A filling equipment with quick line change function

A kind of filling equipment and fast technology, applied in the direction of packaging, etc., can solve the problems of occupying the working time of the filling equipment, the filling process cannot be carried out, and the complete set of equipment cannot be operated, so as to save time, be suitable for popularization and use, and facilitate line change quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

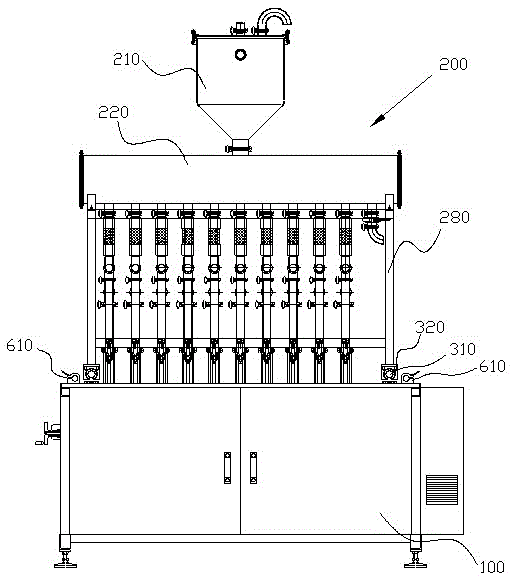

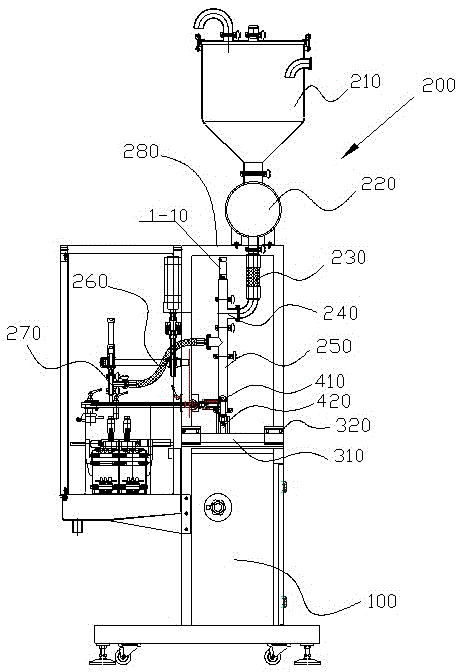

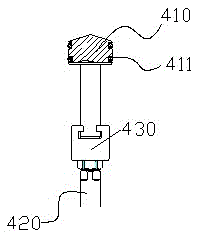

[0028] like Figure 1-9 As shown, the structure schematic diagram of the filling equipment with the function of quick line change in the preferred embodiment of the present invention, the filling equipment of the present invention can replace the equipment parts that are in contact with the materials during the production process, and replace them with different materials to continue Filling is suitable for the production of different materials; and the replaced parts can be moved to the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com