Patents

Literature

53results about How to "Delivery does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

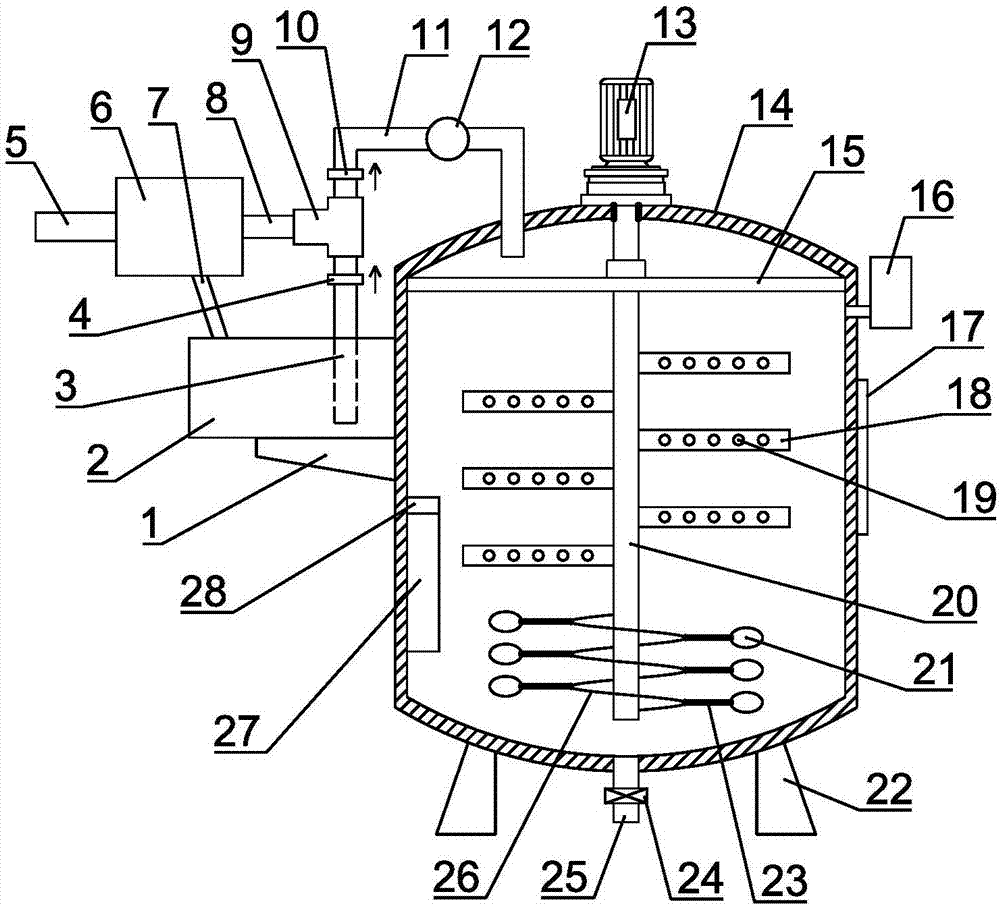

Conveniently filling sour milk beverage homogenizer

InactiveCN107261910APrevent outflowEasy to transportTransportation and packagingRotary stirring mixersSpiral bladeBiochemical engineering

The invention discloses a conveniently filling sour milk beverage homogenizer which comprises a tank body, wherein a stirring shaft is arranged on the middle part on the inner side of the tank body; a plurality of first stirring blades are arranged on a stirring shaft on the lower side of a porous plate on the inner side of the tank body; a spiral blade is arranged on the stirring shaft on the lower side of the first stirring blades; a second stirring blade is arranged on the outer side of the spiral blade through a stirring rod; a liquid pumping drum is arranged above a liquid storage tank on the left side of the tank body; a connecting pipe is connected with the right end of the liquid pumping drum; a tee joint is arranged at the other end of the connecting pipe; a liquid inlet pipe is connected with a lower branch of the tee joint; the lower end of the liquid inlet pipe extends to the lower part on the inner side of the liquid storage tank; a liquid draining pipe is connected with an upper branch of the tee joint; the other end of the liquid draining pipe is connected with the top of the tank body. The conveniently filling sour milk beverage homogenizer is more reasonably designed, has an excellent homogenizing effect, has no influence on the material addition while pressurizing and has higher popularization and utilization values.

Owner:惠安县长信机电科技有限公司

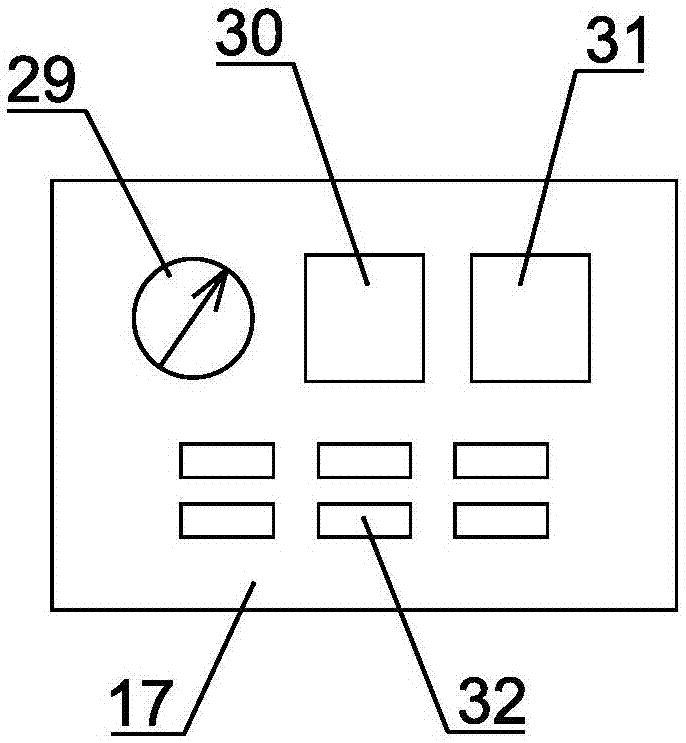

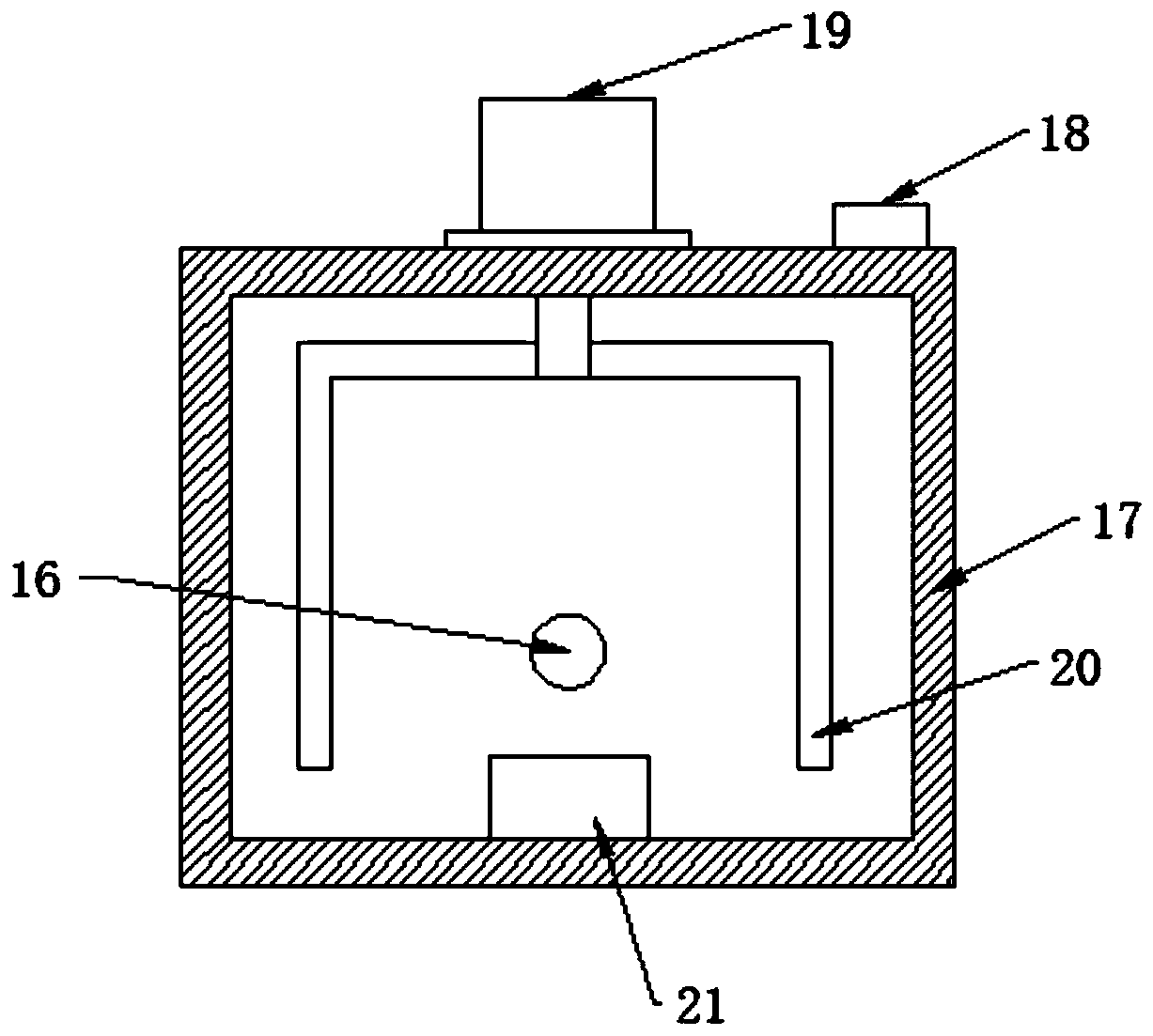

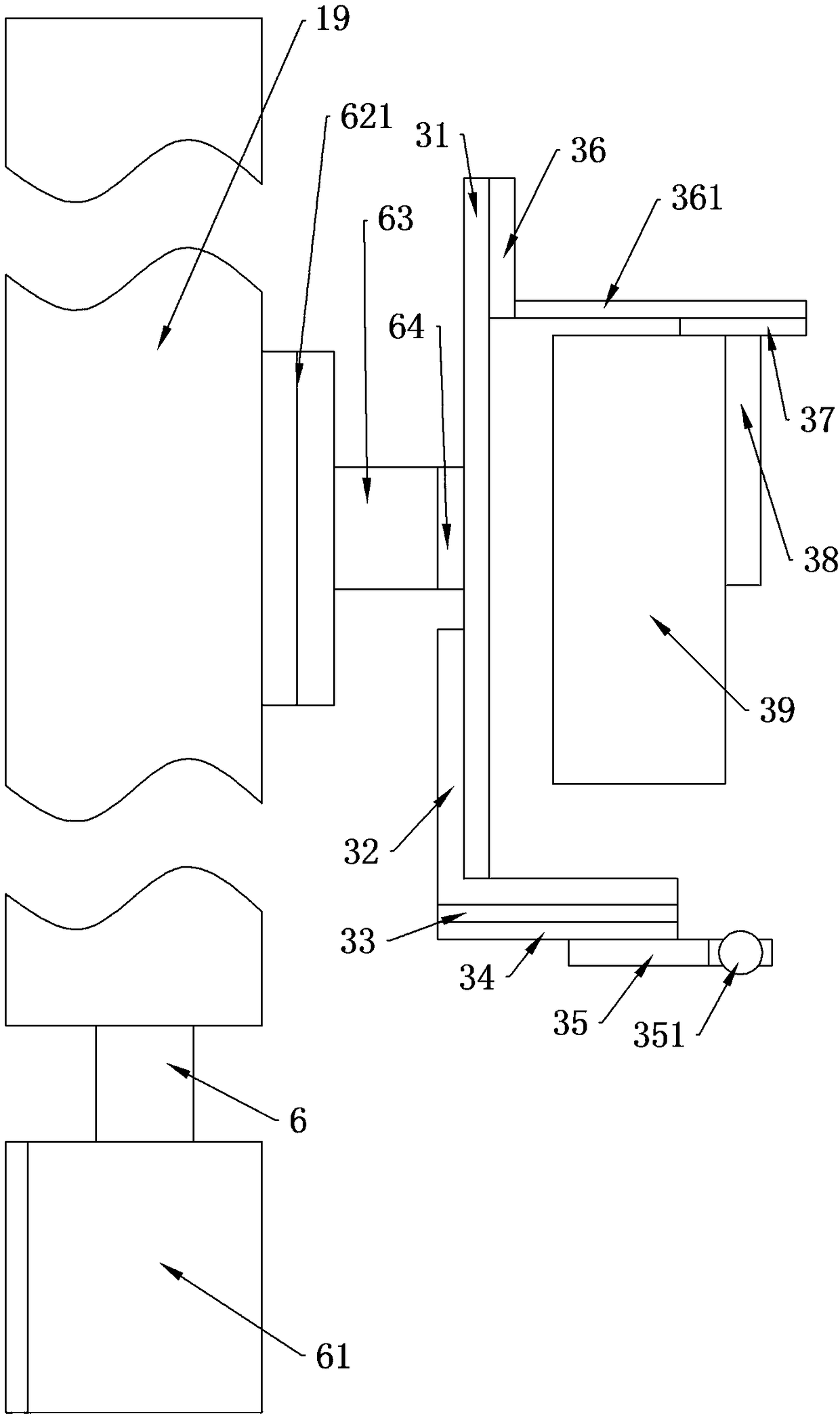

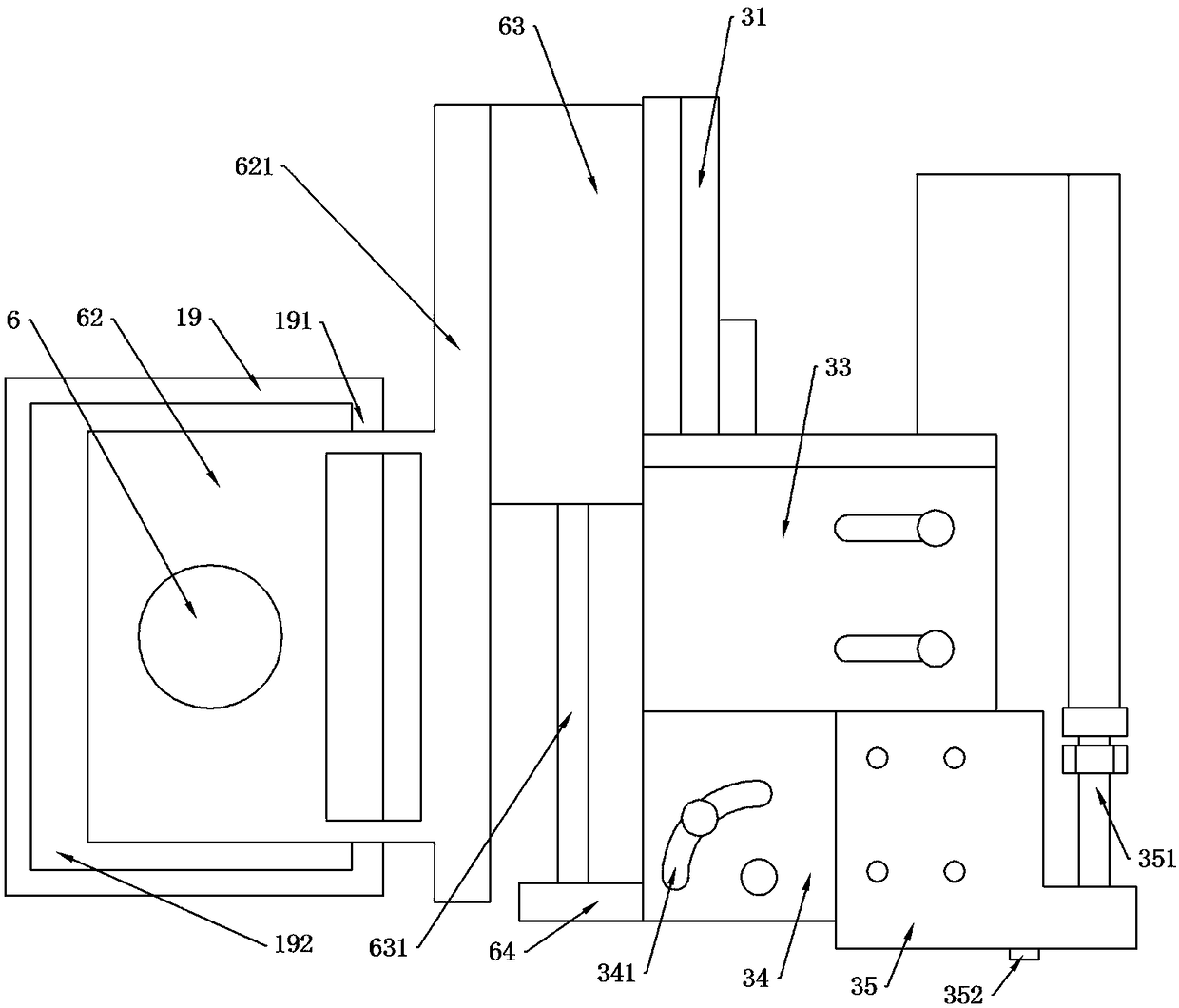

Dustbin buried underground

The invention discloses a dustbin buried underground. The dustbin comprises an outer box which is buried underground, a hydraulic pushing rod driven by a hydraulic pump is arranged in the outer box, an inner box is connected to the hydraulic pushing rod, a dustbin body is arranged in the inner box in a sliding connection mode, two dustbin bases which are movably connected are arranged at the bottom of the dustbin body, a cover plate is further connected to the inner box, the opening of the outer box can be covered with the cover plate in a sealed mode, a filter is further arranged on one side of the outer box, and a gas exhauster is arranged at the bottom of the outer box and connected with the filter through a gas exhausting pipe. The dustbin is simple in structure and convenient to use, the dustbin body can be sealed underground so that the phenomenon that harmful gas emitted by rubbish is spread into air can be reduced, the filter can be utilized for purifying and filtering the volatile harmful gas, and therefore harm of the harmful gas is further reduced.

Owner:HUNAN TANGQIAO TECH DEV

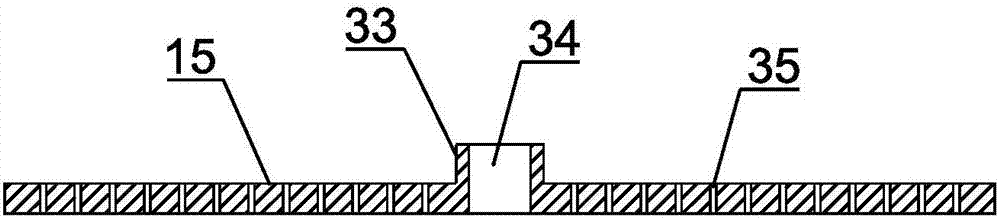

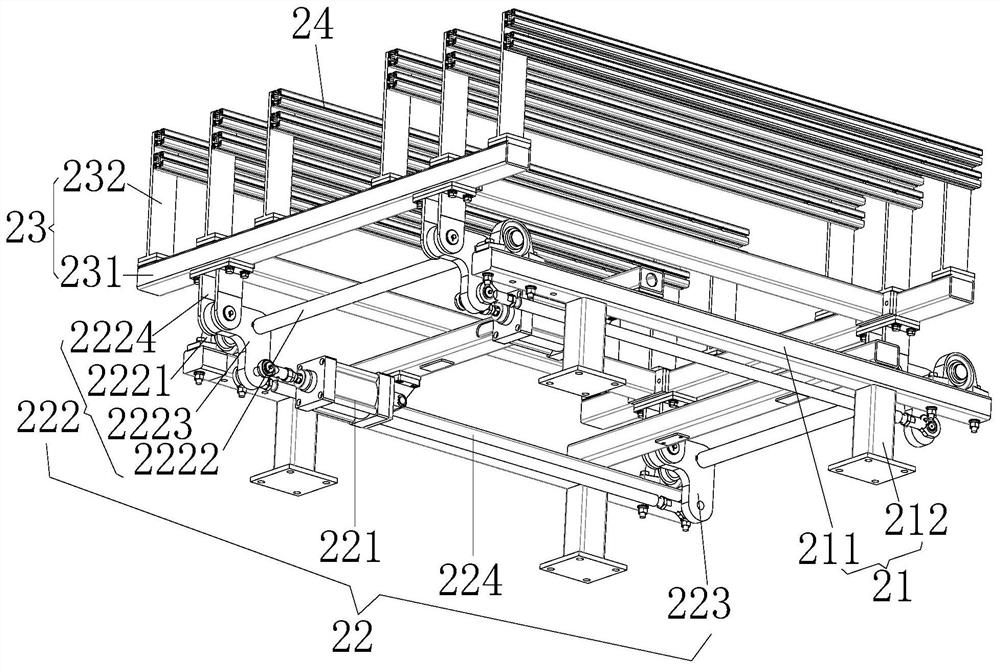

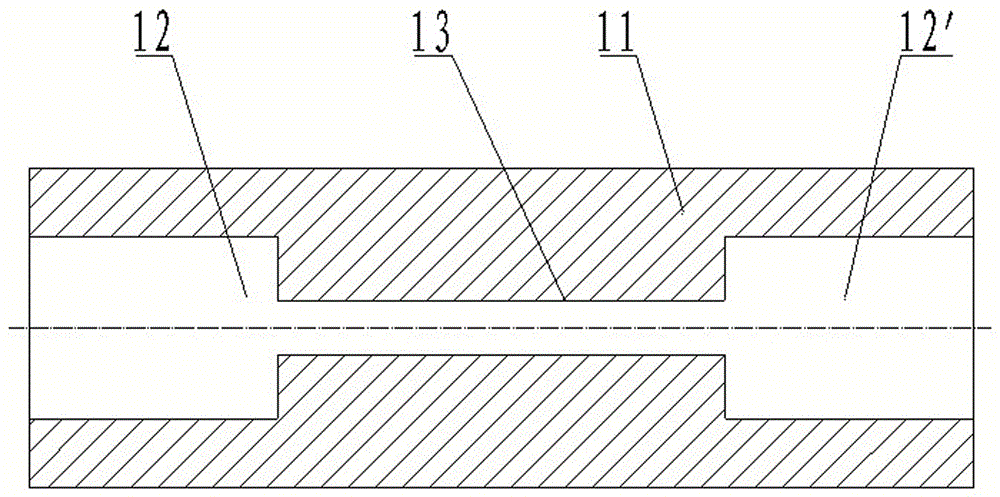

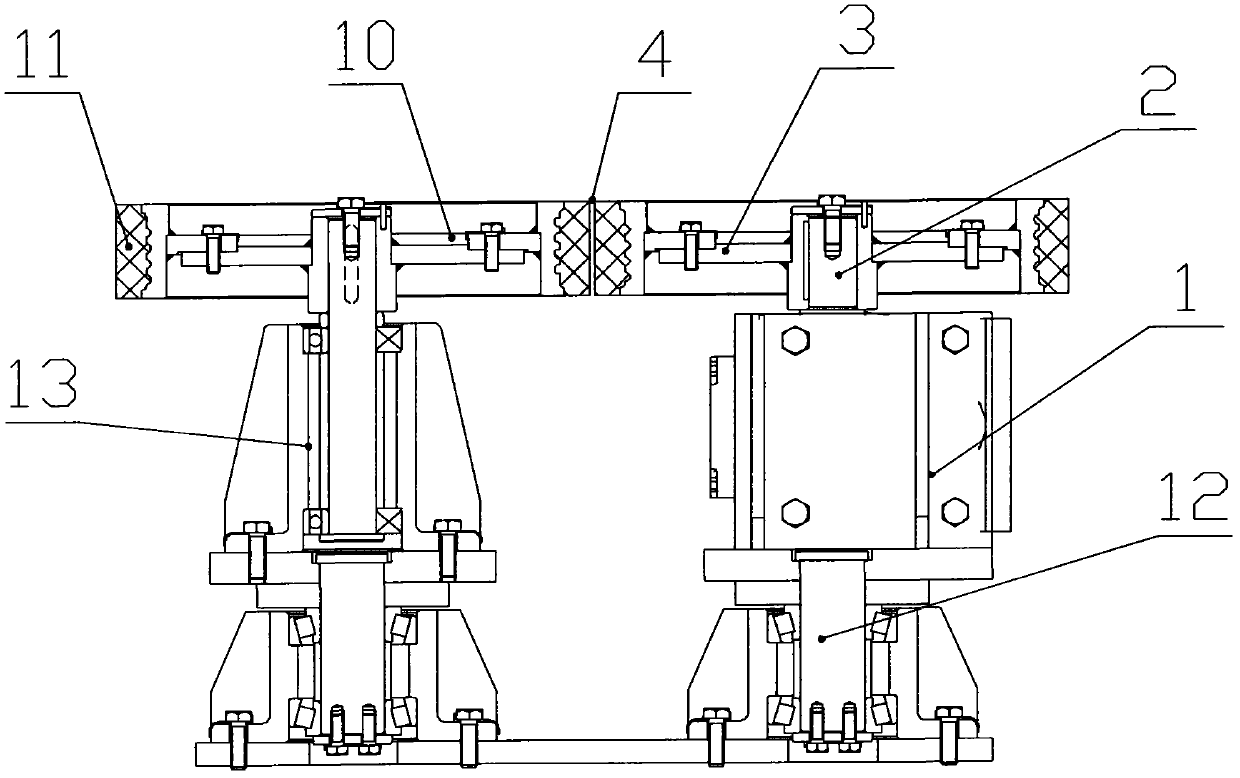

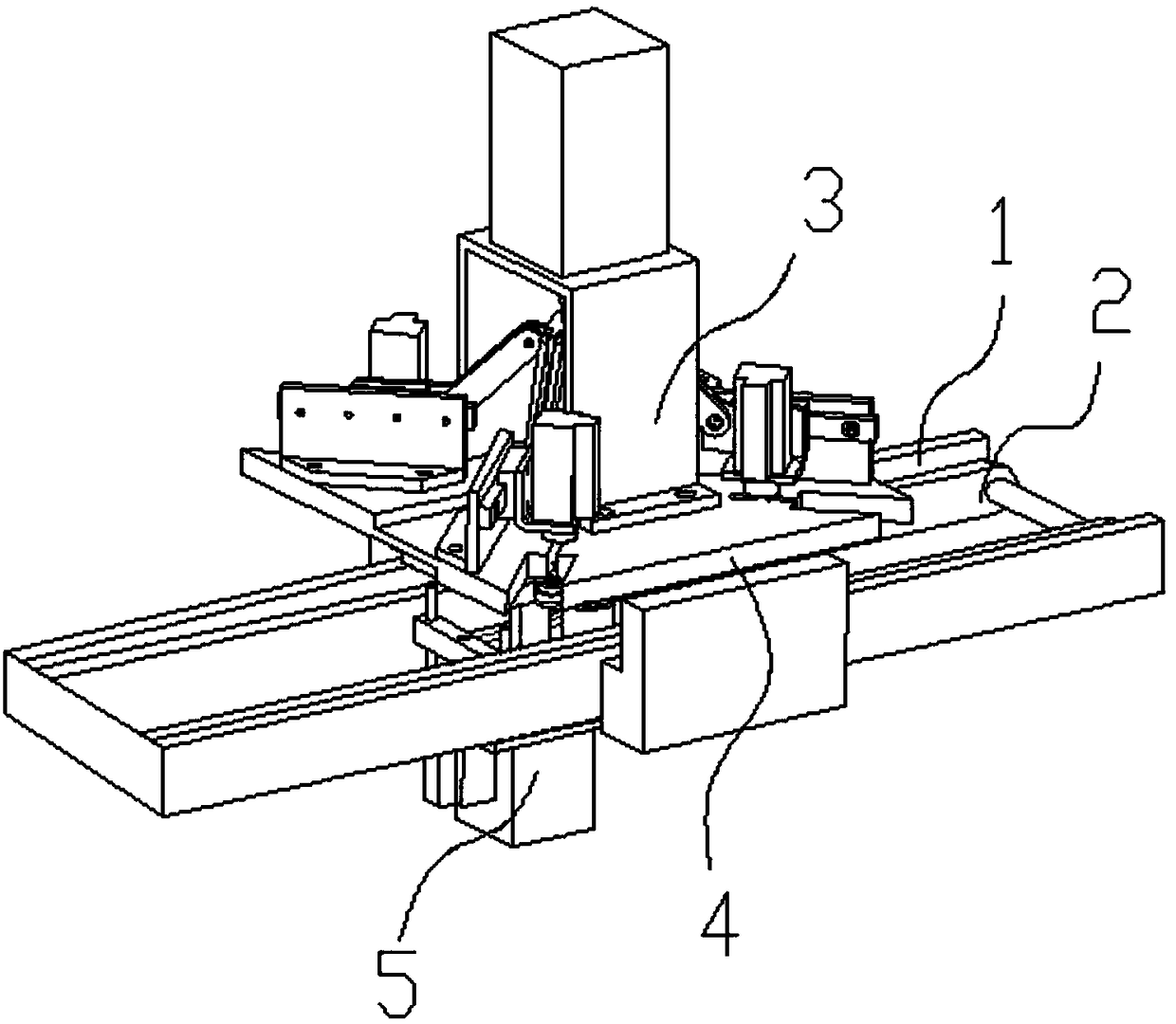

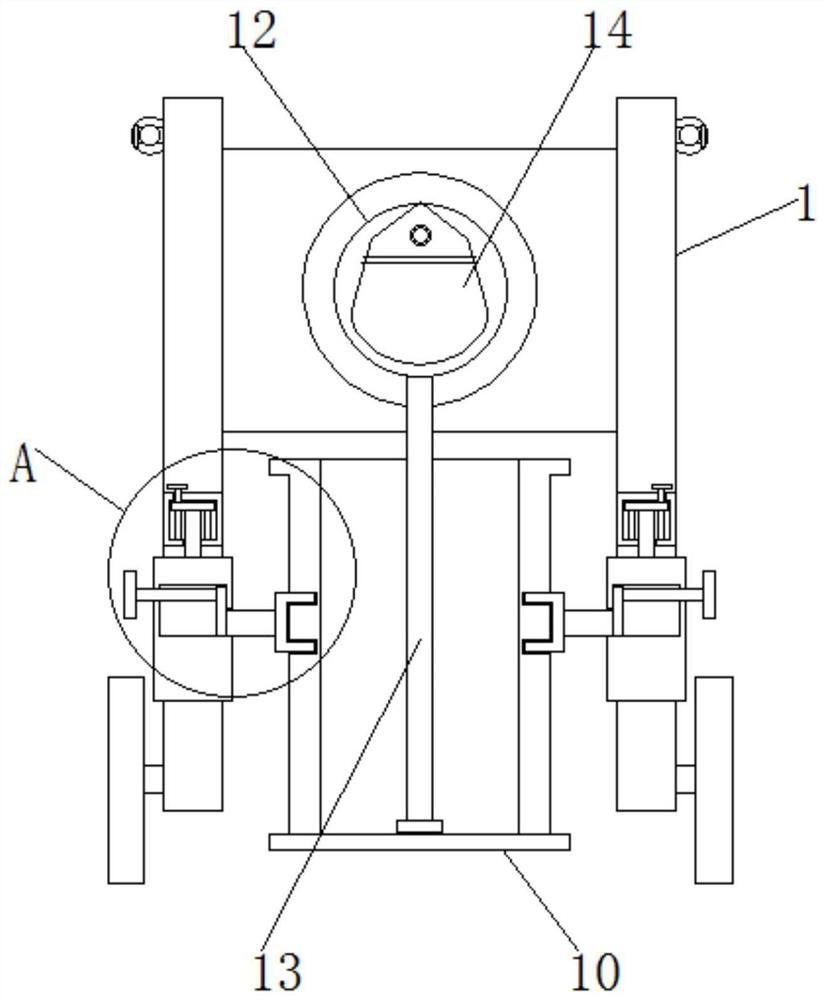

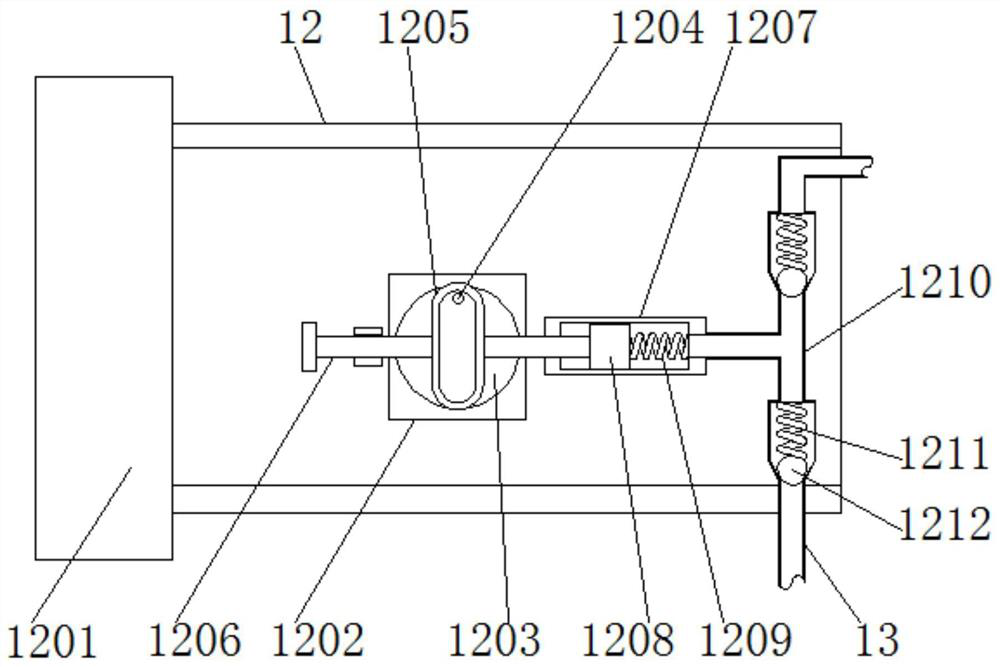

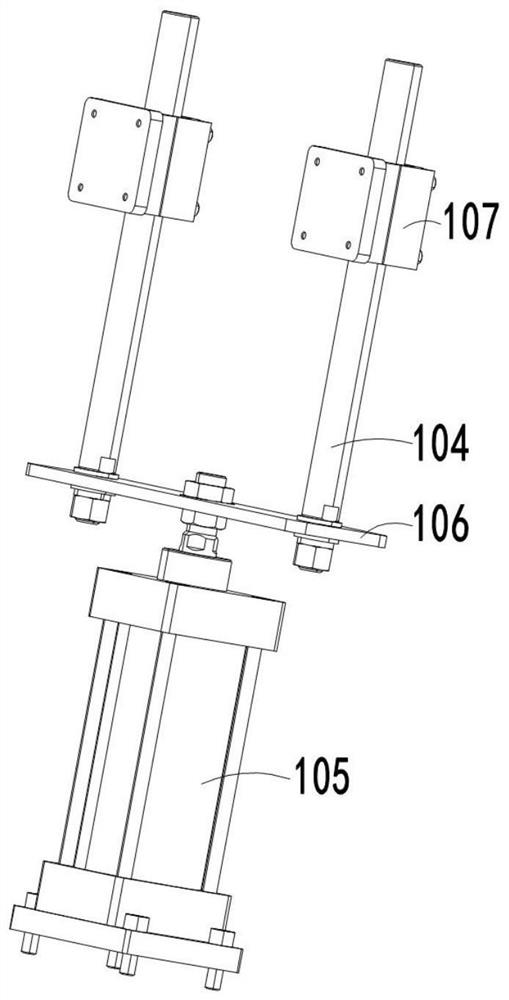

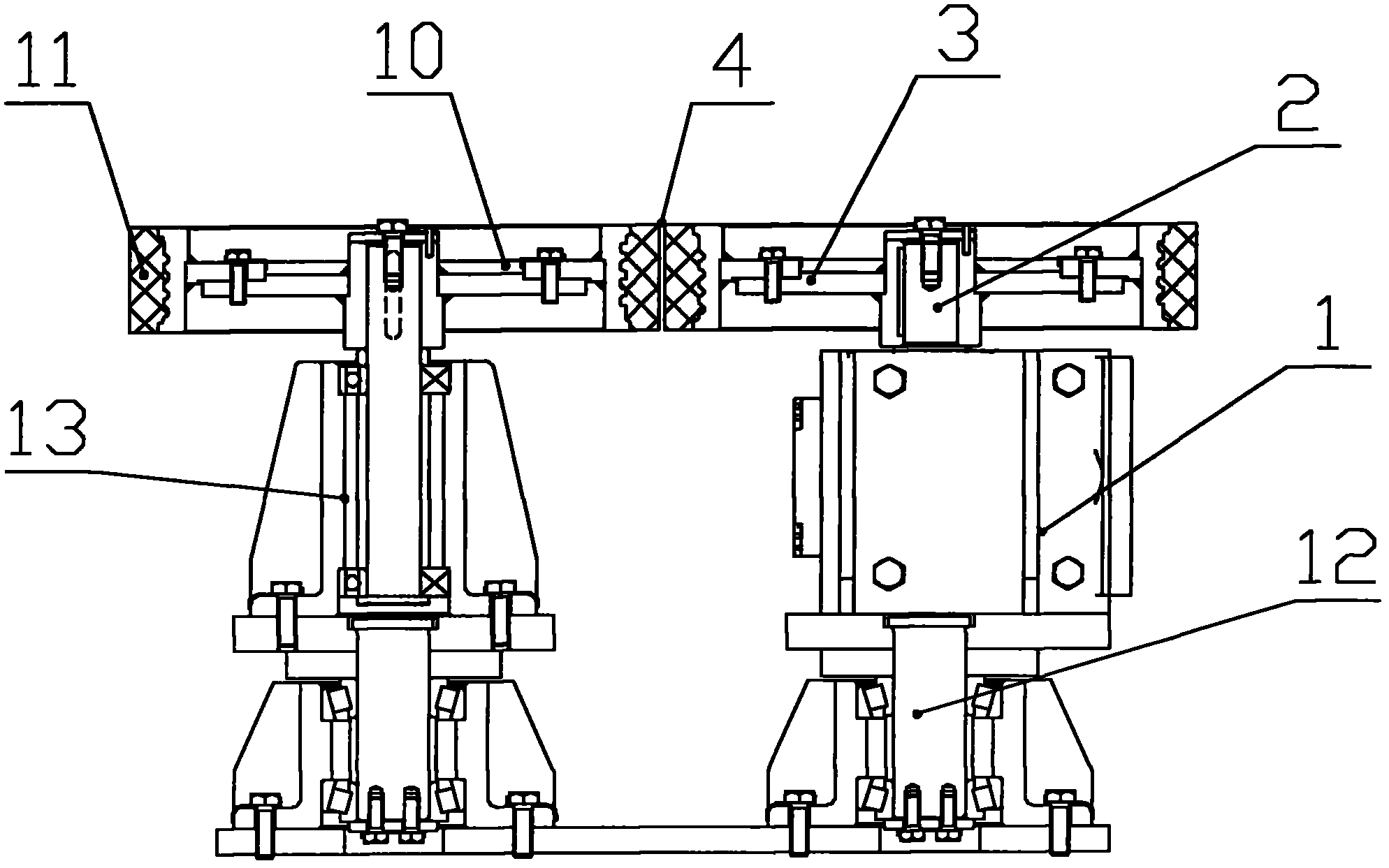

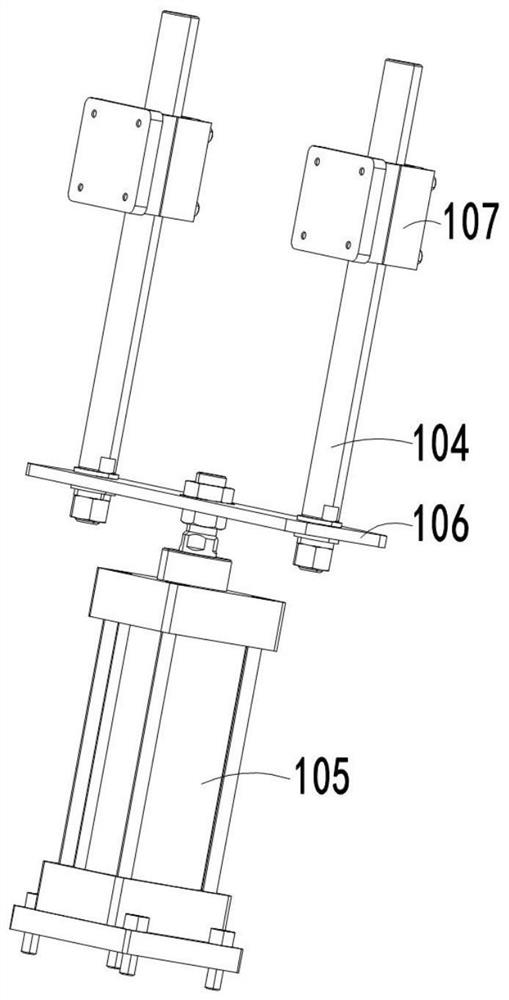

Glass deep processing jacking mechanism

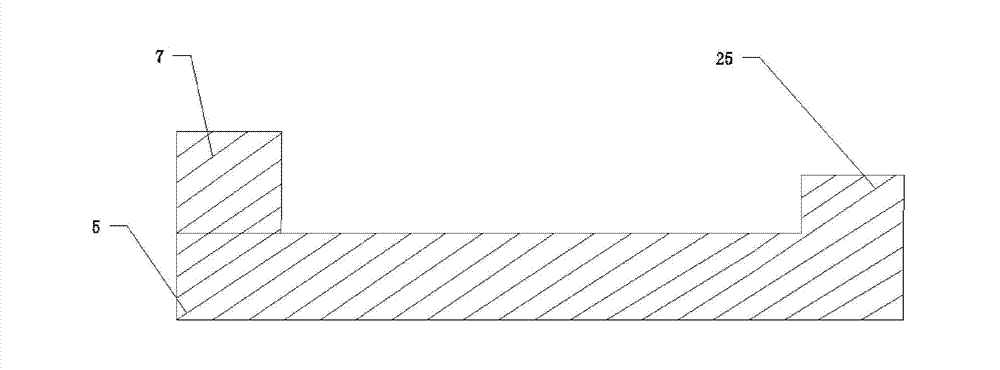

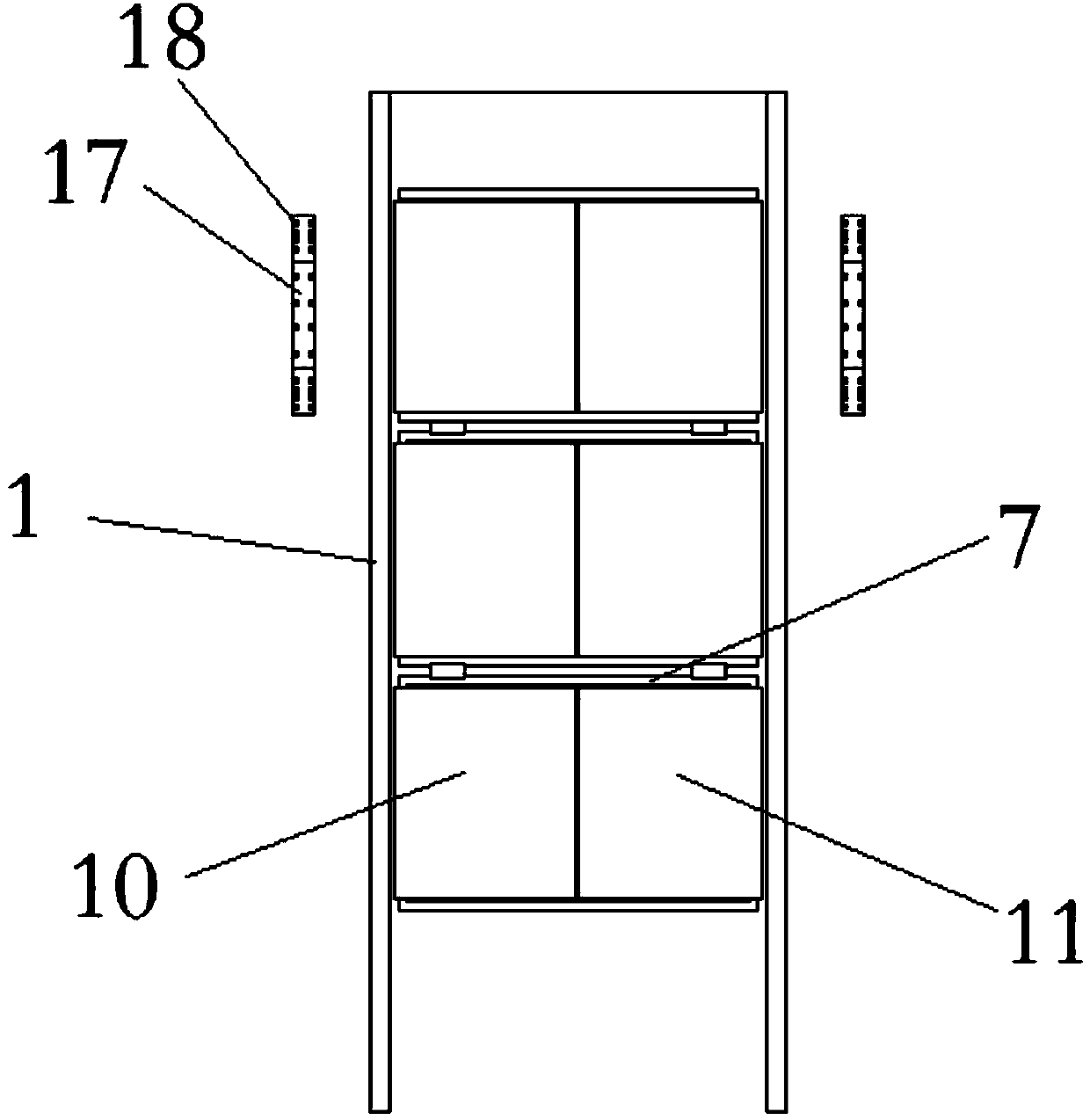

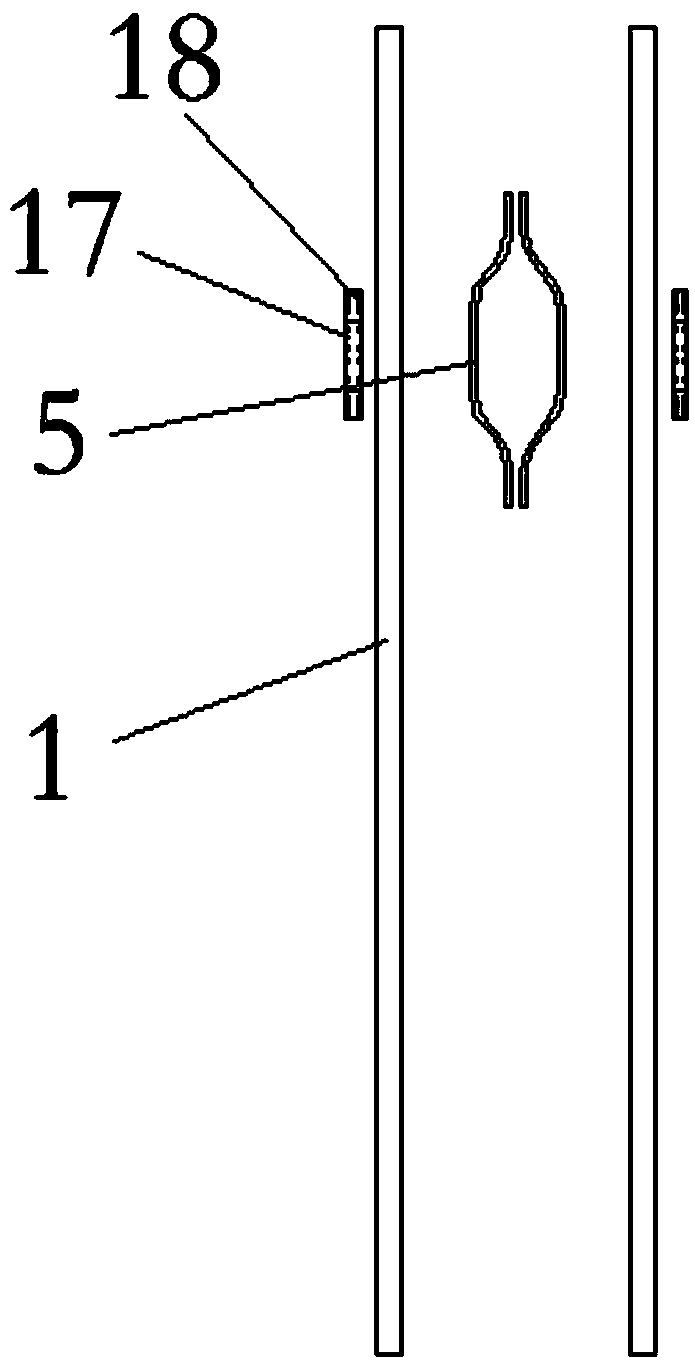

PendingCN111942896AImprove stacking efficiencyIncrease productivityCharge manipulationConveyor partsGlass productionSupport plane

The invention discloses a glass deep processing jacking mechanism. The glass deep processing jacking mechanism comprises a conveying device and a jacking device, wherein the conveying device is provided with the jacking device capable of vertically moving; the conveying device comprises a first rack, a first driving assembly, driving assemblies and driven assemblies, the first driving assembly isdriven, and the driving assemblies rotate to drive the driven assemblies to rotate; and the jacking device comprises a second rack, a second driving assembly, supporting frames and supporting rods, the second driving assembly is driven, and the supporting rods are driven by the supporting frames to vertically move in gaps between the driven assemblies. The glass deep processing jacking mechanism has the advantages that under the condition that the conveying device does not stop running, the jacking mechanism prevents the stacking phenomenon on the conveying device when the manipulators grab and stack glass, and an existing mode of stopping conveying of the conveying device for preventing glass stacking does not need to be adopted, so that the glass stacking efficiency is greatly improved,and then the glass production efficiency is improved.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

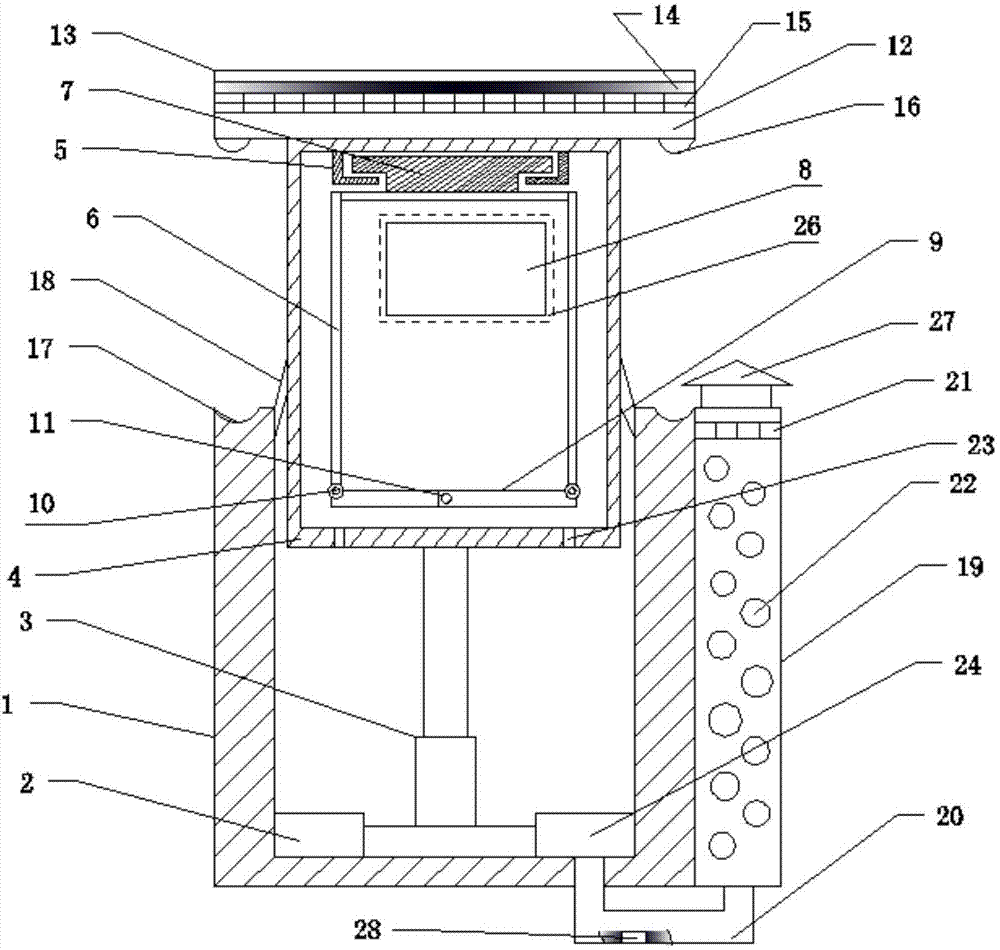

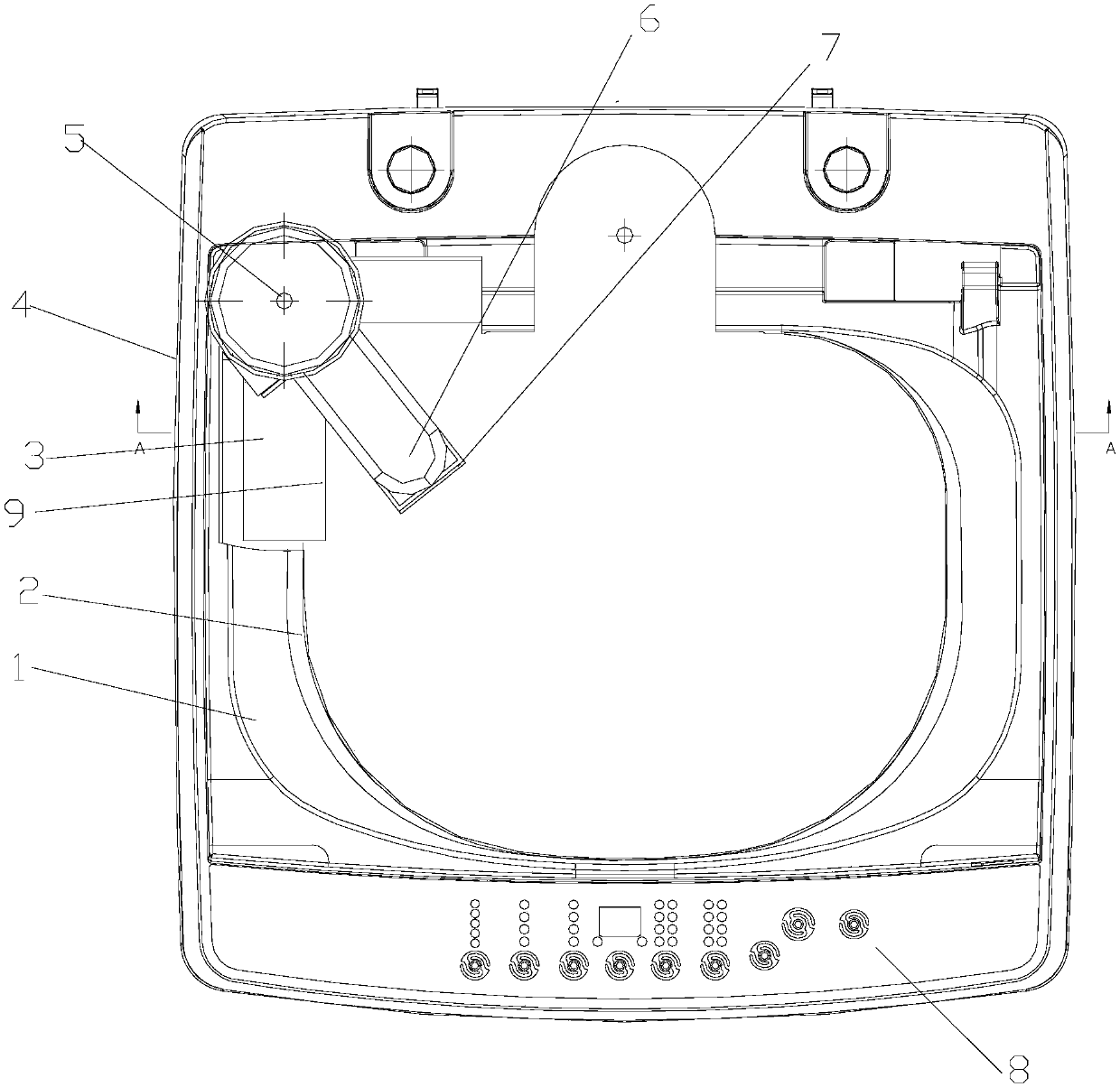

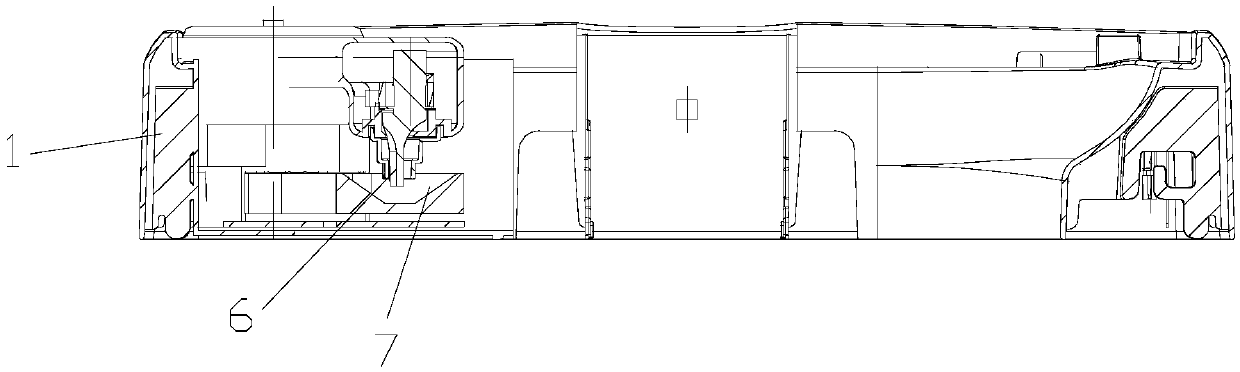

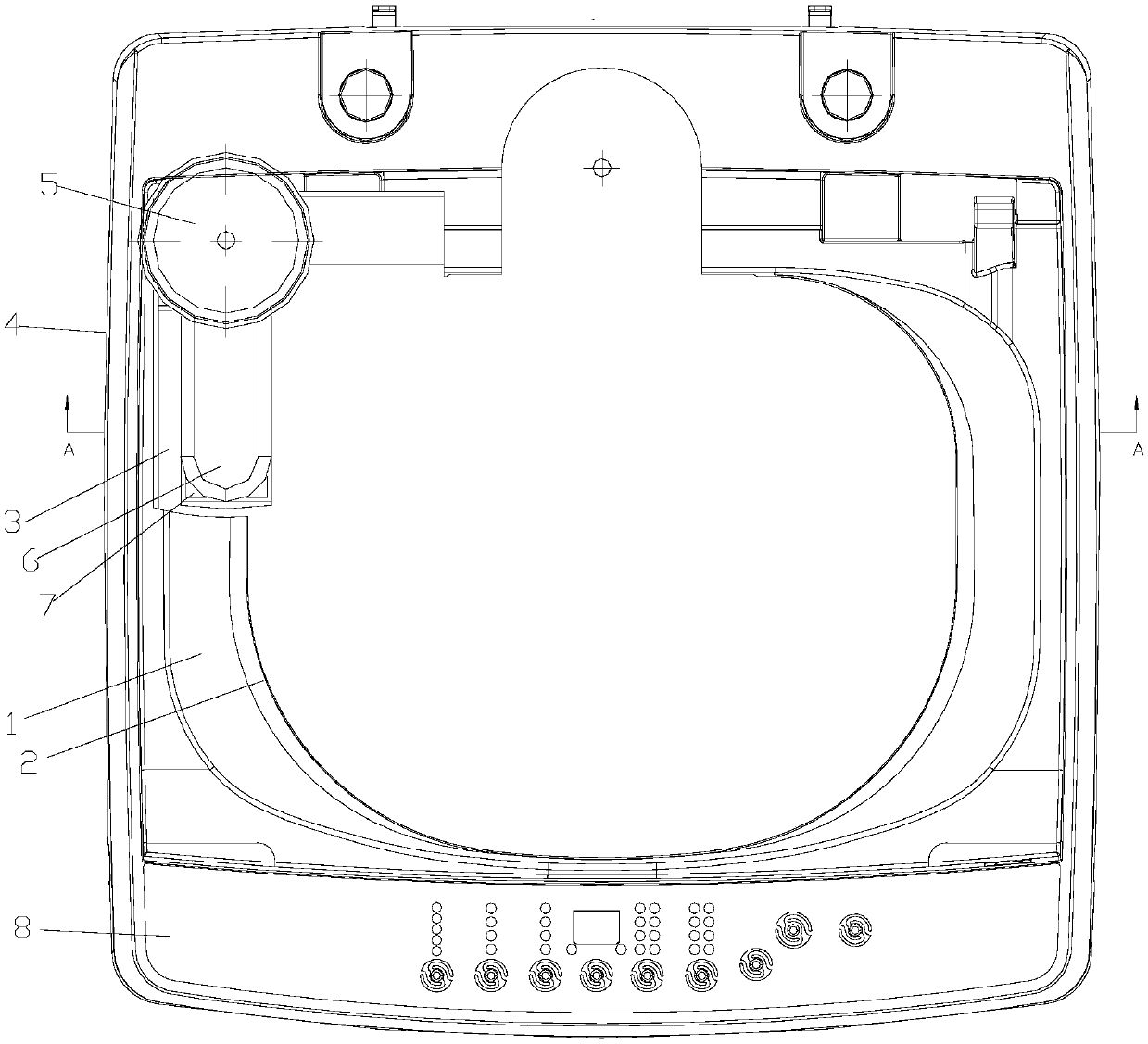

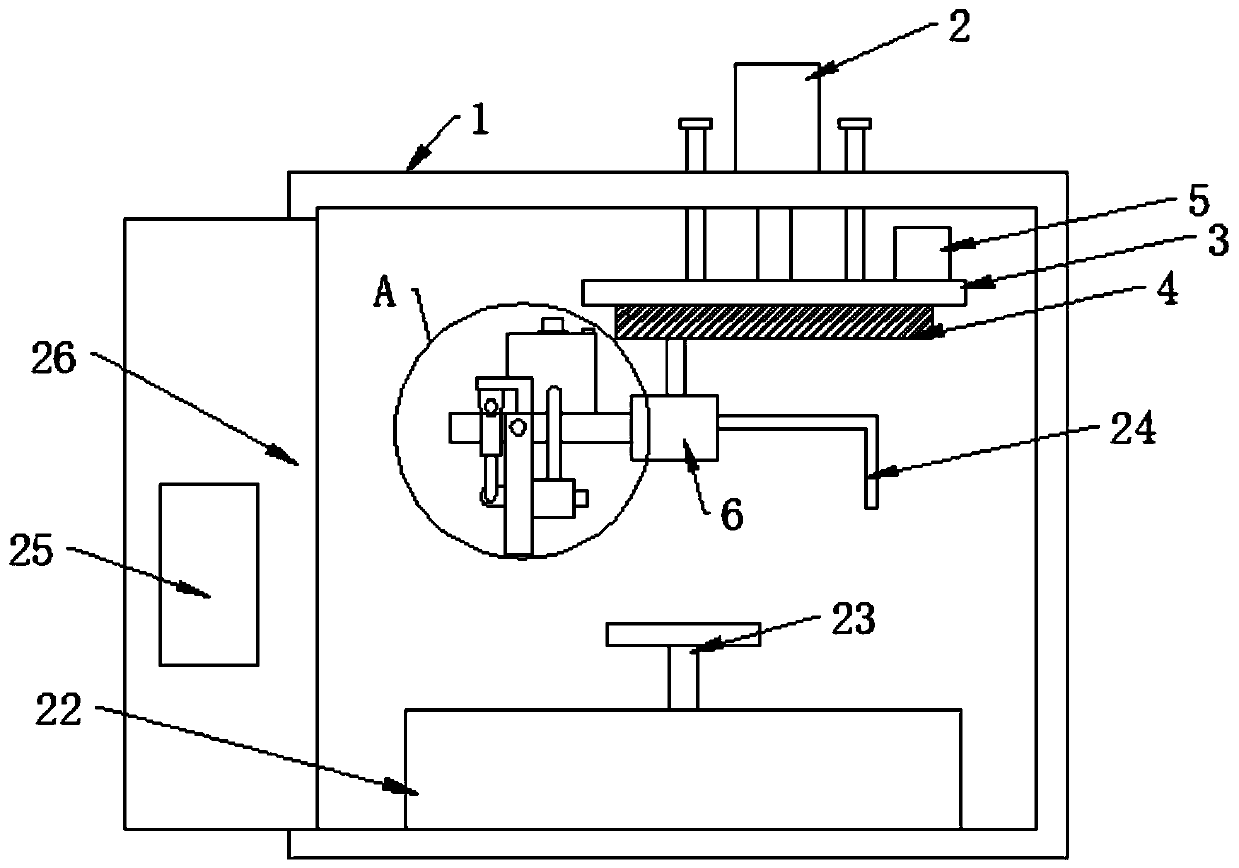

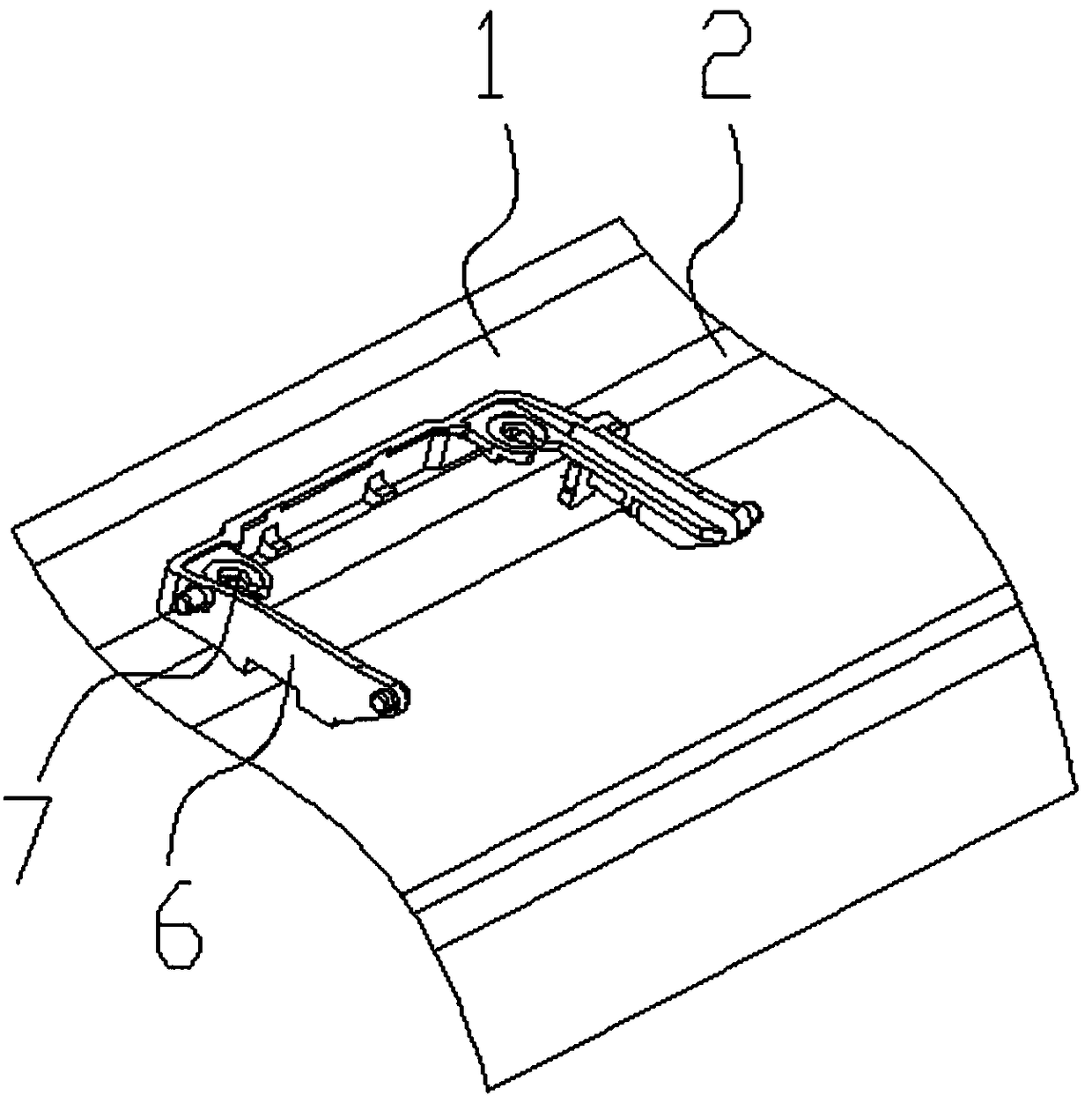

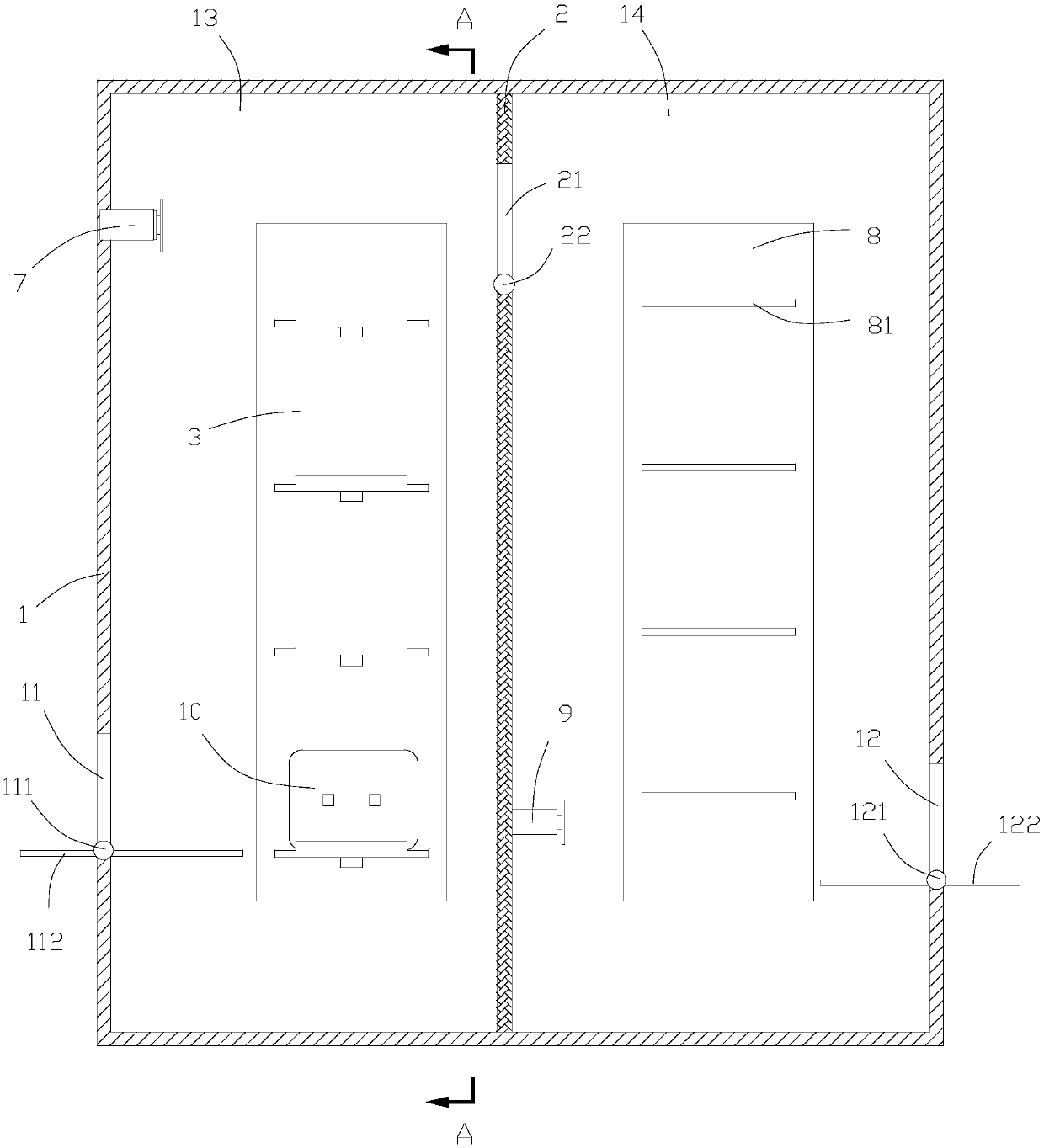

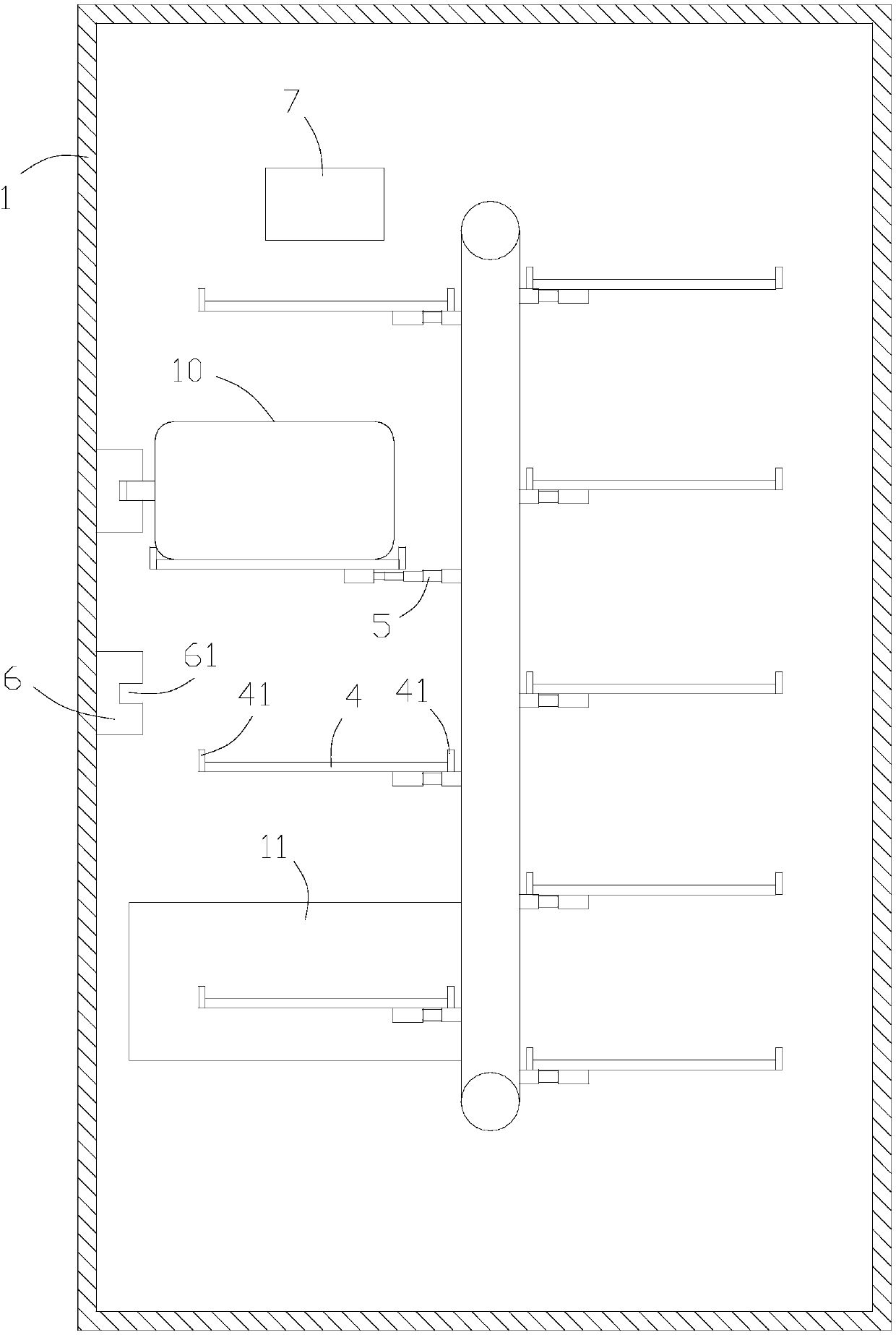

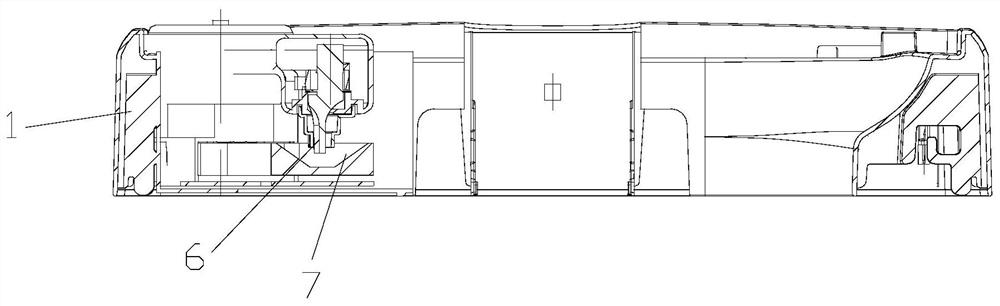

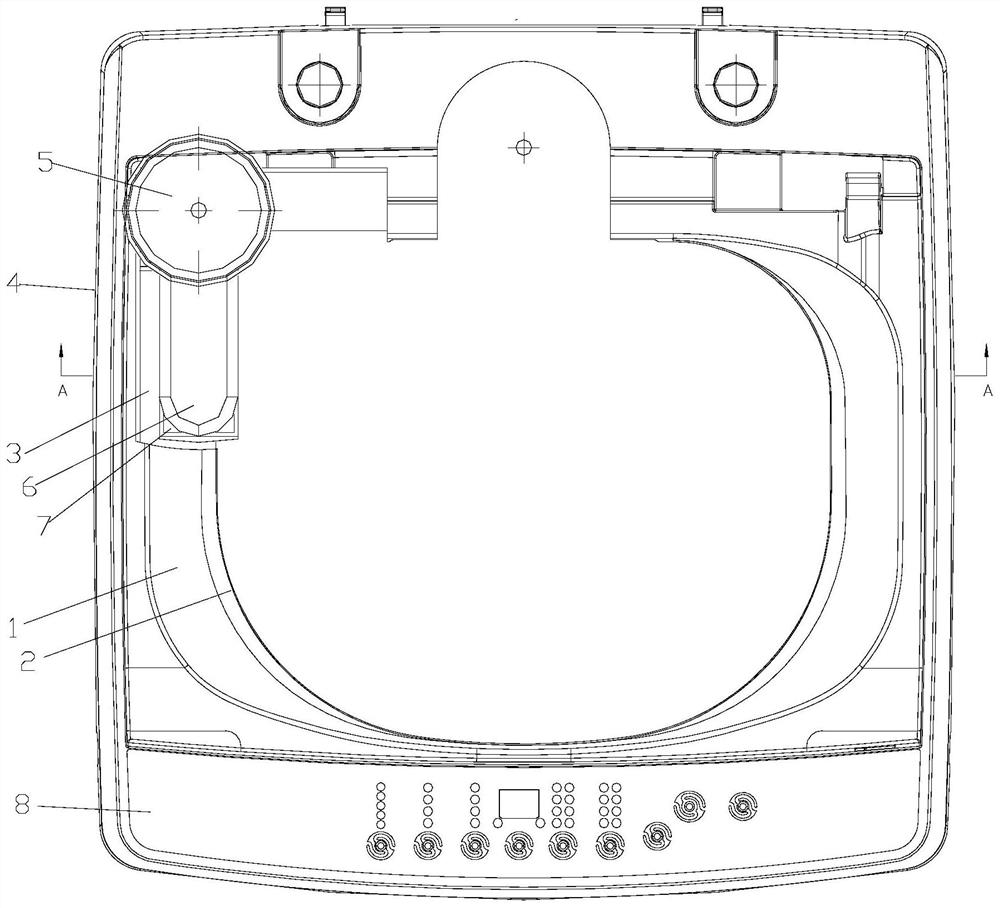

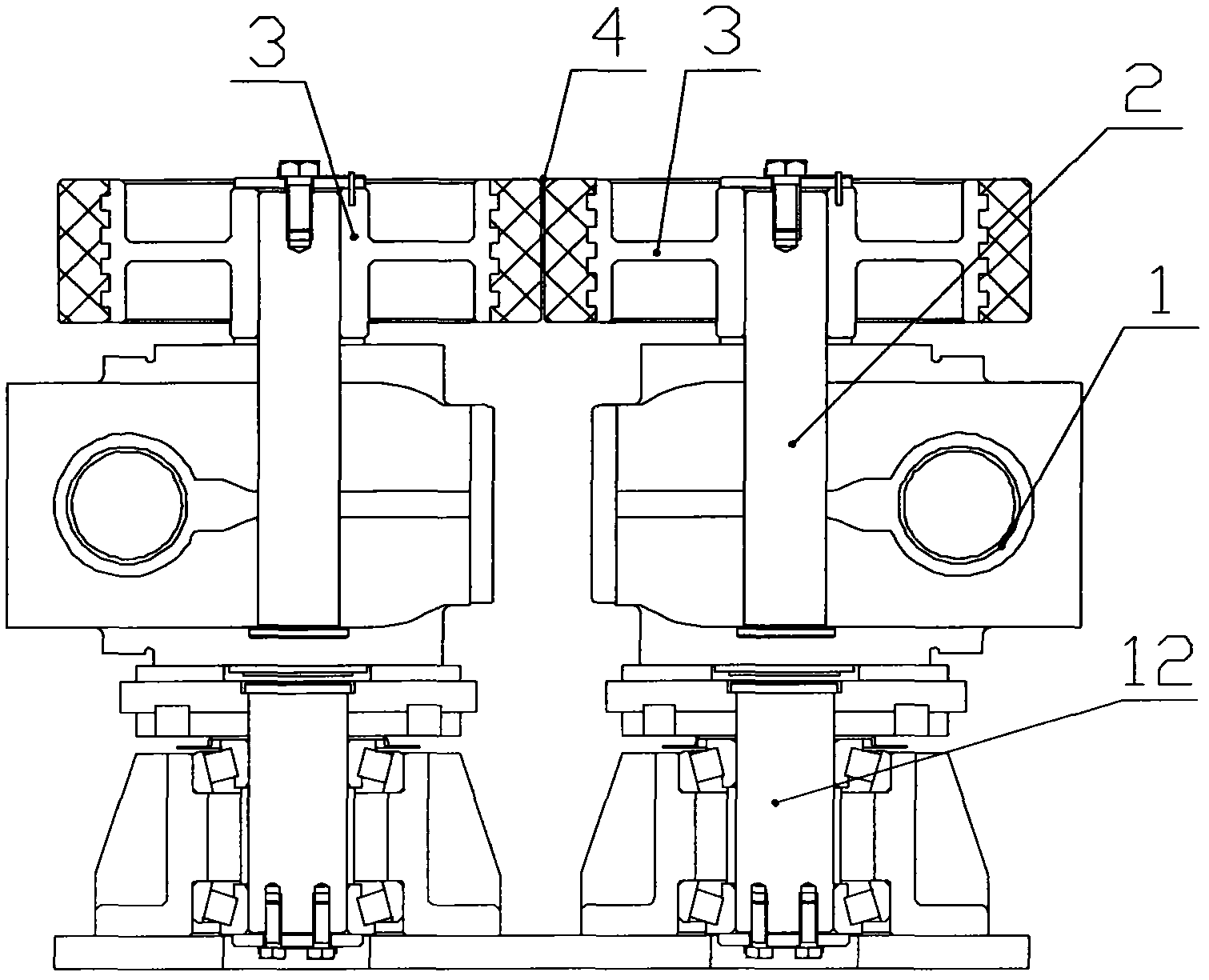

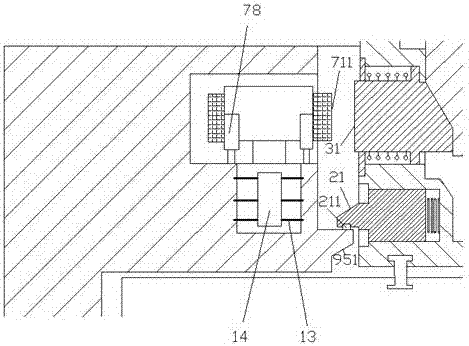

Washing machine with partial pre-washing function

ActiveCN110528223AComplete appearanceMaintain integrityTextiles and paperVibration washing machinesProcess engineeringCavitation

The invention discloses a washing machine with a partial pre-washing function. The washing machine comprises an ultrasonic washing device; the washing machine is provided with an accommodating space for accommodating the ultrasonic washing device, and the ultrasonic washing device can be arranged in the accommodating space in a screw-in / screw-out manner. The whole ultrasonic washing device is embedded in the washing machine and integrally assembled with the washing machine, normal clothes washing is not influenced, and the washing machine is also endowed with the partial pre-washing function.The washing machine partially emits high-frequency ultrasonic waves to initially-wet clothes by utilizing the cavitation function of the ultrasonic waves, so that stains such as oil stains are emulsified under the function of a sound field, solid ions are separated from the clothes, surface purification is achieved, partial stubborn stains are removed, and the partial pre-washing function on the clothes is achieved.

Owner:HEFEI HAIER WASHING MACHINE +1

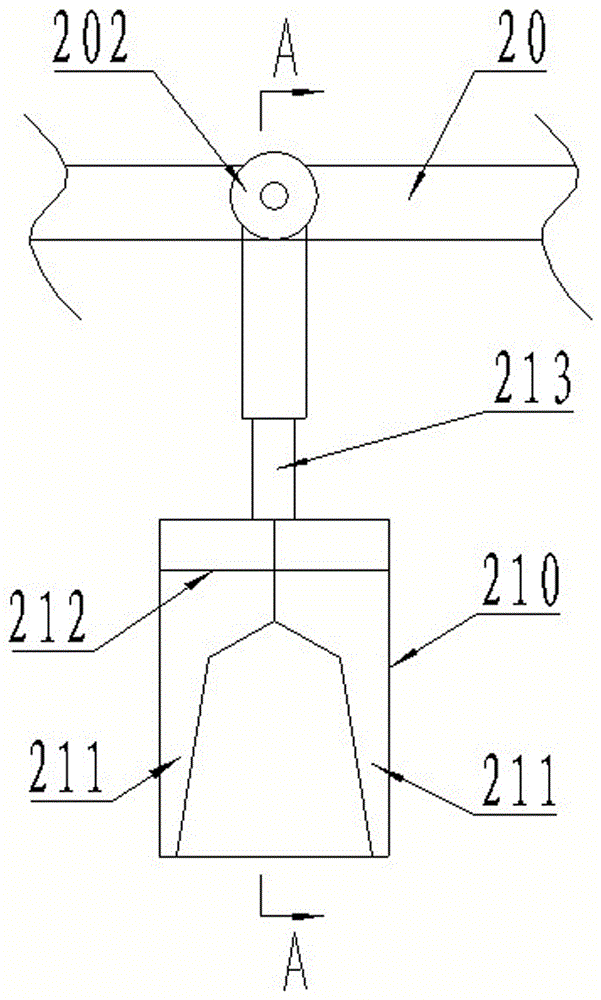

Special boiling water scalding device for poultry slaughtering assembly line

The invention provides a special boiling water scalding device for a poultry slaughtering assembly line. Scalding operation can be carried out on slaughtered poultry meat, and conditions are provided for subsequent feather picking operation, so that the device is efficient, reliable, clean and sanitary. The special boiling water scalding device comprises a boiling water pool, a matched track, a driving belt and a U-shaped hanging arm, wherein the boiling water pool is internally provided with a heating coil, and a plurality of poultry hangers are movably arranged on the track; the driving belt is used for driving the poultry hangers to move along the track; the track above the boiling water pool is bent downwards to form a low track matched with the boiling water pool, and the low track has a height enabling the poultry hangers to be soaked in the boiling water pool integrally; hanging shoulders are arranged at the bottom of the track in an extending manner along the cross section direction of the device; the U-shaped hanging arm is connected with a left pulley and a right pulley through hinge pins, and the left pulley and the right pulley are movably arranged on the hanging shoulders on two sides of the track; and the poultry hangers hang at the bottom of the U-shaped hanging arm through hook rails.

Owner:安徽兴牧畜禽有限公司

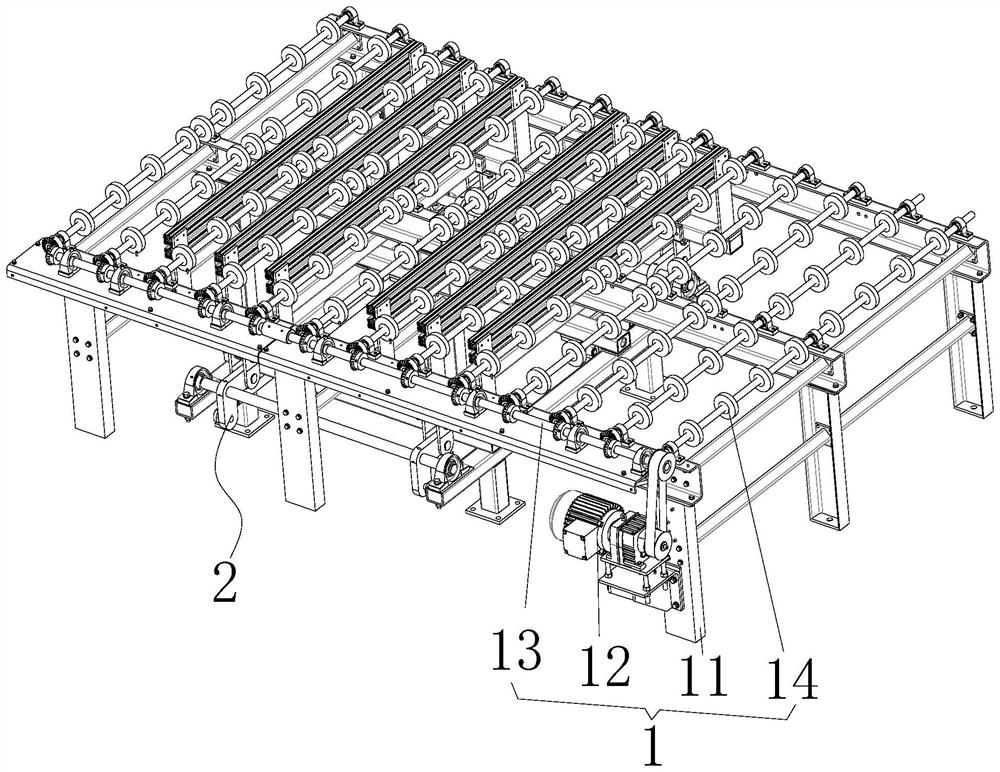

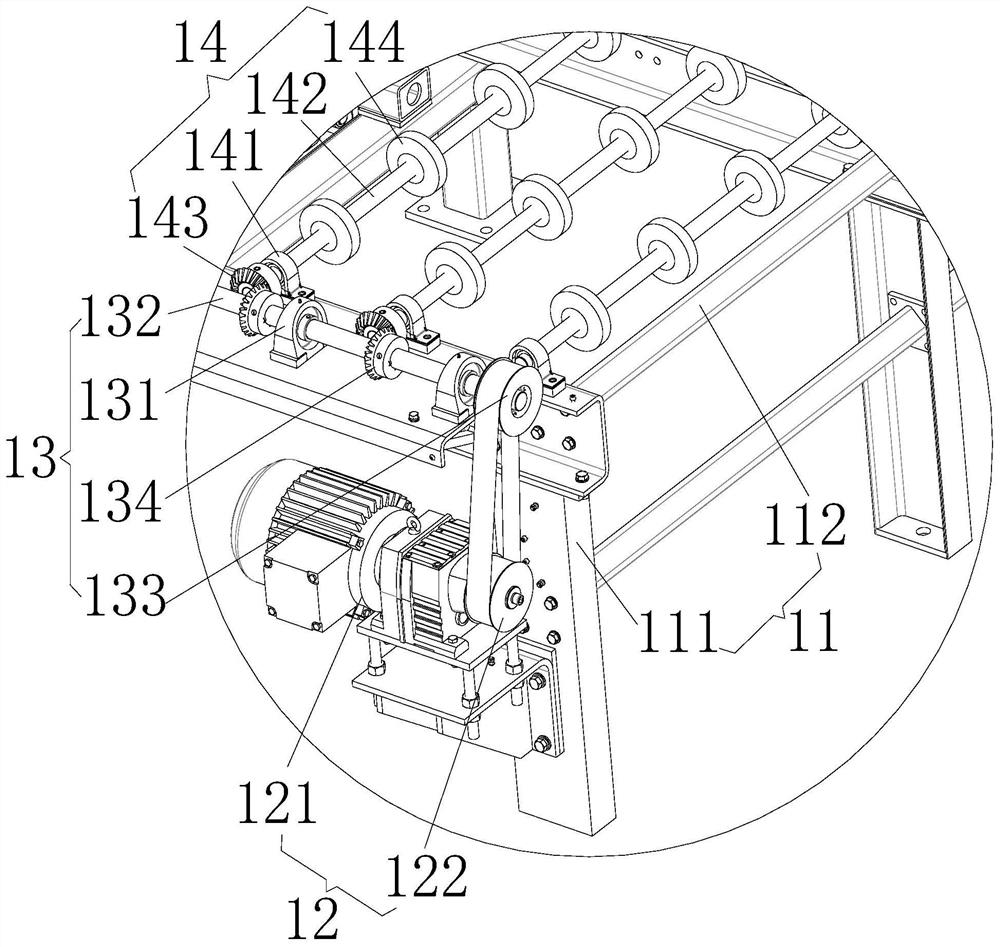

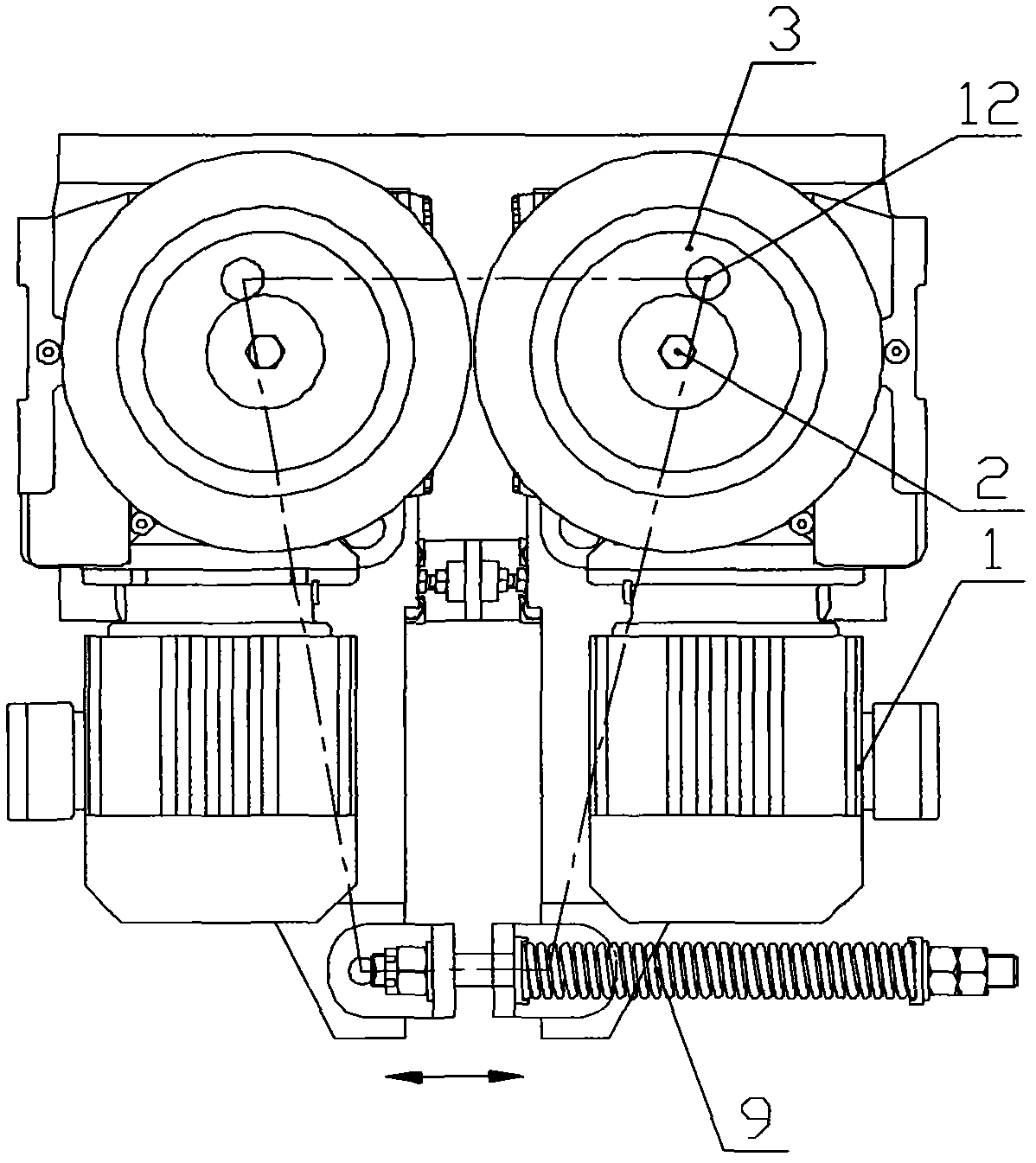

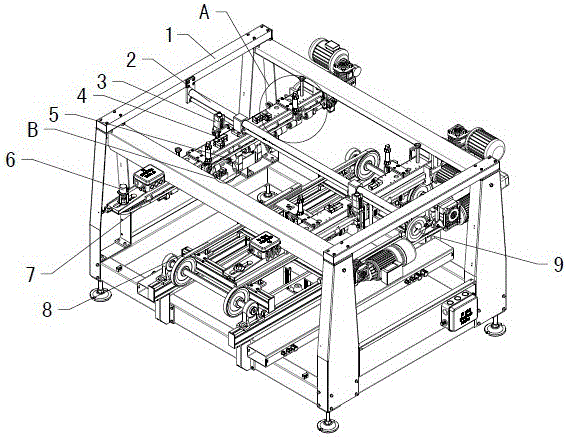

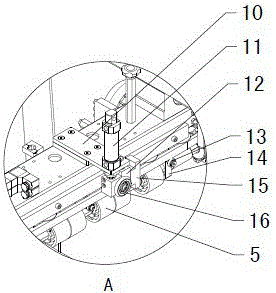

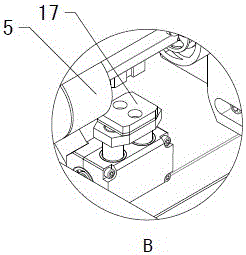

Heavy frictional combined conveying line

InactiveCN102180340ADelivery does not affectEasy to replaceMechanical conveyorsDrive wheelDrive shaft

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

Appearance spraying device for processing electronic product

PendingCN111589624ANovel structural designAchieve sprayingSpray boothsHydraulic cylinderElectric machinery

The invention discloses an appearance spraying device for processing an electronic product. The appearance spraying device comprises a housing; a hydraulic cylinder I is installed at the top of the housing; a belt transmission part is installed at the bottom of a mounting plate; one end of the belt transmission part is connected with a driving motor; the other end of the belt transmission part isconnected with a connecting block; a support plate is horizontally fixed to one sidewall of the connecting block; one sidewall of the support plate is connected with the mounting plate through a rotating shaft; a spraying head is installed at one sidewall of the mounting plate; a paint box and a connecting rod I are installed at the top of the support plate; the mounting plate and the connecting rod I are each equipped with a hinging base; a hydraulic cylinder II is connected between the two groups of hinging bases; the bottom of an inner chamber of the housing is provided with a liquid collection groove; and a workpiece table is installed inside the liquid collection groove. The appearance spraying device realizes full spraying of a workpiece and does not need to manually handhold a spraying tool to spray the electronic product, thereby avoiding aching pain of hands, achieving high work efficiency, neither polluting the shell environment nor causing waste of resources.

Owner:新沂市宏展电子科技有限公司

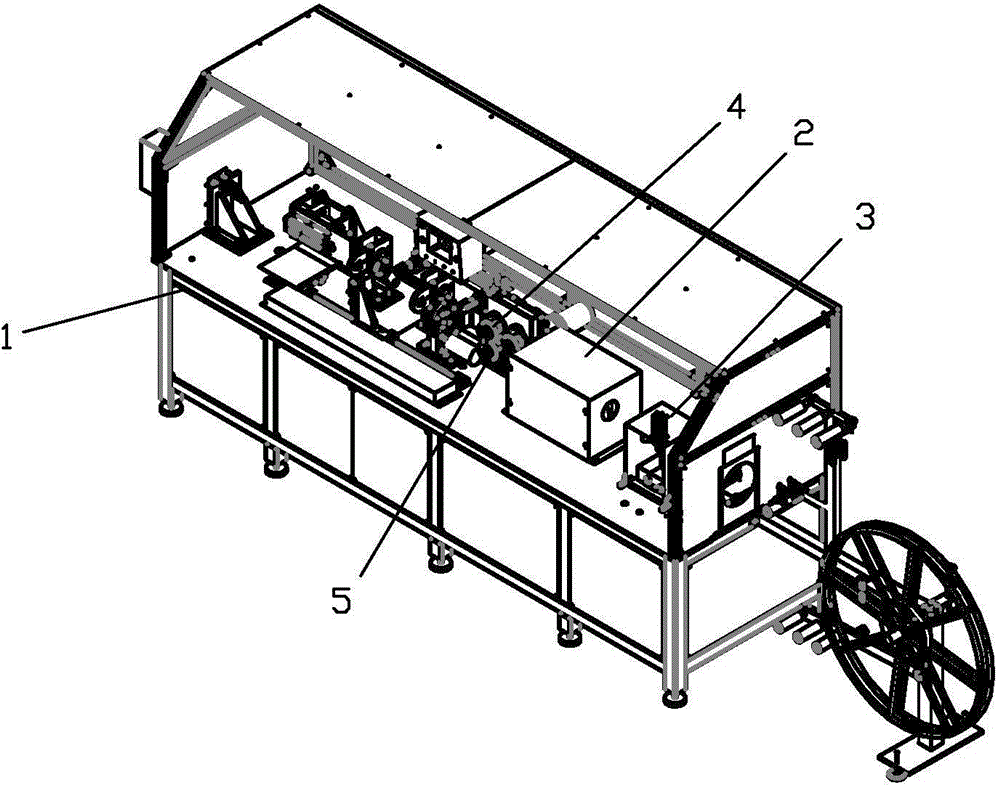

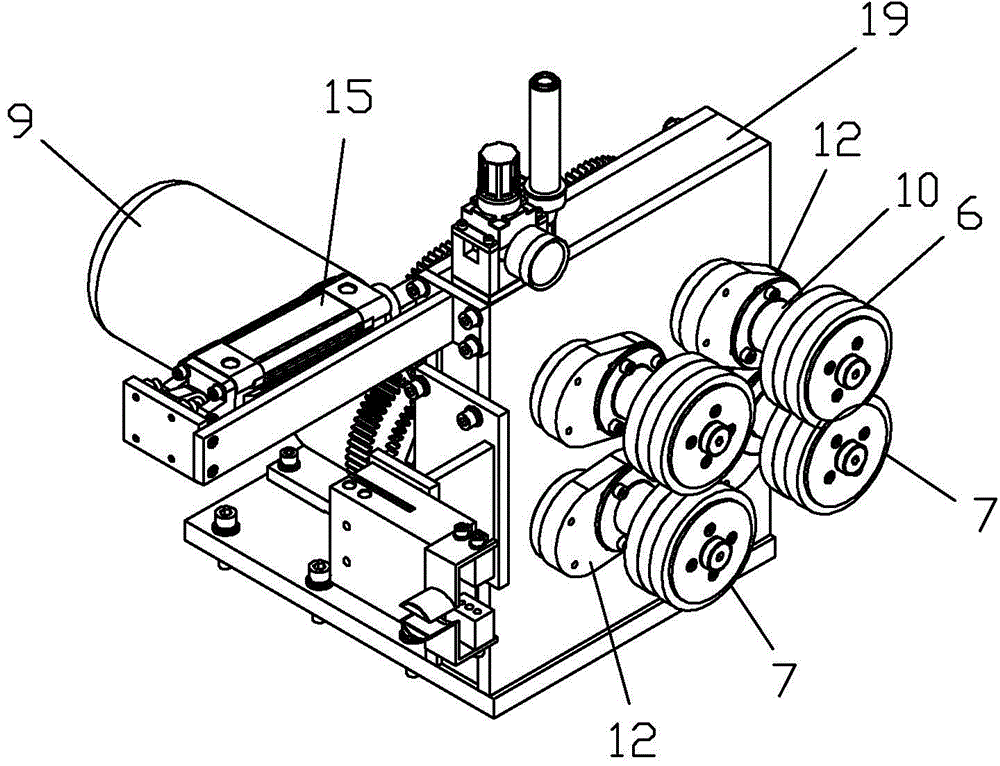

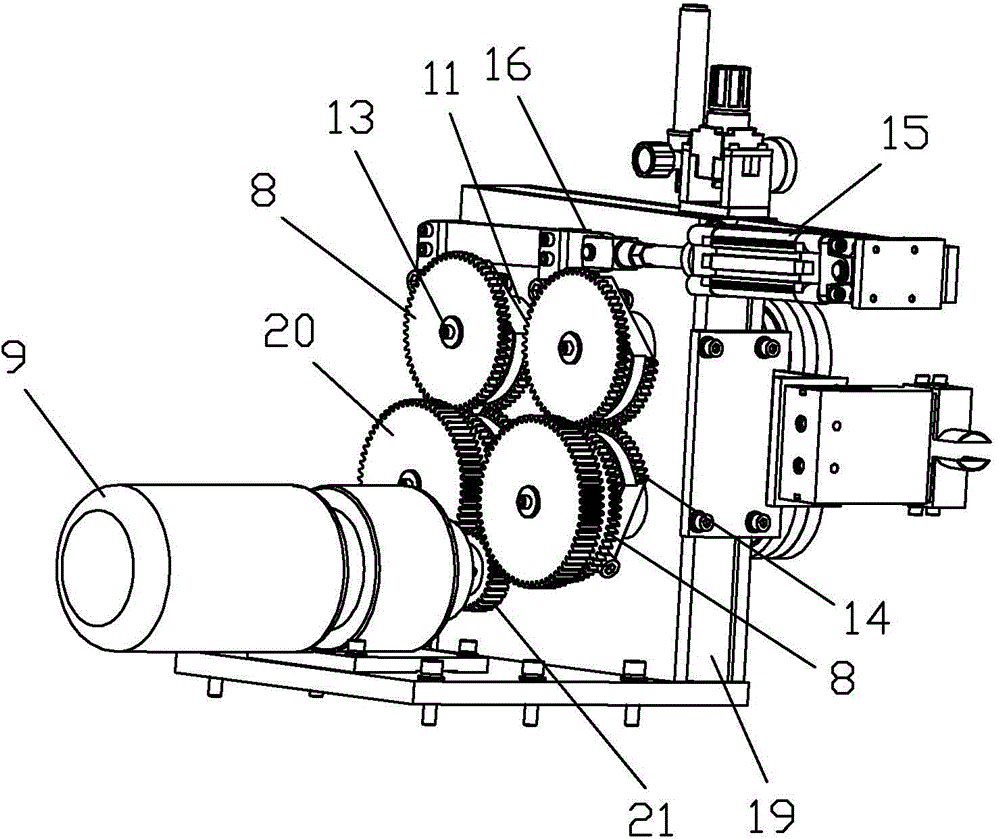

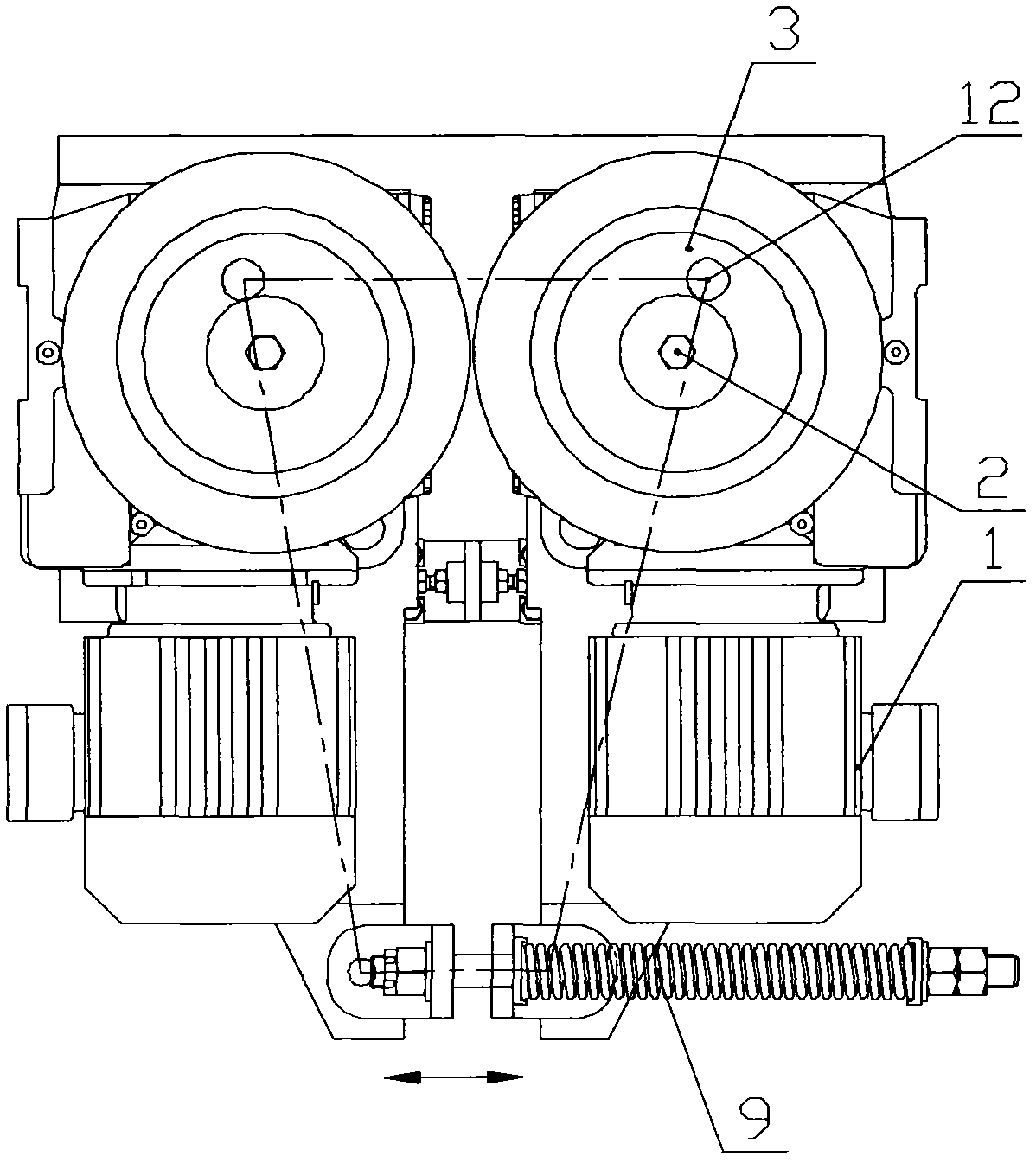

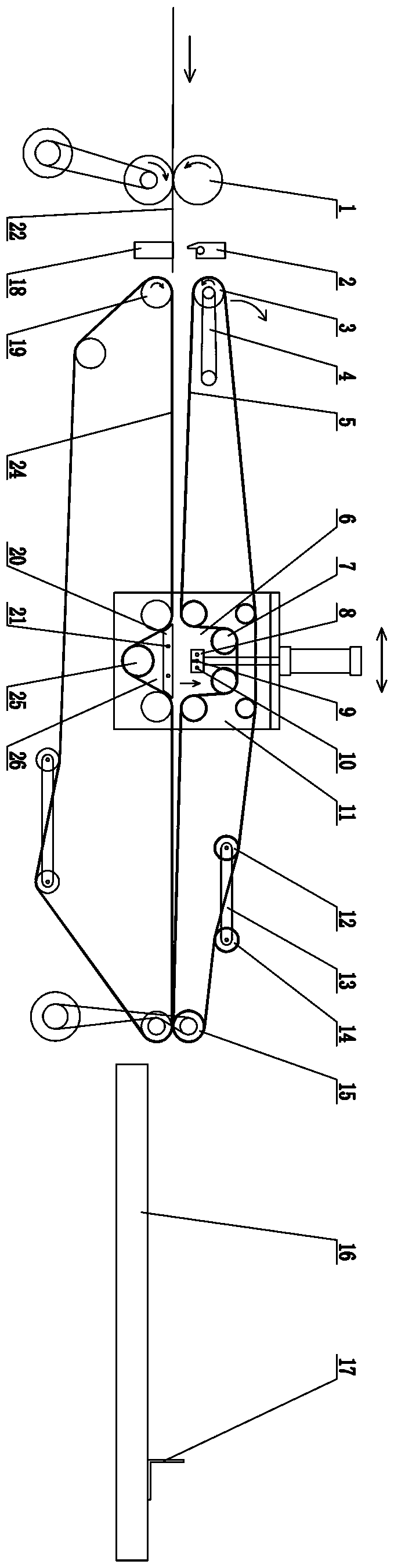

Improved sleeving and shrinking machine

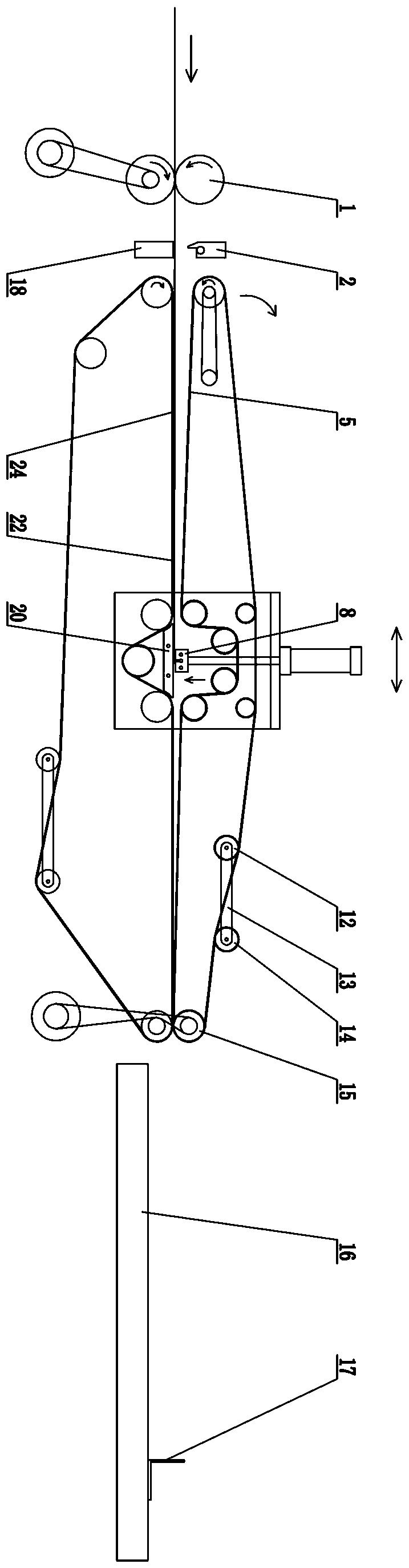

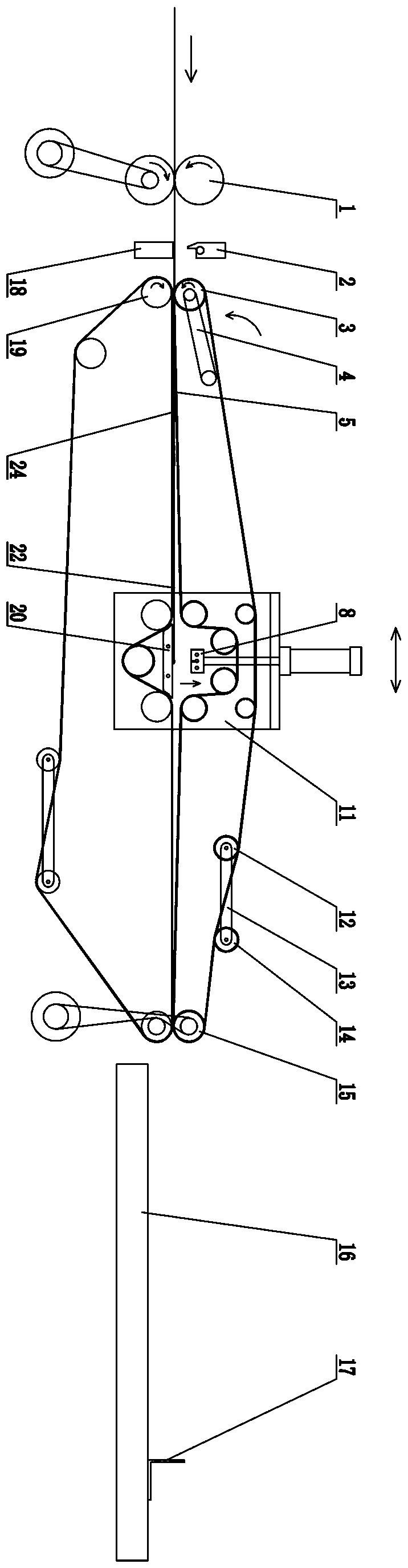

ActiveCN104872263AHigh clothes removal efficiencyIncrease delivery speedSausage casing manufactureSausage casing shirringProduction lineDrive shaft

The invention provides an improved sleeving and shrinking machine which includes a machine frame, wherein the machine frame includes a sleeving and shrinking machine body, oil coating clamps and a casing stripping device; the casing stripping device includes at least two pairs of casing stripping wheels, and each pair of casing stripping wheels includes an upper casing stripping wheel and a lower casing stripping wheel; the upper casing stripping wheels and the lower casing stripping wheels are connected with transmission shafts; the transmission shafts penetrate through a machine panel and are connected with external gears; the external gears are driven by a motor, so as to drive the upper casing stripping wheels or the lower casing stripping wheels to rotate. According to the improved sleeving and shrinking machine provided by the invention, the casing stripping efficiency of the casing stripping wheels is high, the casing conveying speed is increased, and the oil coating clamps can be used for on-line oil coating without affecting the conveying of casings, therefore, the production efficiency of the entire production line is greatly improved.

Owner:广东德福隆生物科技有限公司

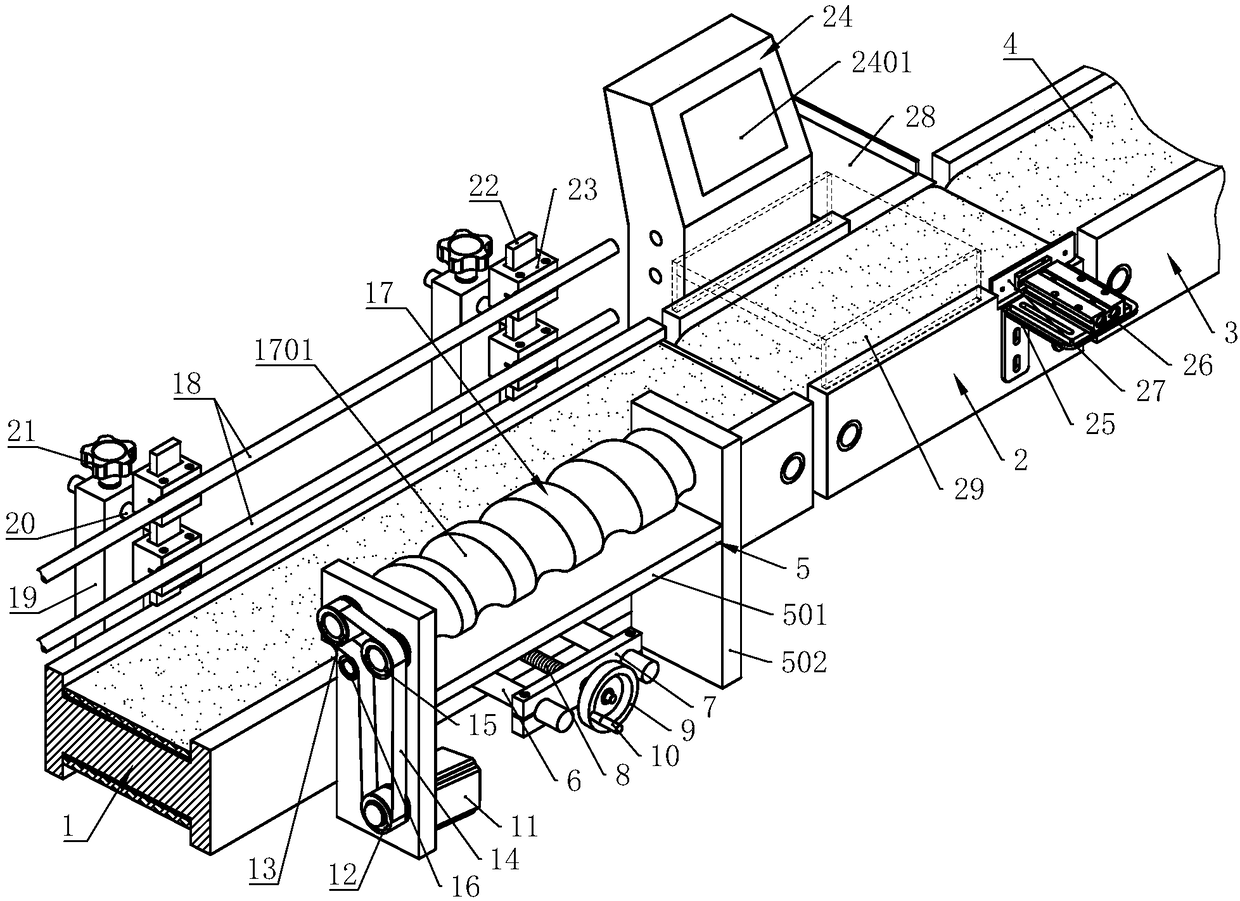

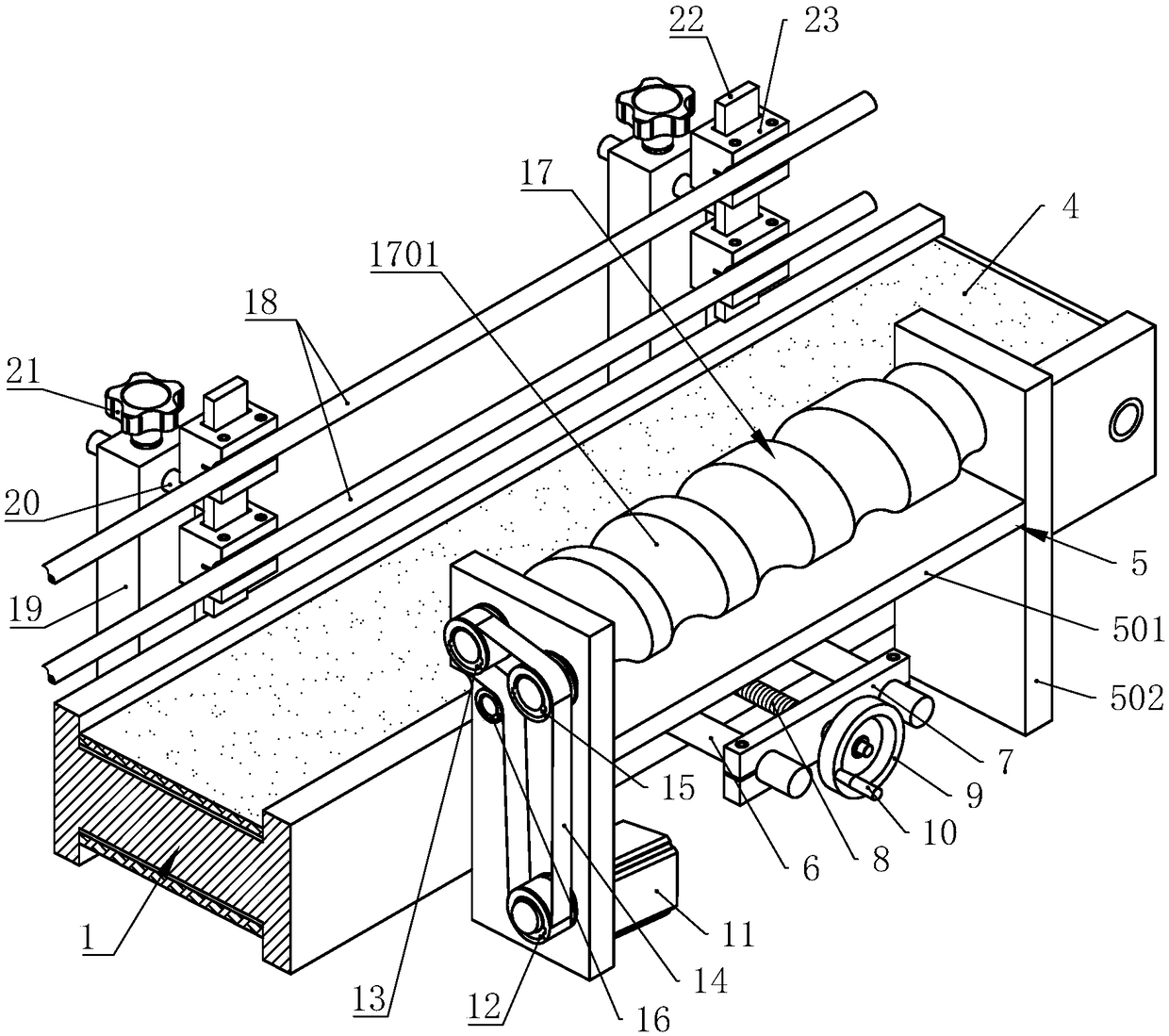

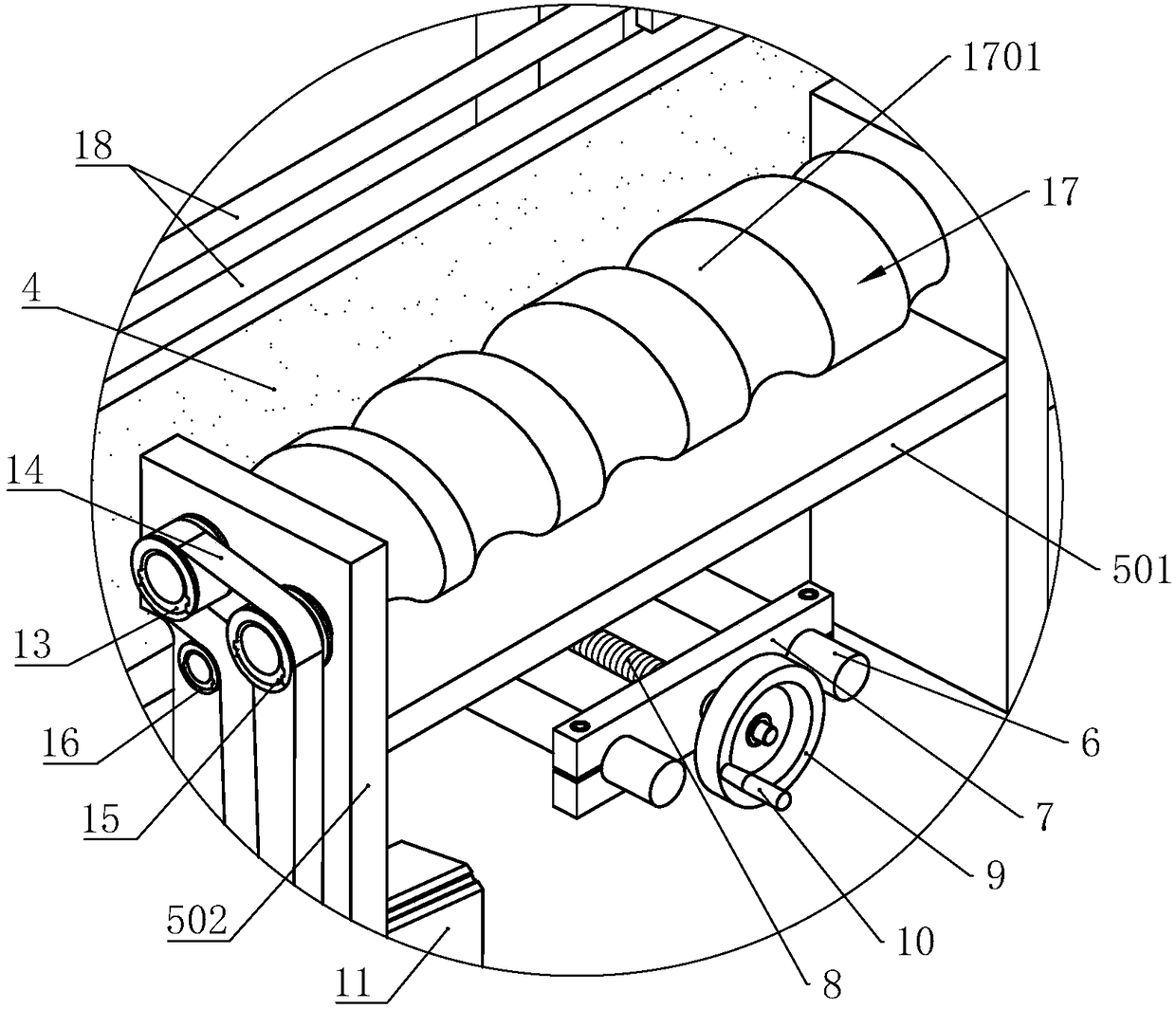

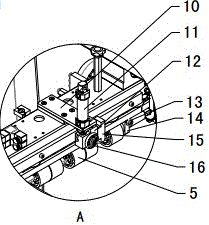

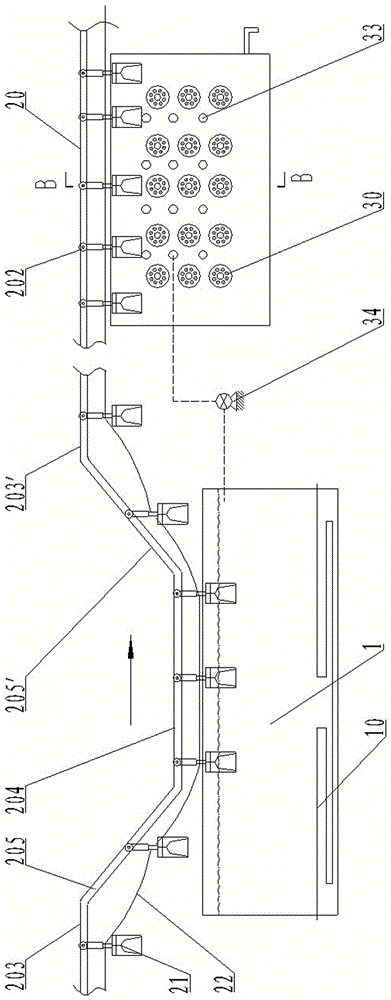

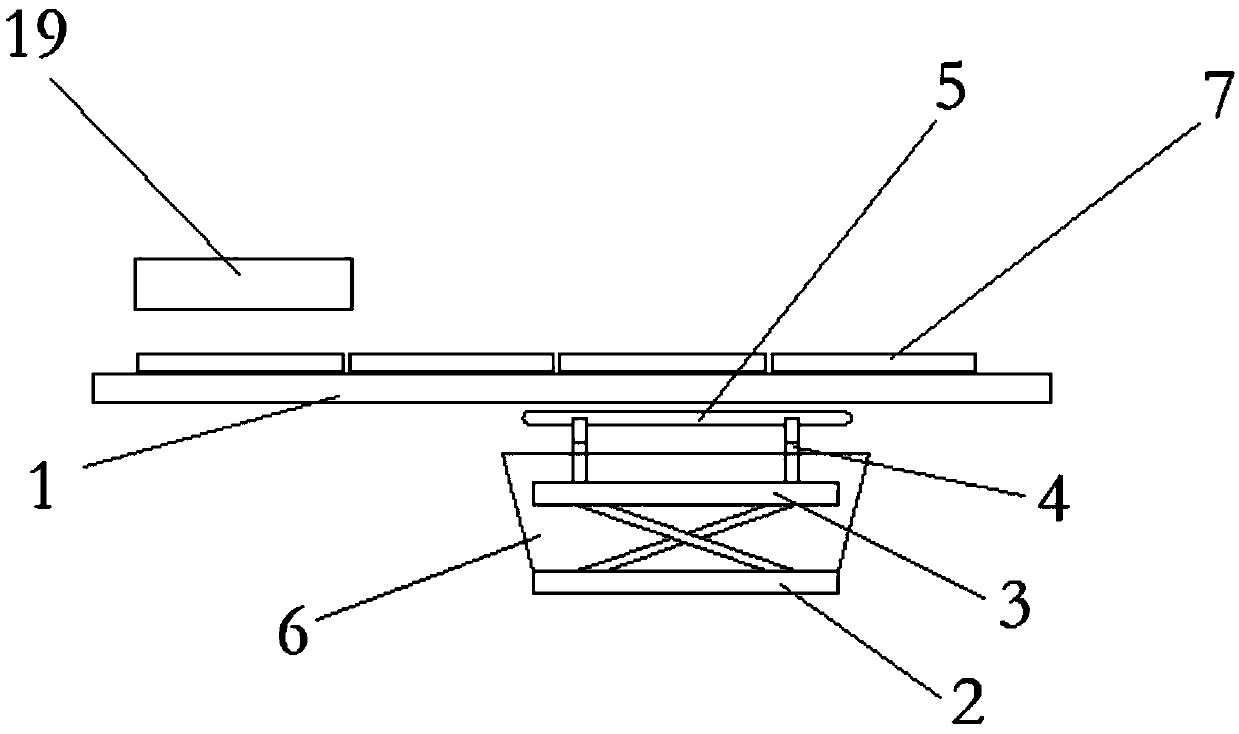

Weighing detecting line and application in processing of bottled medicament, milk powder cans and feed cans thereof

PendingCN108341102ARealize online weighing detectionRealize weighing detectionPackaging automatic controlEngineeringFodder

The invention belongs to the technical field of weighing detection, and provides a weighing detecting line. The weighing detecting line comprises a first conveying platform, a weighing detecting platform and a second conveying platform, which are all arranged in sequence. A mounting frame is movably arranged on one side of the first conveying platform. A first regulating mechanism is arranged between the mounting frame and the first conveying platform. The mounting frame is rotatably provided with a conveying roller which is driven by a driving device. The conveying roller is provided with conveying threads with the thread pitch being wider gradually in the conveying direction of processing products. The other side of the first conveying platform is provided with at least two stop levers.A plurality of second regulating mechanisms is uniformly arranged between the stop levers and the first conveying platform. One side of the weighing detecting platform is provided with a weight detector and a supporting plate, and the other side of the weighing detecting platform is provided with a pushing mechanism which is arranged corresponding to the supporting plate. The upper surface of thesupporting plate and a conveying belt of the weighing detecting platform are located at the same level. Smooth and orderly conveying and automatic weighting detection of the processing products are realized, and efficiency of weighing and detecting quality of the processing products are improved.

Owner:青岛创高世纪信息科技有限公司

Classification mechanism with adjustable size

Owner:山东爱而生智能科技有限公司

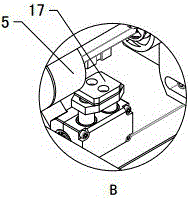

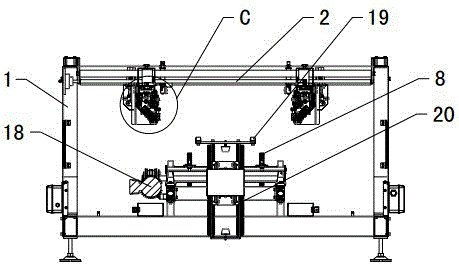

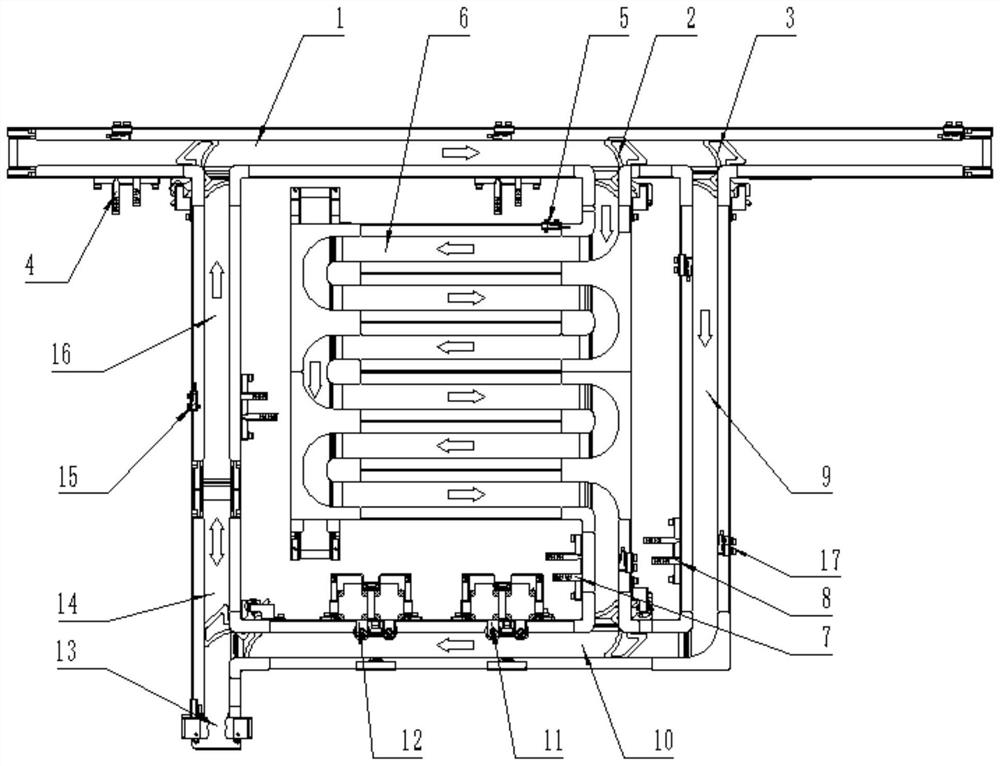

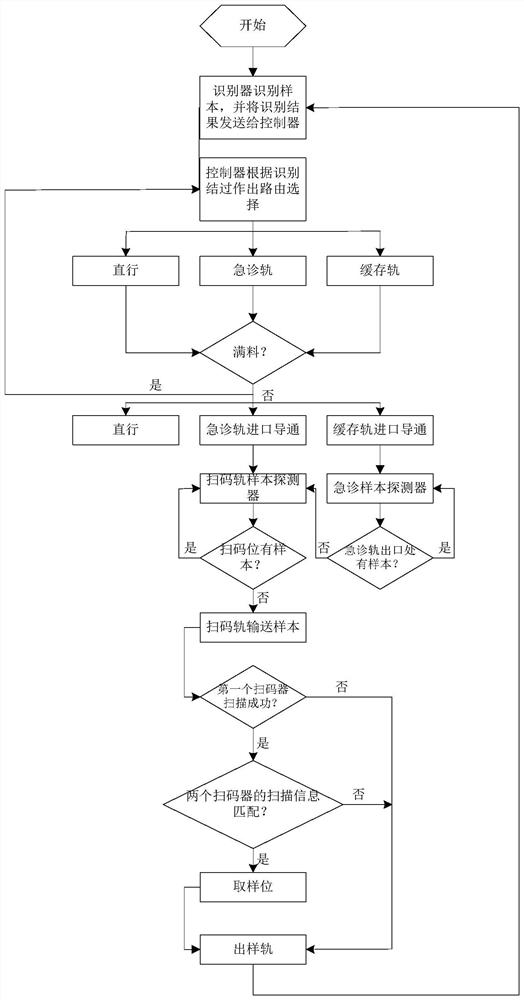

Sample conveying system and method

PendingCN114200150AImprove delivery efficiencySimple structureMaterial analysisEmergency treatmentEnvironmental geology

The invention discloses a sample conveying system. The sample conveying system comprises a sample feeding rail; an inlet of the cache rail can be communicated with the sample introduction rail; an inlet of the emergency treatment rail can be communicated with the sample introduction rail; the outlets of the temporary storage rail and the emergency treatment rail can be communicated with the sampling rail, and the sample located at the outlet of the emergency treatment rail is preferentially moved into the sampling rail according to the sample located at the outlet of the temporary storage rail. In the invention, the cache rail and the emergency treatment rail are mutually independent, and the conveying of the emergency treatment sample does not influence the conveying of the conventional sample, so that the conveying efficiency is improved, and meanwhile, the emergency treatment sample enjoys the priority passing right of the conventional sample. In addition, emergency treatment samples and conventional samples can be conveyed into a sample outlet rail after being sampled. Under the condition that emergency treatment samples are conveyed, conveying of conventional samples to the sample outlet rail cannot be suspended, and therefore conveying efficiency is improved. The invention further discloses a sample conveying method.

Owner:AUTOBIO LABTEC INSTR CO LTD

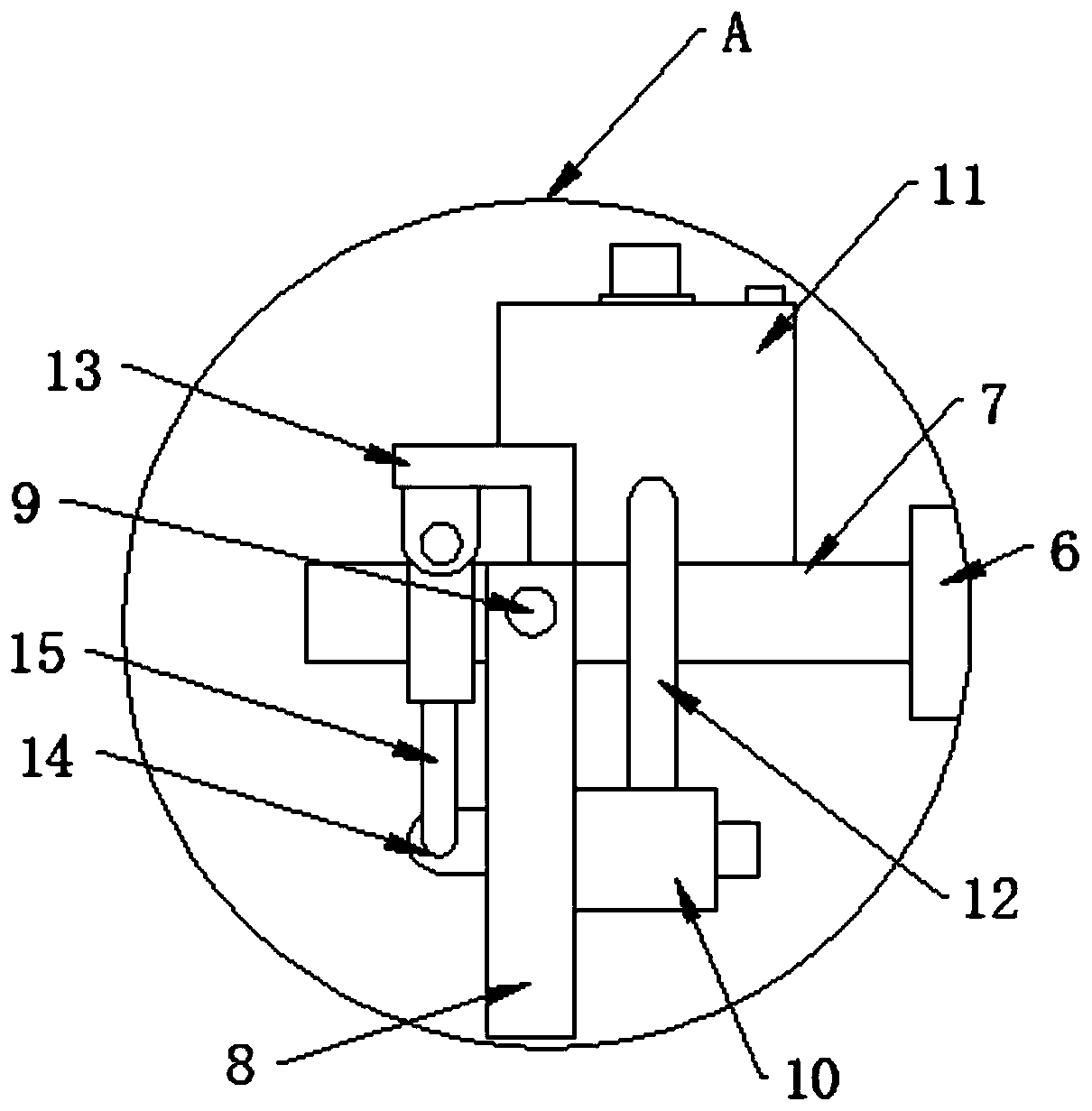

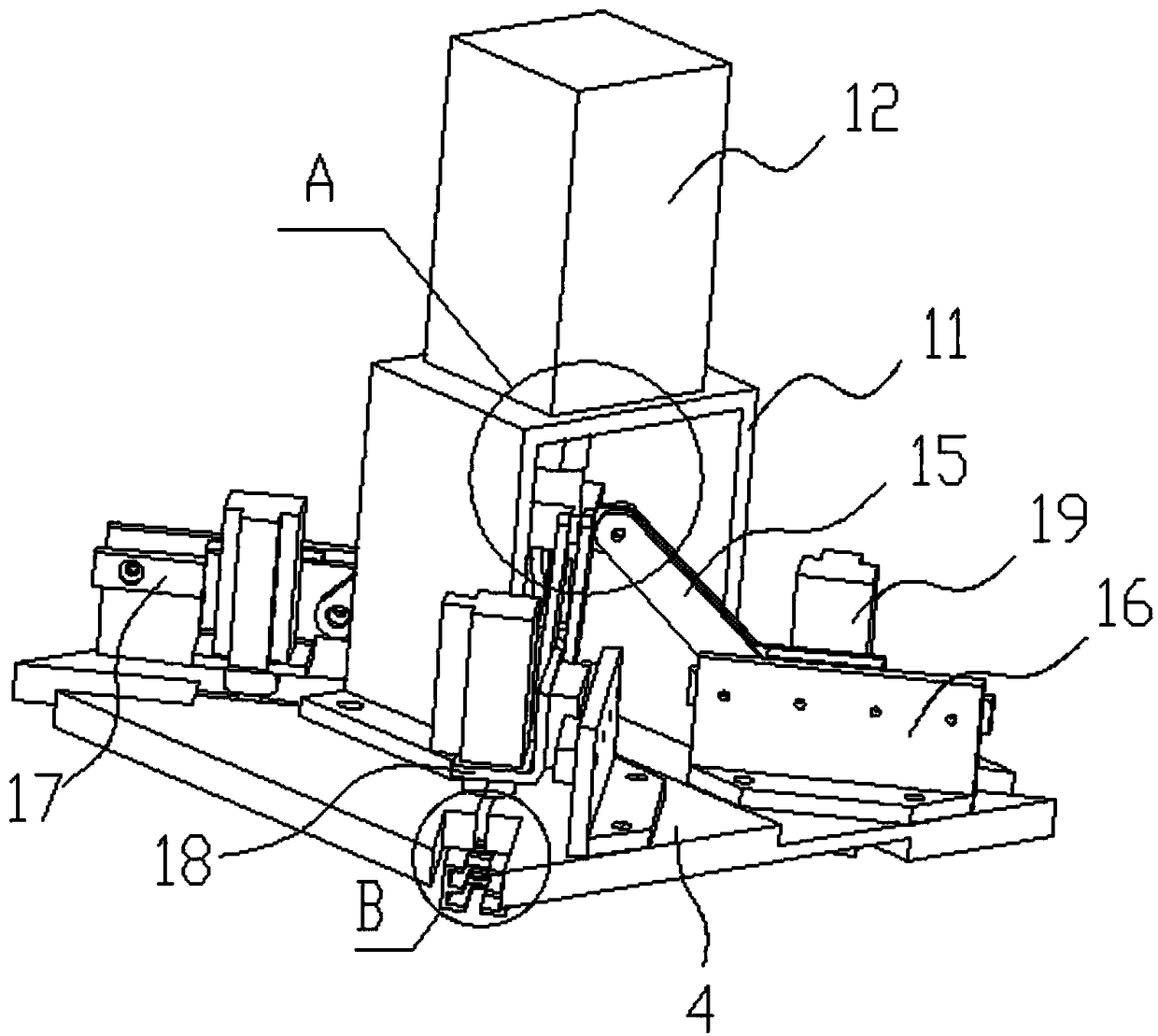

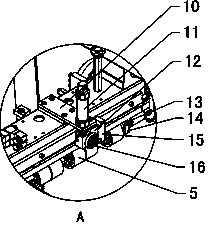

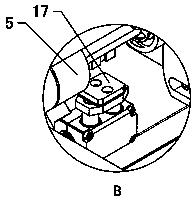

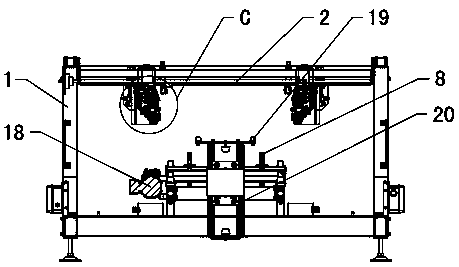

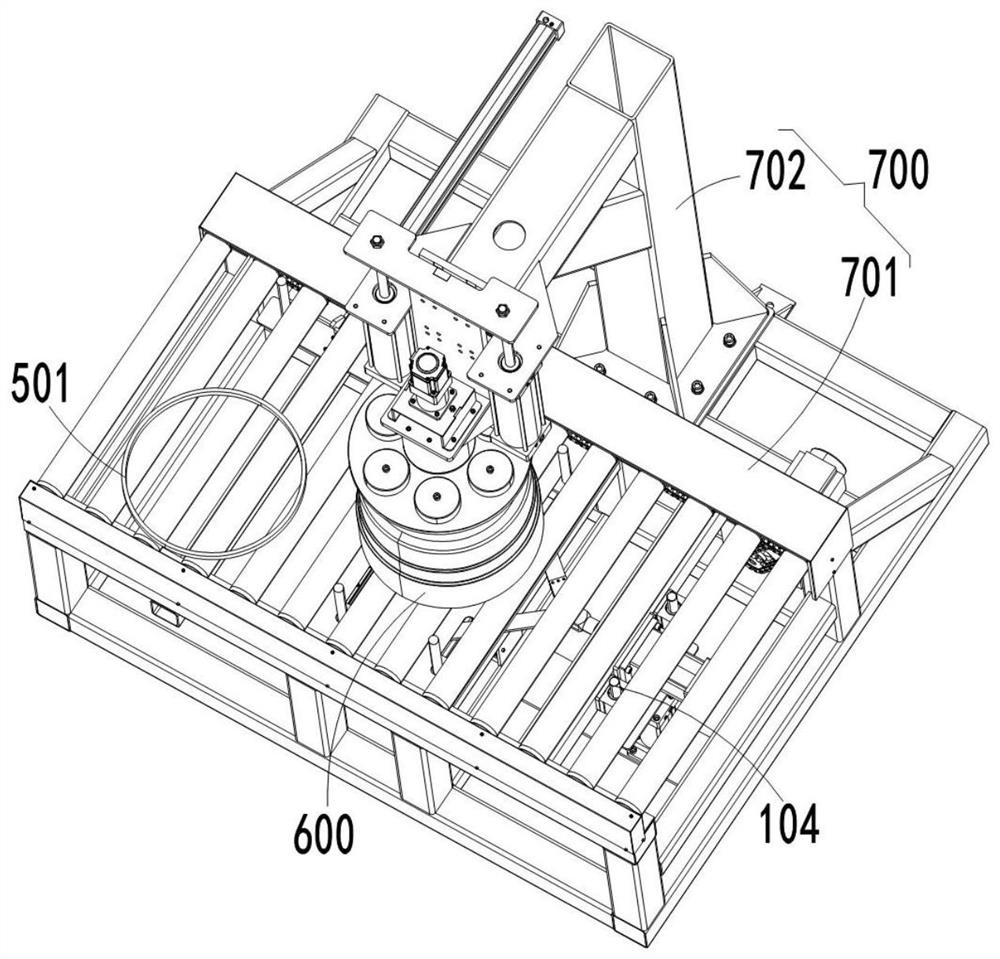

A rubber pad installation mechanism for frame parts

ActiveCN106671431BImprove installation efficiencyShorten the timeMetal working apparatusCylinder headEngineering

The invention relates to a rubber pad mounting mechanism facilitating ejection. The mechanism comprises a conveying frame, a conveying belt matched with a product is arranged on the conveying frame, atransverse frame of the product is attached to the conveying frame, and a pad feeding device matched with the product is arranged on the conveying frame. The pad feeding device comprises a square upper fixing plate above the conveying frame, a material taking groove is formed in the upper fixing plate in the diagonal direction, the material taking groove is matched with a material taking air cylinder, and the material taking air cylinder is connected with a pushing device. An air cylinder head of the material taking air cylinder penetrates through the material taking groove and is matched with a rubber pad. A pushing device and the material taking air cylinder are connected to a controller. The rubber pad mounting mechanism facilitating ejection is provided with the conveying belt matchedwith the product, and a rubber pad feeding device matched with the product is arranged on the conveying belt. The rubber pad is taken and placed through the material taking air cylinder. The rubber pad is pressed in through the pushing device, meanwhile, conveying is not affected, the rubber pad installation efficiency is greatly improved, and the rubber pad installation time is shortened.

Owner:大千纺织(安徽)有限公司

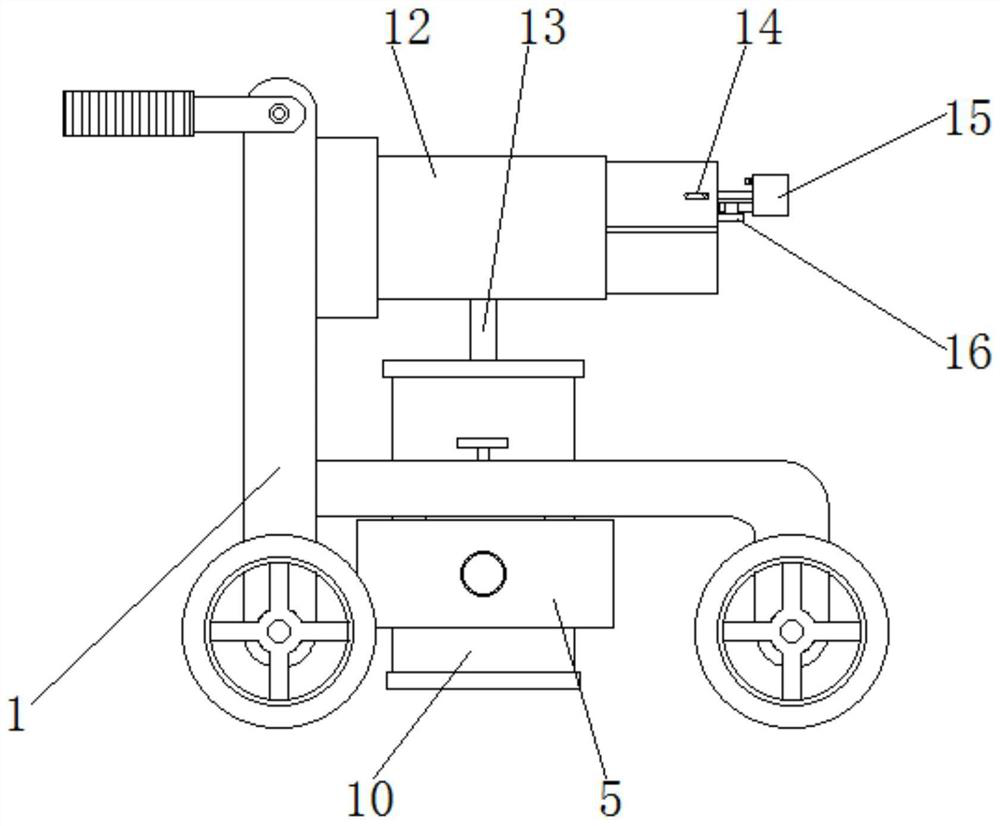

Spraying instrument special for waterproof heat-preservation outer wall coating

InactiveCN112854683AEasy to installEasy accessBuilding constructionsCoatingsSpray nozzleStructural engineering

The invention discloses a spraying instrument special for a waterproof heat-preservation outer wall coating. The spraying instrument comprises a cart and a taking and placing device, wherein one side, close to a first threaded rod, of the cart is connected with a first guide rod, and the taking and placing device is fixed on one side of a binding device. According to the spraying instrument special for the waterproof heat preservation outer wall coating, a spraying device is arranged, the coating in a three-way pipe enters a hose through a conveying pipe, then enters a spraying head at one end through the hose and is sprayed out through a mist spraying opening in one side of the spraying head, a third threaded rod is rotated, the third threaded rod drives the spraying head to move in the direction of a second guide rod, the spraying head moves to extrude sealing gaskets on the two sides, pressure borne by the sealing gaskets is transmitted to a stopping block, the stopping block is stressed to extrude a third spring to enter a groove, the number of spraying nozzles blocked by the sealing gaskets is smaller and smaller, the number of spraying nozzles capable of being sprayed is larger and larger, the spraying area is increased due to the increase of the number of the spraying nozzles, and the spraying area is convenient to control.

Owner:于文琦

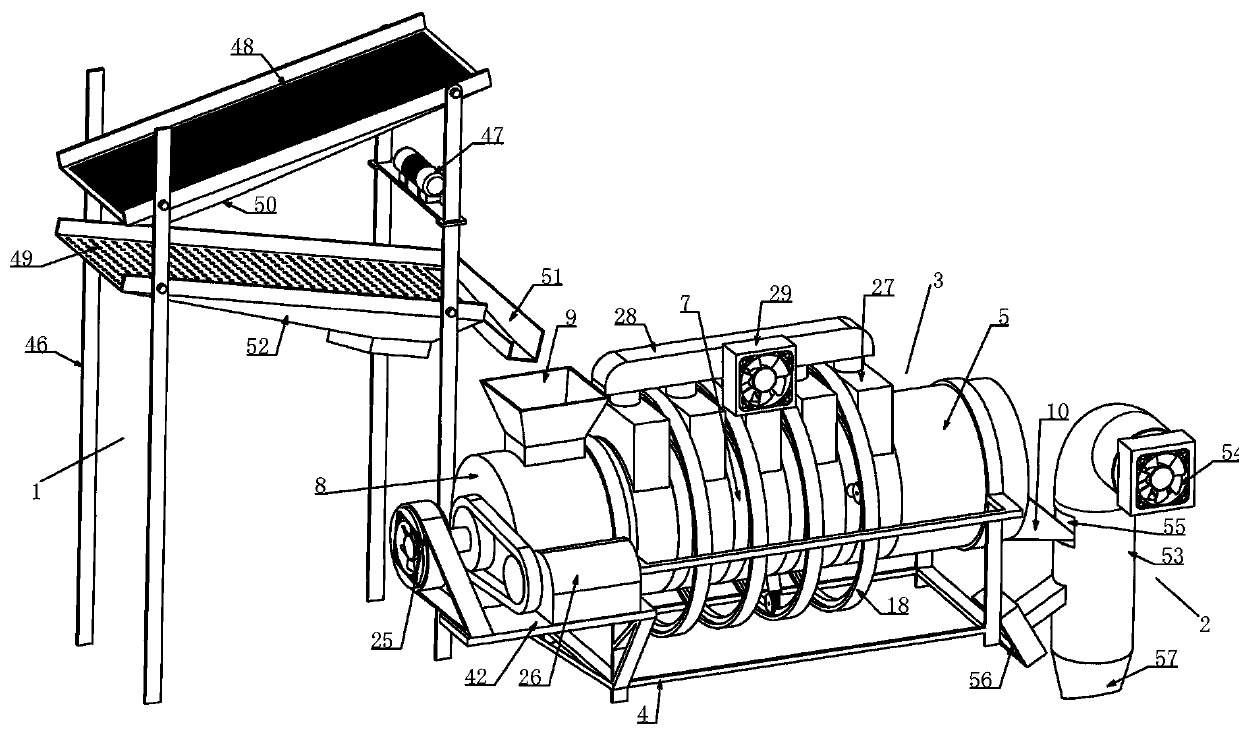

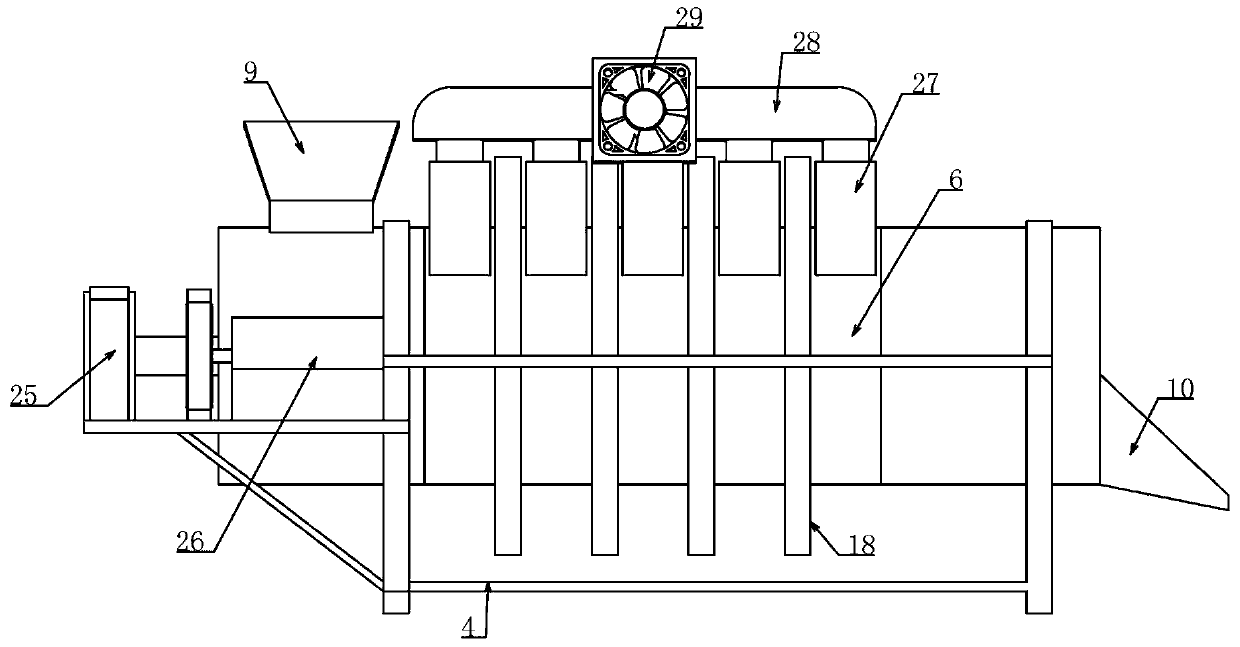

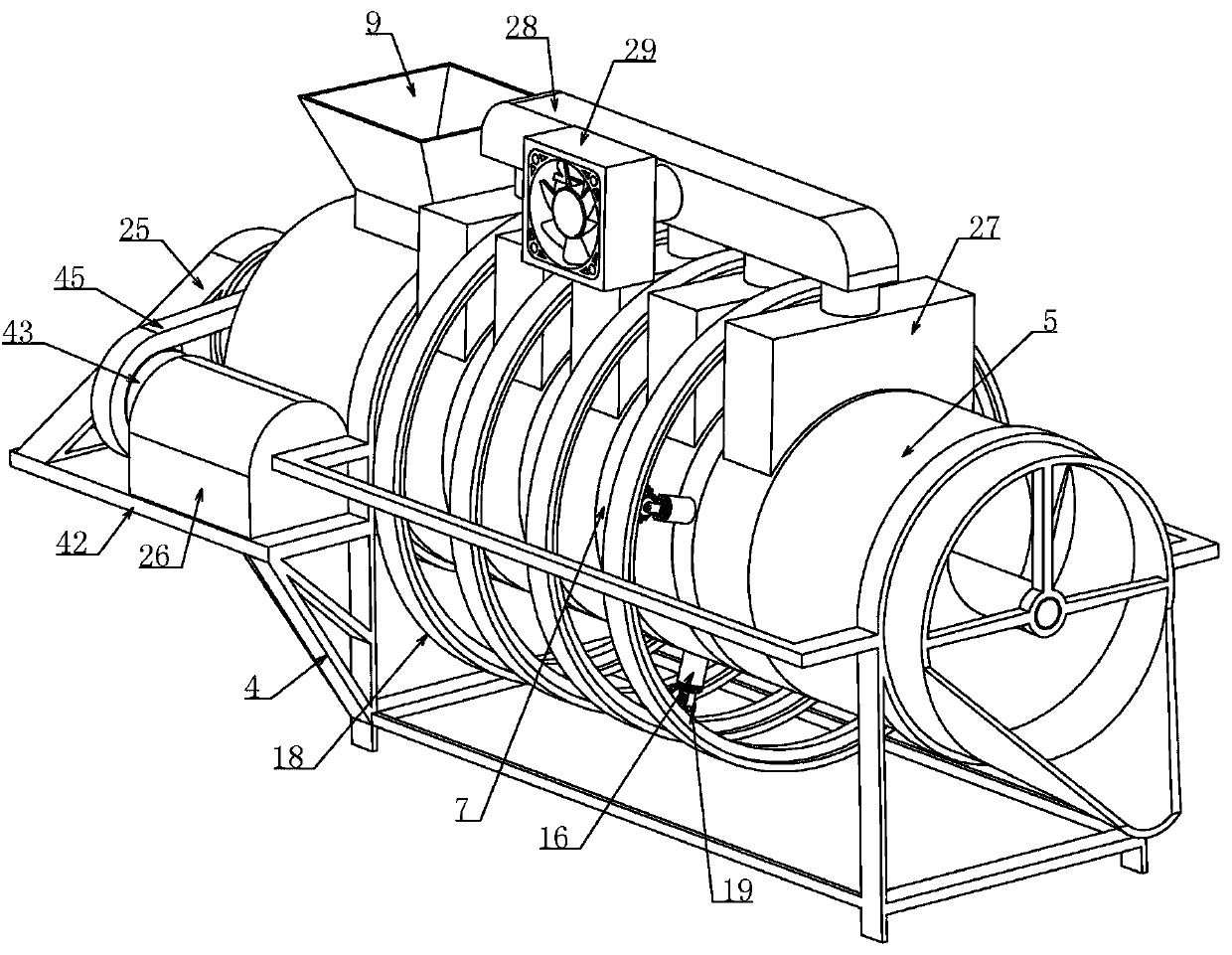

A dust removal and feeding device for a grain color sorter

ActiveCN110153010BDelivery does not affectBlown away in timeGas current separationSortingDust controlProcess engineering

The invention provides a dust removal and discharging device for a grain color sorter, and the problem that the color separation effect is not good due to the fact that dust exists on the surface of the grain when the grain enters the color sorter is effectively solved. According to the device, impurities in soybeans are removed through a vibration dust removal device, then the soybeans are cleaned through a conveying and cleaning device, due to the fact that conveying and wiping are simultaneously carried out, the conveying and wiping efficiency is high; a plurality of roller brushes are arranged along a conveying rod, so that the soybeans can be subjected to multi-stage wiping, the wiping effect is good, the roller brushes can rotate around the conveying rod and an extending rod, the roller brushes can rotate by oneself, rolling and wiping are carried out on the soybeans from a plurality of angles, air blowing and auxiliary wiping are simultaneously carried out in the wiping process,so that the wiping effect is better, the impurities on the soybeans can be timely blown away, the impurities are drawn out from an air collecting pipe at the upper part, the wiped beans are output from a discharging hopper at the outlet of a conveying cylinder to a wind power dust removal device, so that the cleaned impurities of the soybeans can be further cleaned.

Owner:FENGQIU YUFENG METAL PROD CO LTD

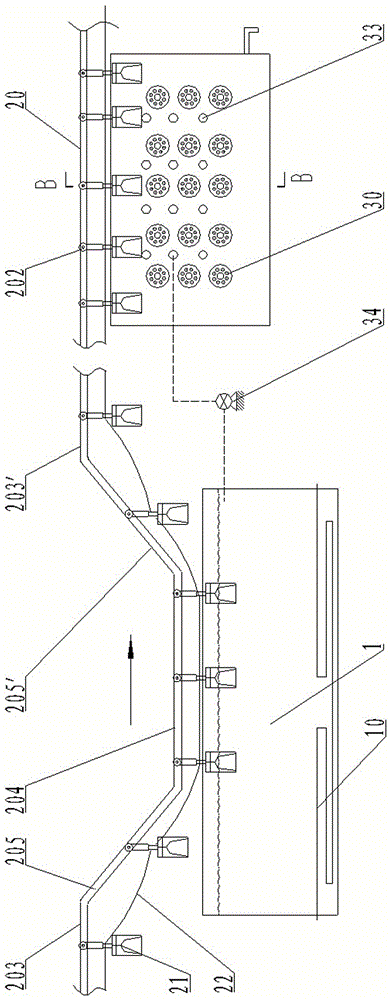

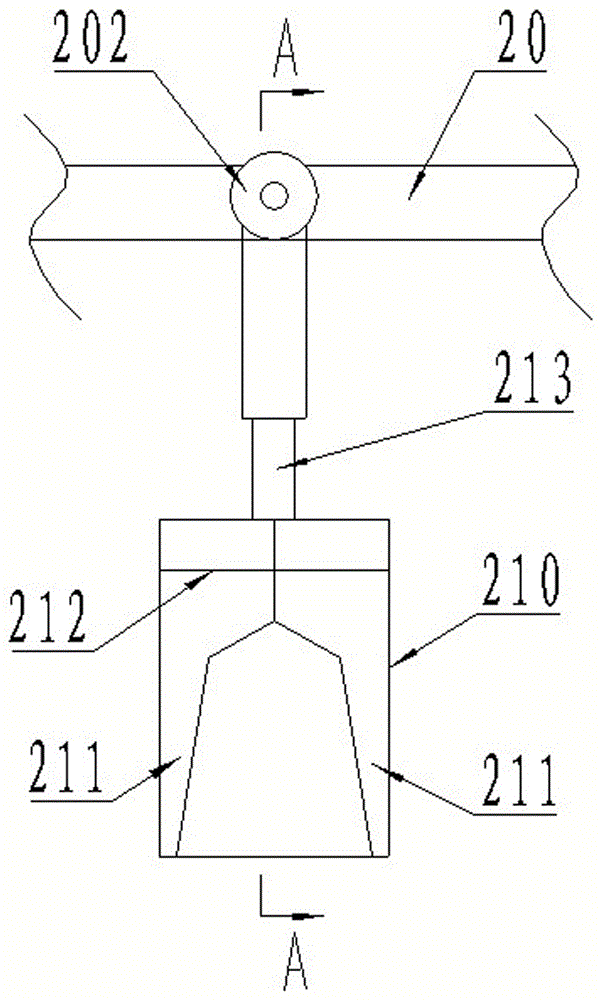

Special track conveying device for poultry processing assembly line

InactiveCN106305953AEasy to layDelivery does not affectPoultry transferring/conveying devicesEngineeringAssembly line

The invention provides a special track conveying device for a poultry processing assembly line. Slaughtered poultry meat can be conveyed, so that the device is high in track transfer rate and good in site adaptability. The special track conveying device comprises a track, a driving belt and a U-shaped hanging arm, wherein a plurality of poultry hangers are movably arranged on the track; the driving belt is used for driving the poultry hangers to move along the track; hanging shoulders are arranged at the bottom of the track in an extending manner; the U-shaped hanging arm is connected with a left pulley and a right pulley through hinge pins, and the left pulley and the right pulley are movably arranged on the hanging shoulders on two sides of the track; the poultry hangers hang at the bottom of the U-shaped hanging arm through hook rails; the track is partially bent downwards to form a low track; the track is partially bent horizontally to form a turning track; and the driving belt is configured to be an iron chain consisting of a plurality of chain links.

Owner:安徽省怀宁县尚寅禽业开发有限责任公司

Product classifying device

The invention discloses a product classifying device, and belongs to the field of product conveying equipment. The device comprises a vision system, an upper conveying mechanism and a lower conveying mechanism; a product separating mechanism used for pushing products to be classified to be separated from the upper conveying mechanism downwards is arranged on the upper side of the upper conveying mechanism, the lower conveying mechanism is located below the upper conveying mechanism, a buffer mechanism is arranged between the upper conveying mechanism and the lower conveying mechanism, the upper conveying mechanism comprises two oppositely-arranged upper conveying belts (7), the products to be classified are clamped between the two upper conveying belts (7), and the vision system and the product separating mechanism are both connected to a control system. The vision system is used for automatically identifying the products to be classified, work efficiency is improved, the buffer mechanism effectively prevents the products from being damaged in the falling process, and the yield is improved.

Owner:山东爱而生智能科技有限公司

Detecting and selective discharging conveying device for injection molded parts of notebook computer shell

The invention discloses a detecting and selective discharging conveying device for injection molded parts of a notebook computer shell, comprising a conveying track, a base and a detection device, wherein the base is located at the bottom of the right side of the conveying track; the detection device is located at the top of the left side of the conveying track; the top of the base is fixedly connected with a lifting platform; the top of the lifting platform is fixedly connected with two sets of guide bars; the top of the conveying track is movably connected with a plurality of chain plate frames; each chain plate frame comprises a connecting frame and a shelf, wherein the inner wall of the chain plate frame is provided with two sets of guide rails, moving blocks are movably connected to the guide rails, two sets of object tables are rotatably connected between the moving blocks through a rotating shaft, and the bottoms of the left sides of the object tables are fixedly provided with clamping wheels; and two sides of the conveying track are fixedly connected with guide slides. The detecting and selective discharging conveying device can automatically detect and selectively discharge the products in the conveying process, collect the unqualified products, and improve the working efficiency and the product quality.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

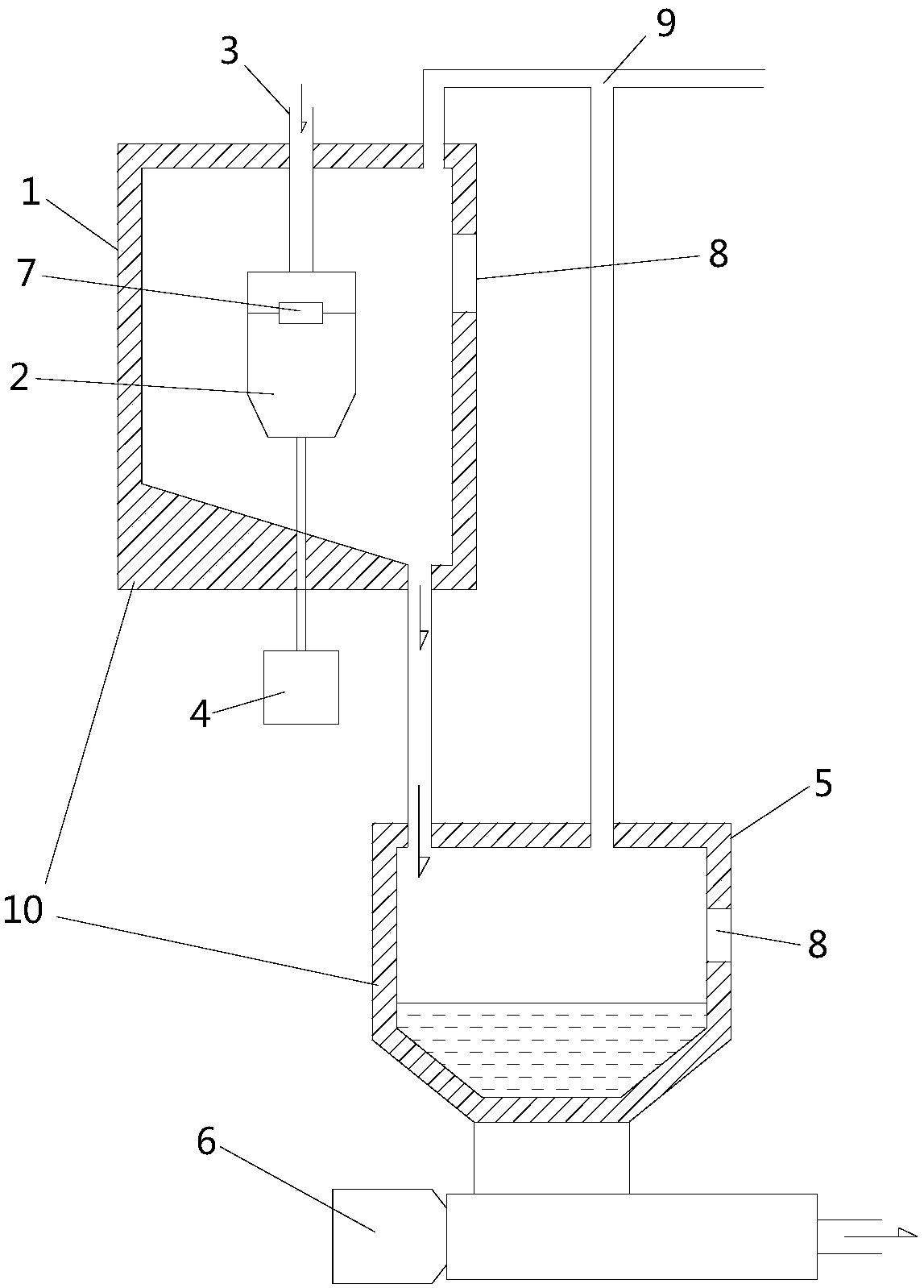

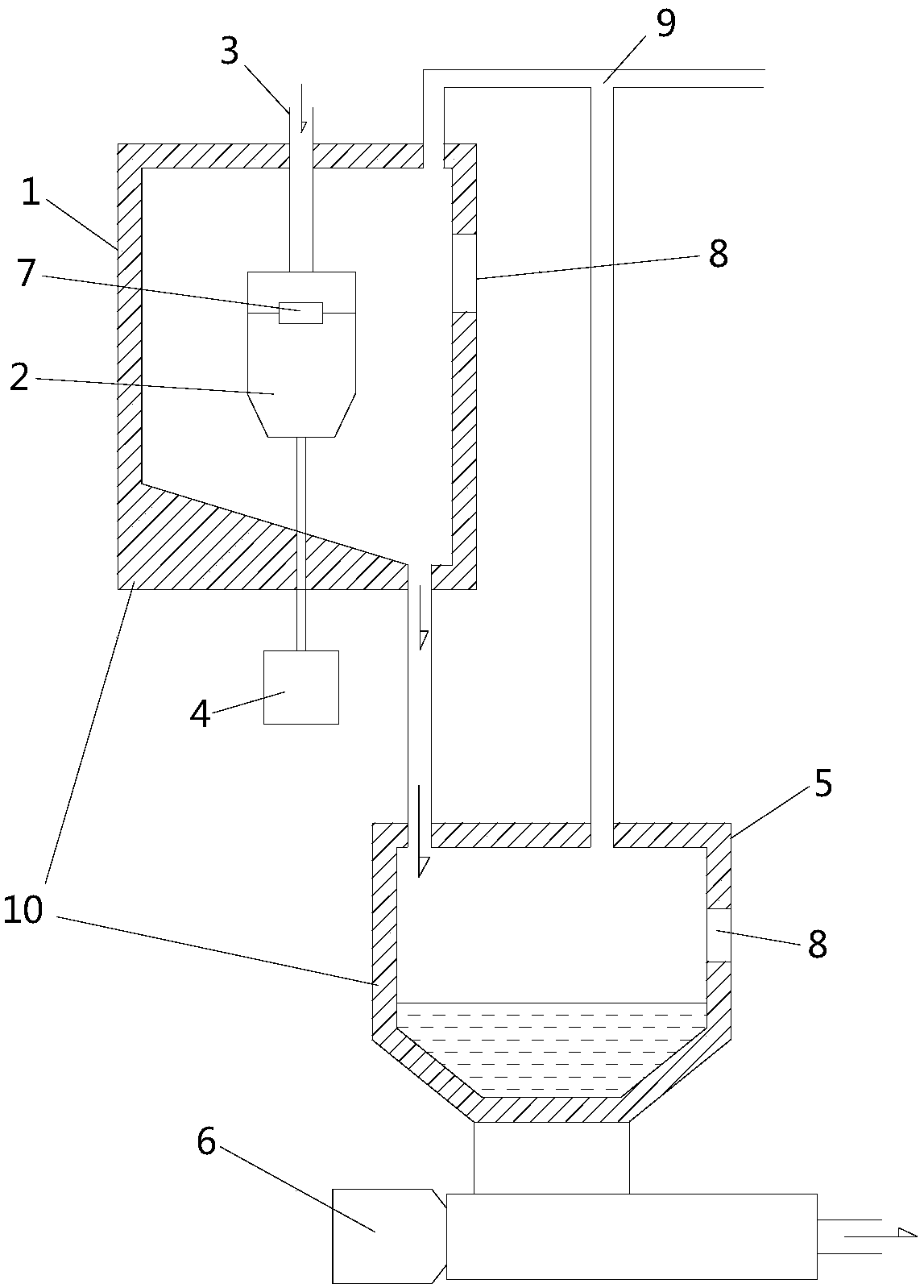

Fluidized bed photocatalytic reactor-based advanced oxidation equipment

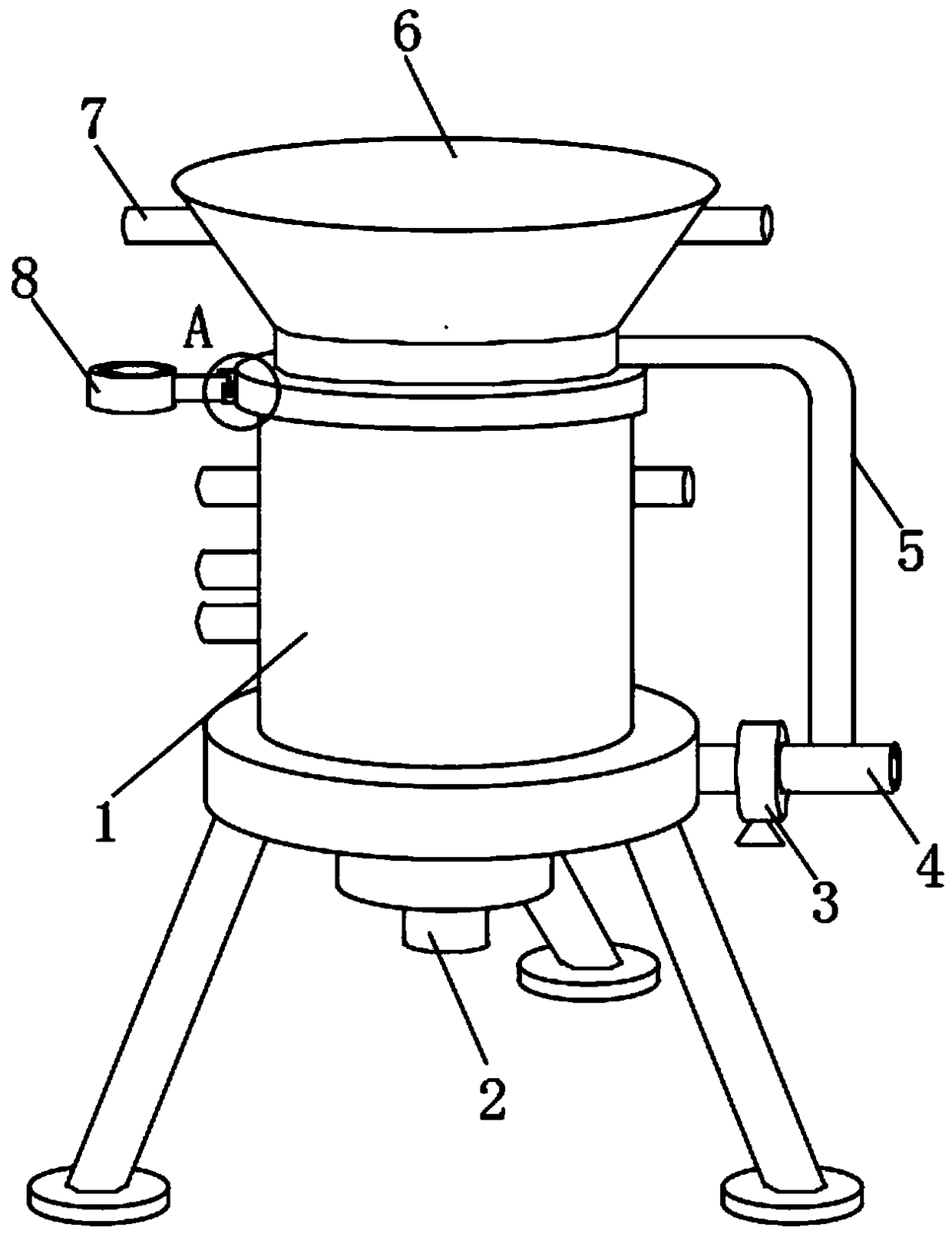

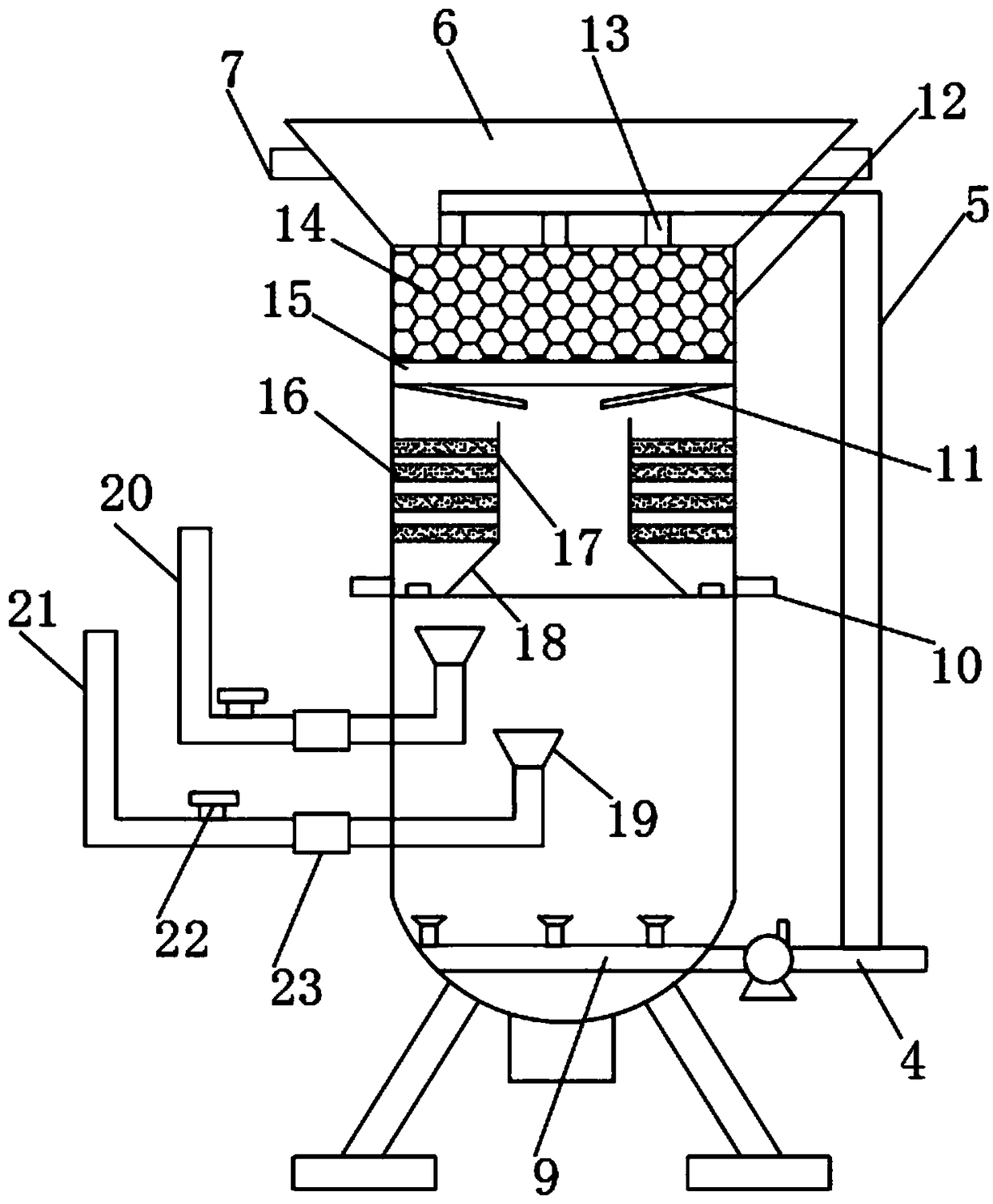

ActiveCN109437367AImprove efficiencyImprove reaction efficiencyWater/sewage treatment by irradiationWater treatment compoundsPipingFenton reaction

The invention discloses fluidized bed photocatalytic reactor-based advanced oxidation equipment which comprises a tank body, a liquid storage tank and a liquid discharging pipe, wherein the top of anannular pipe is uniformly connected with a plurality of material outlet heads; one side of the middle part of the annular pipe is connected with a water inlet pipe; one side of the lower part of the tank body is connected with a hydrogen peroxide pipeline and an ozone pipeline; the middle end of the inside of the tank body is longitudinally connected with a water flow channel; a plurality of ultraviolet lamp tubes are uniformly mounted between the outside of the water flow channel and the middle end of the inside of the tank body; an ozone catalytic oxidation filler layer is mounted inside a loading barrel; one side of the upper part of the tank body is connected with a backflow pipe; the bottom of the backflow pipe is connected with the water inlet pipe. The device reduces introduction ofexternal chemical substances, reduces the operation cost and improves the reaction efficiency; based on chemical Fenton reaction, the fluidized bed photocatalytic reactor-based advanced oxidation equipment has internal and external backflow circulations, so that a good flowing state guarantees the reaction efficiency and no short flow and no dead zones; by adoption of a vertical type reactor, theequipment occupies a small space.

Owner:广东智环创新环境科技有限公司

Charging device

InactiveCN107863799AEasy accessStable deliveryCharging stationsMobile unit charging stationsEngineeringElectrical and Electronics engineering

The invention discloses a charging device which is used for matching the battery of which the electrode posts are outwardly convex and the positive and negative electrode posts are arranged at the same side. The charging device comprises a shell which is provided with an inlet and an outlet. The shell is internally provided with a first conveying device. The conveying surface of the first conveying device is provided with multiple first carrying plates in a spaced way. The first carrying plates are installed on the first conveying device through first telescopic members. The first telescopic members can drive the first carrying plates to stretch and contract. Charging members are arranged in the stretching direction of the first telescopic members. The charging members are arranged on theshell, and one side, which faces the first telescopic members, of each charging member is provided with a charging part. The charging part is connected with the positive and negative electrode posts of the battery on each first carrying plate. One side, which faces the charging member, of each first carrying plate is provided with a limiting baffle plate protruding out of the carrying surface. Theshell is also internally provided with a first push member. The first push member is arranged on the opposite side of the outlet and exactly faces the outlet. The first push member has a telescopic function. Replacing and charging of the battery can be realized.

Owner:罗昌兴

A washing machine with partial pre-washing function

ActiveCN110528223BGuaranteed integrityAvoid getting in the wayVibration washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention discloses a washing machine with a partial pre-washing function. The washing machine includes an ultrasonic cleaning device; the washing machine has an accommodating space for the ultrasonic cleaning device, and the ultrasonic cleaning device can be screwed in / out. in the accommodation space. The whole set of ultrasonic washing device is embedded in the washing machine and assembled with the washing machine as a whole, which does not affect the normal washing, but also adds a partial pre-washing function to the washing machine; the invention uses the cavitation effect of ultrasonic waves to send high-frequency waves locally to the initially wet clothes Ultrasonic waves emulsify oil stains and other stains under the action of the sound field, so that solid ions can be separated from the clothes, realize surface purification, and remove local stubborn stains to realize the partial pre-washing function of clothes.

Owner:HEFEI HAIER WASHING MACHINE +1

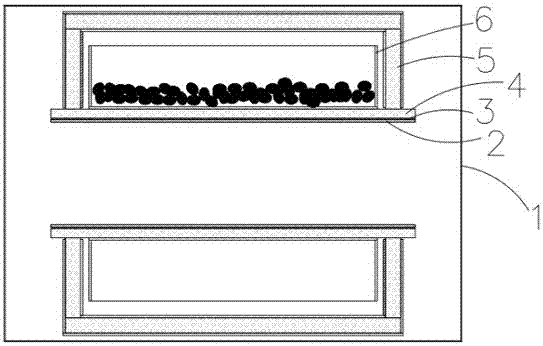

Chain Conveyor

ActiveCN105438722BReduce breakage rateReduce labor intensityConveyorsPackagingChain conveyorSprocket

The invention provides a chain scraper conveyor. The chain scraper conveyor comprises an outer hood, a first conveying chain wheel, a second conveying chain wheel and a conveying chain, wherein the first conveying chain wheel and the second conveying chain wheel are rotatably arranged in the outer hood, the conveying chain is annularly arranged and matched with the first conveying chain wheel and the second conveying chain wheel, and a plurality of conveying chain scrapers are fixedly arranged on the conveying chain and evenly distributed in the length direction of the conveying chain; flexible heat insulating cushion plates are fixedly arranged on the conveying chain scrapers, a plurality of heat insulating plates are fixedly arranged on the heat insulating cushion plates and matched with the conveying chain scrapers in size, and a heat insulating sealing cover is fixedly arranged above the heat insulating plates; a hopper is fixedly arranged above the heat insulating plates and located in a heat insulating sealing cavity formed by the heat insulating plates and the heat insulating sealing cover. The manufacturing cost is low, and the chain scraper conveyor can conveniently convey high-temperature inflammable materials.

Owner:江阴市创裕机械有限公司

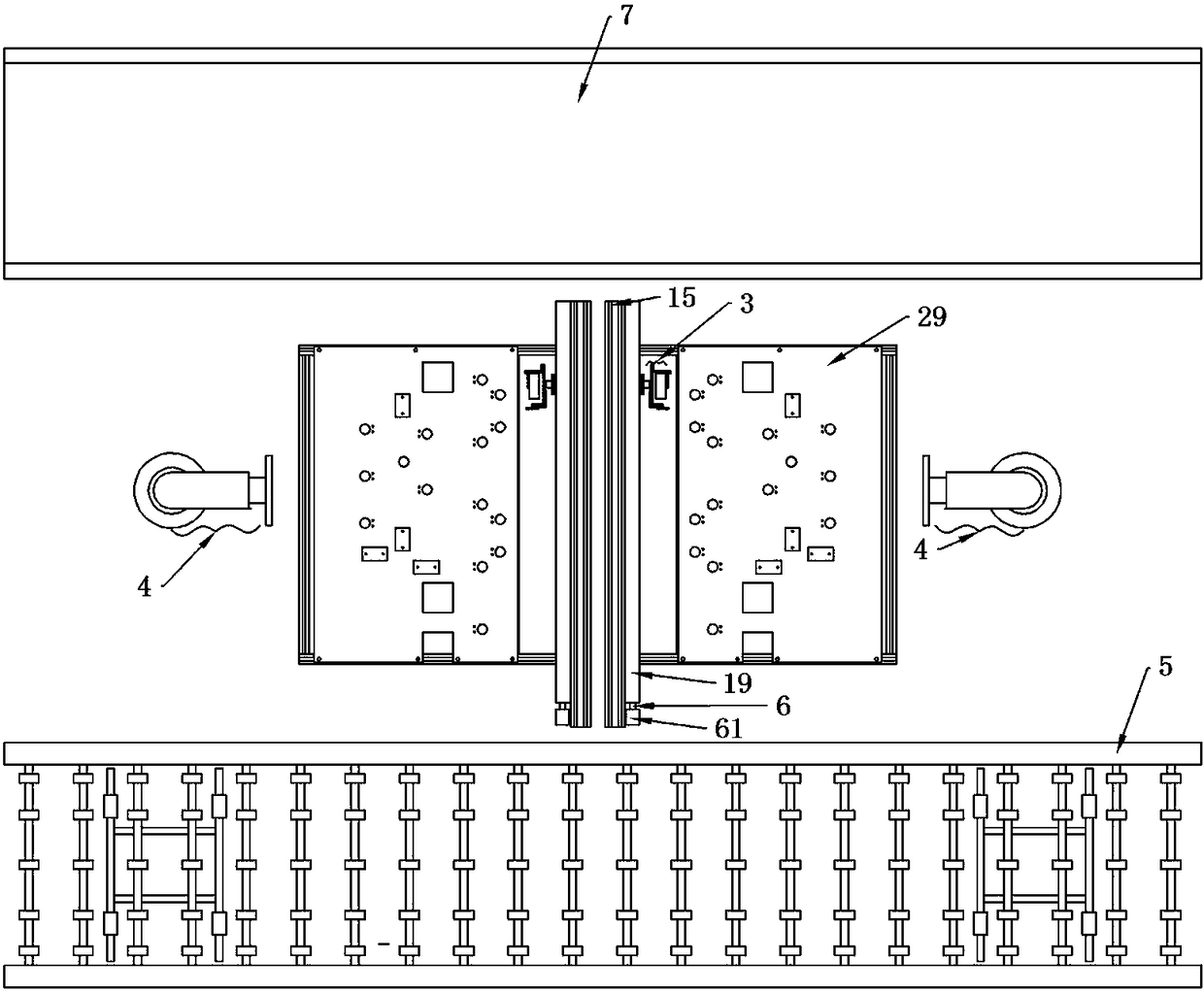

Single line conveying automatic glue dispensing production line

PendingCN109013206ADelivery does not affectImprove work efficiencyPretreated surfacesCoatingsProduction lineHydraulic cylinder

The invention discloses a single line conveying automatic glue dispensing production line. On the single line conveying automatic glue dispensing production line, glass plates on a loading conveying frame are continuously conveyed from the right to the left; when the first glass plate is conveyed to the position of a lifting frame on the right side, the lifting frame rises under the driving of a hydraulic cylinder, the lifting frame lifts the glass plate, and a conveying robot on the right side takes out the glass plate on the lifting frame and transfers the glass plate to a glue dispensing carrying platform to be coated with glue; rectangular frames extending outside are arranged at the middle parts of vertical rods above U-shaped frames; the internal sides of the rectangular frames are open; the two rectangular frames are oppositely arranged to form a glass plate passage; when the lifting frame on the right side lifts upwards, the glass plate can pass through the glass plate passagewithout affecting the conveying of the glass plate; and a lifting frame on the left side rises when the glass plate reaches a position above the lifting frame on the left side. The two conveying robots alternately work so that the working efficiency is high.

Owner:河南天扬光电科技有限公司

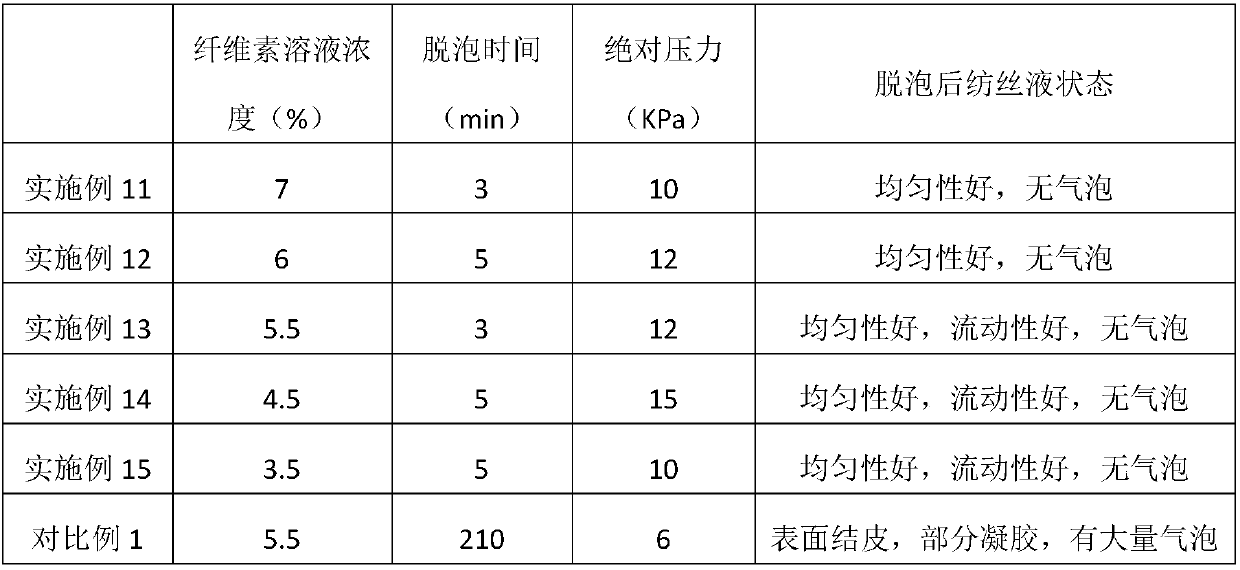

Defoaming device for cellulose solution, and defoaming method of defoaming device

PendingCN109957844AAvoid destructionImprove defoaming efficiencySpinning solution filteringCelluloseEngineering

The invention discloses a defoaming device for a cellulose solution, and a defoaming method of the defoaming device. The defoaming device comprises an outer barrel, a material barrel, a speed regulation device, a liquid inlet pipe and a material storage device, wherein the outer barrel is configured into a main body of the defoaming device; a liquid outlet is formed in the bottom of the outer barrel; the material barrel is arranged in the outer barrel and is provided with a through hole; the speed regulation device is used for driving the material barrel to make centrifugal movement; the liquid inlet pipe passes through the outer barrel and feeds a solution into the material barrel; the material storage device is communicated with the liquid outlet formed in the bottom of the outer barrel,and is arranged at the position lower than the outer barrel; a discharge device is arranged at the bottom of the material storage device. The defoaming device, which is simple in structure and easy to operate, for the cellulose solution has the characteristics of being high in defoaming efficiency, realizing continuous defoaming, and guaranteeing the continuous proceeding of the subsequent spinning; material conveying is not affected by a defoaming process, and efficient defoaming and continuous production are carried out at the same time; furthermore, the defoaming method is good in effect;the defoaming device for the cellulose solution can be used for producing a spinning solution with good stability and evenness, and does not produce gel.

Owner:CHINESE TEXTILE ACAD

A sorting mechanism with adjustable size

Owner:山东爱而生智能科技有限公司

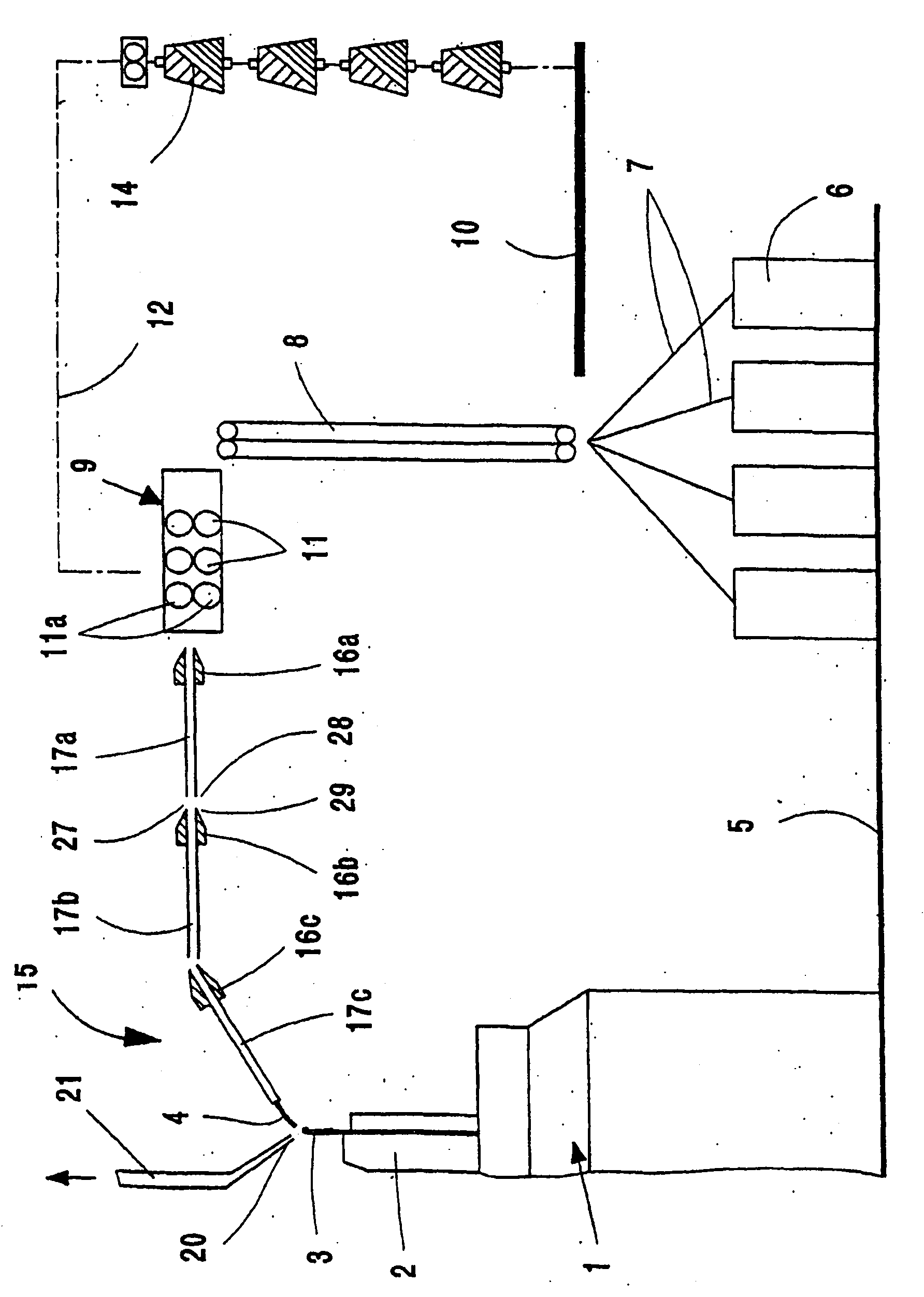

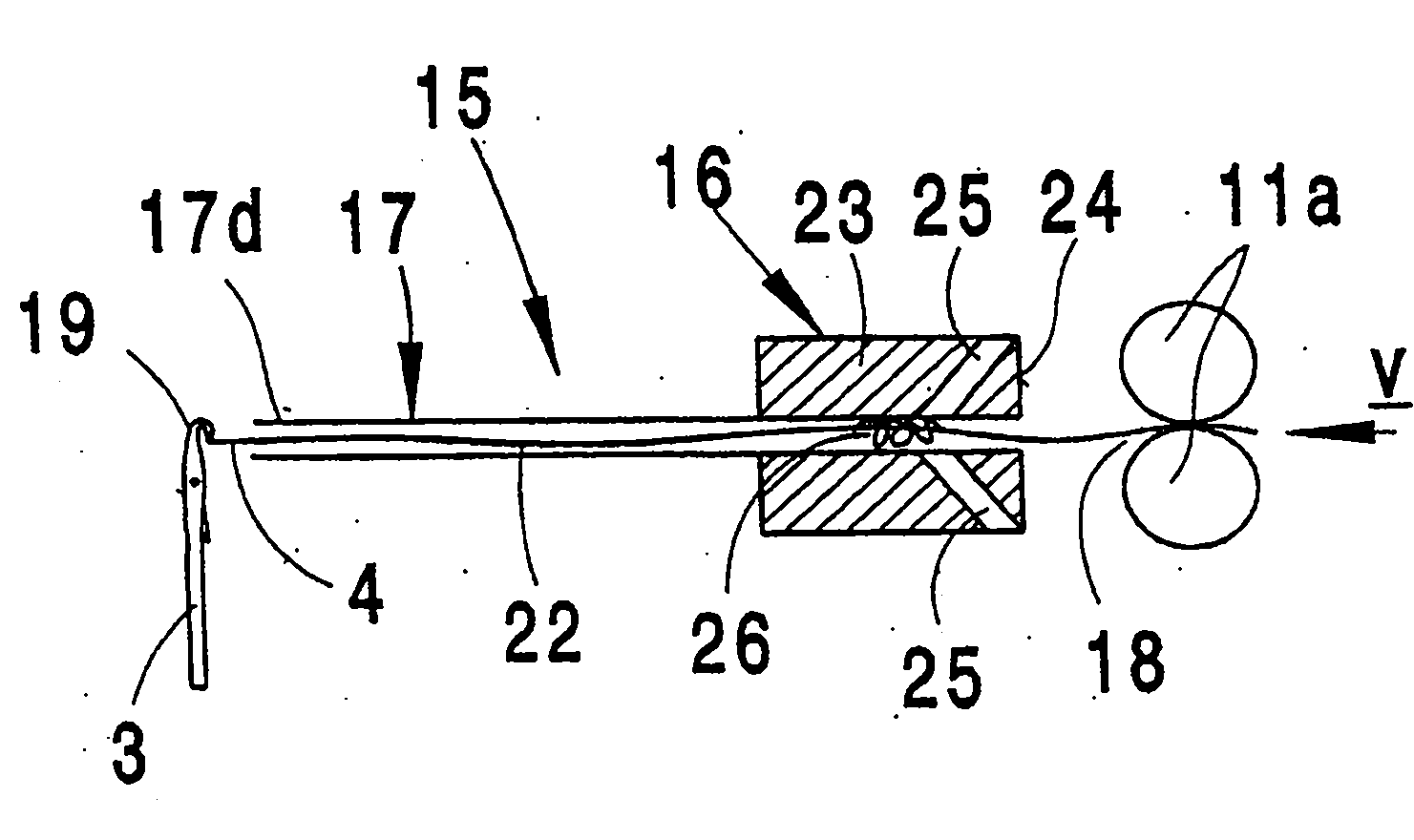

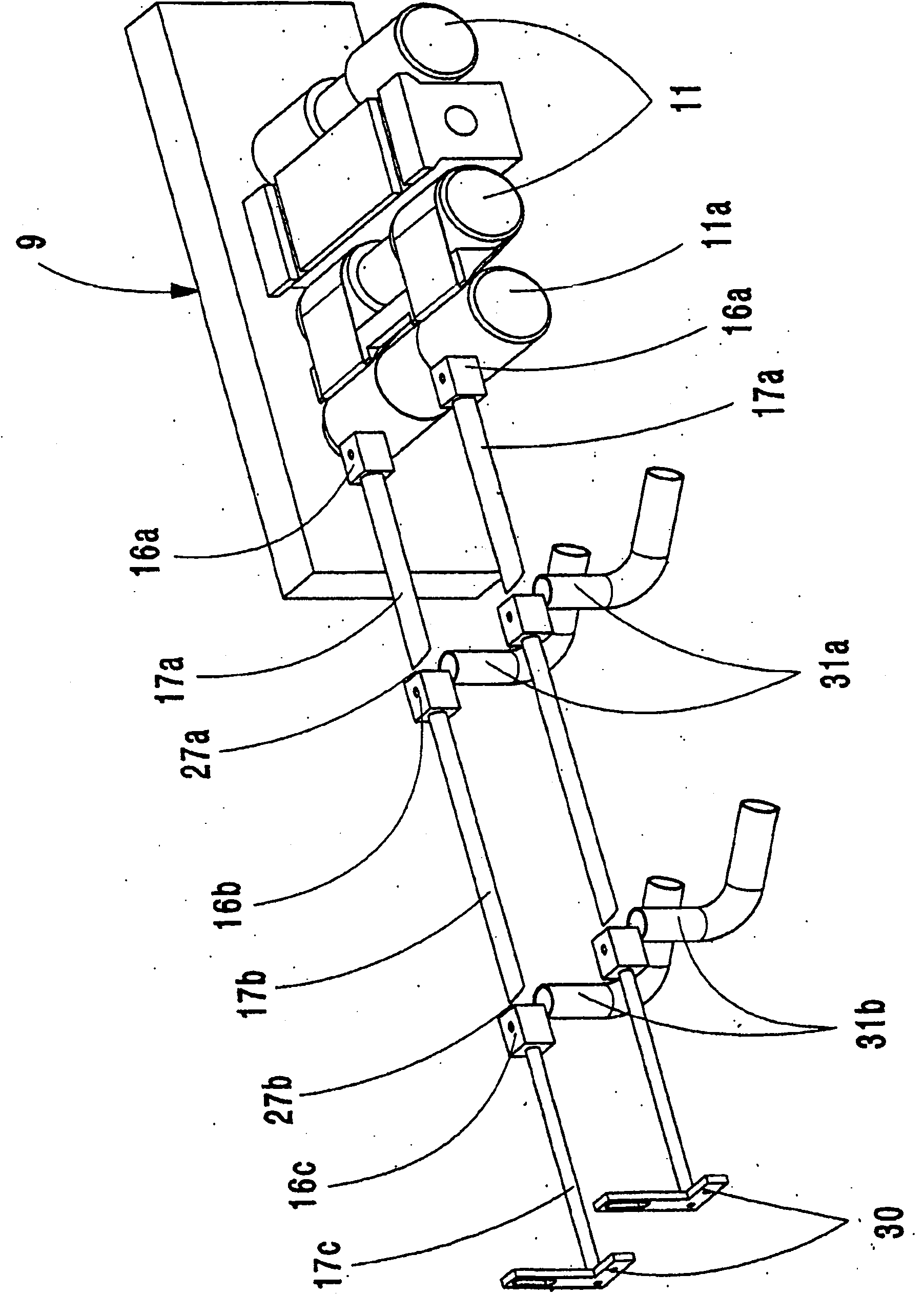

Apparatus for transporting fibre material between a drafting arrangement and a mesh-forming machine, and circular knitting machine equipped with said apparatus

InactiveCN101809214BEasy to cleanCleaning does not affectContinuous wound-up machinesCircular knitting machinesStructural engineeringMechanical engineering

A device for transporting fibre material between a drawing frame and a loop-forming machine is described. The device contains at least two transport units which are disposed in succession and have respectively one inlet- and outlet opening, said transport units being formed from respectively one twisting member (16a, 16b, 16c) and one transport pipe (17a, 17b, 17c) connected thereto, there being provided between an outlet end (28) of a preceding transport unit (16a, 17a) and the inlet end of a subsequent transport unit (16b, 17b) a gap (27a, 27b) which is intended for forming an air removal opening. According to the invention, a suction device (31a, 31b) is disposed in the region of this gap (27a, 27b) (FIG. 4).

Owner:SIPRA PATENTENTWICKLUNGS & BET GMBH

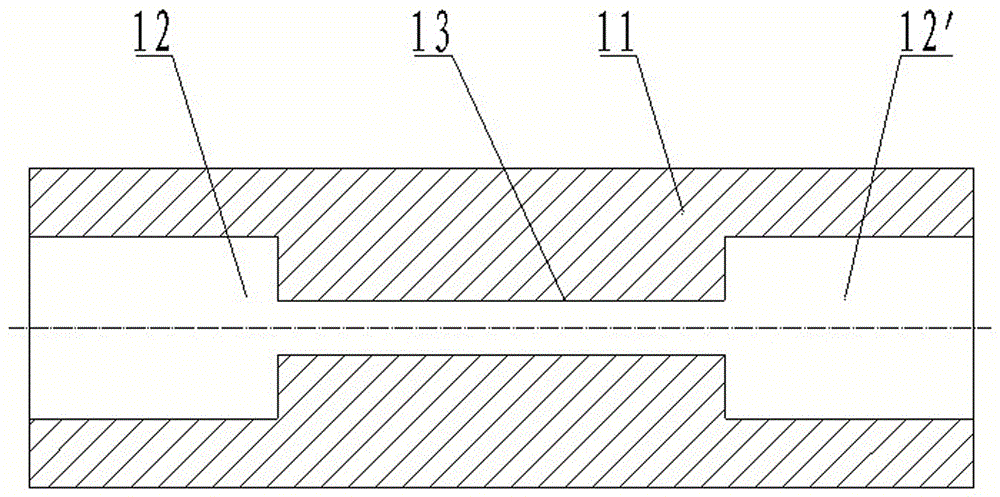

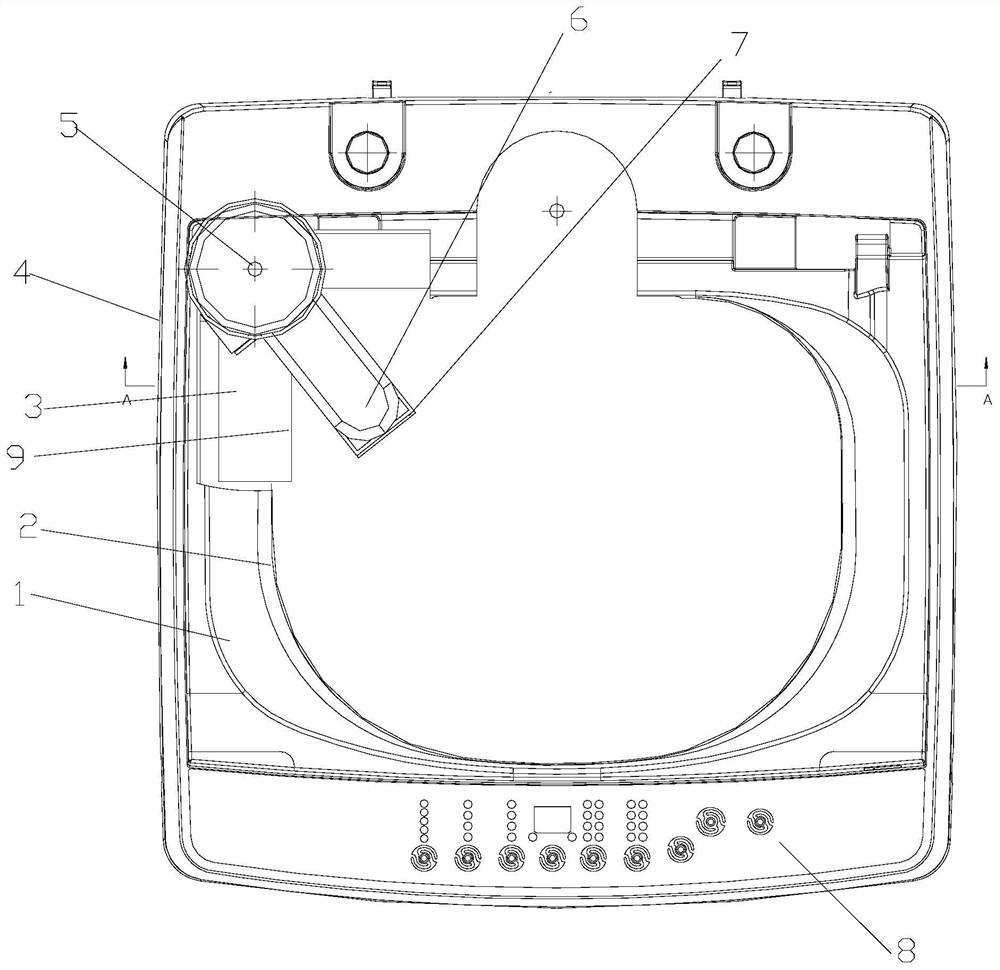

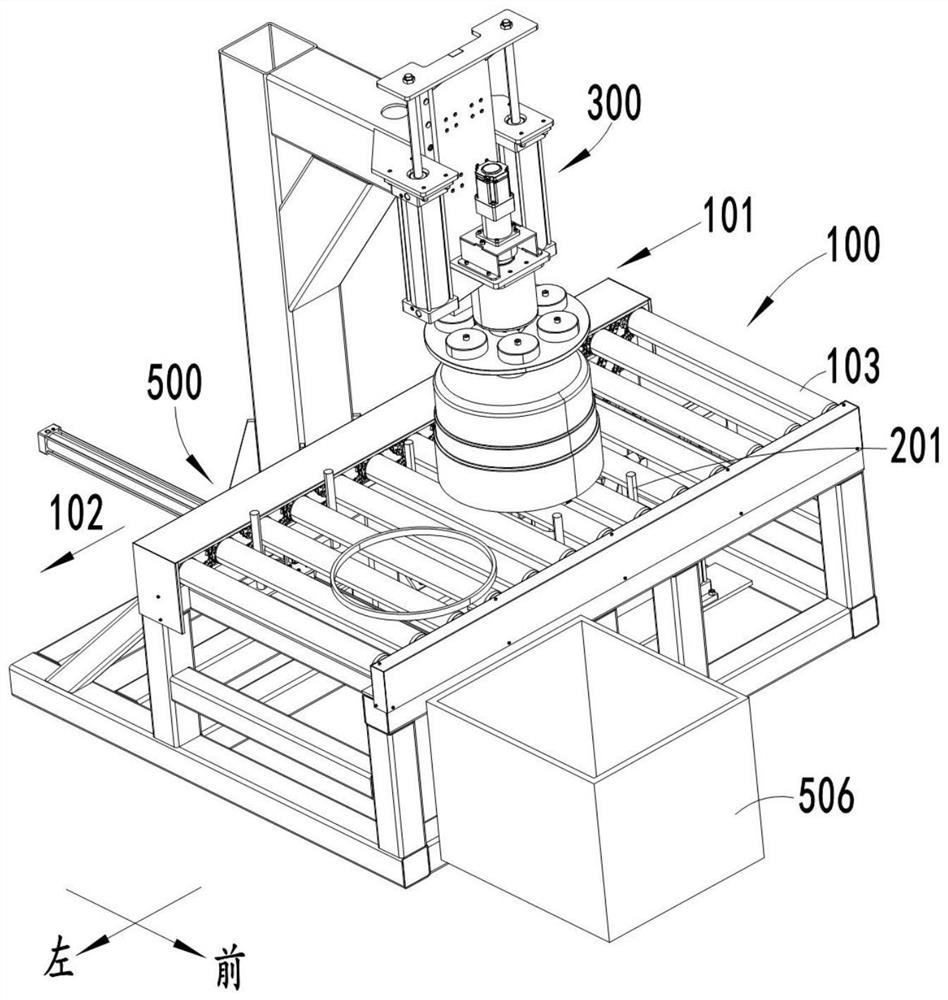

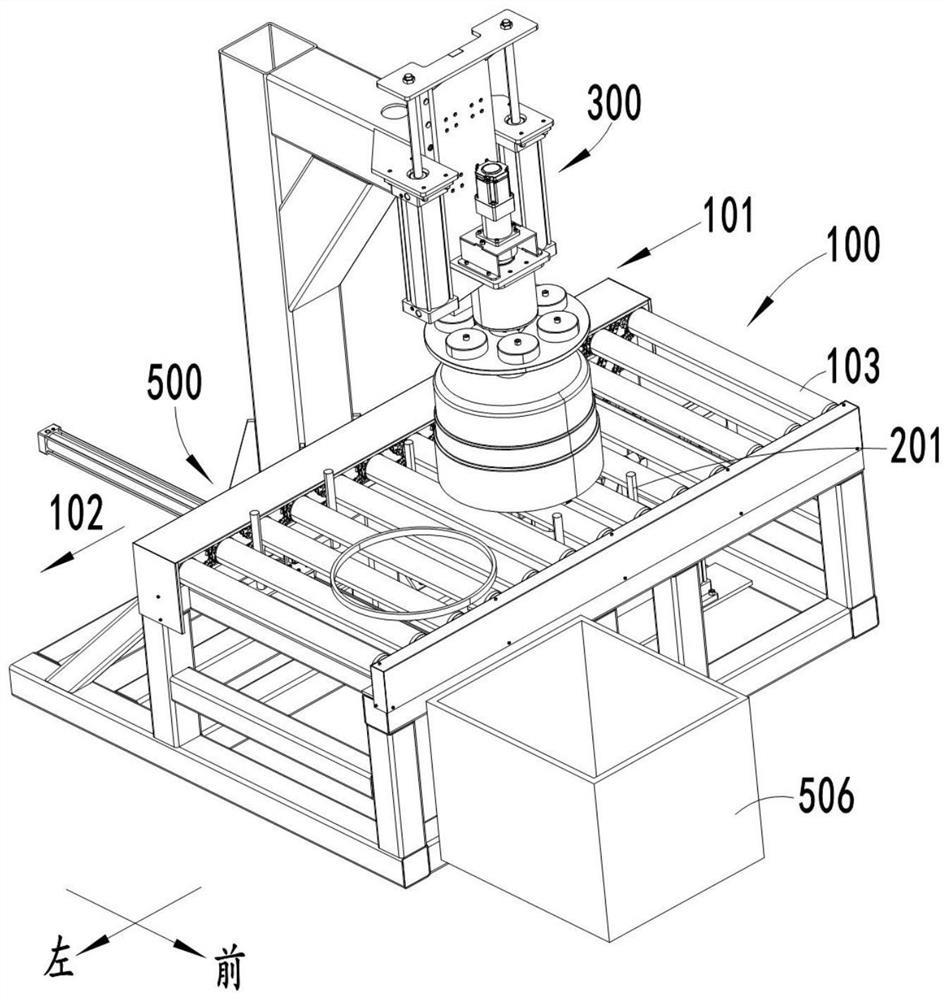

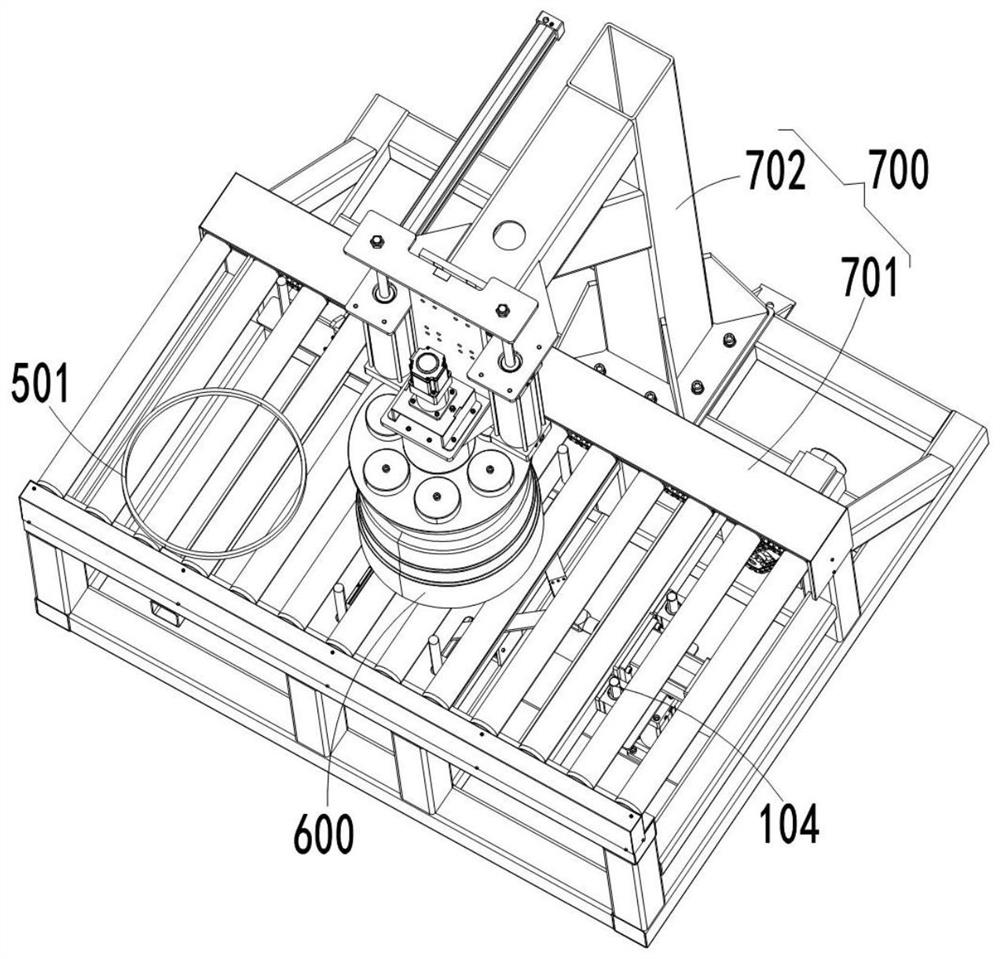

Hub and barrel-shaped workpiece edge cutting equipment and processing method

ActiveCN113275797ASmall footprintNot easy to cause pollutionWelding/cutting auxillary devicesAuxillary welding devicesControl cellCentre of rotation

The invention relates to the technical field of workpiece cutting, in particular to hub and barrel-shaped workpiece edge cutting equipment and a processing method. The cutting equipment comprises a control unit as well as a conveying unit, a positioning unit, a clamping rotating unit and a cutting unit, wherein the positioning unit is provided with a closed state and an open state; when the positioning unit is in the closed state, a workpiece is clamped until the center of the workpiece is coaxial with a rotation center of the clamping rotating unit; when the positioning unit is in the open state, a movable space is formed in the positioning unit; when the control unit is configured to ascend to the cutting position and cut the workpiece when the positioning unit is switched to the open state. The positioning unit in the embodiment of the invention is closed to clamp the workpiece, and is opened; the cutting unit ascends to the cutting position and is matched with the clamping rotating unit for directly cutting the workpiece, so that processing efficiency is not affected by processing margin, and processing efficiency is obviously improved; and cutting liquid is not used in a processing process, so that environmental pollution is not easily caused.

Owner:德州西恩数控设备股份有限公司

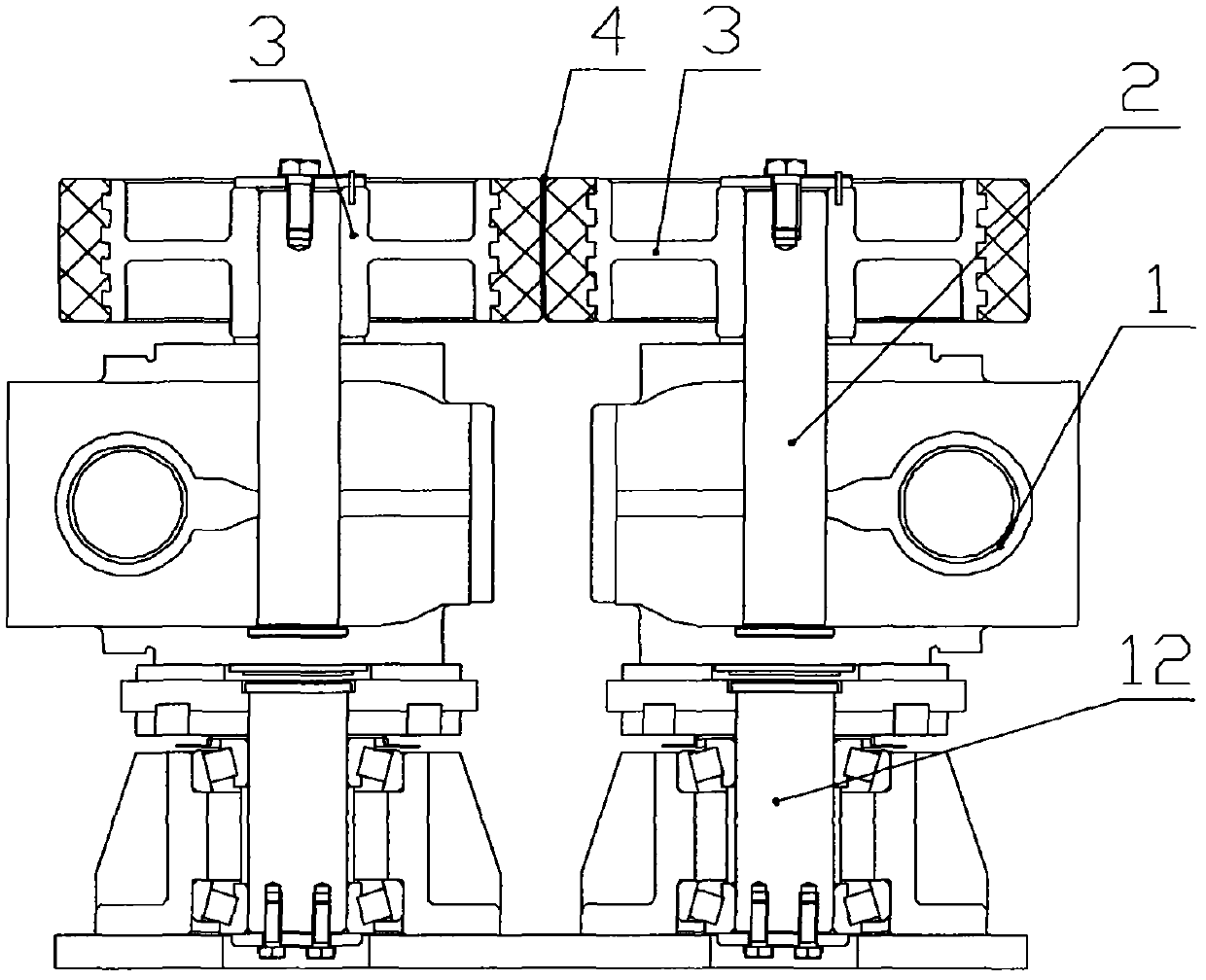

single wheel drive

The single-wheel driving device is characterized in that the base of the motor and the base of the driven friction wheel are connected on the steel structure by using the base shaft and the bearing, and the spring pressing device connects the base of the motor and the base of the driven wheel, and the center of the base shaft and the drive shaft of the motor Not in a straight line, there is a double-sided friction plate on the trolley driven by the single-wheel drive device, the double-sided friction plate can be inserted into the gap, the thickness of the friction plate is slightly greater than the width of the gap, the friction surface of the friction plate is in contact with the driving wheel or from the The friction force between the moving wheels is adjusted by a spring compression device. Advantages: 1. The conveying line carries the workpiece mainly by the track, and the driving device only provides friction; 2. The operation station of the conveying line can be stopped without affecting the transportation of other stations; 3. The friction force is easy to adjust, and the friction wheel can be replaced and maintained Convenience; 4. There are two floors on the conveyor line, which is convenient for automatic production; 5. It is convenient to use the rotary table to change the line and occupy a small space.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

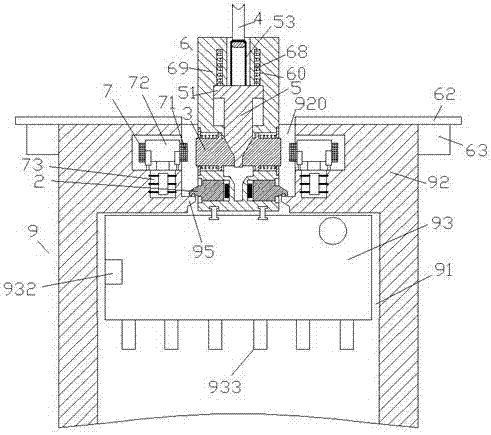

Municipal garden and park nursery stock fertilizer application apparatus

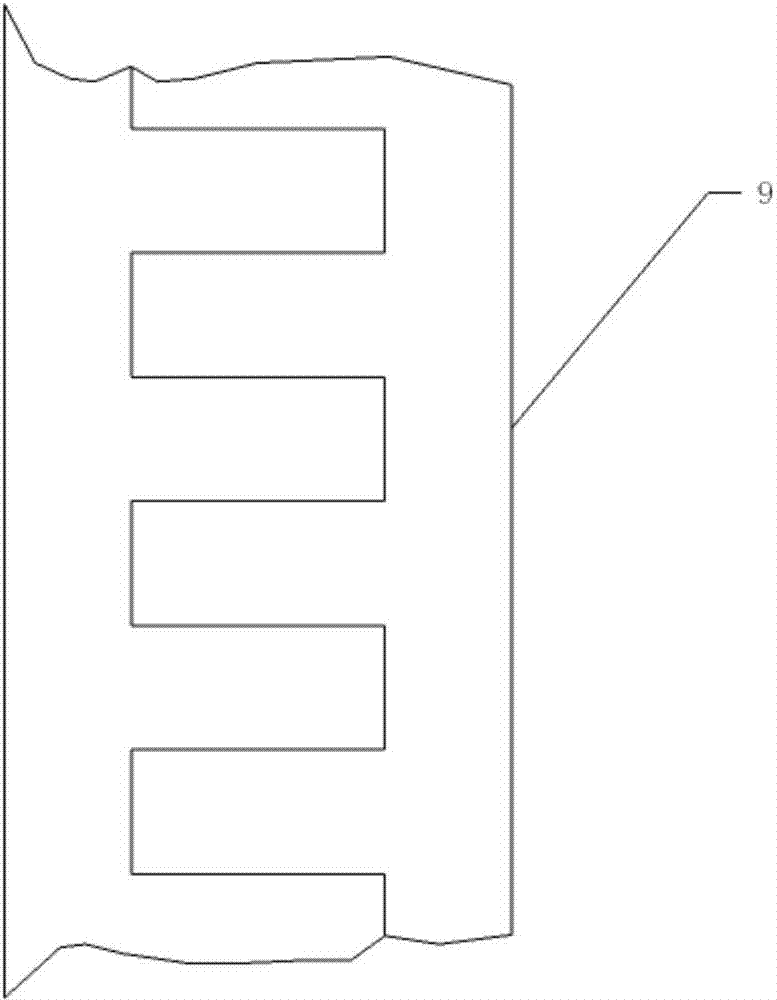

InactiveCN107241950ADelivery does not affectFast deliveryFertiliser distributersEngineeringControl switch

A municipal garden nursery stock fertilization device, comprising a frame (9) and a movable suspension assembly (6), the frame (9) including a walking cavity (91) and a support arm located above the walking cavity (91) (92), the bottom of the movable suspension assembly (6) is fixedly connected to the fertilizer loading box (93) located in the walking cavity (91) and can be placed in the middle channel (920) of the support arm (92) During the middle movement, more than six fertilizer outlets (933) are evenly arranged on the bottom of the fertilizer loading box (93), and an outlet control switch (932) is arranged on the left side of the fertilizer loading box (93), wherein, the The movable suspension assembly (6) includes a base body (69), and telescopic supports (2) that are elastically telescopic and slidable and front and rear drive connectors (3) symmetrically arranged on both sides of the base body (69).

Owner:邹长湾

Sealing mechanism

PendingCN110978638AAvoid breakingQuality improvementBag making operationsPaper-makingCooling effectEngineering

The invention discloses a sealing mechanism which comprises a sealing and cutting device and a conveying device. The sealing mechanism is characterized in that a seal cooling device is arranged in front of the sealing and cutting device, and the seal cooling device comprises an upper cooling plate; the conveying device comprises an upper conveyor belt and a lower conveyor belt, the upper conveyorbelt and the lower conveyor belt are arranged in front of the sealing and cutting device, and the upper cooling plate is arranged on a conveying path of the upper conveyor belt. The upper cooling plate cools a sealed part, so that the sealing part of a bag body is cooled quickly and kept level. A cooled sealing line is not adhered to the bag body, so that the bag body is prevented from being damaged during use, and therefore, the quality of the bag body is improved. The upper cooling plate is arranged on the conveying path of the upper conveyor belt, so that conveyance of the bag body is not affected and the cooling effect is also achieved.

Owner:浙江超伟机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com