is in threaded connection with the outer threaded section of the bush through the inner threaded section; the first thread sleeve annular bulge props against the outer conical surface when the thread sleeve is moved forwards through manual screwing; the outwards tilted radial conical surface of the clamping jaw props against a female annular bulge; the assembly further comprises a cylindrical waterproof sleeve made of an elastic waterproof material; and two ends of the waterproof sleeve tightly sleeve a female outer conductor and a cable respectively. According to the assembly, the female and male connectors are not mutually rotated and moved after being inserted and combined, so that stable dynamic intermodulation and stable radio-frequency signal transmission are achieved and the waterproof effect is good.

Owner:CHANGZHOU XINSHENG ELECTRONICS

Ink fountain with convenience in line changing for building construction

ActiveCN103231358APrevent slidingEasy to put inOther workshop equipmentEngineeringMechanical engineering

The invention discloses an ink fountain with convenience in line changing for building construction, which aims to solve the problems that the line in a conventional ink fountain is complex in changing and easy to jam. The ink fountain comprises an ink fountain box formed by a lower bottom groove and an upper close cover, wherein a line wheel chamber and an ink storing chamber are arranged inside the ink fountain box; a line wheel rocking handle shaft with a polygonal radial section is movably mounted in the line wheel chamber; a line wheel shaft penetrates and is coaxial with the line wheel rocking handle shaft; a plurality of line wheel blades are mounted along the circumference of the line wheel shaft; a ink line is wound on the plurality of blades; and one end of the ink line penetrates out of the ink storing chamber after being wound on the blades. According to the ink fountain provided by the invention, the ink fountain box of the ink fountain is formed by the lower bottom groove and the upper close cover, during line changing, a box body is opened to change the line directly; the line wheel rocking handle shaft is non-cylindrical, so as to avoid relative sliding between the line wheel rocking handle shaft and the line wheel shaft during processes of line releasing or line winding; and meanwhile, line fastening holes, which are formed in the line wheel blades, facilitate penetration of the ink line, so that the phenomenon that the line winding is messed to form a mixed ball is avoided.

Owner:SHAANXI COAL & CHEM CONSTR GRP CO LTD

a pipe winding machine

ActiveCN104444563BSimple structureGood anti-shrink functionFilament handlingControl systemEngineering

The invention relates to a pipe coiler. The pipe coiler comprises a riding wheel used for bearing a pipe to be coiled and is characterized by further comprising a pipe conveying device and a pipe uncoiling device, wherein the pipe conveying device sequentially comprises a pipe conveying base, a lifting mechanism, a fine adjustment mechanism, a supporting base, a radial adjusting mechanism and a riding wheel from bottom to top, the pipe uncoiling device comprises a pipe uncoiling base, a base plate is arranged on the pipe uncoiling base and provided with a support, and the support is provided with a rotating disk which is provided with an axial clamping mechanism, a radial clamping mechanism, a telescopic sleeve, an anti-shrinking mechanism, sensors and a control system. Through the pipe coiler, the pipe feeding position can be tracked in real time, the pipe conveying height, the pipe conveying angle and the pipe conveying speed can be adjusted in real time, the pipe coiling quality is guaranteed, the scrap risk is reduced, the labor intensity of workers is relieved, and manual cost is saved; due to the design of the pipe uncoiling device, it is effectively prevented that in the pipe distributing process, a coiled pipe bundle loosens, the loosened pipe bundle overlaps and is knotted, the pipe can go out smoothly, pipe distribution quality is guaranteed, and product quality is good.

Owner:ZHENHAI PETROCHEM JIANAN ENG

Tension adjusting method for fiber traction laying

The invention discloses a tension adjusting method for fiber traction laying. The gravity of an adjustment block is always disposed above a connecting rod, the tension of an optical cable on a cable tray during traction is always stable, and at the same time, a traction block is rotationally arranged in a rectangular groove through a universal ball, such that a fiber can realize radial swing within a certain scope, large-amplitude swing of the optical cable, caused by a traction strength increase during long-distance laying can be buffered, the tension strength of the optical cable at the cable tray is timely adjusted during the long-distance laying, and optical cable swirling and surge phenomena are avoided.

Owner:成都亨通光通信有限公司

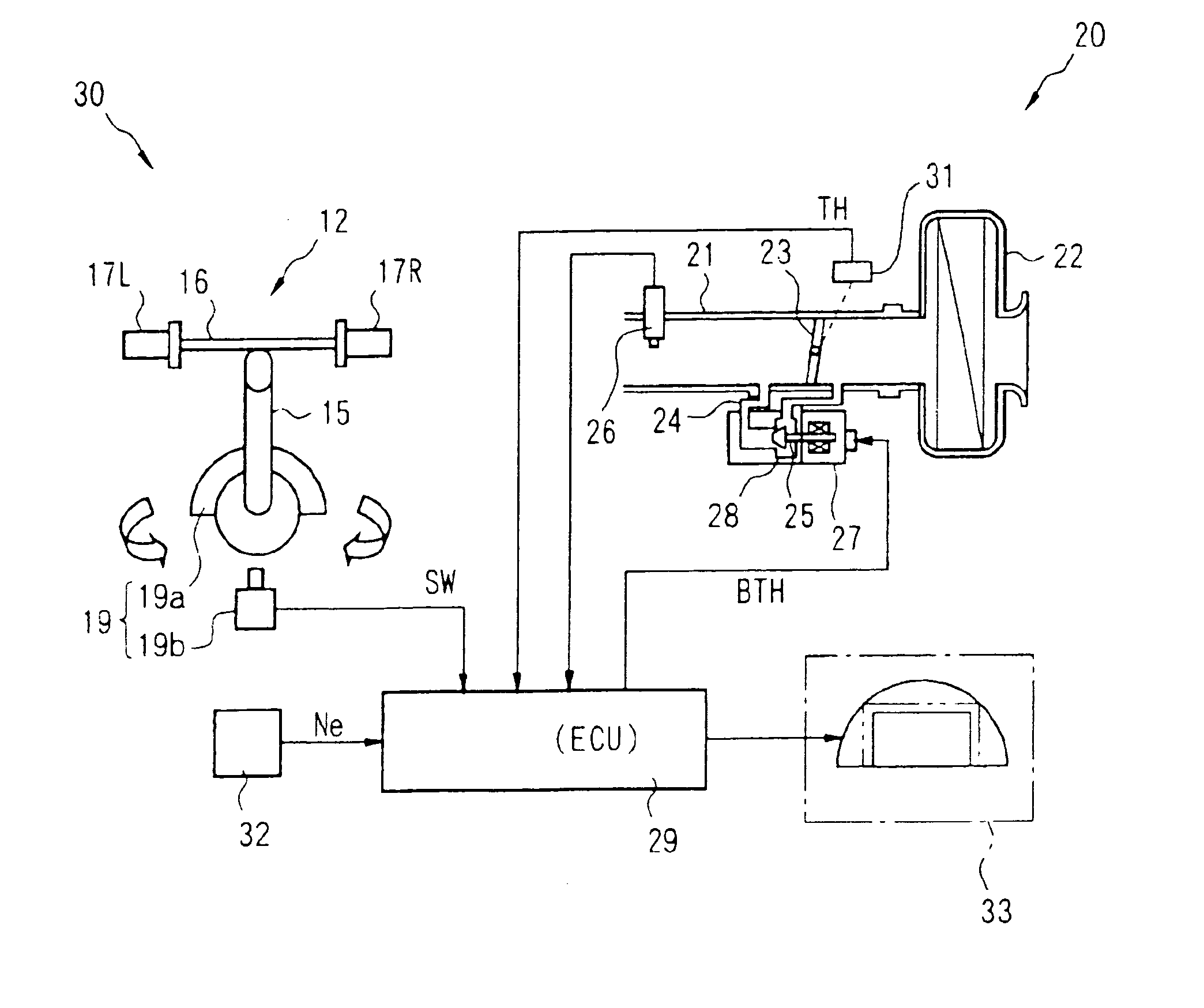

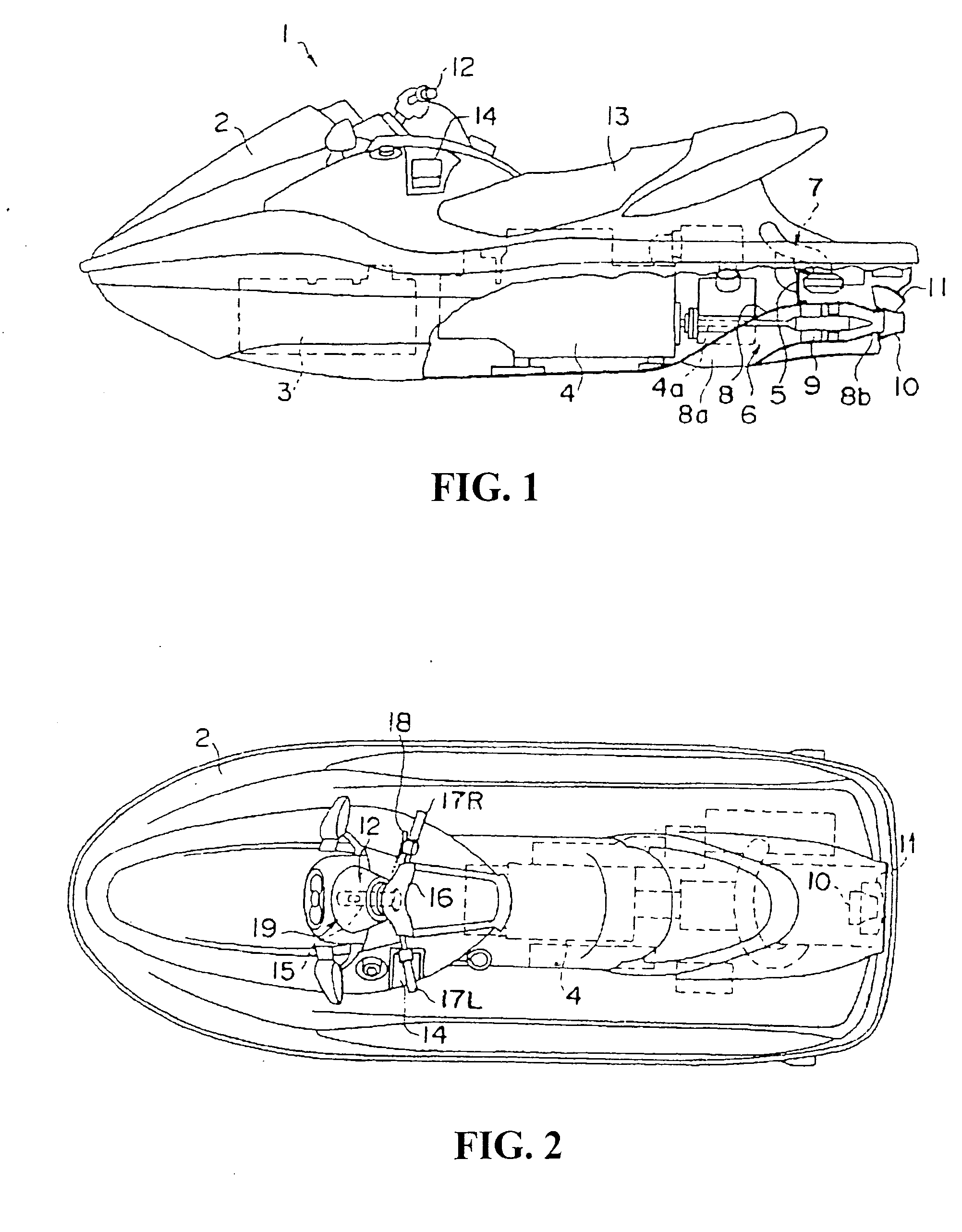

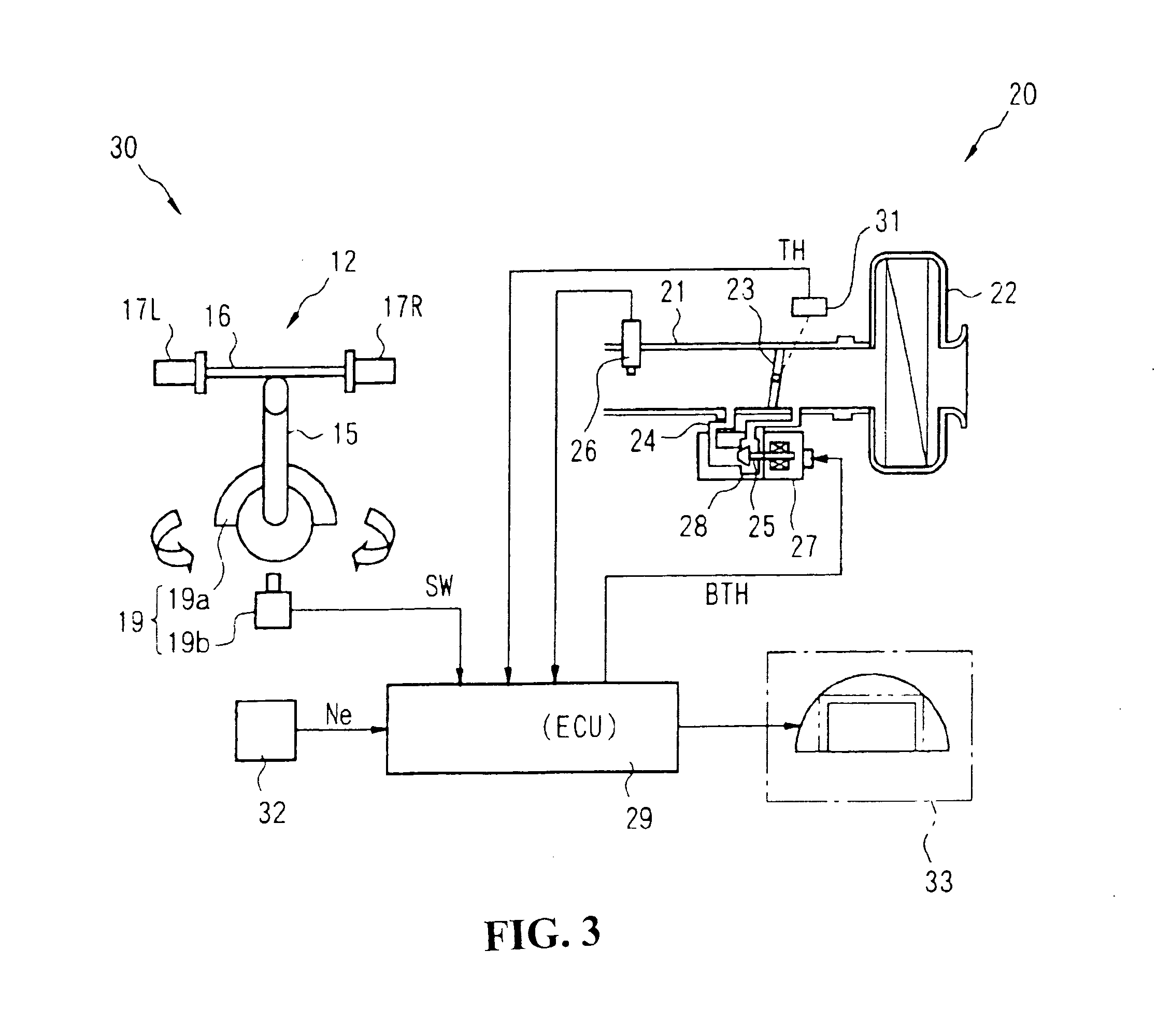

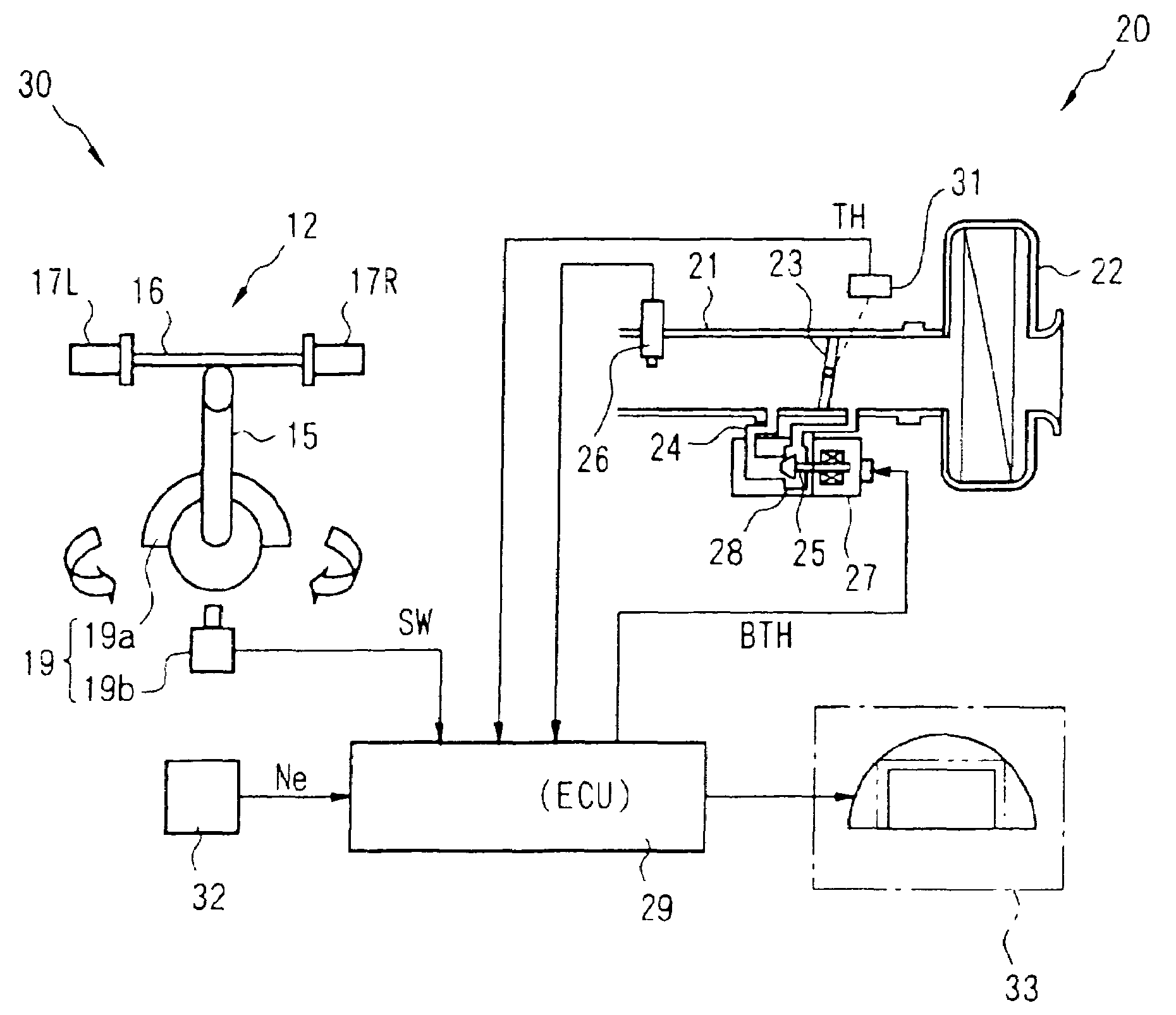

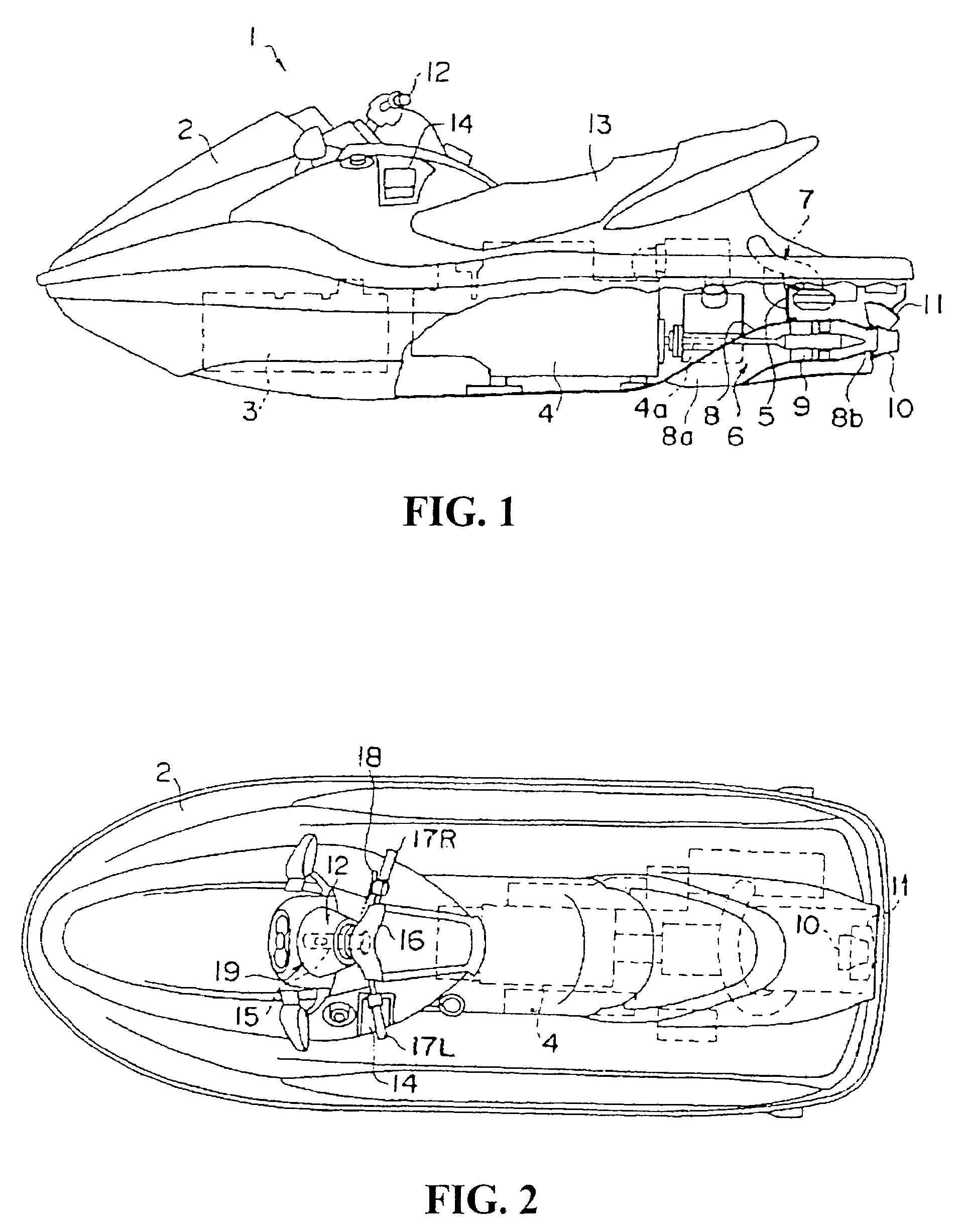

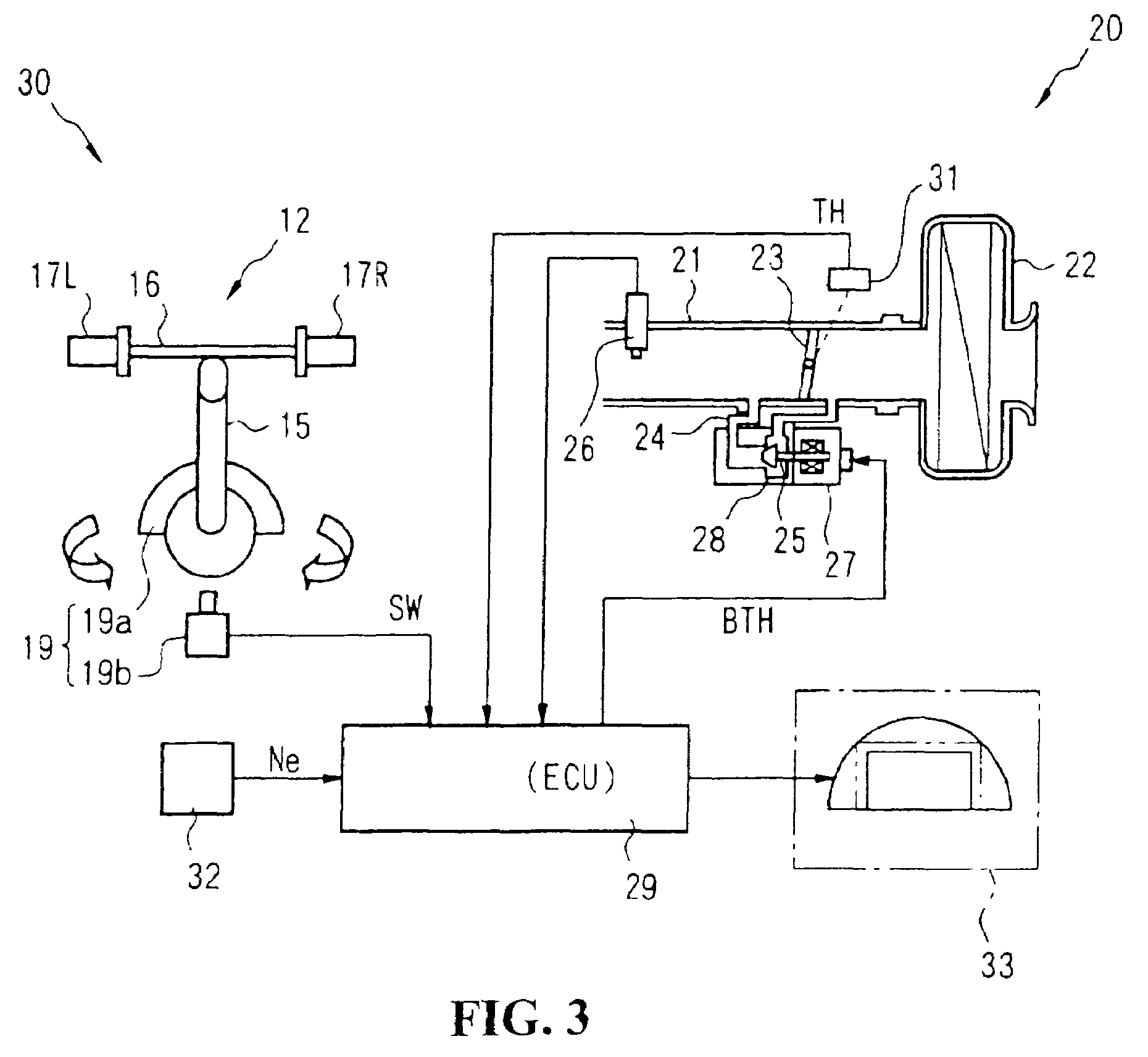

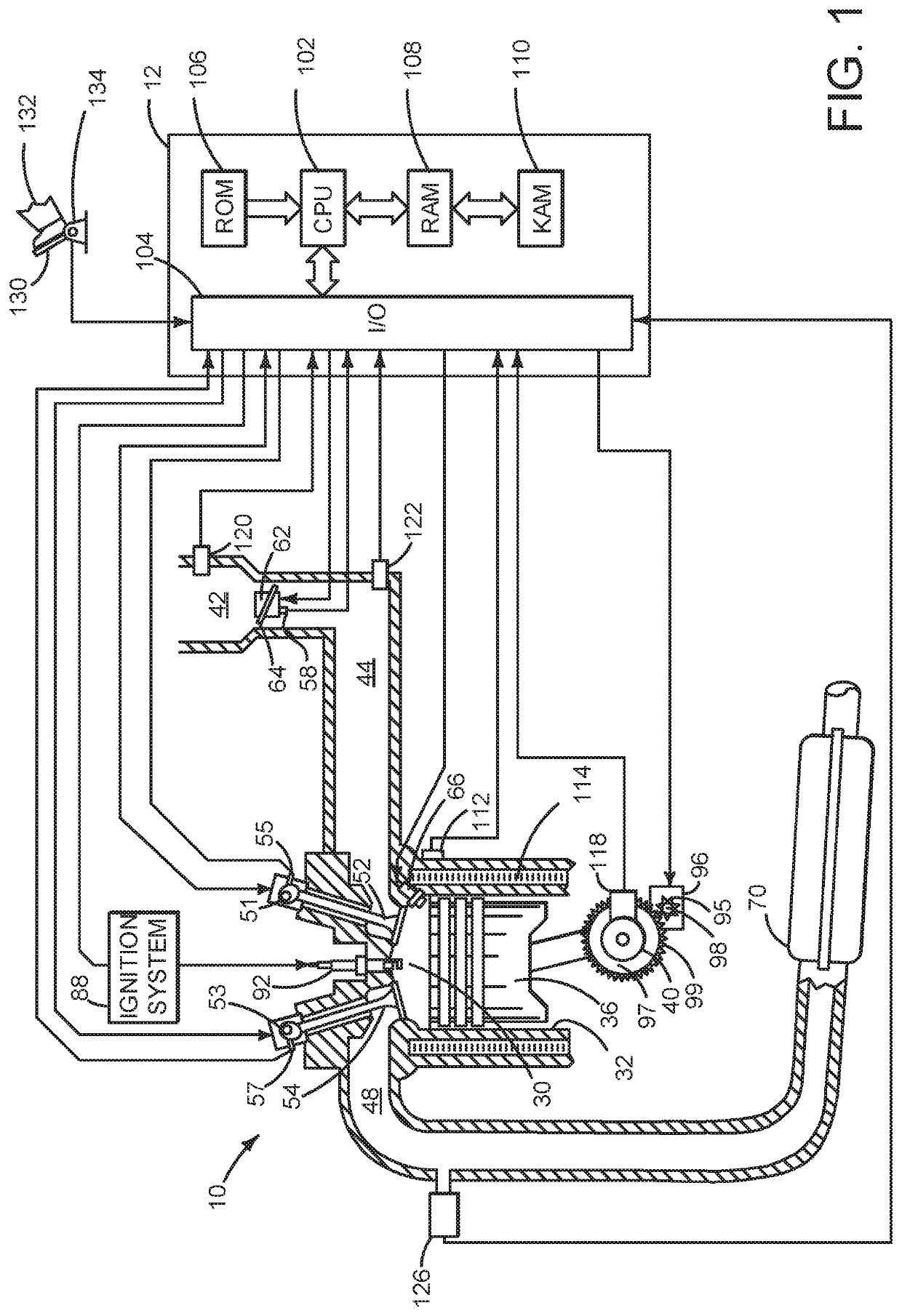

Jet-propelled watercraft

InactiveUS20070082568A1Made evenlySmooth exitInternal combustion piston enginesPropulsion power plantsJet propulsionWatercraft

A jet-propelled watercraft capable of maintaining a propulsion force required for a turn made at the same time as closing of a throttle valve. The jet-propelled watercraft has an auxiliary intake valve and an ECU. The auxiliary intake valve in an intake pipe opens / closes an auxiliary intake passage to bypass a throttle valve. The ECU performs control such that an opening of the auxiliary intake valve in a state where the rotation speed of the engine is not lower than a threshold value is larger than the opening of the auxiliary intake valve in a state where the engine is idling. When in a state where the rotation speed is not lower than the threshold value, it is detected that the throttle valve is completely closed and that a steering mechanism has been turned by a prescribed angle or more, a current opening of the auxiliary intake valve is maintained.

Owner:HONDA MOTOR CO LTD

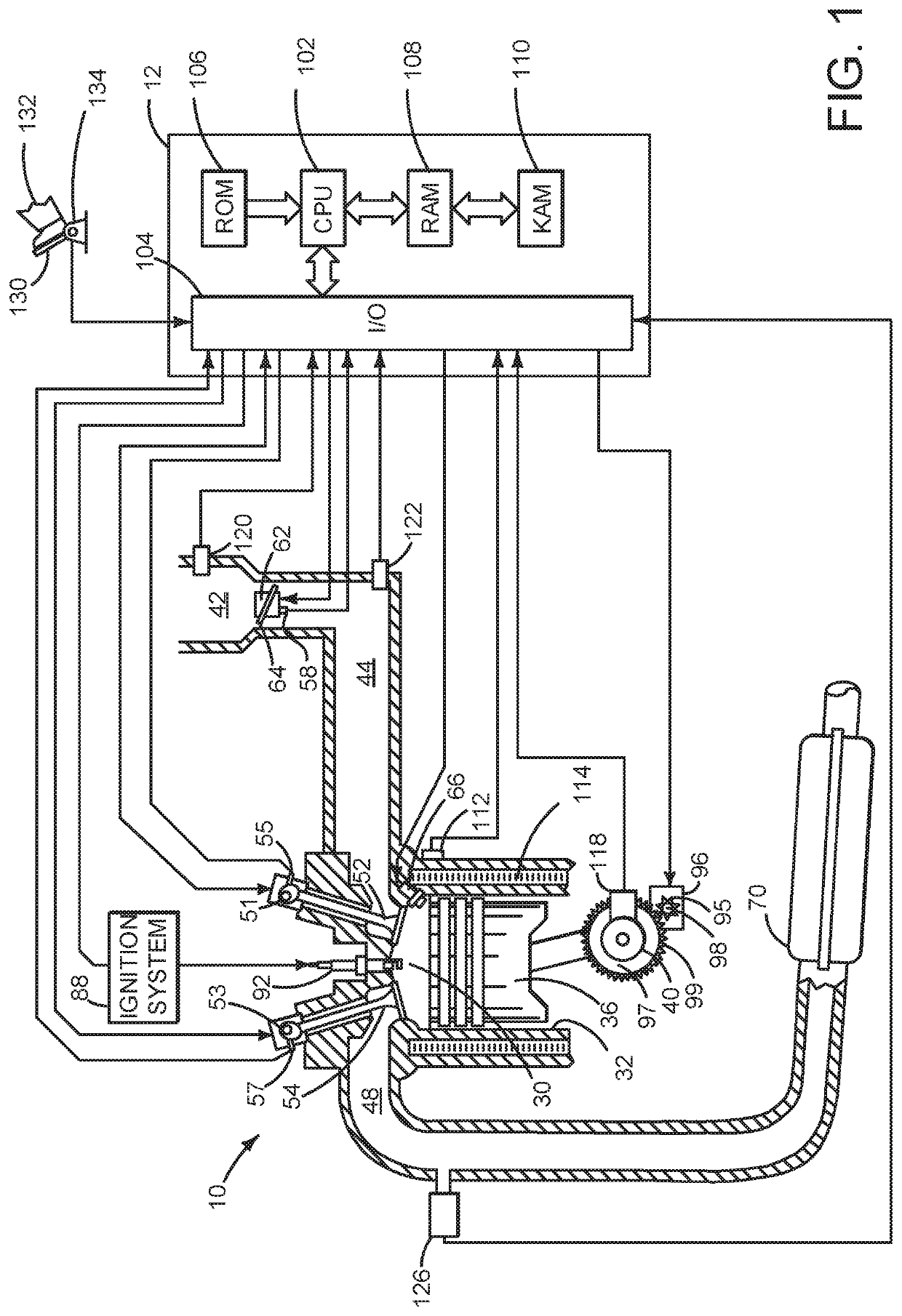

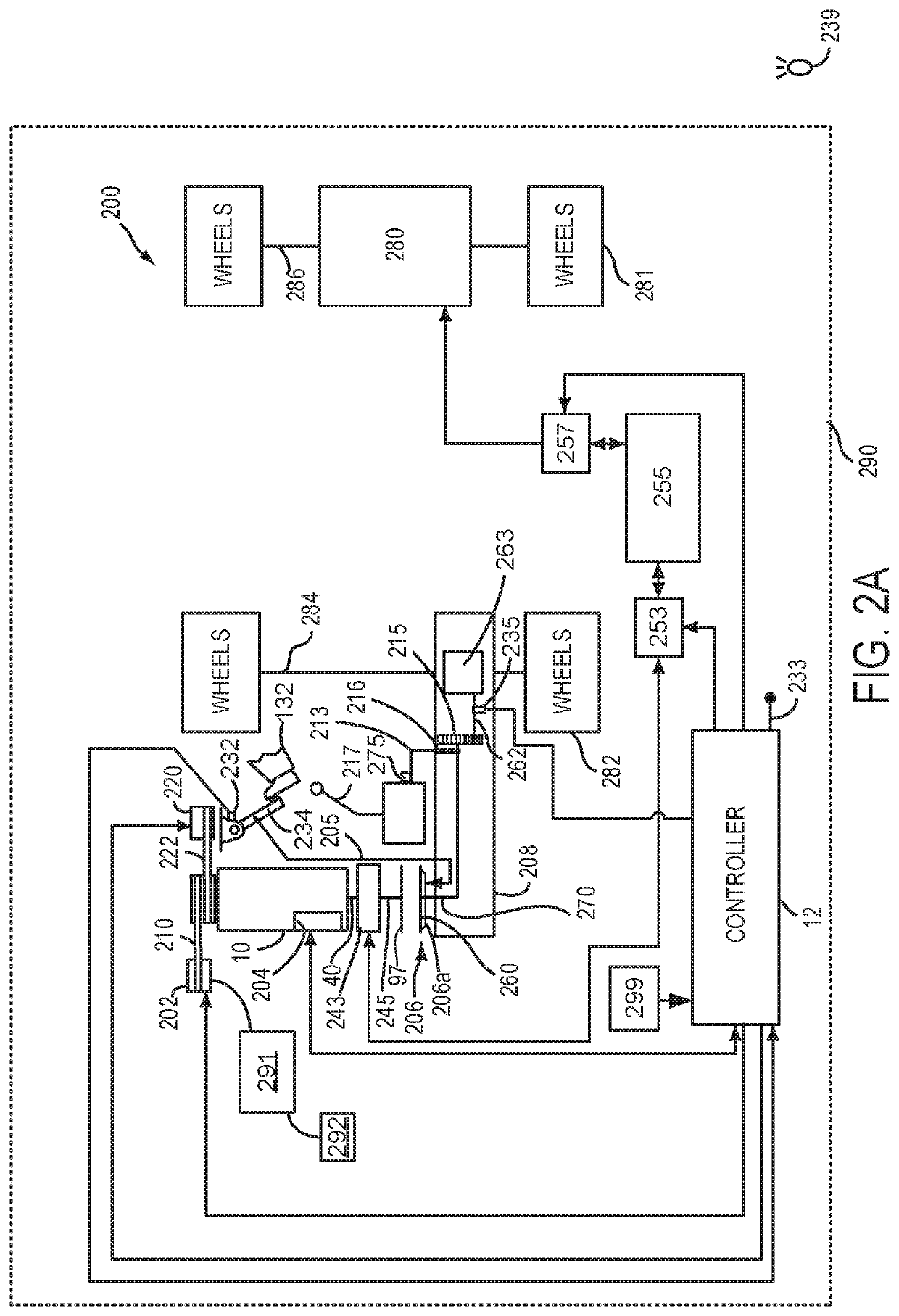

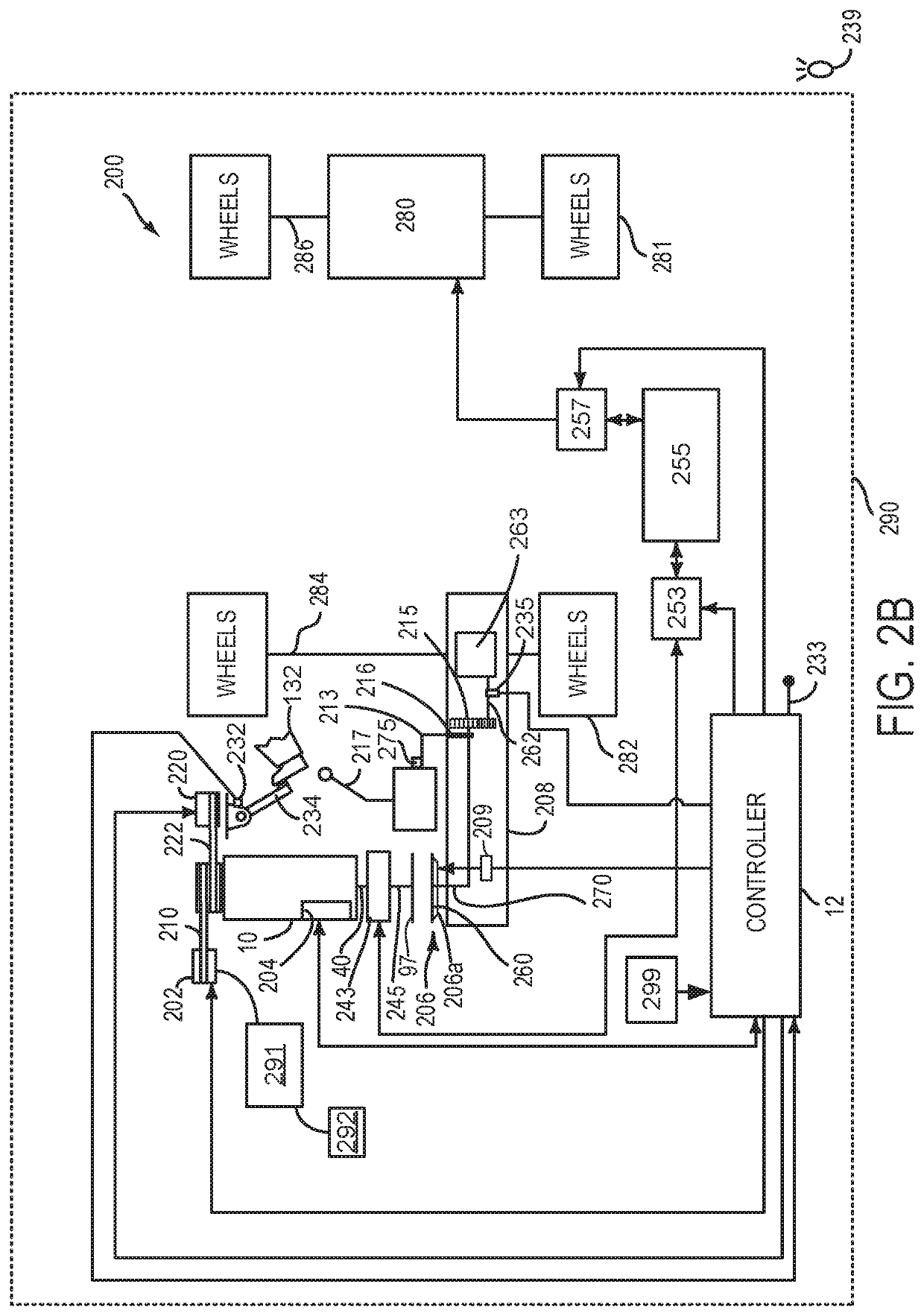

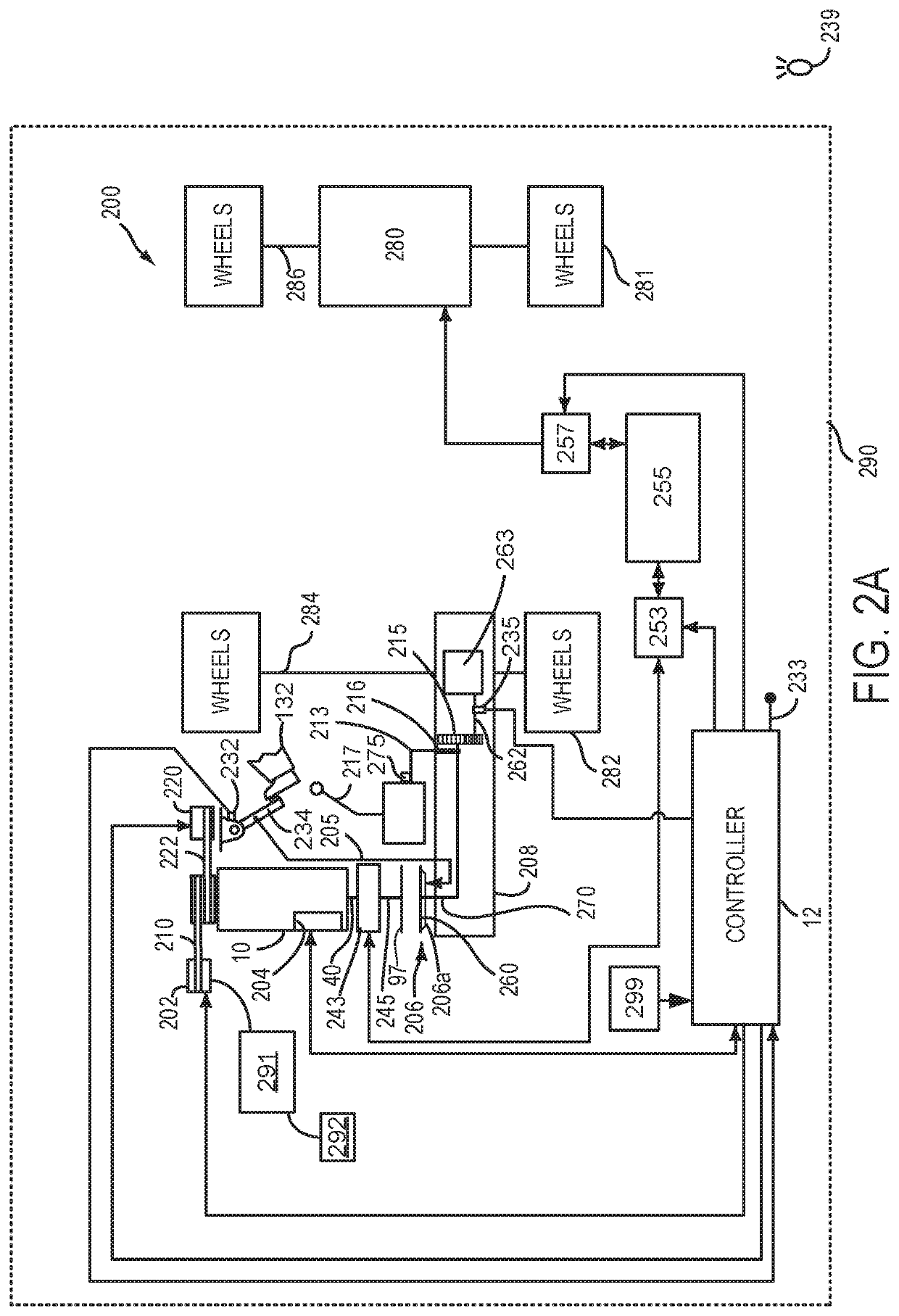

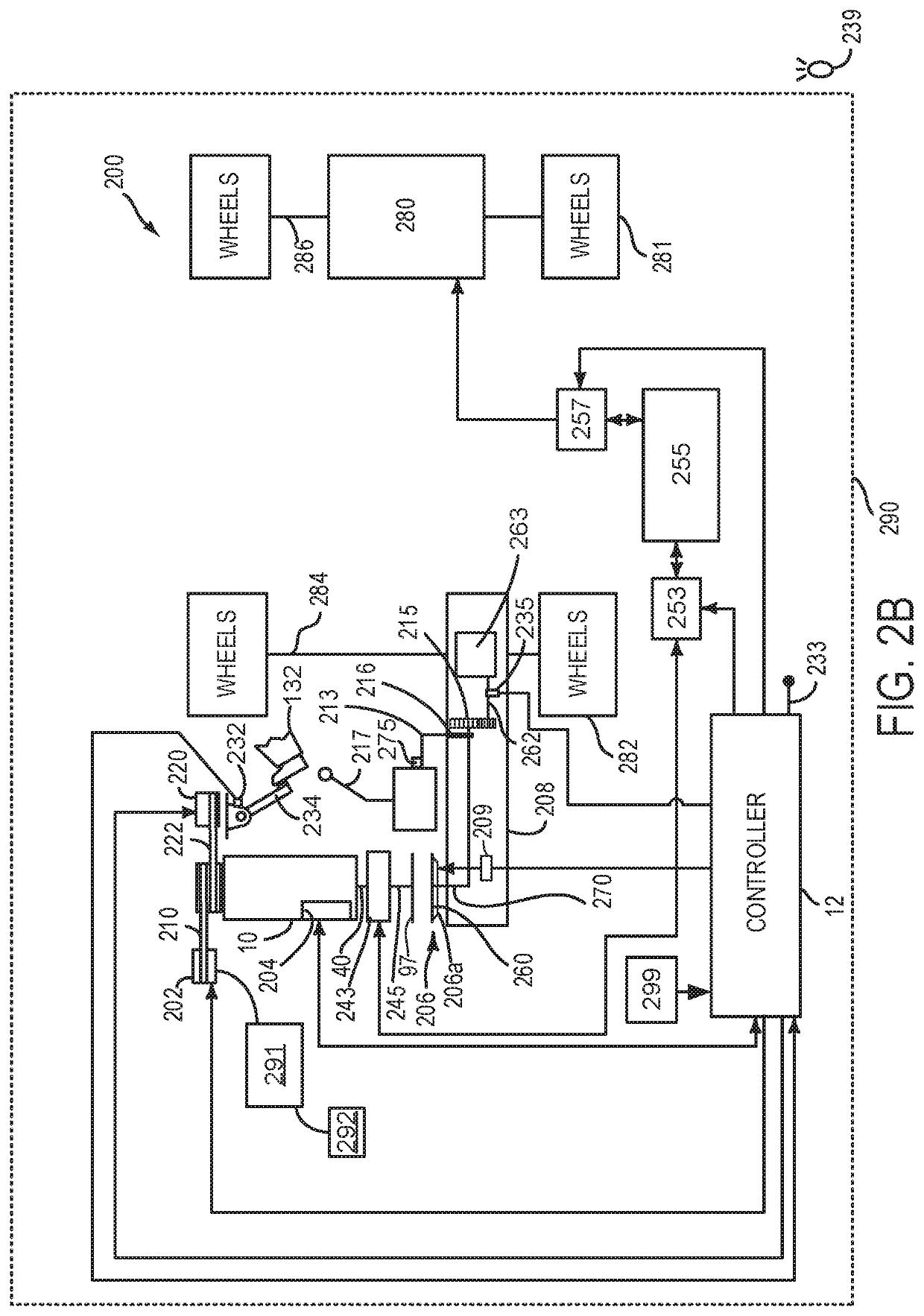

Systems and methods for a hybrid vehicle with a manual shift transmission

ActiveUS20190344780A1Improve vehicle efficiencyGuaranteed uptimeHybrid vehiclesPlural diverse prime-mover propulsion mountingBattery electric vehicleVehicle driving

Systems and methods for operating a vehicle that includes a manual transmission are presented. In one example, a controller enters and exits a vehicle drive mode that is included in a plurality of vehicle drive modes in response to a clutch pedal being applied or released by a human vehicle operator. The vehicle drive modes include series hybrid, parallel hybrid, and electric vehicle only mode.

Owner:FORD GLOBAL TECH LLC

Manufacturing equipment for producing cable

The invention discloses manufacturing equipment for producing a cable. The equipment structurally comprises a frame, a drive rotating shaft, a bobbin, a twisting mechanism, an outgoing holder and a limiting frame, wherein the right end of the drive rotating shaft is embedded into the inner side of the upper end of the frame; the drive rotating shaft is arranged on the surface of the right side of the bobbin; and the twisting mechanism is arranged at the left side of the bobbin. According to the manufacturing equipment, a distance adjusting mechanism and a wire self-adjusting mechanism are arranged on a winch separately and sliding adjustment is carried out on a rack by using the wire self-adjusting mechanism to adjust the direct distance between wires and to control the tension; when the manual adjustment tension is too high, the wires are compressed to compress a reset spring through a movable block at the lower end of the structure to reduce the tension; the wires are in contact with a roller and roll, so that wire outgoing is smoother and better control on the tension can be achieved by the roller; and furthermore, aluminum wires are prevented from being broken off when twisted, so that the frequency of re-threading the wires into a twisting hole die is reduced and the work efficiency is improved.

Owner:陈灯芳

Jet-propelled watercraft

InactiveUS7364481B2Made evenlySmooth exitInternal combustion piston enginesPropulsion power plantsJet propulsionInlet valve

A jet-propelled watercraft capable of maintaining a propulsion force required for a turn made at the same time as closing of a throttle valve. The jet-propelled watercraft has an auxiliary intake valve and an ECU. The auxiliary intake valve in an intake pipe opens / closes an auxiliary intake passage to bypass a throttle valve. The ECU performs control such that an opening of the auxiliary intake valve in a state where the rotation speed of the engine is not lower than a threshold value is larger than the opening of the auxiliary intake valve in a state where the engine is idling. When in a state where the rotation speed is not lower than the threshold value, it is detected that the throttle valve is completely closed and that a steering mechanism has been turned by a prescribed angle or more, a current opening of the auxiliary intake valve is maintained.

Owner:HONDA MOTOR CO LTD

Multi-functional charging pile based on solar energy

InactiveCN106998096ATo protect storageAvoid long-term exposurePhotovoltaic supportsCircuit monitoring/indicationLong axisSolar cell

The invention discloses a multi-functional charging pile based on solar energy. The multi-functional charging pile comprises a solar cell panel, a strut and a base, wherein a storage battery and charging equipment are arranged at an upper part of the strut, a plurality of lead groove cavities are formed in the strut, extension long-axis directions of the lead groove cavities are parallel to an axial direction of the strut, the lead groove cavities are distributed in a circular annular way by taking an axial line of the strut as a reference, a guide rail and a sliding block are arranged in each lead groove cavity along an axial direction, the sliding block is adaptive to the guide rail, a side wall of an outer edge of the sliding block is in contact with an inner wall of the lead groove cavity, the sliding block slides along the guide rail under driving of a servo motor, a lower end part of each lead groove cavity communicates with the outside through an outgoing line hole formed in a side wall of the strut, one end of a charging line is connected with the charging equipment, the other end of the charging line penetrates through the lead groove cavity and the sliding block along the axial direction and is led out of the outgoing line hole, a switch of the servo motor is arranged on an outer side wall of the strut, and the servo motor supplies power through the storage battery. By the multi-functional charging pile, the charging line is convenient to store and is prevented from being exposed for a long time to affect the service lifetime of the charging line.

Owner:四川浩能新能源有限公司

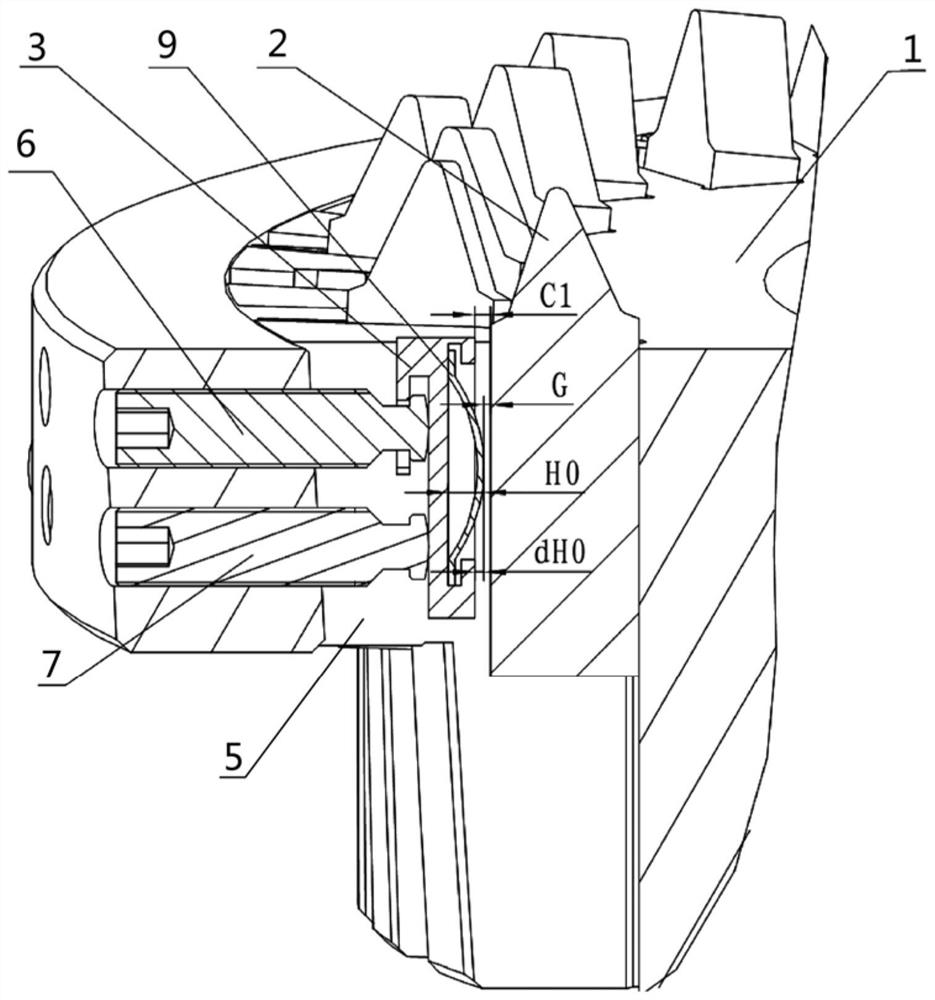

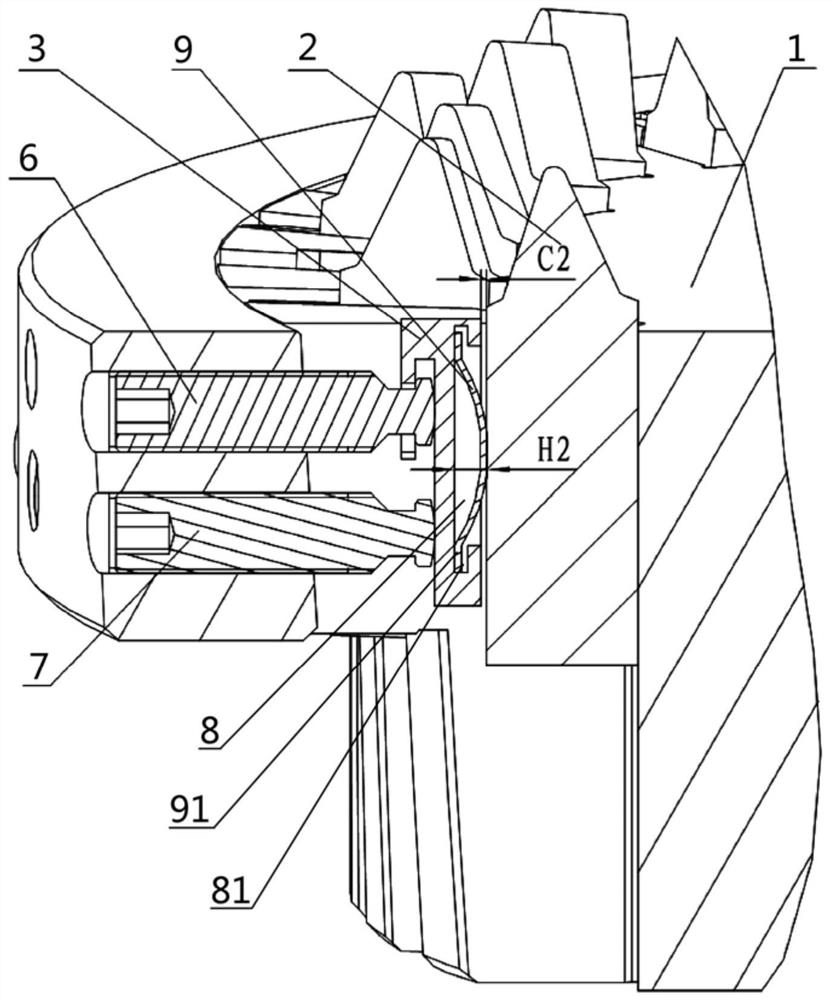

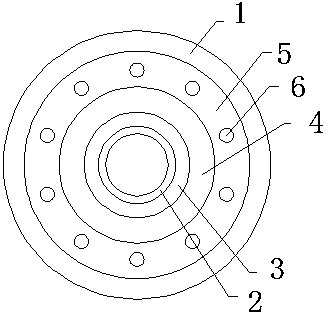

Cutting tool with preloaded springs and assembling method thereof

PendingCN112958851AInsert continuousInsert smoothlyGear teeth manufacturing toolsGear-cutting machinesClassical mechanicsEngineering

The invention discloses a cutting tool with preloaded springs and an assembling method thereof. The cutting tool comprises a tool body, wherein tool grooves are formed in the tool body, threaded through holes are formed between the outer edge of the tool body and the tool grooves, locking screws are arranged in the threaded through holes, pressing blocks are arranged between the locking screws and blades, a spring groove is formed in the inner side face of each pressing block, the preloaded springs are arranged in the spring grooves, the preloaded springs are each provided with a pressure applying portion which makes contact with the pressed face of a blade in the inserting and withdrawing directions in a smooth transition mode, and in a preloaded state, the pressure applying portions of the preloaded springs are higher than the inner side faces of the pressing blocks and are in contact with the pressed surface of the blade. According to the cutting tool, when the tool is assembled, the blade can enter a preloaded state after being inserted into the tool grooves, the blade can be continuously and smoothly inserted into and withdrawn from the tool grooves, adjustment is easy, the number of parts is small, and it can be guaranteed that the blade is in a reasonable stress state.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

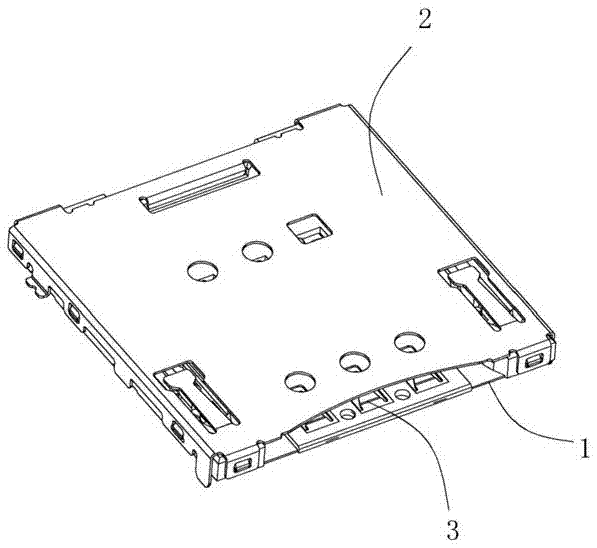

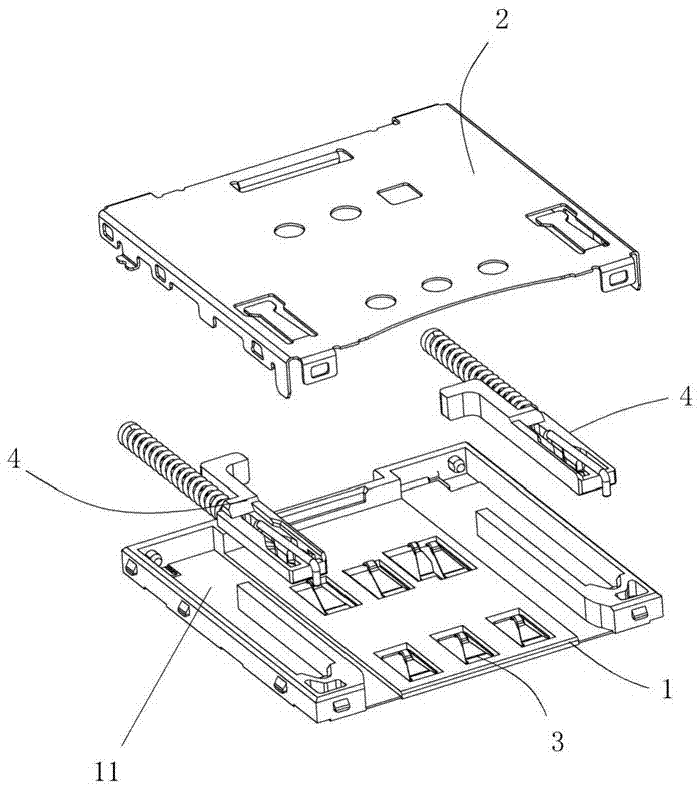

Subscriber identity module (SIM) card seat with dual pop-up mechanisms

The invention discloses a SIM card holder with a double self-elastic mechanism, comprising a base and a shell, the base is provided with connecting terminals, the left side and the right side of the base are oppositely provided with a cavity, the cavity Self-bounce devices are respectively arranged in the inside. The present invention is simple in structure, and self-elastic devices are designed on the left and right sides of the base at the same time, so that the overall force on the base is uniform, and a single spring can ensure the smooth withdrawal of the SIM card and the card holder even if the force is small. It is not easy to tilt in the deck.

Owner:DONGGUAN OLN ELECTRONICS TECH CO LTD

Quick locking device for self-locking machine tool part

ActiveCN111408960ARealize automatic lockingQuick lockLarge fixed membersPositioning apparatusLocking mechanismControl engineering

The invention discloses a quick locking device for a self-locking machine tool part. The quick locking device comprises a lock pin, a lock body upper end cover, a lock body upper part, a lock body lower part, a lock body lower end cover and a self-locking mechanism. A pressing plate is driven to be linked in the inserting process of the lock pin, so that a wedge-shaped limiting block of the self-locking mechanism is driven to slide out to achieve automatic locking, meanwhile, the self-locking mechanism reaches a self-locking position at a tail position, and stable locking is achieved. When unlocking is needed, a reset pin is used for pressing the pressing plate to drive the self-locking mechanism to deviate from the self-locking position, and a reset mechanism is triggered to reset after the lock pin is taken out. According to the technical scheme disclosed by the invention, quick positioning and locking are achieved, and the good effect of stable and quick locking is achieved throughthe self-locking characteristic of the mechanism; in addition, the technical scheme of the invention is high in integration level, convenient to operate and simple in configuration.

Owner:湖南九五精机有限责任公司

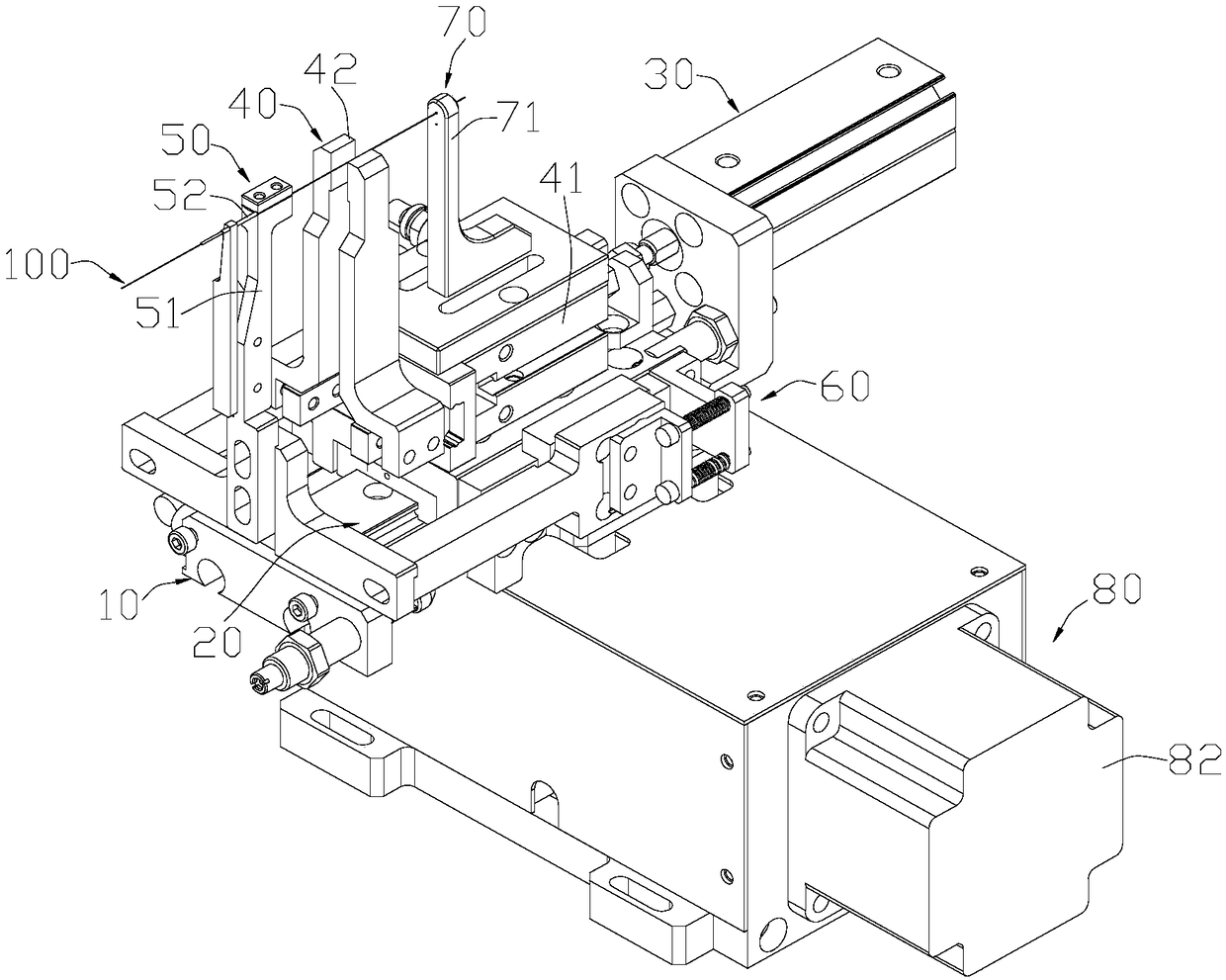

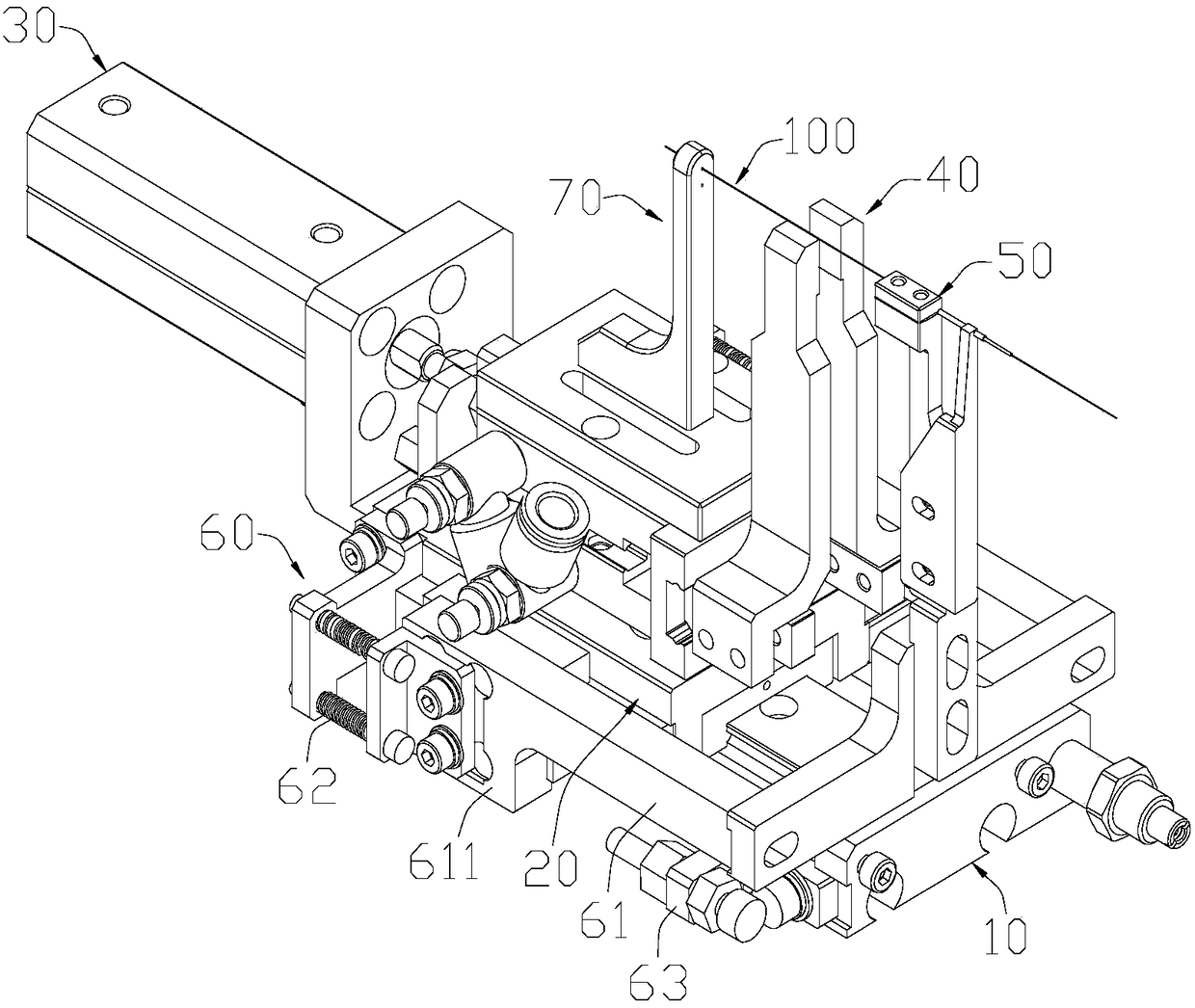

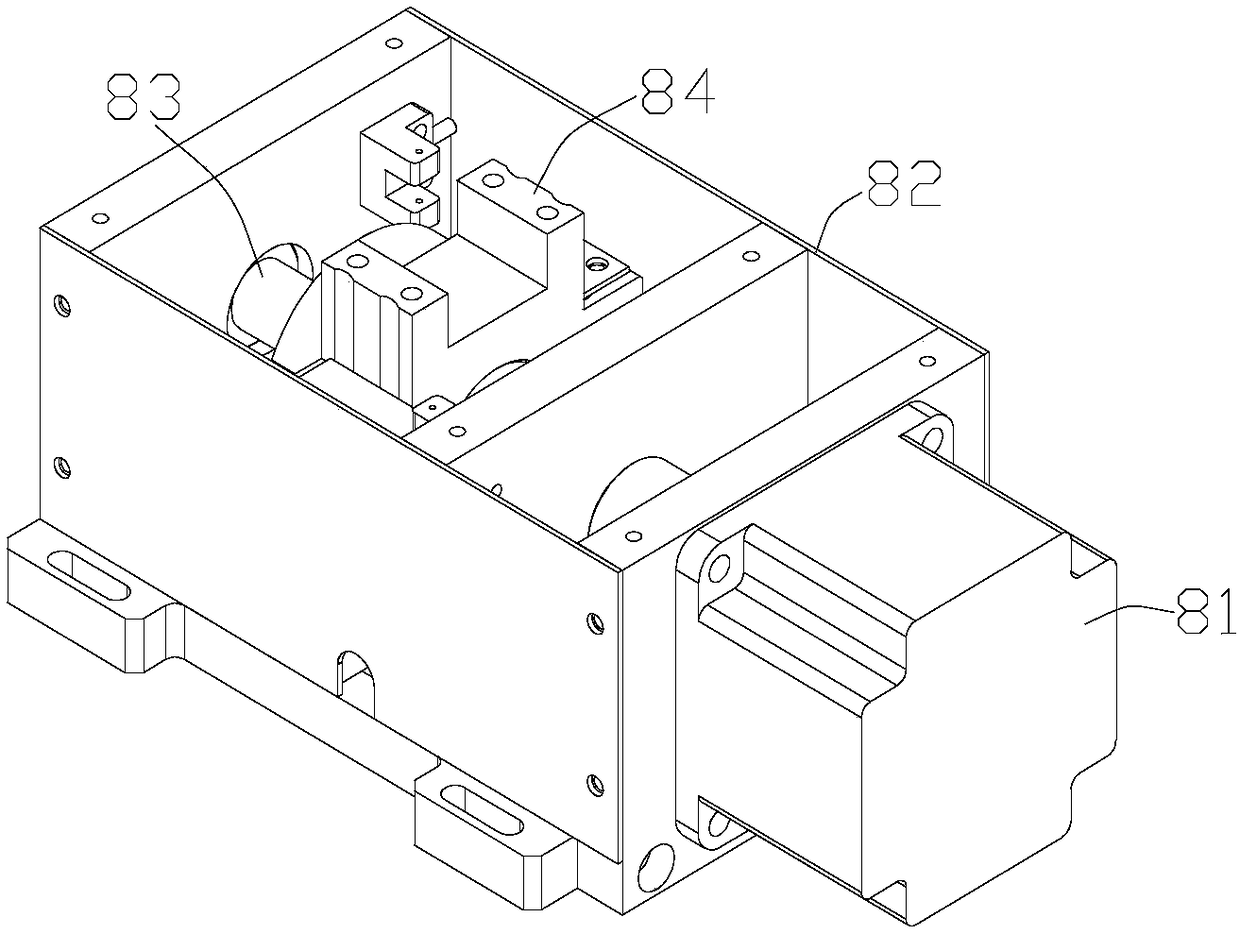

Heating wire feeding device

PendingCN108584535ARealize fully mechanized automatic productionWire feeding is stable and accurateFilament handlingReciprocating motionEngineering

The invention discloses a heating wire feeding device. The heating wire feeding device comprises a base, a slide base cooperating with the base in a reciprocating motion manner, a driving mechanism connected with and driving the slide base to perform a reciprocating motion on the base, a clamping mechanism mounted on the slide base and used for clamping heating wires, a first guide mechanism arranged on one side of the clamping mechanism in a heating wire arrangement direction and used for enabling the heating wires to penetrate through, and a linkage mechanism; the first guide mechanism is mounted on the linkage mechanism; the linkage mechanism is connected between the base and the slide base; and after the slide base moves along the base, the first guide mechanism is driven to move in adirection of approaching the clamping mechanism to send out the heating wires. The heating wire feeding device realizes automatic feeding of the heating wires, and is stable and accurate in wire feeding.

Owner:中山市胜裕丰贸易有限公司

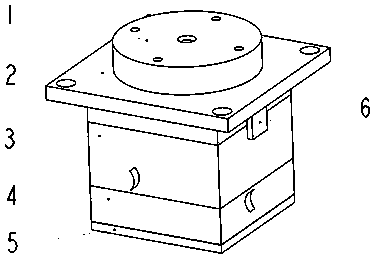

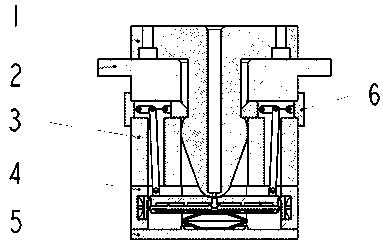

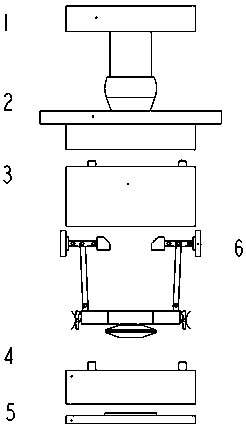

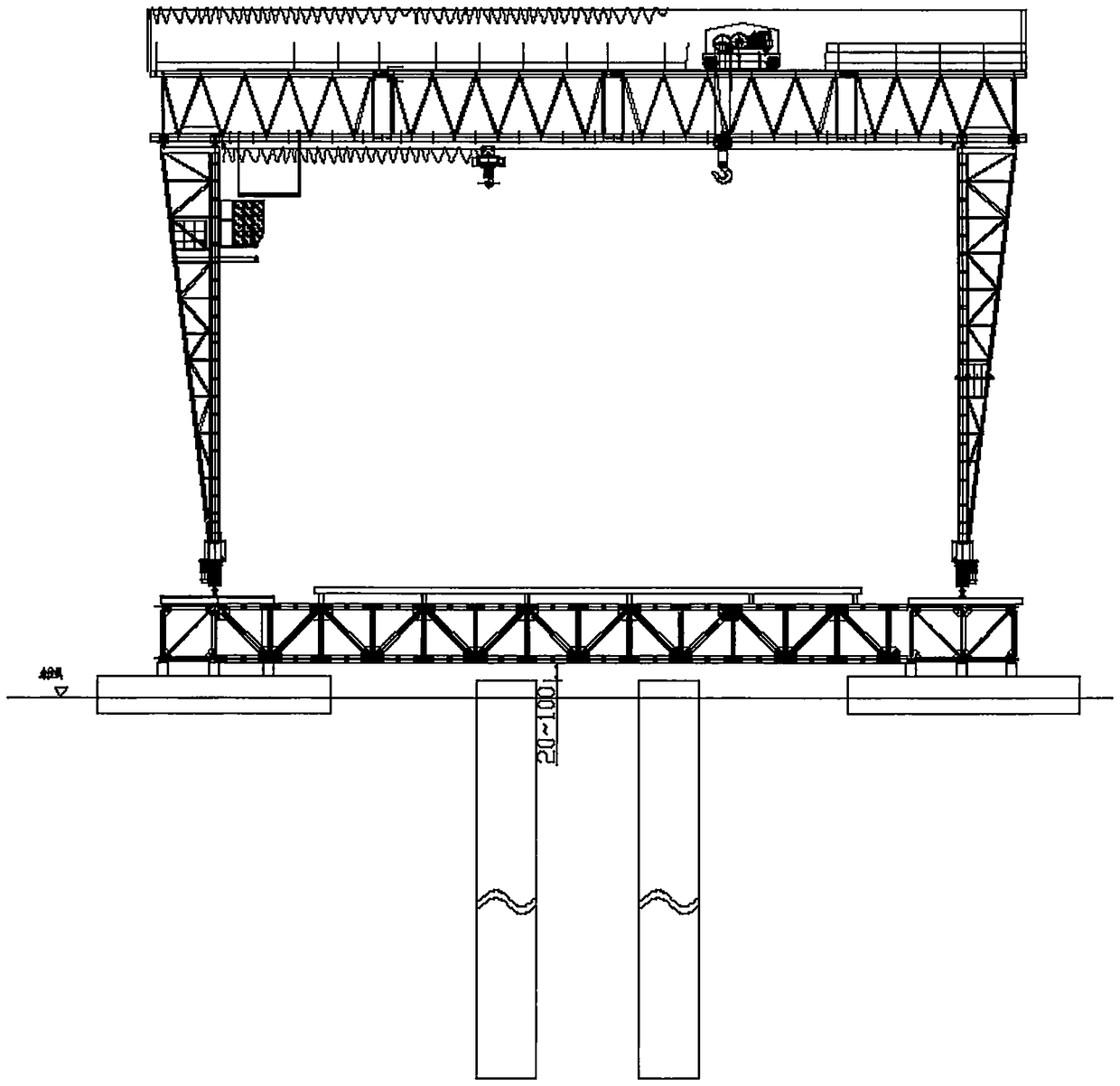

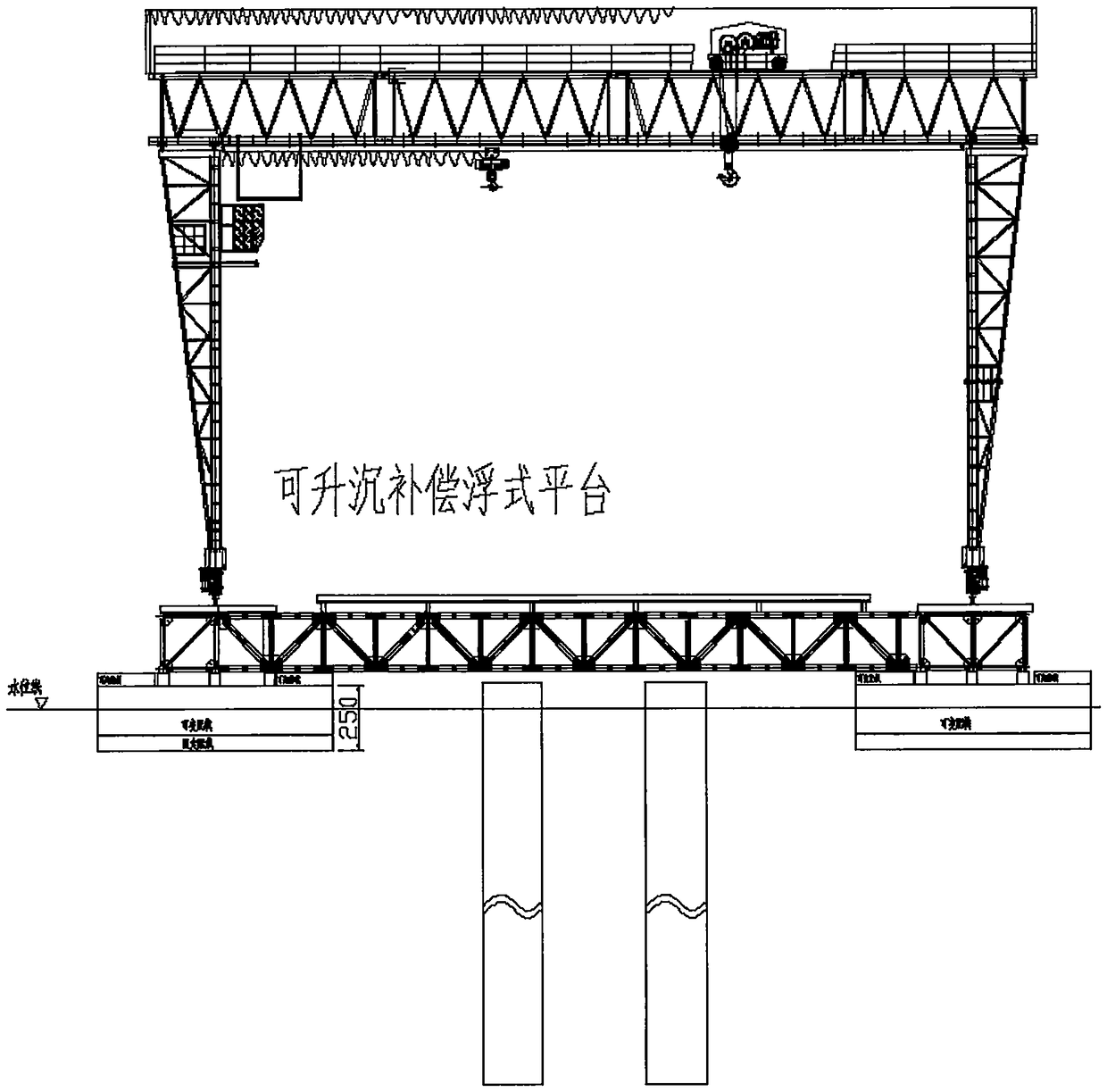

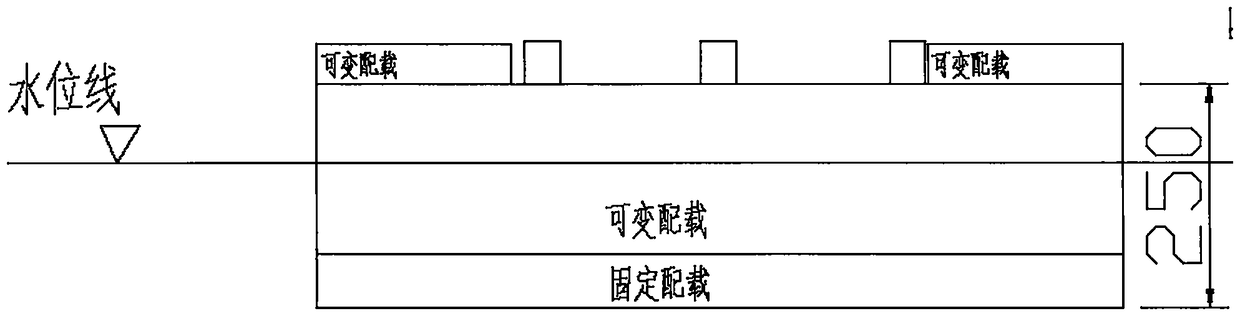

Heave compensation floating platform and heave compensation device thereof

InactiveCN108909962APossess active ascension abilitySmooth exitFloating buildingsInternal variableWater level

The invention discloses a heave compensation device of a floating platform. The heave compensation device comprises a fixed stowage pontoon and a variable stowage, wherein the variable stowage comprises an internal variable load arranged inside the fixed stowage pontoon and an external variable load arranged on the top of the fixed stowage pontoon; and the dimensions of the fixed stowage pontoon are 900 cm x 150 cm x 250 cm. The heave compensation device of the floating platform enables the floating platform to have an active ascending capability when the water level descends by more than 1.5m, so that the floating platform can be smoothly withdrawn without the need for dismounting so as to facilitate circulating use.

Owner:SHAANXI RAILWAY INST

Systems and methods for a hybrid vehicle with a manual shift transmission

ActiveUS10773710B2Improve vehicle efficiencyGuaranteed uptimeHybrid vehiclesPlural diverse prime-mover propulsion mountingPure electric vehicleControl theory

Systems and methods for operating a vehicle that includes a manual transmission are presented. In one example, a controller enters and exits a vehicle drive mode that is included in a plurality of vehicle drive modes in response to a clutch pedal being applied or released by a human vehicle operator. The vehicle drive modes include series hybrid, parallel hybrid, and electric vehicle only mode.

Owner:FORD GLOBAL TECH LLC

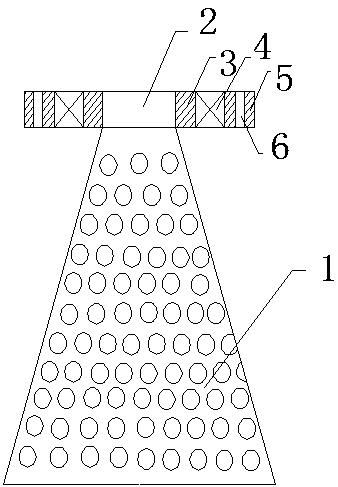

Conical bobbin

The invention discloses a conical bobbin. The conical bobbin comprises a conical bobbin body made of plastic, a notch is formed in the large-diameter end face of the conical bobbin body, through holes are evenly distributed in the wall of the conical bobbin body, a section of threaded pipe is arranged on the small-diameter end face of the conical bobbin body, and one end of the threaded pipe is fixedly connected with the small-diameter end face of the conical bobbin body; a yarn outlet rotating disc is connected to the threaded pipe and comprises an inner rotating disc body, a bearing and an outer rotating disc, internal threads are arranged on the inner rotating disc, the inner rotating disc is located in an inner ring of the bearing, fixedly connected with the bearing and connected with the threaded section through the threads in a matched mode, the outer rotating disc is connected to an outer ring of the bearing in a sleeved mode and fixedly connected with the bearing, and a circumferential disc face of the outer rotating disc is provided with through holes evenly distributed in a circumferential shape. The conical bobbin is simple in structure and capable of improving working efficiency, and yarn outgoing is smooth.

Owner:CHONGQING YUBI TEXTILE

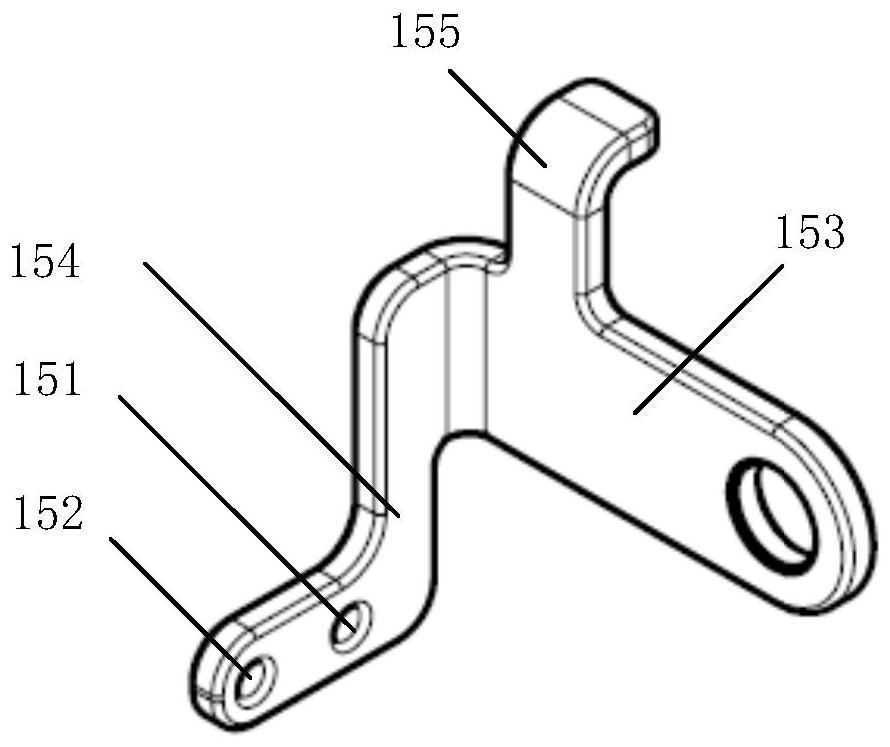

Sewing machine thread passing structure and sewing machine

PendingCN113235236AStable line storageStable thread consumptionThread-break detectorsTake-up devicesEngineeringSewing machine

The invention provides a sewing machine thread passing structure and a sewing machine. The sewing machine thread passing structure comprises a first thread clamping device, a second thread clamping device, a first threading plate, a thread picking plate, a thread passing plate, an upper curved needle and a lower curved needle; the thread picking plate is rotatably connected with a machine body of the sewing machine; the thread passing plate is provided with a first thread passing part and a second thread passing part; a first needle thread sequentially penetrates through the first threading plate, the thread picking plate, the first thread passing part and the upper curved needle through the first thread clamping device; and a second needle thread sequentially penetrates through the first threading plate, the thread picking plate, the second thread passing part and the lower curved needle through the second thread clamping device. The first thread passing part and the second thread passing part are arranged on the thread passing plate to pass threads respectively, so that the thread storage amount and the thread use amount of the upper curved needle and the lower curved needle can be stabilized, various sewing processes such as thin, medium and thick material overlocking and the like can be met, smooth thread outgoing and flat and attractive stitches can be ensured, and meanwhile, the product quality can be improved.

Owner:上海富山精密机械科技有限公司

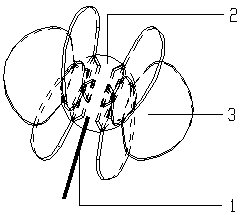

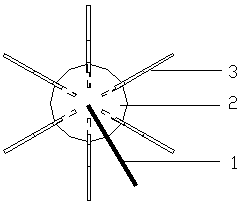

Anti-winding coil structure for 3D printing

InactiveCN109532017AAvoid entanglementSmooth exitManufacturing enclosuresCoil structureConductor Coil

The invention discloses an anti-winding coil structure for 3D printing. The anti-winding coil structure comprises a control rod, a central sphere and wings, and is characterized in that the control rod is connected with the bottom end of the wire winding sphere; the wings are fixed to the wire winding sphere; and the wings are arranged around the vertical direction of the central axis of the wirewinding sphere in a central symmetry mode and form corresponding wire grooves. The anti-winding coil structure has the beneficial effects that printed wires are regularly wound in the wire grooves constituted by the central sphere and the wings, thus the wires form intersections at the two ends of the central sphere in the winding process, winding and extrusion between the wires are avoided, and in the 3D printing process, wire discharging is smoother.

Owner:JIANGSU HUAXIA INTPROP SERVICE CO LTD

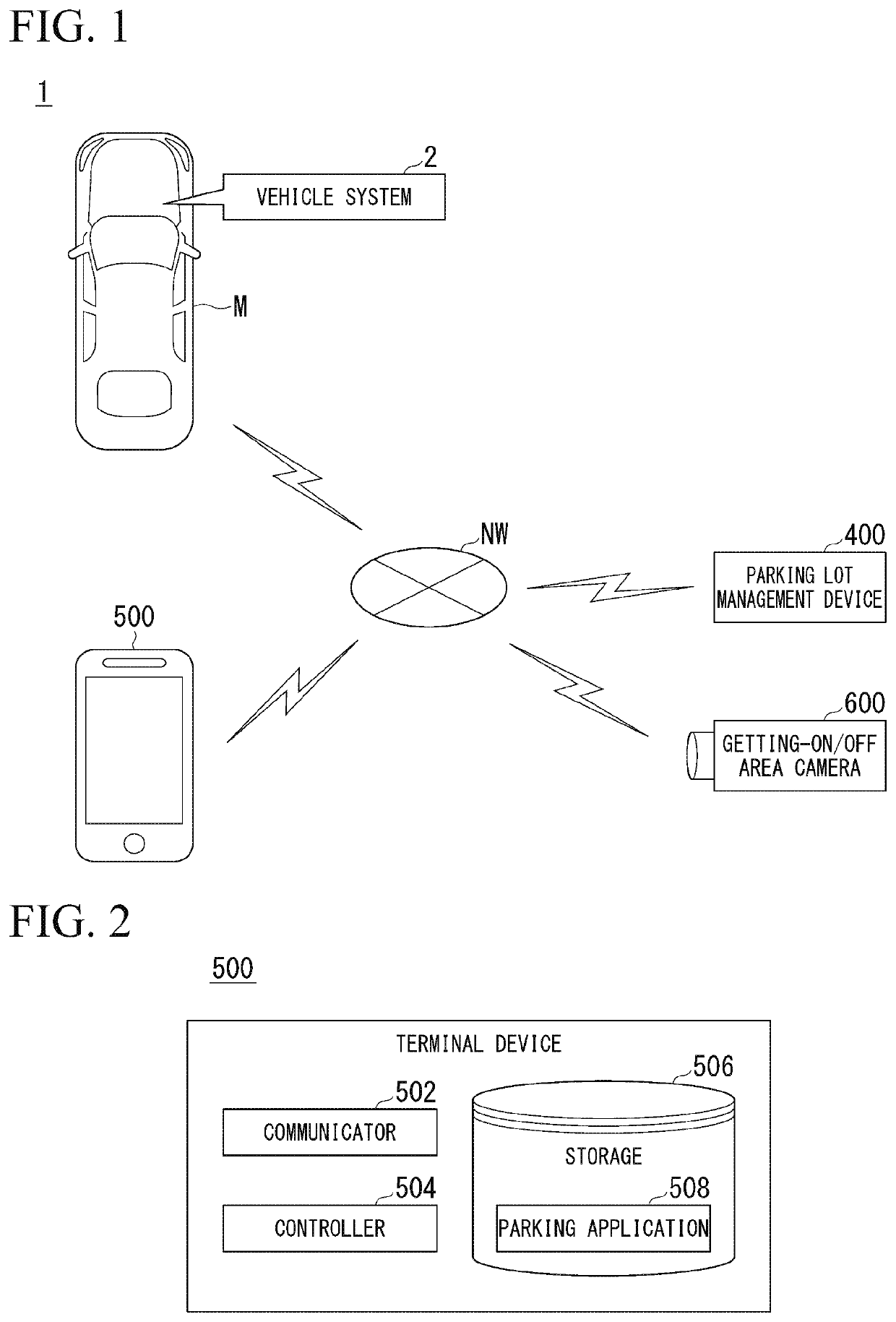

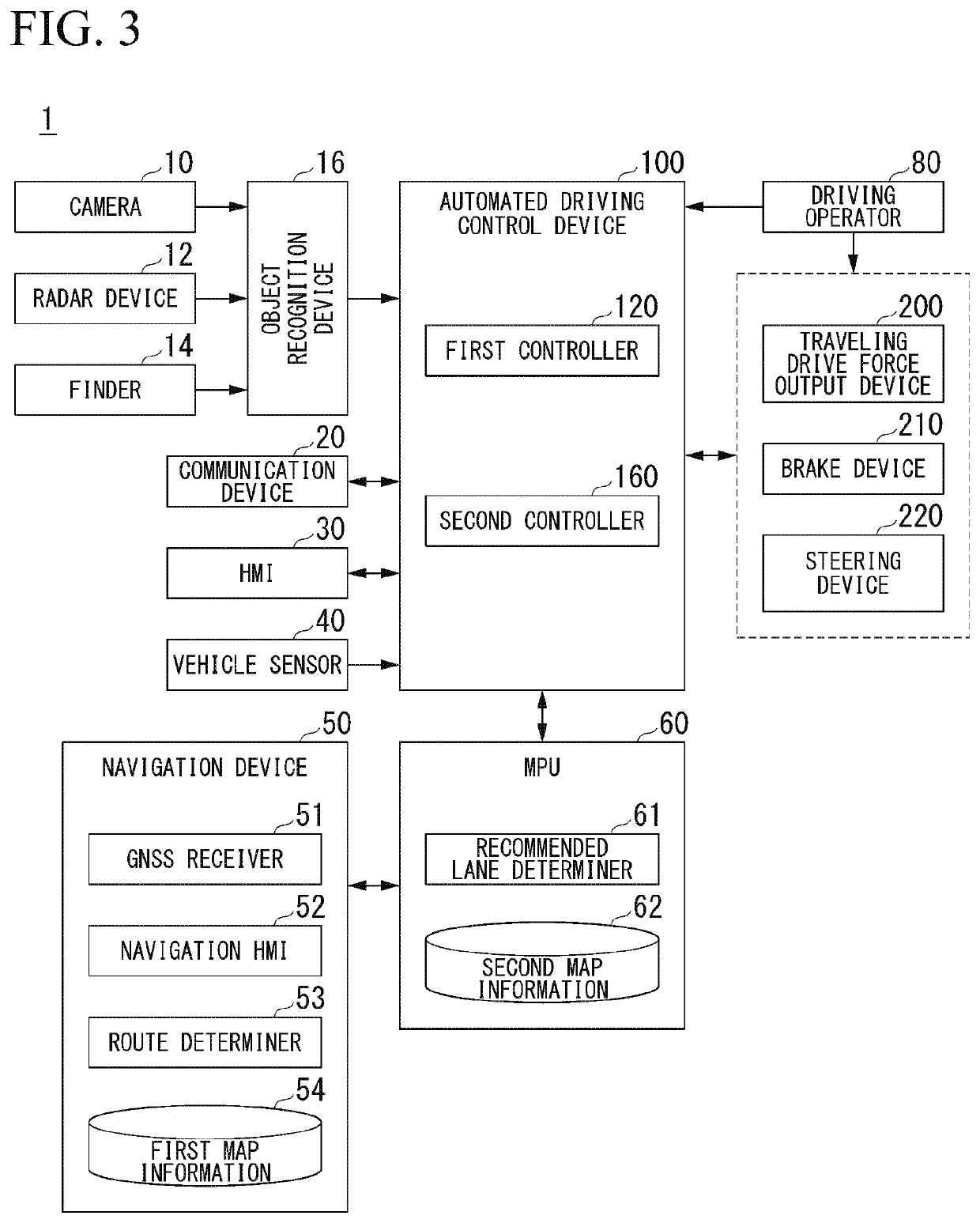

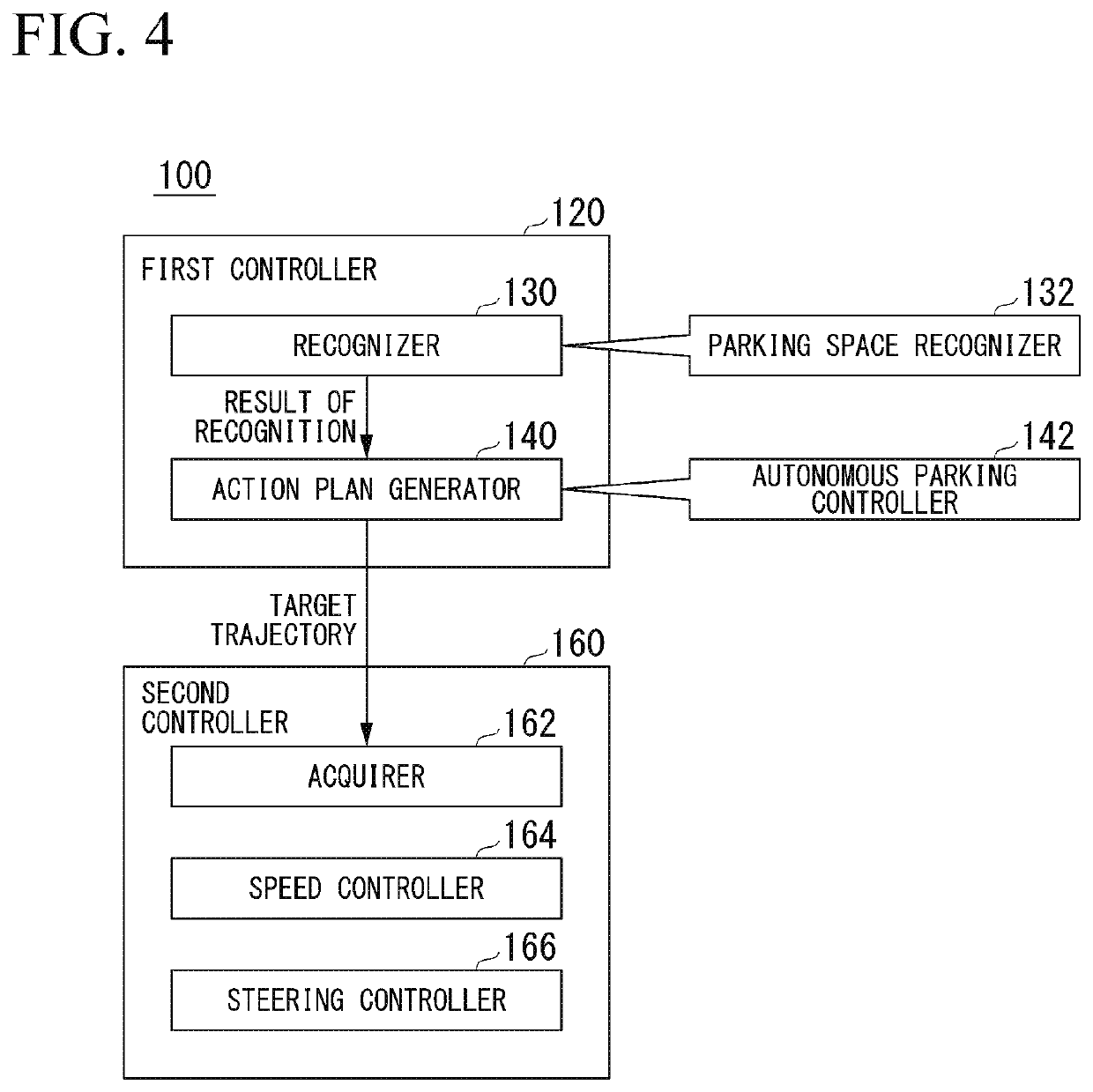

Management device, management method, and storage medium

ActiveUS11302194B2Smooth exitImprove convenienceControl with pedestrian guidance indicatorDetection of traffic movementSimulationParking space

A management device includes an acquirer configured to acquire a plurality of requests for automated exit processing, a classifier configured to classify the requests into first requests of first users who are permitted to use a specific parking space and second requests of second users who are not permitted to use the specific parking space, and an instructor configured to cause vehicles associated with terminal devices which are transmission sources of the first requests to perform automated exit processing such that automated exit processing according to the first requests is continuously executed, or to cause vehicles associated with terminal devices which are transmission sources of the second requests to perform automated exit processing such that automated exit processing according to the second requests is continuously executed, on the basis of a result of the classification.

Owner:HONDA MOTOR CO LTD

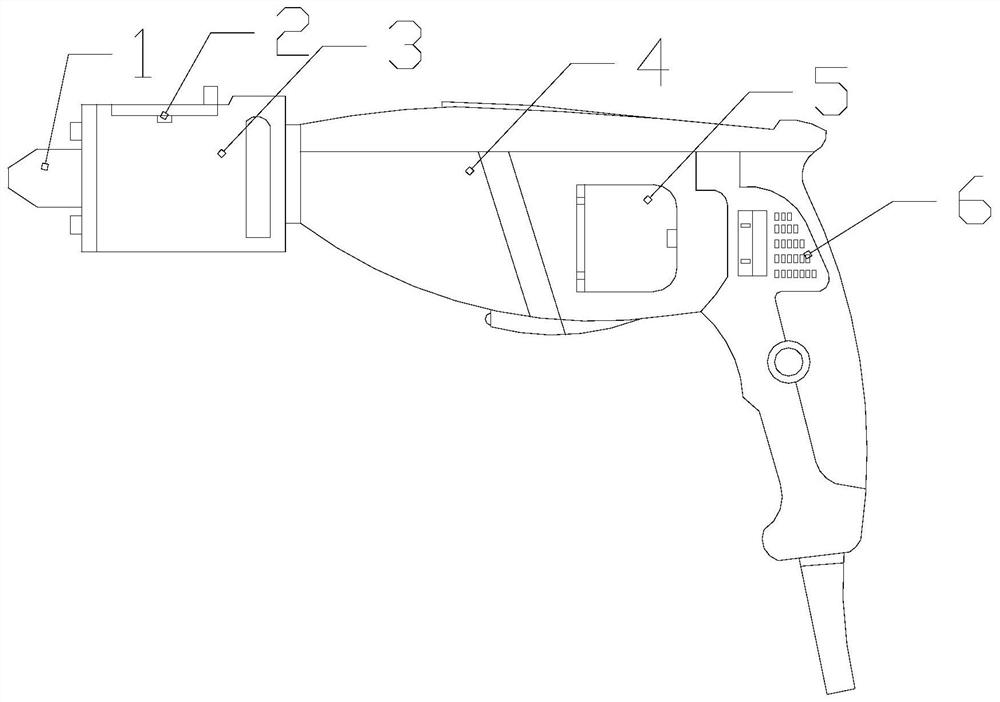

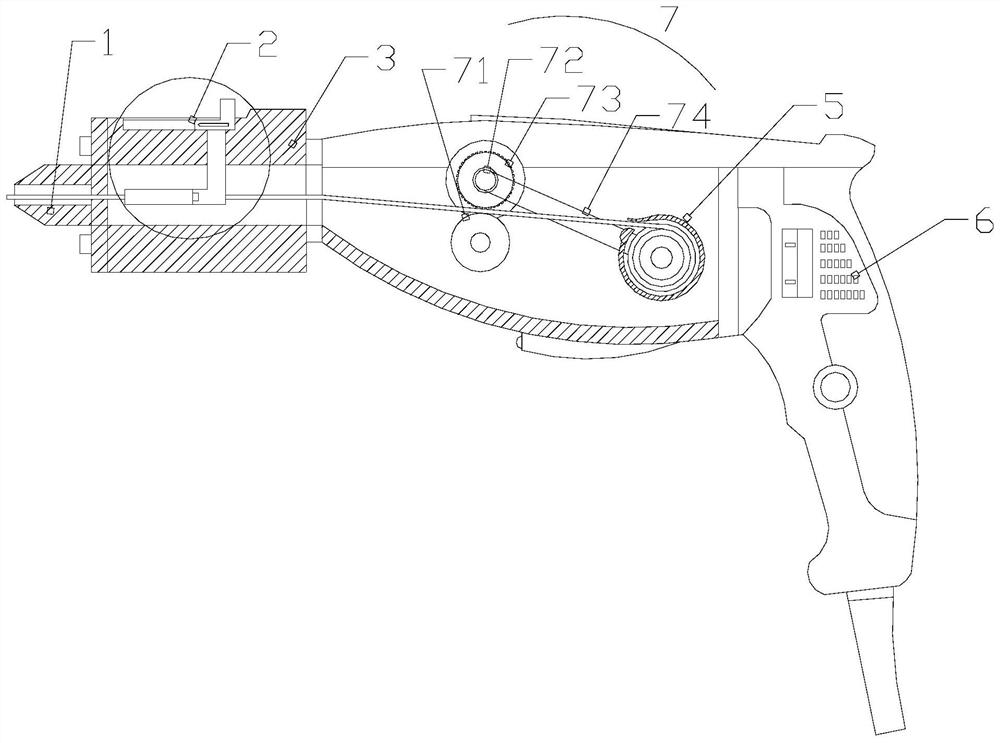

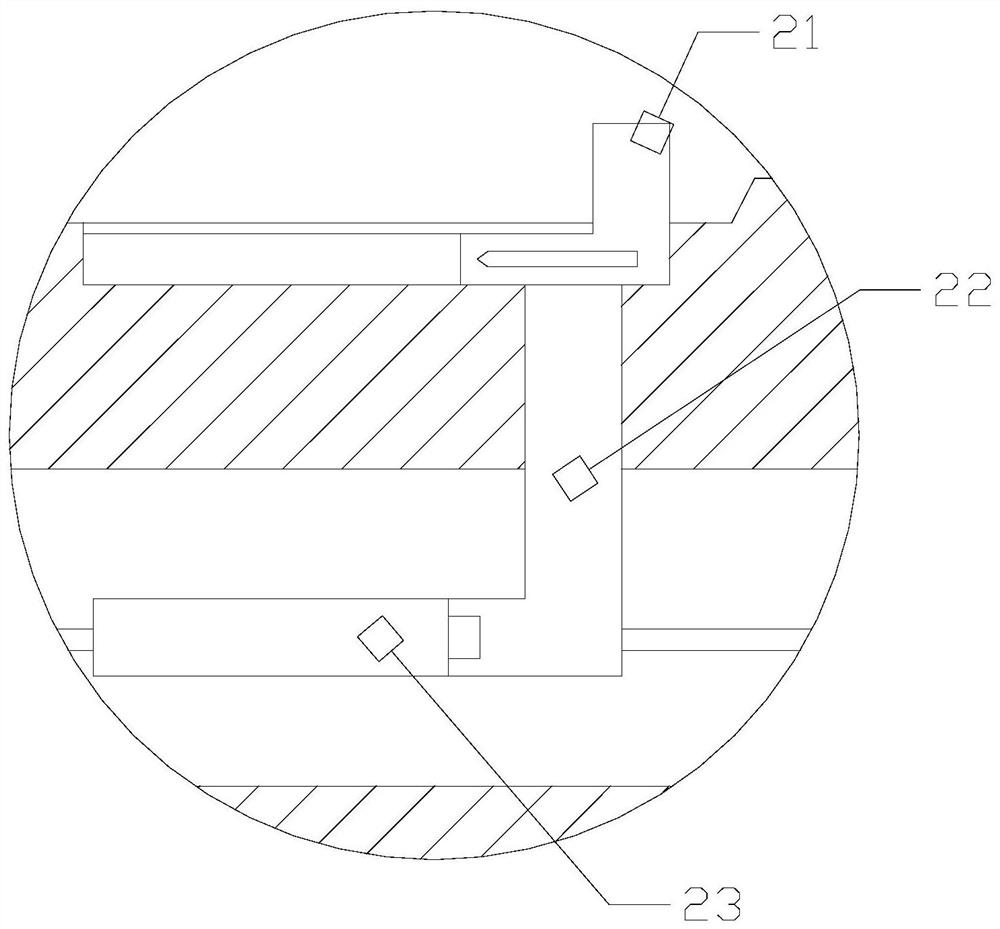

Circuit board welding gun achieving automatic feeding

InactiveCN111745248AAccurate outputIncrease strengthWelding/soldering/cutting articlesMetal working apparatusElectrical and Electronics engineeringSoldering gun

The invention discloses a circuit board welding gun achieving automatic feeding. The circuit board welding gun structurally comprises an electric welding head, a wire wiping structure, a front end, abody, an automatic wire discharging device and a handle. The front end and the handle are mounted at the two horizontal ends of the body correspondingly. The automatic wire discharging device is mounted in the body. The electric welding head is mounted on the other side, opposite to the body, of the front end and cooperates with the wire wiping structure. A rotating shaft is sleeved with the circuit board welding gun through a tin wire barrel, after a motor is powered on to rotate, a tin wire is conveyed out from wire outlets of housings, the tin wire comes out from the electric welding head after being guided by the wire wiping structure, heating is achieved on the electric welding head together, and tin and heating are achieved together; and through the housings on the two sides of the wire outlet, one housing is warped outwards, the other end is in an outward semicircular shape, the two ends of each housing are smooth and free of burrs, tin wire discharging is smoother, and the problems that tin wires are broken due to mutual friction, and wires cannot be fed smoothly cannot happen.

Owner:蔡彪

Manufacturing equipment for cable production

The invention discloses manufacturing equipment for producing a cable. The equipment structurally comprises a frame, a drive rotating shaft, a bobbin, a twisting mechanism, an outgoing holder and a limiting frame, wherein the right end of the drive rotating shaft is embedded into the inner side of the upper end of the frame; the drive rotating shaft is arranged on the surface of the right side of the bobbin; and the twisting mechanism is arranged at the left side of the bobbin. According to the manufacturing equipment, a distance adjusting mechanism and a wire self-adjusting mechanism are arranged on a winch separately and sliding adjustment is carried out on a rack by using the wire self-adjusting mechanism to adjust the direct distance between wires and to control the tension; when the manual adjustment tension is too high, the wires are compressed to compress a reset spring through a movable block at the lower end of the structure to reduce the tension; the wires are in contact with a roller and roll, so that wire outgoing is smoother and better control on the tension can be achieved by the roller; and furthermore, aluminum wires are prevented from being broken off when twisted, so that the frequency of re-threading the wires into a twisting hole die is reduced and the work efficiency is improved.

Owner:陈灯芳

Telescopic wire shell

The invention discloses a telescopic wire shell. The telescopic line shell comprises a fishing reel seat, wherein a line reel and a main shaft are installed in the fishing reel seat, a line shell body is arranged on the front side of the line reel, the line shell body comprises an outer line shell fixedly connected with the main shaft, the outer line shell is connected with an inner line shell in a sliding mode, the inner line shell is at least provided with two supporting feet, the supporting feet are provided with first rivets in a penetrating mode, the first rivets are riveted to the inner side end face of the outer line shell, the first rivets are sleeved with first springs, the first springs drive the inner line shell to retreat from a winding area of the line reel, a second rivet is riveted to the end face of the inner side of the outer line shell and sleeved with a base, a line hanging pin is installed at the free end of the base and telescopically protrudes out of the outer side of the outer line shell under driving of the base, a notch for storing the line hanging pin is formed in the inner line shell, a slope is arranged on the side edge of the notch, and the slope drives the inner line shell to extend to a wire winding area of the wire reel under the pressure of the line hanging pin. According to the telescopic wire shell, the problems that when an existing closed fishing reel throws a line, line outgoing is not smooth, and throwing is not far are solved.

Owner:扬州久扬渔具有限公司

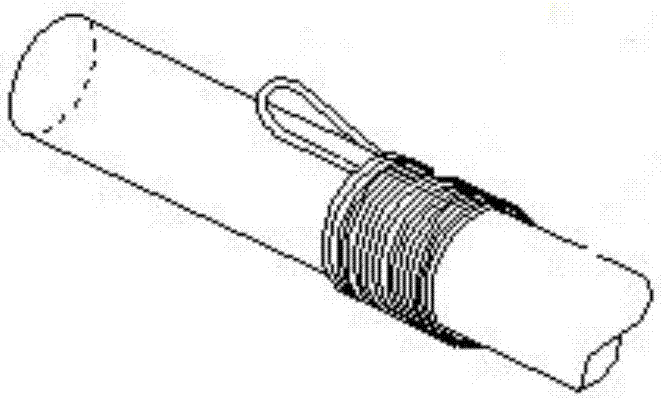

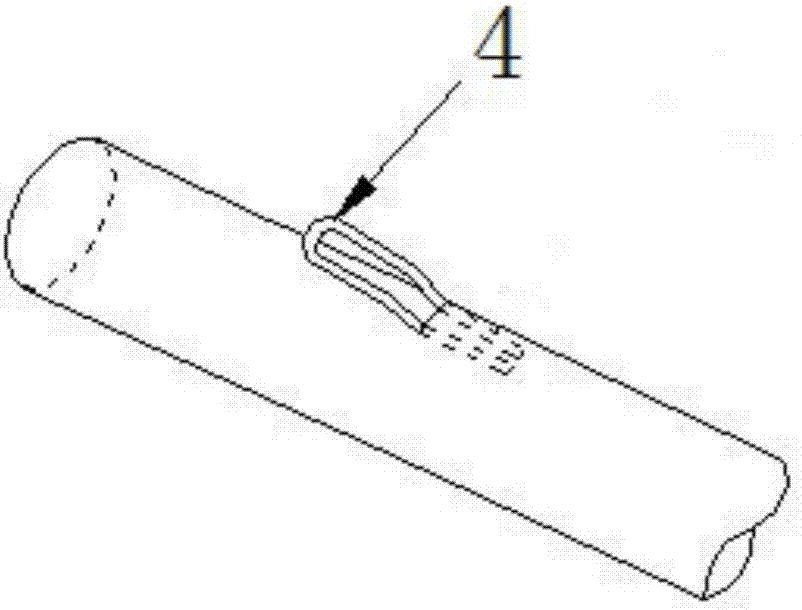

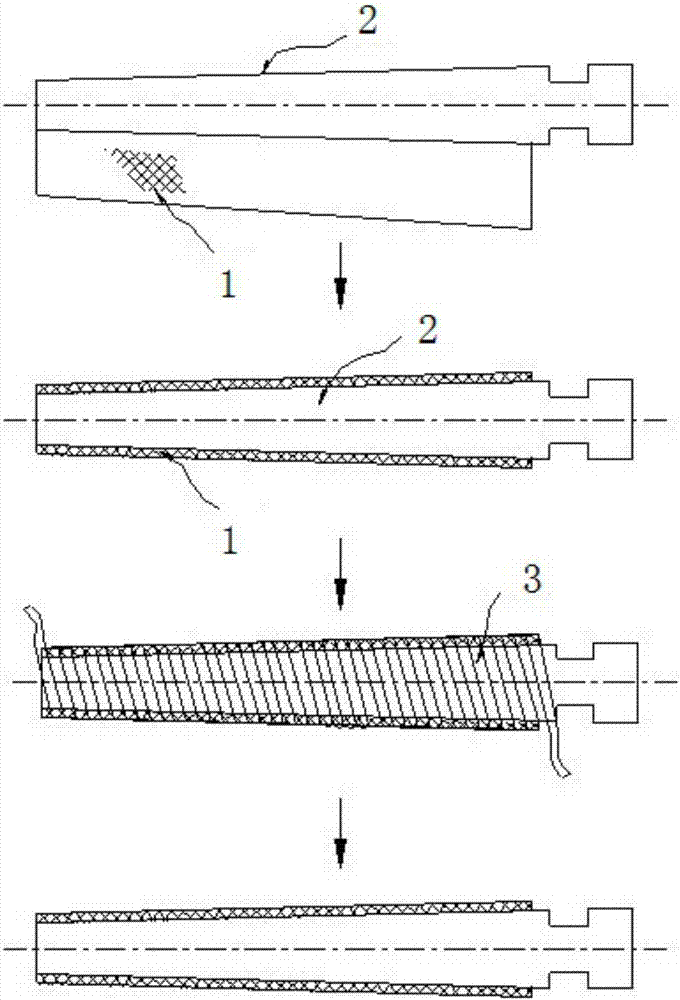

Mounting technology for integrally formed fixing wire ring of fishing rod

The invention relates to a mounting technology for an integrally formed fixing wire ring of a fishing rod. The mounting technology comprises the following steps: cutting a fiber cloth as required and rolling onto a prepared iron core of the fishing rod, and then winding on a high temperature resisting protecting film for performing high-temperature plasticizing and removing the high temperature resisting protecting film after plasticizing, thereby acquiring a basic fishing rod section; placing a wire ring on a required position of the rod section, adhering a fixing pin of the wire ring to the fishing rod, binding the fiber cloth and fixing; winding the high temperature resisting protecting film on the outer sides of the wire ring and the fiber cloth, winding the high temperature resisting protecting film on the fiber cloth and then performing high-temperature plasticizing and removing the high temperature resisting protecting film after the high-temperature plasticizing. The mounting technology has the advantages that the structure is simple, the wire ring is mounted in the manufacturing process of the fishing rod body, the wire ring is integrally formed and the wire ring can be firmly fixed after the forming and fixing of the rod body of the fishing rod and the appearance is attractive.

Owner:NINGBO EVER WINNER INDAL FISHING TACKLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com