Tool for pressing metal insert into electronic transmission range selection (ETRS) electronic gear support

A technology of electronic gear shifting and inserts, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of convenient installation, meeting assembly requirements, and convenient line change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

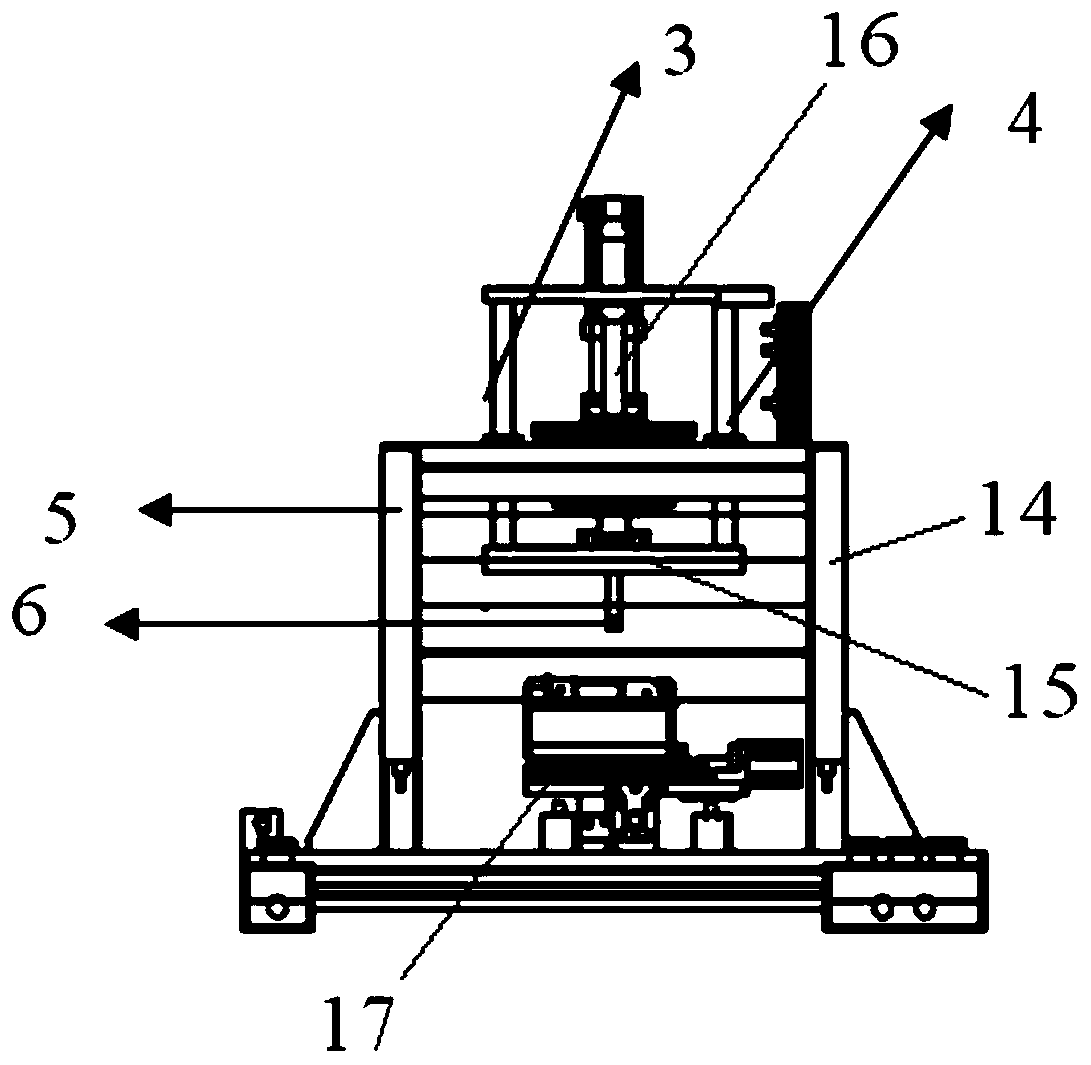

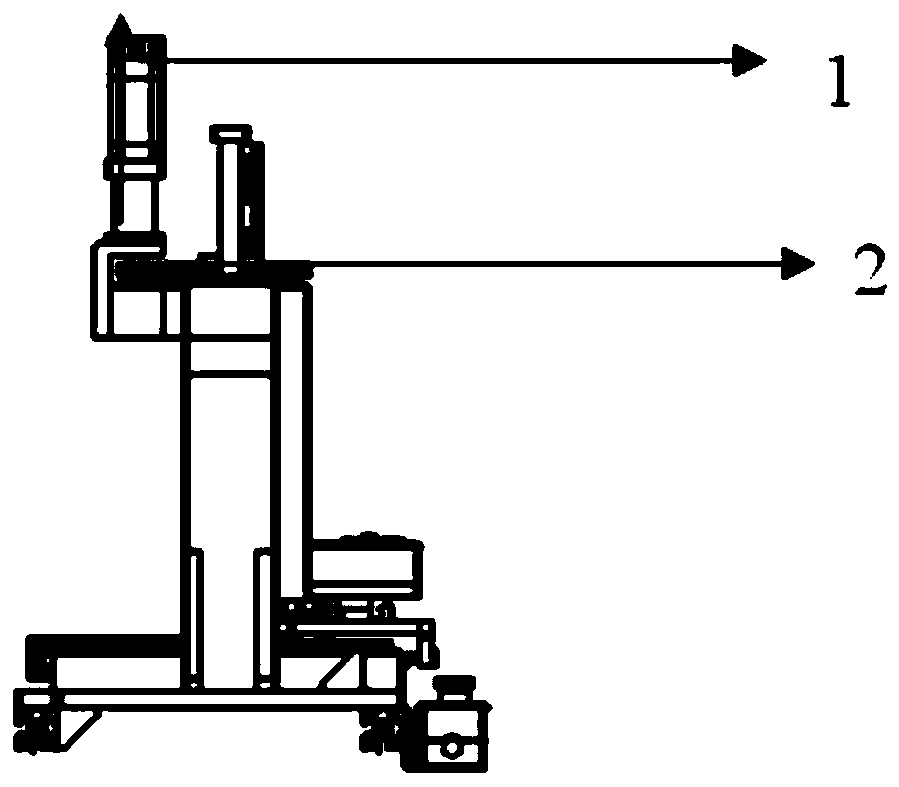

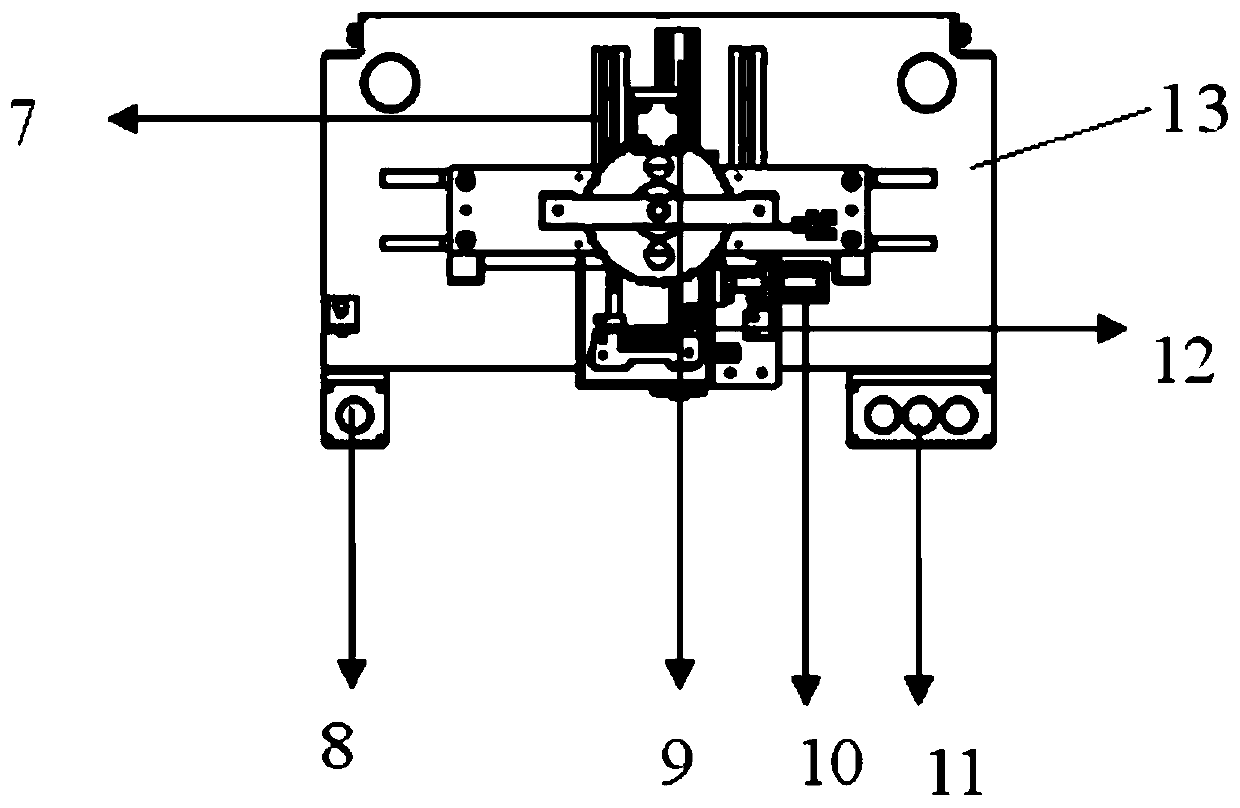

[0014] The present invention is a kind of tooling that metal inserts are pressed into the ETRS electronic gear bracket, such as Figure 1-Figure 4 As shown, it comprises a base 13, the base 13 is provided with a door-shaped frame 14, and the top of the frame 14 is provided with a square mobile frame 15 that can move up and down. 3 runs through the top of the frame 14, the top of the frame 14 is also provided with a gear 2, the teeth on the circumference of the gear 2 are engaged with the rotating end of the motor 1, and the center of the gear 2 is provided with a threaded hole, and the threaded hole is provided with a matching and The screw mandrel 16 that runs through the top of the frame 14, the upper and lower ends of the screw mandrel 16 are fixedly connected with the upper and lower ends of the moving frame 15, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com