Ink fountain with convenience in line changing for building construction

A construction and ink fountain technology, which is applied in the field of easy-change ink fountains for construction construction, can solve the problems of inaccurate line control, troublesome operation, and easy twisting of ink lines, etc., and achieves the advantages of easy threading and connection, and smooth line take-up or exit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

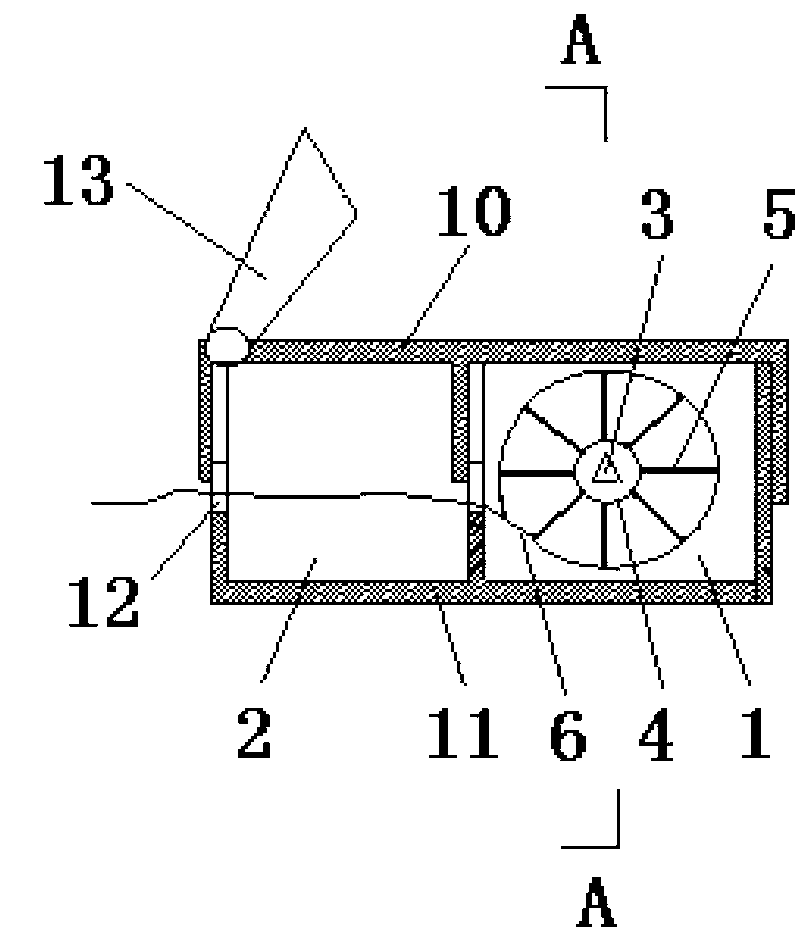

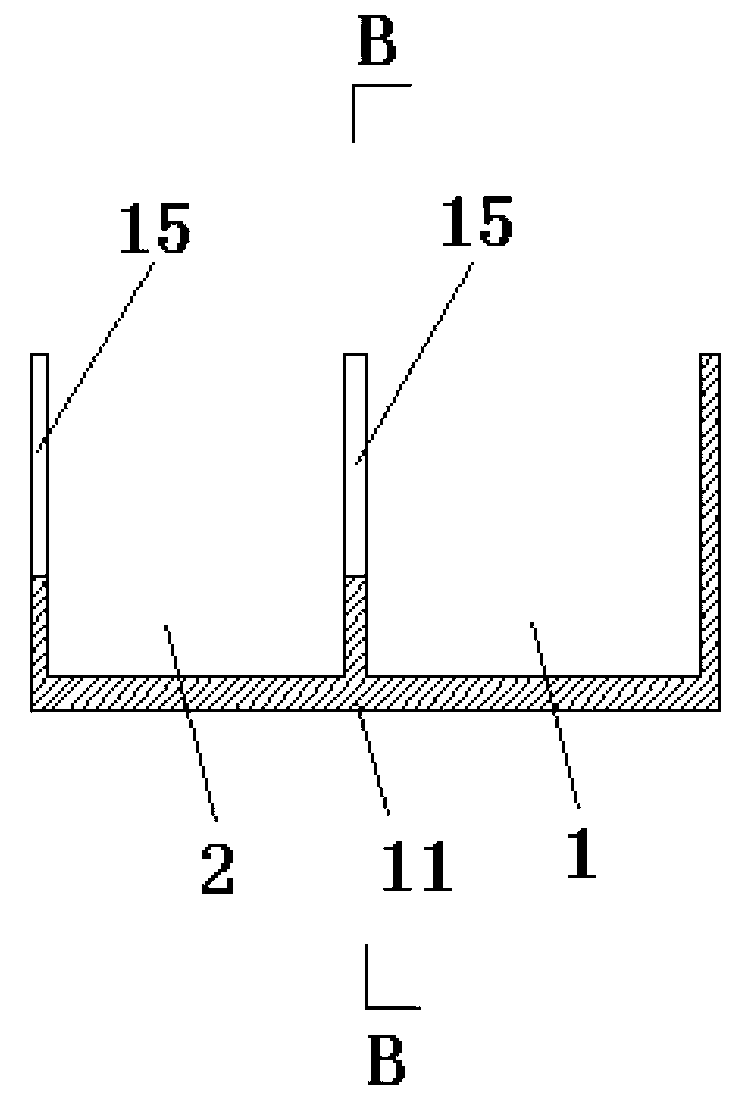

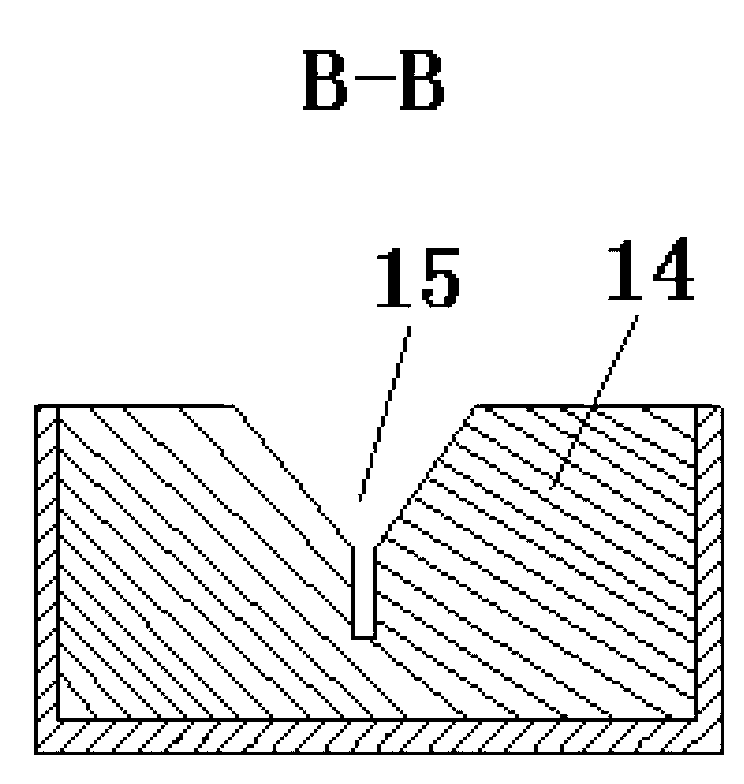

[0027] refer to figure 1 , the building construction ink fountain of the present invention comprises the ink fountain box that is made up of upper cover 10 and lower bottom groove 11, is provided with wire wheel chamber 1 and ink storage chamber 2 in the ink fountain box, and radial section is installed movable type in the wire wheel chamber 1 The shape is a multi-deformed wire wheel handle shaft 3, which is threaded with a wire wheel shaft 4 coaxial with it, and six or more wire wheels are installed on the wire wheel shaft 4 along its circumference Blades 5, at least one or each wire wheel blade 5 is provided with a tie hole 7, a plurality of wire wheel blades 5 are wound with ink lines 6, and the beginning end of the ink line 6 is bound in a line hole 7, and the other is free. The end passes through the ink-absorbing sponge in the ink storage chamber 2 after passing through a plurality of wire wheel blades 5, and passes through the outlet hole provided on the wall of the ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com