Apparatus for transporting fibre material between a drafting arrangement and a mesh-forming machine, and circular knitting machine equipped with said apparatus

A technology of conveying device and drafting device, which is applied to the circular knitting machine for weft knitting, knitting, weft knitting, etc. with individual moving needles, and can solve the problems of hindering work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

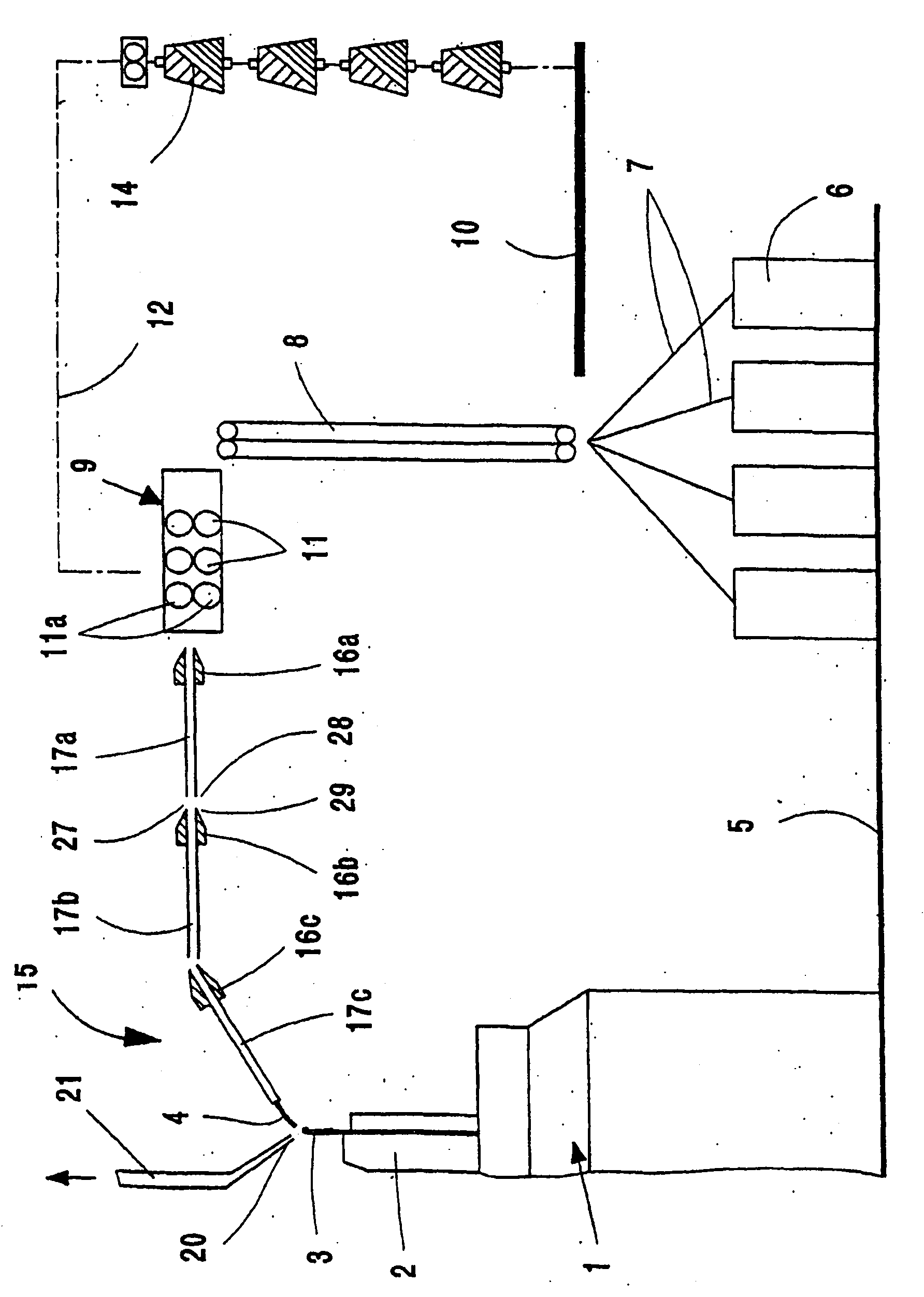

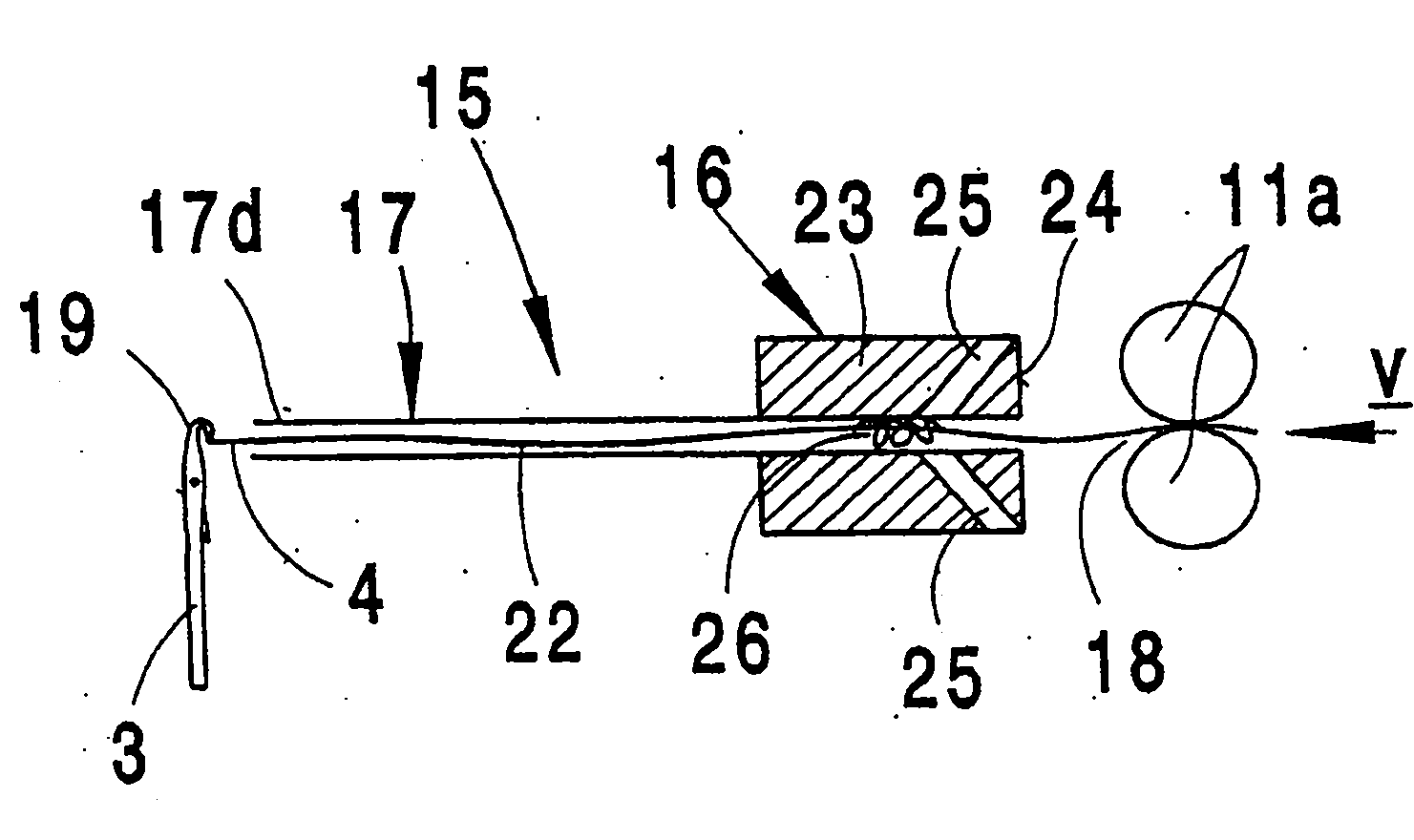

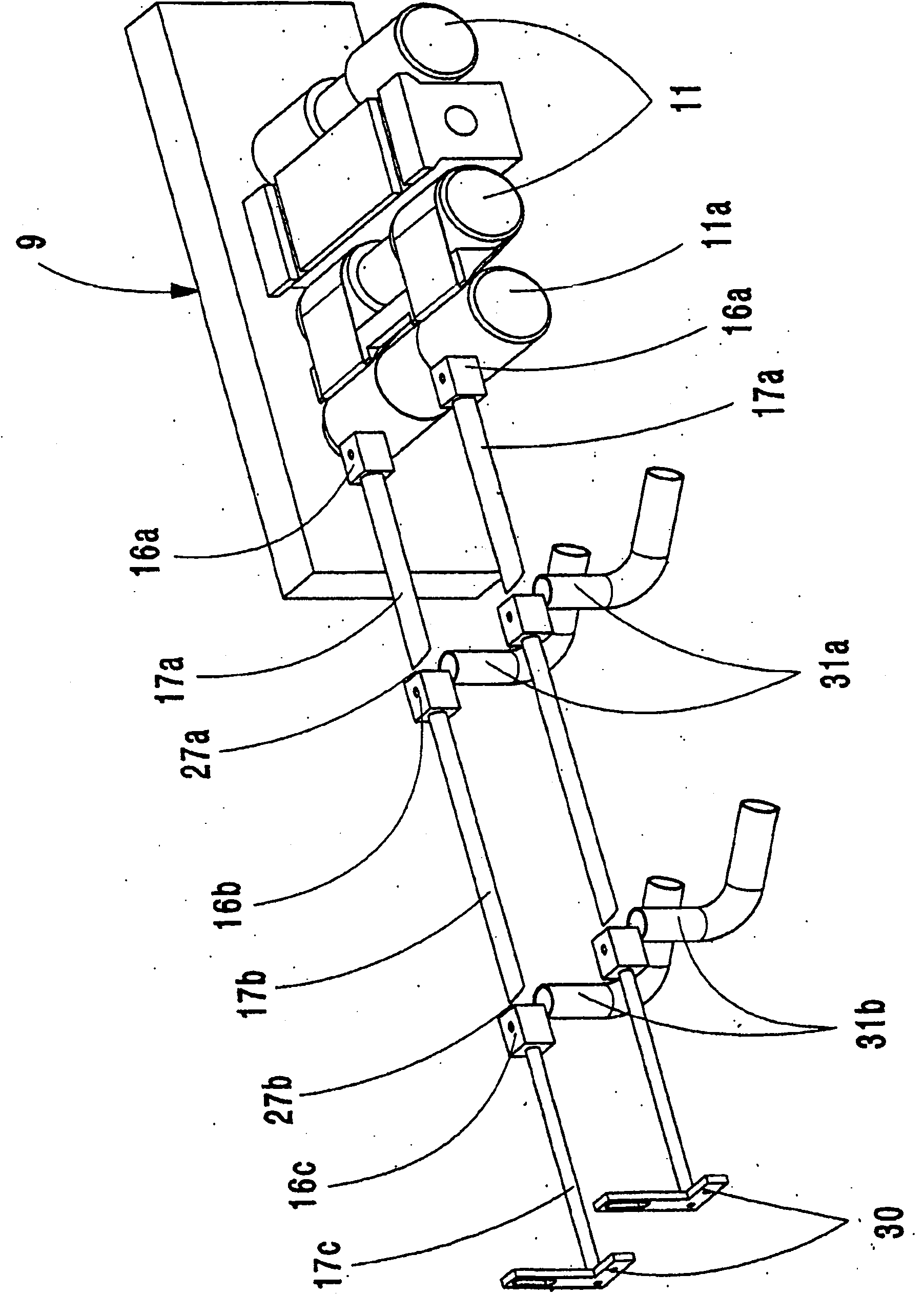

[0028] figure 1 Roughly schematically shown in a vertical partial section, a knitting machine in the form of a circular knitting machine 1 comprising a needle cylinder 2 in which conventional knitting needles 3 are movably supported, said needles hereinafter referred to as The knitting position, which is the knitting system, can be moved into a receiving position suitable for receiving the fiber material 4 by means of cams not described. The circular knitting machine 1 , which can be designed, for example, as a multi-triangle circular knitting machine, is located on the floor of the hall or needle hall, indicated by reference numeral 5 . An operator can operate the knitting machine 1 from the hall floor 5 . Furthermore, a plurality of cans 6 in which rovings 7 made of fibers are deposited are placed on the hall floor 5 .

[0029] The roving 7 is conveyed by means of a conveyor belt 8 or the like to a drafting device 9 accessible to the operator from a workbench 10 arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com