Classification mechanism with adjustable size

A technology for adjusting the mechanism and size, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as unreliable work, lower yield, and easy cracks, so as to improve work efficiency, increase yield, and ensure normal work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

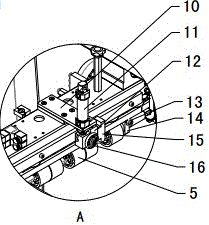

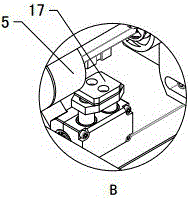

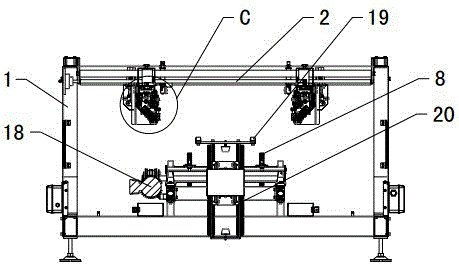

[0029] Figure 1~9 It is the best embodiment of the size-adjustable sorting mechanism, below in conjunction with the attached Figure 1~9 The present invention will be further described.

[0030] refer to figure 1 , the size-adjustable sorting mechanism includes an upper conveying mechanism, a buffer mechanism and a lower conveying mechanism arranged in sequence from top to bottom. The buffer wheels 5 on both sides of the lower part of the channel, the axis of rotation of the buffer wheels 5 is parallel to the transmission direction of the products to be sorted in the upper conveying mechanism, the buffer wheels 5 are made of elastic material, and the distance between the buffer wheels 5 on both sides is smaller than the width of the transmission channel. The distance between the axes of the buffer wheels 5 on both sides is greater than the width of the transmission channel, and the products to be sorted on the upper conveying mechanism fall between the buffer wheels 5 on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com