Circuit board welding gun achieving automatic feeding

An automatic feeding and circuit board technology, which is applied in the direction of tin feeding device, welding equipment, welding/welding/cutting items, etc., can solve the problems of easy blockage, feeding jam, low accuracy of tin material staining, etc., and achieve enhanced strength , Precise effect of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

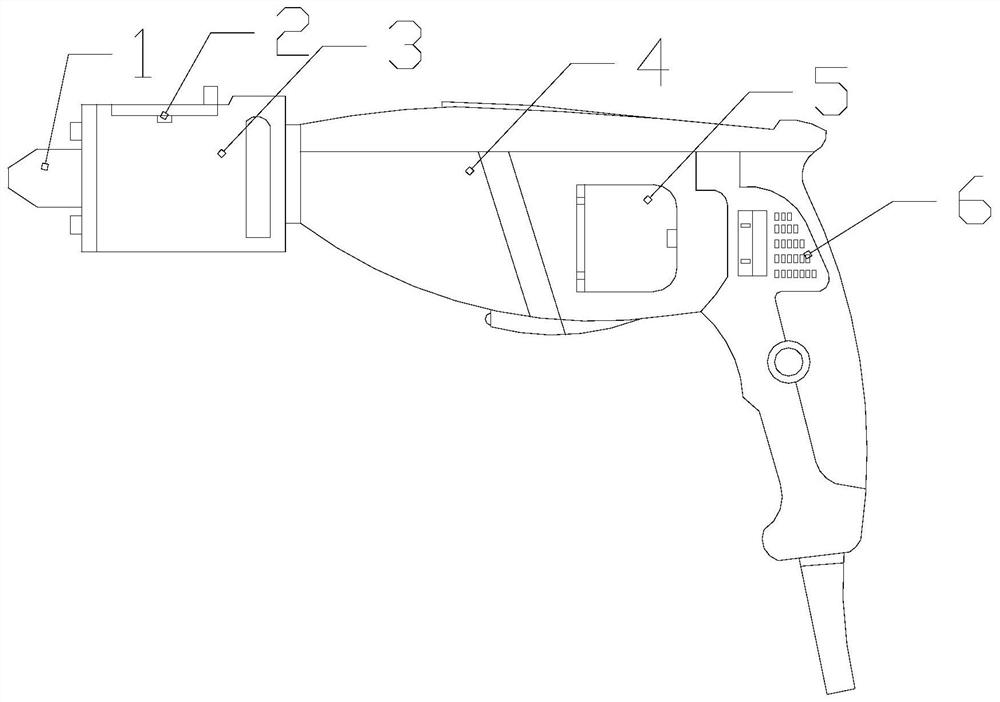

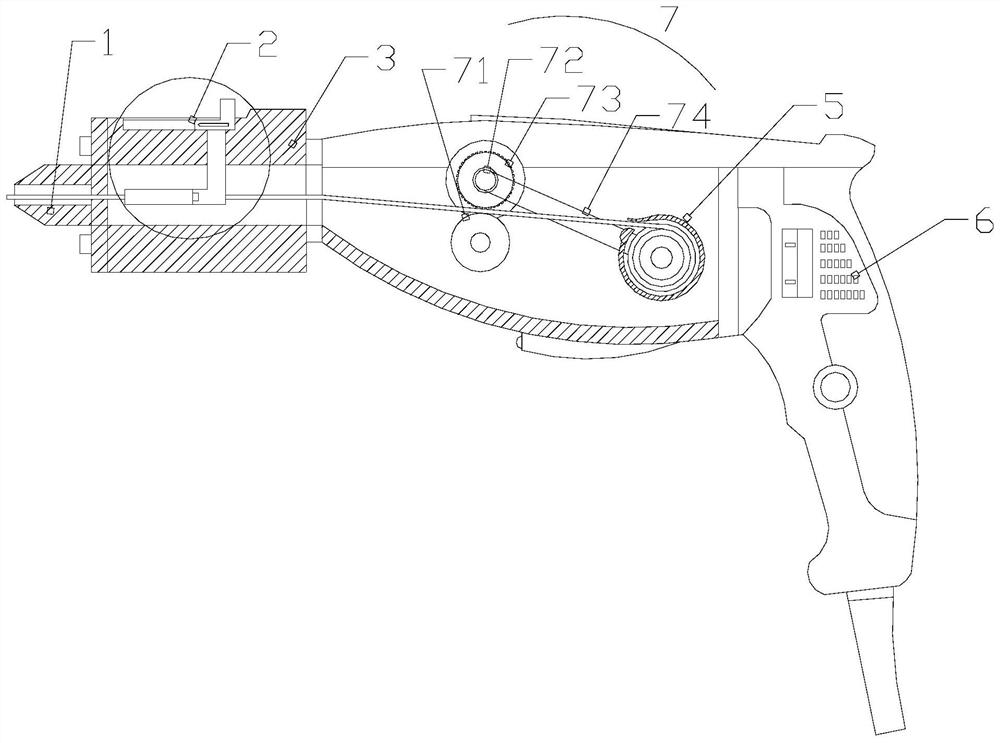

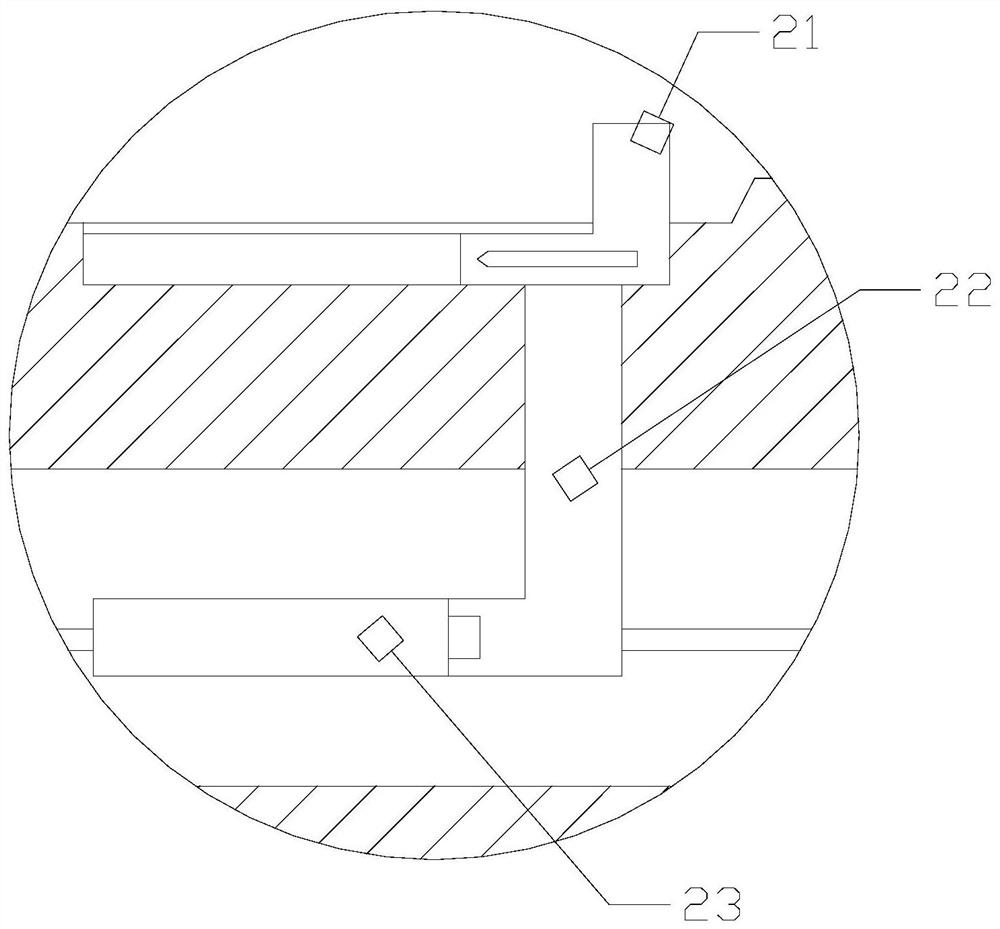

[0024] see Figure 1-Figure 5 , a circuit board welding torch for automatic feeding. The invention provides a circuit board welding gun for automatic feeding. Its structure includes a welding head 1, a wire wiping structure 2, a front end 3, a main body 4, an automatic outlet 5, and a handle 6. The horizontal ends of the main body 4 are respectively equipped with a front end 3 and a handle 6, an automatic outlet 5 is installed inside the main body 4, and an electric welding head 1 is installed at the opposite end of the front end 3 and the main body 4, so The electric welding head 1 and the wire wiping structure 2 are matched.

[0025] The automatic outlet device 5 is provided with a casing 51, a motor 52, and a rotating shaft 53. The cross section of the casing 51 is an incomplete circle, and the opening of the incomplete circle of the casing 51 is the outlet. A motor 52 is installed in the middle of the shell 51, the output shaft of the motor 52 is mechanically connected to...

Embodiment 2

[0031] see Figure 1-Figure 5 , a circuit board welding torch for automatic feeding. The invention provides a circuit board welding gun for automatic feeding. Its structure includes a welding head 1, a wire wiping structure 2, a front end 3, a main body 4, an automatic outlet 5, and a handle 6. The horizontal ends of the main body 4 are respectively equipped with a front end 3 and a handle 6, an automatic outlet 5 is installed inside the main body 4, and an electric welding head 1 is installed at the opposite end of the front end 3 and the main body 4, so The electric welding head 1 and the wire wiping structure 2 are matched.

[0032] The automatic outlet device 5 is provided with a casing 51, a motor 52, and a rotating shaft 53. The cross section of the casing 51 is an incomplete circle, and the opening of the incomplete circle of the casing 51 is the outlet. A motor 52 is installed in the middle of the shell 51, the output shaft of the motor 52 is mechanically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com