Patents

Literature

44results about How to "Easy to change lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

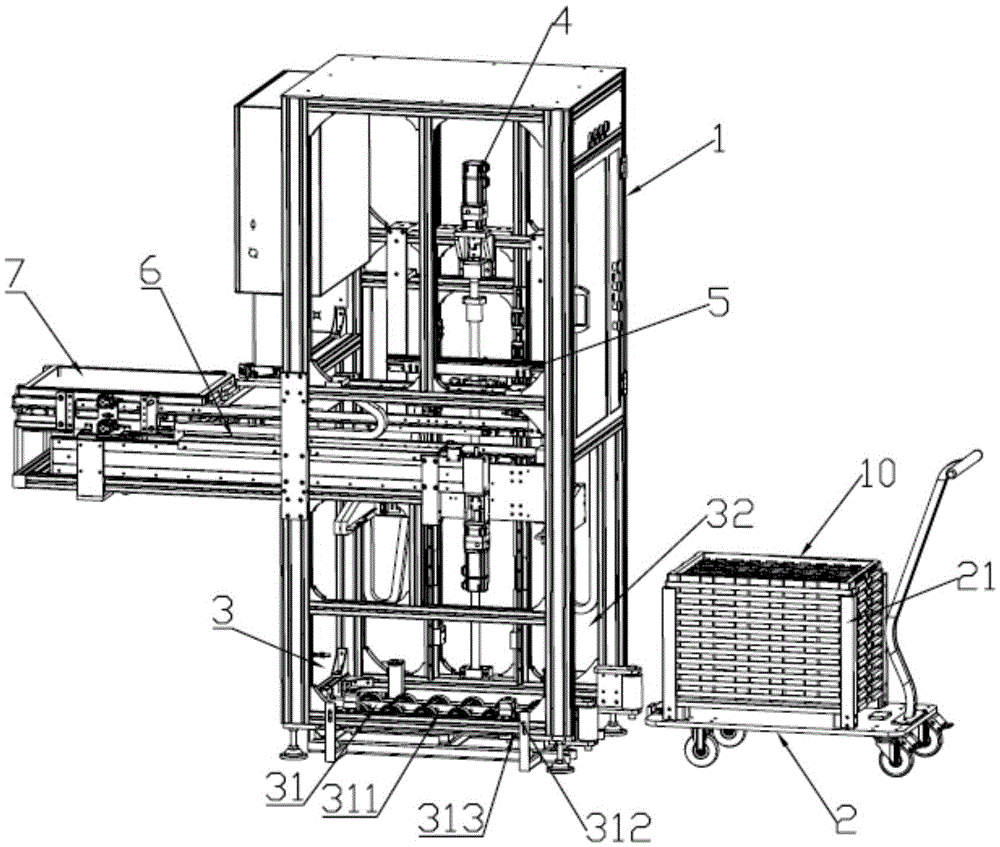

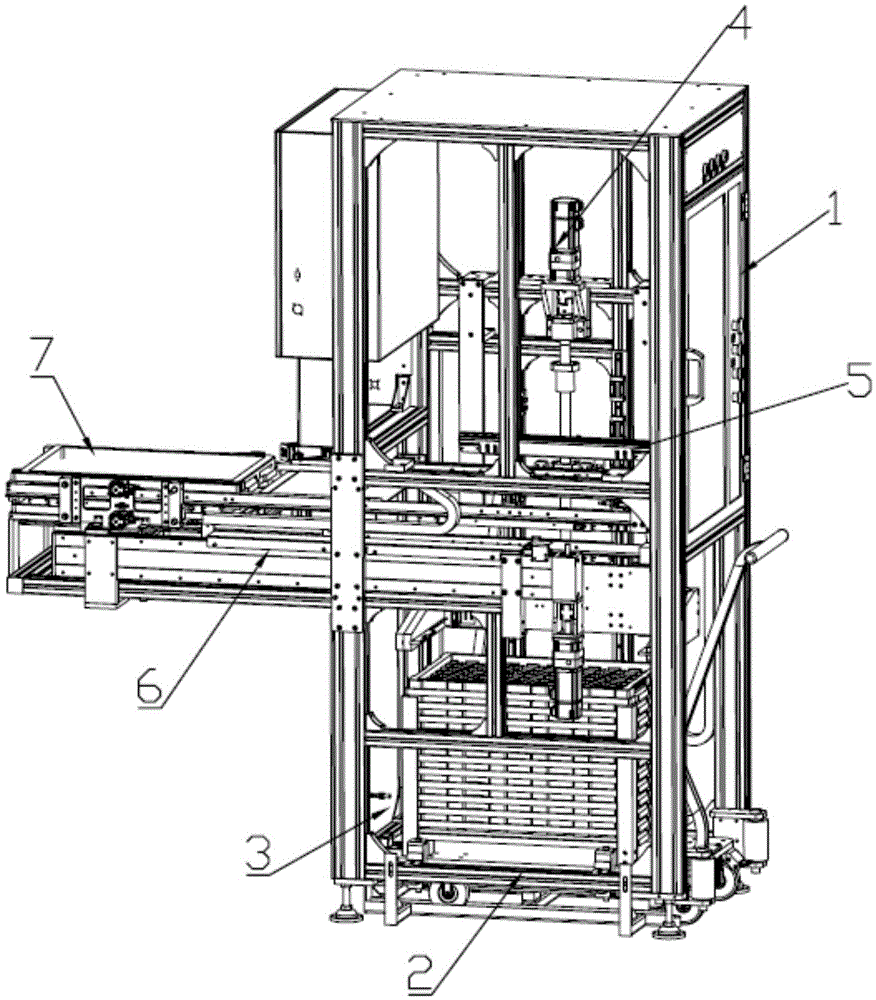

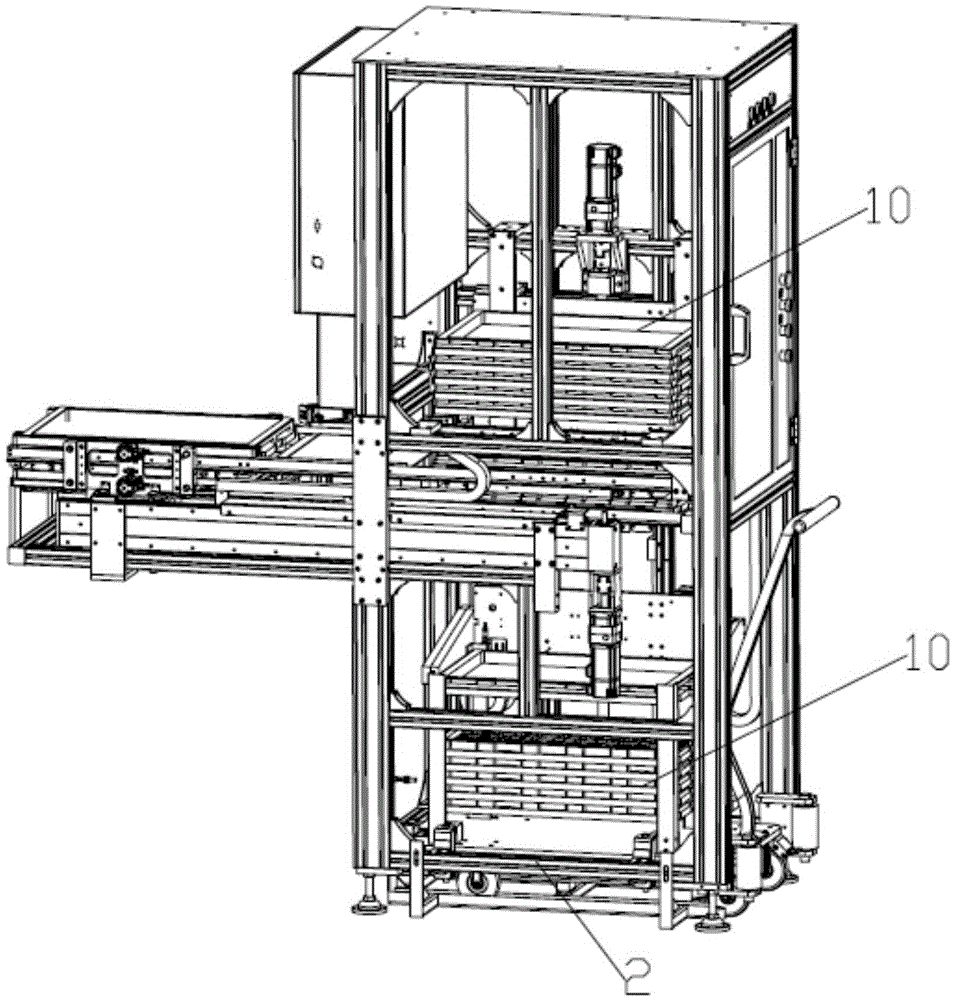

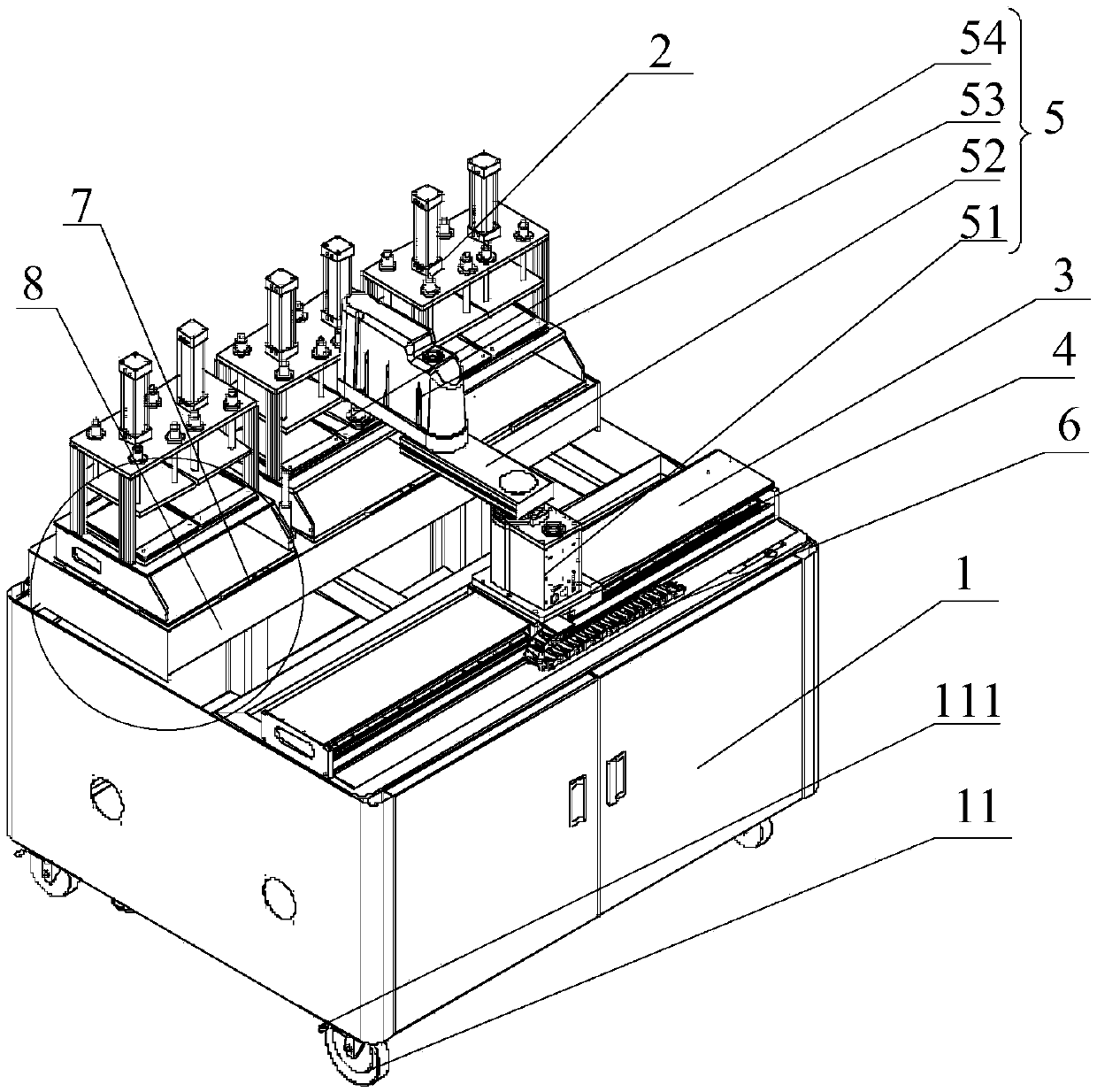

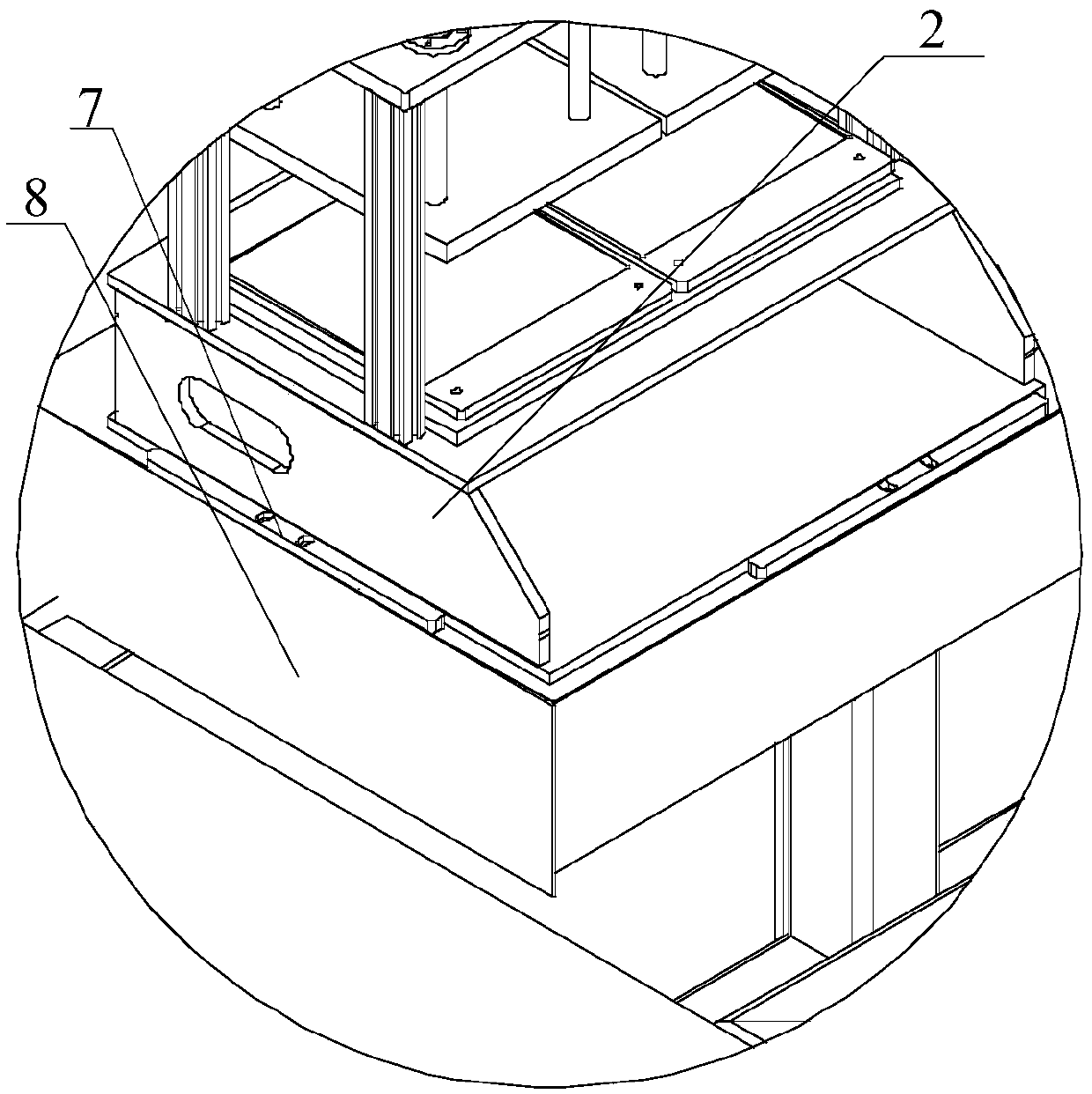

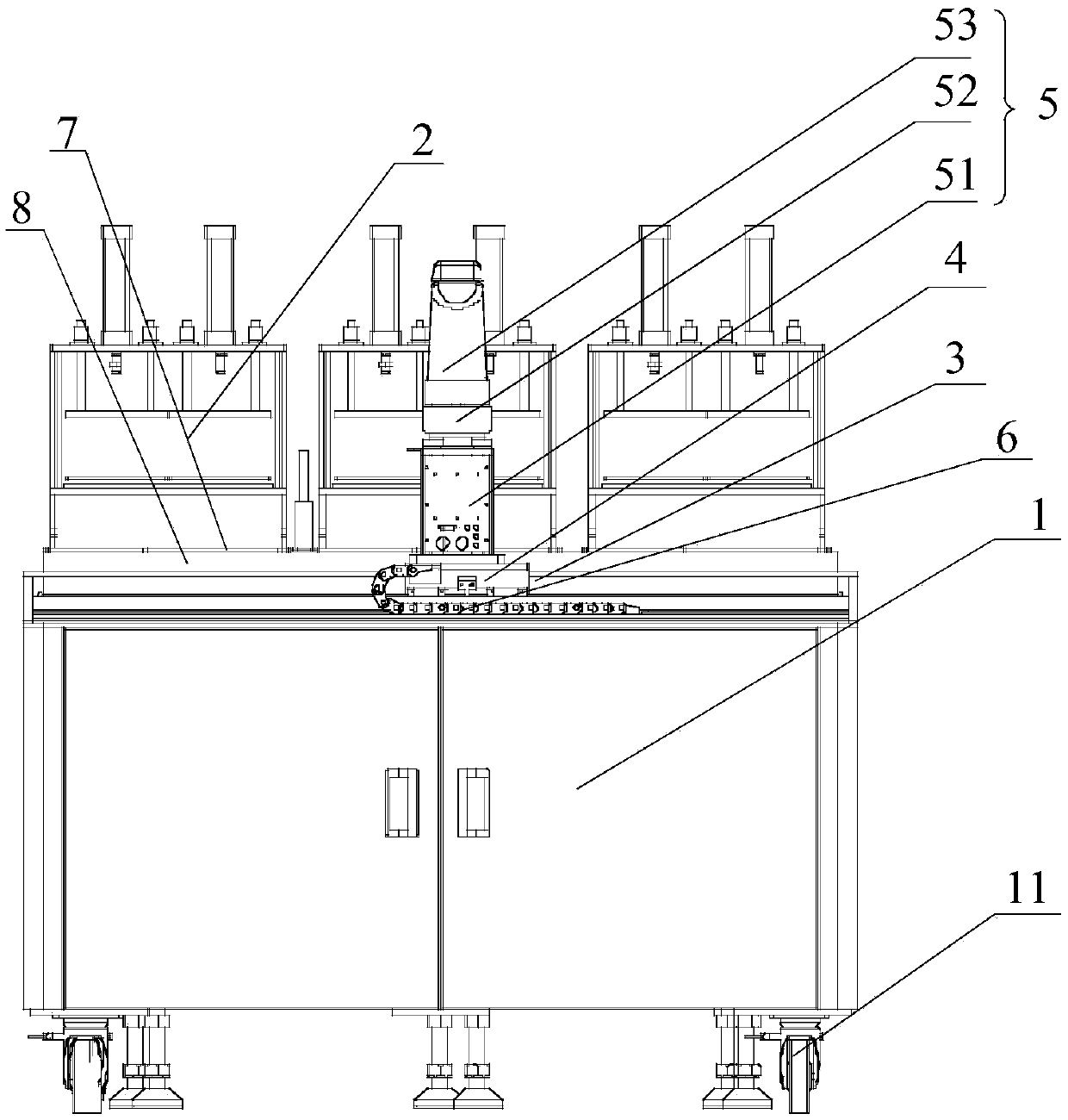

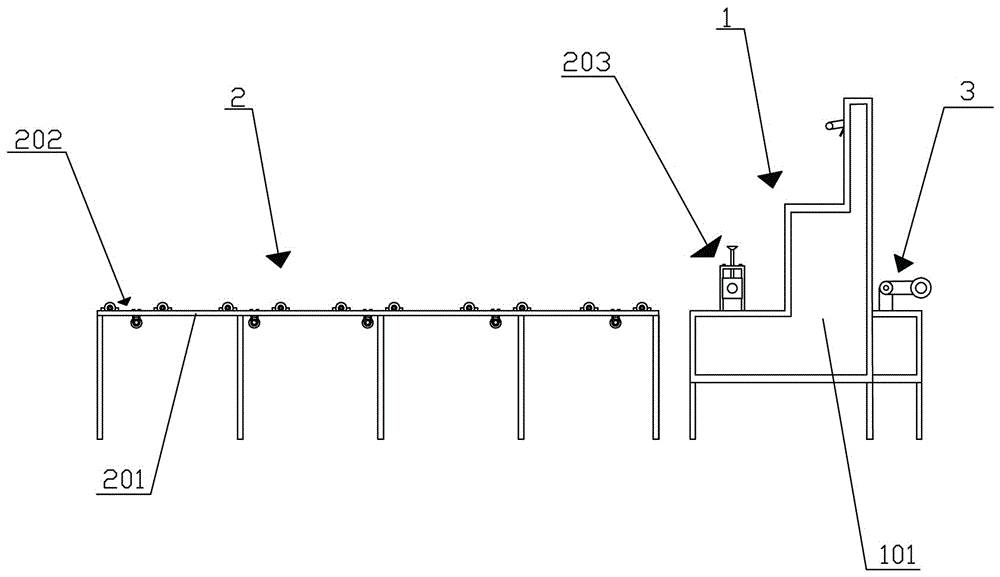

Tray type automatic supply and retraction equipment

InactiveCN105621110AFully automatedRealize intelligenceConveyorsStacking articlesButt jointEngineering

The invention discloses tray type automatic supply and retraction equipment. The equipment comprises a frame and multiple supply cars; a loading area is formed under the frame; a car positioning mechanism is arranged in the loading area; a supply car feed port is formed in one side surface of the loading area in the X direction; and after the support cars enter the loading area from the supply car feed port, the car positioning mechanism locks and positions the supply cars. The frame is provided with a tray hoisting mechanism in the Z direction in an area above the loading area; three layers of tray lifting mechanisms are symmetrically spaced on two sides of the Y direction of the middle part of the frame; a tray carrying mechanism in the X direction is arranged corresponding to two layers of tray lifting mechanisms on the lower side; and a butt joint equipment taking area is formed on the outer side of the tray carrying mechanism. The tray type automatic supply and retraction equipment divides a tray into a mother tray and son trays; for materials with different shapes, only the corresponding son trays need to be replaced, so that the replacement is convenient, and the resource is saved; and a robot is matched to clamp the materials so as to realize the material supply automation and intelligence more efficiently, more accurately and more quickly.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

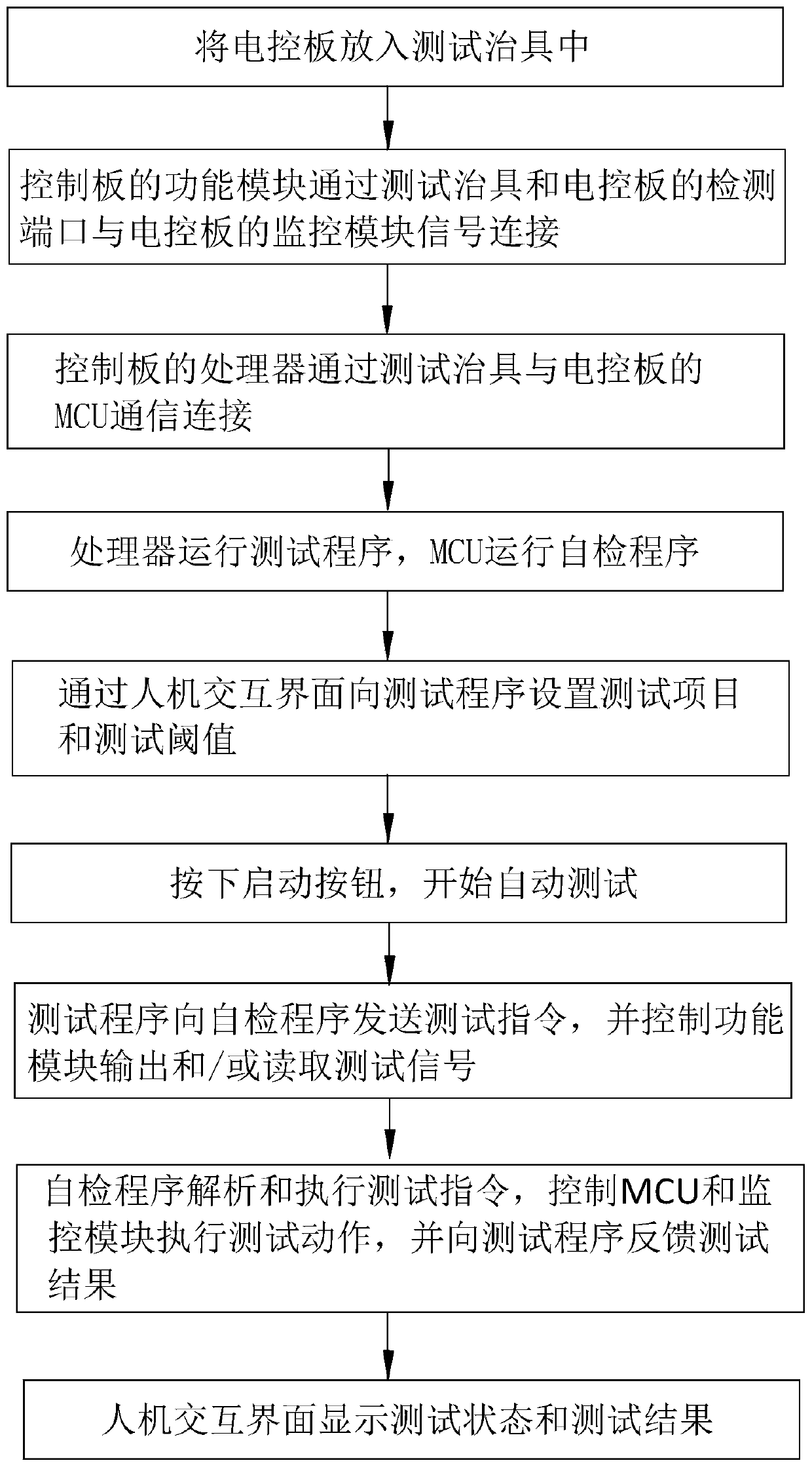

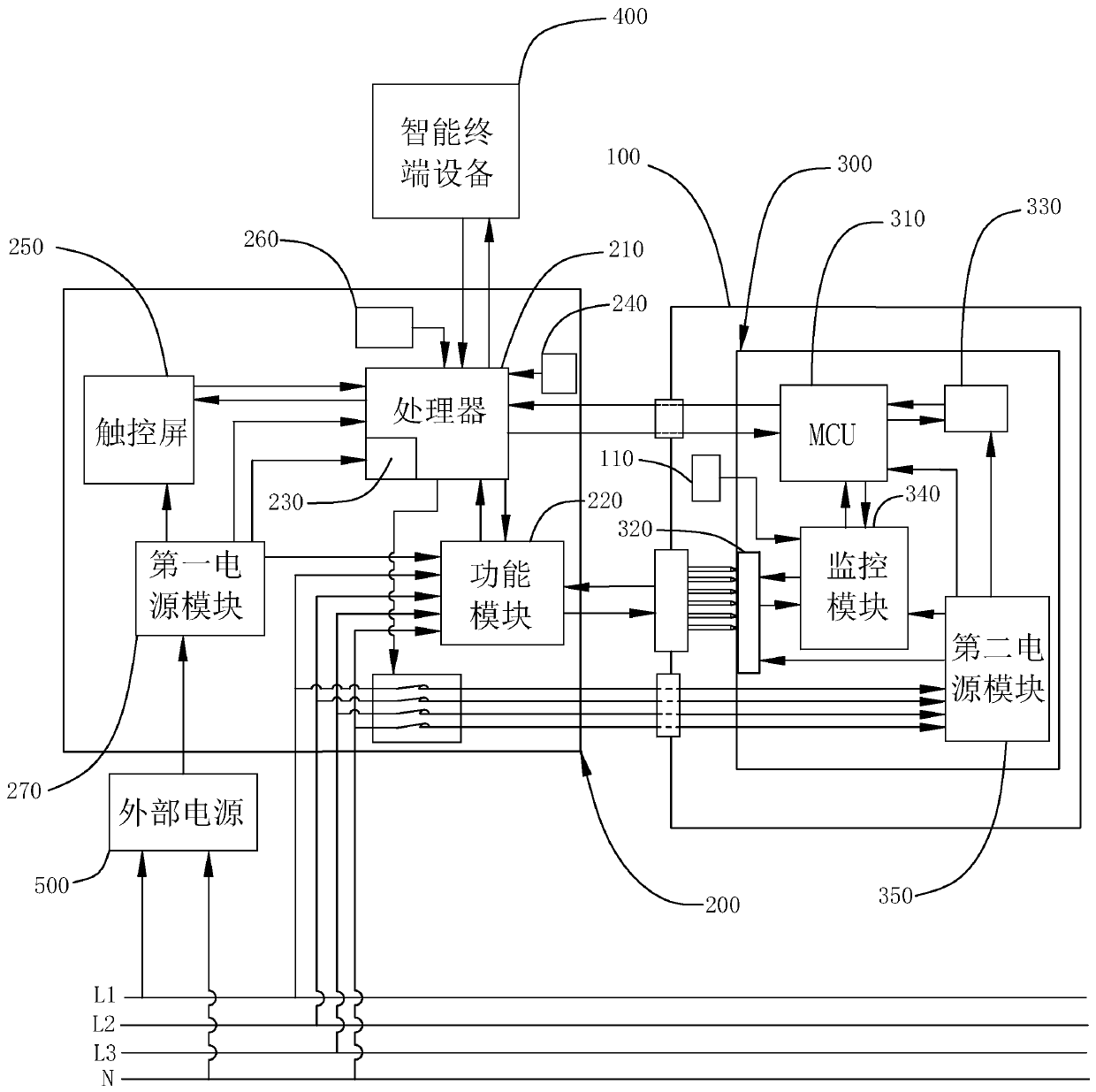

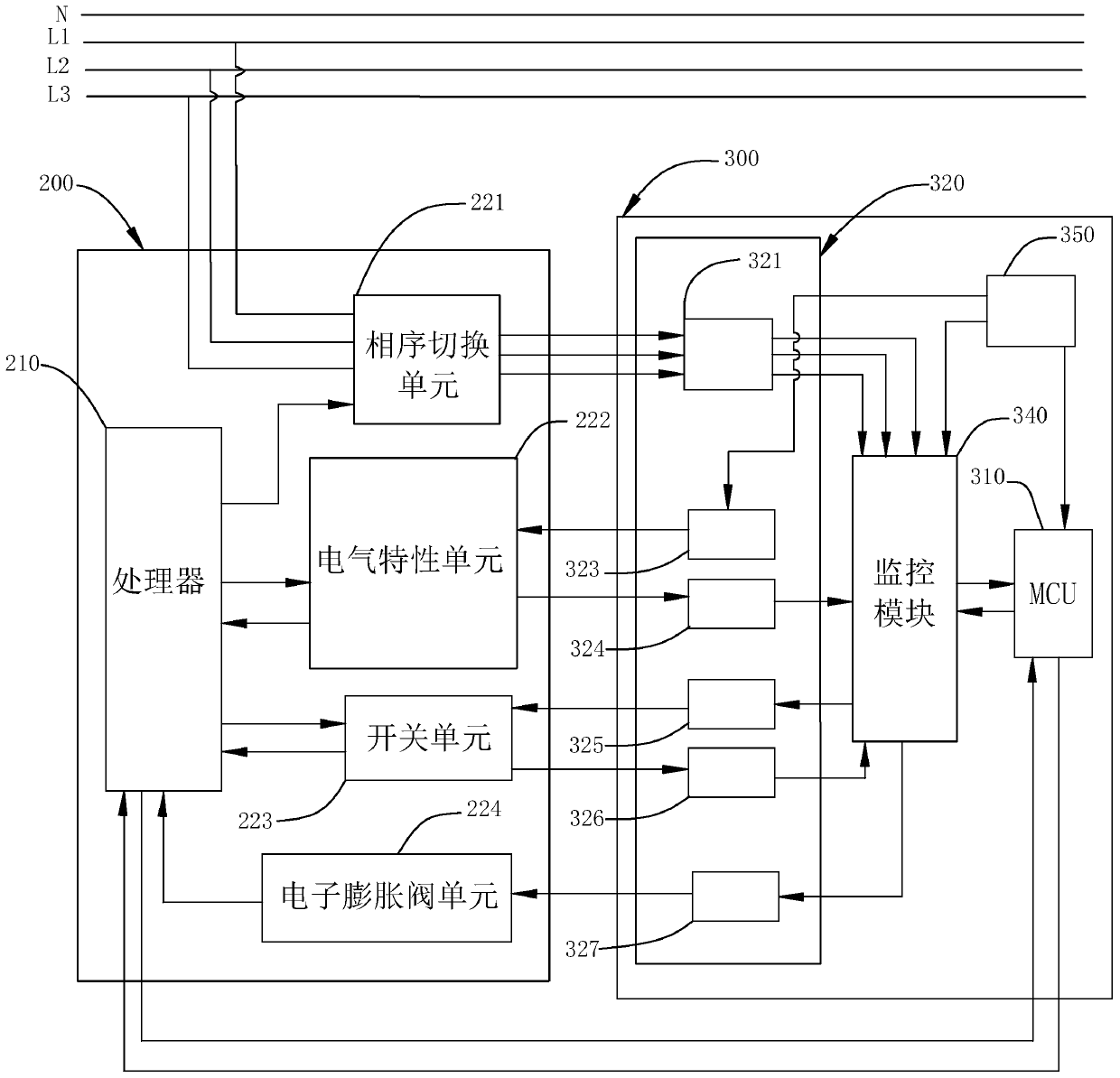

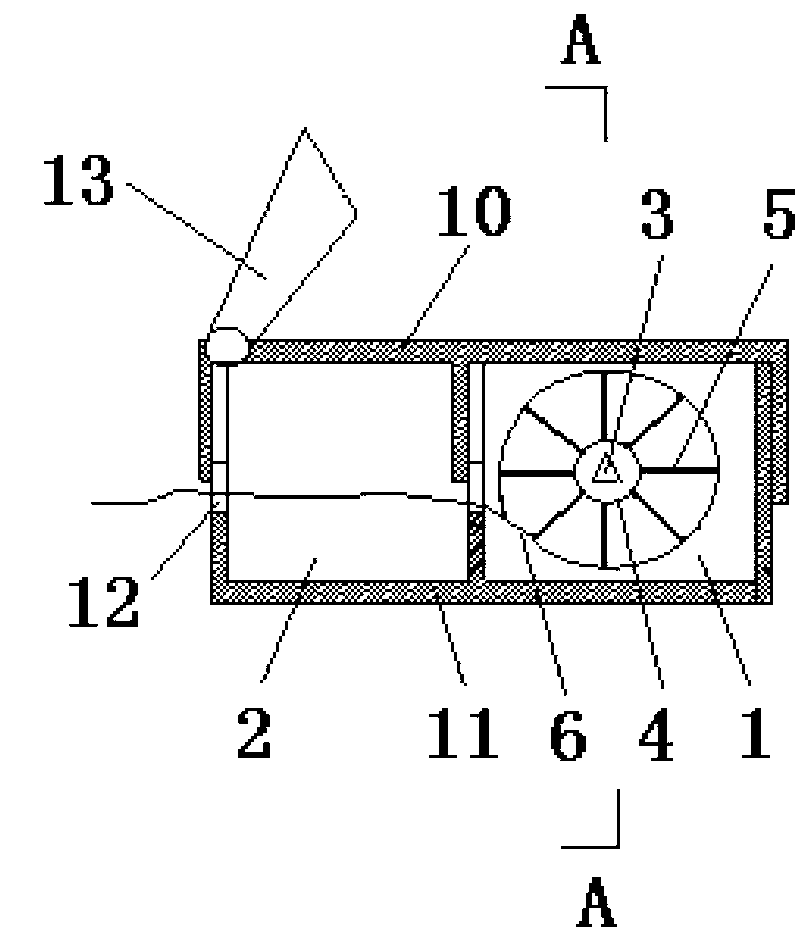

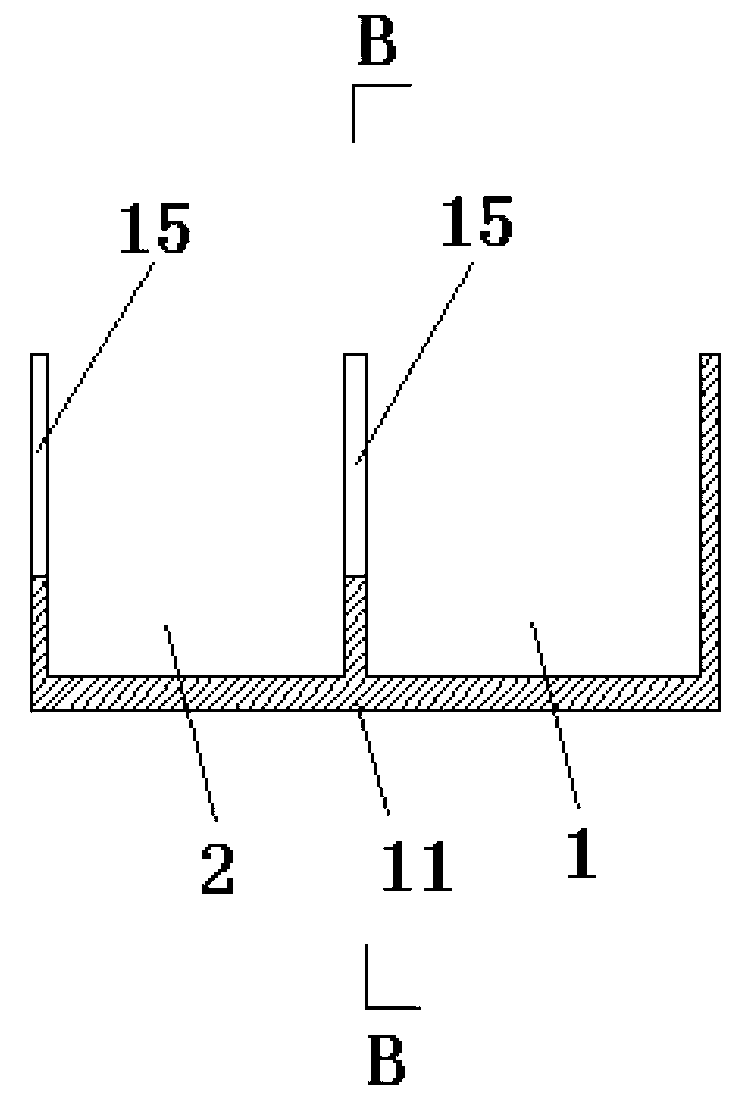

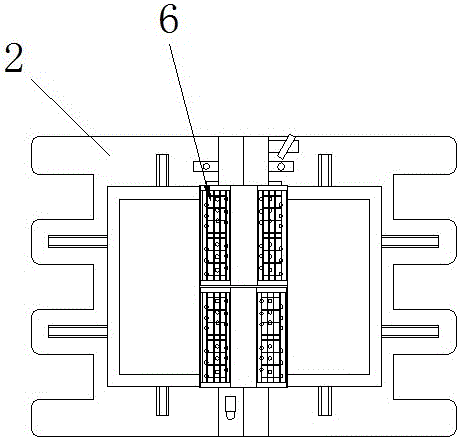

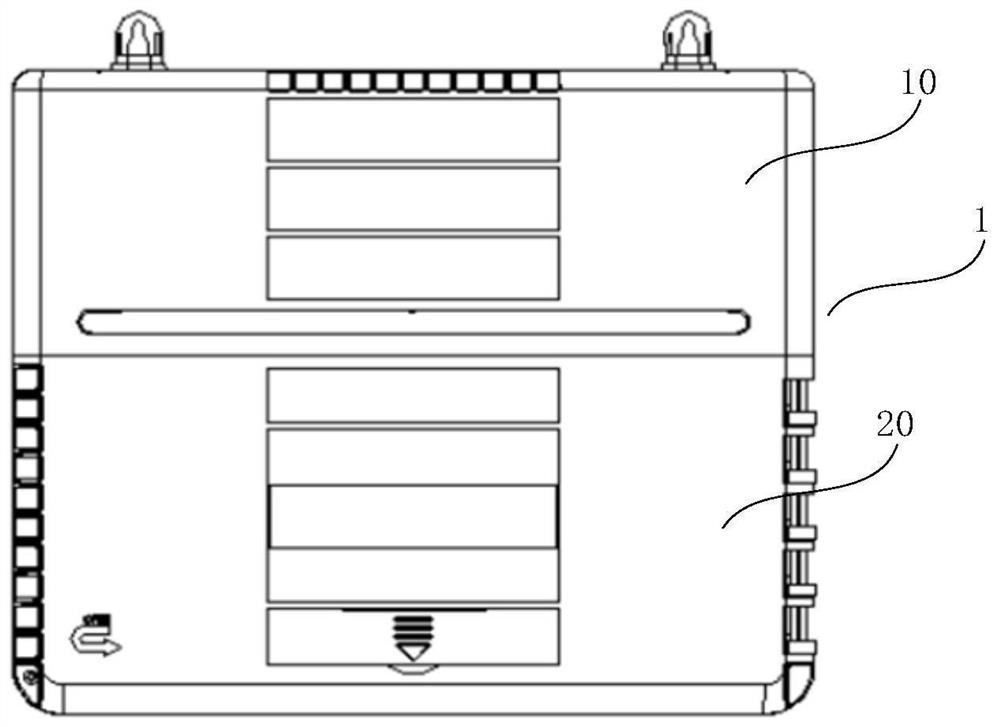

Electric control board test method and test system

PendingCN111366835AEasy to change linesIncrease productivityThermometers using electric/magnetic elementsUsing electrical meansSimulationInteraction interface

The invention discloses an electric control board test method and test system. The electric control board test method comprises steps that an electric control board is put into a test fixture; a functional module of the control panel is in signal connection with a detection port of the electric control panel through the test fixture; a processor of the control panel is in communication connectionwith an MCU of the electric control panel through the test fixture; the processor runs a test program, and the MCU runs a self-check program; a test item and a test threshold are set for the test program through a human-computer interaction interface; a start button is pressed, and automatic testing is started; the test program sends a test instruction to the self-test program and controls the function module to output and / or read a test signal; the test instruction is analyzed and executed by the self-test program, and the test result is fed back to the test program; the human-computer interaction interface displays a test state and the test result. The test system based on the method is suitable for electric control board products with various function combinations, the development timeof the test system can be saved, and production requirements of small-batch electric control boards are met.

Owner:GUANGDONG CHICO ELECTRONIC INC +1

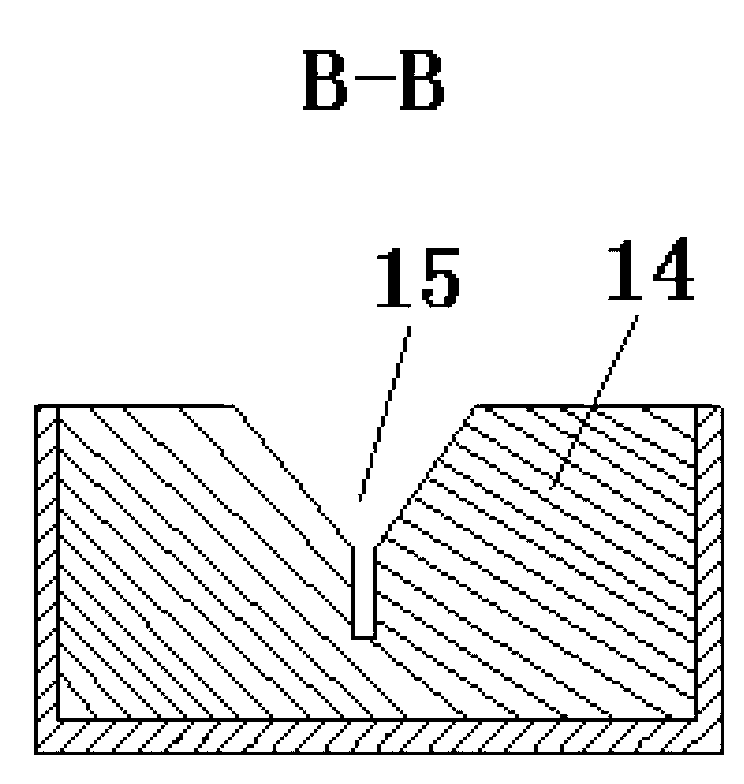

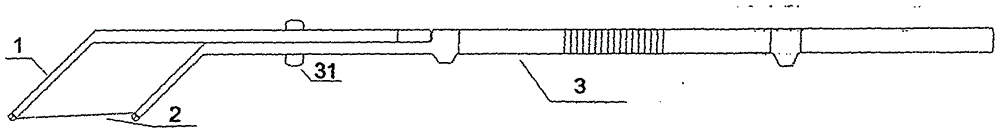

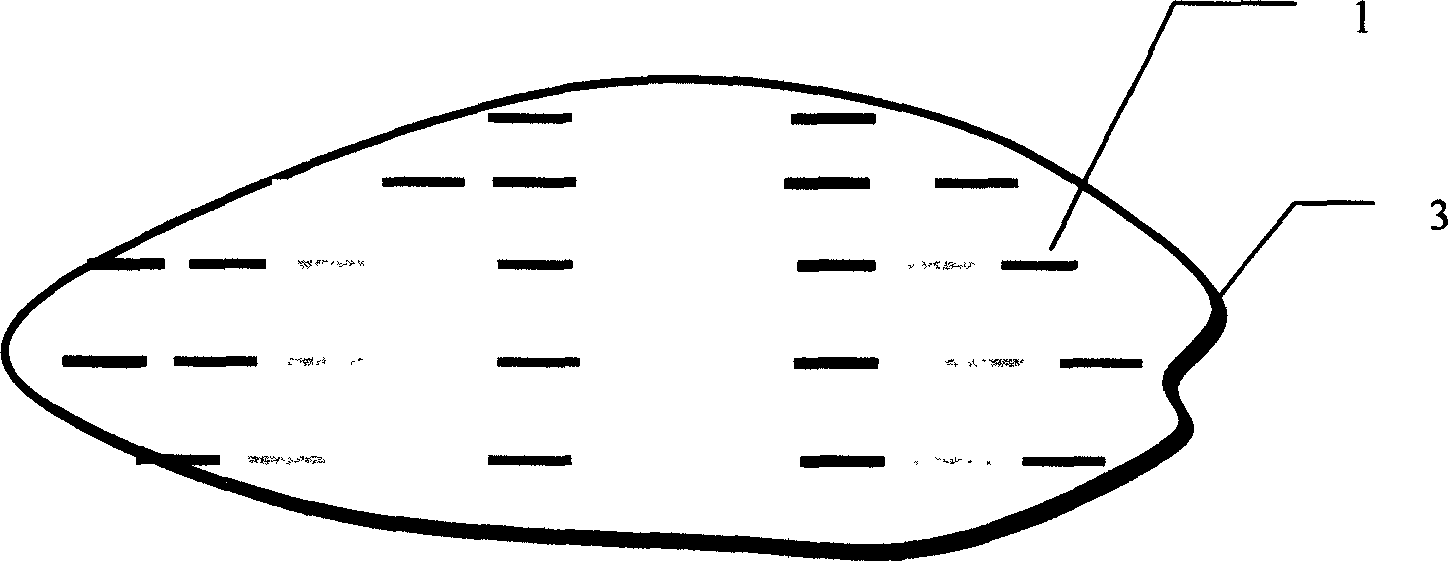

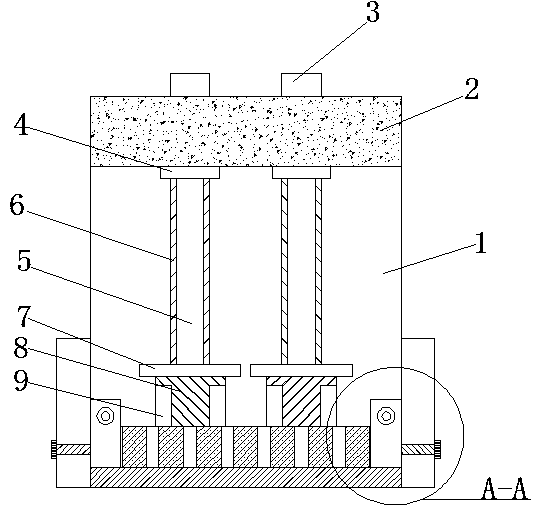

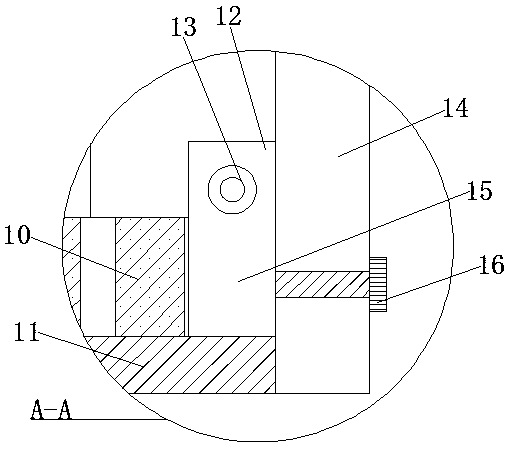

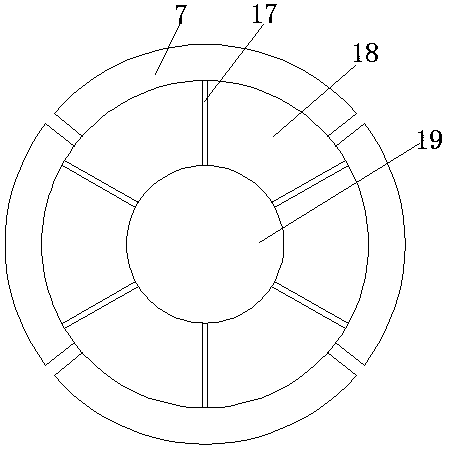

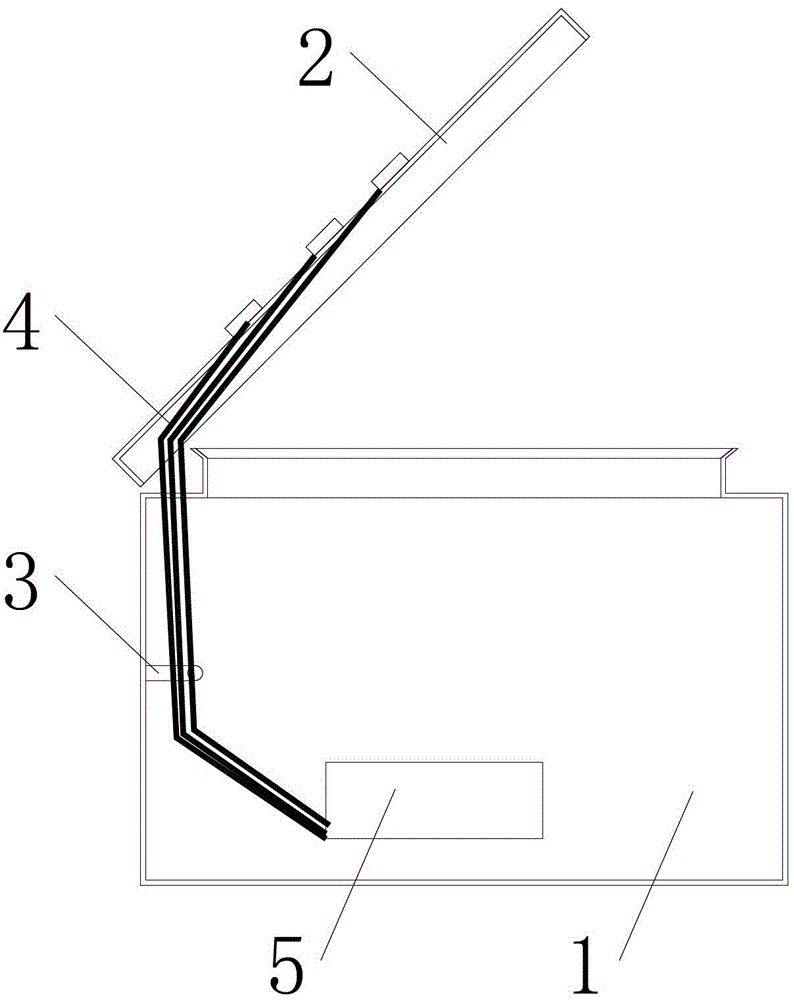

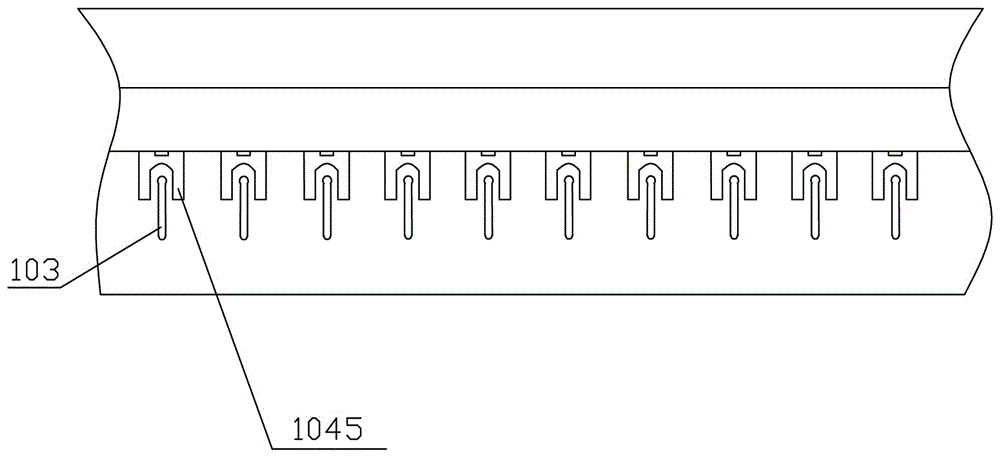

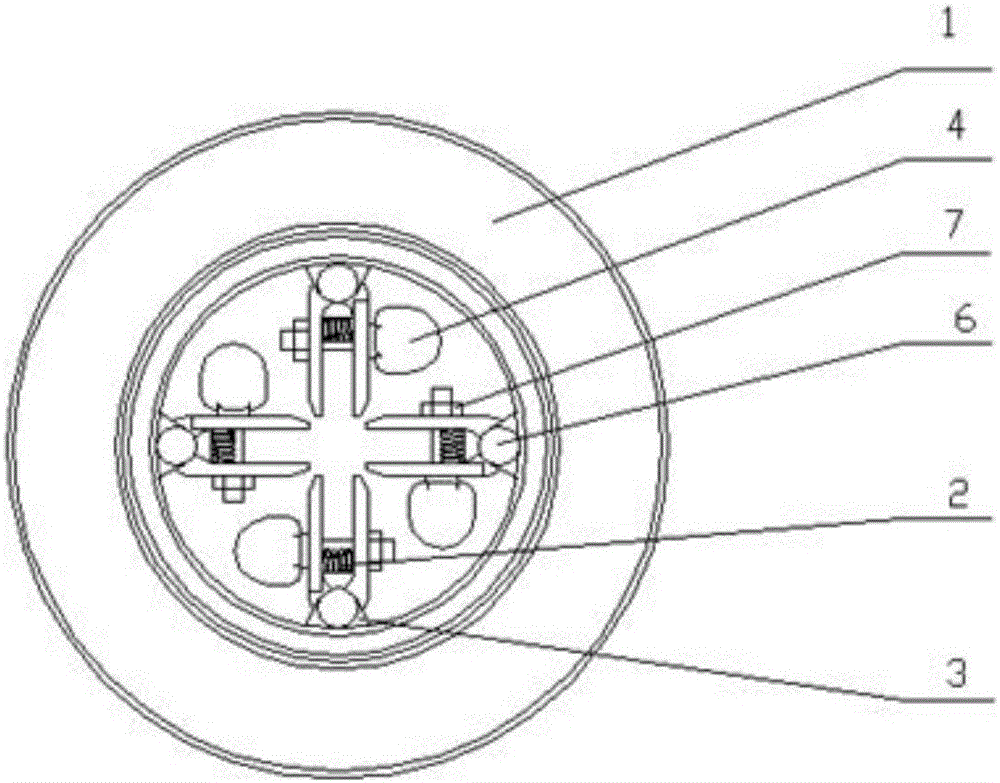

Ink fountain with convenience in line changing for building construction

ActiveCN103231358APrevent slidingEasy to put inOther workshop equipmentEngineeringMechanical engineering

The invention discloses an ink fountain with convenience in line changing for building construction, which aims to solve the problems that the line in a conventional ink fountain is complex in changing and easy to jam. The ink fountain comprises an ink fountain box formed by a lower bottom groove and an upper close cover, wherein a line wheel chamber and an ink storing chamber are arranged inside the ink fountain box; a line wheel rocking handle shaft with a polygonal radial section is movably mounted in the line wheel chamber; a line wheel shaft penetrates and is coaxial with the line wheel rocking handle shaft; a plurality of line wheel blades are mounted along the circumference of the line wheel shaft; a ink line is wound on the plurality of blades; and one end of the ink line penetrates out of the ink storing chamber after being wound on the blades. According to the ink fountain provided by the invention, the ink fountain box of the ink fountain is formed by the lower bottom groove and the upper close cover, during line changing, a box body is opened to change the line directly; the line wheel rocking handle shaft is non-cylindrical, so as to avoid relative sliding between the line wheel rocking handle shaft and the line wheel shaft during processes of line releasing or line winding; and meanwhile, line fastening holes, which are formed in the line wheel blades, facilitate penetration of the ink line, so that the phenomenon that the line winding is messed to form a mixed ball is avoided.

Owner:SHAANXI COAL & CHEM CONSTR GRP CO LTD

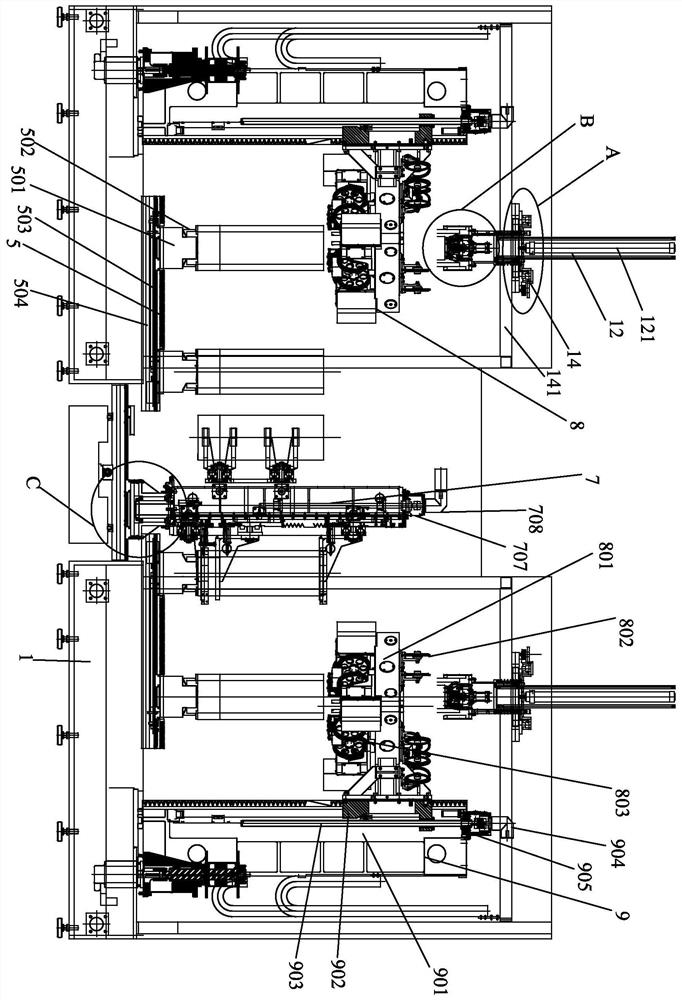

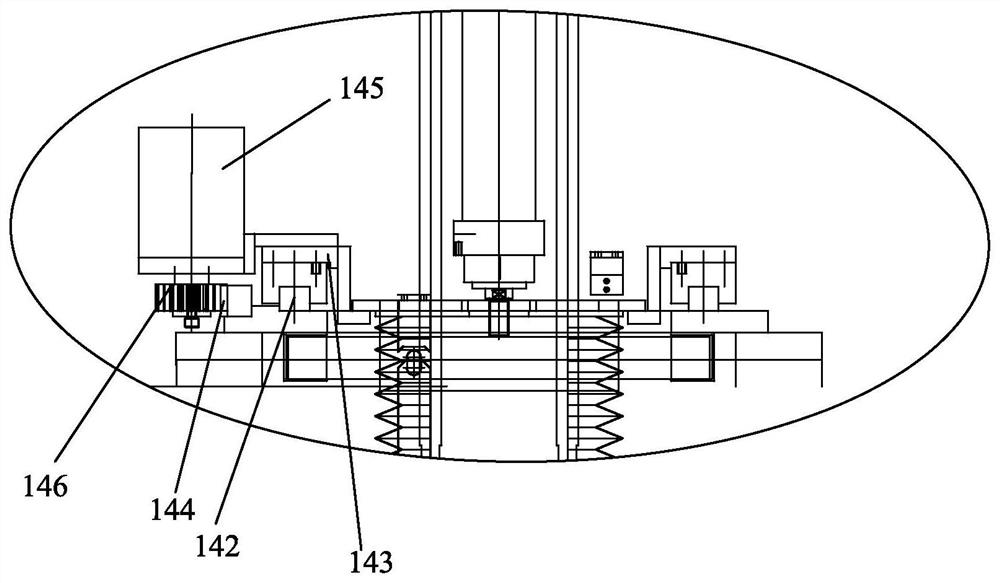

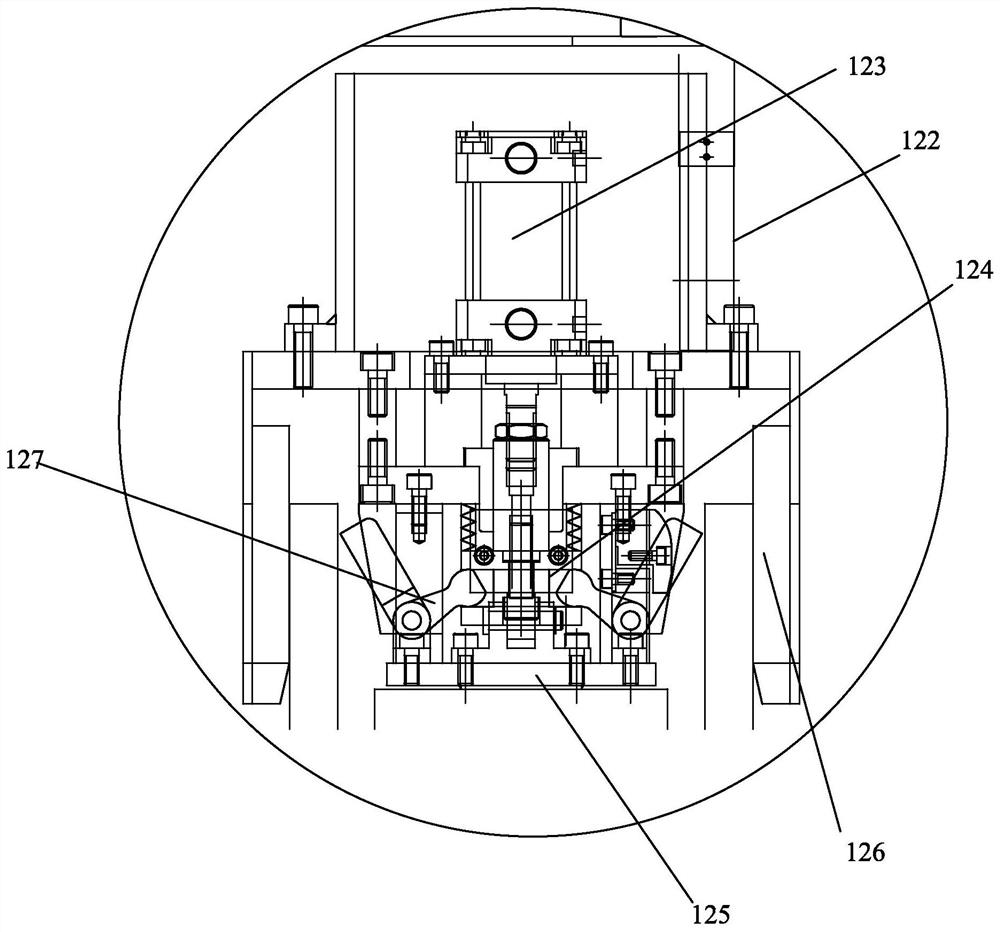

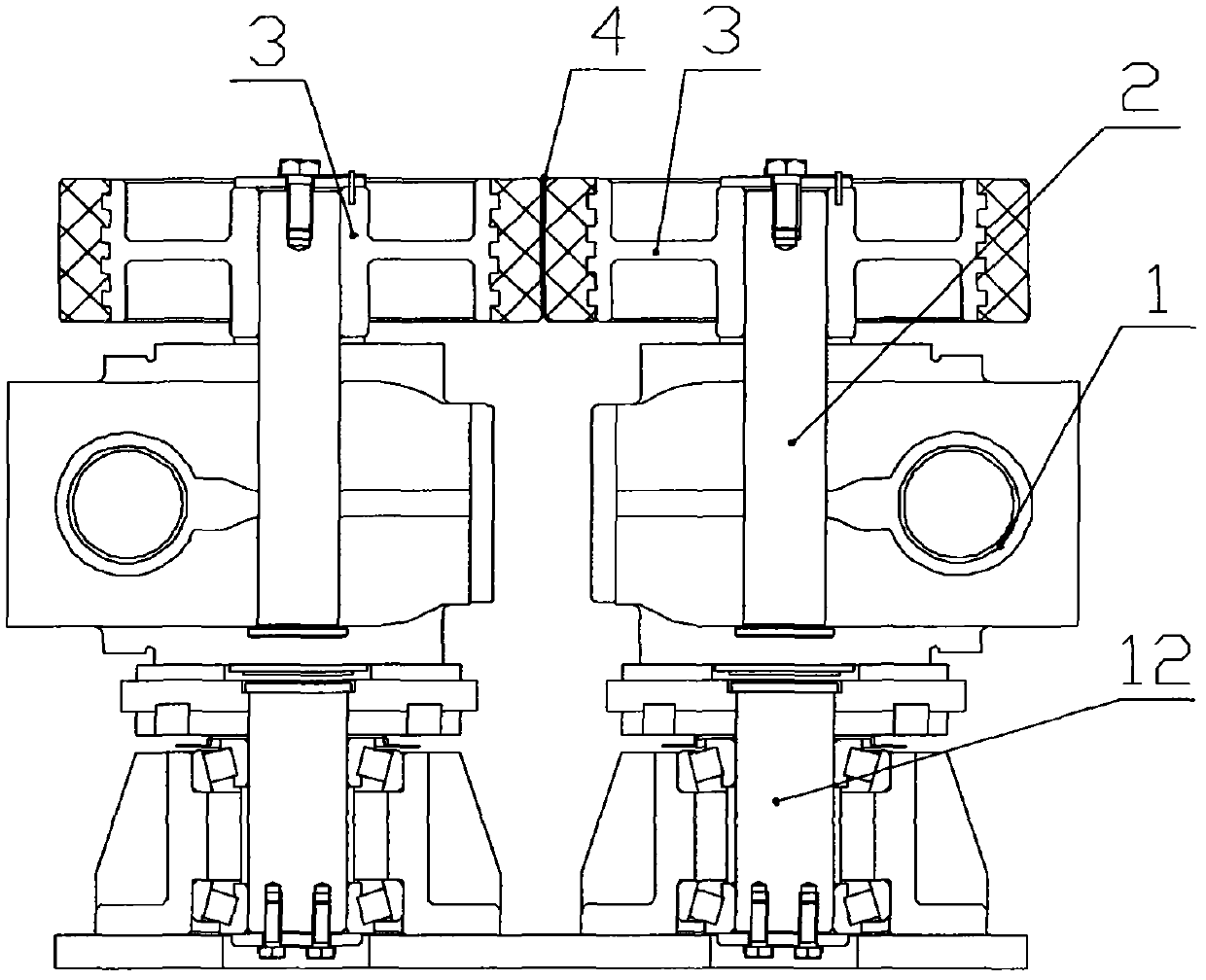

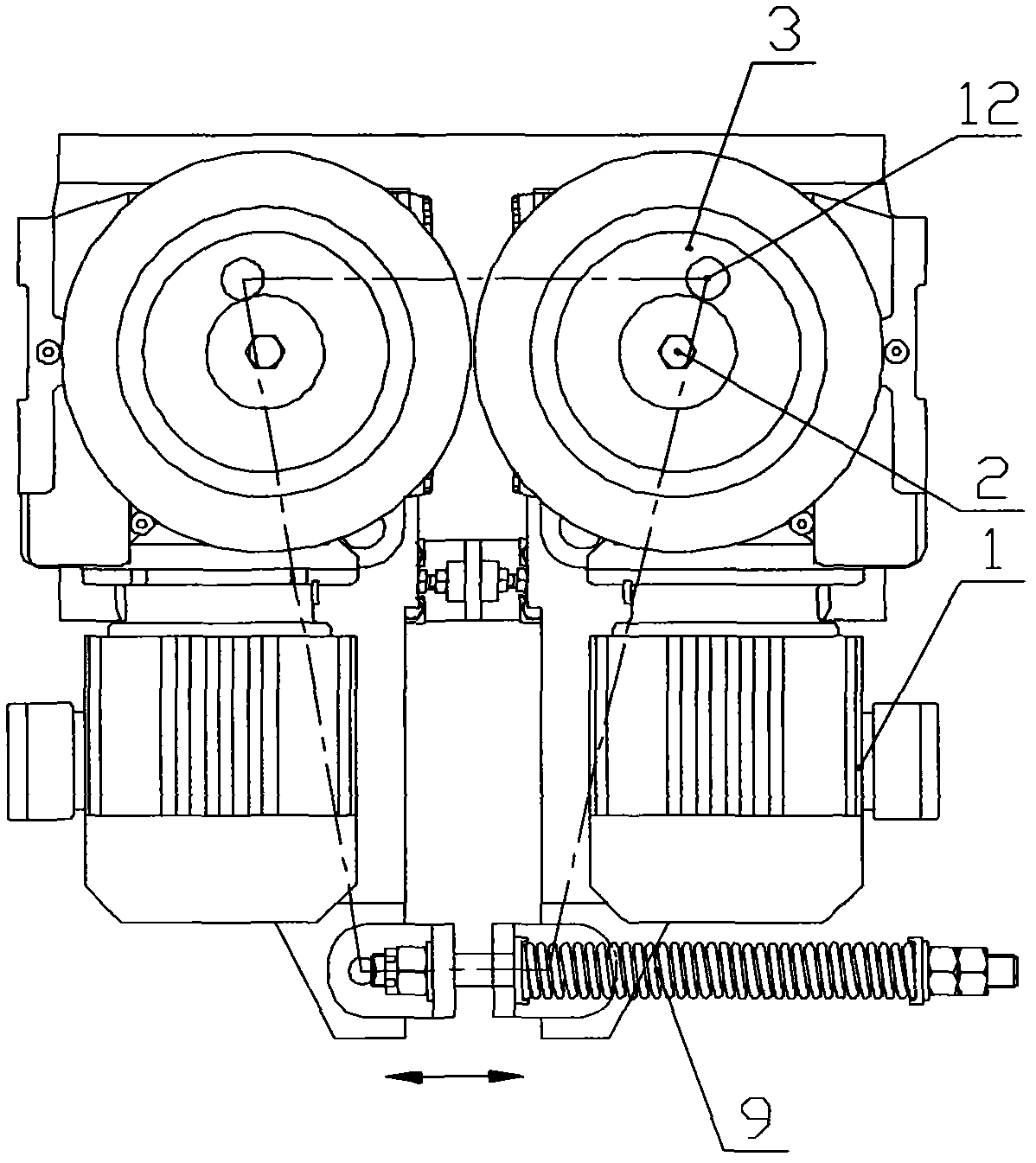

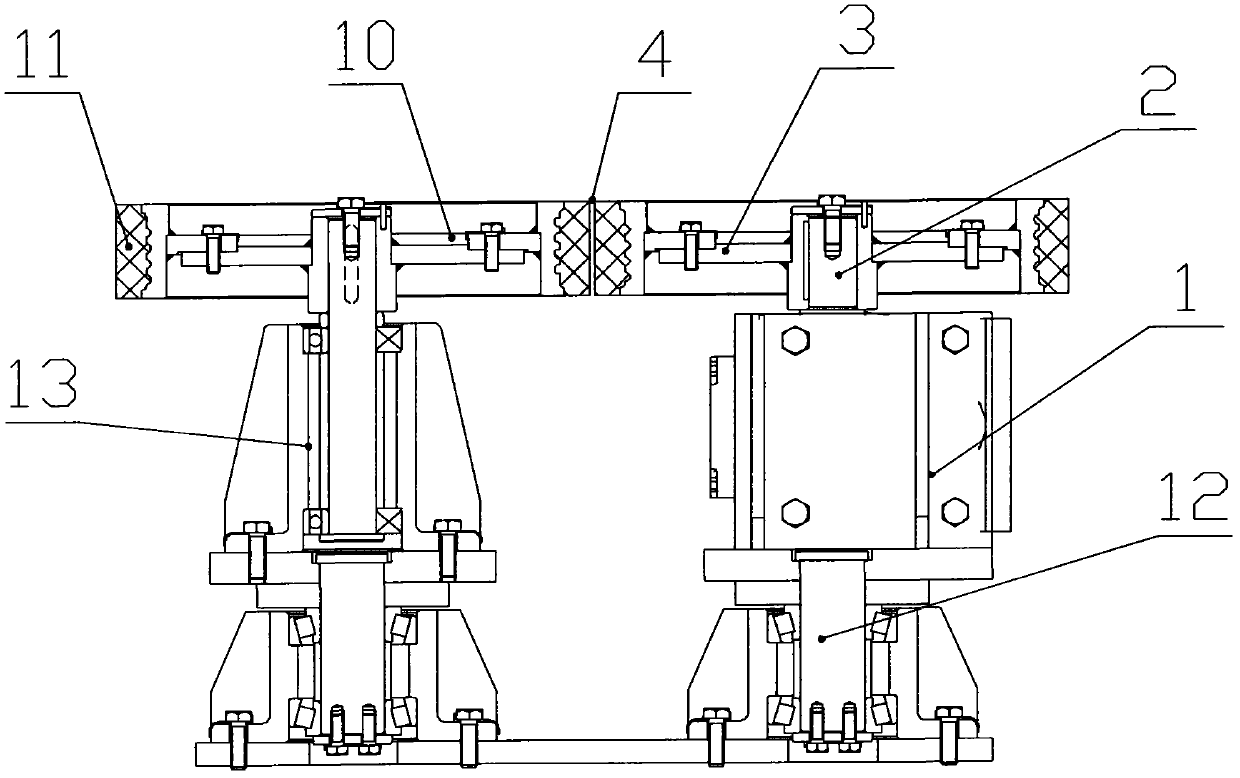

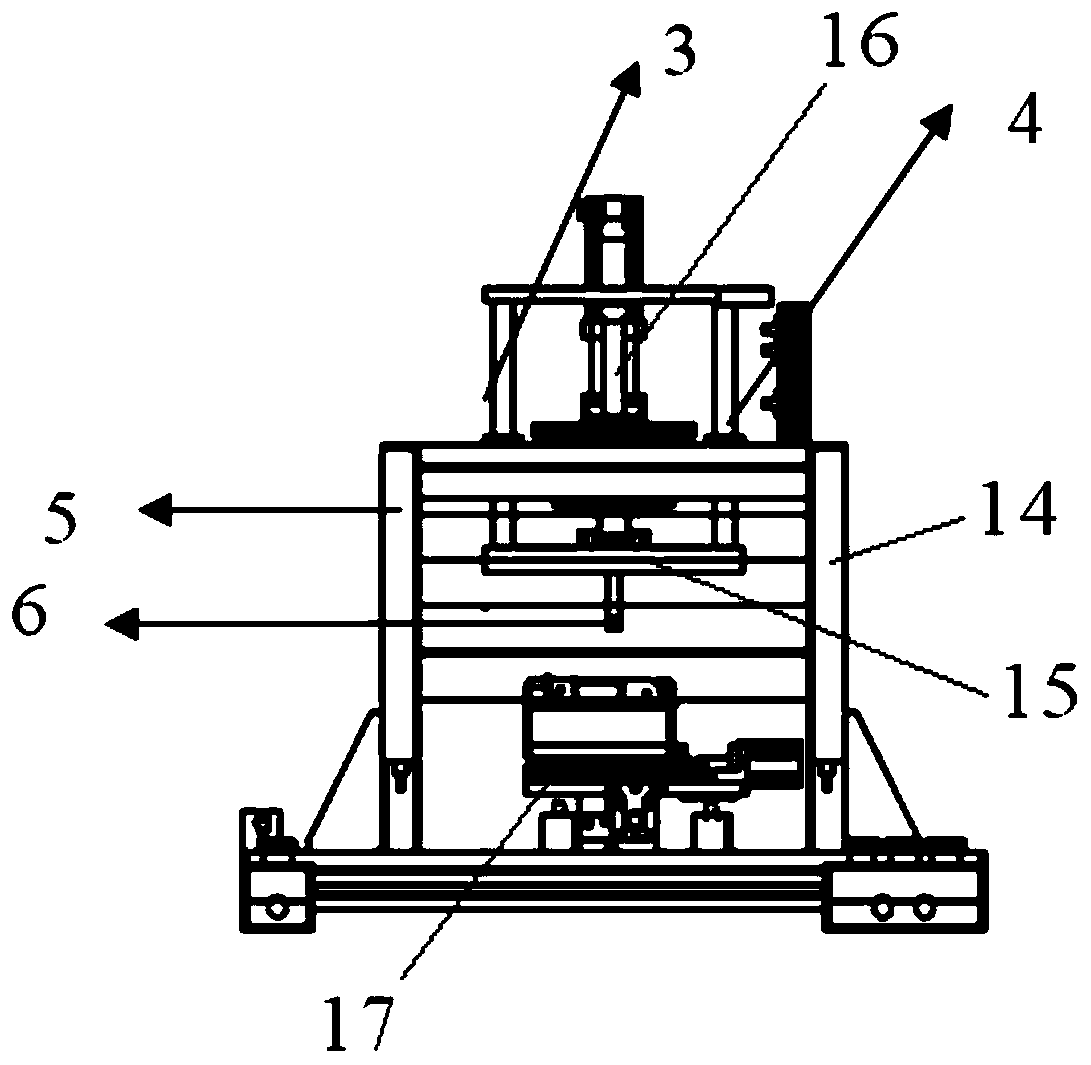

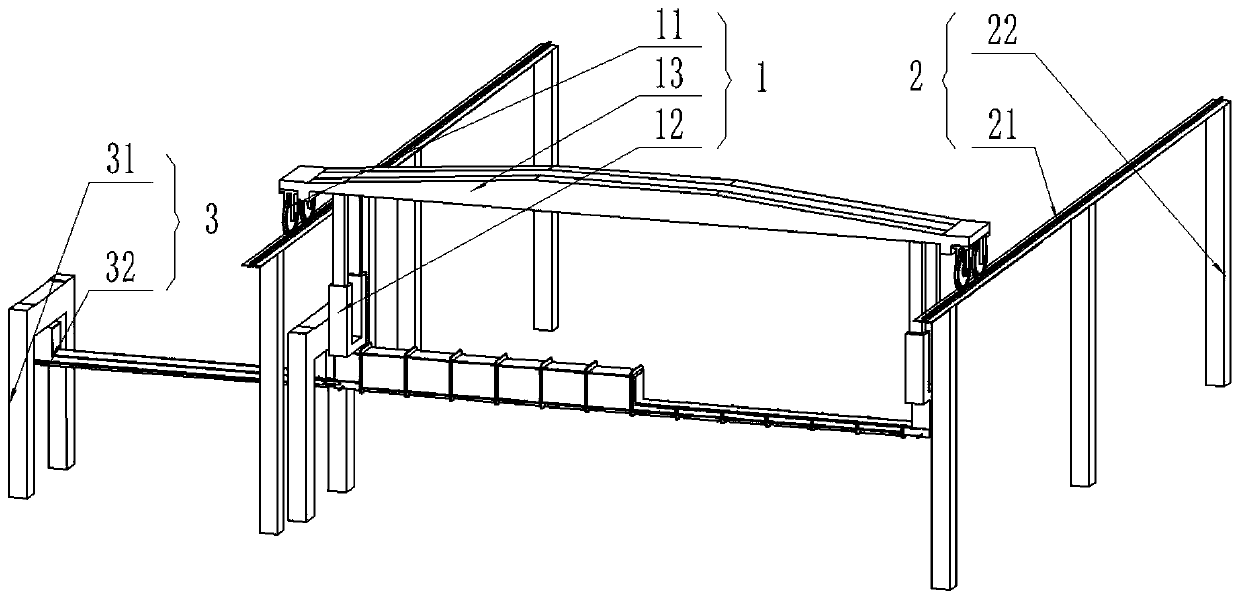

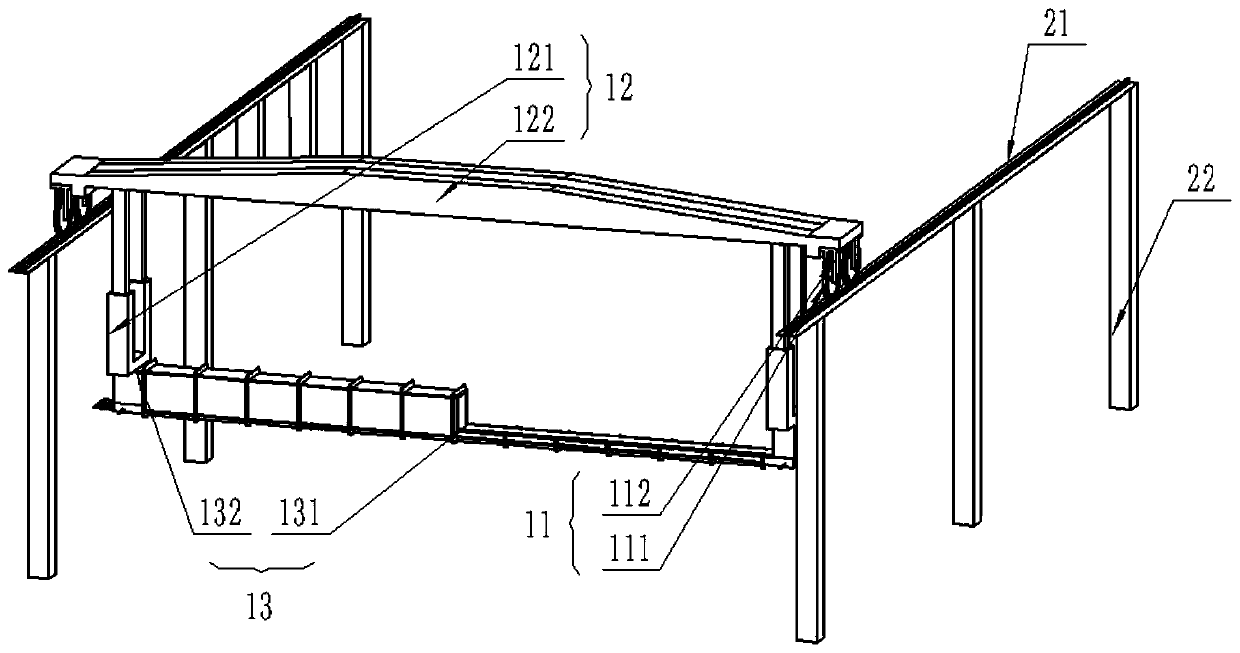

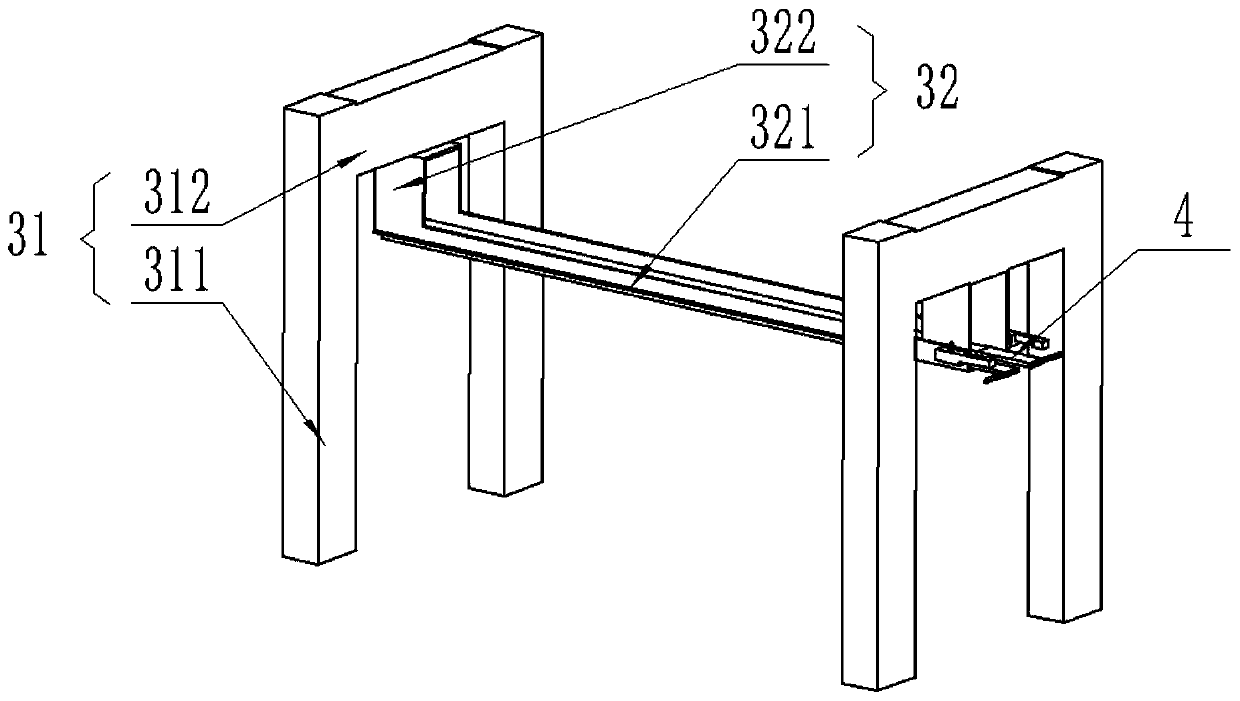

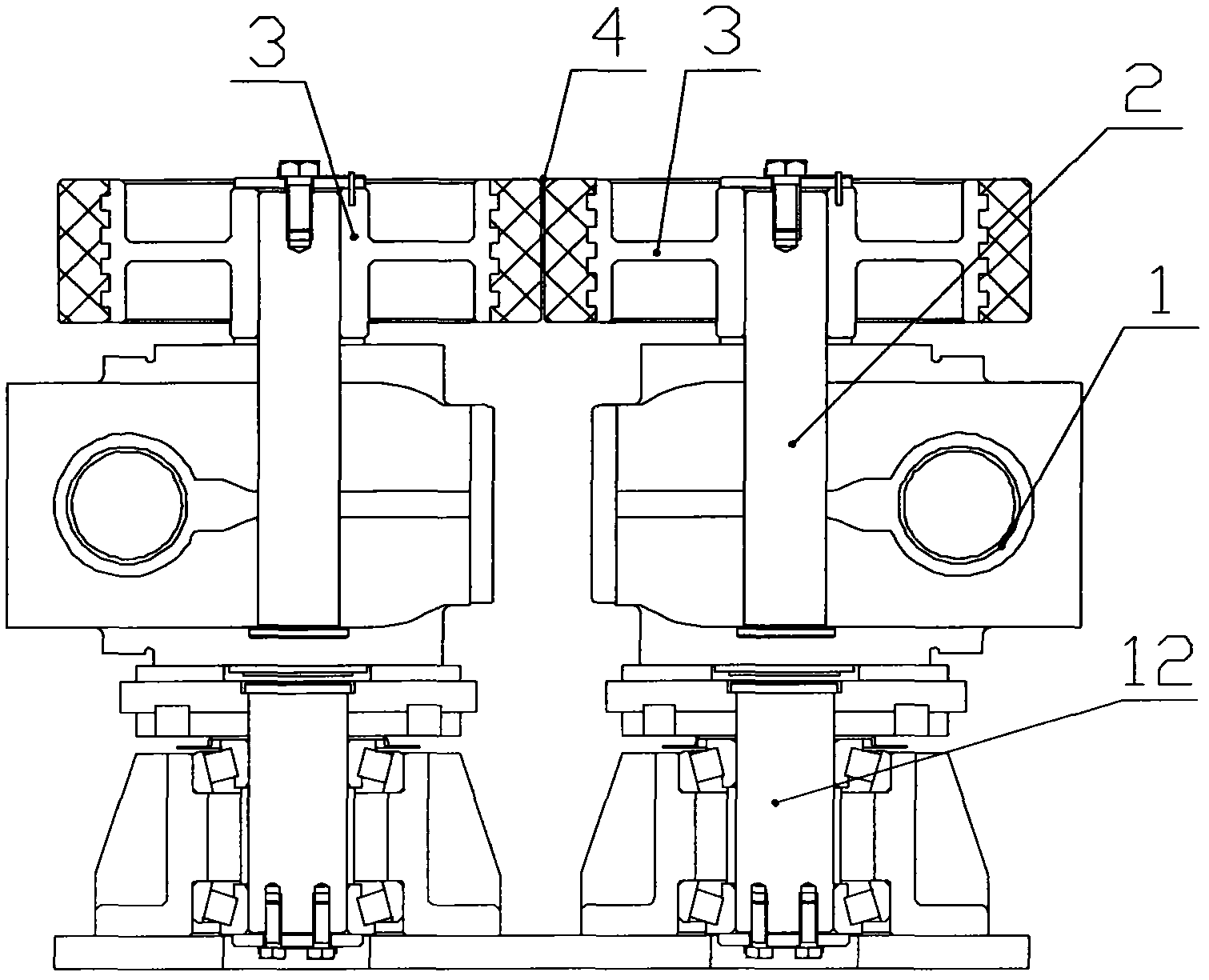

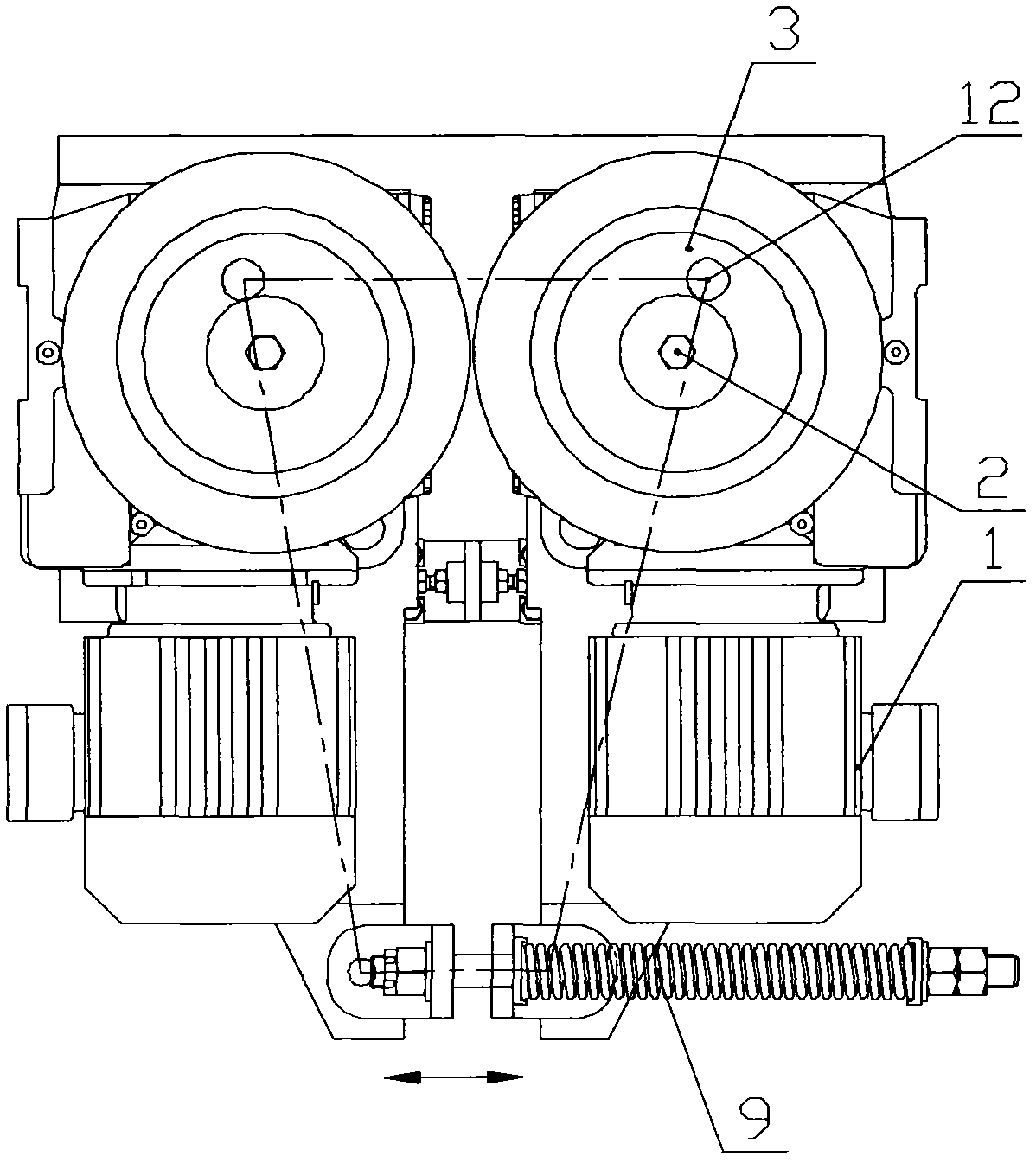

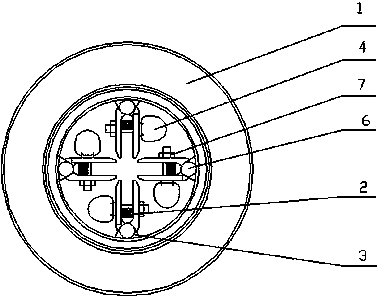

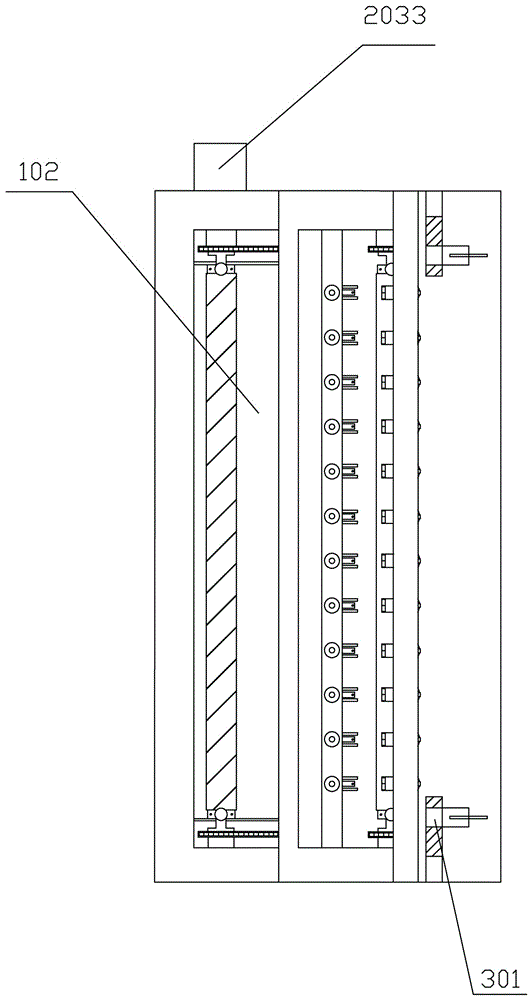

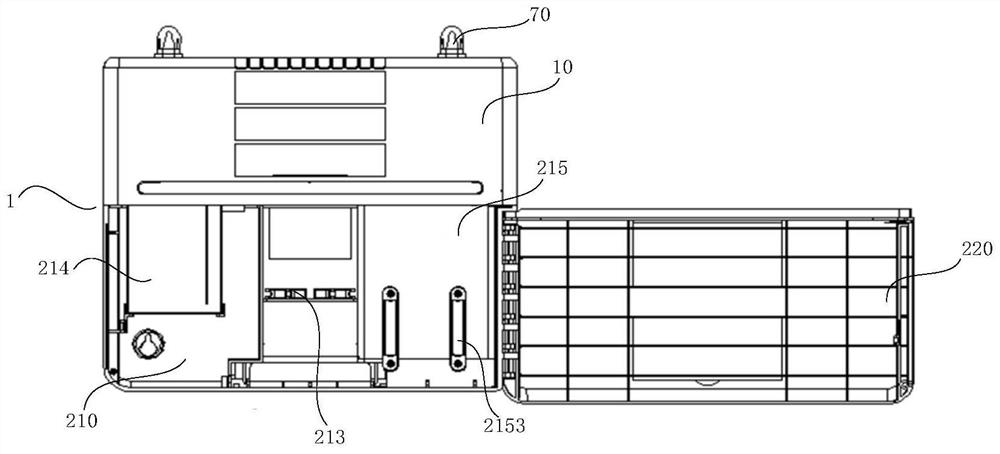

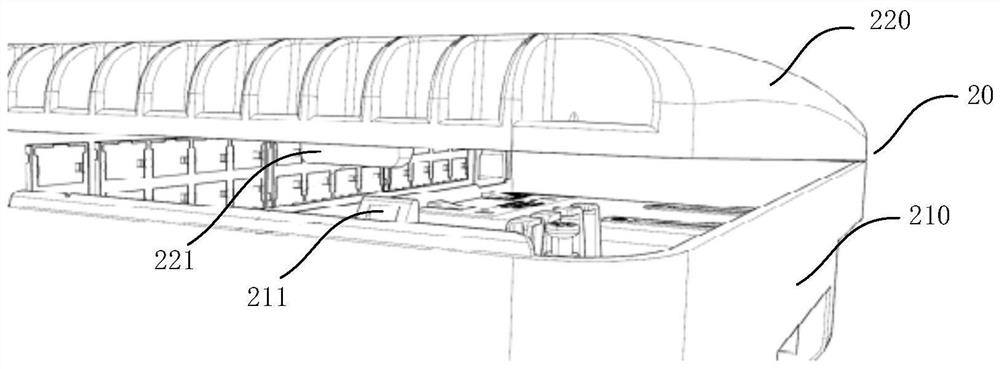

Double-silicon-rod diamond wire squaring machine

PendingCN111619026AImprove flowGood cutting precisionWorking accessoriesFine working devicesRobot handEngineering

The invention provides a double-silicon-rod diamond wire squaring machine comprising a lathe bed extending in the left-right direction. Single-silicon-rod cutting systems are symmetrically arranged onthe left side and the right side of the lathe bed. A feed system and a discharge system are arranged on the front side of the middle portion of the lathe bed. A crystal line detection system used fordetecting silicon rod crystal lines is arranged on the rear side of the middle portion of the lathe bed. A cross slide table system is arranged on the middle portion of the lathe bed and comprises alower slide table system extending in the front-back direction and an upper slide table system extending in the left-right direction. A silicon rod grabbing mechanical hand system used for grabbing silicon rods is installed on the upper slide table system. Two squaring machines share one crystal line detection device and one silicon rod grabbing mechanical hand system, and meanwhile cutting nets of the two squaring machines do not influence each other.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

Heavy frictional combined conveying line

InactiveCN102180340ADelivery does not affectEasy to replaceMechanical conveyorsDrive wheelDrive shaft

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

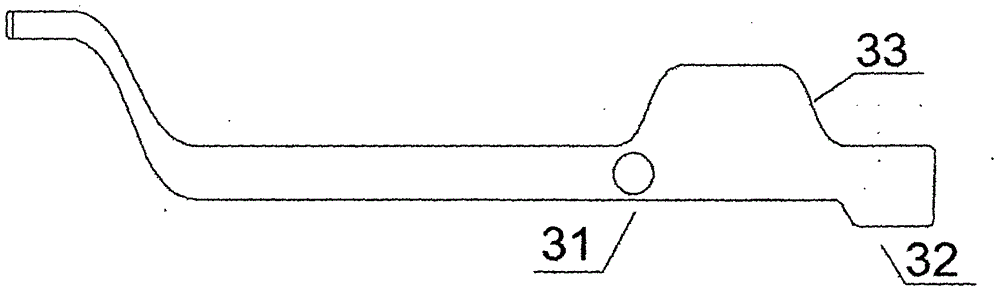

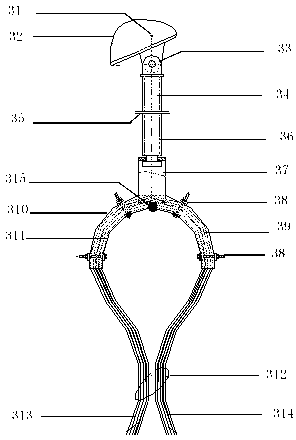

Rotary type floss-replaceable floss pick

The invention discloses a rotary replaceable dental floss stick, which comprises a handle, a dental floss holder, dental floss and other parts. The handle has a base handle, a rotating handle and a rotating shaft, and the base handle and the rotating handle are connected through the rotating shaft and can rotate relatively. The dental floss holder has a fixed bracket and a rotating bracket, the fixed bracket is fixed on the base handle, and the rotating bracket is fixed on the rotating handle. There are fixers at the ends of the fixed bracket and the rotating bracket, and there may also be a cutter for cutting dental floss. The fixer can adopt Y-shaped clamping seams, the structure is simple and reliable, and it is easy to use and clean. The dental floss can be conveniently fixed on the holder, and can also be easily removed. The cutter can safely and conveniently cut off the remaining part of the dental floss. The rotary replaceable dental floss stick has the characteristics of being able to clean the crevices and sides of the teeth, comfortable and easy to use, simple and scientific in structure, easy to clean, hygienic and safe, multi-functional, antibacterial and antibacterial, and the like.

Owner:徐泱忠

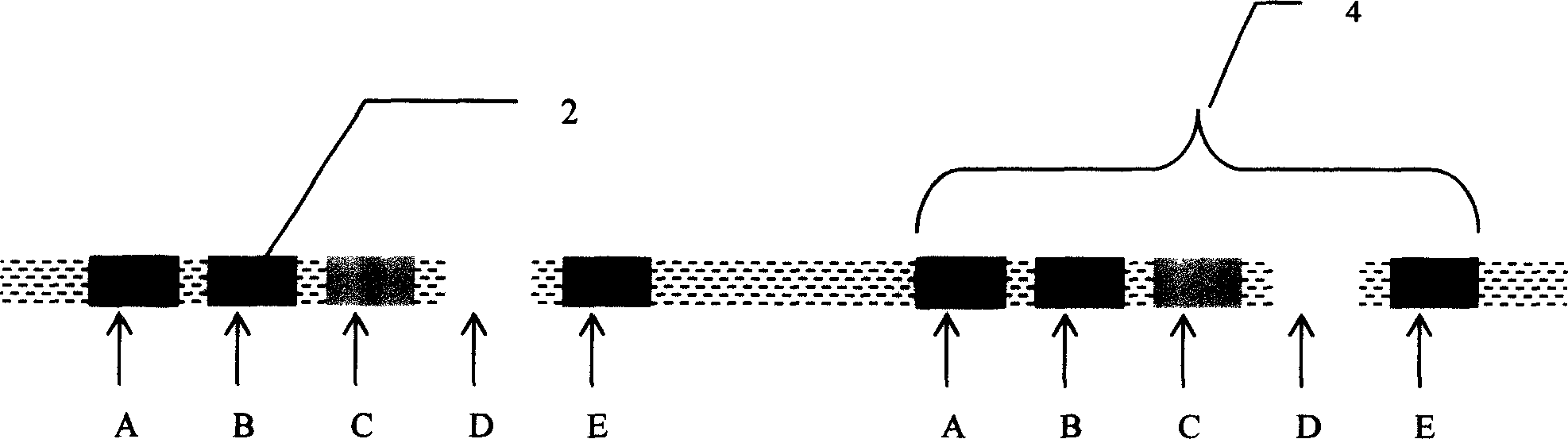

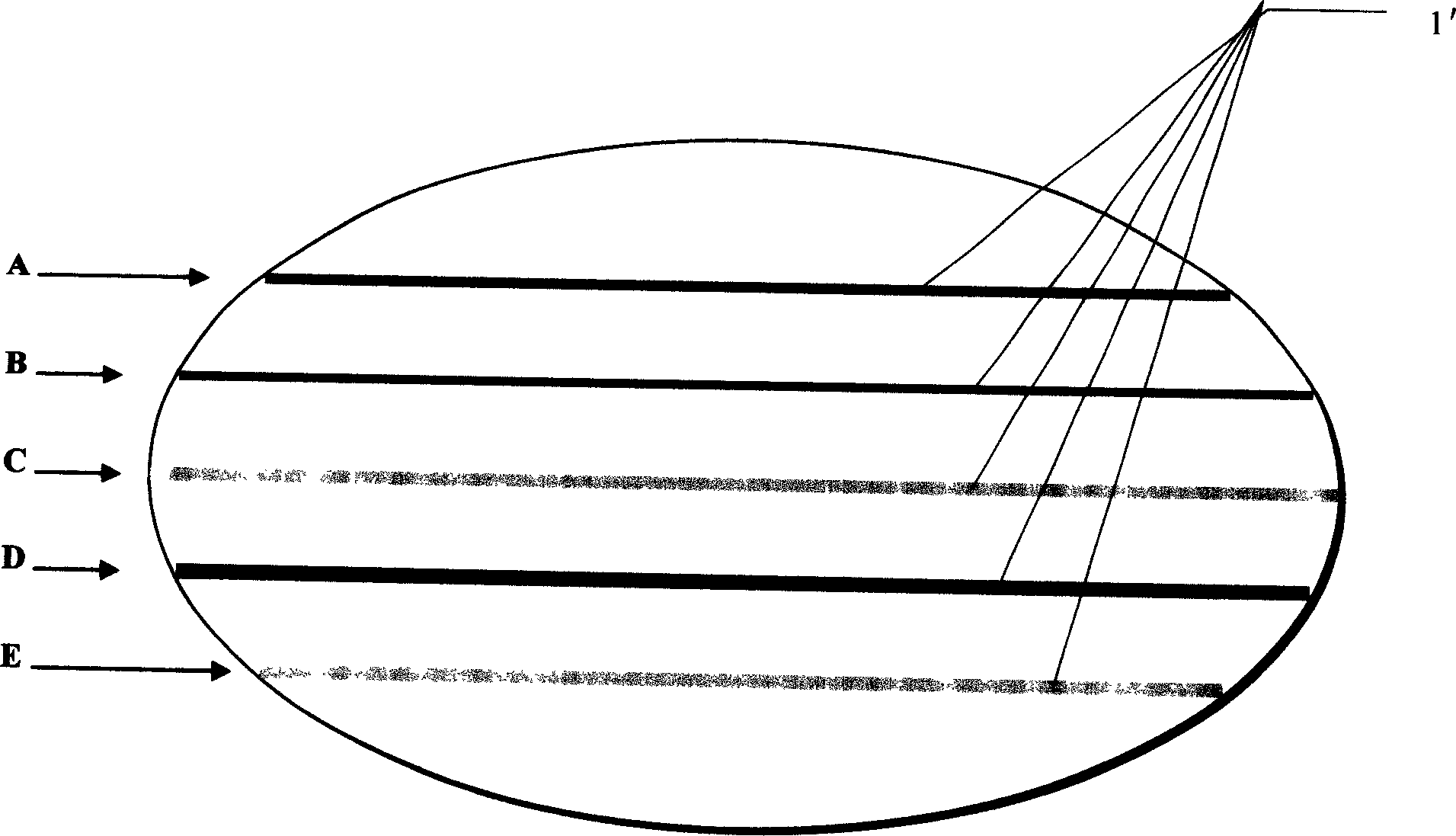

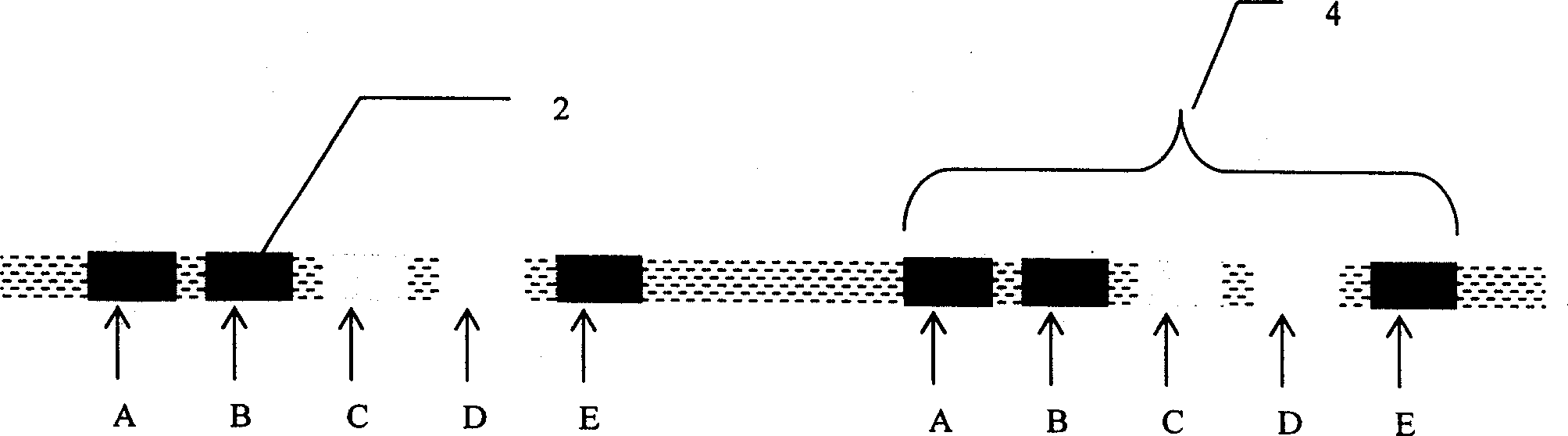

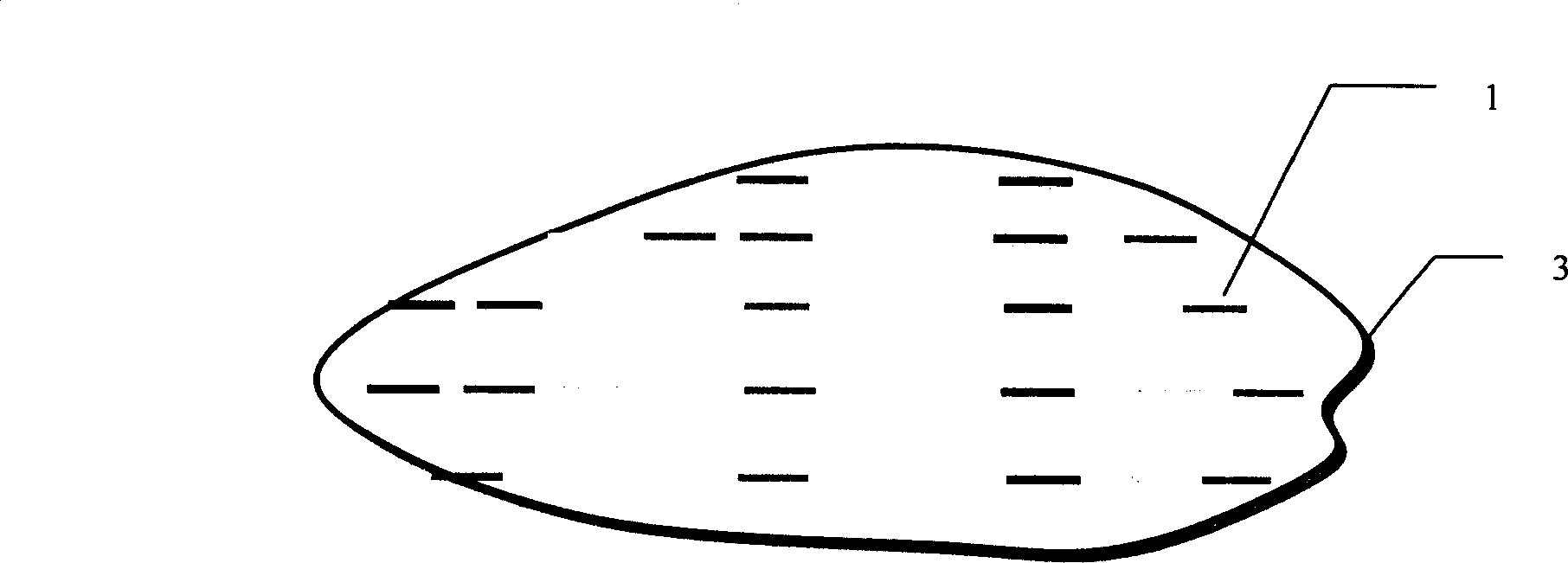

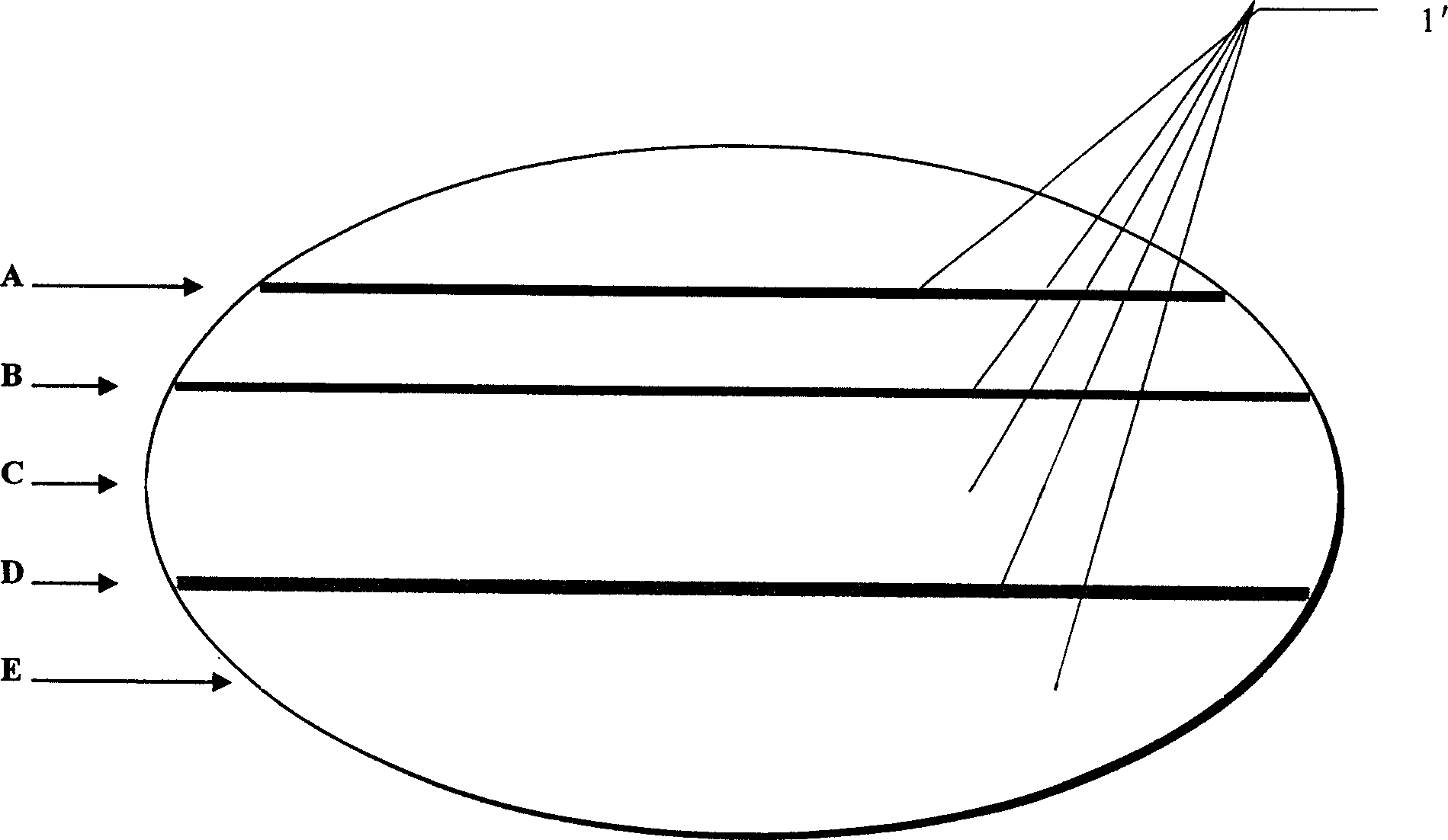

Chromatoghraph line antiforge method chromatograph line antiforge paper

InactiveCN1598140AFacilitate high-speed productionFacilitated releaseNon-fibrous pulp additionColor/spectral properties measurementsFine linePulp and paper industry

The invention provides a chromatoghraph line antiforge method and antiforge paper. Fine lines are buried in the paper and the colour permutatuin combination character of fine line is called as colour order character and as antiforge character. The antiforge paper of the same colour order character is only used for the same users or the same brand or other the same antiforge object. The chromatoghraph line antiforge paper is suitable for high-speed production and is hard to forge and easy to identifying.

Owner:吉林桑源科技有限公司

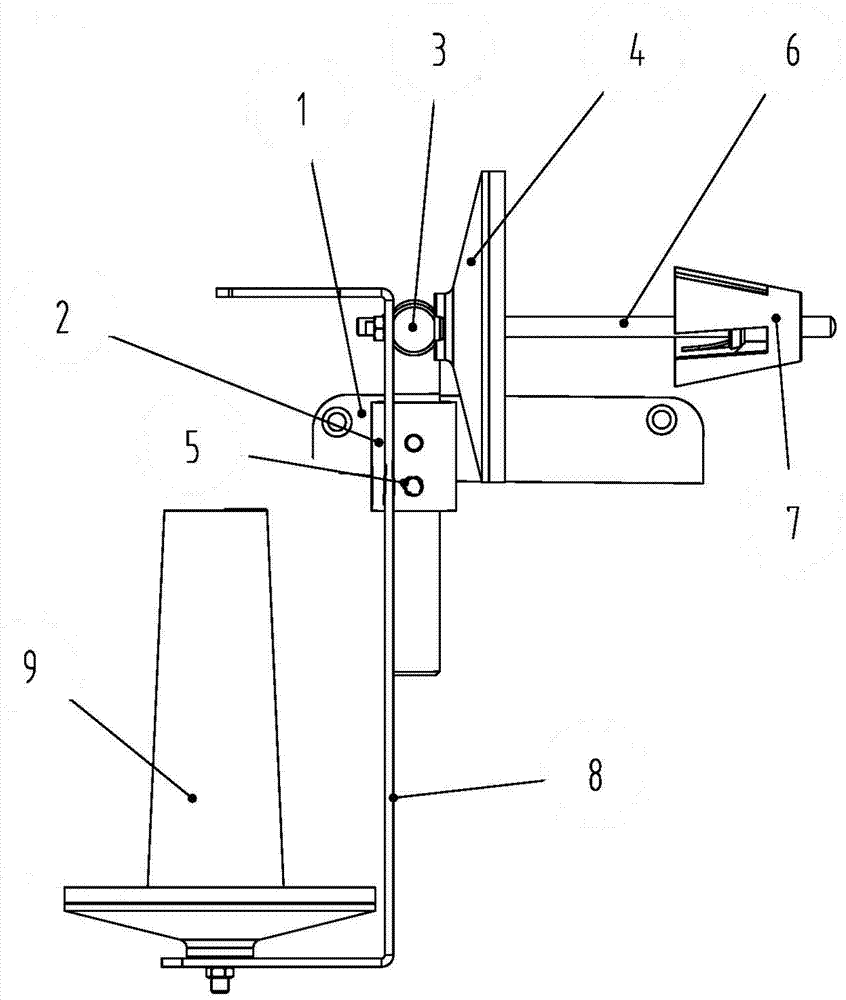

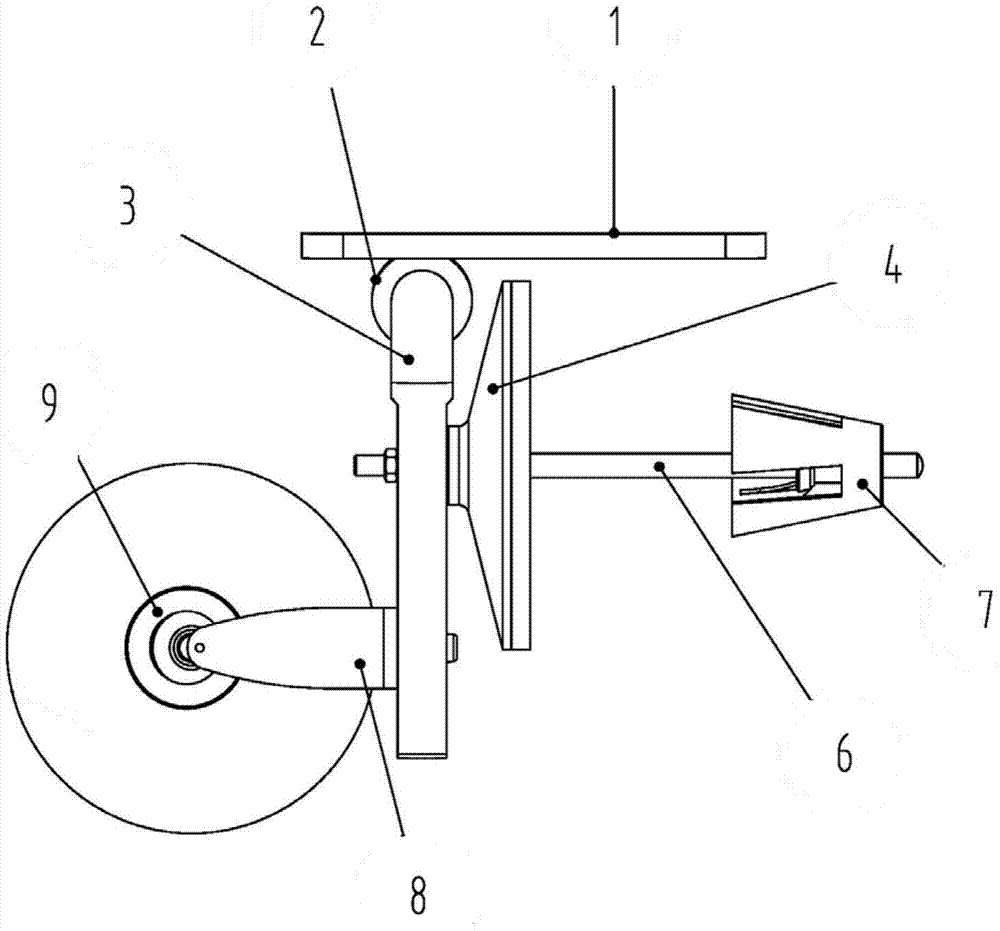

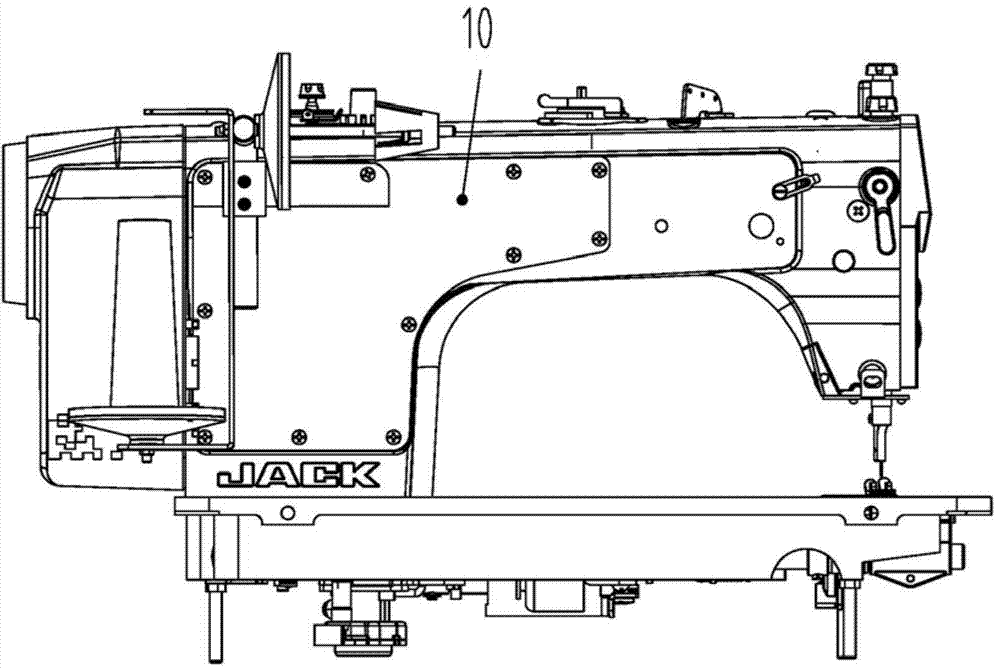

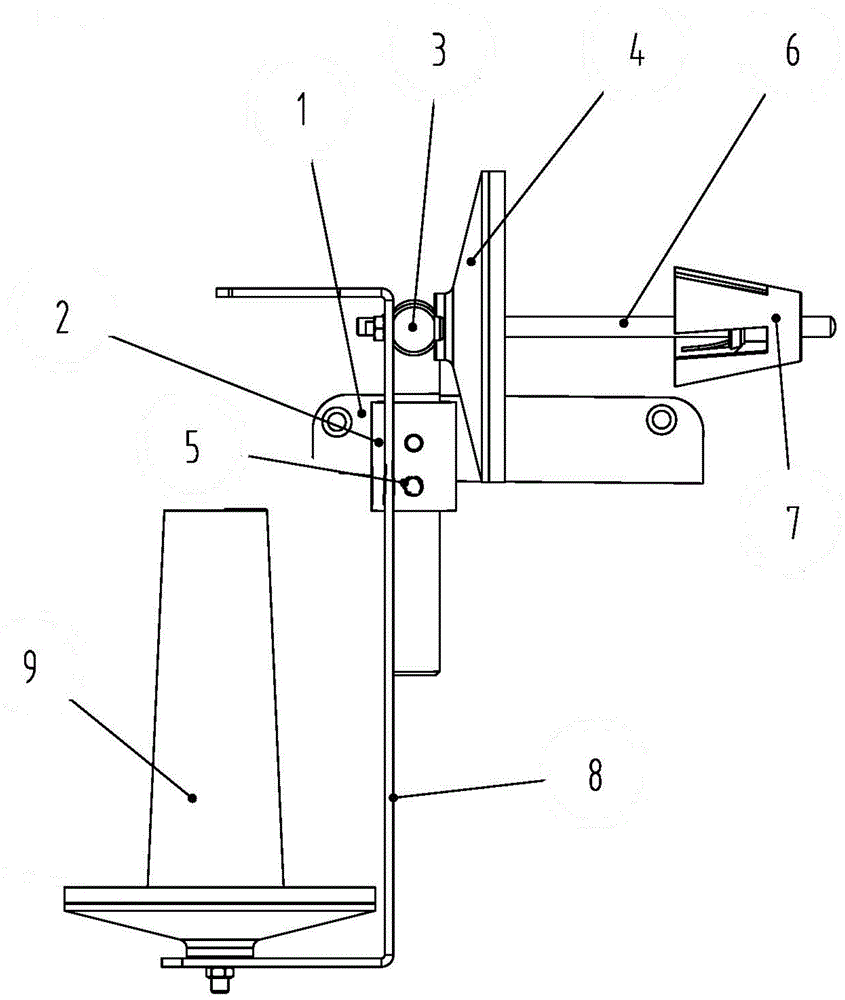

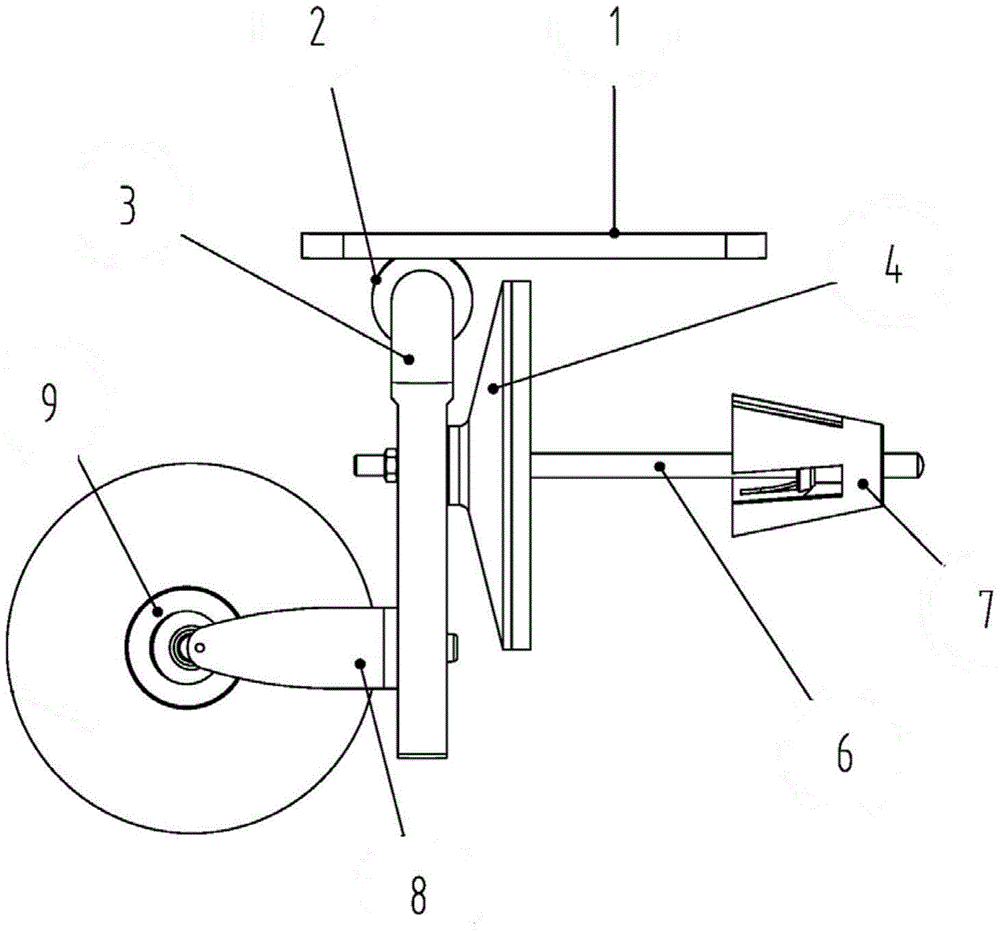

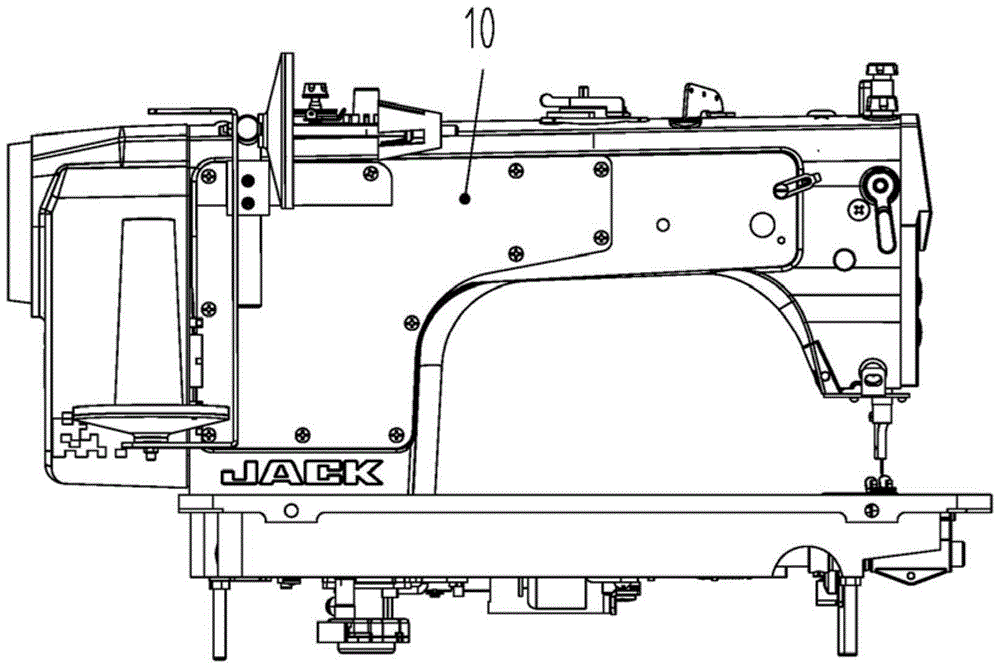

Sewing machine and thread stand thereof

The invention discloses a thread stand of a sewing machine. The thread stand comprises at least two pay-off devices and connecting devices, wherein the at least two pay-off devices are respectively used for accommodating wound upper threads (12) and accommodating wound bottom threads (13); the connecting devices are used for connecting the pay-off devices and the sewing machine. By utilizing the connecting devices, the pay-off devices are installed on a machine body of the sewing machine, that is, the thread stand is installed on the machine body of the sewing machine. The thread stand is simple in structure, and is convenient to install; the existing installation mode is changed, the thread stand is close to users; threads are relatively convenient to change and adjust, and the thread stand is convenient to operate by users, and is fixedly connected so as to prevent from being knocked off effectively, and further the working efficiency is improved. The invention also discloses the sewing machine comprising the thread stand.

Owner:JACK SEWING MASCH CO LTD

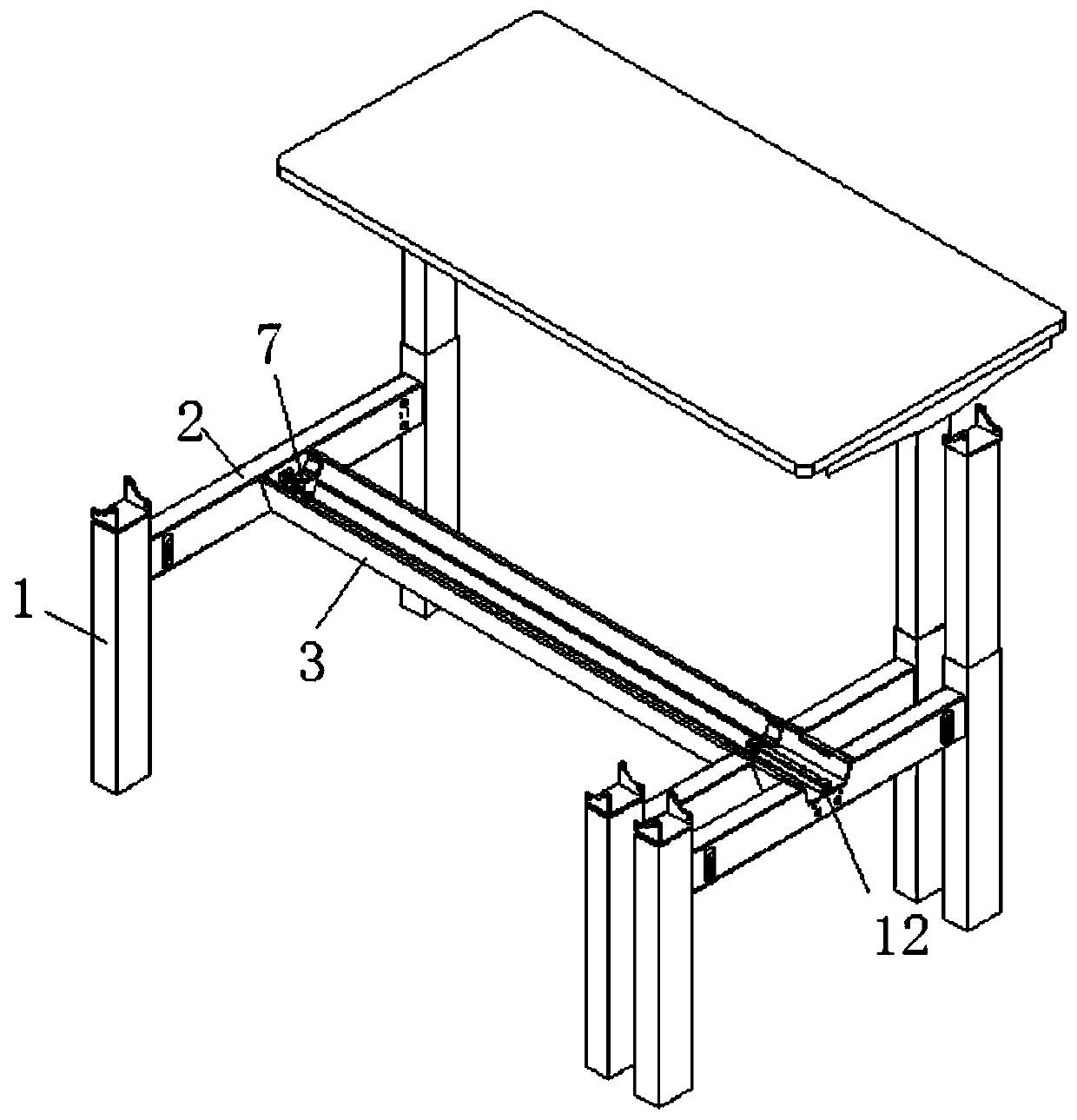

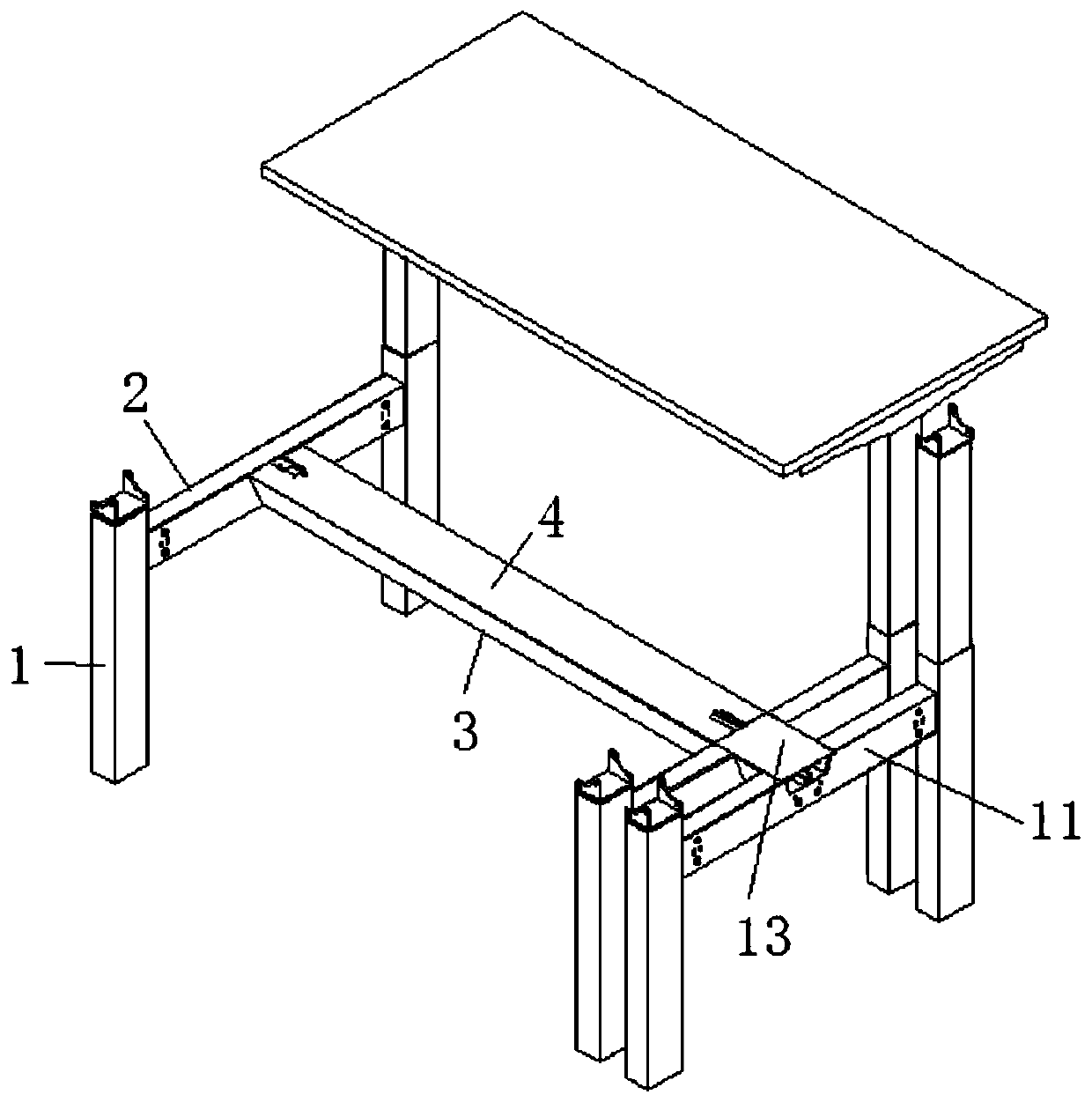

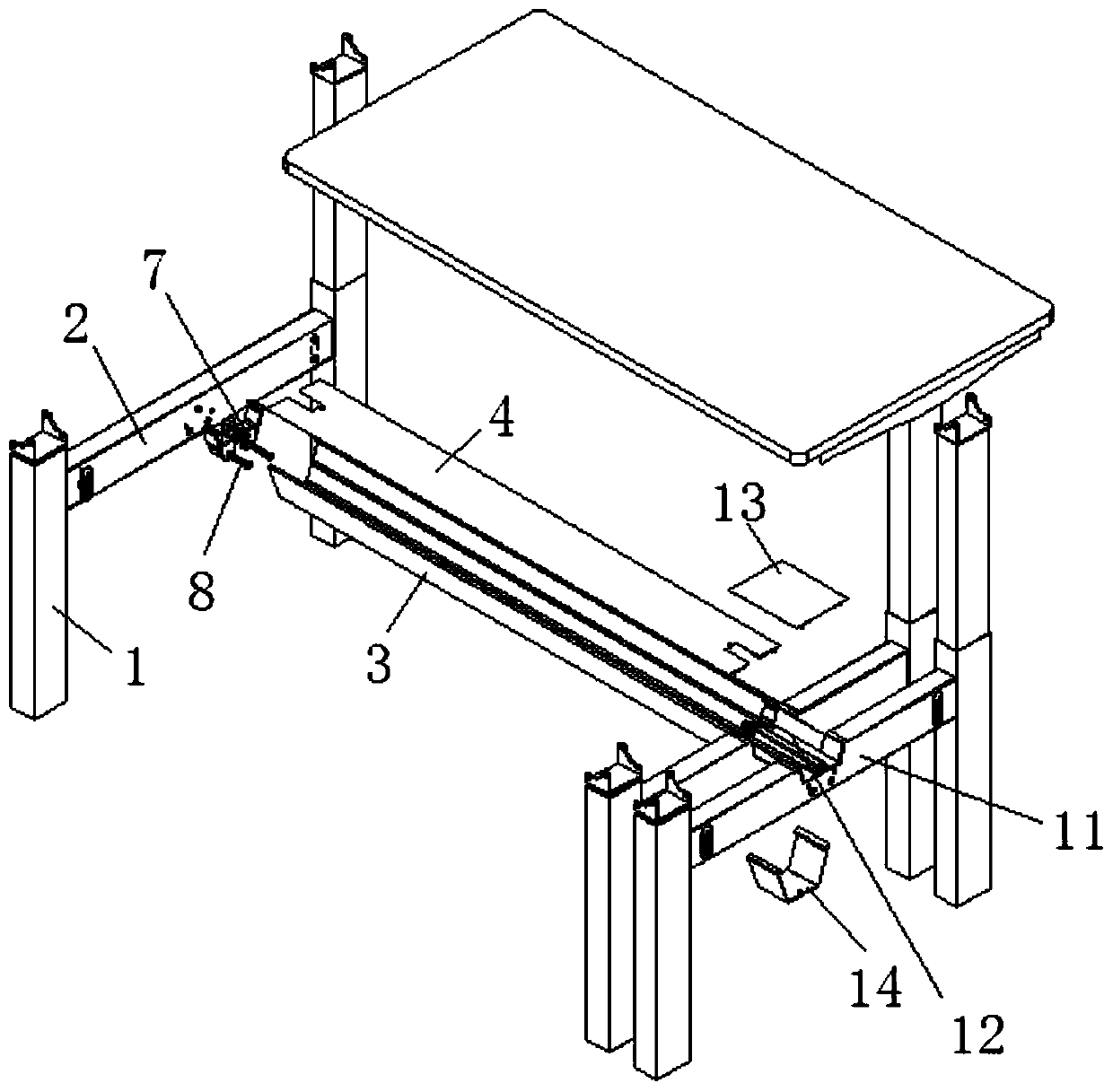

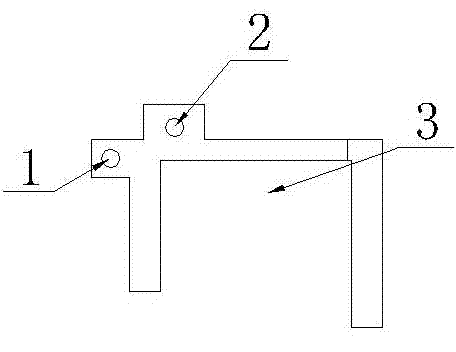

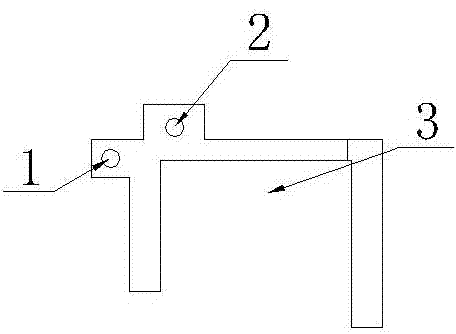

Wiring structure under office desk

PendingCN109728547AThe office environment is beautiful and tidyReduce security risksElectrical apparatusDeskElectrical and Electronics engineering

The invention relates to the technical field of office furniture, and discloses a wiring structure under an office desk. According to the invention, a connecting beam is arranged between two side legsof the office desk, the connecting beam is provided with a wiring duct fixing component at the middle position, a wiring duct is fixed on wiring duct fixing components on both sides, the wiring ductis provided with an opening at one end or both ends, one or more legs of the office desk is / are provided with a wire arrangement bag, cables are arranged in the wiring duct, the cables get in or out from the opening of the wiring duct, and the cables connect equipment on the office desk to a wiring terminal through the arrangement of the wiring duct and the wire arrangement bags. The office cablesare arranged in the wiring duct below the office deck, thereby being beautiful and safe. The simultaneous connection of a row of office decks is realized by requiring at least one wiring position.

Owner:上海泽奉实业有限公司

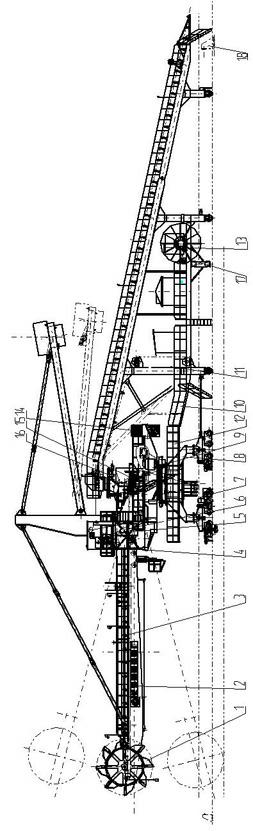

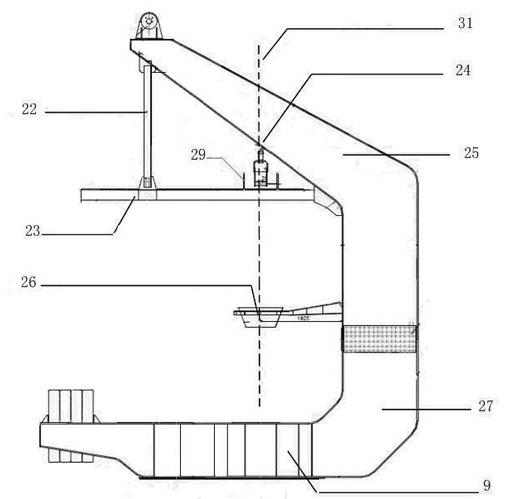

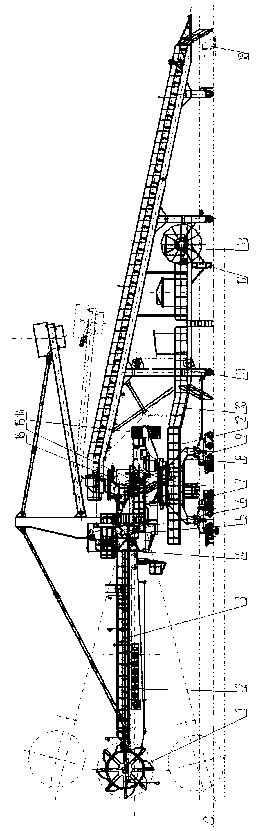

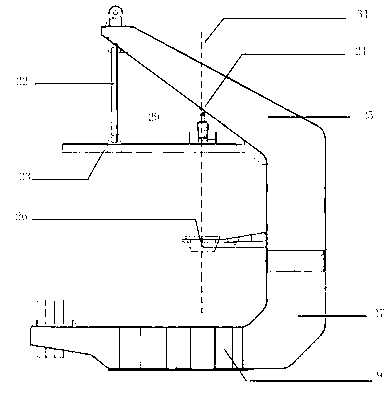

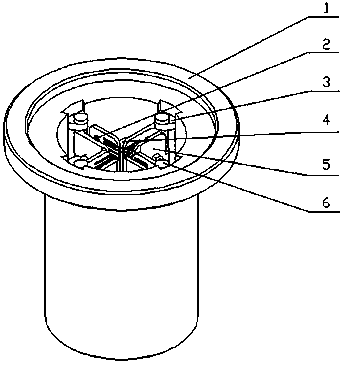

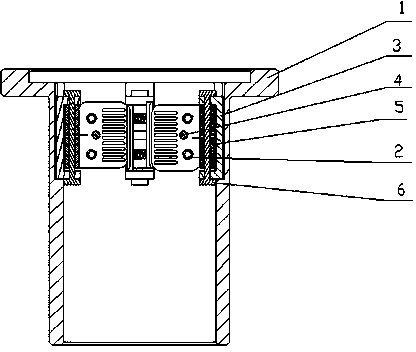

Novel electrifying way and device for bucket wheel machine

ActiveCN102431810AImprove anti-interference abilitySave control cablesLoading/unloadingElectricityControl room

The invention relates to a novel electrifying way and device for a bucket wheel machine. A conductor line is selected preferably for supplying power to the bucket wheel machine; a collector brush on a current collector at the bottom end of a machine body is in sliding contact with a guide rail; electric energy is directly conducted to a walking system; the current collector of a conductor line system is electrically connected with the walking system through a cable; the walking system is used for controlling a part of lines to enter an auxiliary control room on a trailer; a communication linegetting out of the auxiliary control room reaches upwards to an electrifying device on the revolving central line of an upright post through a trailer main beam together with power lines of a bucket wheel, a belt feeder, a revolving mechanism and a pitching system; the power lines of the bucket wheel, the belt feeder, a revolving mechanism and the pitching system and a communication line between the auxiliary control room and a driving cab pass through the electrifying device; a communication line which gets out of the electrifying device and is used for connected the auxiliary control room with the driving cab directly enters the driving cab; a power wire getting out of the electrifying device is introduced into the bucket wheel, the belt feeder, the revolving mechanism and the pitching system for supplying power respectively; and communication lines of these parts get back to the driving cab.

Owner:HUNAN CHANGZHONG MACHINERY

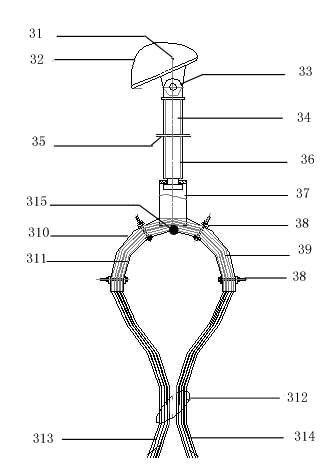

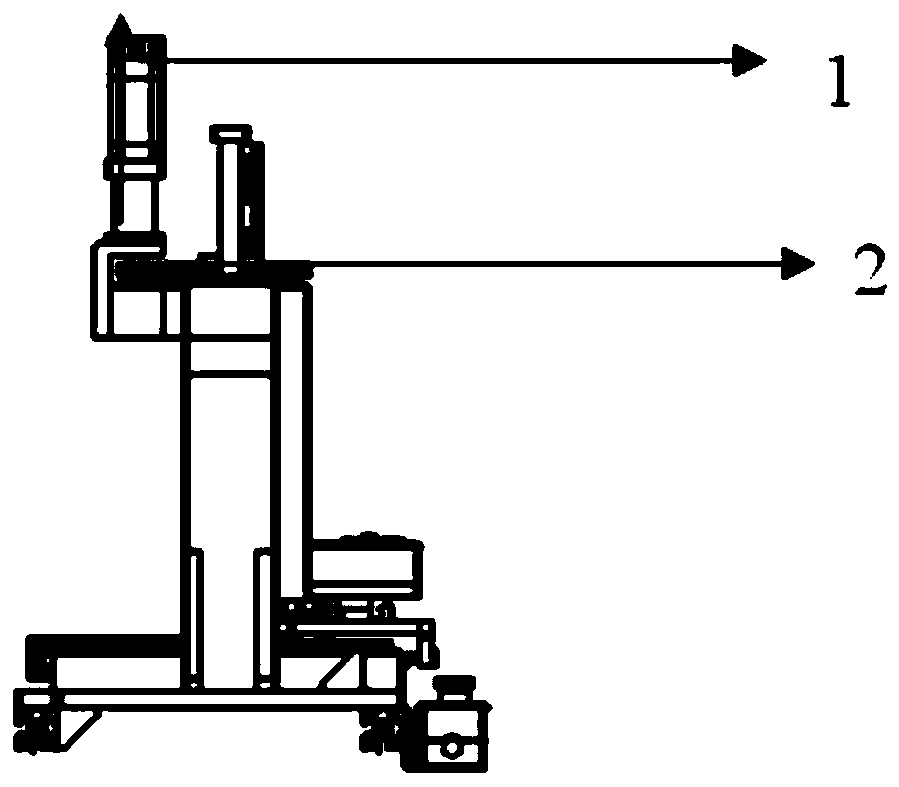

High-angle rotation wire feeding device of bucket wheel machine

ActiveCN103224143AImprove securityReduce maintenance costsLoading/unloadingSmall amplitudeSheet steel

Owner:HUNAN CHANGZHONG MACHINERY

Threading hook base of single-needle embroidering robot

InactiveCN102234883ARealize functions such as no need to change needlesImprove work efficiencyEmbroidering machines apparatusChange colorEngineering

The invention discloses a threading hook base of a single-needle embroidering robot. A limit groove is arranged below the threading hook base; and an air tube mounting hole and a limit screw mounting hole are arranged on the threading hook base. The threading hook base of a single-needle embroidering robot is a device for supporting and mounting a threading hook as well as an indispensable component for realizing the automatic threading function under the computer control of an embroidering machine. By using the threading hook base to carry out automatic threading, the working efficiency is improved, the labor is saved, threads can be changed conveniently, and the functions of changing colors and threads without changing needles and the like can be achieved.

Owner:DALIAN DASEN NUMERICAL CONTROL CO LTD

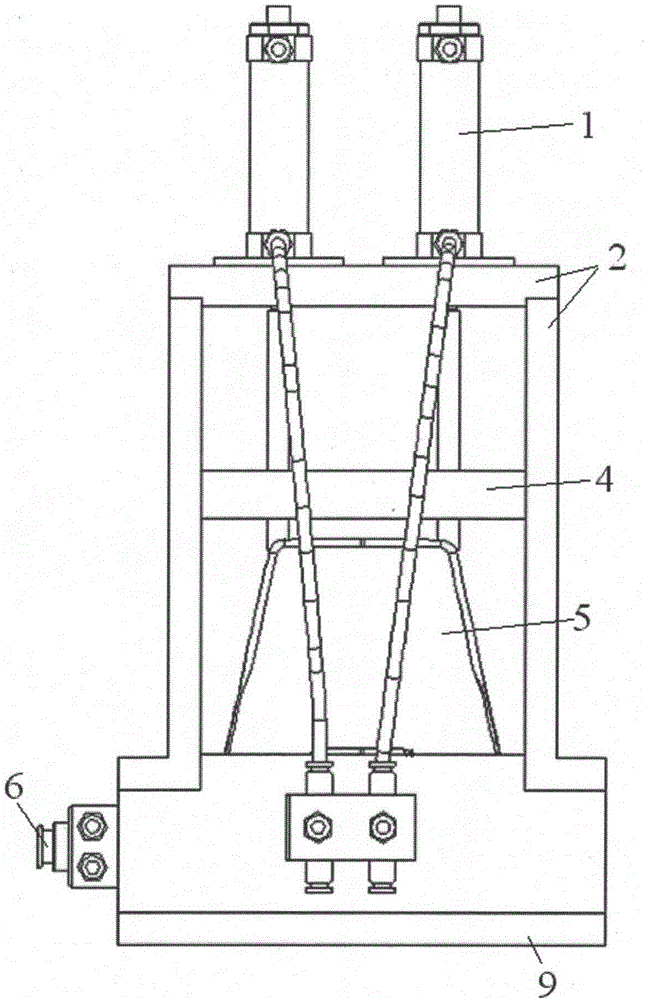

Car pillow assembling fixture and method

The invention provides a car pillow assembling fixture. The car pillow assembling fixture comprises a fixed base. A pillow skeleton is positioned on the fixed base. Air cylinders are arranged above the pillow skeleton. Cylinder rods of the air cylinders are connected with lead-in pins, and the lead-in pins are located over slotted holes, used for assembling metal pins, of the pillow skeleton. A control switch used for the air cylinders is arranged on the fixed base. The invention further provides a car pillow assembling method. The method includes the steps that the air cylinders are pushed by air pressure to ascend to the top end, and meanwhile the lead-in pins are driven to ascending positions; the pillow skeleton is put into the fixed base to be positioned; the metal pins are put into the slotted holes of the pillow skeleton; and the air cylinders descend, the lead-in pins on the cylinder rods also descend, and the metal pins are pressed into the pillow skeleton. The car pillow assembling fixture provided by the invention overcomes the defects in the prior art, the structure is simple, operation is convenient, installation and wire replacement are made convenient and fast, production efficiency is greatly improved, the pillow metal pins can be quickly assembled and produced, and the purposes of saving manual work and improving production capacity and quality stability are achieved.

Owner:上海飞尔汽车零部件股份有限公司

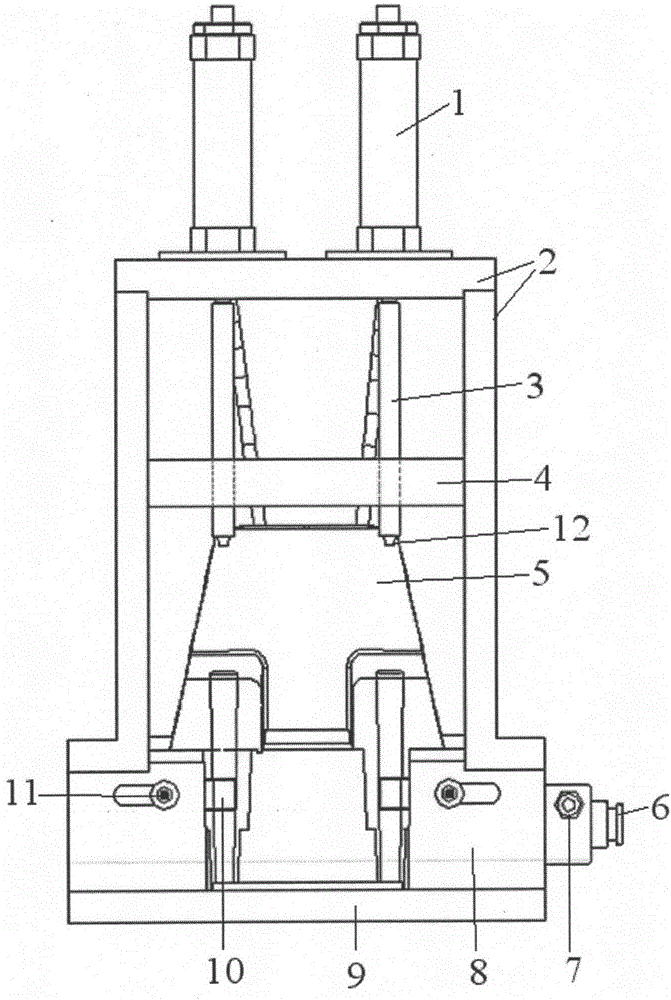

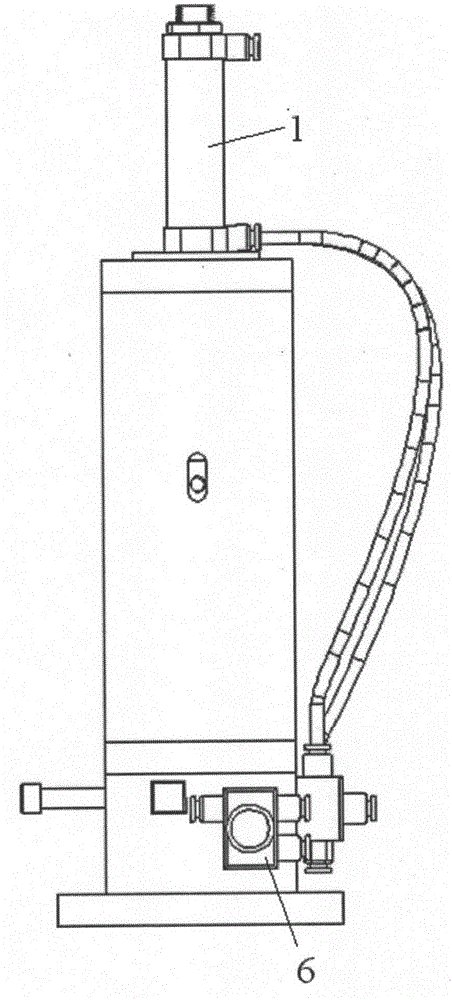

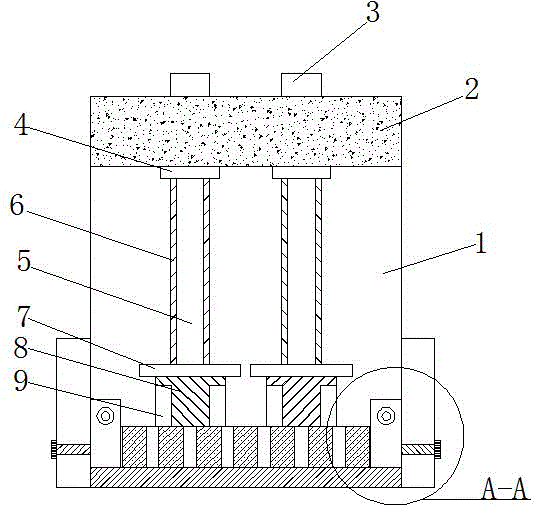

Tool for pressing metal insert into electronic transmission range selection (ETRS) electronic gear support

InactiveCN110303324AReduce investmentRapid assembly productionMetal working apparatusElectronic transmissionEngineering

The invention discloses a tool for pressing a metal insert into an electronic transmission range selection (ETRS) electronic gear support. The tool for pressing the metal insert into the ETRS electronic gear support comprises a base. An n-shaped frame is arranged on the base. A square movable frame which can move up and down is arranged on the top of the frame. The movable frame comprises guide rods located on the left side and the right side. A gear is also arranged on the top of the frame. Teeth in the circumference of the gear are connected with the rotary end of a motor in a meshing manner. A threaded hole is formed in the center of the gear. A screw rod is arranged in the threaded hole. The upper end and the lower end of the screw rod are fixedly connected with the upper end and the lower end of the movable frame. A first locating block is fixed to the lower end of the movable frame. A first guide rail fixed to the base is arranged below the first locating block. A movable block is arranged on the first guide rail. A second guide rail is fixed to the movable block. A second locating block is arranged on the second guide rail. The movable block is connected with the telescopicend of a first cylinder. The second locating block is connected with the telescopic end of a second cylinder. According to the tool for pressing the metal insert into the ETRS electronic gear support,the operation is simple and convenient, the personnel input can be effectively reduced, and in addition, the on-site production efficiency can be improved.

Owner:上海飞尔汽车零部件股份有限公司

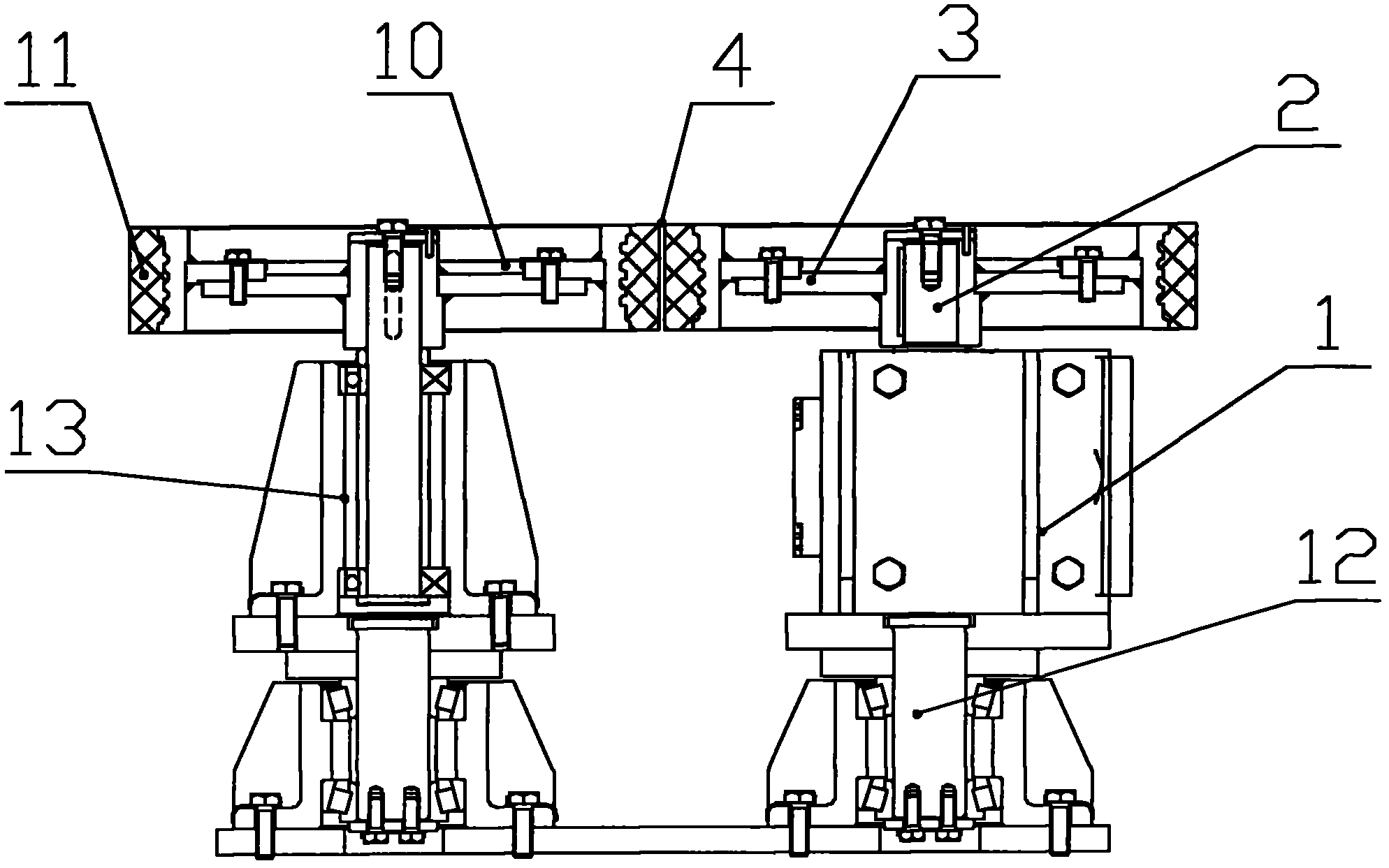

Suspension train incoming and outcoming system, suspension train transfering device and hanging type garage

PendingCN110748213AEasy to change linesAchieve rational useRailway componentsRailway stationSuspension (vehicle)Control theory

The invention belongs to the technical field of suspension type train traffic, aims to solve the problems of large floor space and complex structure of a vehicle incoming and outcoming line changing system, and provides a suspension train incoming and outcoming system. The system comprises a suspension train transferring device and a hanging type garage, wherein the suspension train transferring device can run along an air guide rail arranged parallel to the hanging type garage to the butt joints of different sublibraries of the hanging type garage, and a communication track is formed througha butt joint device to realize train incoming and outcoming of the suspension train transferring device and the sub-libraries. The system has the beneficial effects that a walking device of the suspension train transferring device is used for carrying out air transferring of the train in the air, the space is fully utilized, the floor space occupation area is reduced, the structure is simple, andincoming and outcoming of the suspension type train can be flexibly realized.

Owner:ZHONGJIAN AIR TRAIN BEIJING TECH CO LTD

A Leakage Protector with High Safety Performance

ActiveCN106449290BAvoid safety hazardsAvoid LeakageProtective switch terminals/connectionsEngineeringMechanical engineering

The invention discloses a leakage protector with high safety performance. The leakage protector comprises a device body, the top and the bottom of the device body are respectively provided with a clamping plate and an insulation base, the top portion and the bottom portion of the clamping plate are respectively provided with wiring holes and protection sleeves, the bottom portions of the protection sleeves are fixedly connected with wire bodies, the outer surfaces of the wire bodies are sleeved by insulation sleeves, one end of the bottom portion of each wire body penetrates a pre-tightening portion, the inner cavities of the pre-tightening portions are provided with through holes, the bottom portions of the wire bodies are fixedly connected with wiring copper members, the bottom portions of the wiring copper members are fixedly connected with the insulation base, the inner cavity of the insulation base is provided with a pressure column, the two sides of the insulation base are each fixedly connected with a connection plate, and one side of each connection plate is fixedly connected with a corresponding support plate. According to the invention, through arrangement of the protection sleeves, the insulation sleeves and the insulation base for cooperative application, the wire bodies can be protected, a waterproof effect can also be exhibited, the wire bodies are prevented from electric leakage caused by a safety hidden risk of the device body due to water, and the safety hidden risk can be effectively prevented.

Owner:湖南奇力新电子科技有限公司

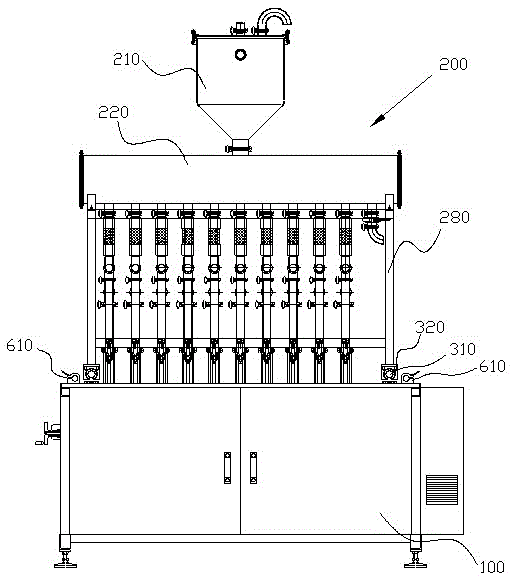

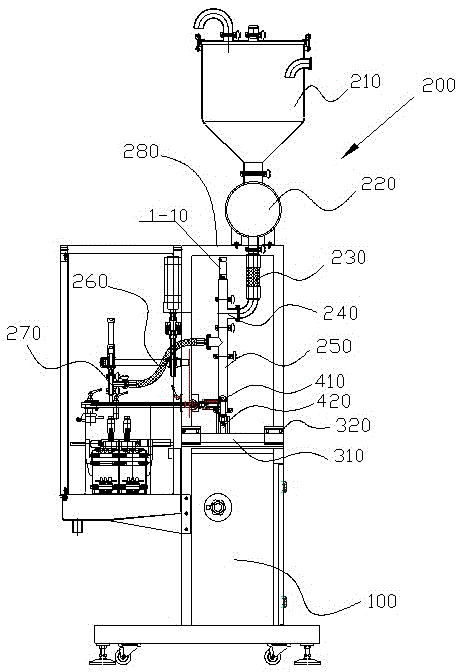

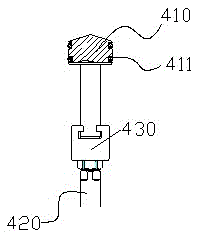

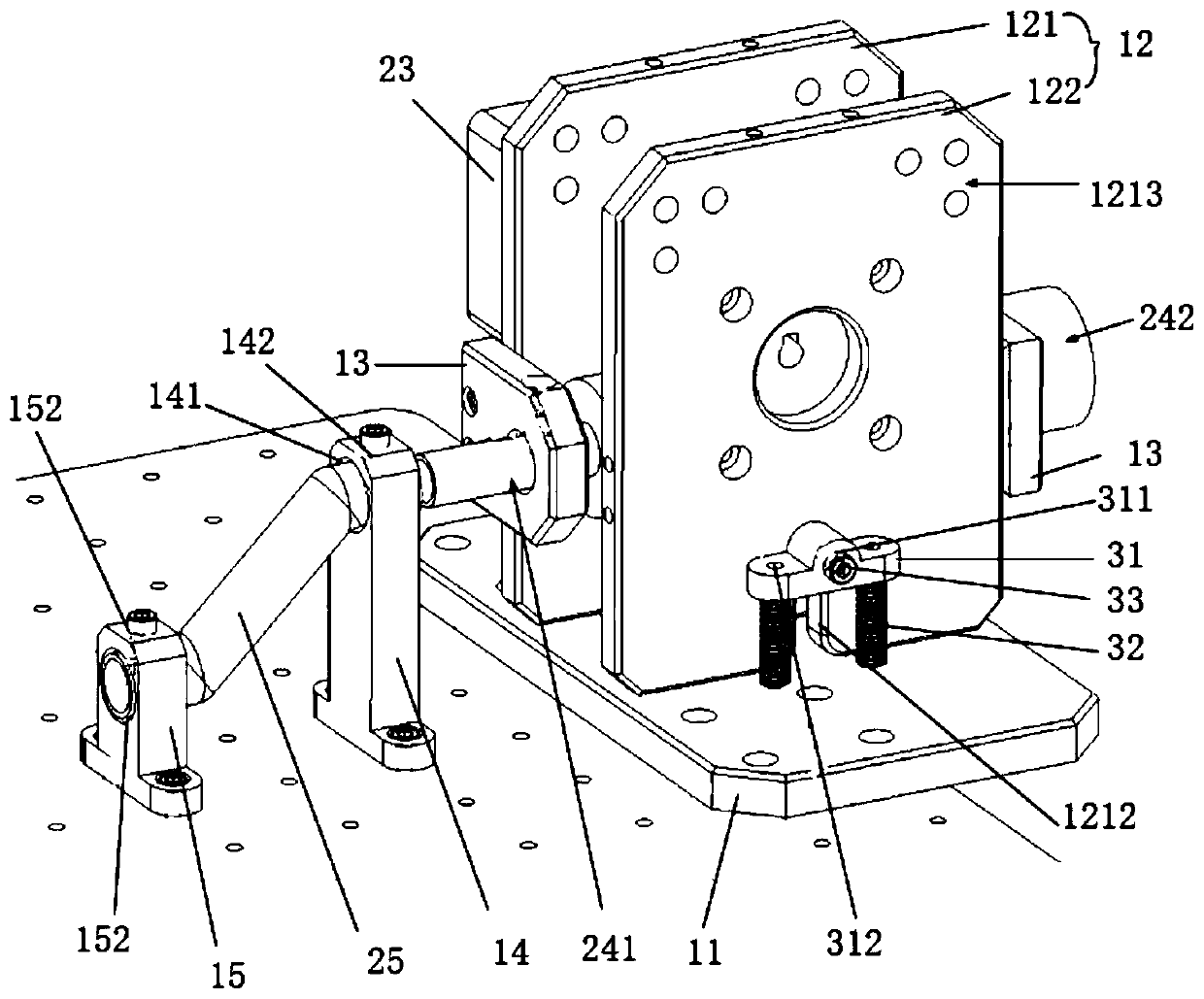

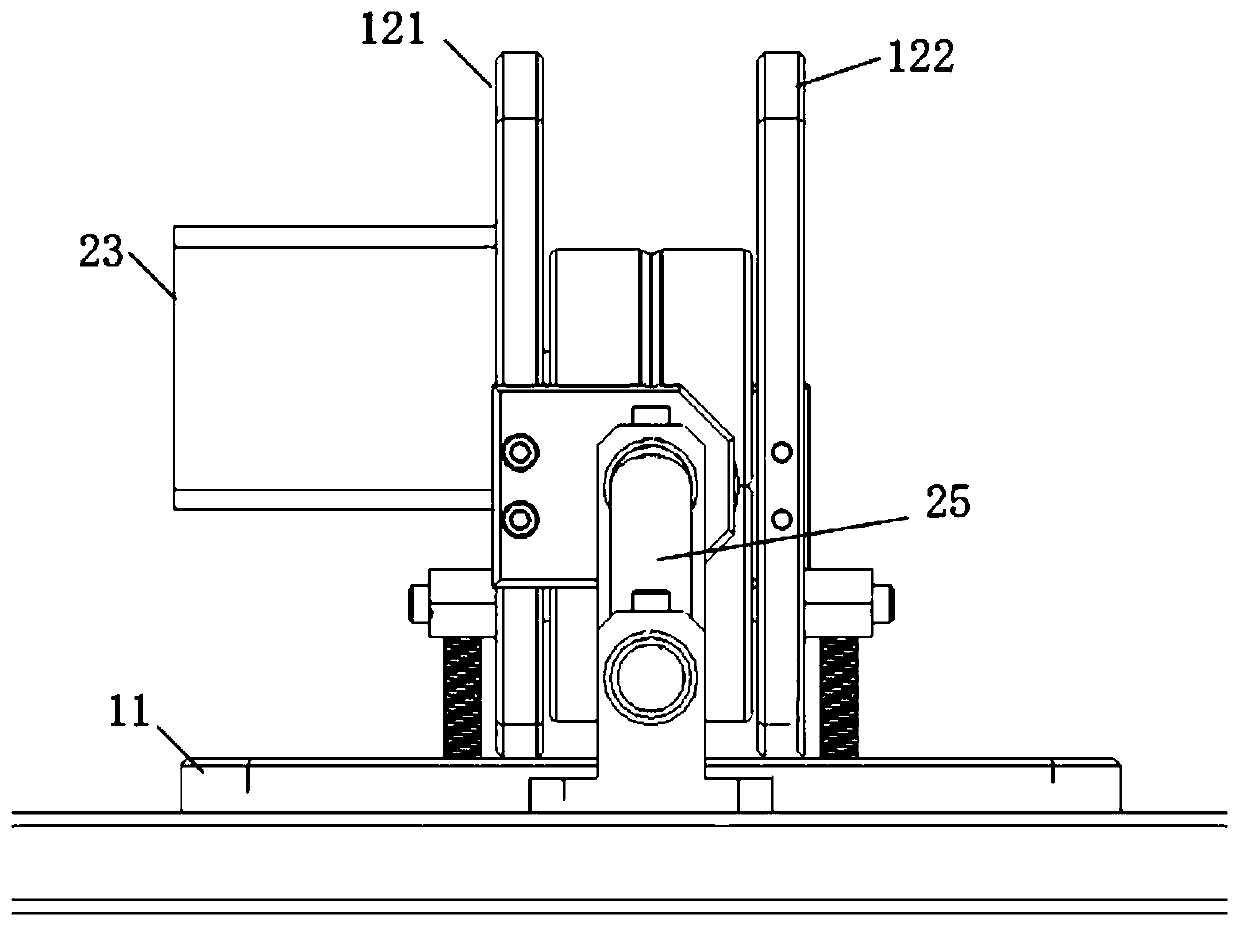

A filling equipment with quick line change function

The invention relates to a filling device with a quick wire-exchanging function. The filling device comprises a rack main body, a material flow system module, an inserting switching mechanism, a plugging-pulling mechanism and a wire-exchanging turnover vehicle, wherein the inserting switching mechanism comprises a first linear guide rail and a guide sleeve matched with the first linear guide rail; the plugging-pulling mechanism comprises a piston head and a positioning rod base fixedly connected with the rack main body; one end of the piston head is in quick plugging-pulling connection with the positioning rod base; the wire-exchanging turnover vehicle comprises a frame, a second linear guide rail, wheels and a positioning land foot; the size of the second linear guide rail is consistent with the size of the first linear guide rail; the wheels are arranged at the bottom of the frame; the second linear guide rail can linearly slide in the guide sleeve of the inserting switching mechanism. The filling device further comprises a positioning mechanism for connecting the wire-exchanging turnover vehicle with the rack main body. The filling device with the quick wire-exchanging function provided by the invention has convenience and quickness in wire exchanging and is compact and simple in structure, reasonable in design, simple in operation, time-saving, labor-saving and applicable to various filling devices. The filling device with the quick wire-exchanging function can ensure the wire-exchanging convenience and quickness and is fit for application and popularization.

Owner:GUANGZHOU BEAUTY STAR CO LTD

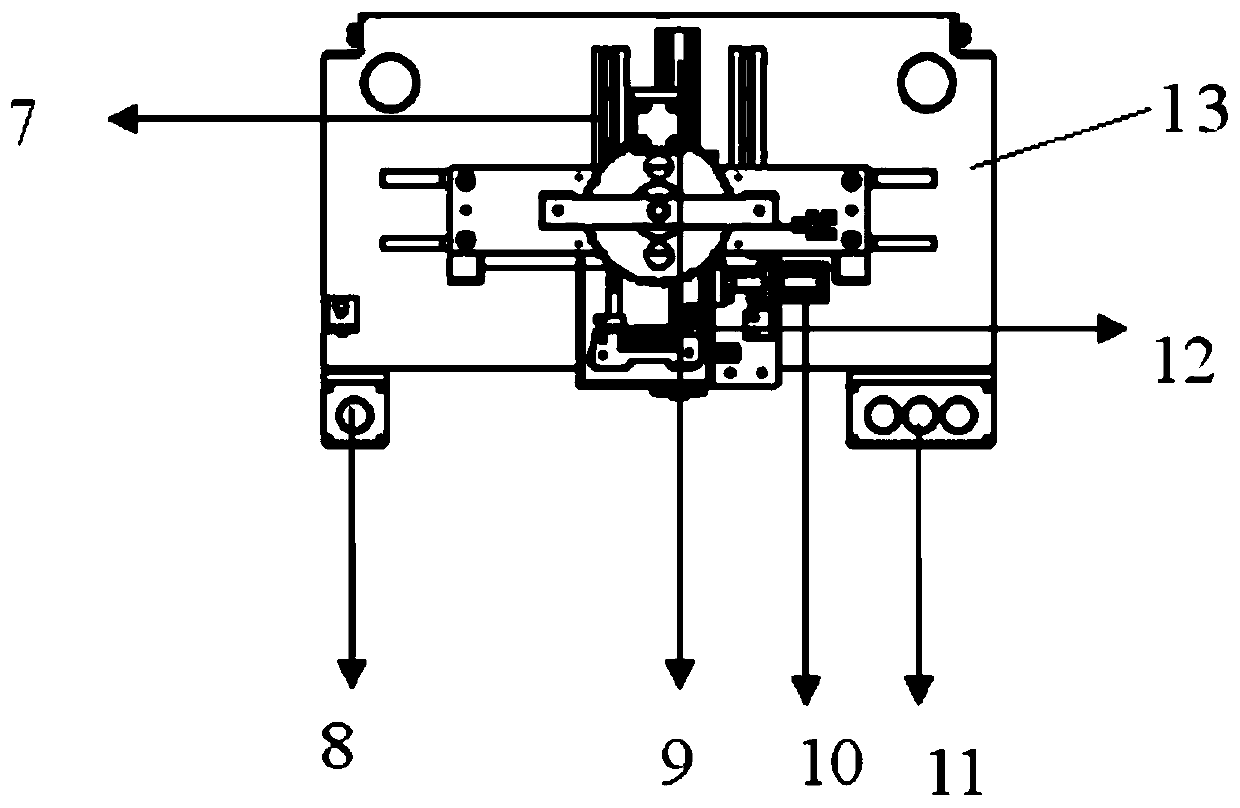

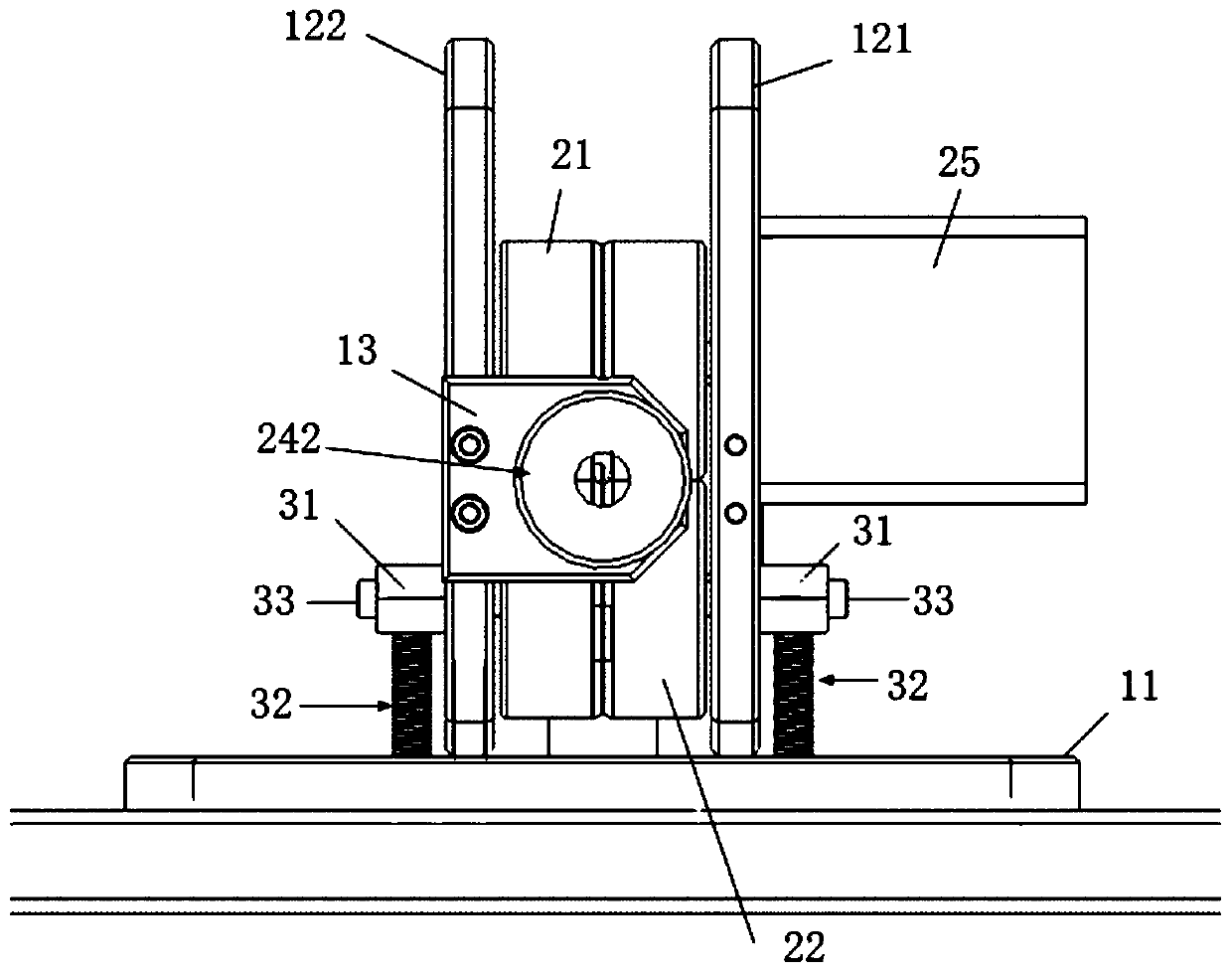

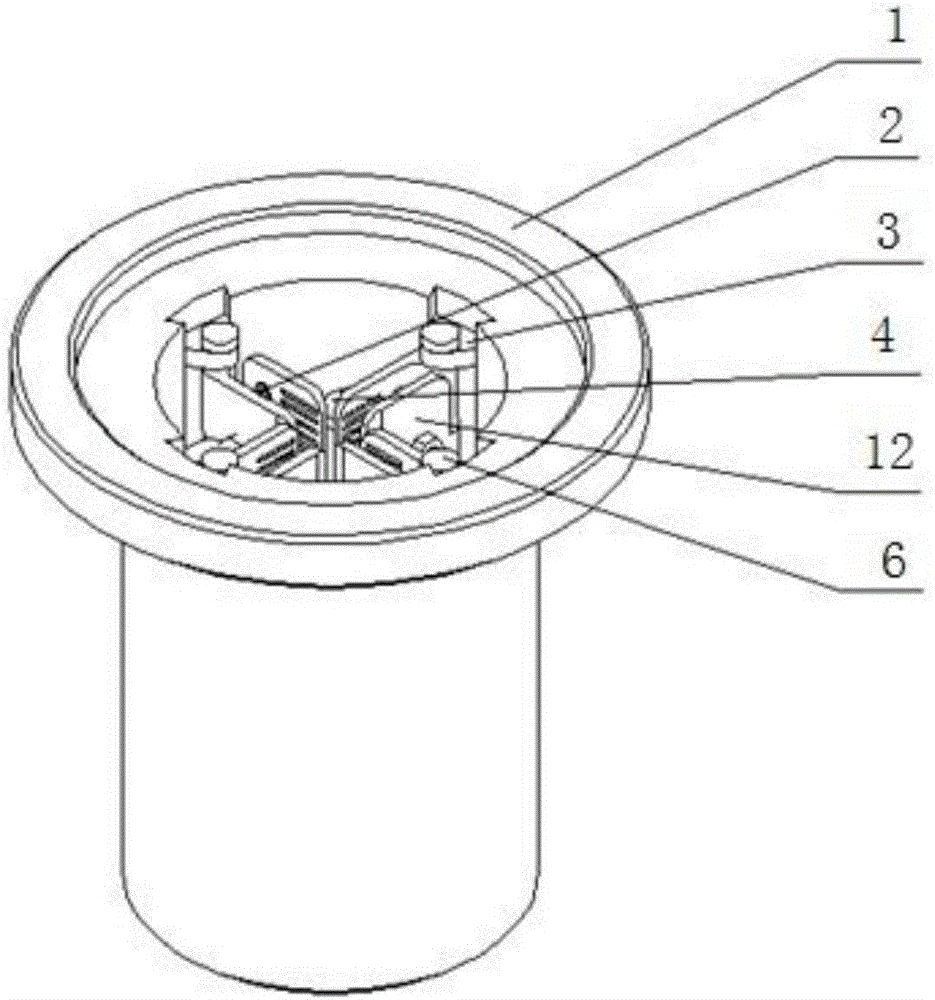

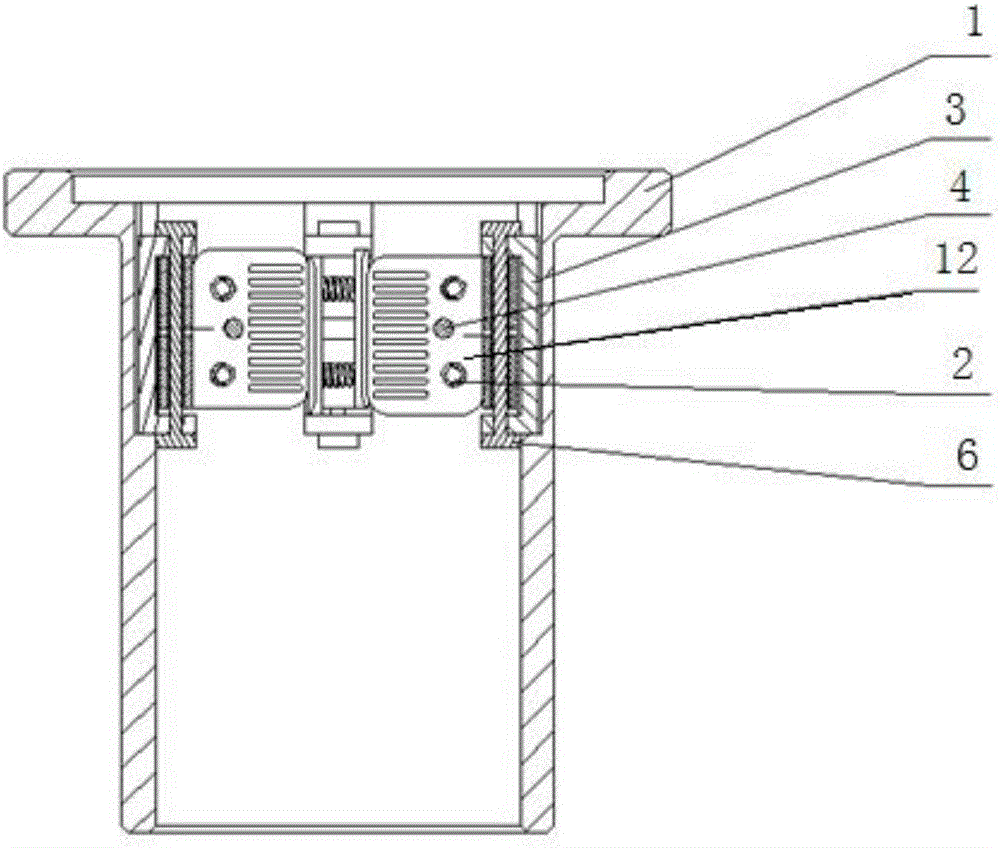

Wire conveying mechanism facilitating wire replacement

ActiveCN111115353ARealize moving up and downAchieve compactionFilament handlingDrive wheelStructural engineering

The invention relates to a wire conveying mechanism facilitating wire replacement, and belongs to the field of wire manufacturing. The wire conveying mechanism is used for solving the problems that anexisting wire feed mechanism cannot adapt to wires of different specification diameters, and wire replacement operation is complex. The wire conveying mechanism comprises a fixed supporting unit, a wire feed unit and an adjusting unit. The fixed supporting unit comprises a fixed base plate, a supporting plate and fixed blocks, the supporting plate is connected with the fixed base plate, and the fixed blocks are connected with the supporting plate. The wire feed unit comprises a driving wheel, a driven wheel and wire nozzle, and the wire nozzle is connected with the fixed blocks. The adjustingunit comprises adjusting supports and adjusting shafts, and the adjusting shafts penetrate through the adjusting supports to be connected with the driven wheel. According to the wire conveying mechanism, the adjusting support can move up and down by rotating adjusting nuts or through the elasticity of adjusting springs, then the trunking gap of the driving wheel and the driven wheel is adjusted,wires of different specification diameters are pressed and conveyed, and wire replacement operation is simple and convenient.

Owner:BEIJING MECHANICAL EQUIP INST

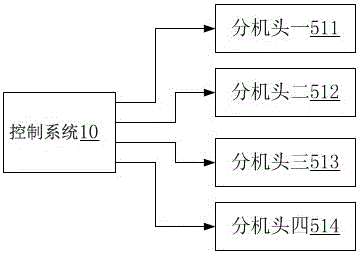

A double-sided intelligent embroidery machine

The invention discloses a double-sided intelligent embroidering machine comprising a rack and two embroidering units, wherein each embroidering unit comprises a workbench, an embroidering frame and an embroidering element; the embroidering element comprises a machine head and a thread stand; the two embroidering units are symmetrically arranged at two sides of a central line of a beam; one group of machine heads comprises a plurality of branch machine heads, and the signal outlet end of a control system is respectively connected with the signal output ends of the plurality of branch machine heads; the thread stand is movable, is provided with a supporting frame at the bottom and is arranged on the rack through the supporting frame, the movable thread stand is driven by a first driving device, and the first driving device comprises a slide block I arranged on the supporting frame as well as a guide rail I and a driving body I which are matched with the slide block I. The double-sided intelligent embroidering machine disclosed by the invention is simple in structure and capable of simultaneously operating two working units, intelligently selecting the machine heads, combining various colors and processing a large-amplitude and super-multiple color embroidery, so that the work efficiency is greatly increased.

Owner:杭州大云自动化科技有限公司

Control box body favorable for fixing of internal cable

The invention discloses a control box body favorable for fixing of an internal cable. The control box body favorable for the fixing of the internal cable comprises a casing, wherein a door plate is arranged on one side of the casing, and a U-shaped cable binding frame is fixed on the side wall in the casing connected with the door plate. The control box body favorable for the fixing of the internal cable has the advantage that the cable is drawn in through the cable binding frame to be connected onto the door plate, the cable is fixed in the door plate and a box, the control box body favorable for the fixing of the internal cable is simple in structure and strong in practicability, no extra part is needed, the cable stretches out and draws back freely, and the cable can be changed and replaced conveniently.

Owner:镇江船舶电器有限责任公司

single wheel drive

The single-wheel driving device is characterized in that the base of the motor and the base of the driven friction wheel are connected on the steel structure by using the base shaft and the bearing, and the spring pressing device connects the base of the motor and the base of the driven wheel, and the center of the base shaft and the drive shaft of the motor Not in a straight line, there is a double-sided friction plate on the trolley driven by the single-wheel drive device, the double-sided friction plate can be inserted into the gap, the thickness of the friction plate is slightly greater than the width of the gap, the friction surface of the friction plate is in contact with the driving wheel or from the The friction force between the moving wheels is adjusted by a spring compression device. Advantages: 1. The conveying line carries the workpiece mainly by the track, and the driving device only provides friction; 2. The operation station of the conveying line can be stopped without affecting the transportation of other stations; 3. The friction force is easy to adjust, and the friction wheel can be replaced and maintained Convenience; 4. There are two floors on the conveyor line, which is convenient for automatic production; 5. It is convenient to use the rotary table to change the line and occupy a small space.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

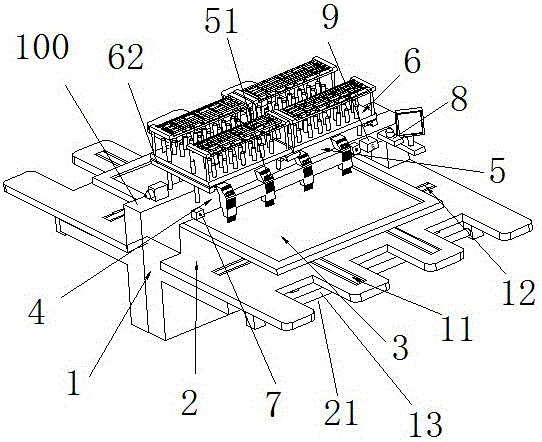

Testing device

PendingCN109581198AIncrease flexibilityEasy to change linesAutomated test systemsProduction lineFunctional testing

The invention provides a testing device. The testing device comprises a mounting bracket, one or more testing tools, a taking device and a control system, the testing tools are detachably mounted at one end of the mounting bracket; the taking device is movably mounted at the other end of the mounting bracket and moves relative to the mounting bracket; the control system is connected with the taking device and controls operation of the taking device; and the taking device receives an instruction of the control system to take to-be-tested target plates and place the to-be-tested target plates into the testing tools for functional testing, after testing is completed, the control system controls the taking device to take out the to-be-tested target plates which are tested in the testing toolsand place the to-be-tested target plates at the next station. The testing device is high in flexibility, the testing tools can be replaced, and a product line is convenient to replace.

Owner:合肥市航嘉电子技术有限公司

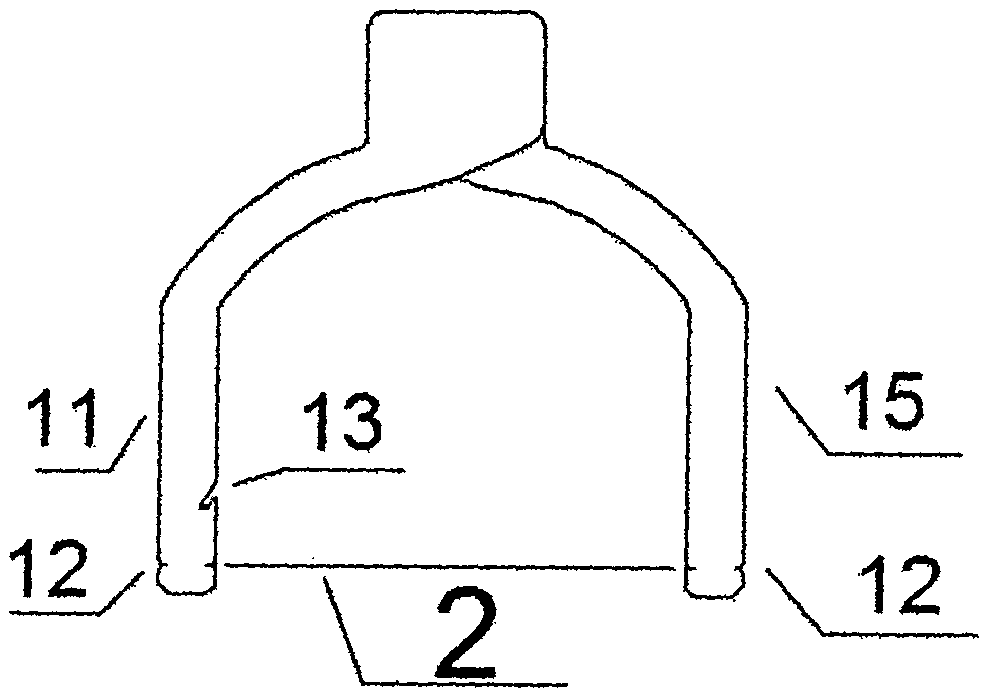

Sewing machine and its thread frame

The invention discloses a thread stand of a sewing machine. The thread stand comprises at least two pay-off devices and connecting devices, wherein the at least two pay-off devices are respectively used for accommodating wound upper threads (12) and accommodating wound bottom threads (13); the connecting devices are used for connecting the pay-off devices and the sewing machine. By utilizing the connecting devices, the pay-off devices are installed on a machine body of the sewing machine, that is, the thread stand is installed on the machine body of the sewing machine. The thread stand is simple in structure, and is convenient to install; the existing installation mode is changed, the thread stand is close to users; threads are relatively convenient to change and adjust, and the thread stand is convenient to operate by users, and is fixedly connected so as to prevent from being knocked off effectively, and further the working efficiency is improved. The invention also discloses the sewing machine comprising the thread stand.

Owner:JACK SEWING MASCH CO LTD

Chromatoghraph line antiforge method chromatograph line antiforge paper

InactiveCN1277022CFacilitate high-speed productionFacilitated releaseNon-fibrous pulp additionColor/spectral properties measurementsFine linePulp and paper industry

The invention provides a chromatoghraph line antiforge method and antiforge paper. Fine lines are buried in the paper and the colour permutatuin combination character of fine line is called as colour order character and as antiforge character. The antiforge paper of the same colour order character is only used for the same users or the same brand or other the same antiforge object. The chromatoghraph line antiforge paper is suitable for high-speed production and is hard to forge and easy to identifying.

Owner:吉林桑源科技有限公司

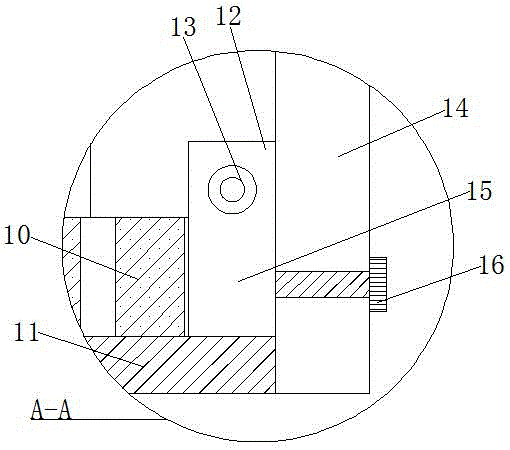

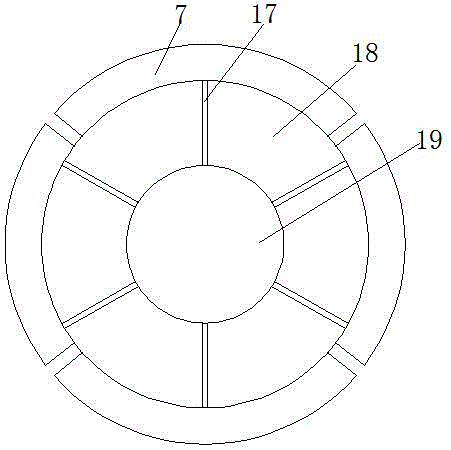

Humanity hole orifice cover

InactiveCN104897233AEffectively fixedEasy to take outMachines/enginesLevel indicatorsEngineeringWater level

The invention discloses a humanity hole orifice cover. The humanity hole orifice cover comprises a sleeve and a clamping mechanism which is arranged in the sleeve; the sleeve comprises a circular ring body and an annular platform which is formed at the upper end of the circular ring body; the outer diameter of the annular platform is larger than the hole diameter of a humanity hole; the inner side of the circular ring body is provided with more than one sliding groove; a sliding block is arranged in every sliding groove; every sliding block comprises a sliding block body and connecting blocks with holes, wherein the connecting blocks extend from two ends of every sliding block body respectively; the clamping mechanism comprises a spring, a fastening bolt, a nut and two hinge pieces with through holes; the two hinge pieces with the through holes are connected together through a pin shaft due to every sliding block so as to enable the two hinge pieces to form a hinge; the fastening bolt penetrates the holes formed in the two hinge pieces respectively to enable the hinge to form an opening; the spring is horizontally arranged in the opening. According to the humanity hole orifice cover, the opening is a horizontal plane and accordingly the measurement of a water level meter is not affected and the clamping mechanism is used for clamping a fixed measuring line so as to reduce the impact of the measuring line slipping-down or measuring line break points on the monitoring accuracy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

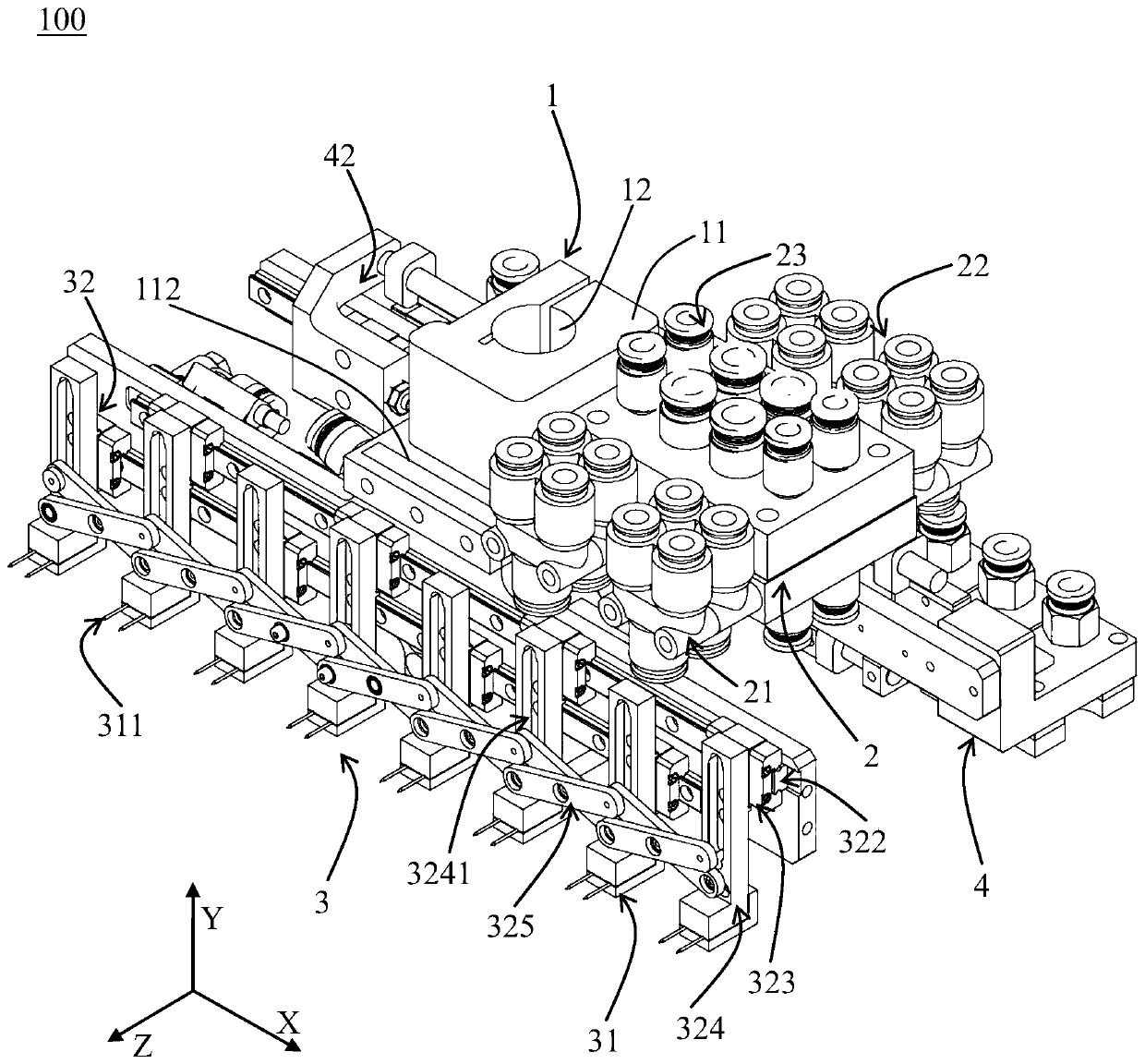

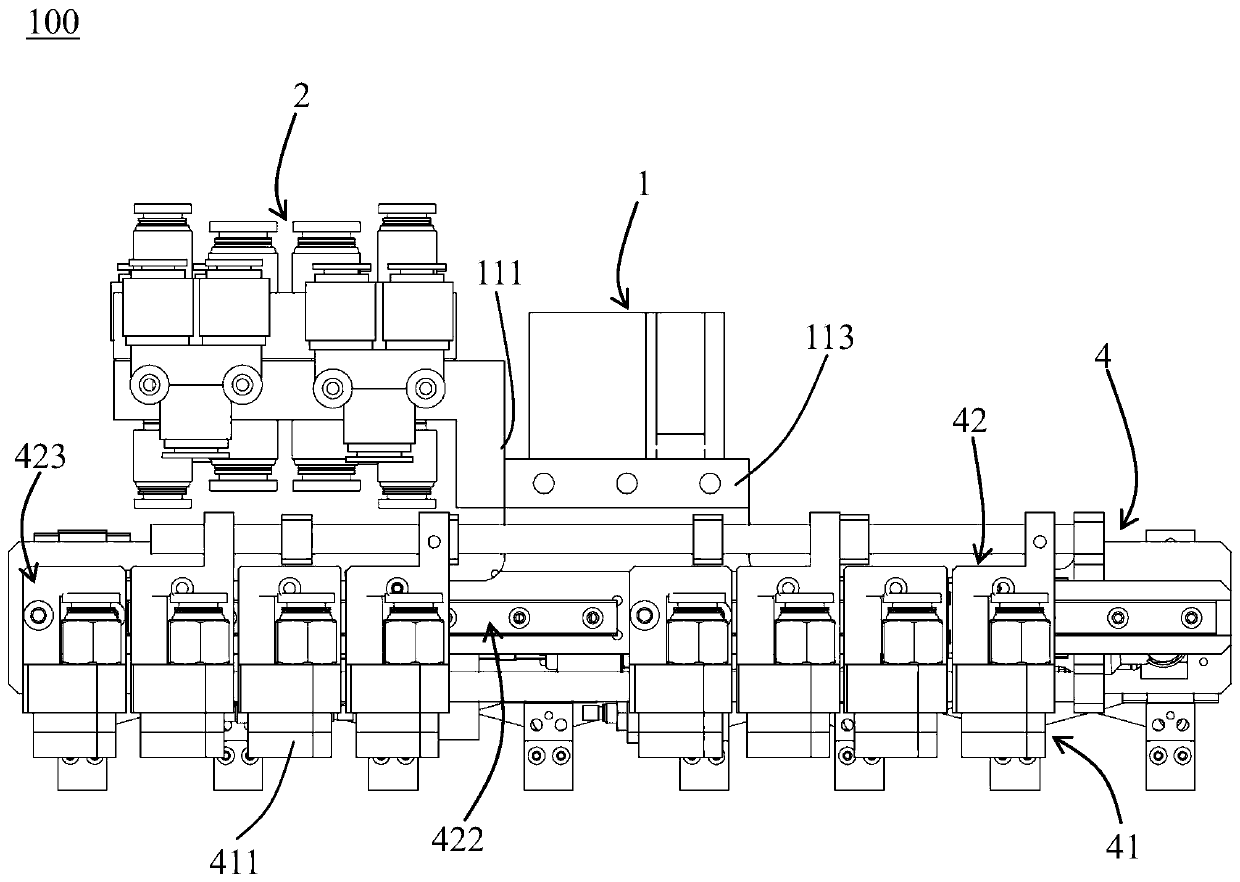

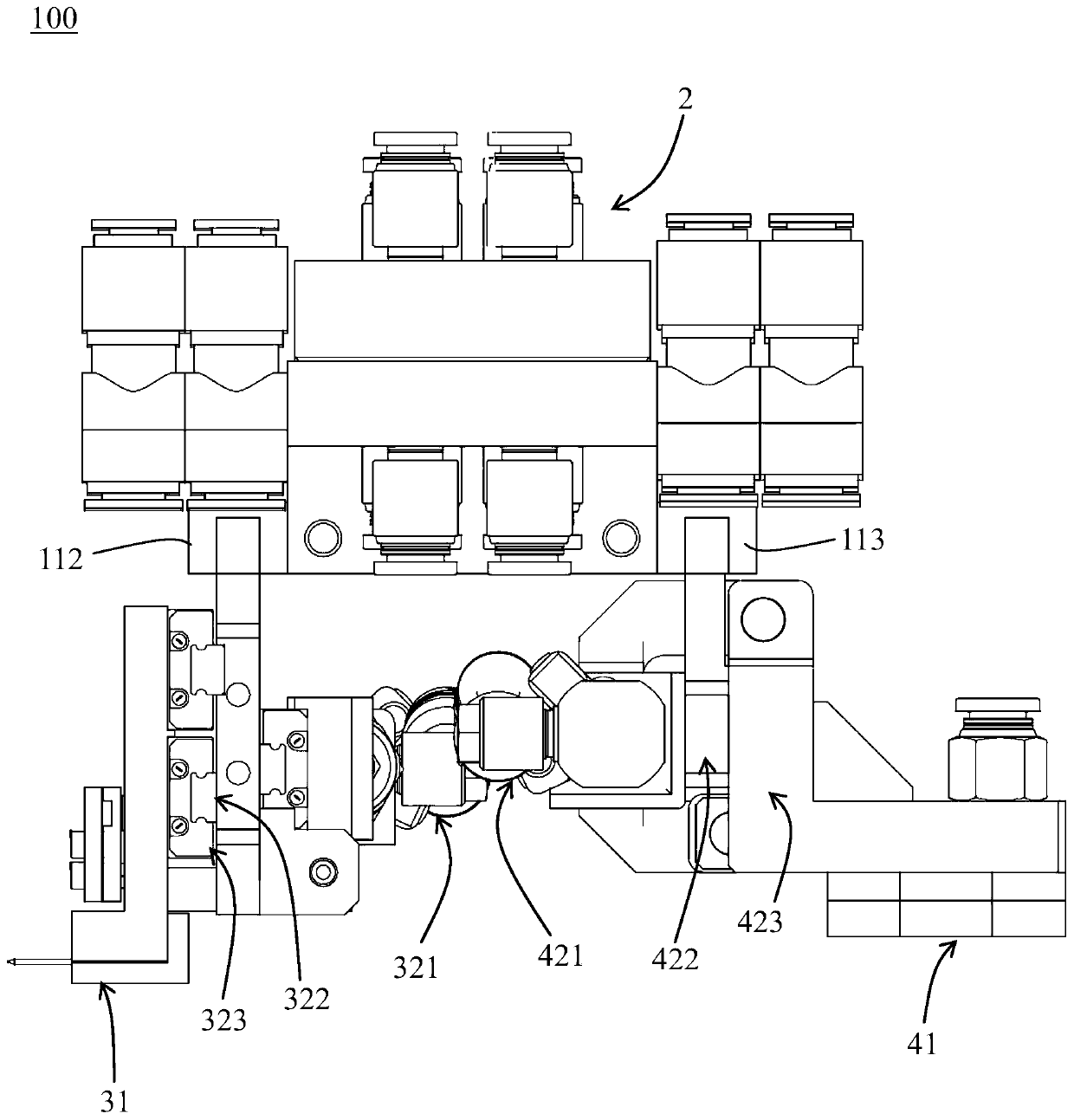

Multi-head quick attachment fixture and multi-board quick attachment method

ActiveCN108724754BIncrease the level of automationReduce manual labor intensityRobot handEngineering

The invention provides a multi-head quick attachment fixture and a quick attachment method on a multi-yoke-plate. The attachment fixture comprises a mechanical arm holding clamp bracket, an air pipe multi-stage quick interface module fixedly connected to the mechanical arm holding clamp bracket, a block material separating module and a sheet material separating module. The mechanical arm holding clamp bracket includes a boss body capable of moving along with a mechanical arm and a clamping hole for fixedly connecting the mechanical arm. The block material separating module and the sheet material separating module are correspondingly mounted on the two sides of the boss body, the block material separating module includes a plurality of first take-up portions for taking up and placing blockmaterials to be attached and a first driving portion for driving the first take-up portions, and the sheet material separating module includes a plurality of second take-up portions for taking up andplacing sheet material to be attached and a second driving portion for driving the second take-up portions. The first driving portion and the second driving portion are connected to the air pipe multi-stage quick interface module through pluggable air pipes. The multi-head quick attachment fixture can improve the automation level, the line change is quick in the processing of the yoke plate, and therefore the production efficiency is improved.

Owner:QISDA SUZHOU

A 3D mesh sewing machine

ActiveCN104532486BNovel structureEasy to useSewing-machine elementsMattress sewingEngineeringMaterial supply

Owner:SANMING HUAFANG TEXTILE TECH DEV

Leakage protector with high safety performance

ActiveCN106449290AAvoid safety hazardsAvoid LeakageProtective switch terminals/connectionsCopperMechanical engineering

The invention discloses a leakage protector with high safety performance. The leakage protector comprises a device body, the top and the bottom of the device body are respectively provided with a clamping plate and an insulation base, the top portion and the bottom portion of the clamping plate are respectively provided with wiring holes and protection sleeves, the bottom portions of the protection sleeves are fixedly connected with wire bodies, the outer surfaces of the wire bodies are sleeved by insulation sleeves, one end of the bottom portion of each wire body penetrates a pre-tightening portion, the inner cavities of the pre-tightening portions are provided with through holes, the bottom portions of the wire bodies are fixedly connected with wiring copper members, the bottom portions of the wiring copper members are fixedly connected with the insulation base, the inner cavity of the insulation base is provided with a pressure column, the two sides of the insulation base are each fixedly connected with a connection plate, and one side of each connection plate is fixedly connected with a corresponding support plate. According to the invention, through arrangement of the protection sleeves, the insulation sleeves and the insulation base for cooperative application, the wire bodies can be protected, a waterproof effect can also be exhibited, the wire bodies are prevented from electric leakage caused by a safety hidden risk of the device body due to water, and the safety hidden risk can be effectively prevented.

Owner:湖南奇力新电子科技有限公司

Manhole orifice cover

InactiveCN104897233BEffectively fixedEasy to take outMachines/enginesLevel indicatorsEngineeringPore diameter

The invention discloses an orifice cover for a manhole, which includes a sleeve and a clamping mechanism inside the sleeve; the sleeve includes a ring body and an annular platform placed on the upper end of the ring body, and the outer diameter of the ring platform is larger than that of the human body. The aperture of the hole; the inner side of the annular body is provided with more than one chute, the chute is provided with a slider, and the slider includes a slider body and a connecting block with holes extending from the two ends of the slider body; clamping The mechanism includes springs, fastening bolts, nuts and two hinges with through holes. The slider connects the two hinges with through holes through the pin shaft, so that the two hinges form a hinge; After the fastening bolt passes through the holes on the two hinge sheets, the hinge forms an opening, and the spring is horizontally arranged in the opening. The opening of the invention is a horizontal surface, which will not affect the measurement of the water level gauge; the invention is provided with a clamping mechanism for clamping and fixing the measuring line, so as to reduce the influence of the sliding of the measuring line and the inflection point of the measuring line on the monitoring accuracy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

POE switch with waterproof function

PendingCN111865833ASolve technical problems that do not have waterproof functionEnsure water tightnessData switching networksSelection arrangementsStructural engineeringMechanical engineering

Owner:深圳市艺通能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com