Method for replacing coal mine main fan without blowing-down on basis of adjustable moving blades

A ventilator and fan technology, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problems of wind stop, jam, switch not in place, etc., to ensure safety, prevent machine failure, and air volume The effect of a smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

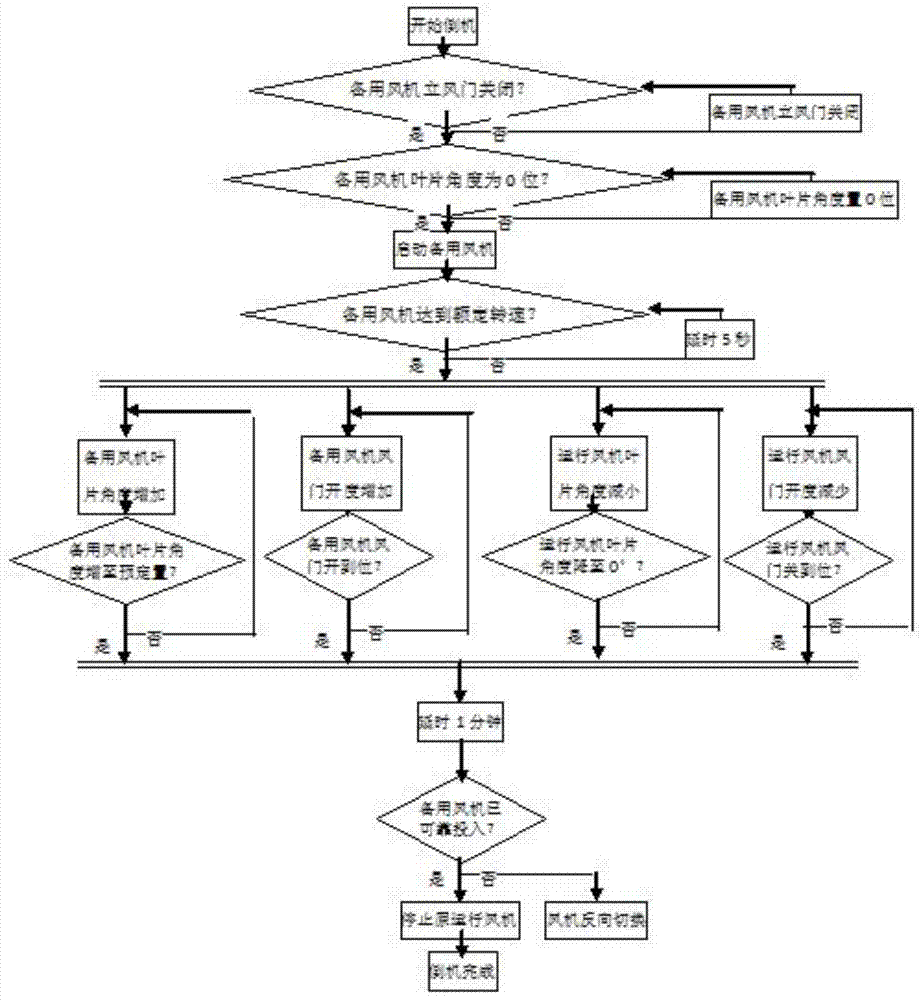

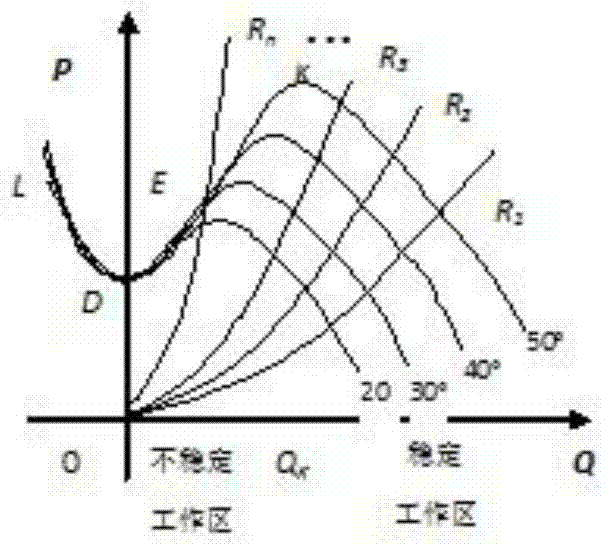

[0025] Embodiment 1: The non-stop wind reverse method: that is, the method of non-stop wind reverse from the running fan to the standby fan. During the normal reverse process, the operation of the two fans is always maintained to ensure the continuous supply of ventilation power; through Parallel air distribution makes the air volume stable during the reversing process and realizes non-stop wind reversing; when the normal operation fan fails, a comprehensive judgment is given through the vibration sensor, air volume negative pressure sensor, temperature sensor and motor electrical parameter sensor, and the fault is detected. Depending on the degree of abnormality, the fan will give an early warning, set a fault flag, and stop the wind until the fault mode is activated;

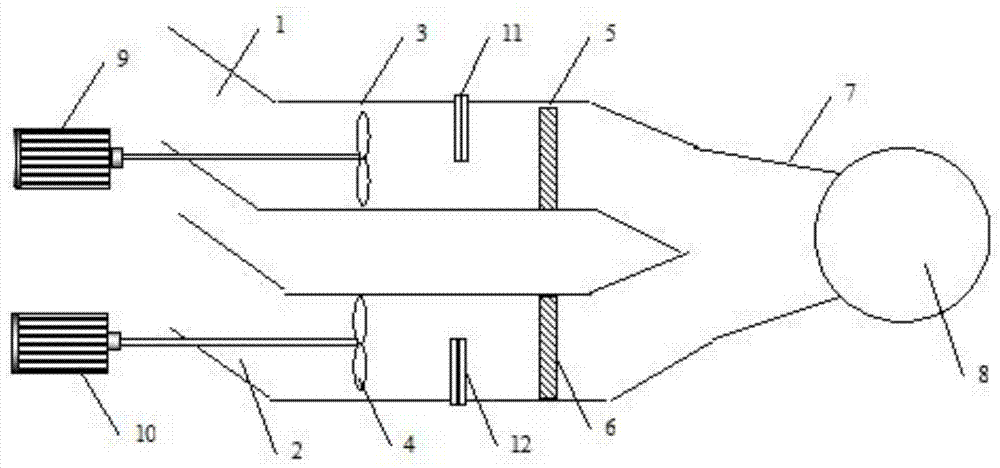

[0026] 1. Transition stage: under the premise that the running fan 1 is in normal operation, the backup fan 2 starts when the backup fan blade 4 is at zero angle, and the backup fan 2 transitions from a cold ba...

Embodiment 2

[0039] Embodiment 2: The core component of the device is a set of four-section keyboard-type console, and the peripheral sensors and control actuators are installed at the corresponding positions of the fan and its ancillary facilities; wherein, the keyboard-type console is placed in the centralized control room , the four panel layouts are computer display panel, fan and high-voltage cabinet indicator and control button panel, temperature and damper indicator and control button panel, and another hot standby computer display panel; the installation panel is arranged behind the console , on which are arranged power supply and lightning protection modules, one-use and one-standby soft redundant PLC and its remote I / O modules, isolation relays and wiring, and the two sides of each cabinet are terminal blocks connected to external sensors and actuators.

[0040] Figure 5 The hardware topology of the distributed system is shown. The non-stop wind blower control system is compose...

Embodiment 3

[0043] Embodiment 3: The core part of the device is a set of three-section control cabinet and a customized computer console that can place two industrial computers and displays, and the peripheral sensors and control actuators are installed at the corresponding positions of the fan and its auxiliary facilities; wherein, The computer console is placed in the centralized control room, and the control cabinet is placed in the low-voltage power distribution room. The two communicate through Ethernet. The layout of the three panels of the control cabinet is the No. 1 main control screen, the local display touch screen, and the No. 2 standby master control panel. screen; the fan, damper and high-voltage cabinet indicators and control buttons are arranged on the control panel, the indicator buttons are arranged on the top, and the control buttons are arranged on the bottom, which is convenient for users to operate. Control: the inner side of the lower part of the cabinet is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com