Detecting and selective discharging conveying device for injection molded parts of notebook computer shell

A notebook computer and conveying device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of manpower and material resources, consumption, affecting production efficiency, etc., achieve simple operation, simple structure, and improve work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

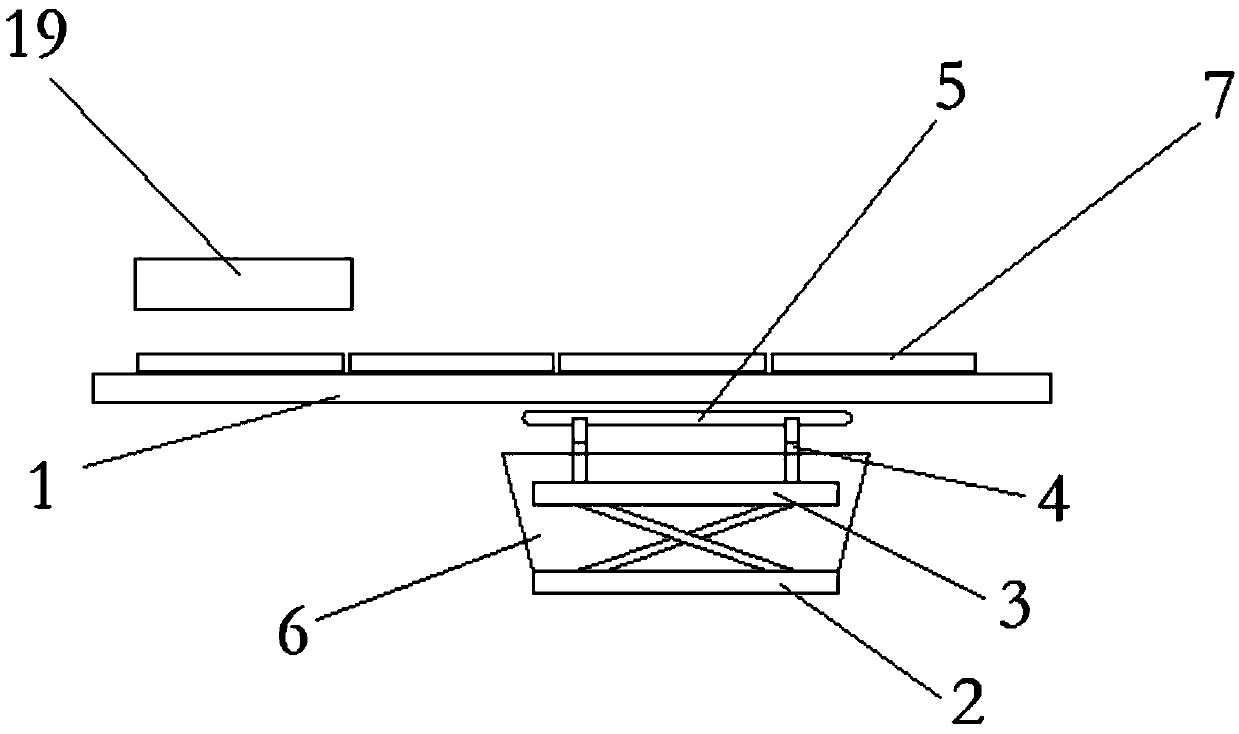

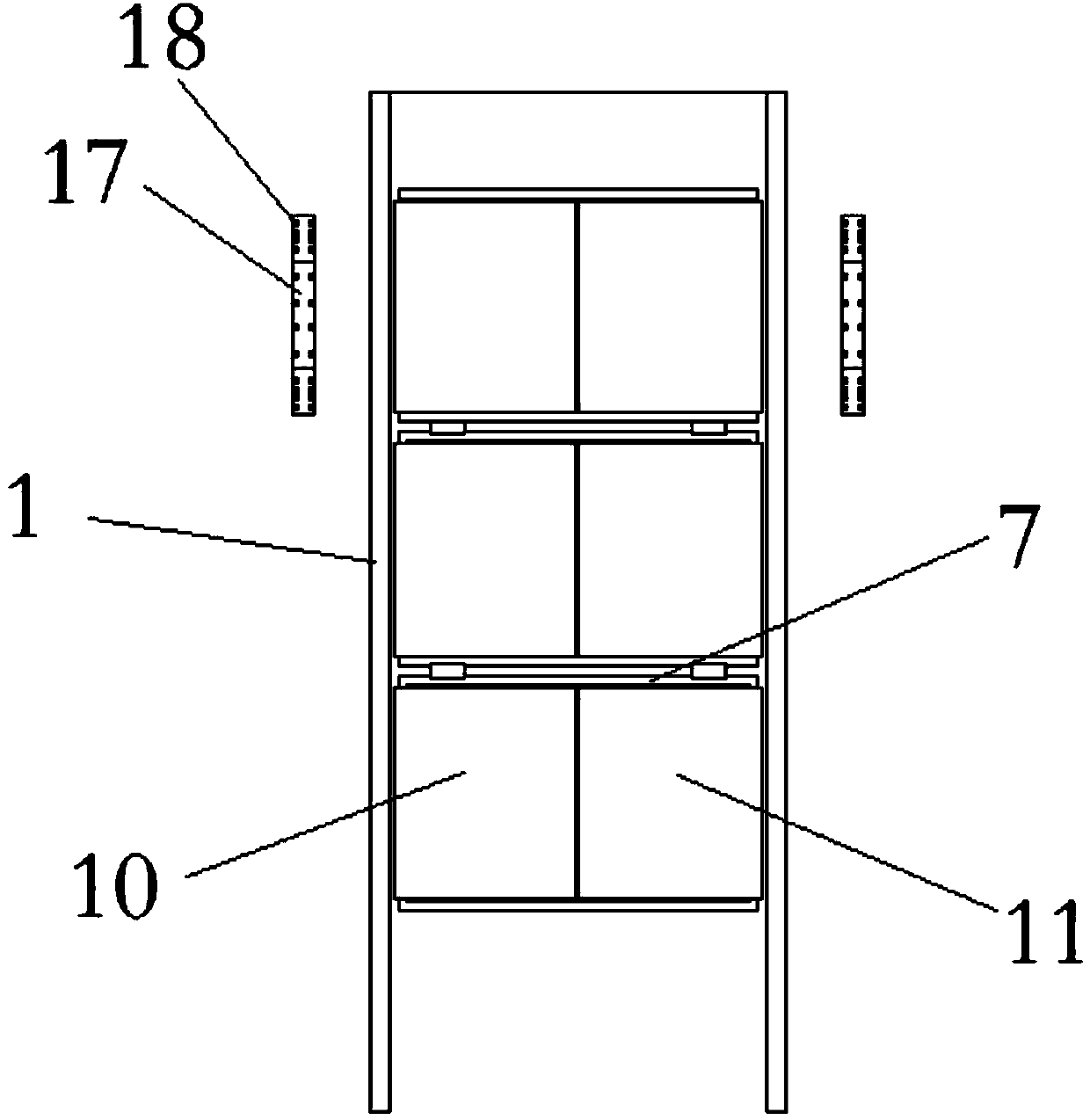

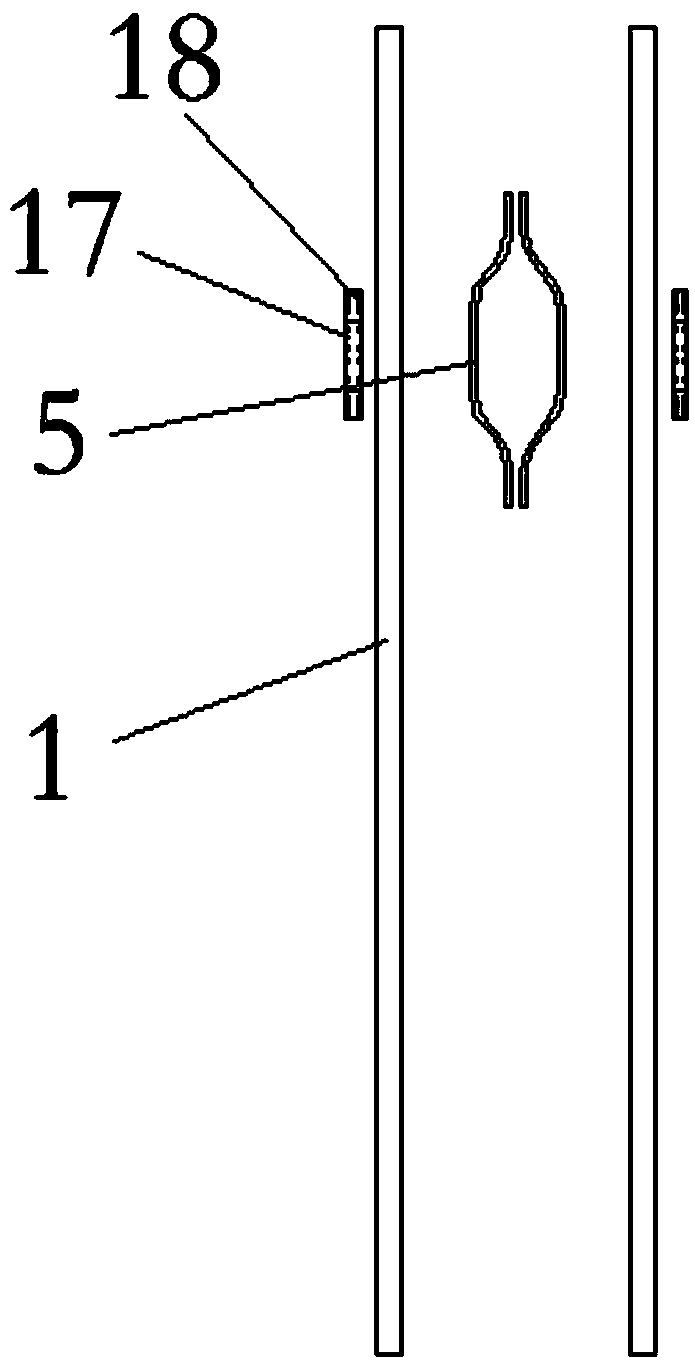

[0024] Embodiment 1: as Figure 1-9 As shown, a detection, sorting and conveying device for injection molded parts of a notebook computer case includes a conveying track 1, a base 2 and a detection device 19, the base 2 is located at the right bottom of the conveying track 1, and the detection device 19 is located 1, the top of the base 2 is fixedly connected with a lifting platform 3, the top of the lifting platform 3 is fixedly connected with a bracket 4, and the top of the bracket 4 is fixedly connected with two sets of guide strips 5, the guide The middle part of the strip 5 bends outwards, and the top of the conveying track 1 is movably connected with several chain plate frames 7, and the chain plate frame 7 includes a connecting frame 701 and a shelving frame 702, and the inner wall of the chain plate frame 701 is provided with two A group of guide rails 8, the guide rails 8 are movably connected with moving blocks 9, and the first object stage 10 and the second object s...

Embodiment 2

[0025] Embodiment 2: as Figure 1-10 As shown, a detection, sorting and conveying device for injection molded parts of a notebook computer case includes a conveying track 1, a base 2 and a detection device 19, the base 2 is located at the right bottom of the conveying track 1, and the detection device 19 is located 1, the top of the base 2 is fixedly connected with a lifting platform 3, the top of the lifting platform 3 is fixedly connected with a bracket 4, and the top of the bracket 4 is fixedly connected with two sets of guide strips 5, the guide The middle part of the strip 5 bends outwards, and the top of the conveying track 1 is movably connected with several chain plate frames 7, and the chain plate frame 7 includes a connecting frame 701 and a shelving frame 702, and the inner wall of the chain plate frame 701 is provided with two A group of guide rails 8, the guide rails 8 are movably connected with moving blocks 9, and the first object stage 10 and the second object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com