Heavy frictional combined conveying line

A conveyor line and friction-type technology, which is applied in the field of heavy-duty friction-type combined conveyor lines, can solve problems such as large differences, heavy weight, and failure to meet requirements, and achieve the effects of easy adjustment, convenient maintenance, and convenient automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

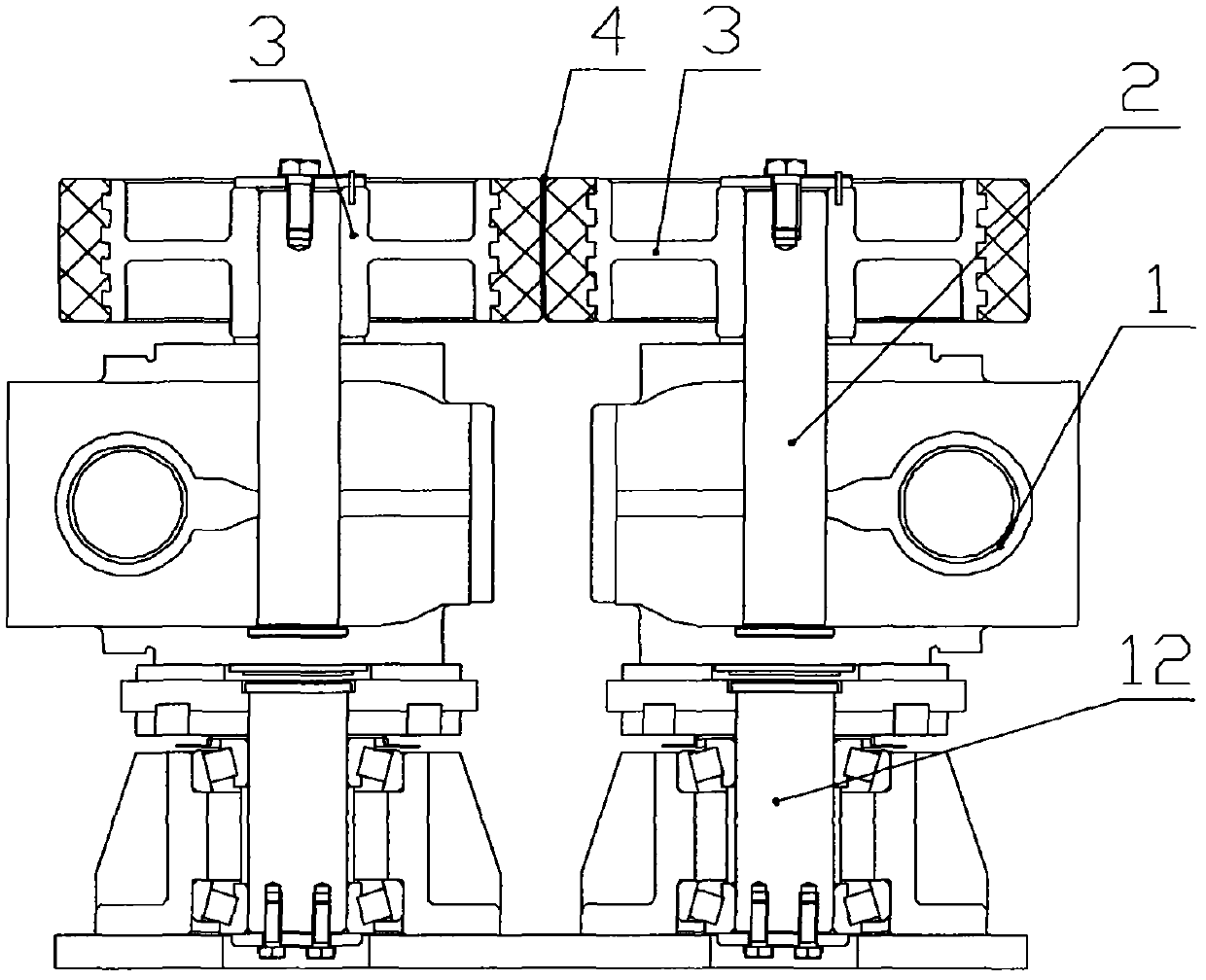

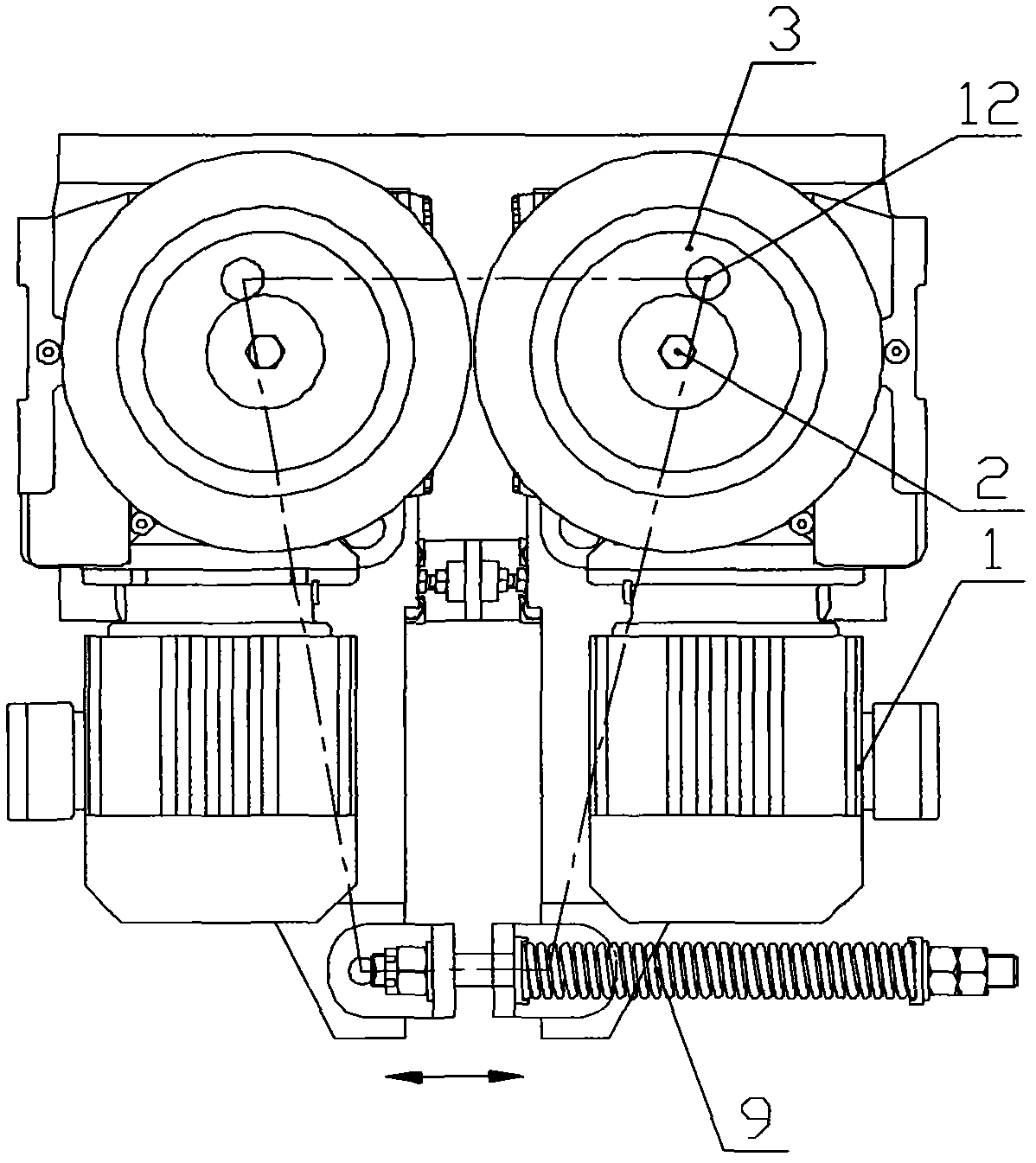

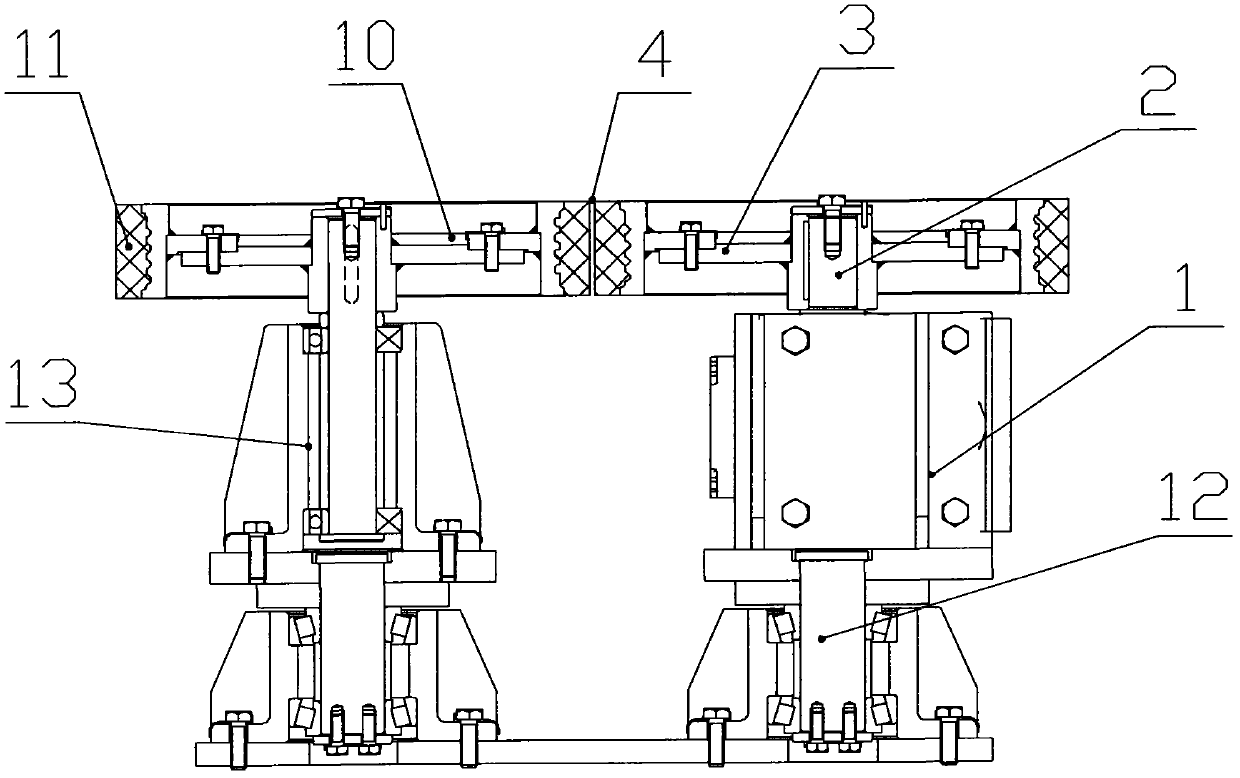

[0015] The heavy-duty friction combined conveying line is characterized in that it includes a rail 8, a two-wheel drive device 18 and / or a single-wheel drive device 19, and a trolley 5; the two-wheel drive device includes a motor 1, a drive wheel 3, a friction plate 11, The spring pressing device 9, the drive friction wheel 3 is installed on the drive shaft 2 of the motor 1, the drive friction wheel is externally poured or installed with a friction object 11, there is a gap 4 between the friction plates 11 on the two drive wheels, and the direction of rotation is opposite The base of the motor 1 is connected to the steel structure using the base shaft 12 and the bearing respectively, and the spring compression device 9 connects the bases of the two motors, and the center of the base shaft 12 and the motor drive shaft 2 is not on a straight line; the single-wheel drive device, Including motor 1, driving friction wheel 3, driven friction wheel 10, spring pressing device 9, drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com