Patents

Literature

64results about "Sausage casing shirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

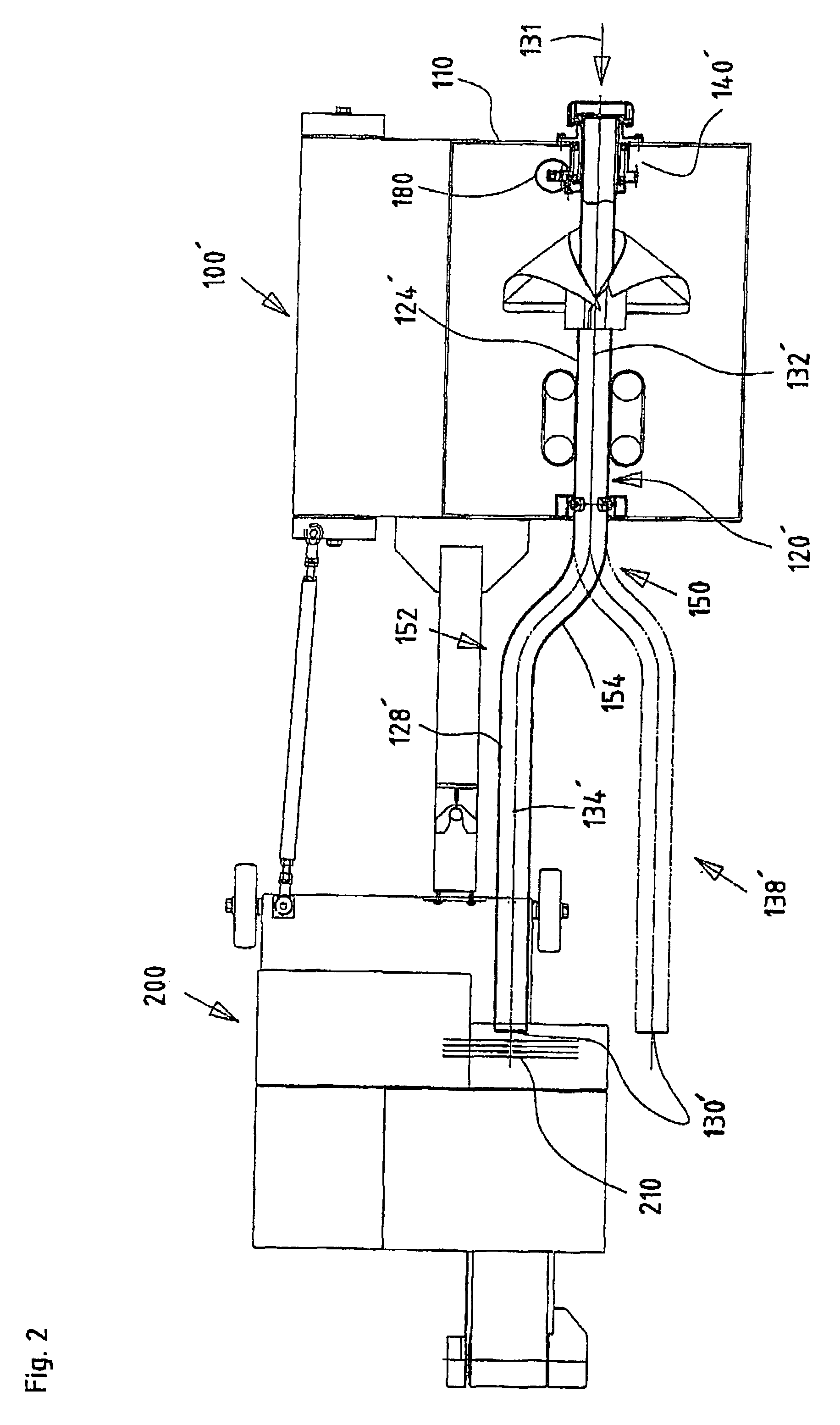

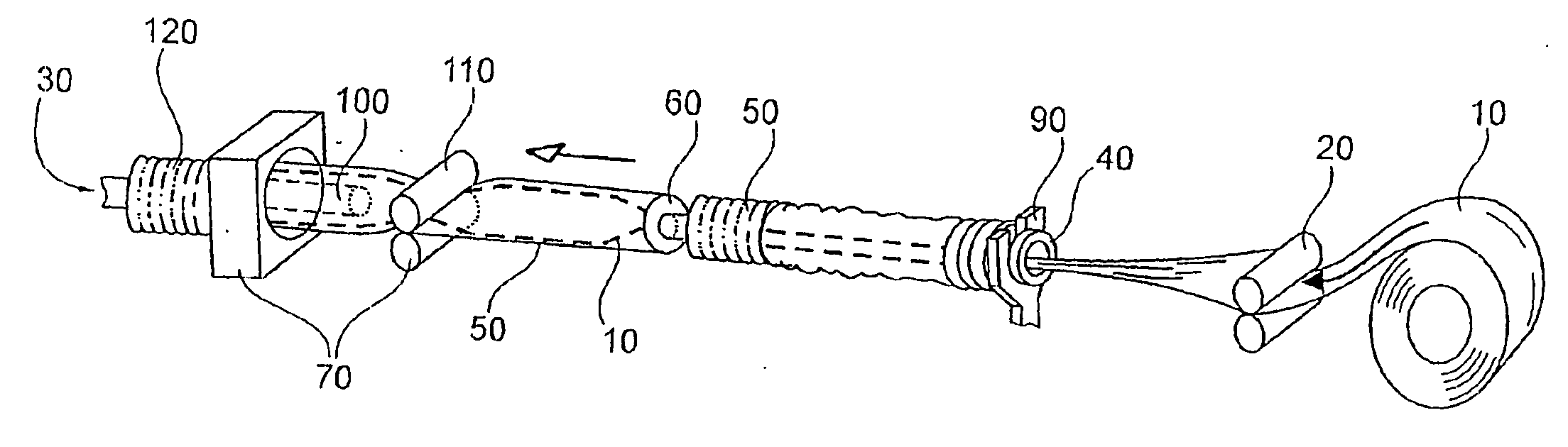

Net rucking apparatus and method

An apparatus and method for shirring netting onto a netting tube. A second tube is placed over and coaxially to the netting tube and netting is stretched over the second tube. The two tubes are caused to move in a reciprocating manner through a plurality of spring-loaded fingers, which allow the netting to pass on the downstroke and hold the netting on the upstroke. As the two tubes move, the netting is pulled over the second tube and shirred onto the netting tube. An annular space formed by a tube ring placed between the netting tube and the second tube causes the netting to shir in multiple, neatly aligned layers.

Owner:POLY CLIP SYST

Process for the preparation of smoke-impregnated tubular casings

A method of preparing smoke-impregnated tubular casings is described. The process comprises: (a) providing a tubular casing having interior and exterior surfaces, the tubular casing being selected from cellulose fiber tubular casings and synthetic tubular casings, and the tubular casing being suitable for encasing food fillings having a form selected from one of liquid and paste; (b) applying to the interior surface of the tubular casing a mixture comprising, (i) liquid smoke, (ii) browning agents, and (iii) optionally water; (c) allowing the mixture to remain in contact with the interior surface of the tubular casing for at least 5 days; and (d) optionally shirring and watering the mixture treated casing. The smoke-impregnated tubular casings prepared in accordance with the method of the present invention are suitable for liquid or paste-like food fillings, such as sausagemeat emulsions.

Owner:WOLFF WALSRODE AG

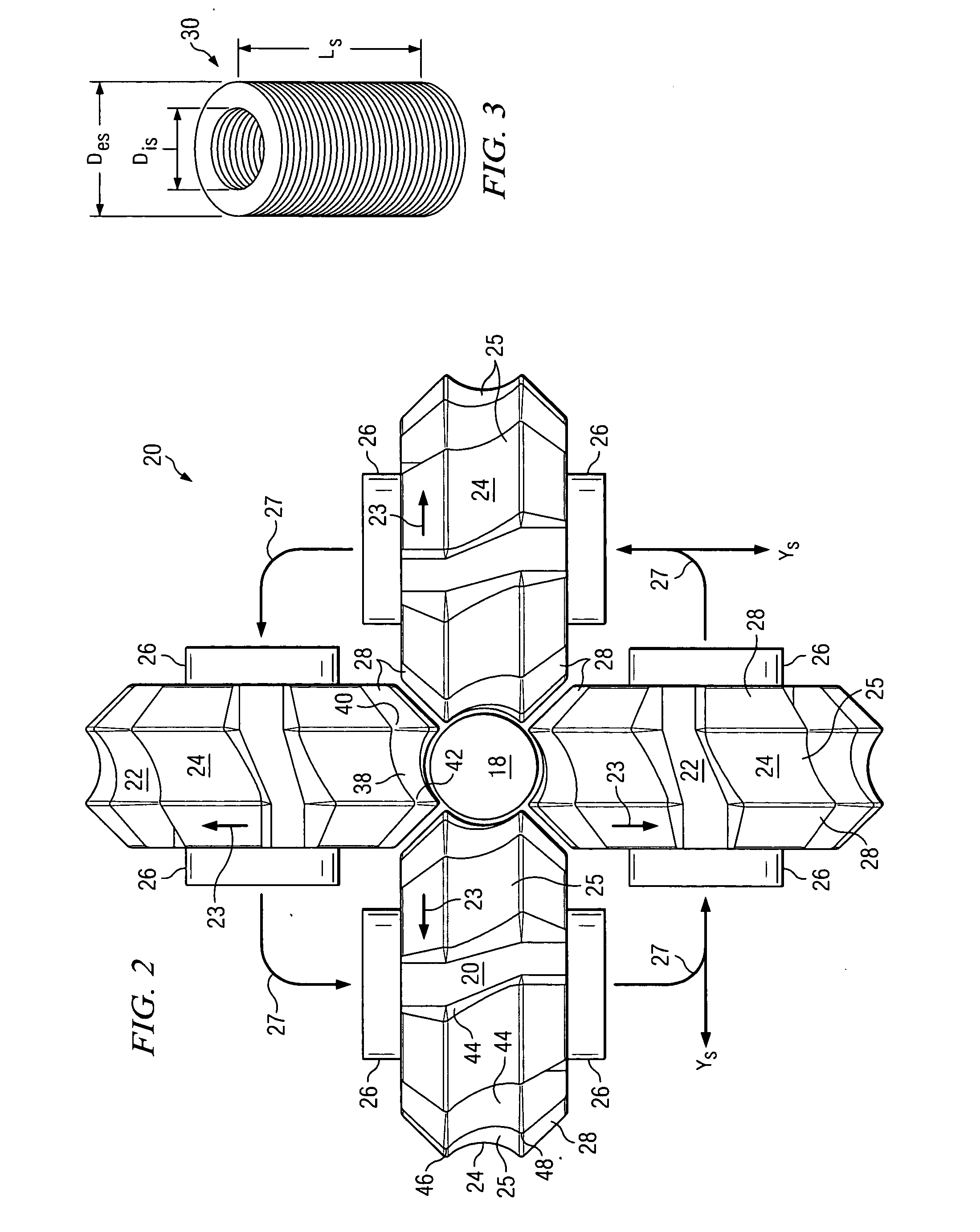

Shirred casing

A shirred fibrous food casing defines a shirred stick formed from a tubular fibrous casing. The shirred stick includes an average outside diameter at least 120% of the average inflated diameter of the deshirred casing. Additionally, the shirred stick includes an average inside diameter of at least 70% of the casing inflated diameter and a pleat pitch defined as the distance between adjacent apexes of major pleats measured on the casing after the shirred stick is deshirred.

Owner:VISKOTEEPAK BELGIUM NV

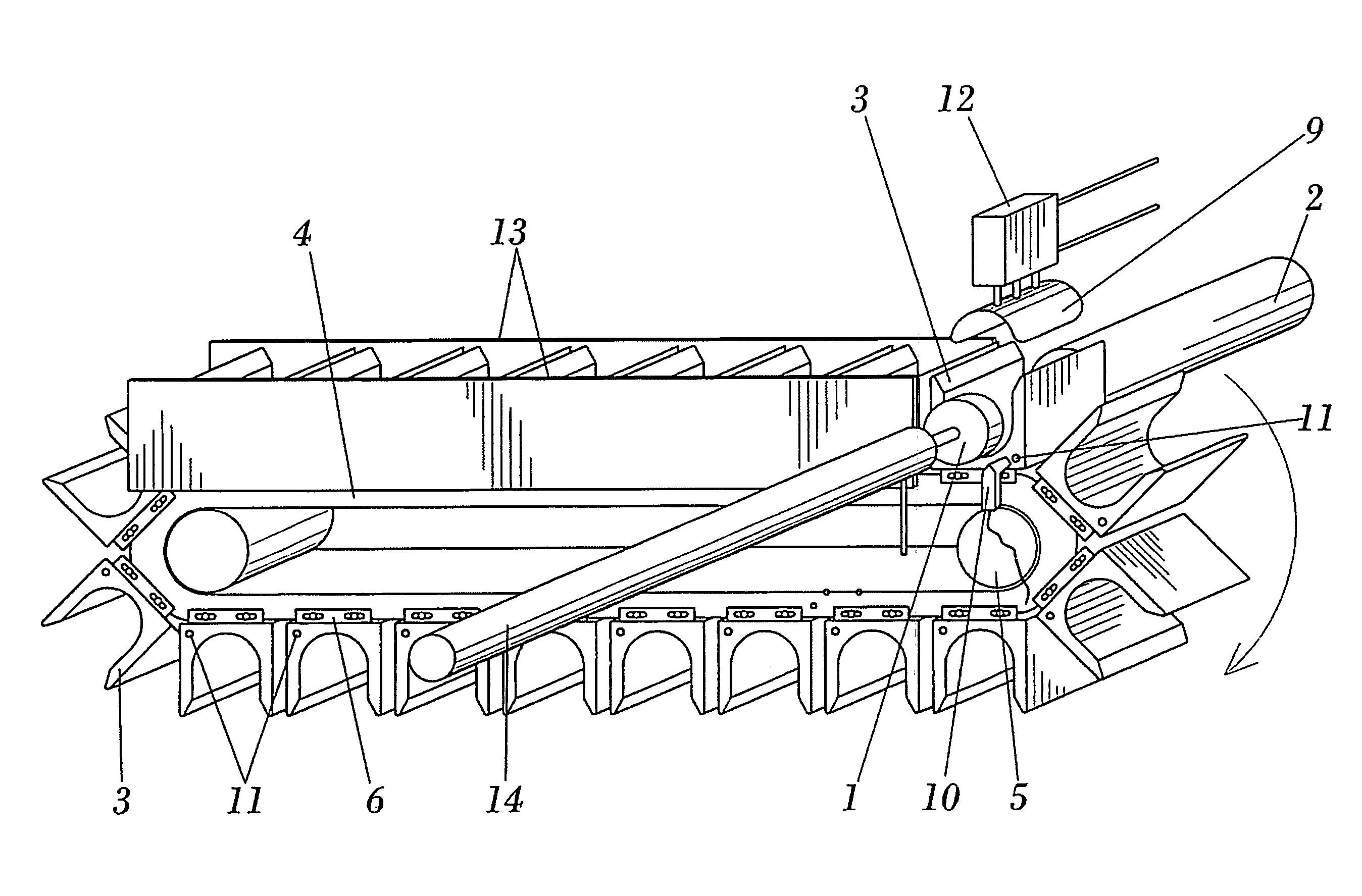

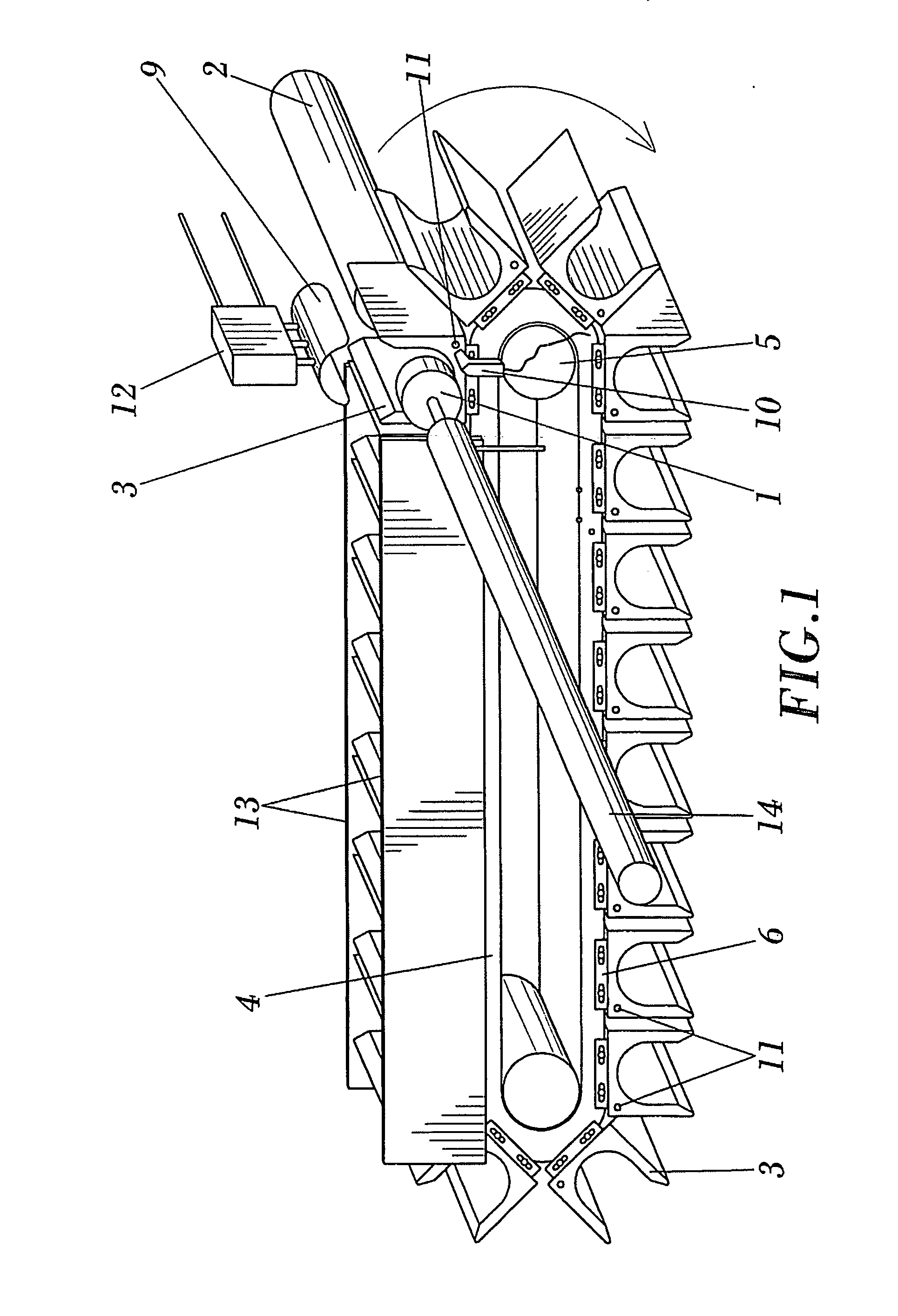

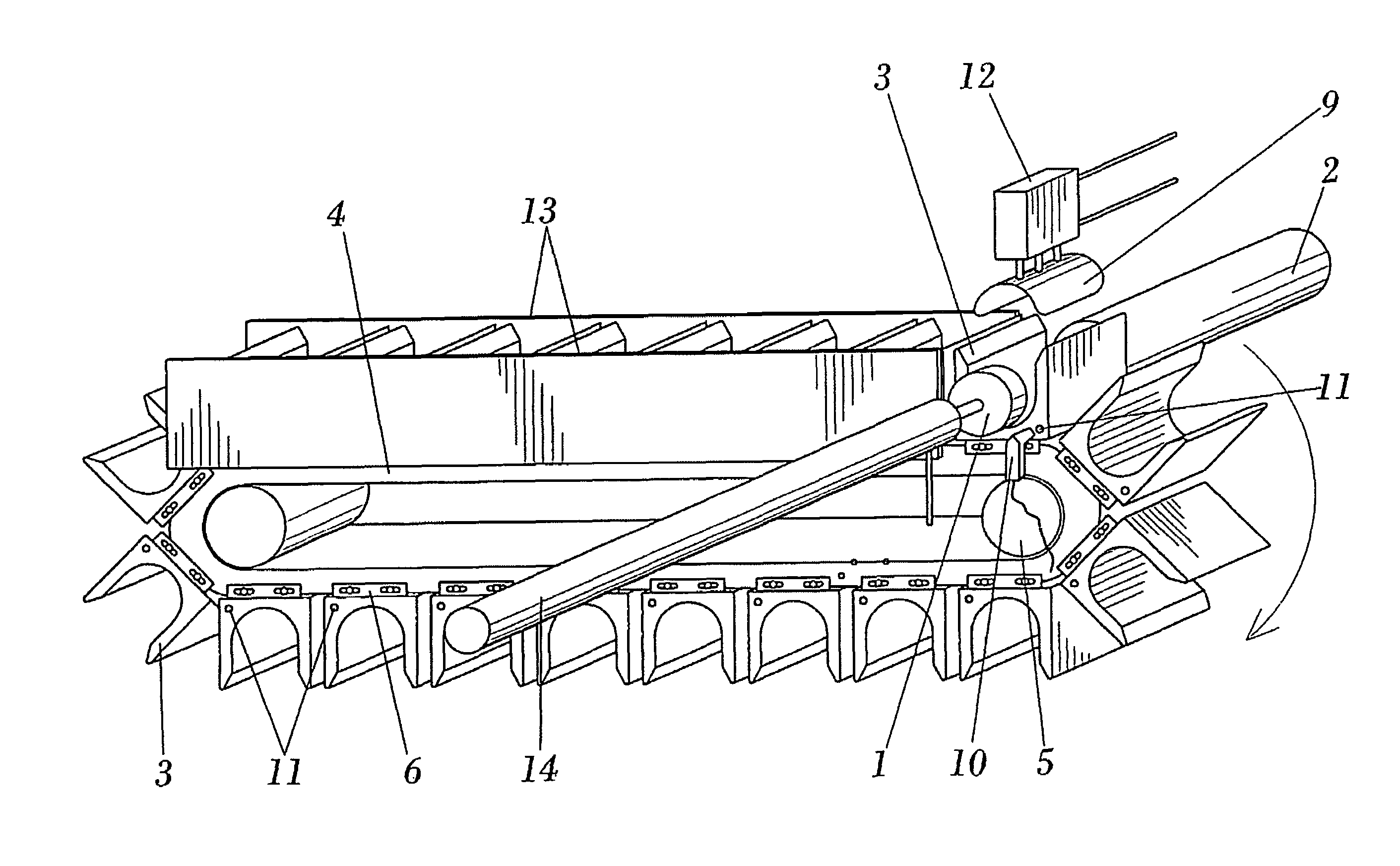

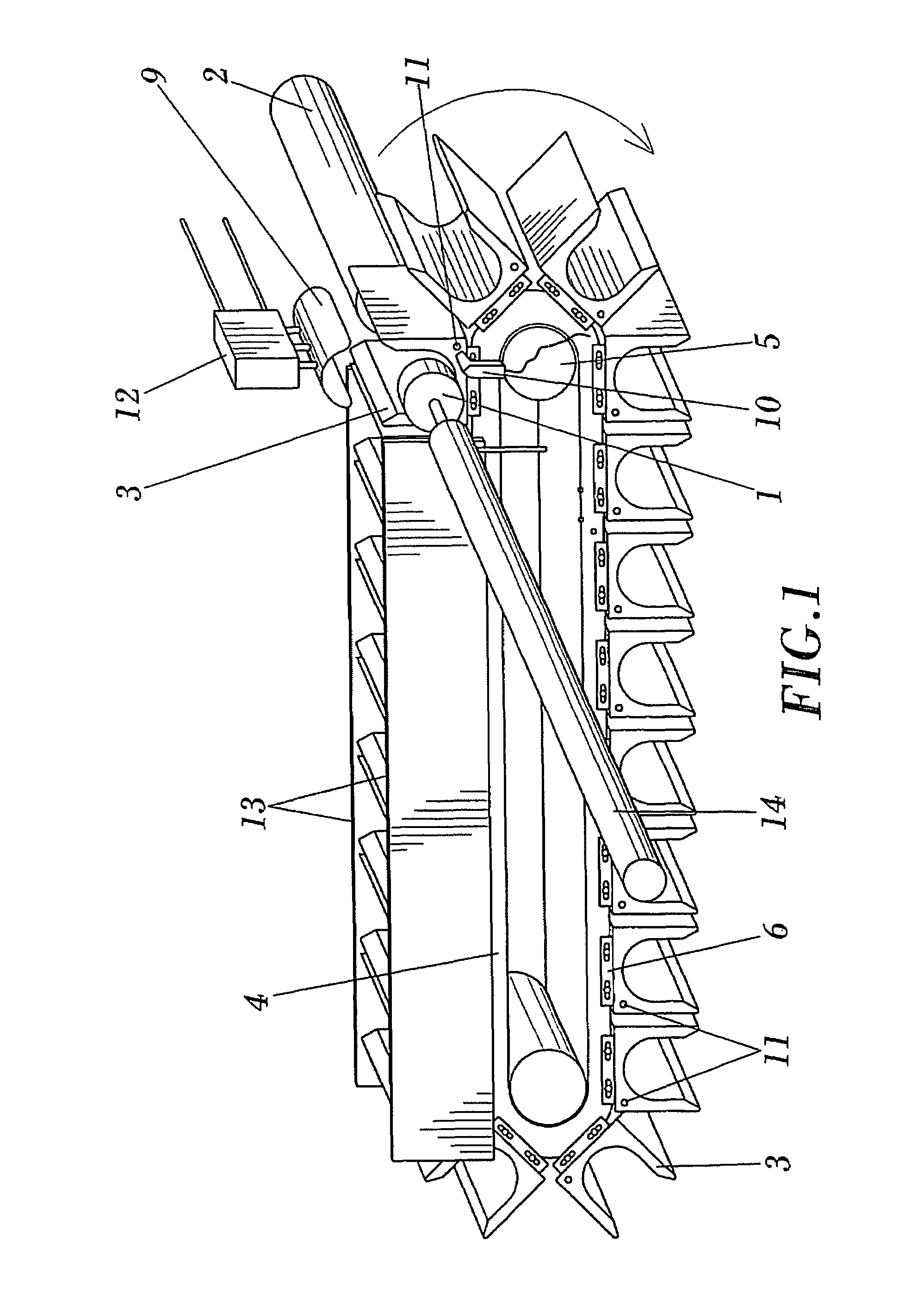

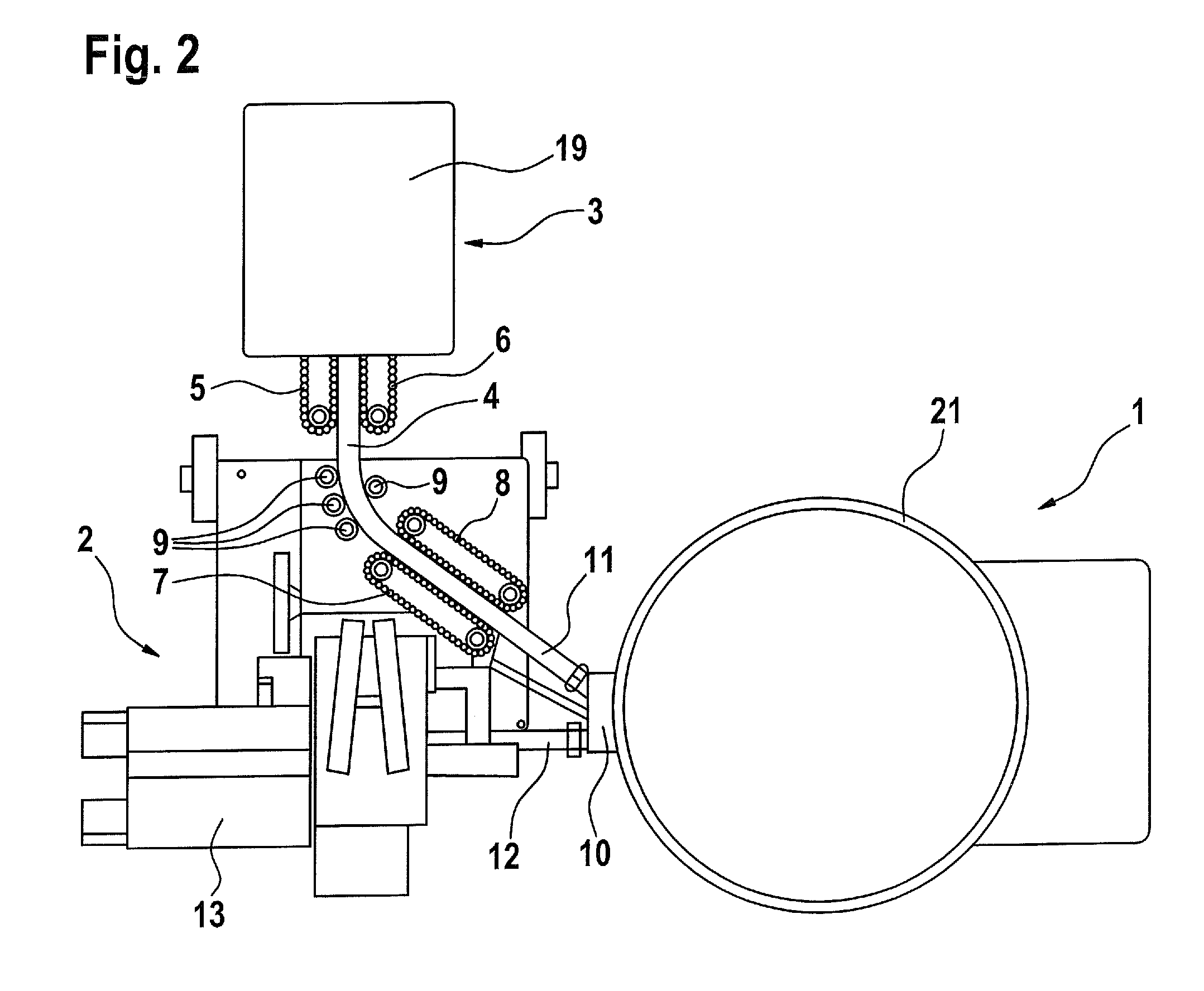

Feeder for meat pieces made of entire muscles for a piston stuffing machine

ActiveUS20060183413A1Meat/sausage hanging-upSausage filling/stuffing machinesClassical mechanicsEngineering

Incorporates buckets (3) open on their top in which the meat pieces are loaded, moving on traction means (4) that execute a step by step motion towards the feeding area located between the piston (1) and the body of the stuffing machine (2), where the meat piece is pushed by the piston (1) towards the body of the stuffing machine (2) for compacting and subsequently wrapping it. The buckets (3) have open front and rear faces to facilitate the run of the piston (1) and the exit of the meat piece towards the body of the stuffing machine (2). In addition, means are provided for facilitating the centred position of the bucket with respect to the position of the piston (1) in the feeding area.

Owner:VISCOFAN

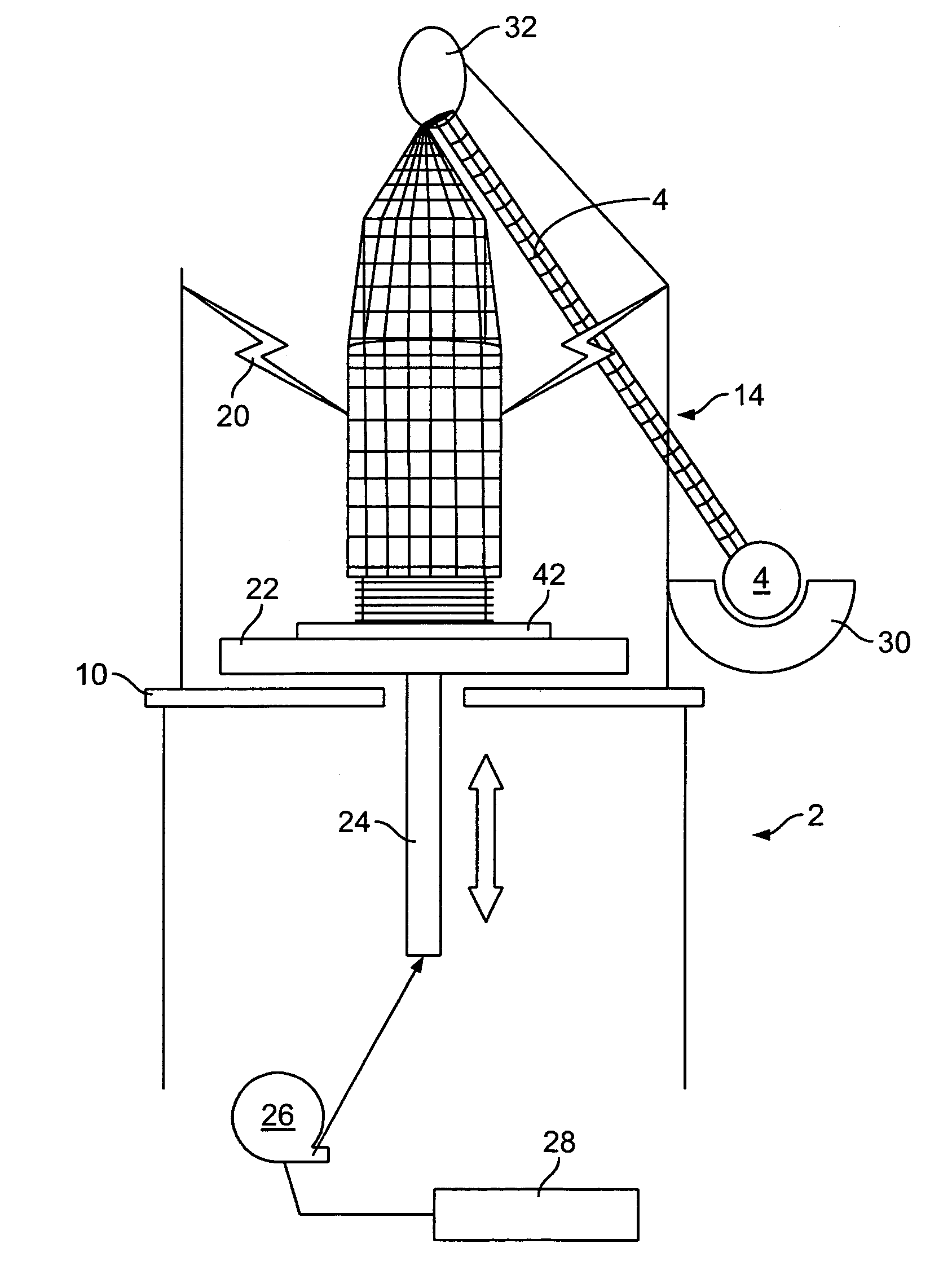

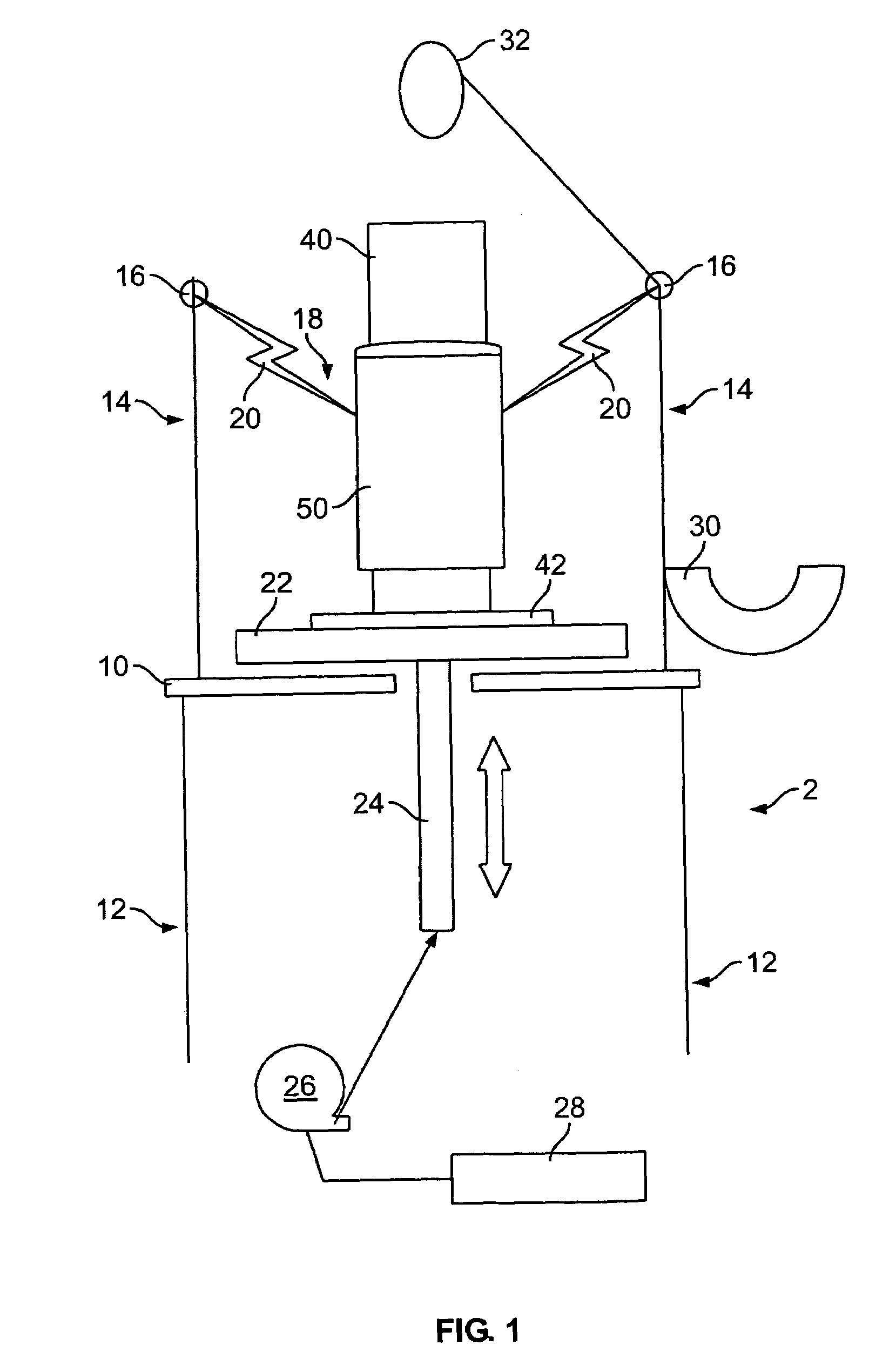

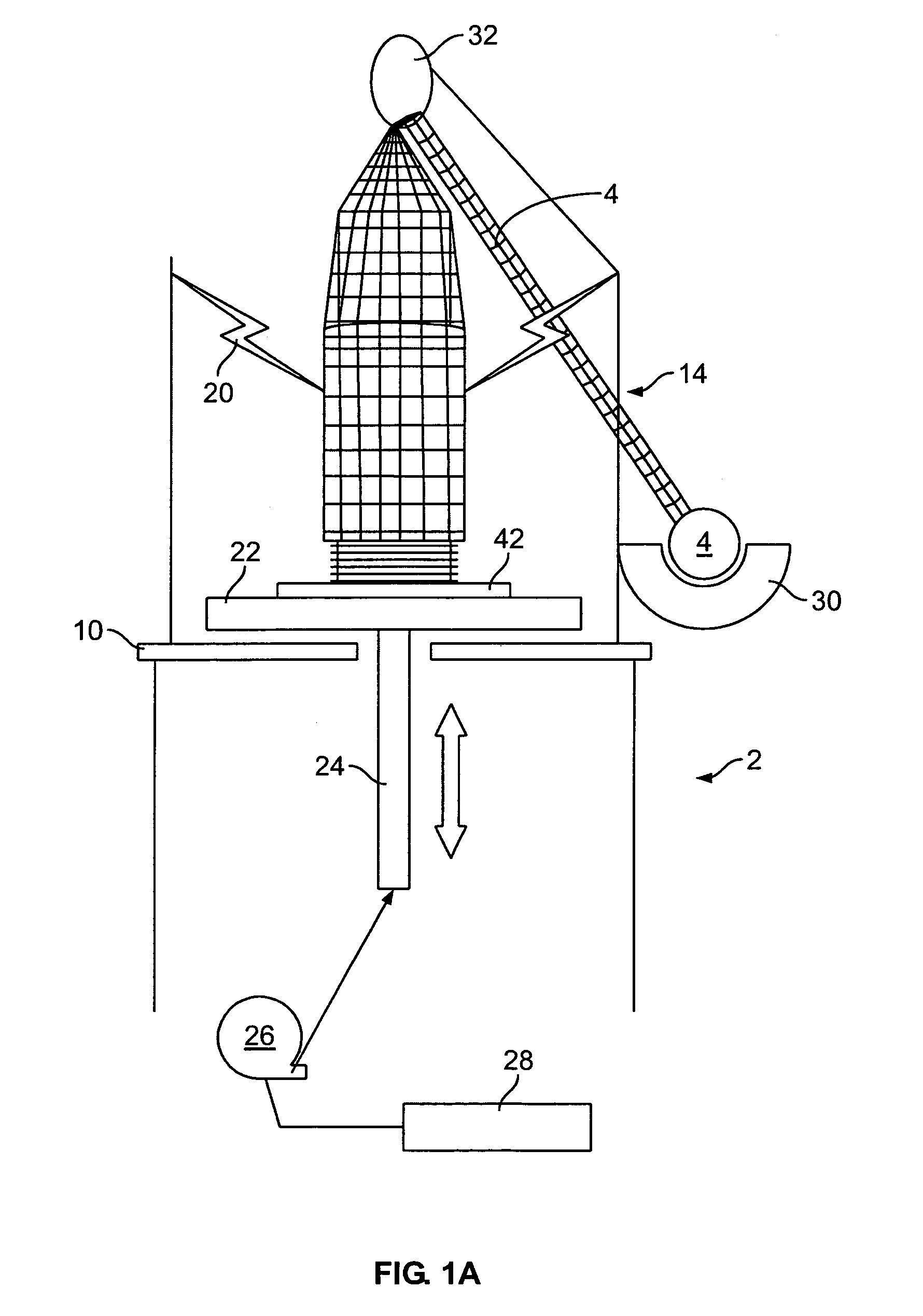

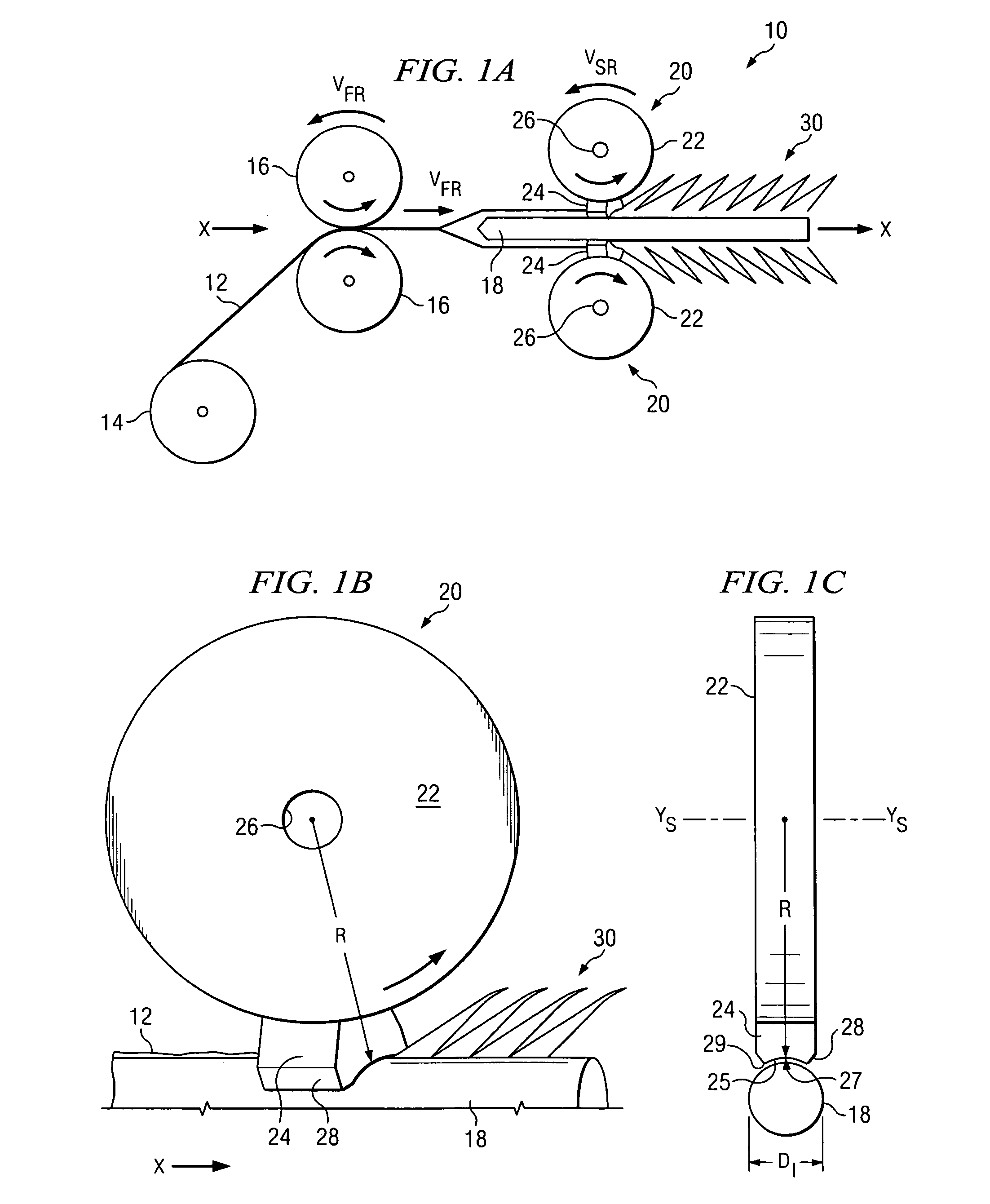

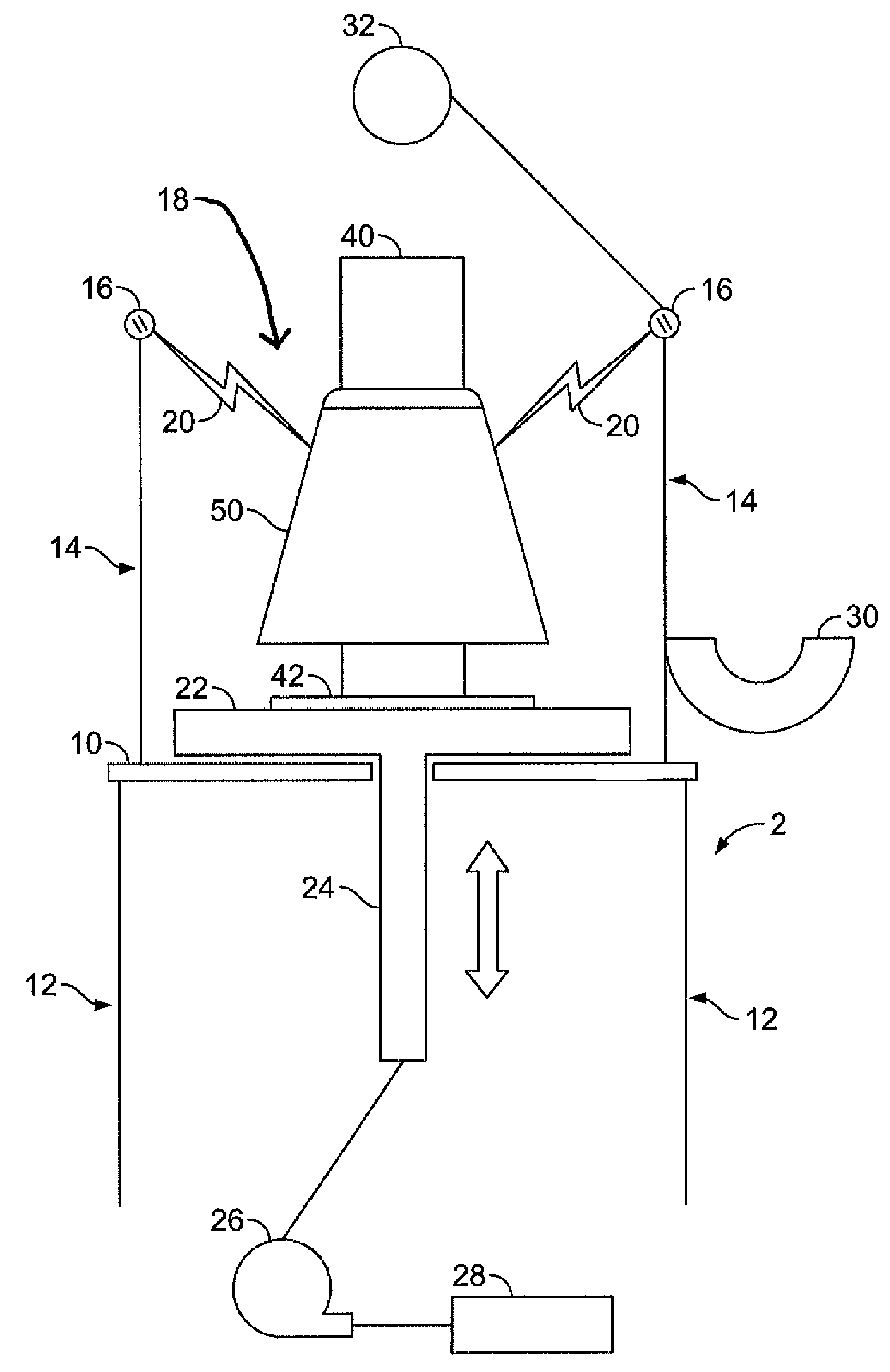

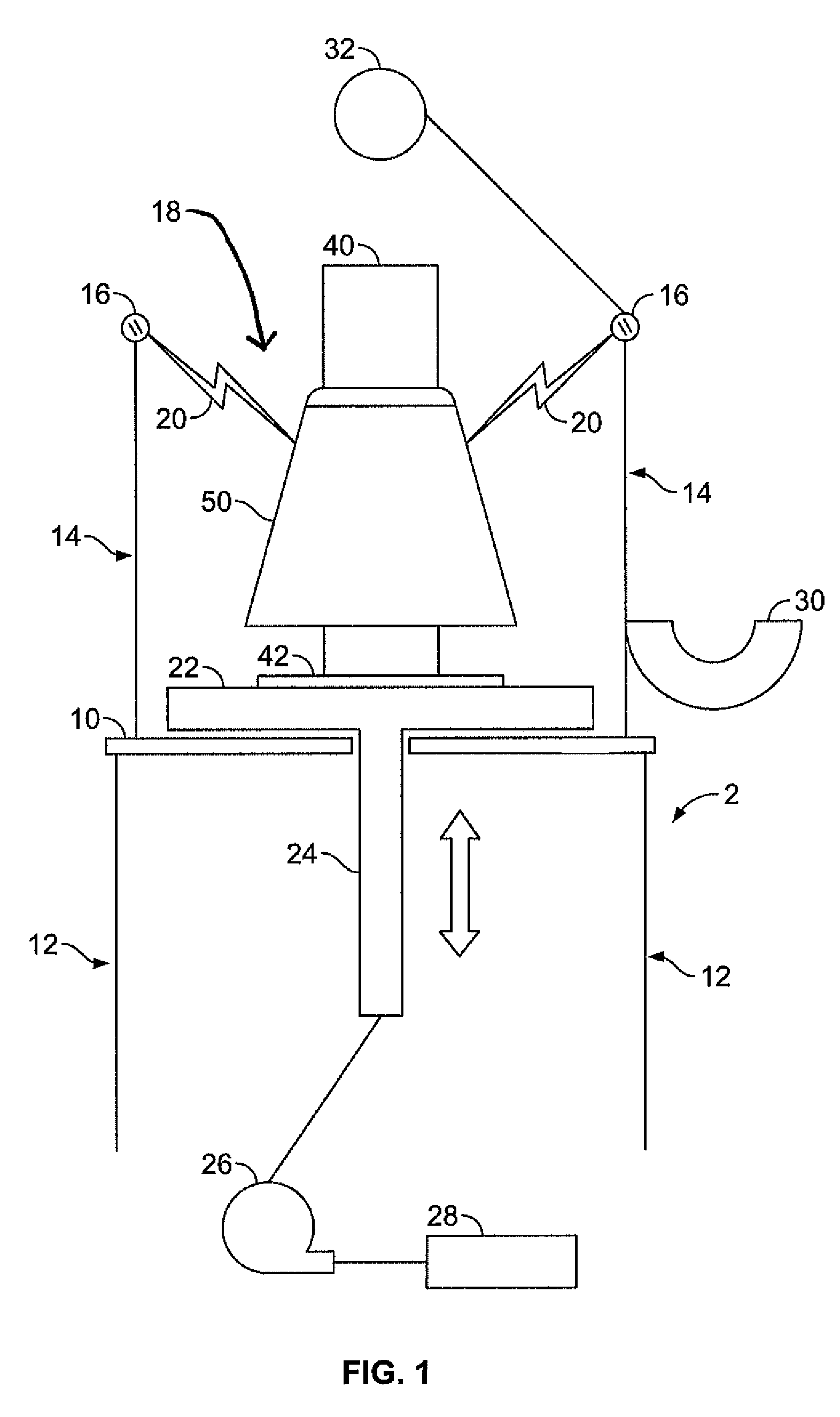

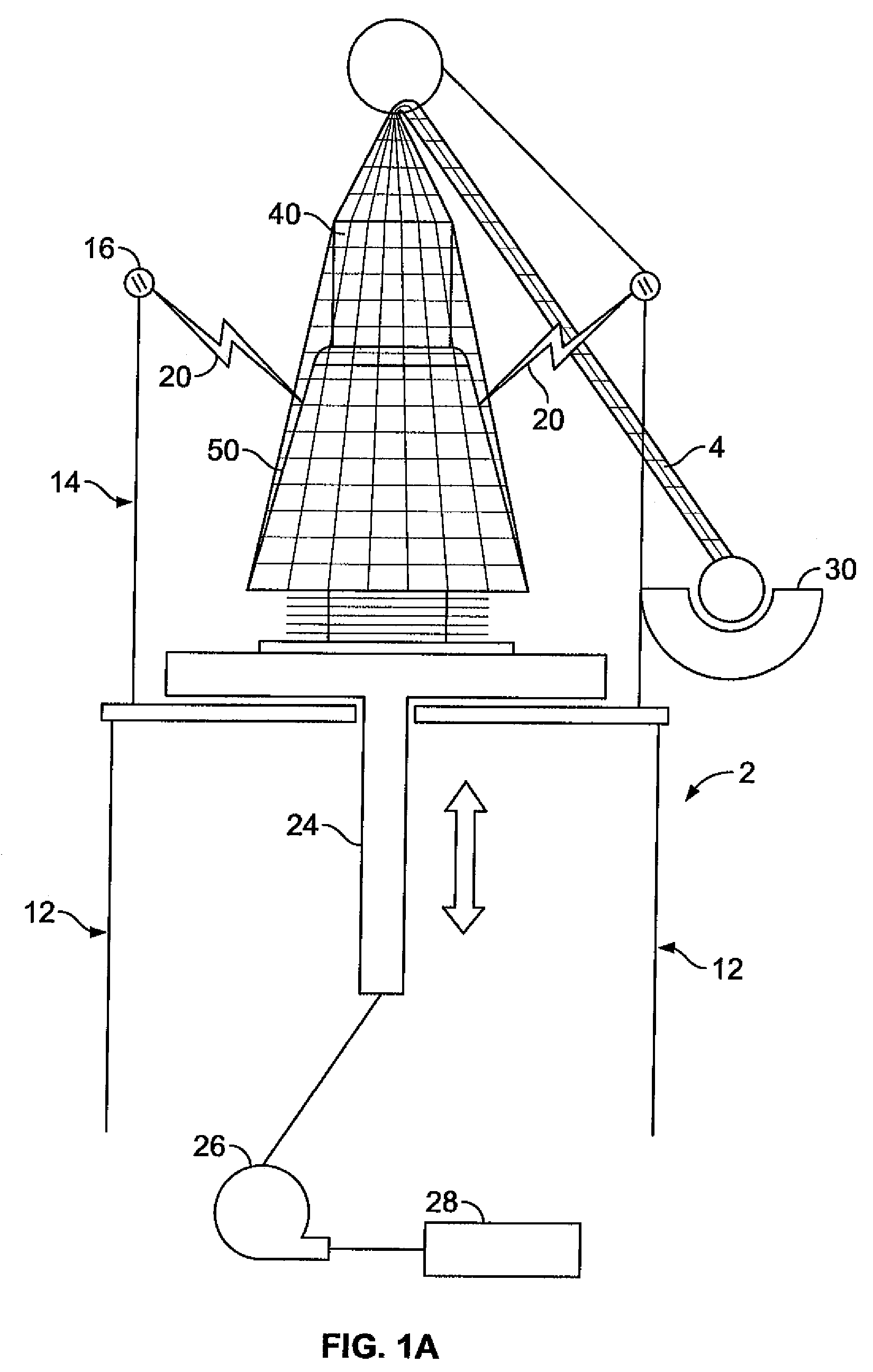

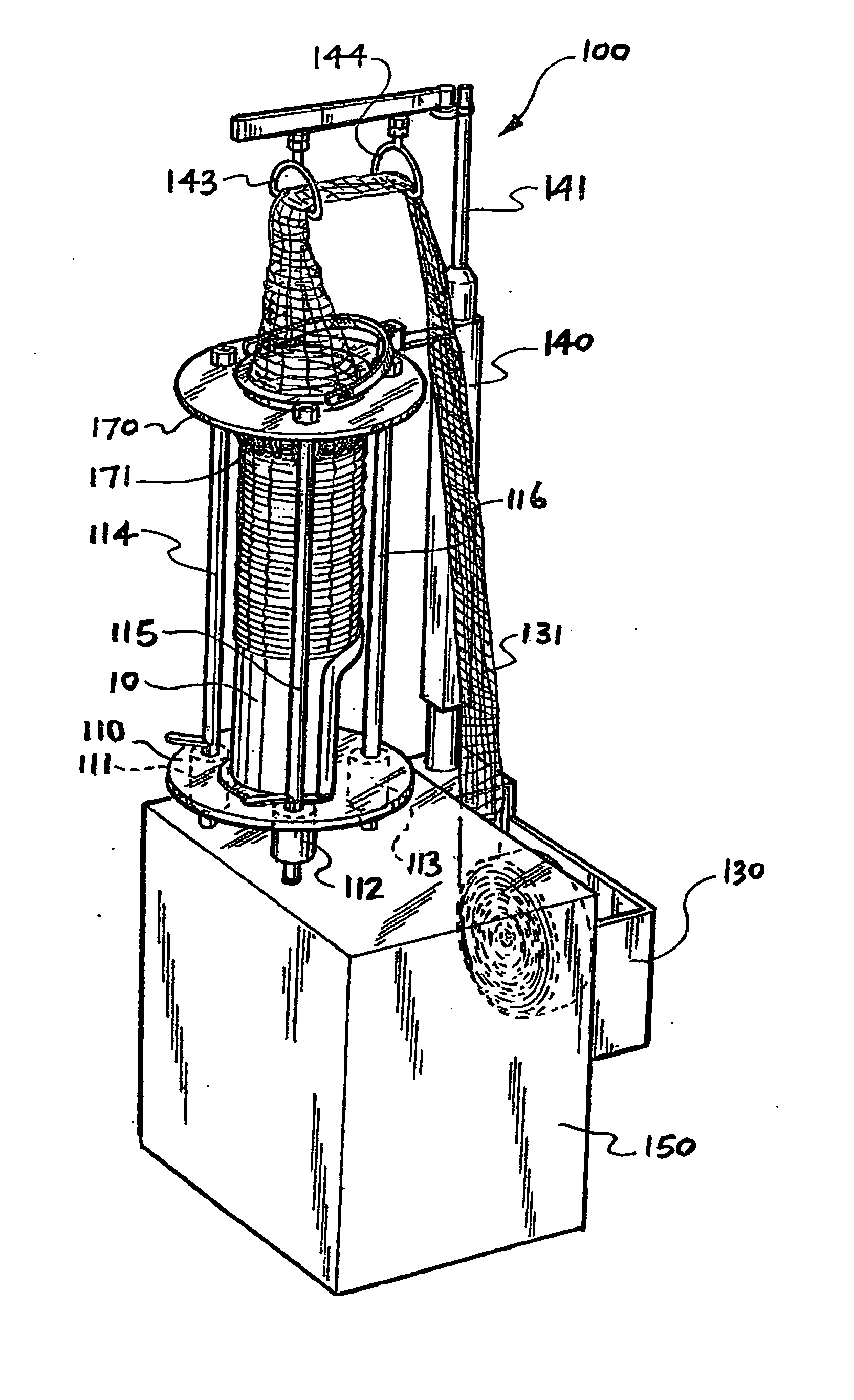

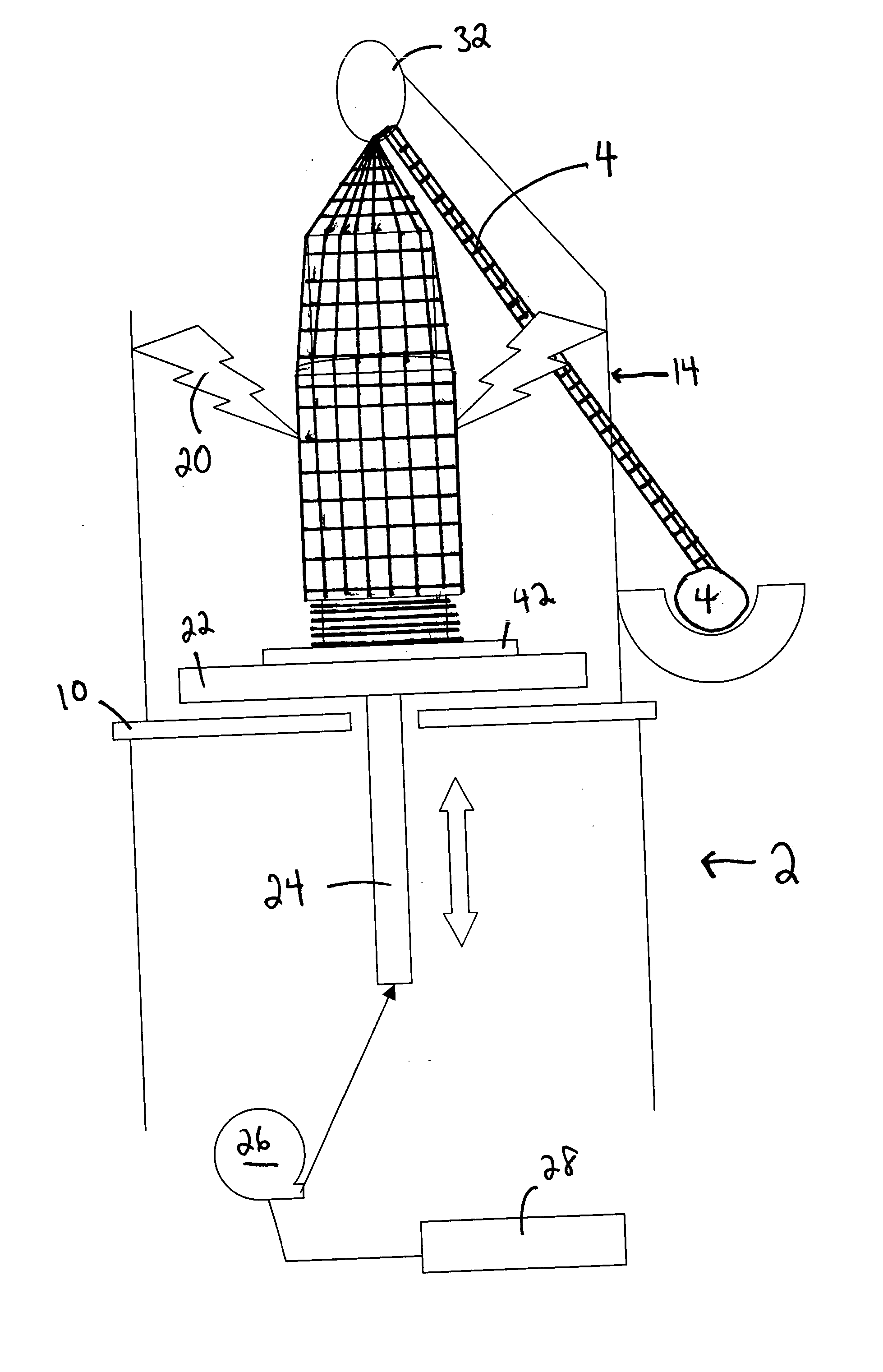

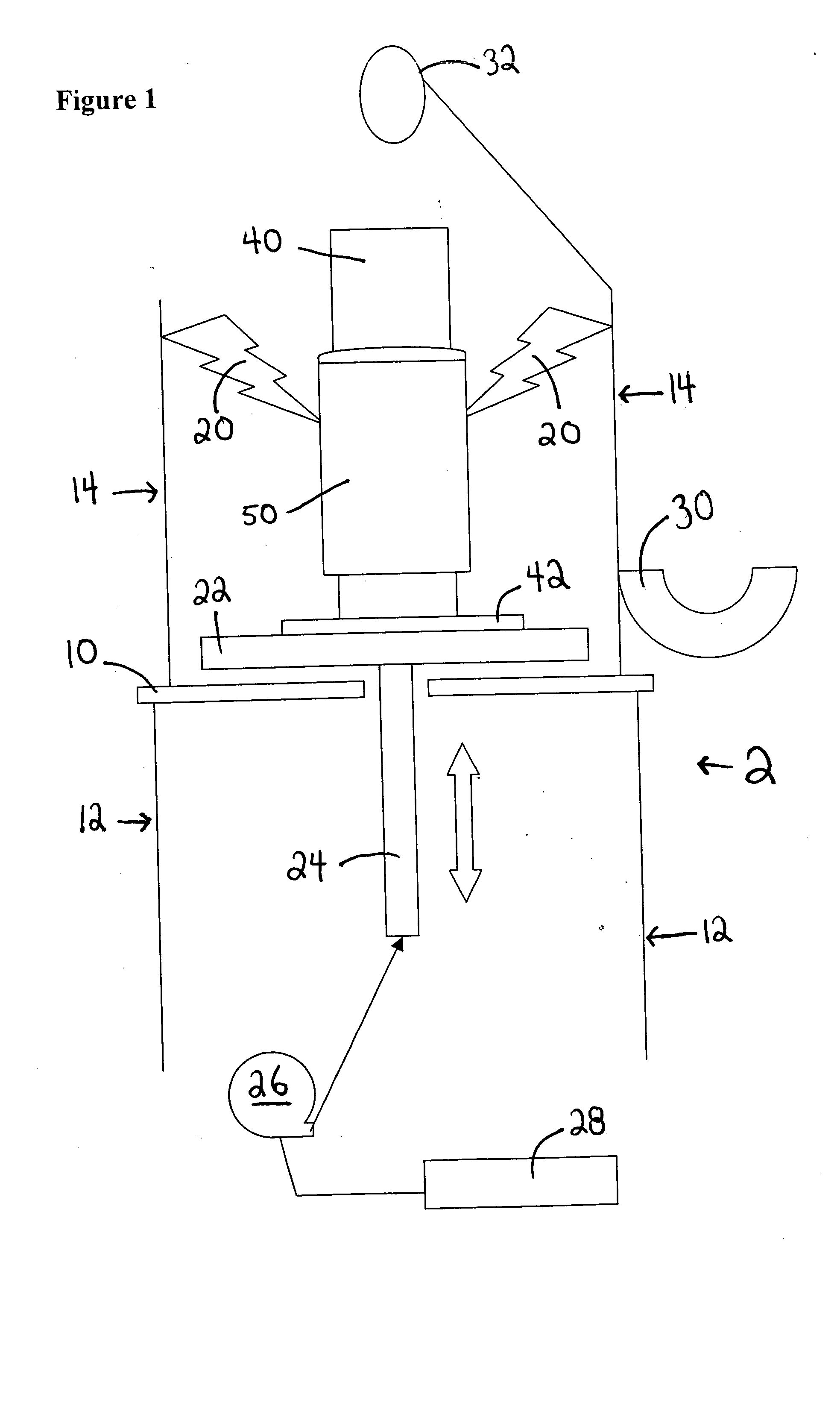

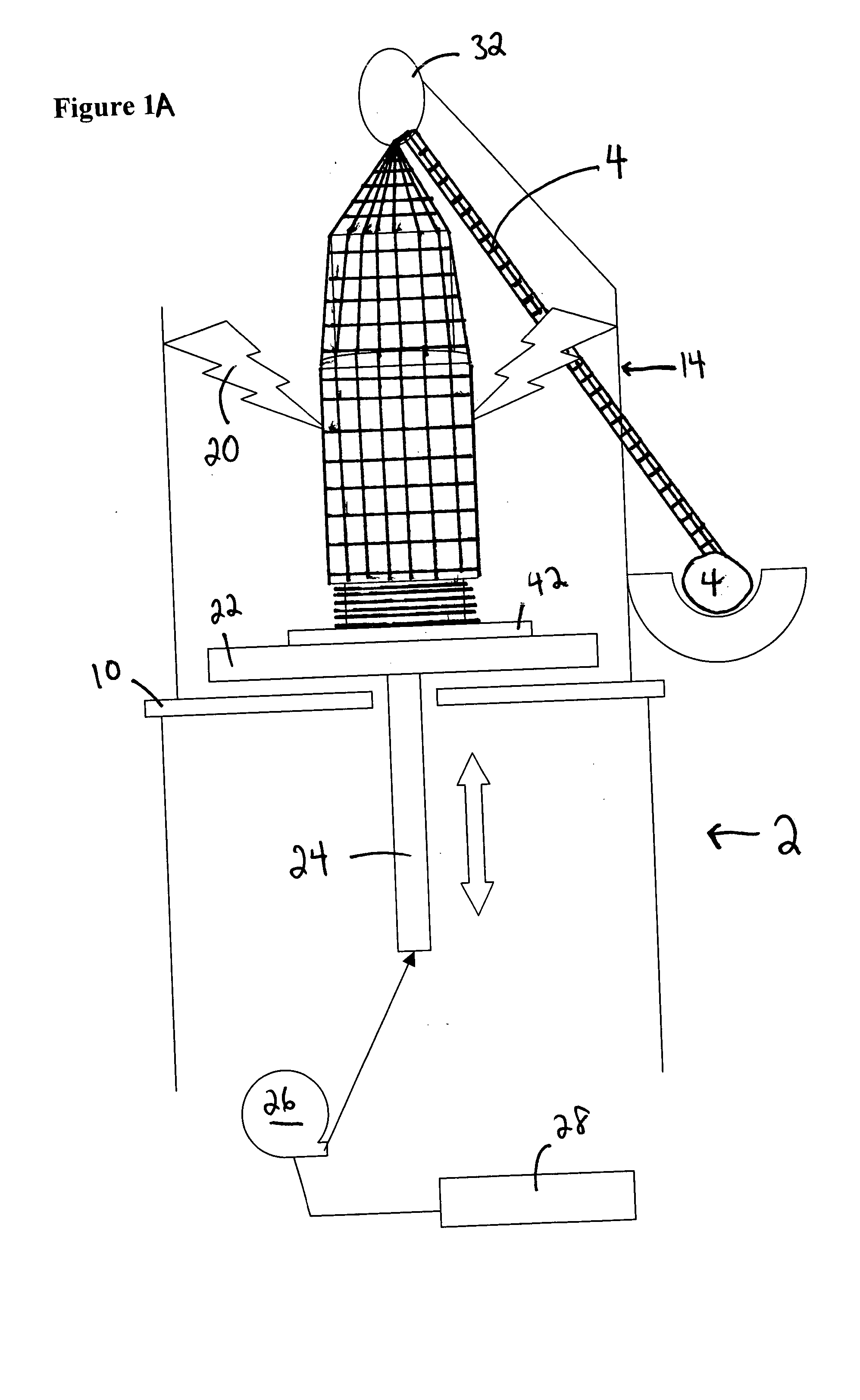

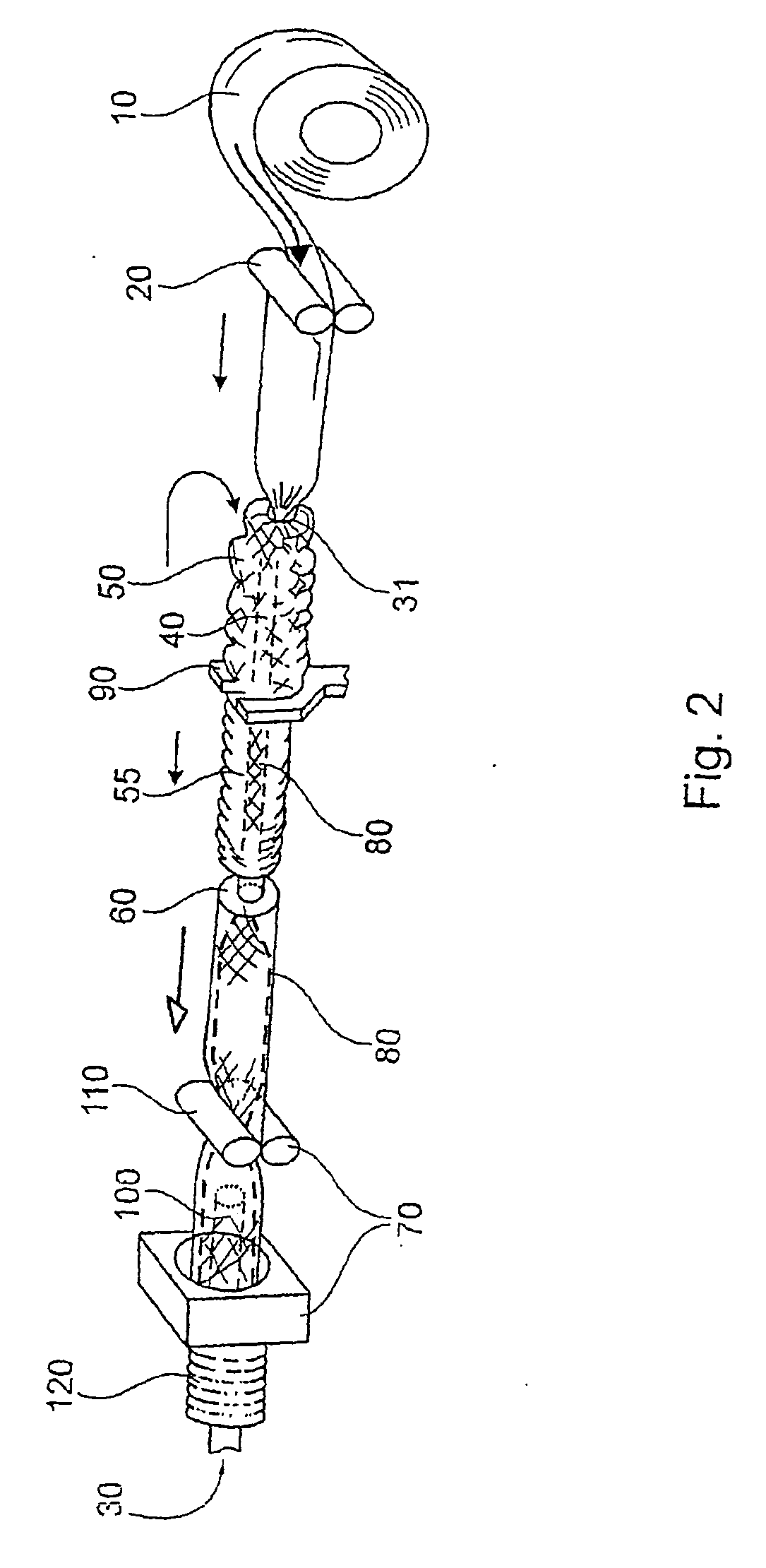

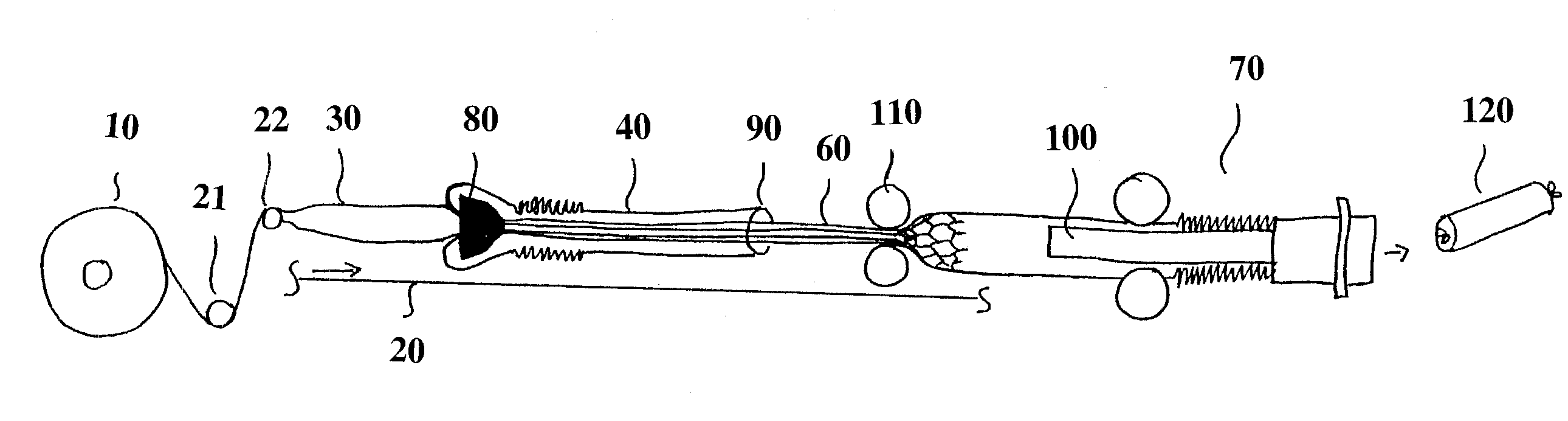

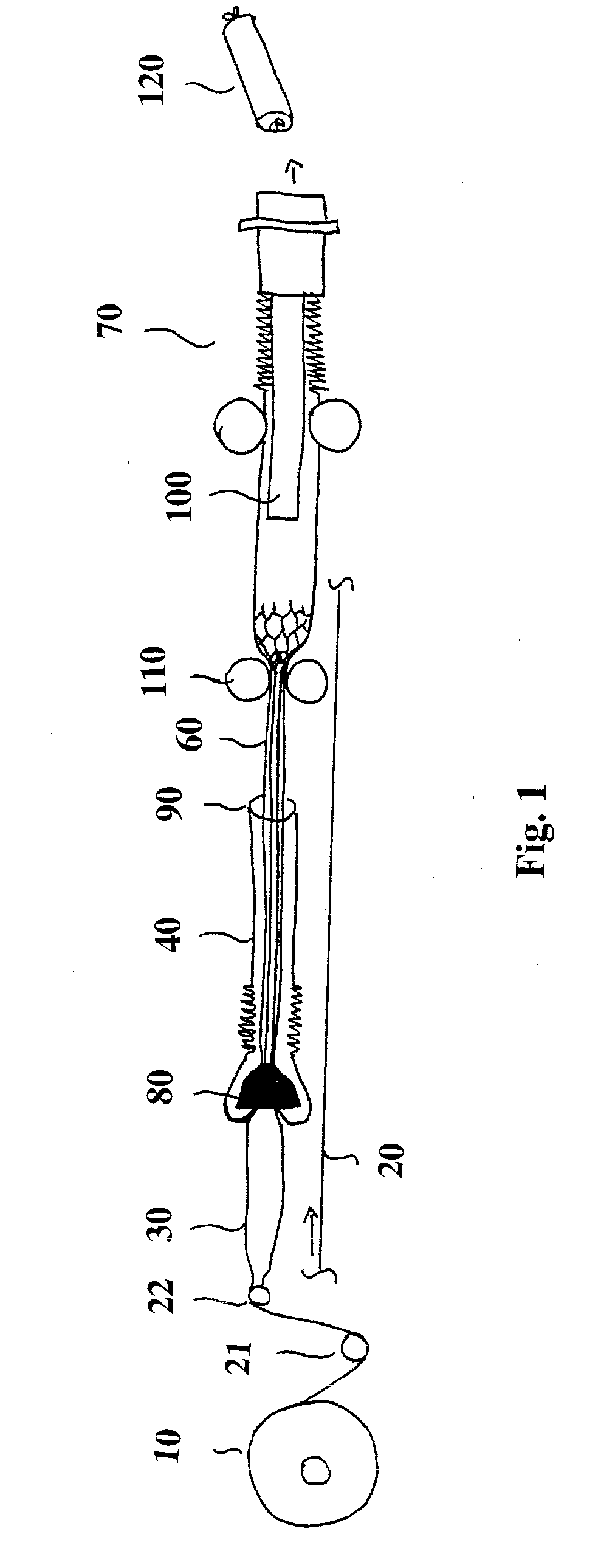

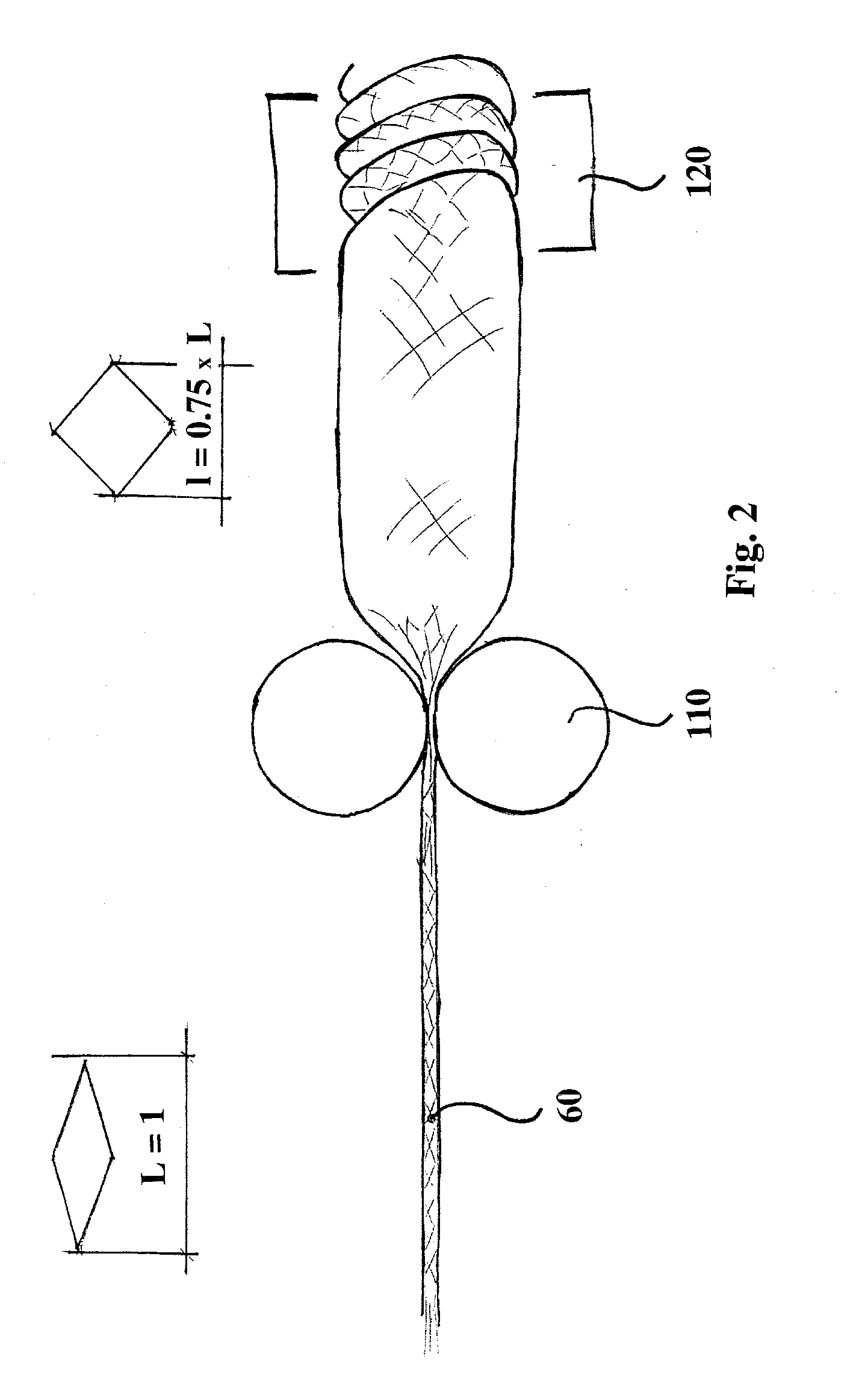

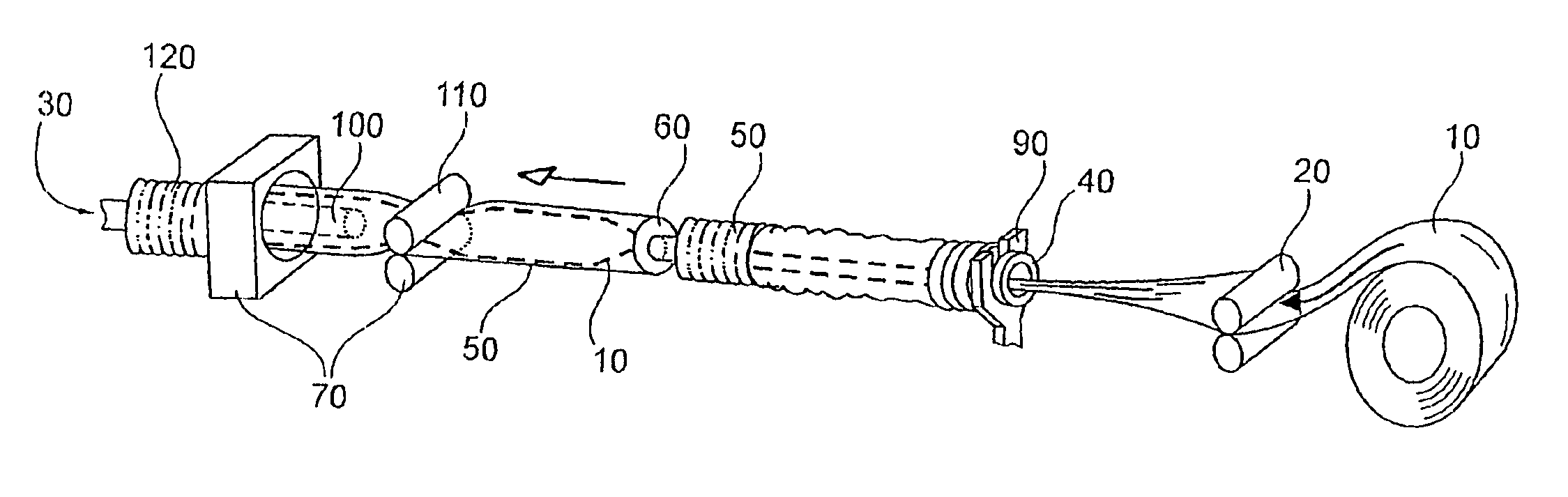

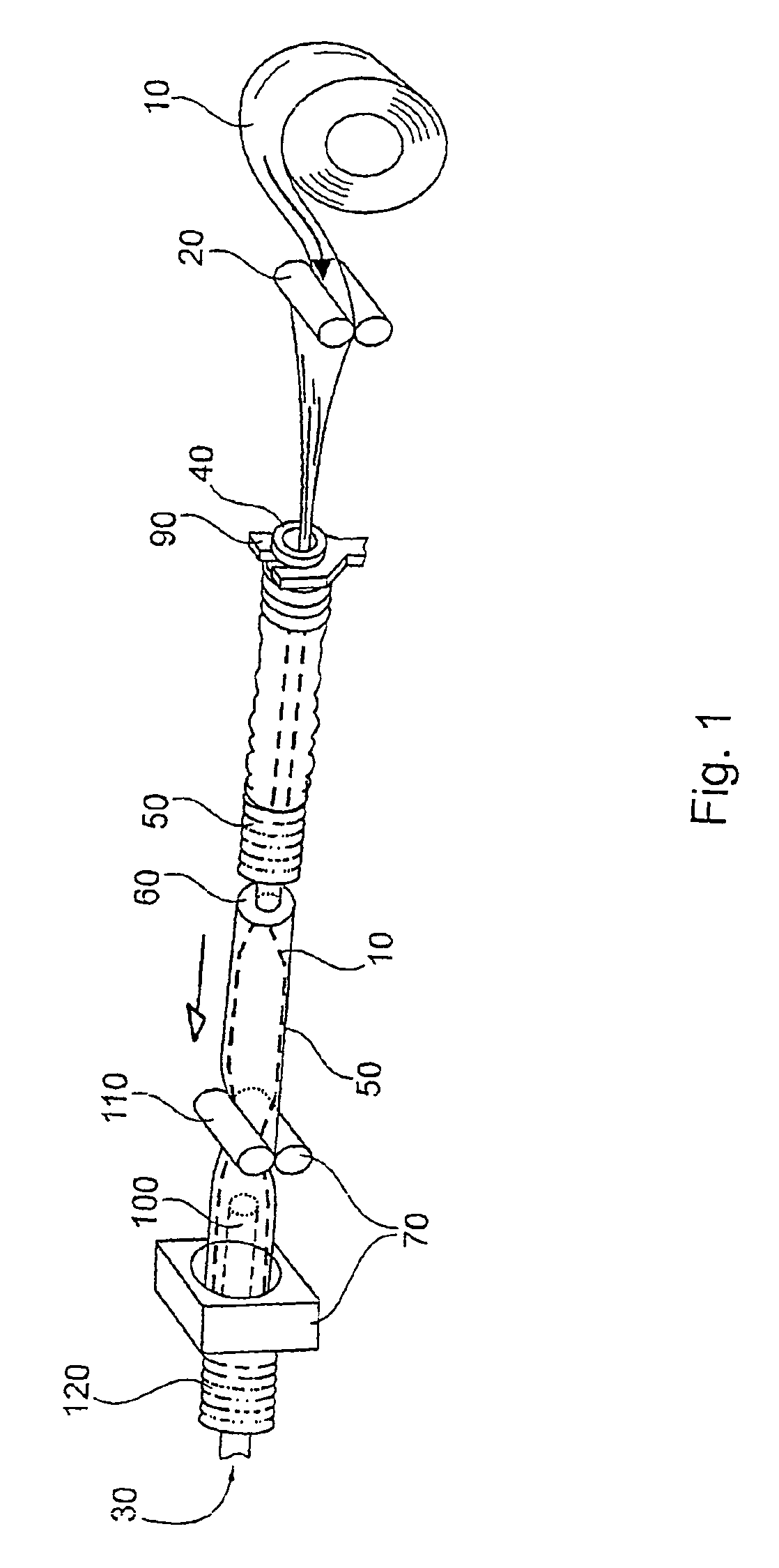

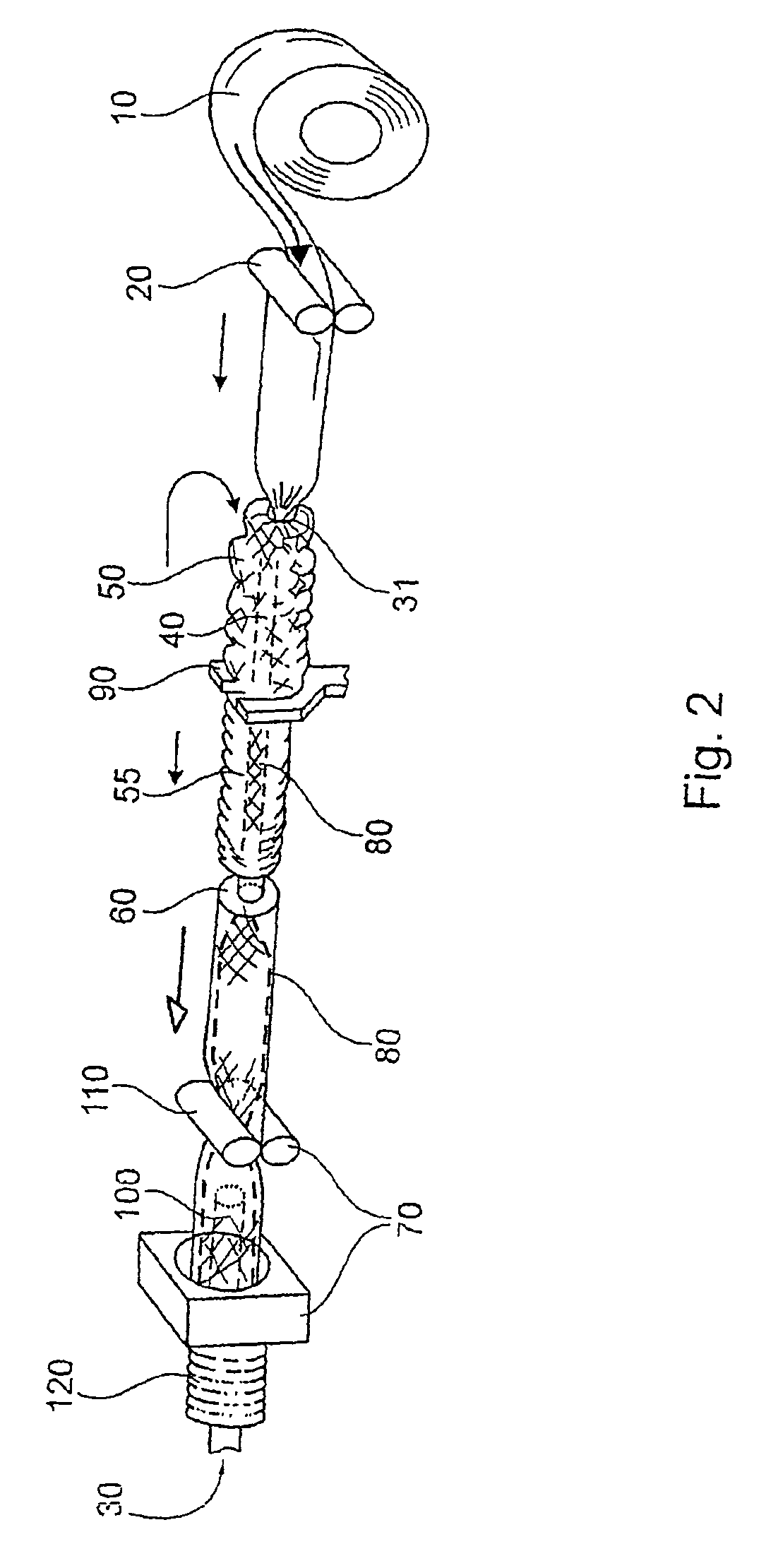

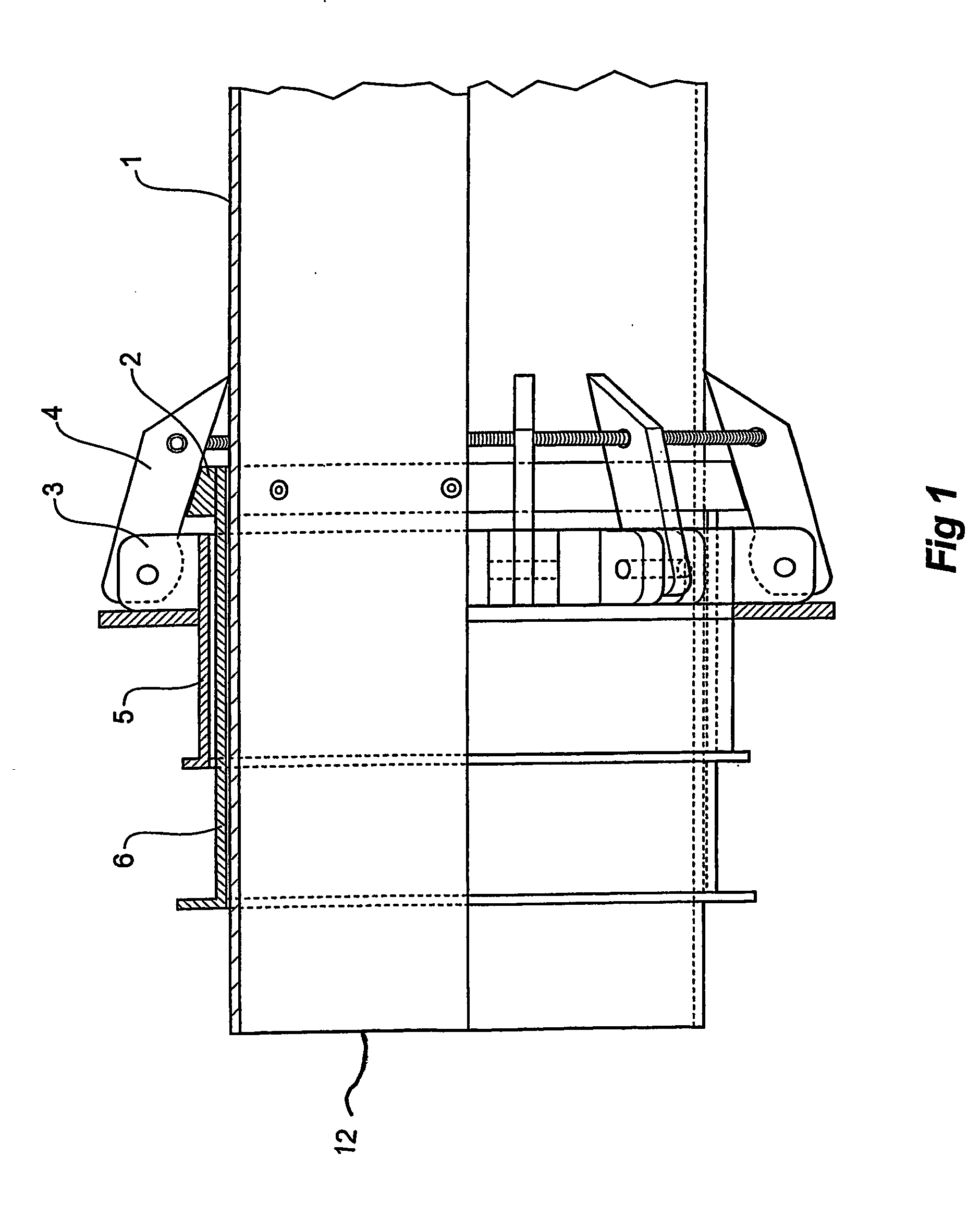

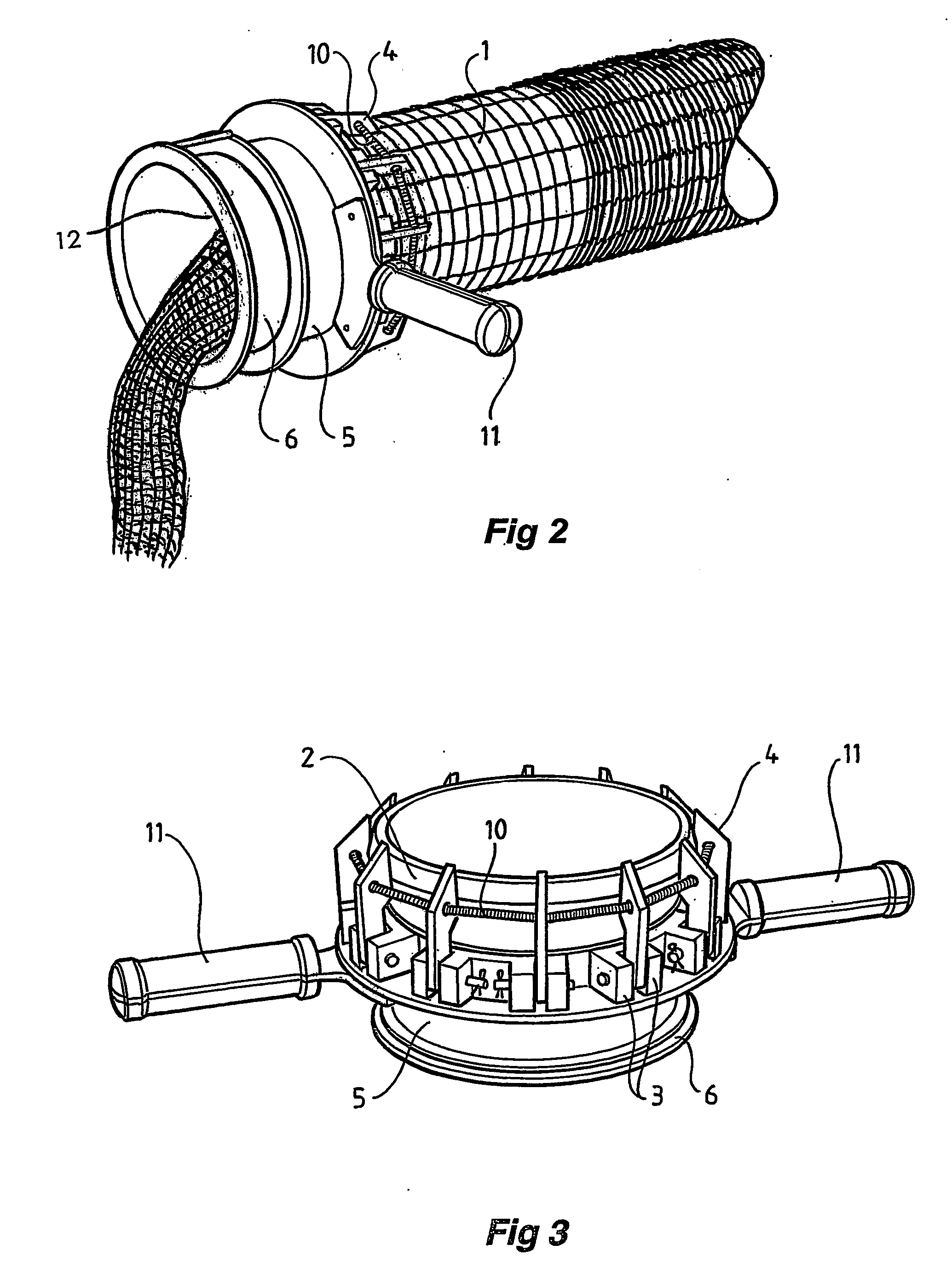

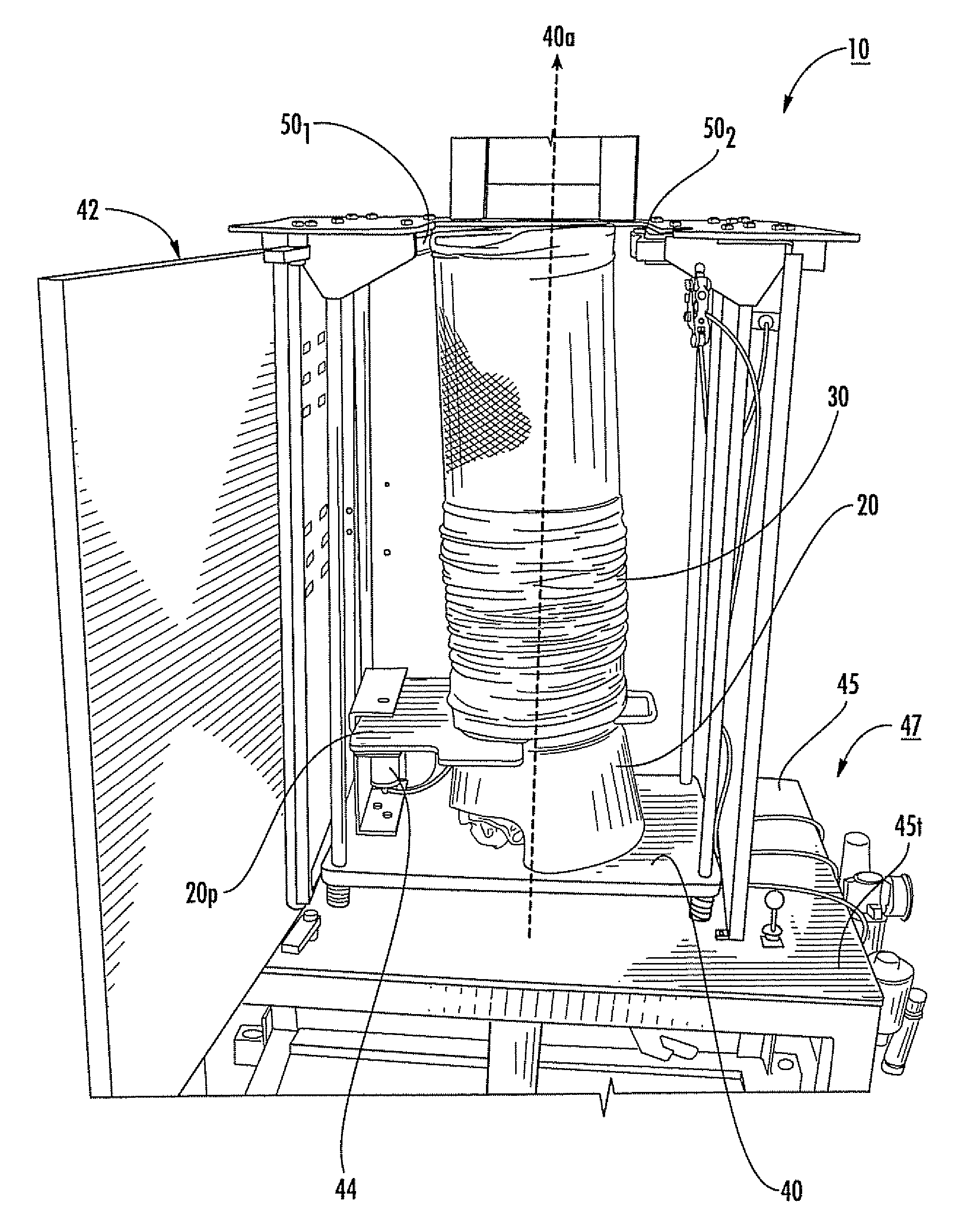

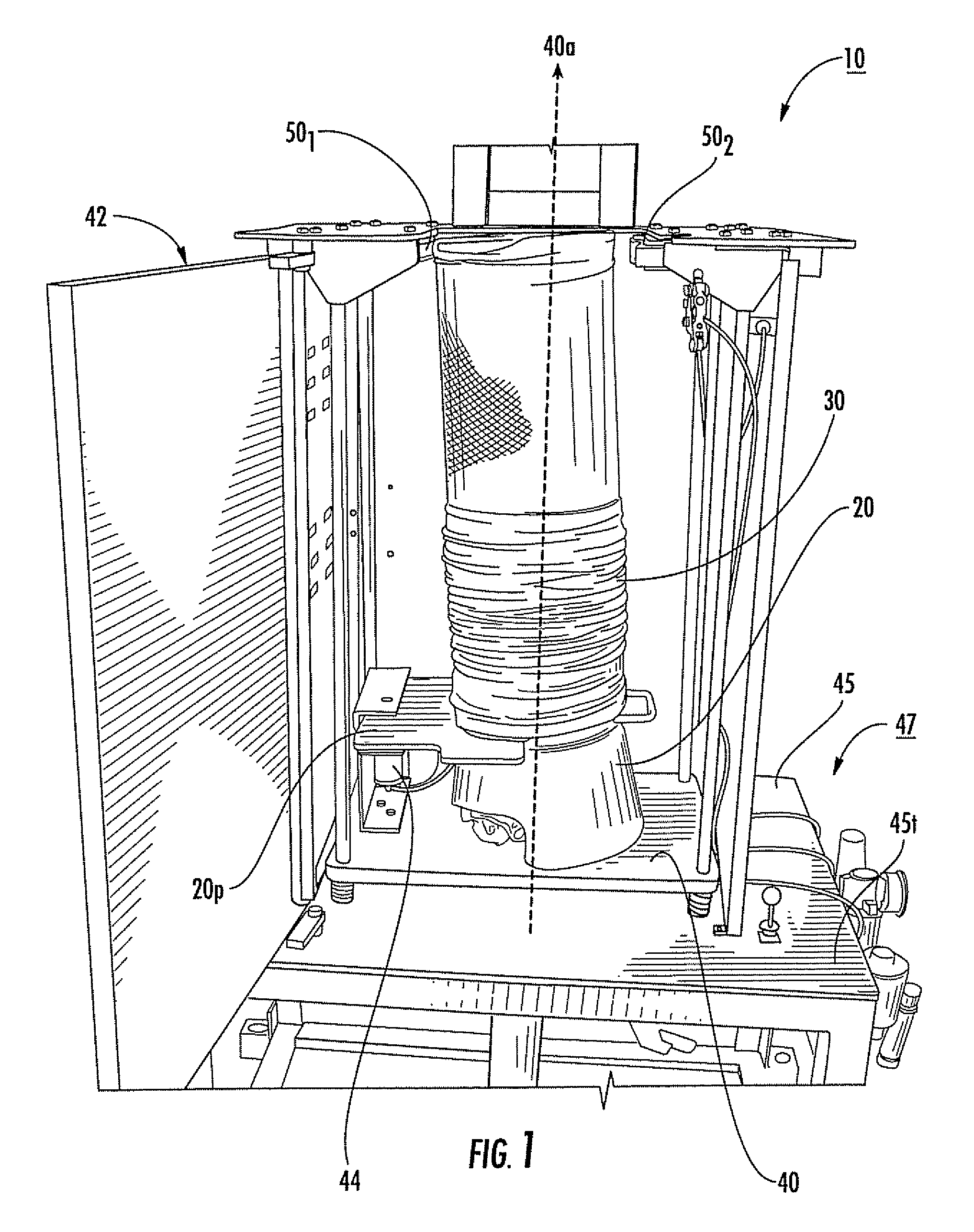

Net rucking apparatus and method

An apparatus and a method for rucking netting onto a tube are described. The apparatus, in a first embodiment, comprises a frame having an axis, a passage along the axis, means for reciprocating movement along the axis, a netting tube releasably attachable to the means for reciprocating movement, a second tube comprising a frustum having a bore, the second tube being slidable co-axially to the netting tube, an annular space defined by the second tube and the netting tube, and spring-loaded fingers attached to the frame and extending into the passage. In another embodiment, a method for rucking netting onto a tube comprises attaching a netting tube to a moveable platform, mounting a second tube axially over the netting tube, the second tube comprising a frustum having a bore therethrough, placing an end of a netting over the second tube, forming an annular space between the netting tube and the second tube, and moving the second tube reciprocatingly through spring-loaded fingers. The second tube is a frusto-conical shape, a frusto-pyramidal shape, or another frustum shape

Owner:PRETSITEK KORP

Packaging from a polymer film for food products

InactiveUS7361392B2Improve permeabilityEffective smoking and/or drying of a productWrappers shrinkageCocoaPolyamidePolymer thin films

A polymer film is disclosed for effectively smoking and / or drying products packed therein, which are to be smoked and / or air dried, in particular, smoked cheeses, smoked, uncooked smoked, and air-and-sunshine dried sausages, meat and fish products. This single-layer film is produced on the base matrix of an aliphatic polyamide and / or copolyamide and / or terpolyamide and contains 4.0-50.0 wt % of a hydrophilic compound which is in a highly dispersed state, wherein the hydrophilic compound forms a disperse phase with a linear size of the domain being 0.1-3.0 μm in a direction perpendicular to the plane of the film, and either a polymer compound or a low-molecular substance-salt, may be used as such.

Owner:OOO PKFATLANTIS PAK

Net loader

InactiveUS20050048886A1Easy to manufactureEasy to cleanSkinless sausage makingSausage filling/stuffing machinesManual insertionEngineering

A device for filling tubular casings with edible material is disclosed. The device includes a tube upon which the casing can be shirred onto, a tube inlet, a tube outlet and tube support means. The support means allows the device to be supported for the manual insertion of edible material into the tube inlet and furthermore the manual forcing of this edible material through the tube and out of the tube outlet.

Owner:MERCTECH

Feeder for meat pieces made of entire muscles for a piston stuffing machine

ActiveUS7314405B2Meat/sausage hanging-upSausage filling/stuffing machinesEngineeringMechanical engineering

Owner:VISCOFAN

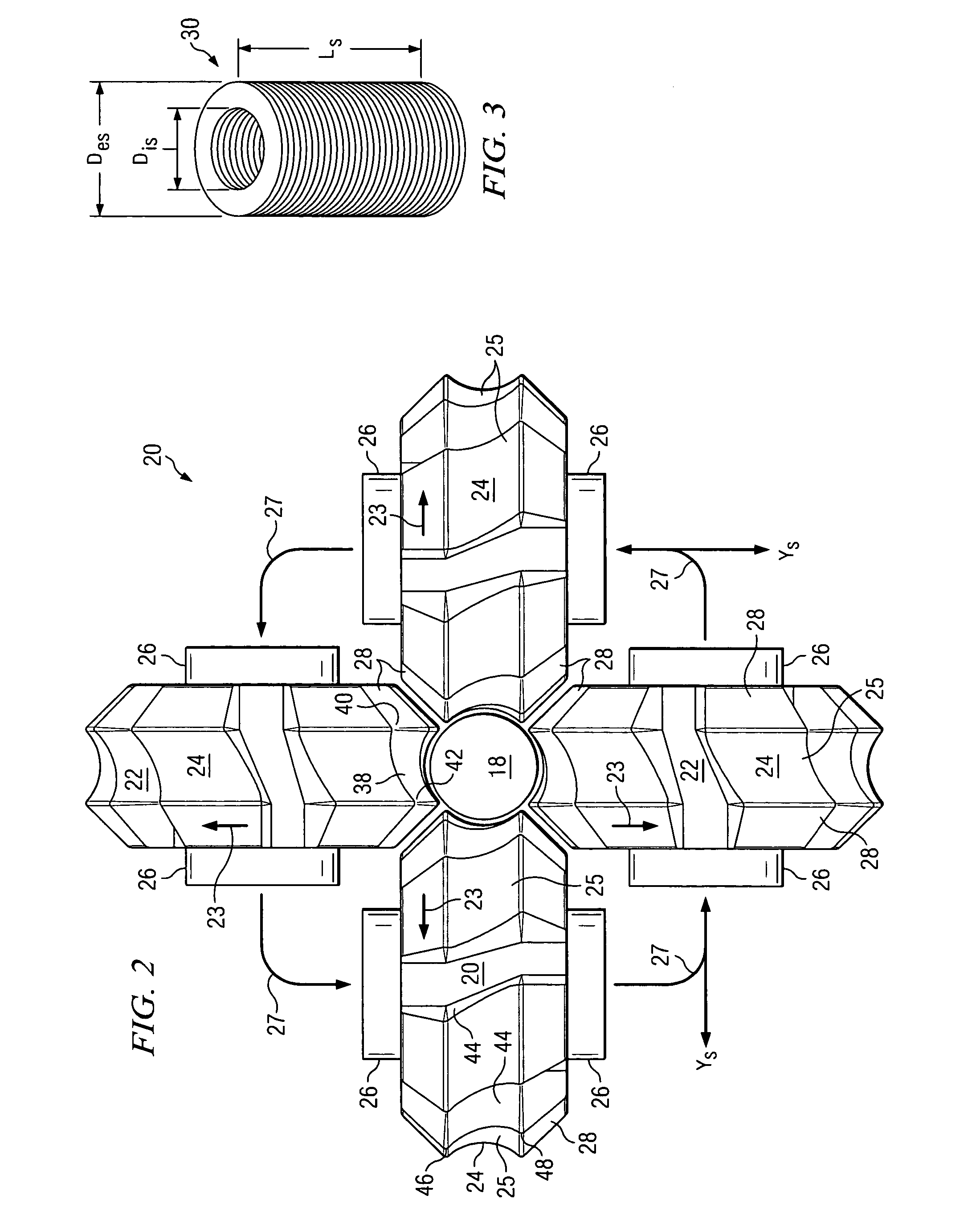

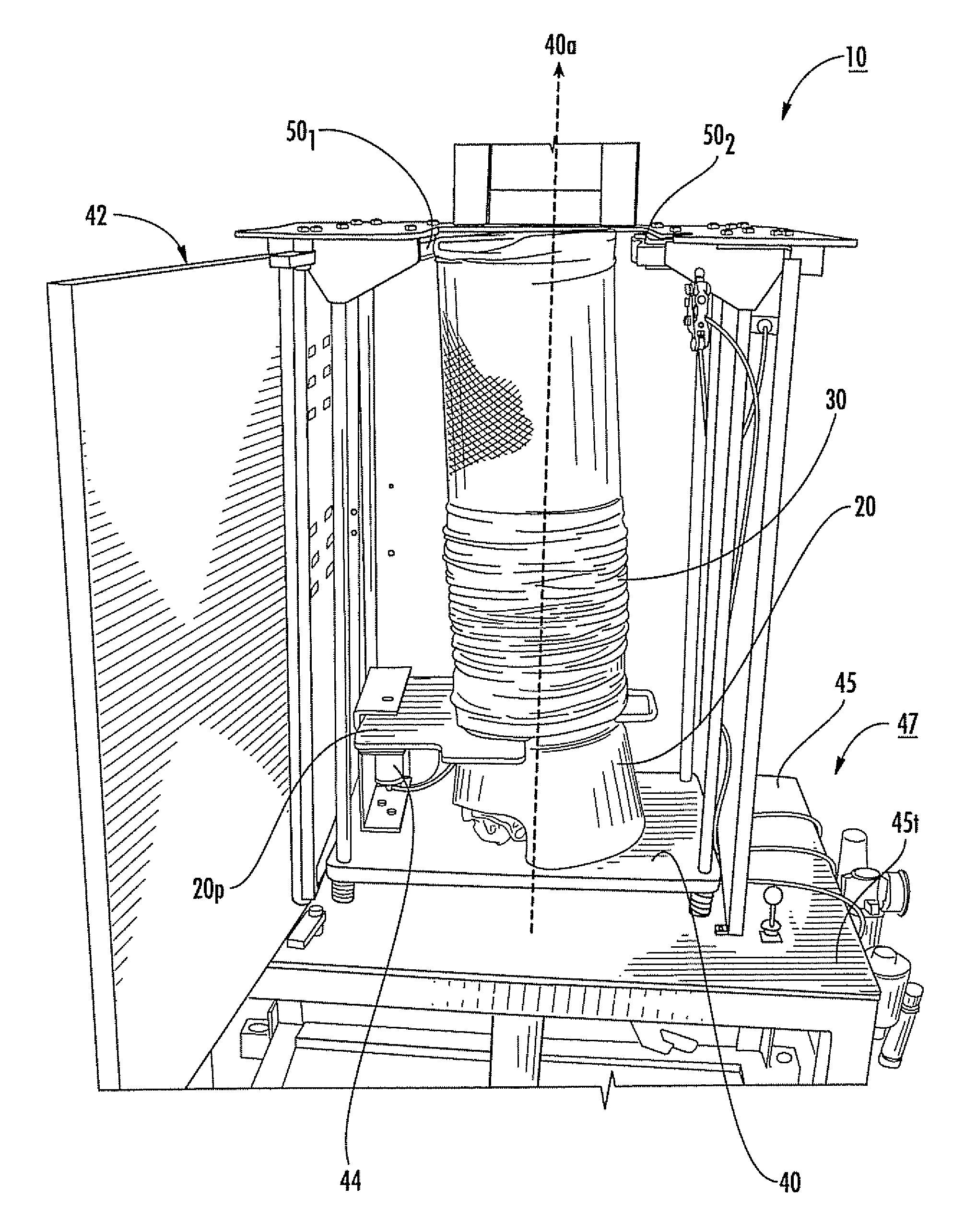

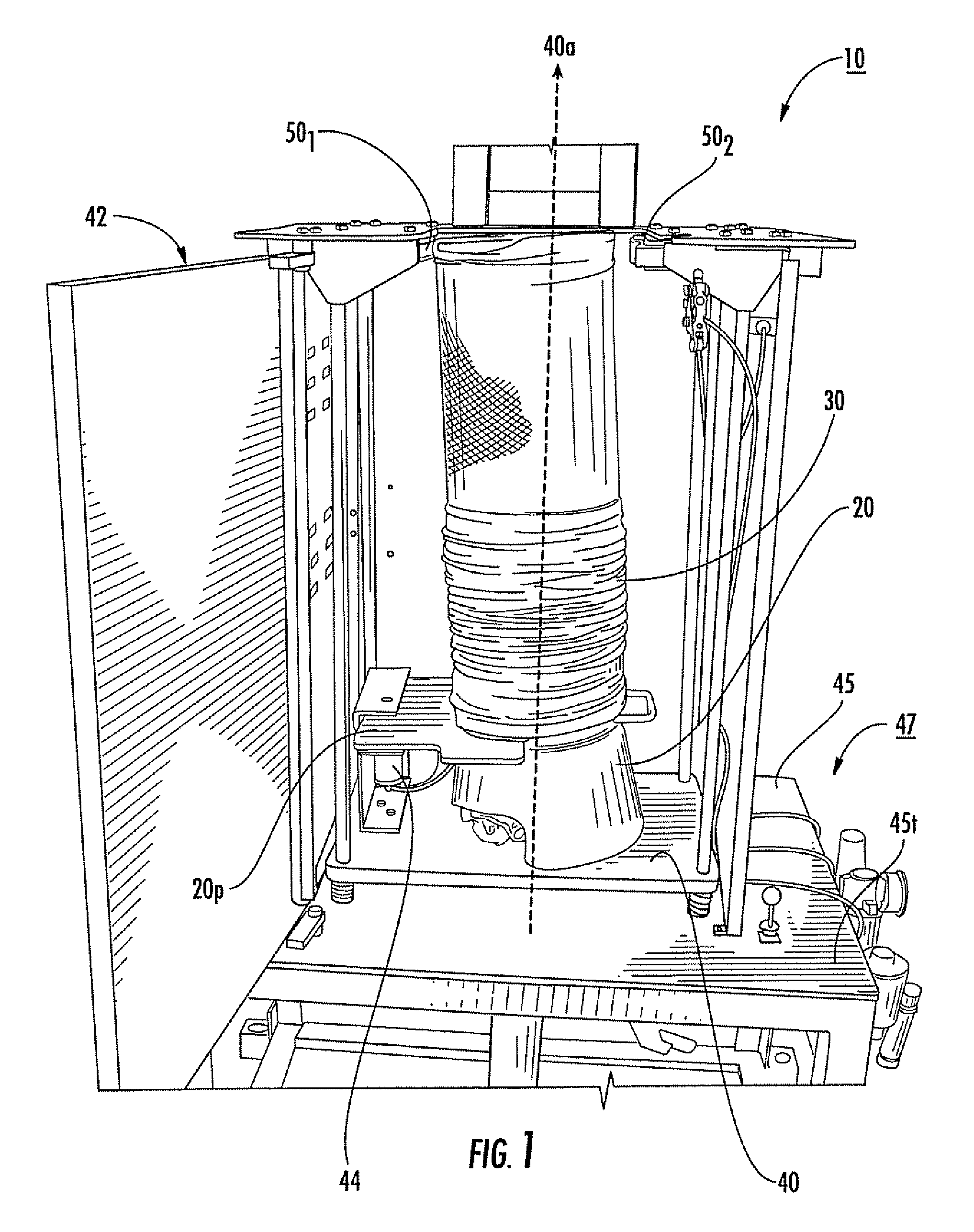

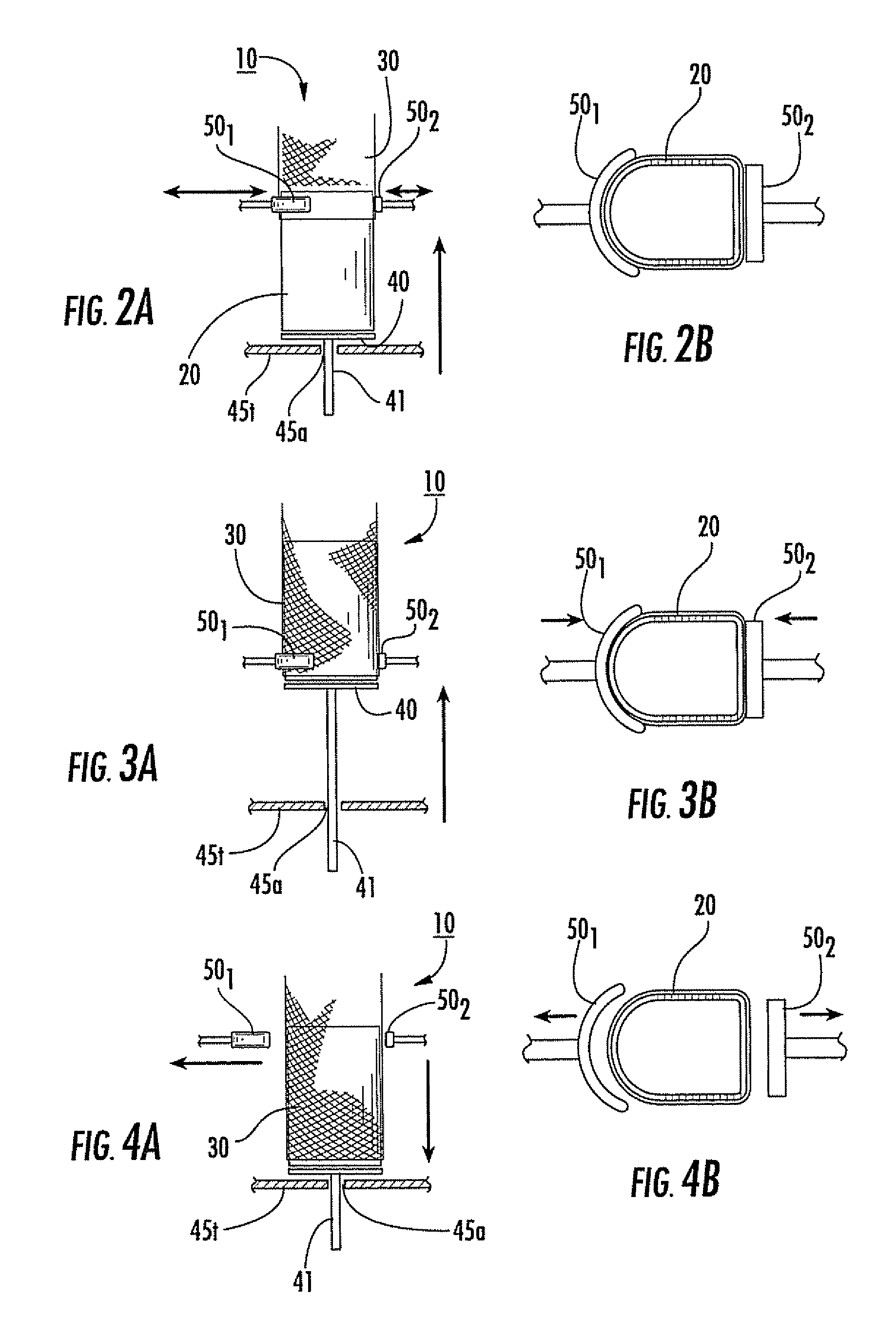

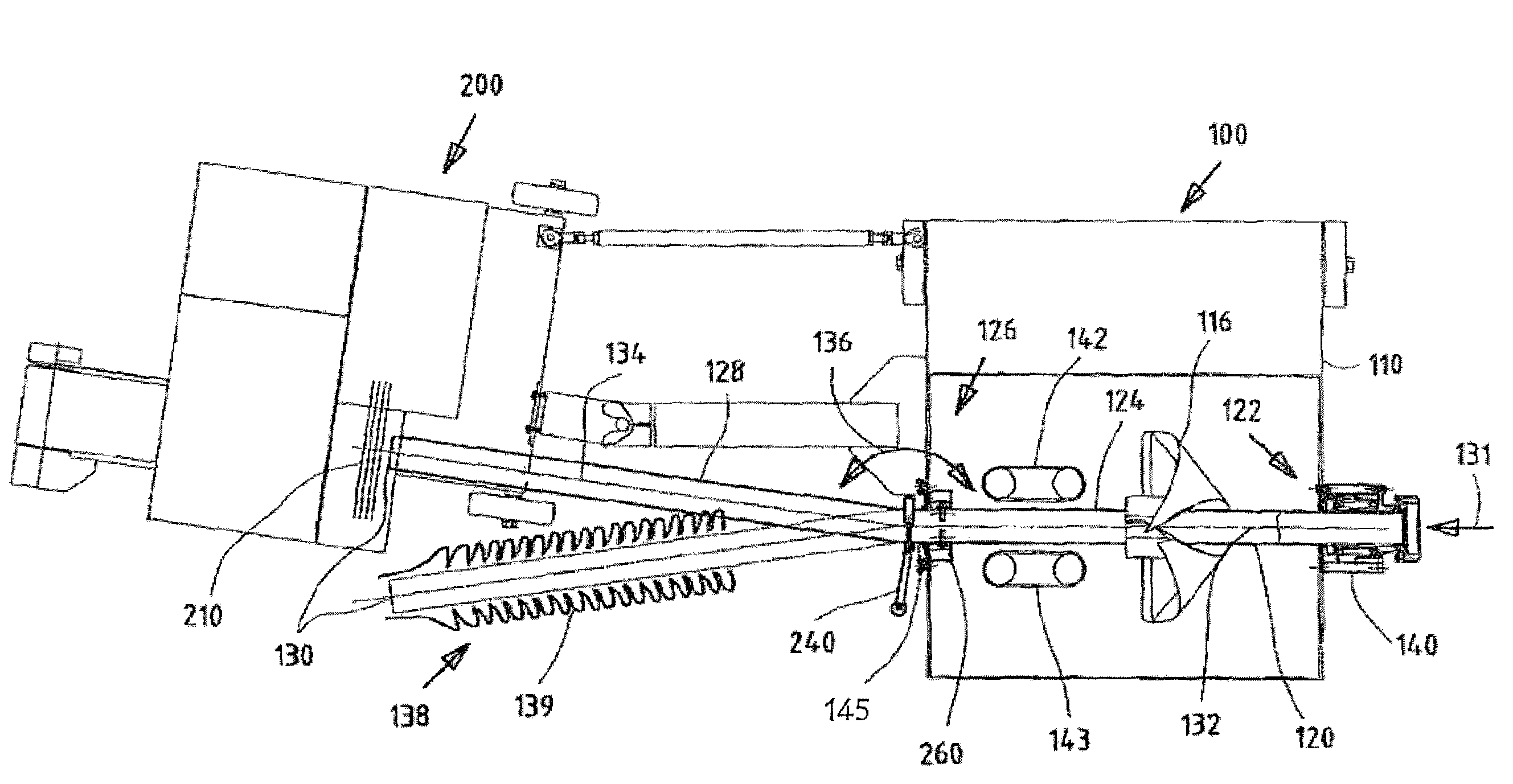

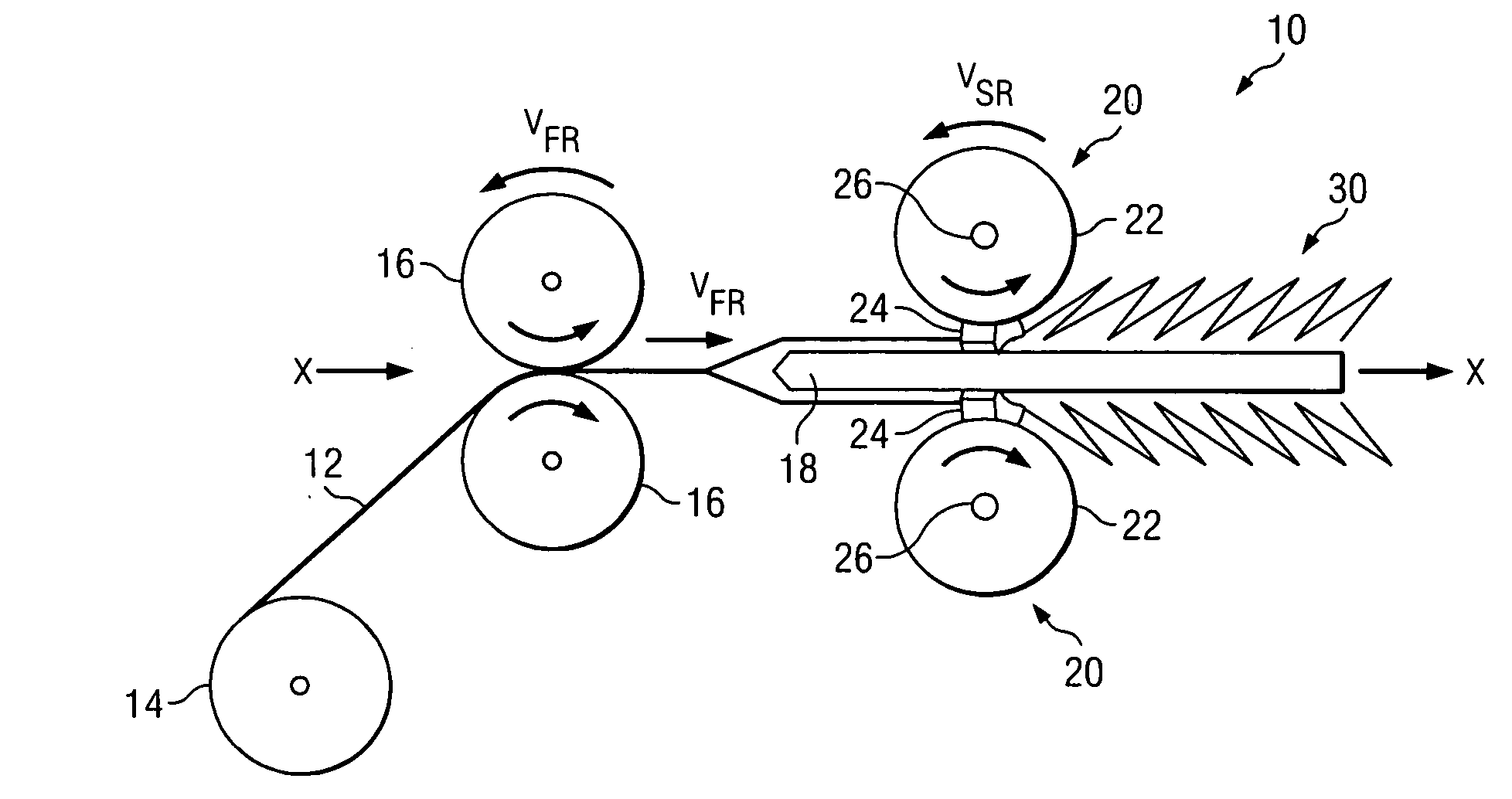

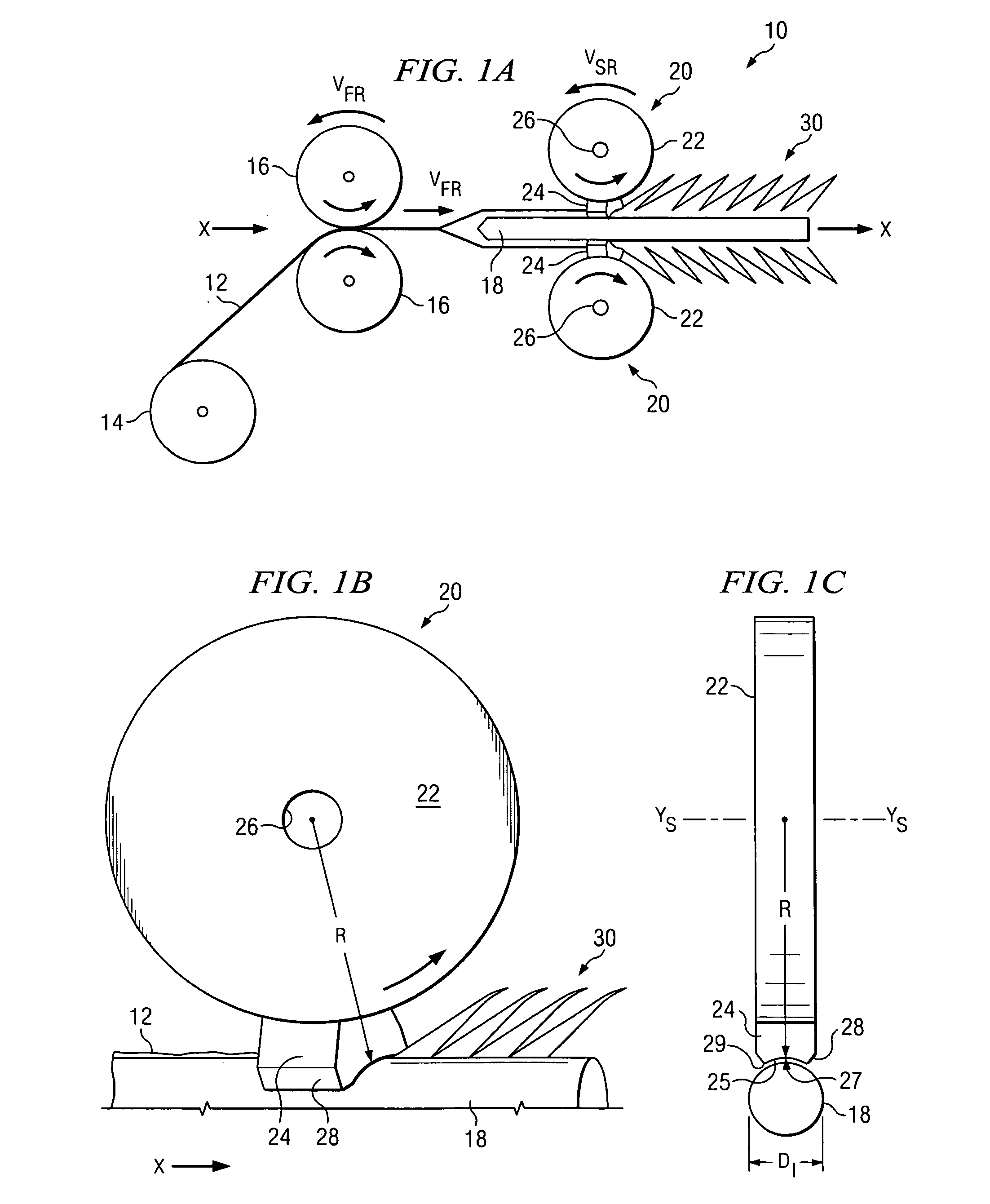

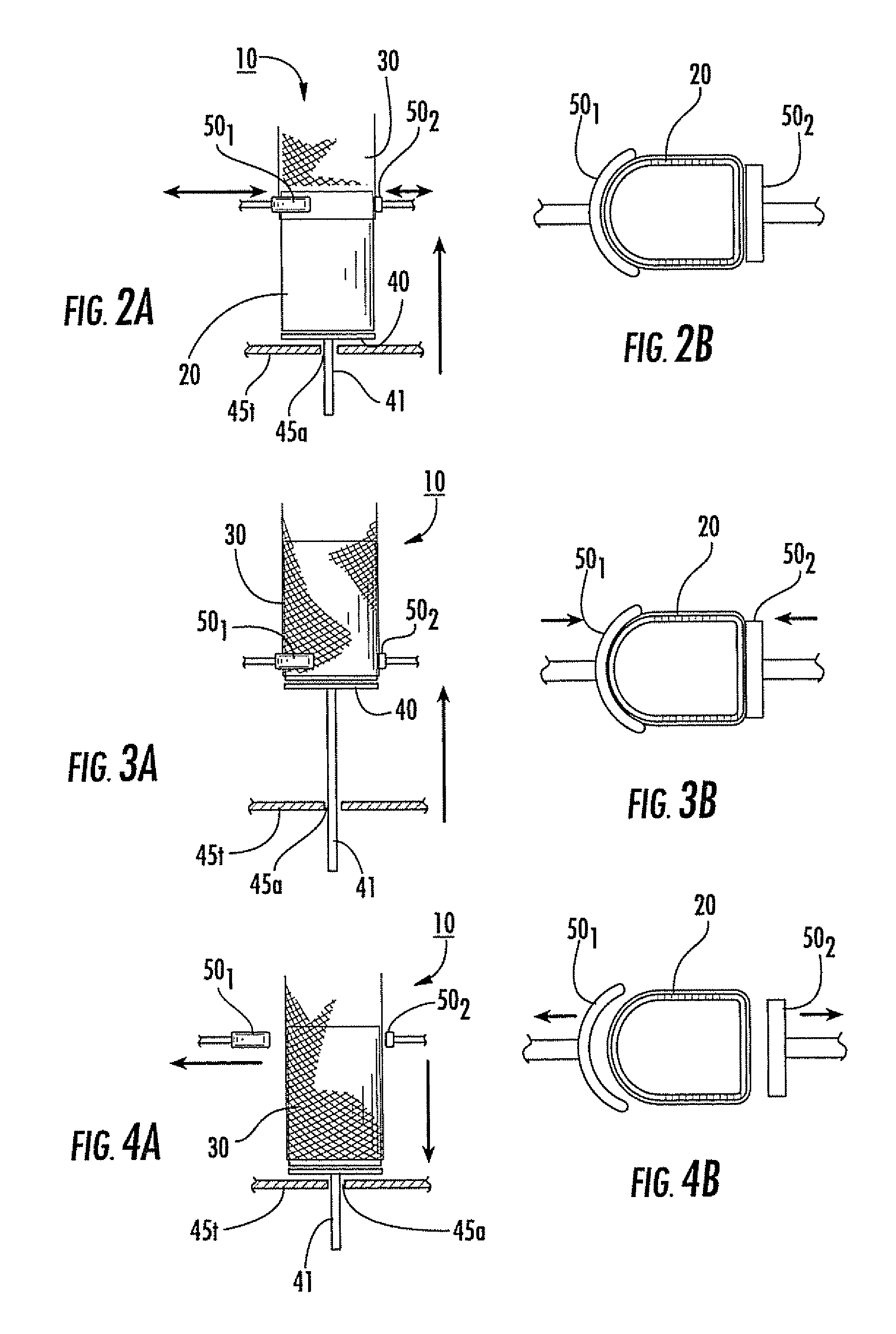

Ruckers capable of rucking fixed diameter coverings and associated devices, methods, systems and computer program products

Methods, apparatus and associated devices for rucking sleeves of covering material onto a chute body include a translating member disposed in a housing having an axis of movement configured to reciprocally translate a chute body about the axis of movement; and at least one gripping member disposed in the housing in cooperating alignment with the translating member. Each at least one gripping member has a gripping edge portion that defines a gripping surface. The at least one gripping member configured to reciprocally translate substantially orthogonal to the axis of movement. In operation, the at least one gripping member has an automated stroke cycle whereby the at least one gripping member is configured to travel inwardly a distance sufficient to snugly abut an outer surface of the chute body while the chute body travels in a first direction about the axis of movement and to travel outwardly a sufficient distance to prevent contact with the chute body while the chute body travels in a second opposing direction about the axis of movement.

Owner:TIPPER TIE

Net rucking apparatus and method

An apparatus and method for shirring netting onto a netting tube. A second tube is placed over and coaxially to the netting tube and netting is stretched over the second tube. The two tubes are caused to move in a reciprocating manner through a plurality of spring-loaded fingers, which allow the netting to pass on the downstroke and hold the netting on the upstroke. As the two tubes move, the netting is pulled over the second tube and shirred onto the netting tube. An annular space formed by a tube ring placed between the netting tube and the second tube causes the netting to shir in multiple, neatly aligned layers.

Owner:POLY CLIP SYST

Packaging device for free-flowing bulk material (filling)

InactiveUS7392642B2Simple designEasy to handleSausage makingSausage casing shirringFilling materialsEngineering

Owner:POLY CLIP SYST

Process For Producing A Composite Food Casing

InactiveUS20100255230A1Avoid entanglementThermoplastic sausage casingsMultilayer sausage casingsPulp and paper industry

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shining the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

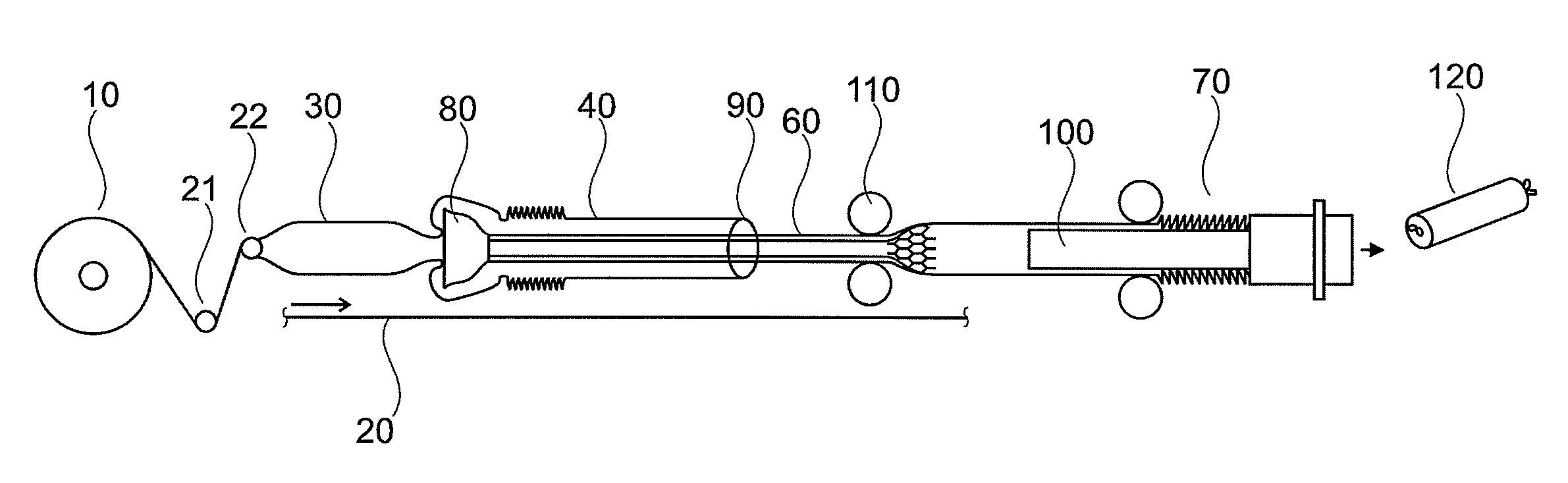

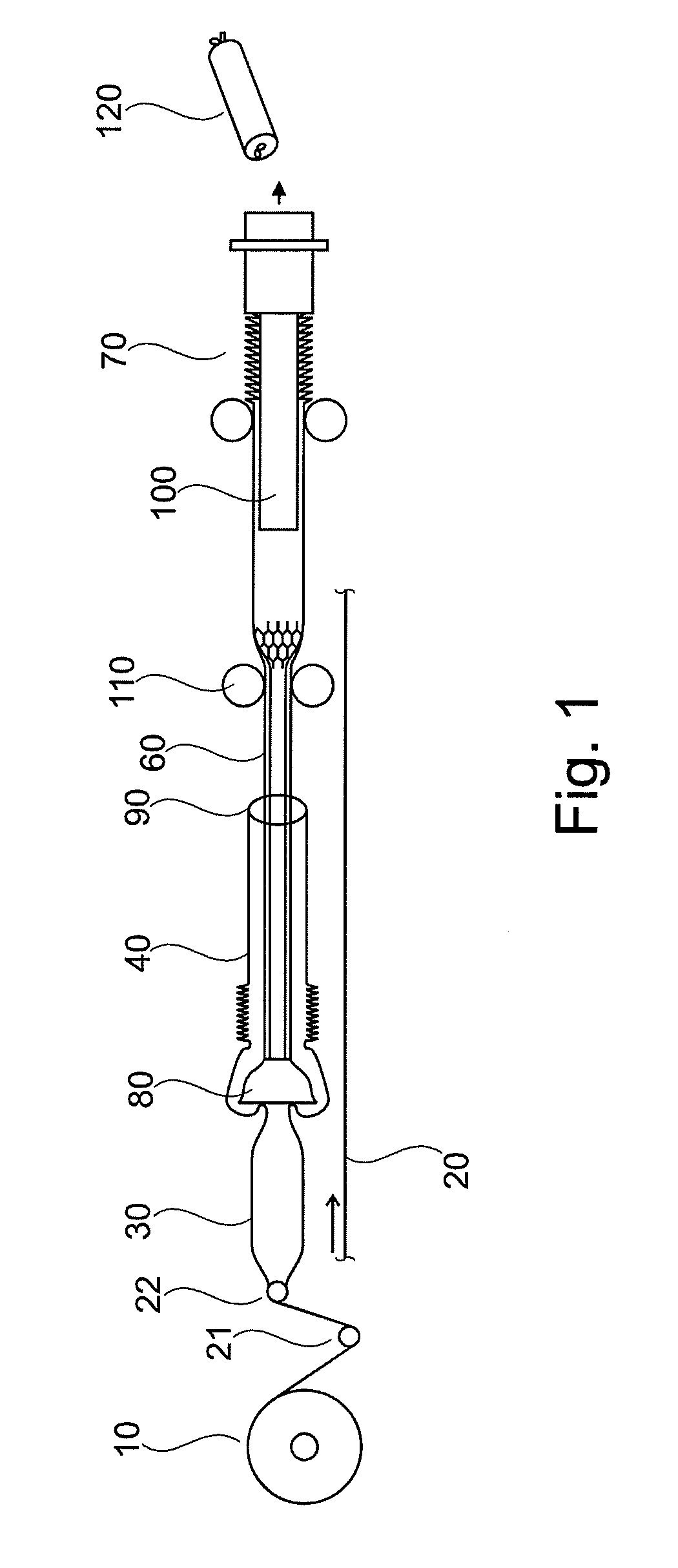

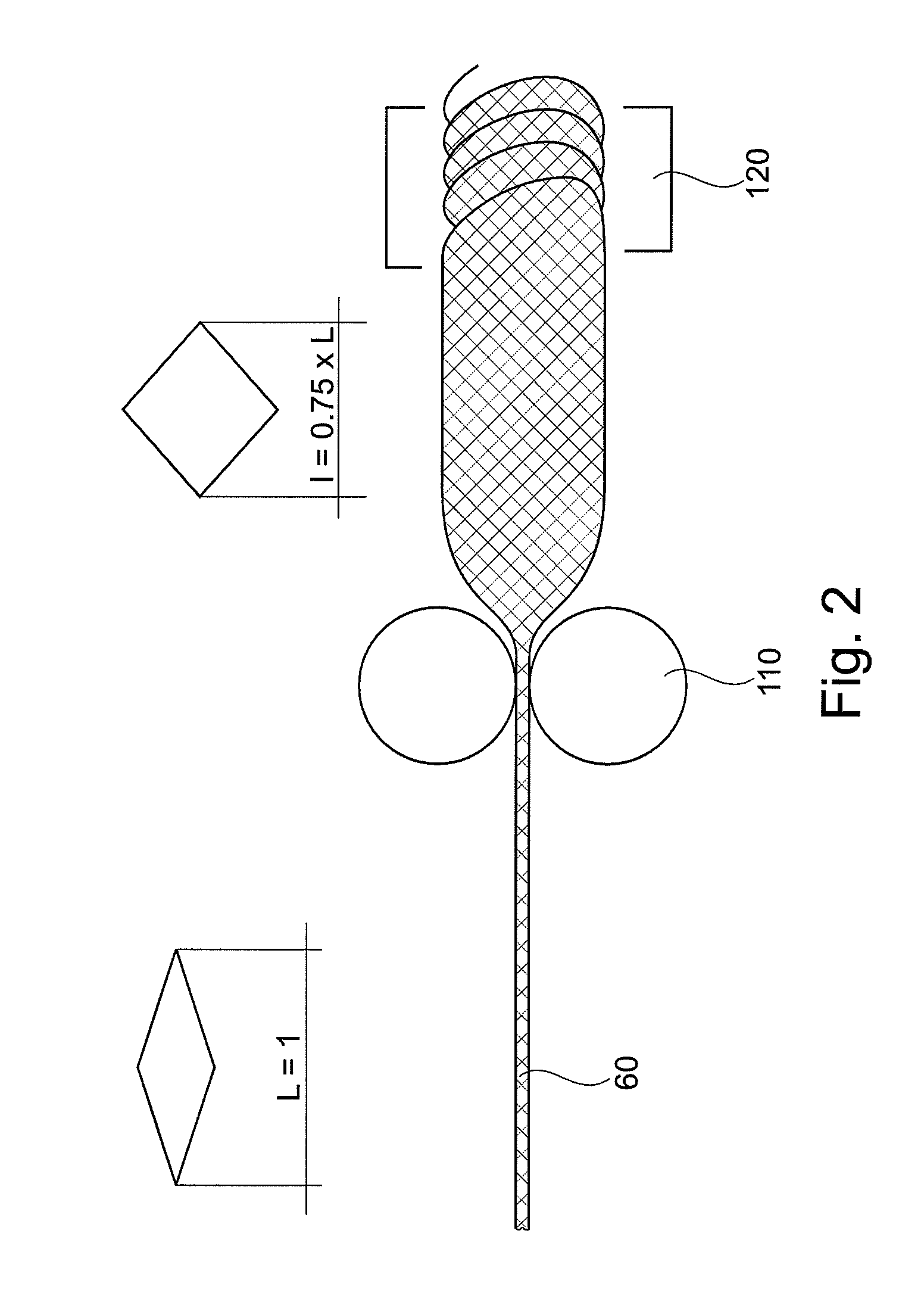

Method for Producing a Netted Casing

InactiveUS20090075575A1Avoid bendingShorten the lengthSausage casing manufactureSausage casing shirringEngineeringMechanical engineering

The invention relates to a method for producing a shirred food casing covered by a net, and a method for combining a net with a surface of a carrier casing, said method comprising steps wherein air or an inert gas is blown into the carrier casing, the carrier casing inflated / pressurized to be round is pulled in the direction of the tubular net towards a pleating head attached to one end of the tubular net, said net being attached at the open end thereof to a clamp centralized with a shirring mandrel, the carrier casing being thus folded into the tubular net while pulling the net inside out over itself, followed by pulling the carrier casing through the pleating head to the shirring machine where the pressure of air or an inert gas blown from inside of the shirring mandrel forces the areas of the carrier casing between the meshes of the net to form bulges, and finally the net / carrier casing combination is shirred by the shirring machine. The invention is further directed to a shirred product produced with the method.

Owner:VISKOTEEPAK BELGIUM NV

Process for producing a composite food casing

InactiveUS8226457B2Thermoplastic sausage casingsMultilayer sausage casingsPulp and paper industryCaterpillar

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shirring the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Moulded articles of cellulose hydrate with enzymatically modified surface

InactiveUS6761944B1Increase roughnessEvenly distributedCellulosic pulp after-treatmentWrappersCellulaseHydrate

The invention relates to a process for the treatment, in particular for the roughening, of the surface of hydrated cellulose shaped articles, in which at least one cellulase is allowed to act on the surface and is then inactivated permanently. The tubular films modified in this way are particularly suitable as foodstuff casings, specifically as sausage casings.

Owner:KALLE NALO

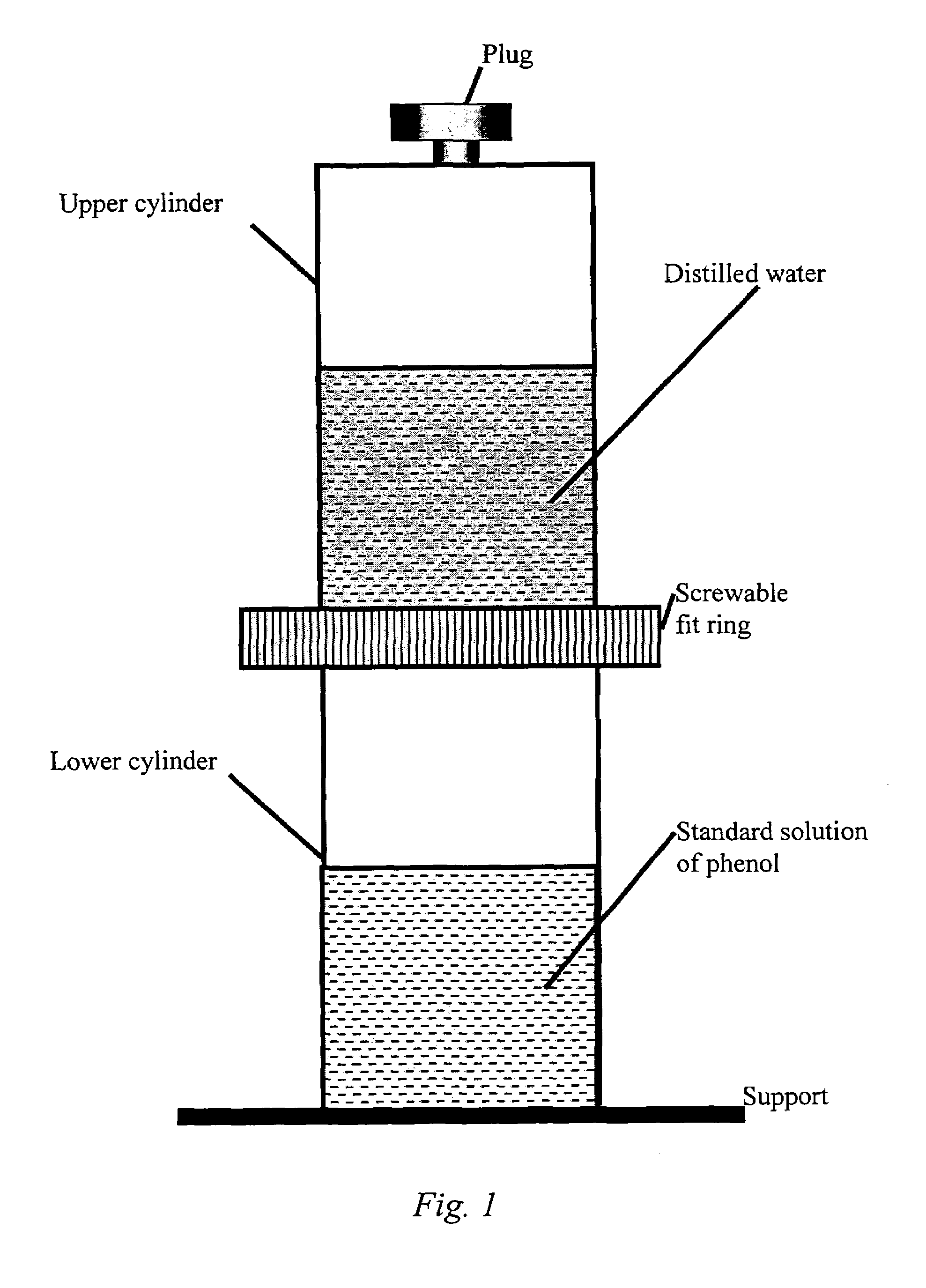

Special tool for processing guide sheet casing and method for sleeving guide sheet casing

The invention discloses a special tool for processing a guide sheet casing, which comprises a sleeving pipe for sleeving the casing, wherein the sleeving pipe is a thin-walled pipe with an opening at an operating end thereof and with a pipe cavity thereof capable of being sleeved with the guide sheet, and which further comprises a plug matched with the opening. One embodiment of the invention further comprises a mounting base which can be fixed to an operating platform. A method for sleeving the processed guide sheet casing is characterized by comprising the following steps: 1) inserting the plug into the opening of the sleeving pipe; 2) sleeving the casing outside the sleeving pipe for crumpling; 3) taking off the plug; 4) inserting the guide sheet into the sleeving pipe; 5) transferring the crumpled casing onto the guide sheet; 6) withdrawing the guide sheet out of the sleeving pipe; and 7) infecting tongue parts at two end parts of the guide sheet. The special tool is simple in structure and low in cost; the casing has no contact with the guide sheet during crumpling, so the finished rate of casing is high; and the special tool has the advantages of: being free from lubrication by water flushing, saving water, convenient and fast operation and enhancing efficiency by about 30% compared with the prior art.

Owner:GUANGYUAN HAIPENG BIOLOGICAL TECH

Method for producing a netted casing

InactiveUS7883399B2Sausage casing manufactureSausage casing shirringEngineeringStructural engineering

Owner:VISKOTEEPAK BELGIUM NV

Multi-rod shrinking machine

InactiveCN104909004ASimple structureLow costPackagingSausage casing shirringButt jointPulp and paper industry

The invention discloses a multi-rod shrinking machine which comprises a frame, a shrinking mechanism, a shrinking rod, a cutting mechanism, a multi-rod receiving mechanism, a moving clamp, a first rod supporting clamp and a second rod supporting clamp, wherein the shrinking mechanism, the shrinking rod, the cutting mechanism, the multi-rod receiving mechanism, the moving clamp, the first rod supporting clamp and the second rod supporting clamp are mounted on the frame. The moving clamp is used for moving shrinking materials, and the first rod supporting clamp and the second rod supporting clamp are used for clamping the shrinking rod. The two ends of the shrinking rod are provided with a first air inlet and a first air outlet respectively. The first air inlet and the first air outlet are communicated with a first inner cavity. The two ends of each receiving rod are provided with a second air inlet and a second air outlet respectively. The second air inlet and the second air outlet are communicated with a second inner cavity. The second air inlet is connected with an inflation pump. When the receiving rod is in butt joint with the shrinking rod, air is conveyed to the shrinking rod from the receiving rod, and therefore the inflation process is completed. The mode that through a traditional technology, inflation is completed through a vacuum pump is replaced, the structure is simple, cost is effectively lowered, automatic production efficiency is improved, and market popularization is facilitated.

Owner:莫少难

Food casing release coating comprising polyglyceryl esters

A food casing having an internal surface coating of a dried aqueous emulsion including at least one polyglyceryl ester. The polyglyceryl ester in the coating covers the internal surface of the food casing in an amount of from about 200 to about 1200 mg per square meter. The polyglyceryl ester may be almost any polyglyceryl ester having from about 1 to about 4 ester groups formed with carboxylic acids having from about 6 to about 18 carbon atoms. The polyglyceryl ester may for example be selected from triglyceryltetraoleate and triglycerylmonooleate. The food casing has superior meat release characteristics in certain applications.

Owner:HARRIS TRUST & SAVINGS BANK +1

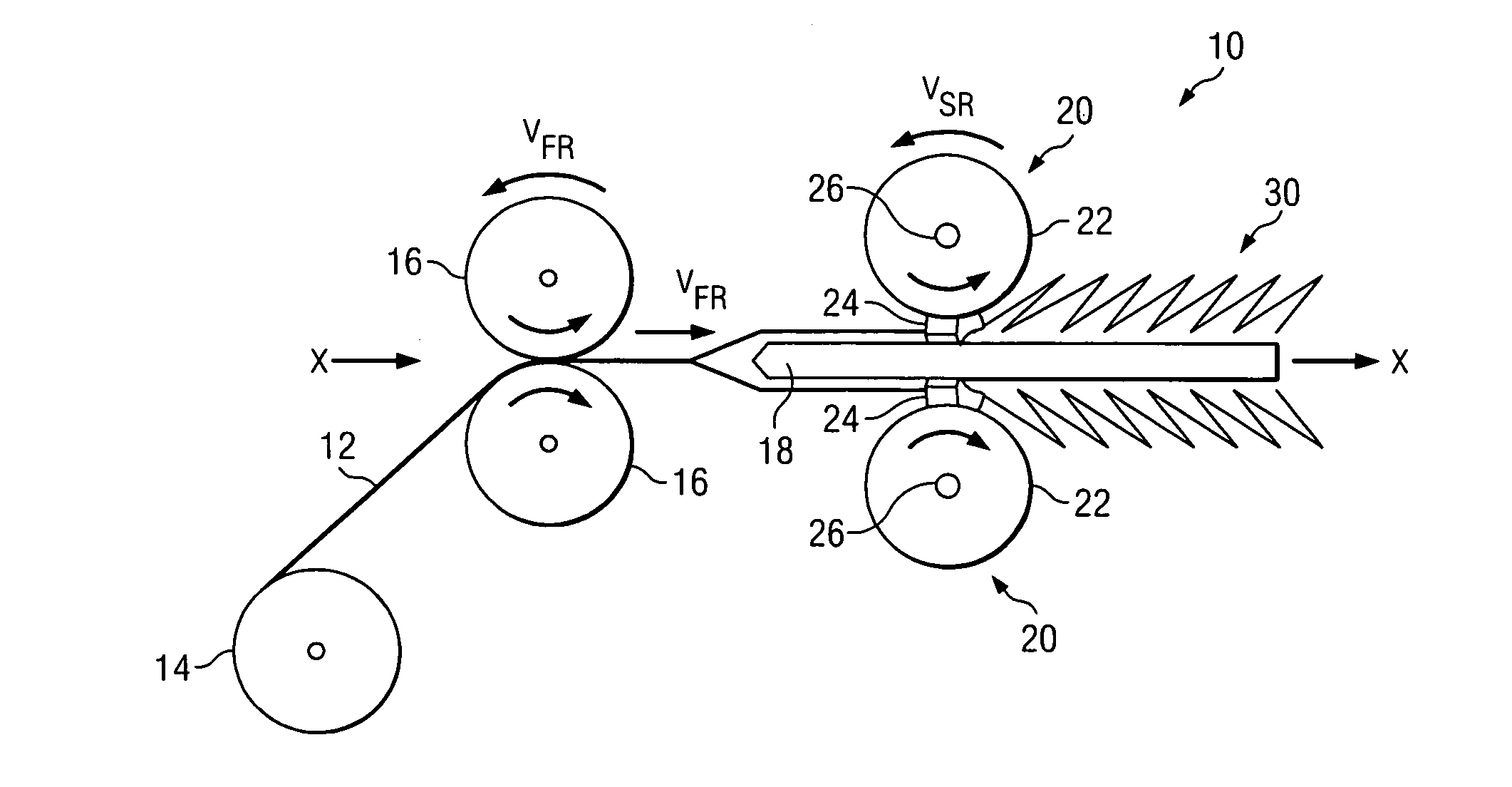

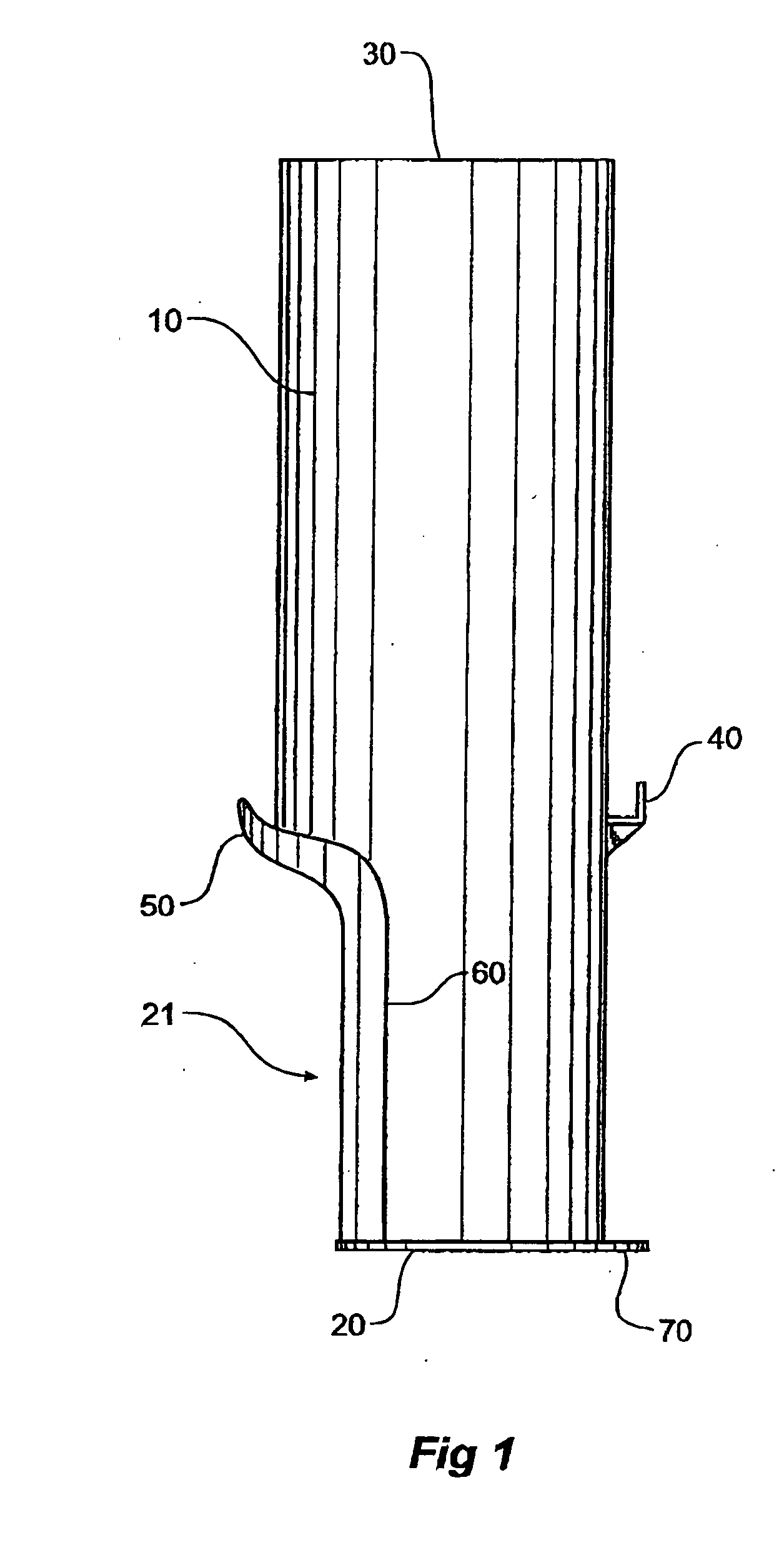

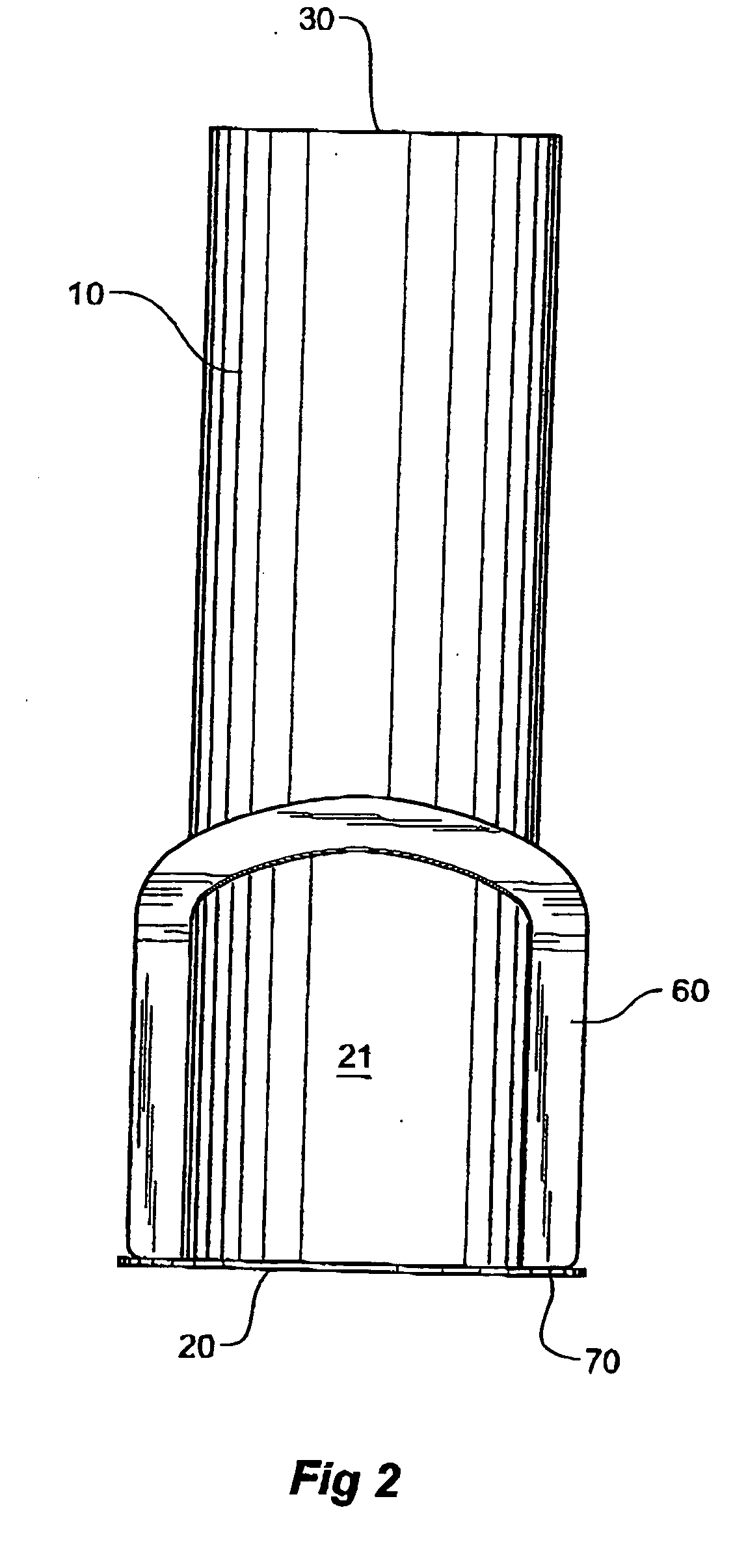

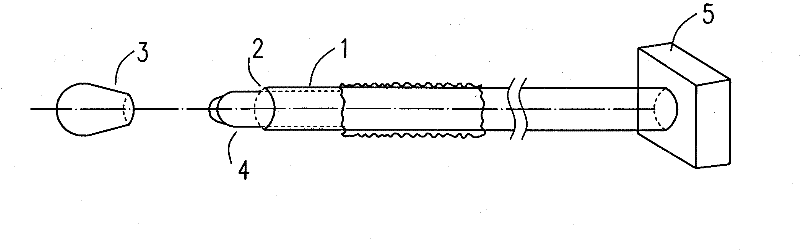

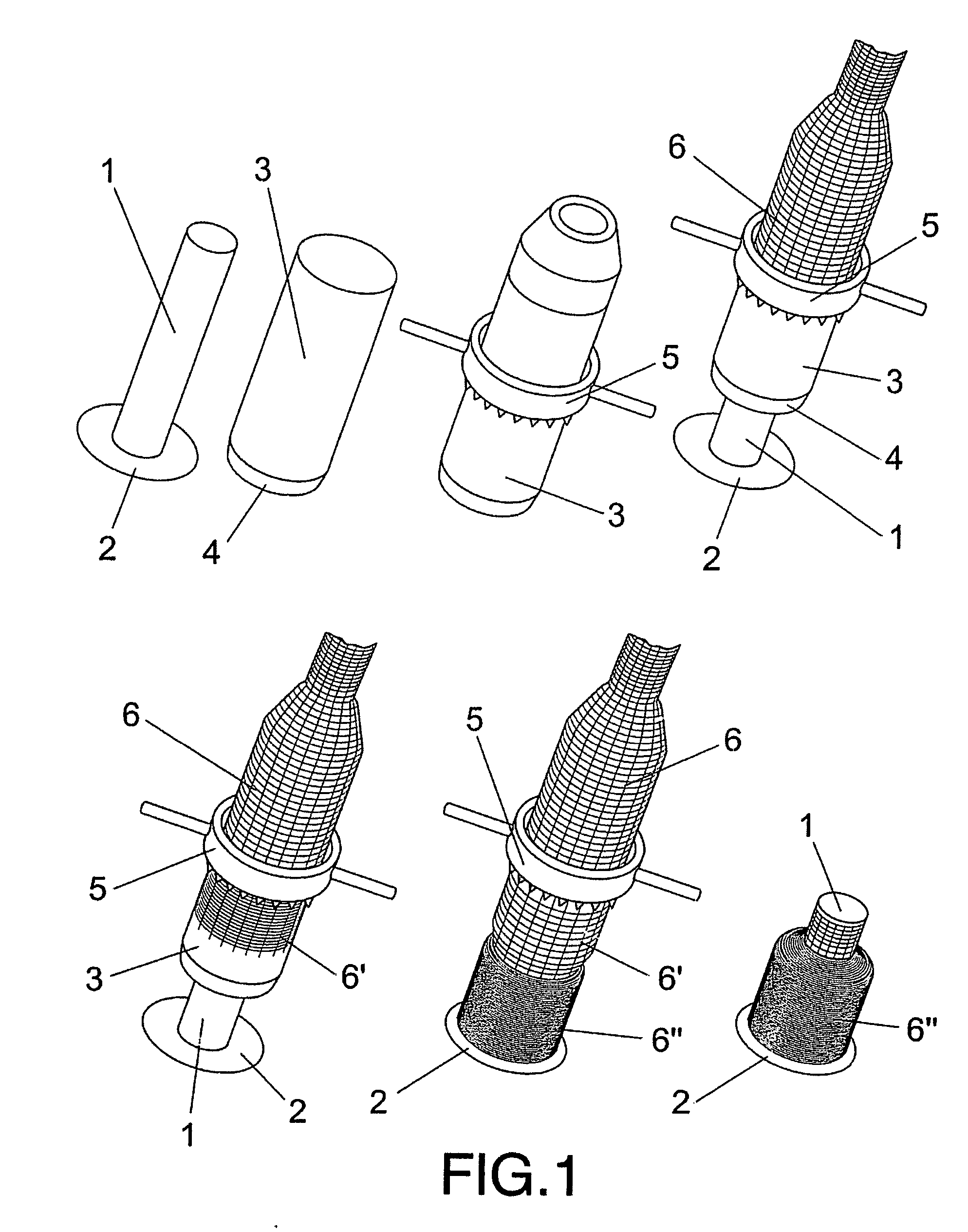

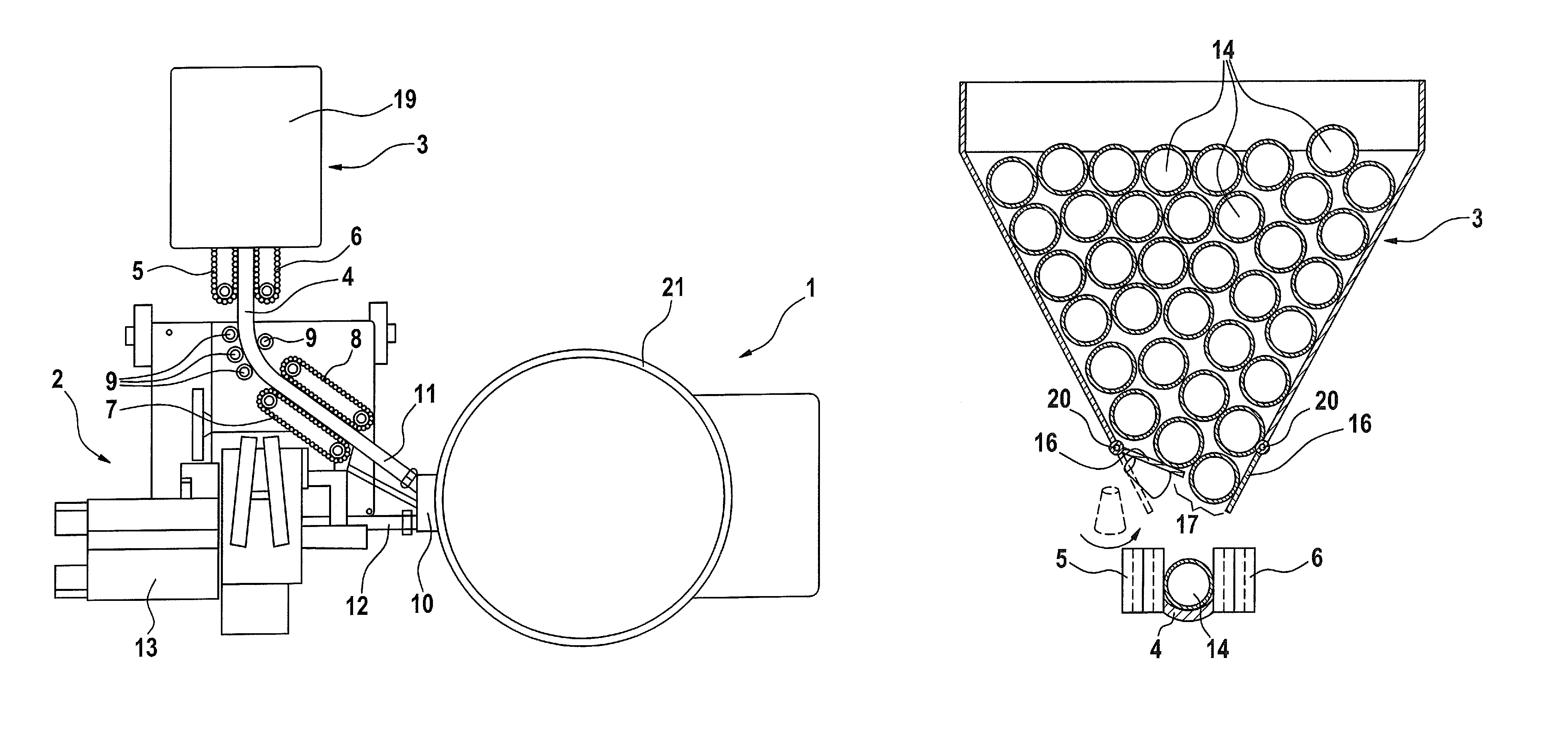

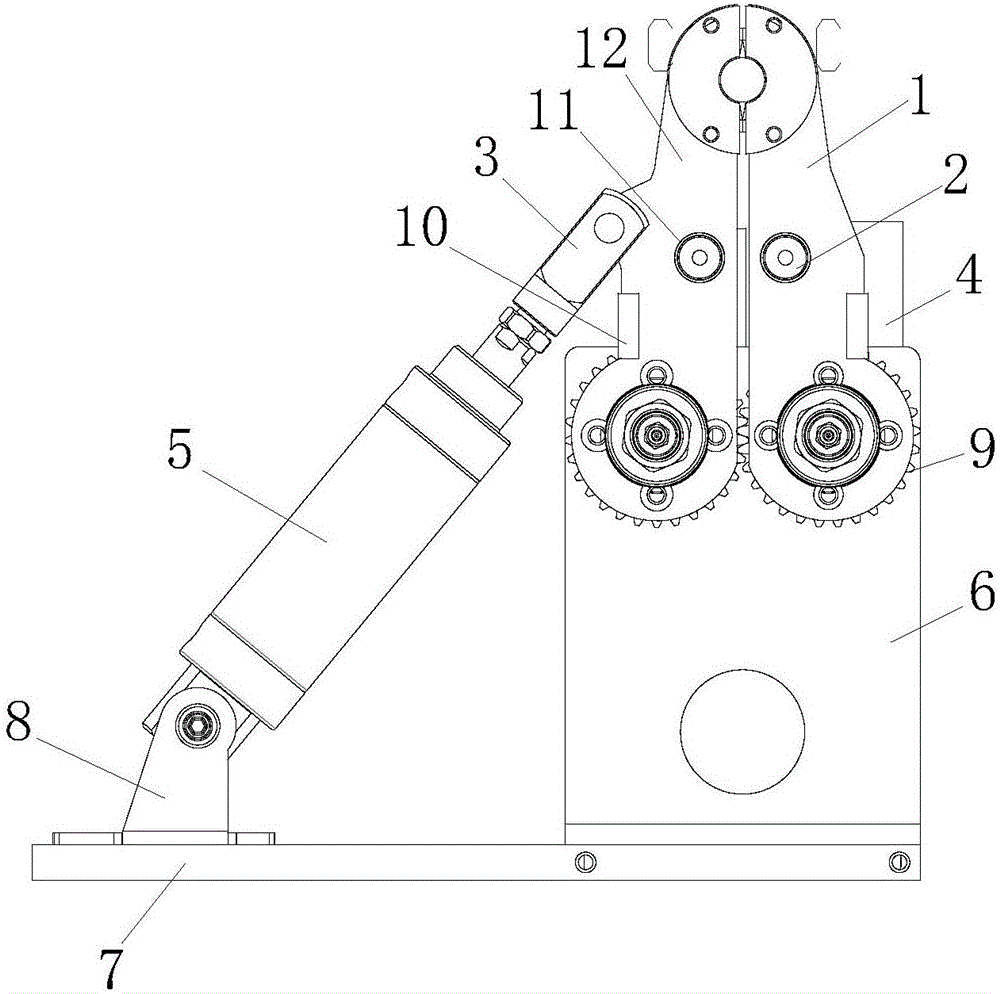

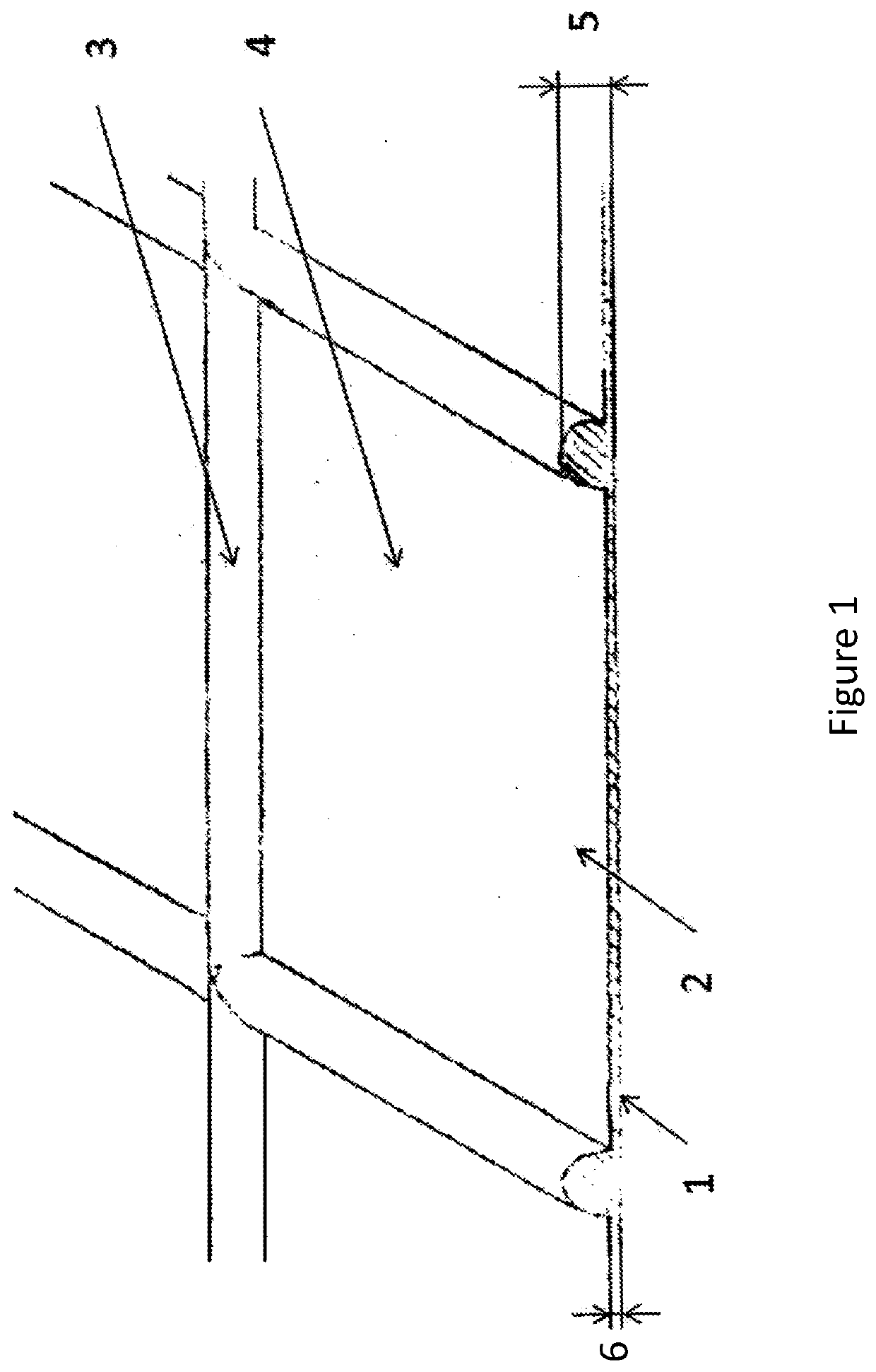

Multi-layer arrangement of a tubular net on a support tube, and device and method for obtaining same

ActiveUS20050281924A1Smoothly unfoldSmooth unloadingContainers for flexible articlesReady-for-oven doughsMaximum diameterEngineering

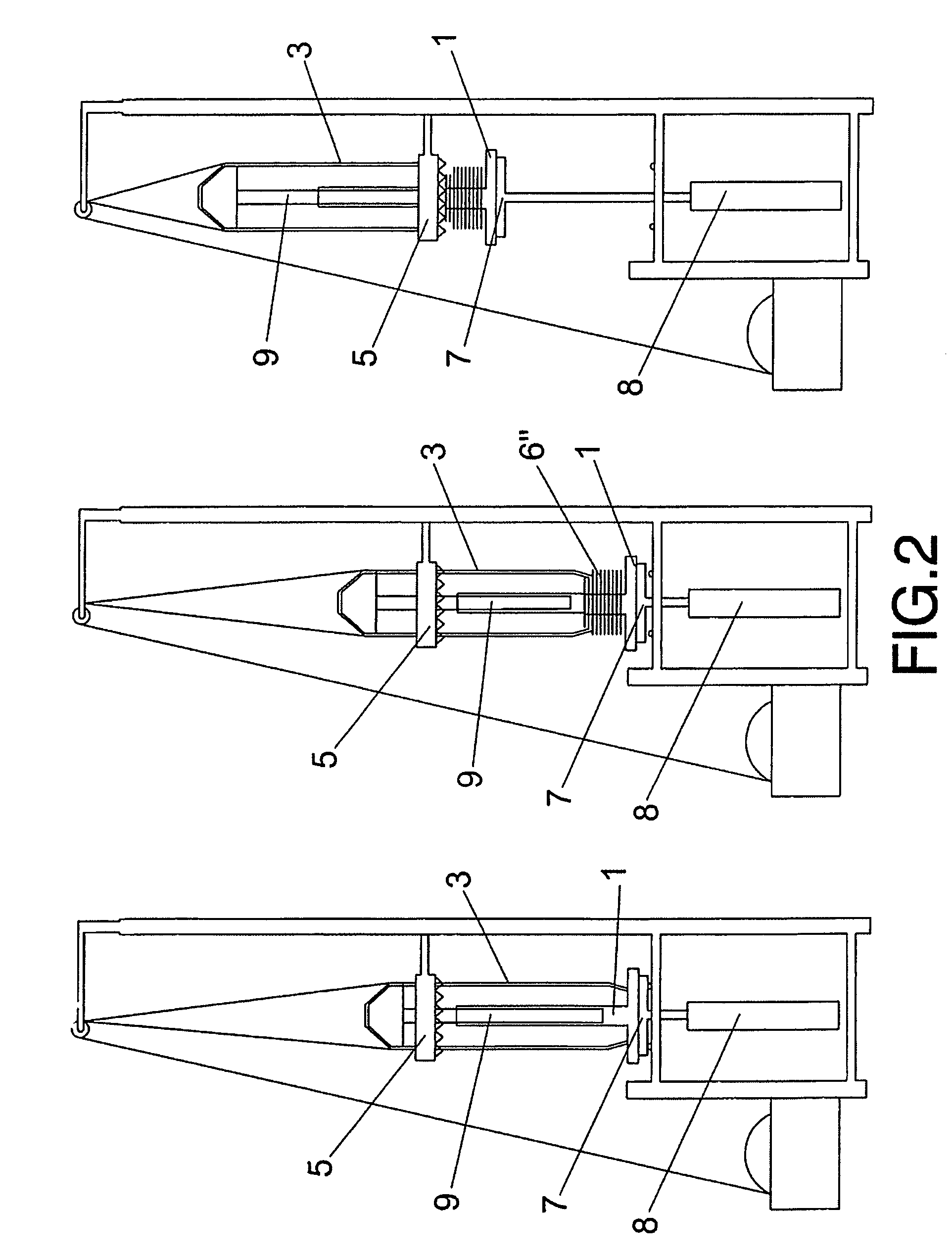

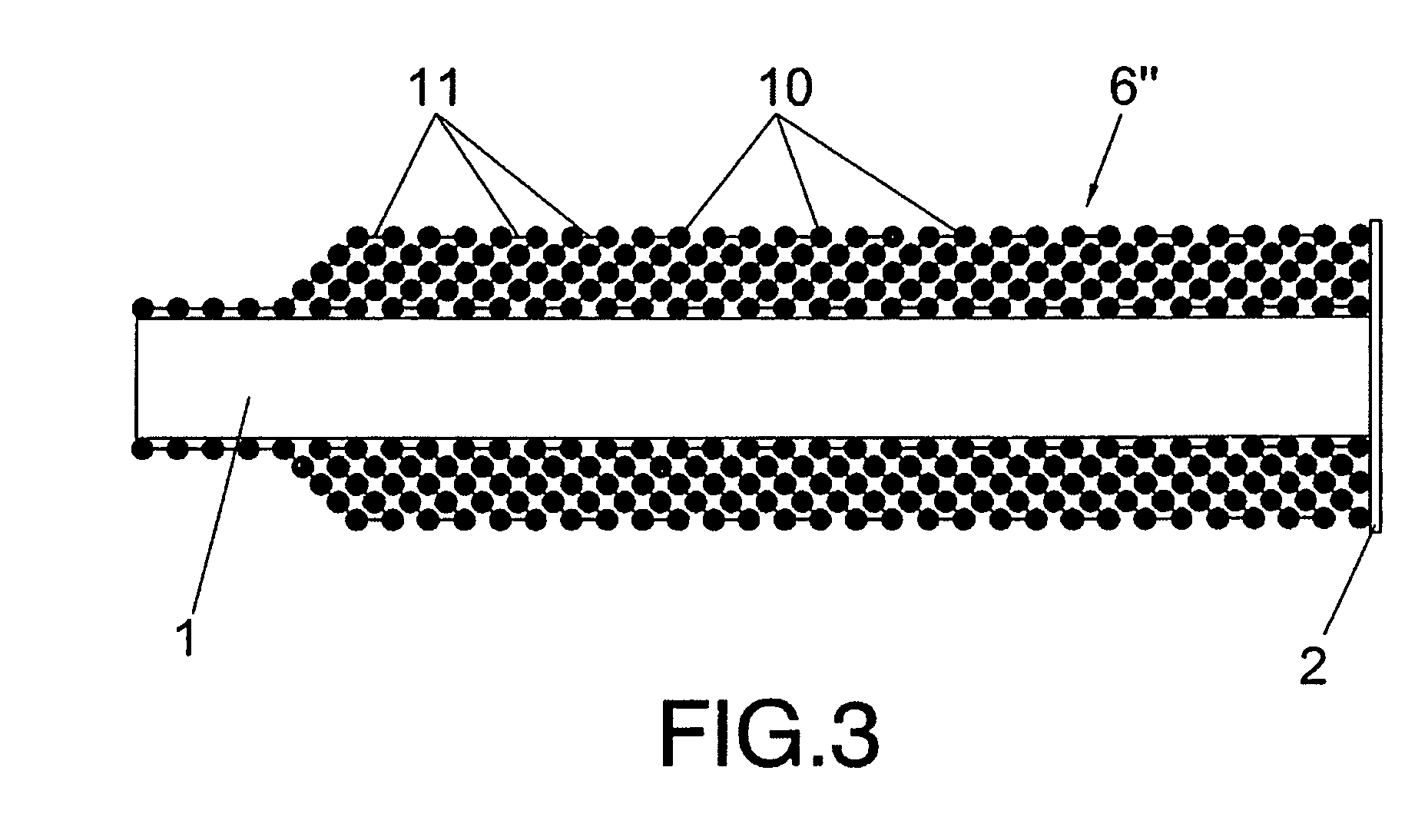

The invention relates to a method and means which are used to obtain a multi-layer arrangement of a tubular net (6) which is first positioned on a transfer tube (3). According to the invention, a toothed loader (5) is used to slide the net (6) along the outside of the transfer tube (3) to the end thereof, said end comprising a slightly conical end zone (4). When the net (6′) reaches said end zone (4), it falls on to the support tube (1) in an arrangement of concentric layers (6′). In this way, the outer layers of the loaded net (6″) have a maximum diameter equal to that of the transfer tube (3) while the inner diameter of the loaded net (6″), which corresponds to the outer diameter of the support tube (1) is less than the maximum diameter of the stretched net.

Owner:VISCOFAN

Shirred casing

ActiveUS20060040602A1Sausage filling/stuffing machinesSausage casing shirringAgricultural engineeringPleat

A shirred fibrous food casing defines a shirred stick formed from a tubular fibrous casing, The shirred stick includes an average outside diameter at least 120% of the average inflated diameter of the deshirred casing. Additionally, the shirred stick includes an average inside diameter of at least 70% of the casing inflated diameter and a pleat pitch defined as the distance between adjacent apexes of major pleats measured on the casing after the shirred stick is deshirred.

Owner:VISKOTEEPAK BELGIUM NV

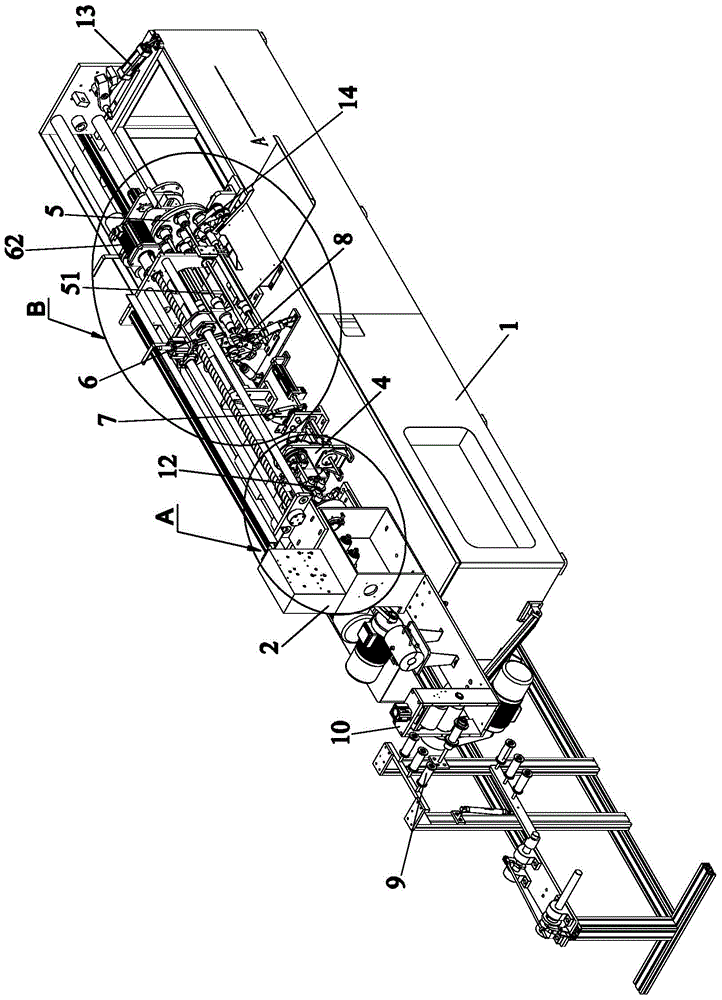

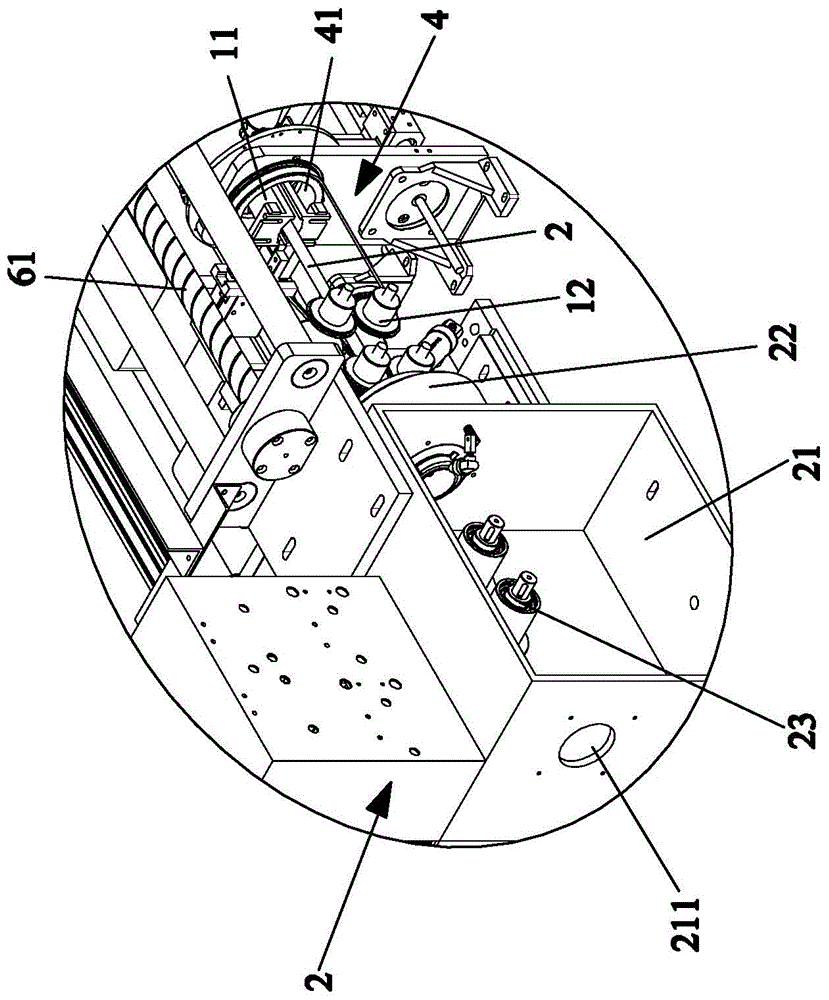

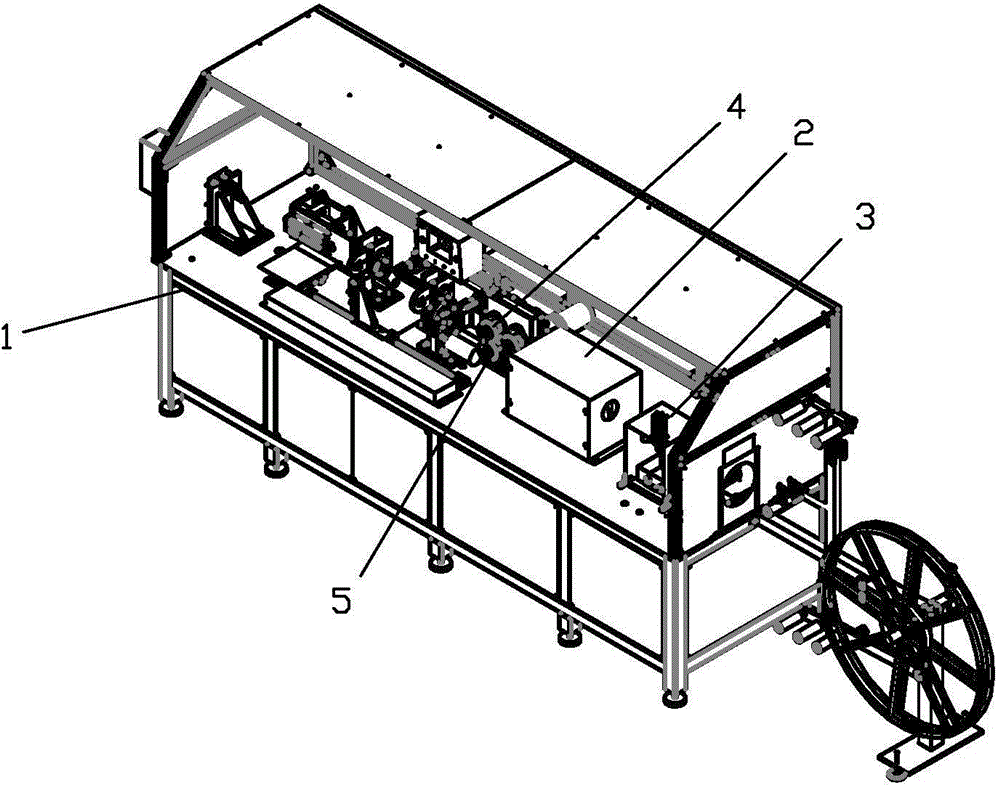

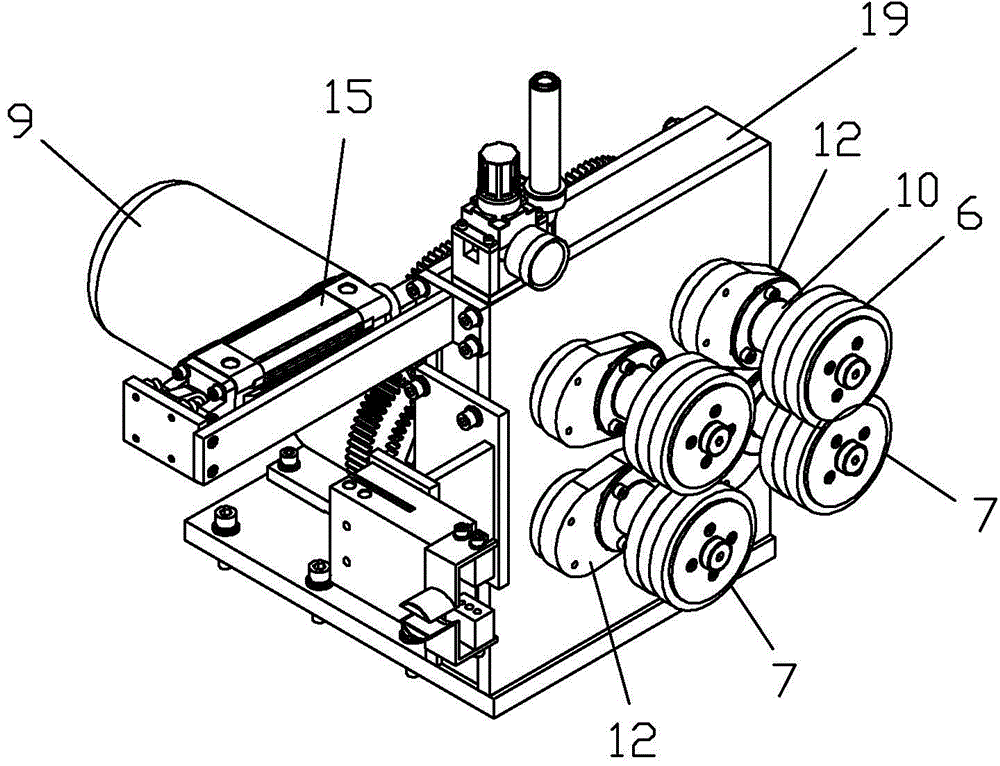

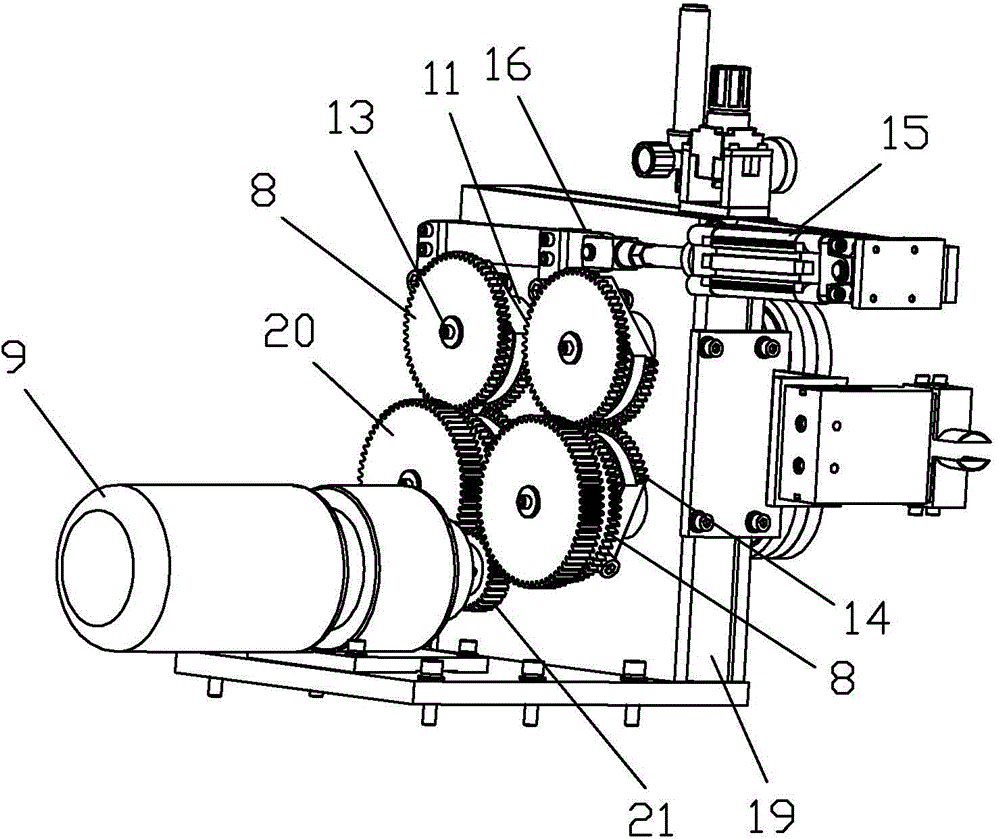

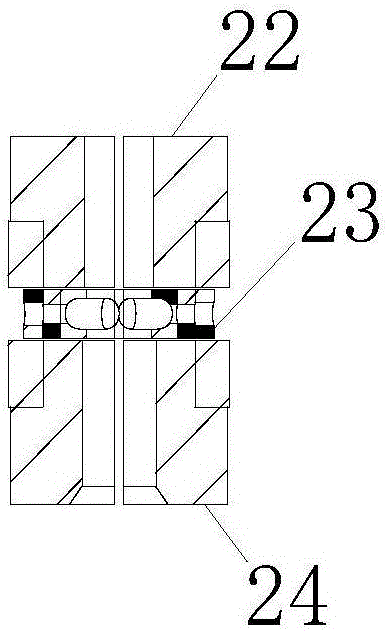

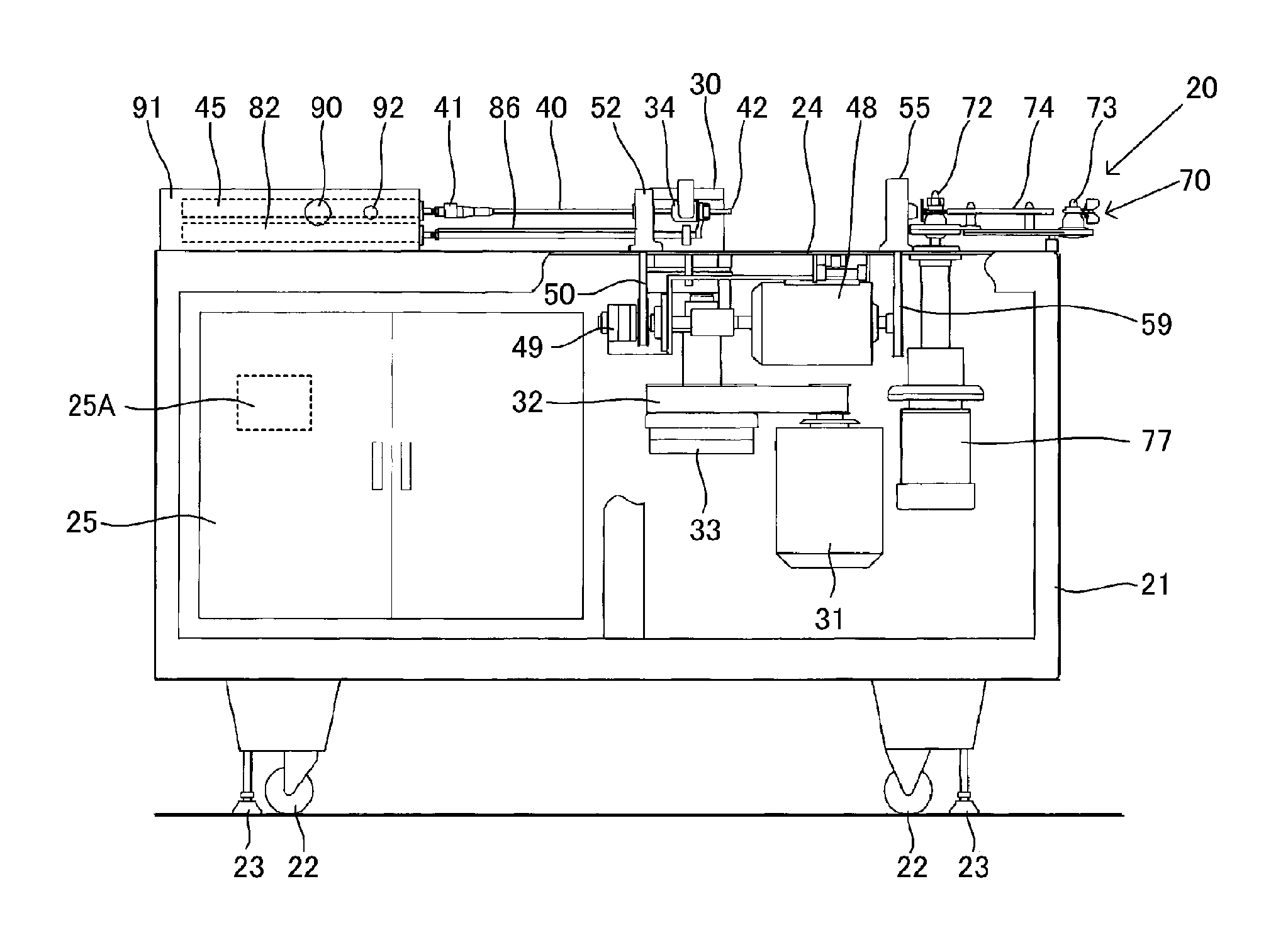

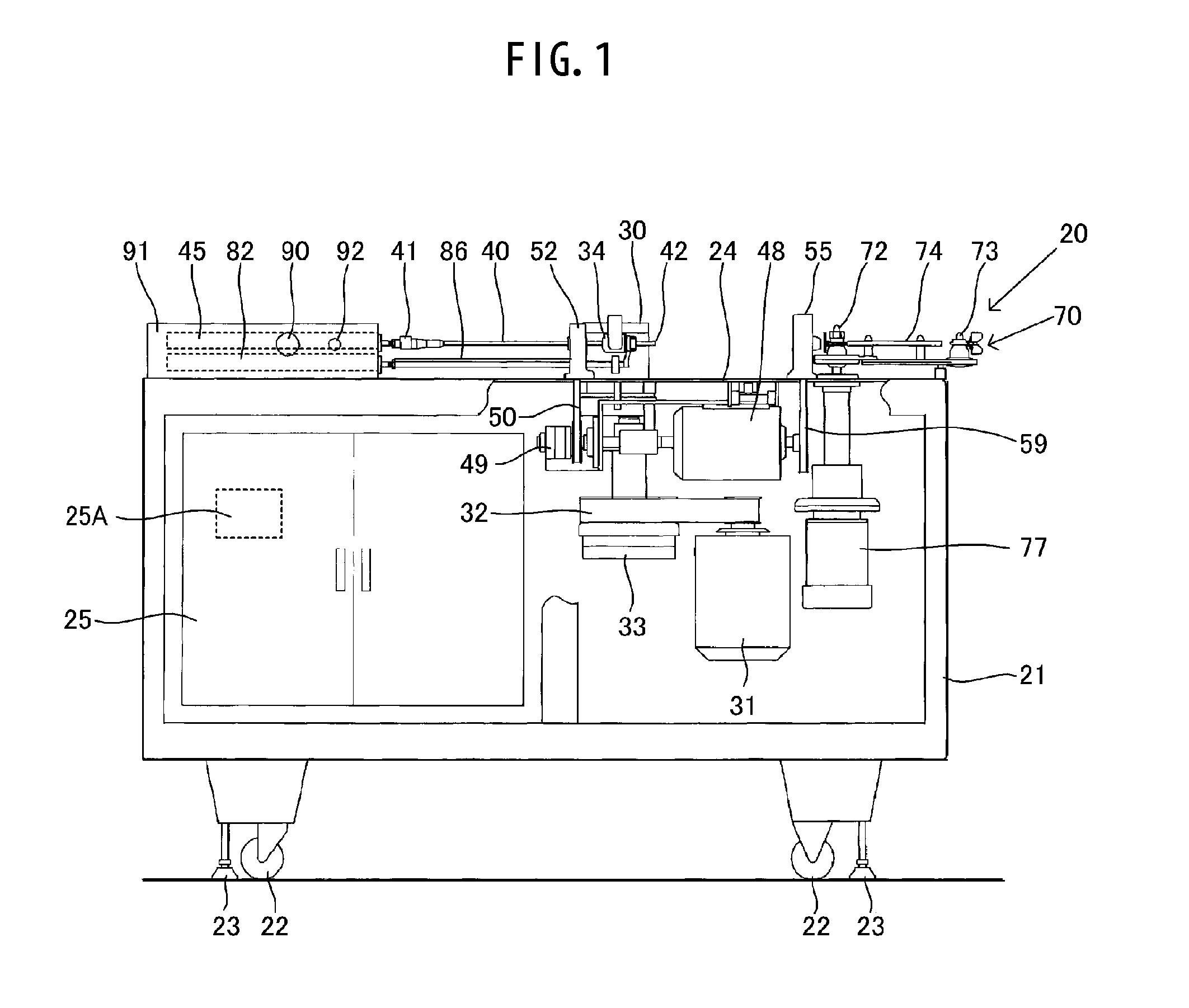

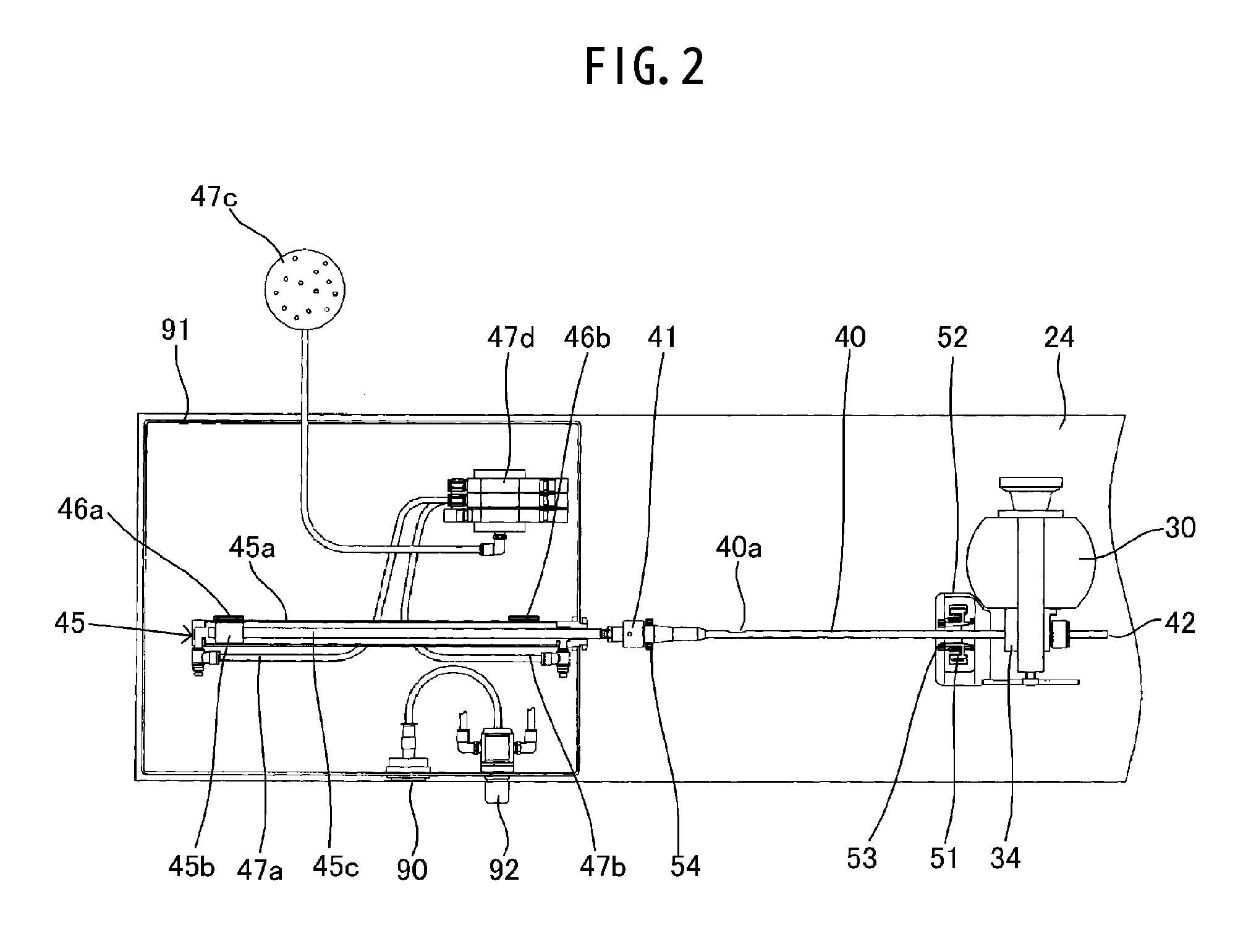

Improved sleeving and shrinking machine

ActiveCN104872263AHigh clothes removal efficiencyIncrease delivery speedSausage casing manufactureSausage casing shirringProduction lineDrive shaft

The invention provides an improved sleeving and shrinking machine which includes a machine frame, wherein the machine frame includes a sleeving and shrinking machine body, oil coating clamps and a casing stripping device; the casing stripping device includes at least two pairs of casing stripping wheels, and each pair of casing stripping wheels includes an upper casing stripping wheel and a lower casing stripping wheel; the upper casing stripping wheels and the lower casing stripping wheels are connected with transmission shafts; the transmission shafts penetrate through a machine panel and are connected with external gears; the external gears are driven by a motor, so as to drive the upper casing stripping wheels or the lower casing stripping wheels to rotate. According to the improved sleeving and shrinking machine provided by the invention, the casing stripping efficiency of the casing stripping wheels is high, the casing conveying speed is increased, and the oil coating clamps can be used for on-line oil coating without affecting the conveying of casings, therefore, the production efficiency of the entire production line is greatly improved.

Owner:广东德福隆生物科技有限公司

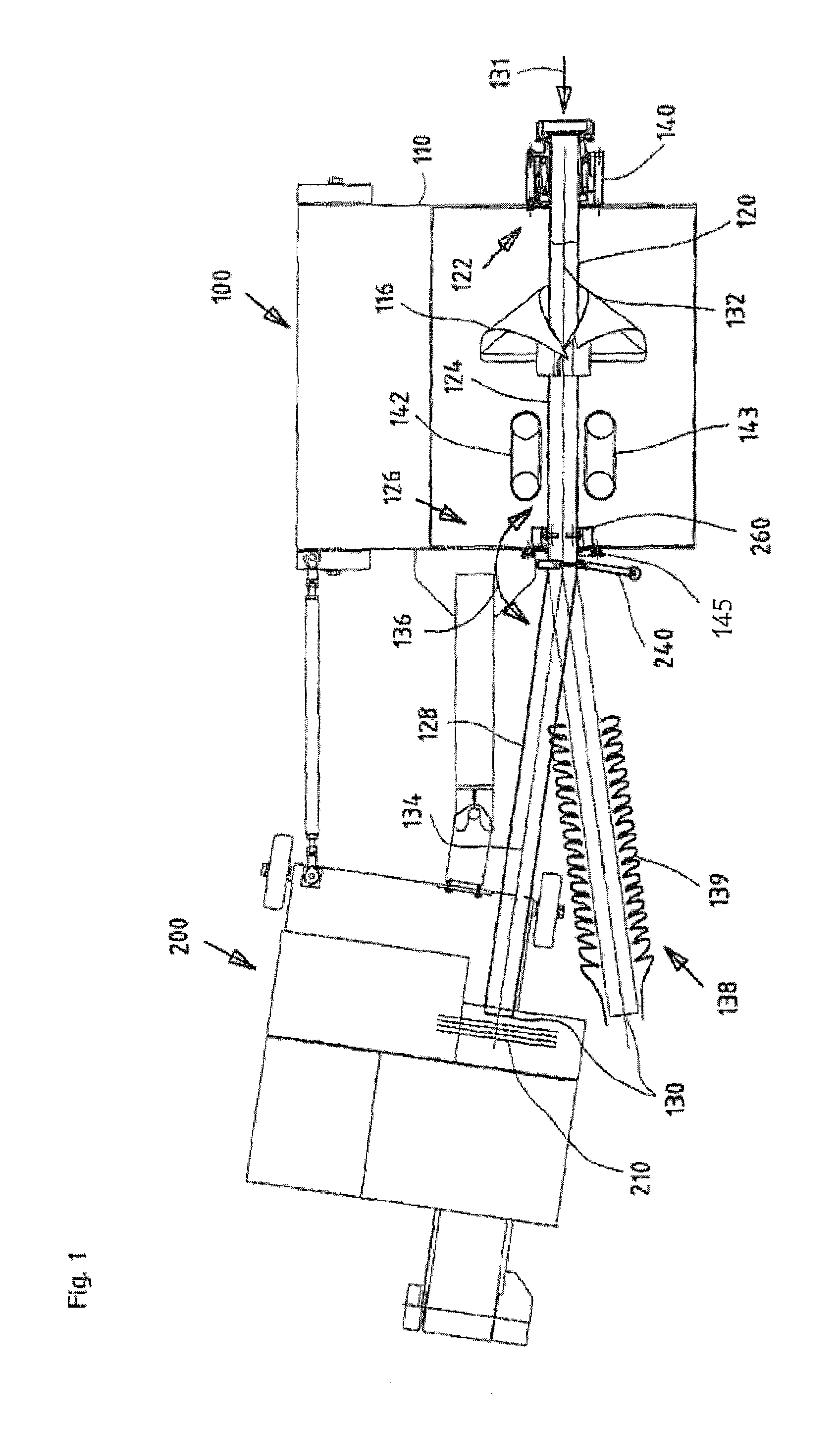

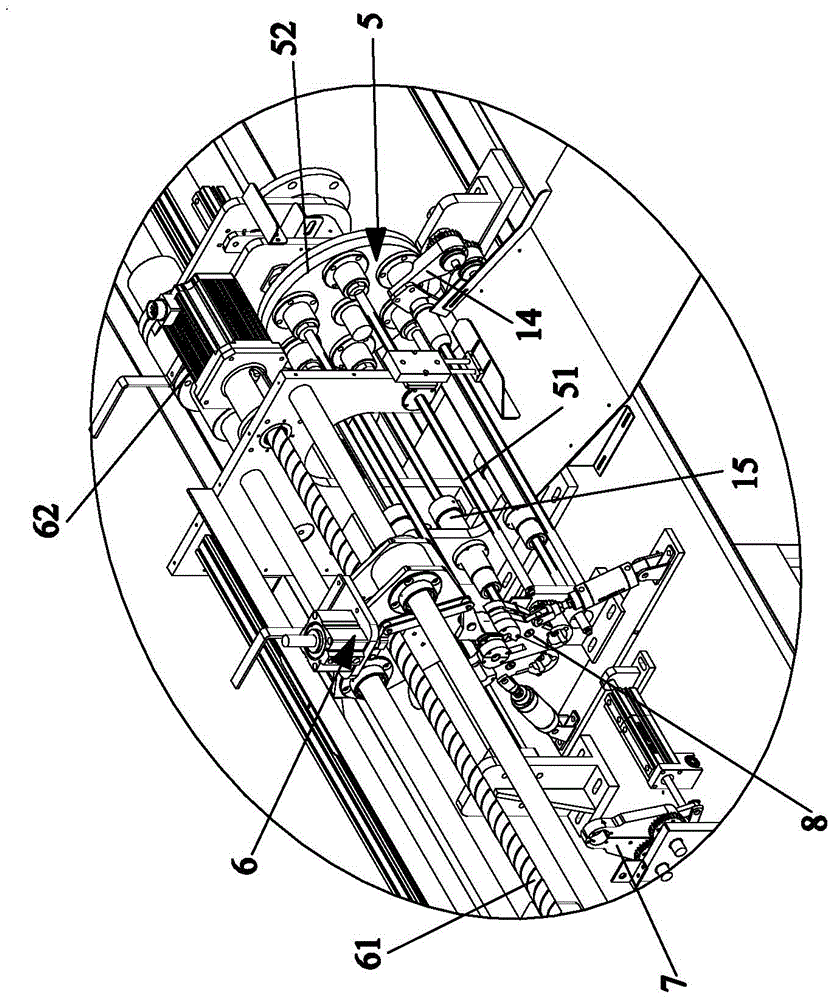

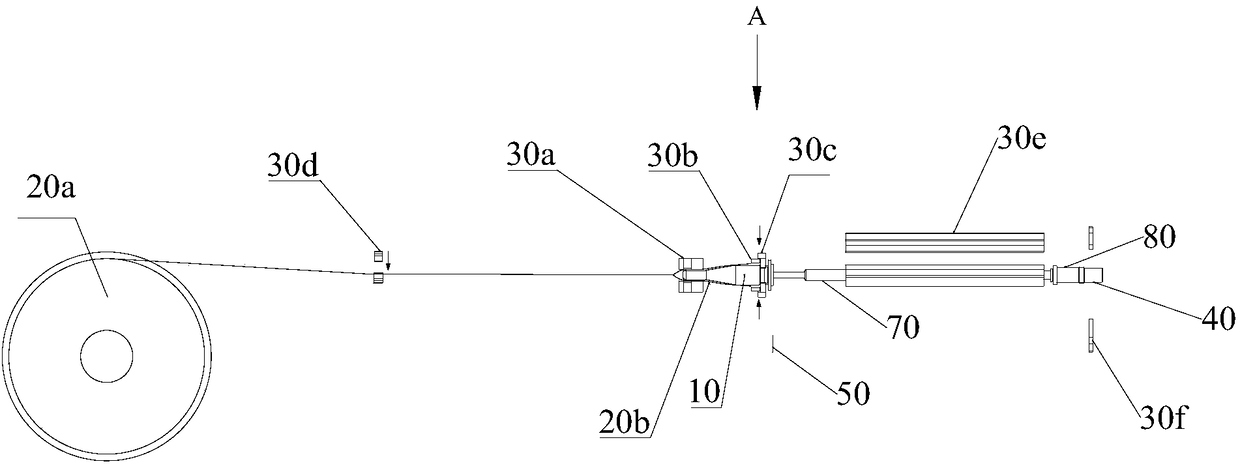

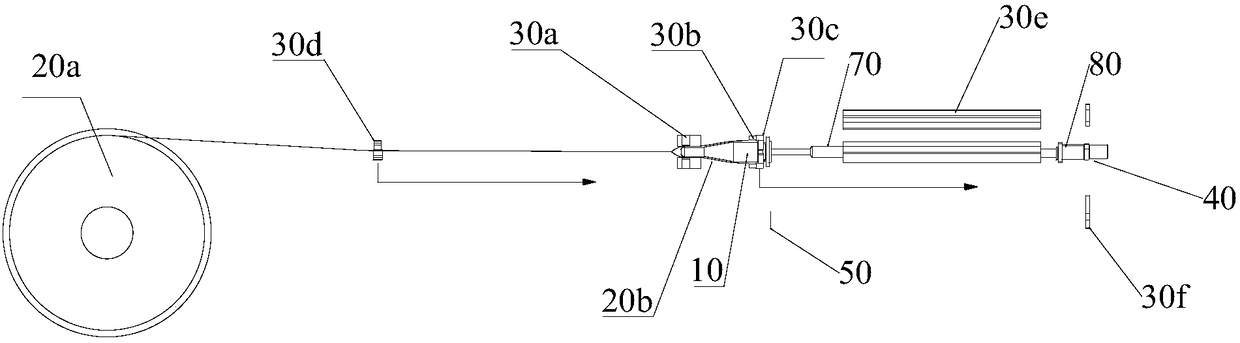

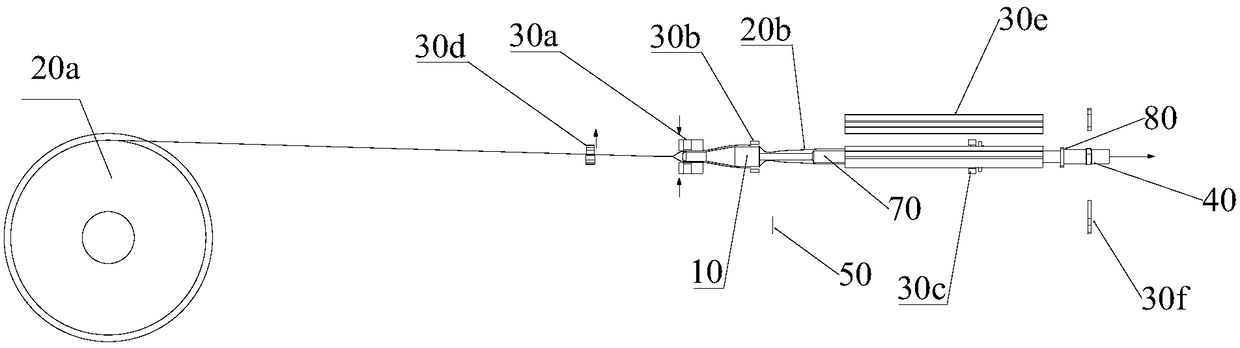

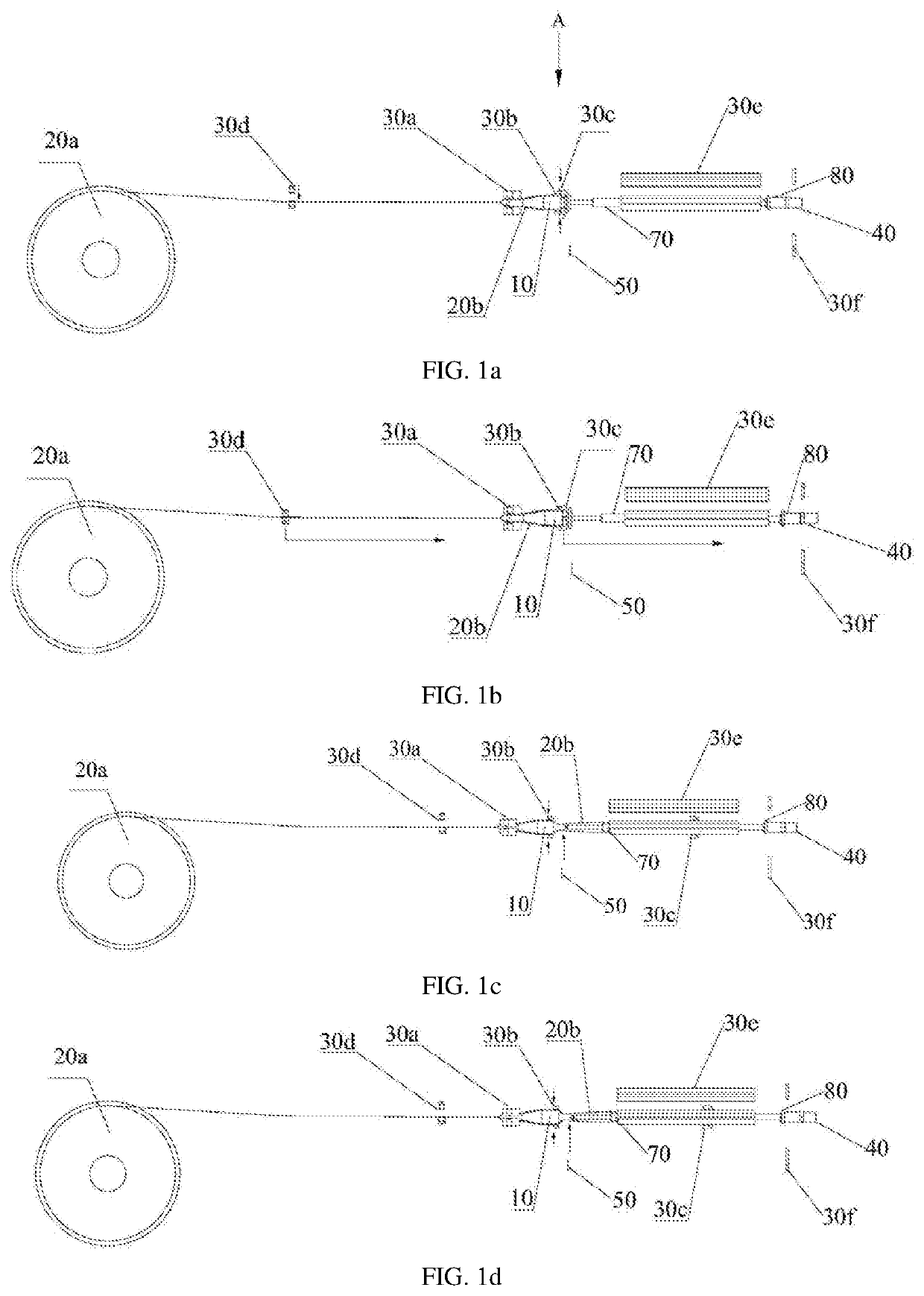

Packaging equipment, sleeving and shrinking machine and packaging method for performing continuous and automatic mesh sleeving of sausage casings

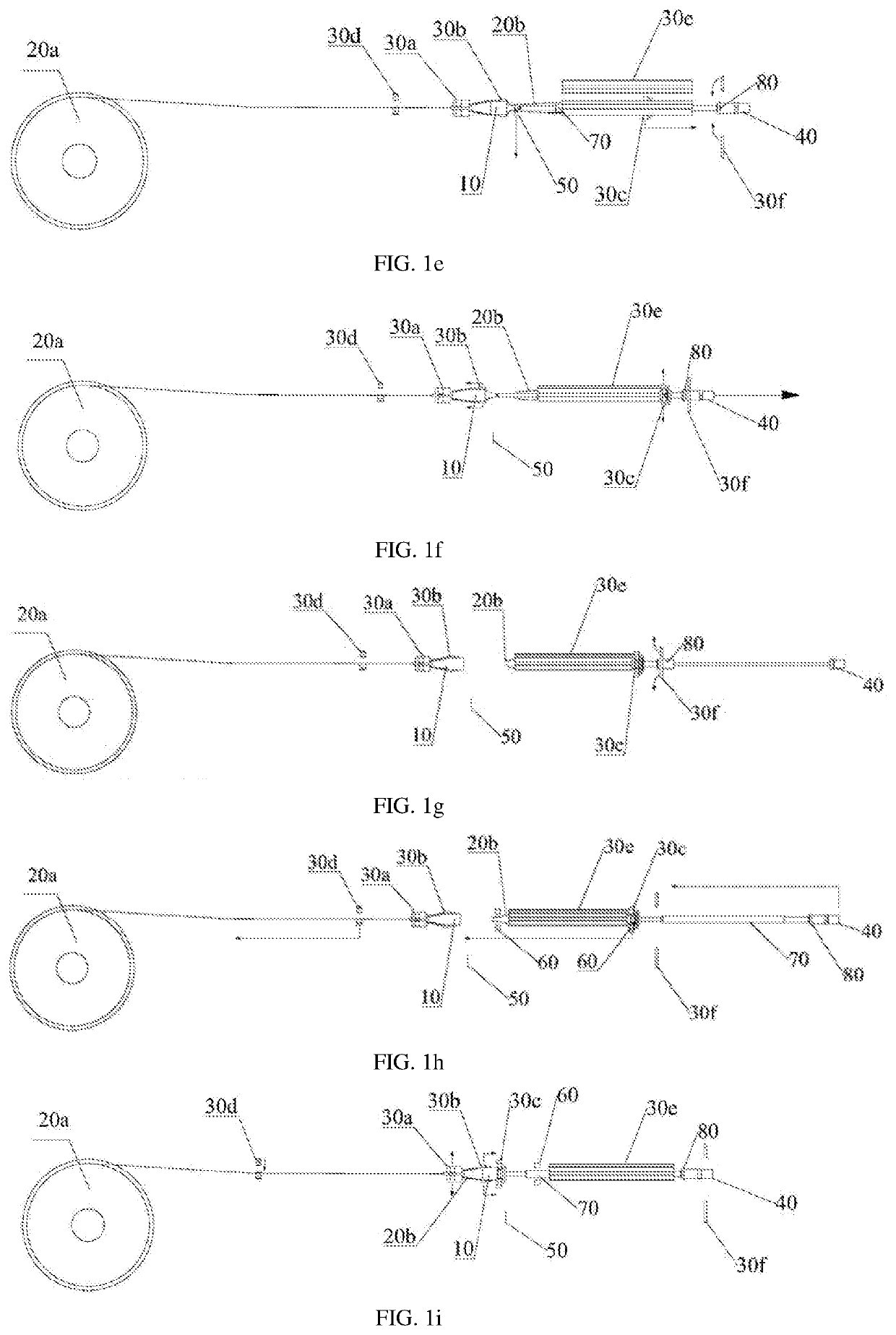

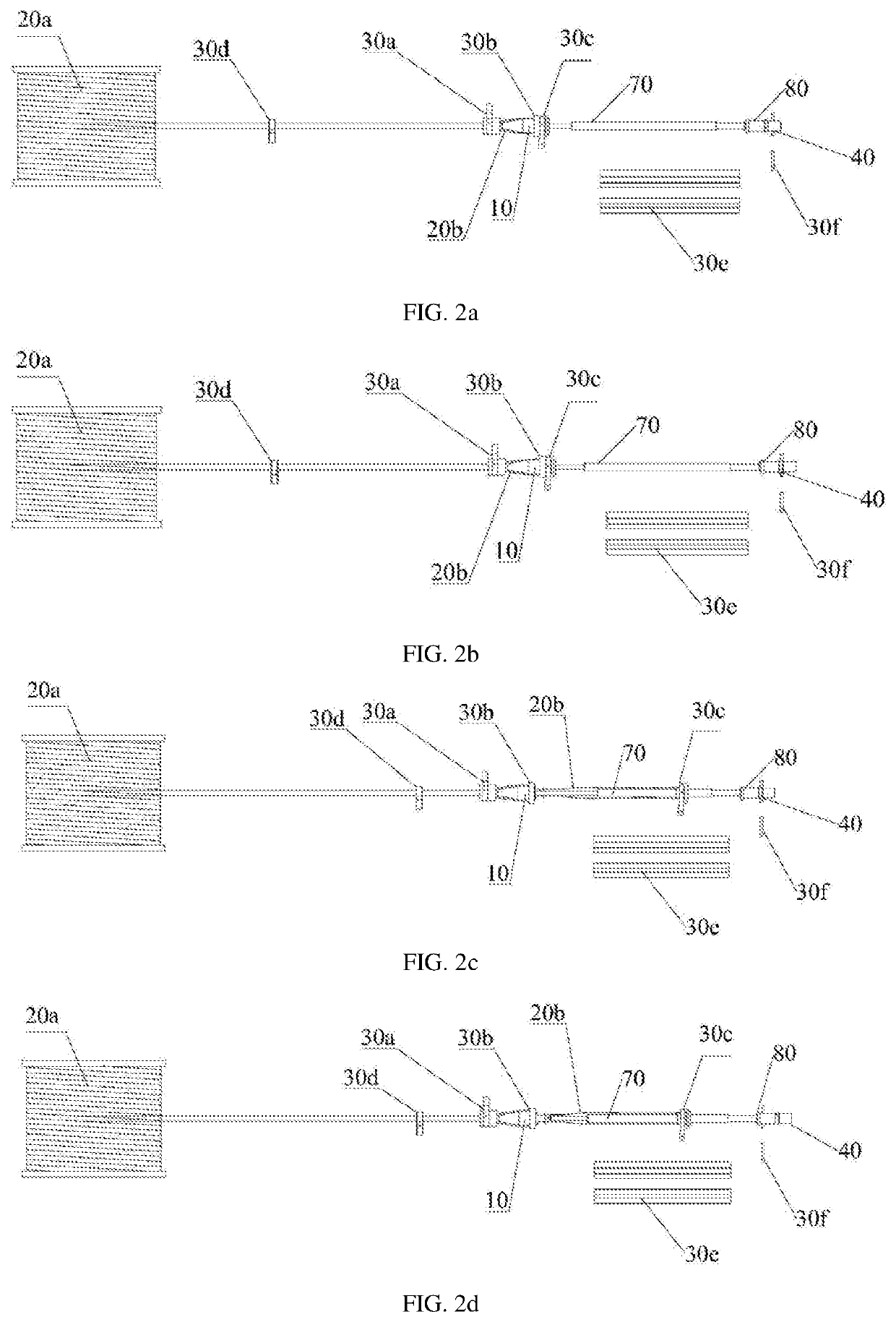

ActiveCN108477273ARealize fully automatic packagingSkinless sausage makingSausage casing manufactureReciprocating motionBiomedical engineering

The invention relates to packaging equipment, a sleeving and shrinking machine and a packaging method for performing continuous and automatic mesh sleeving of sausage casings. The packaging equipmentcomprises a shuttle (10), a first clamp hand (30a), a second clamp hand (30b), a third clamp hand (30c) and a fourth clamp hand (30d), wherein the shuttle (10) is used for sleeving mesh bags (20b); the first clamp hand (30a) can be opened or closed to release or fixedly clamp the shuttle (10); when closed, the second clamp hand (30b) can drive an open end of the mesh bag (20b) to perform reciprocating motion between a first position and a second position on the shuttle (10), and when opened, the second clamp hand (30b) can allow the mesh bag (20b) to move freely along a conveying direction ofthe mesh bag; the third clamp hand (30c) is used for clamping the open end of the mesh bag (20b) and dragging the mesh bag to sleeve a whole sleeved and shrunk sausage casing (70); and the fourth clamp hand (30d) is used for dragging the mesh bag (20b) to unwind the mesh bag (20b) from a mesh bag roll (20a), and the fourth clamp hand (30d) is designed in a form of capable of moving together with the third clamp hand (30c).

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

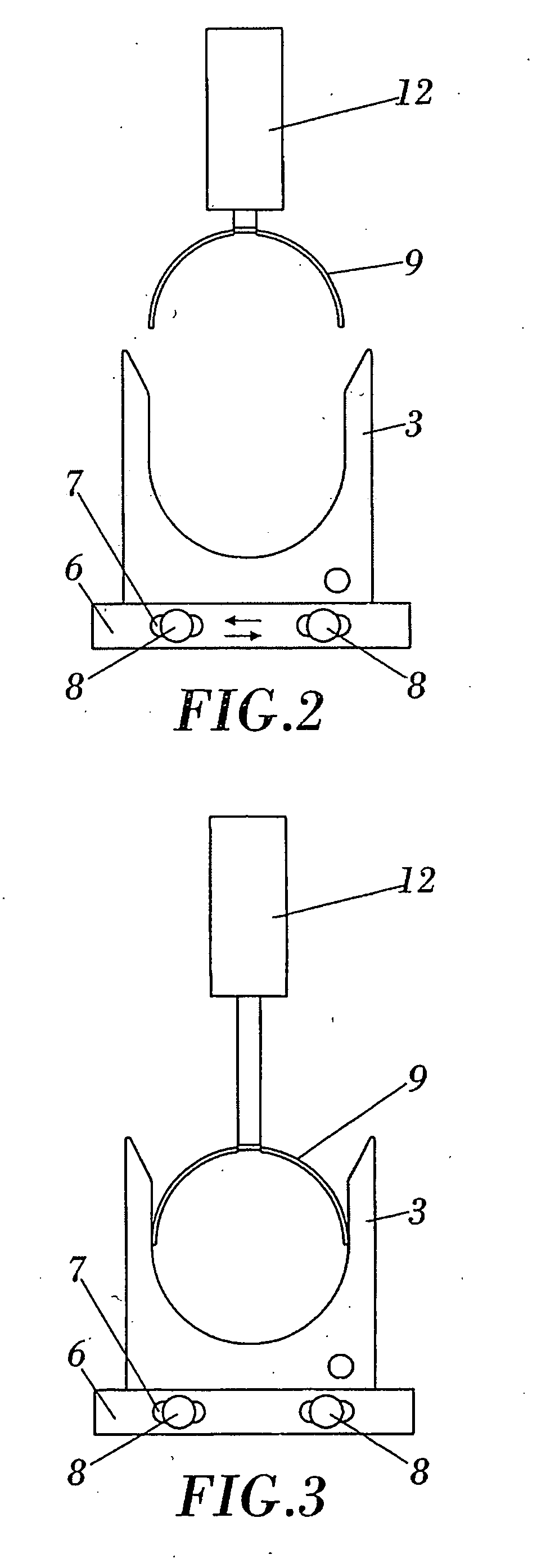

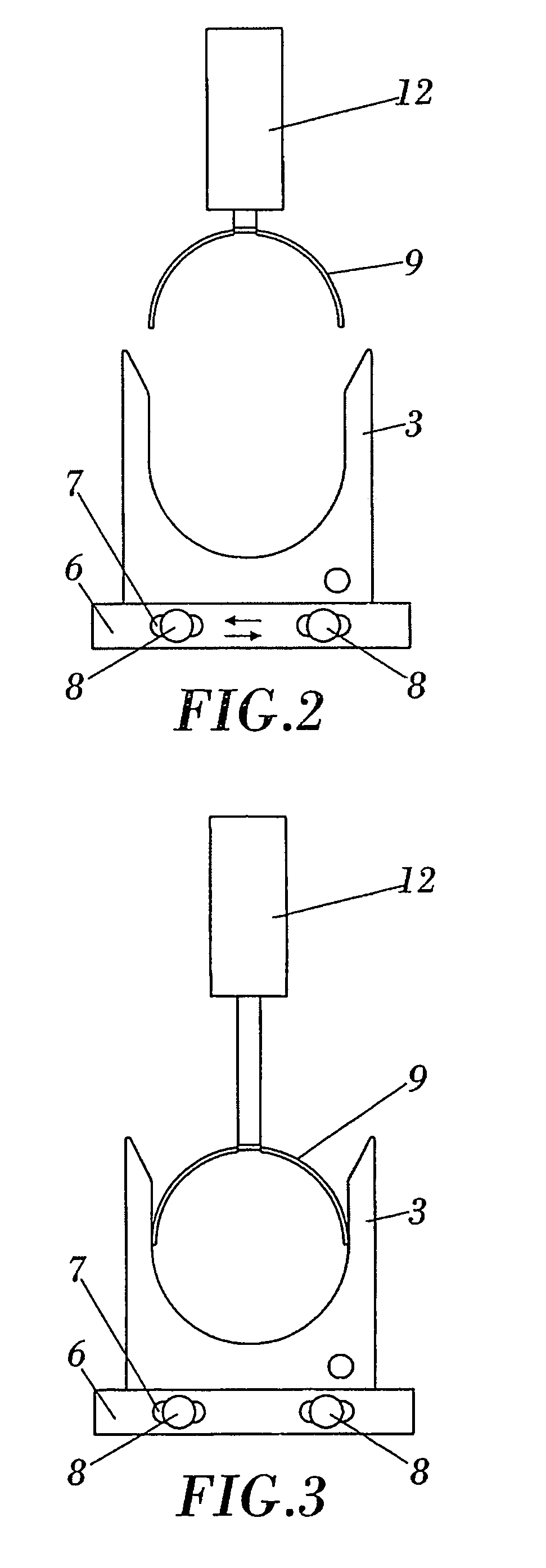

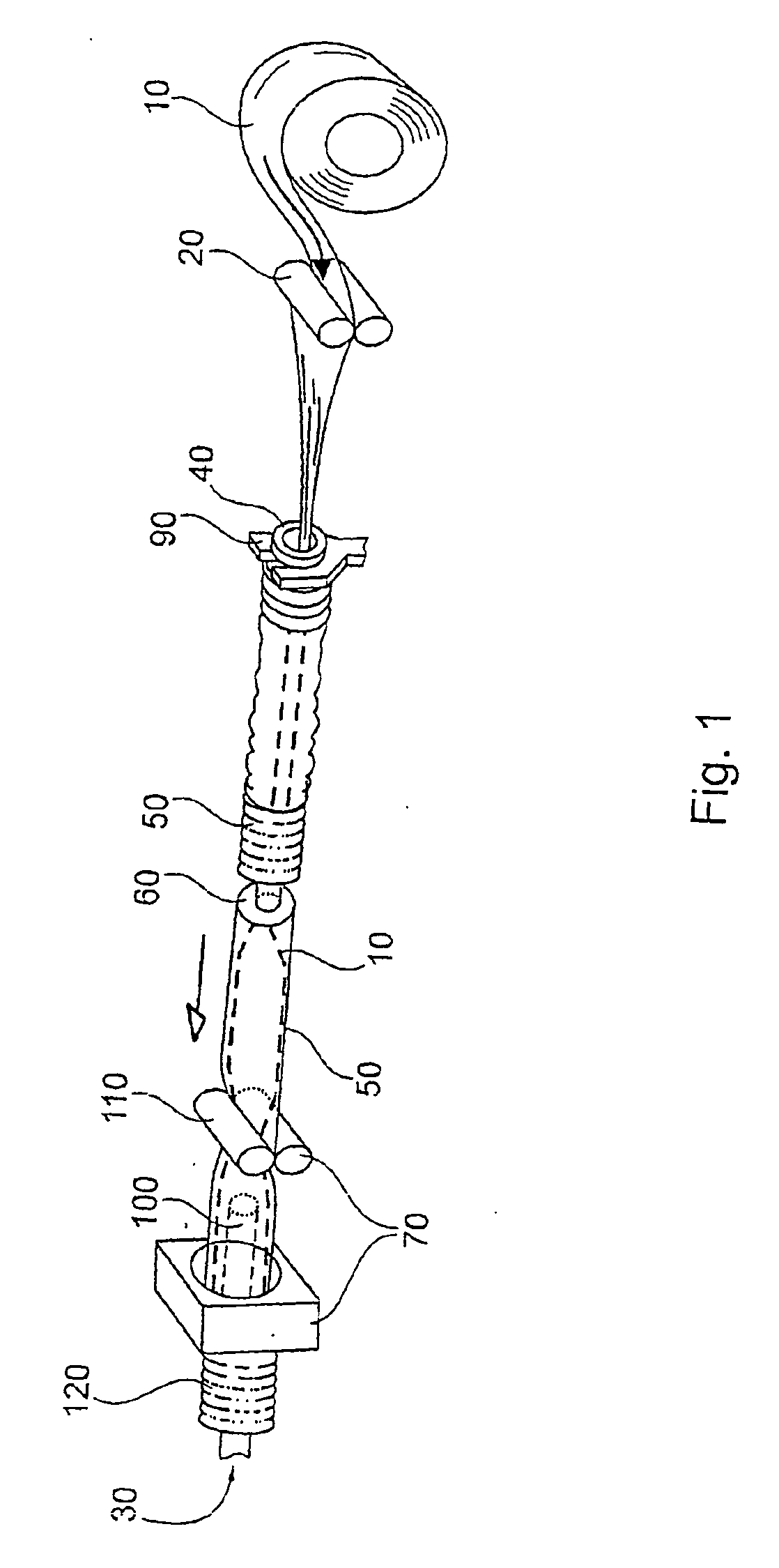

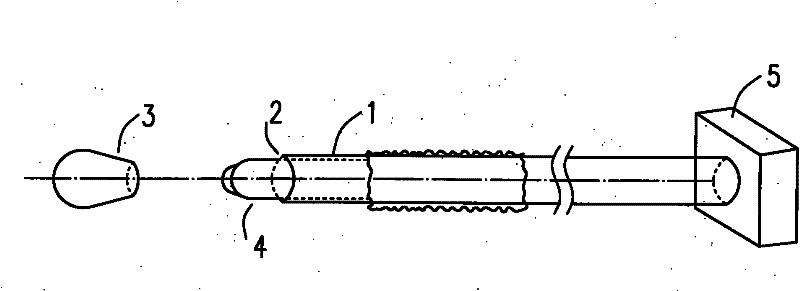

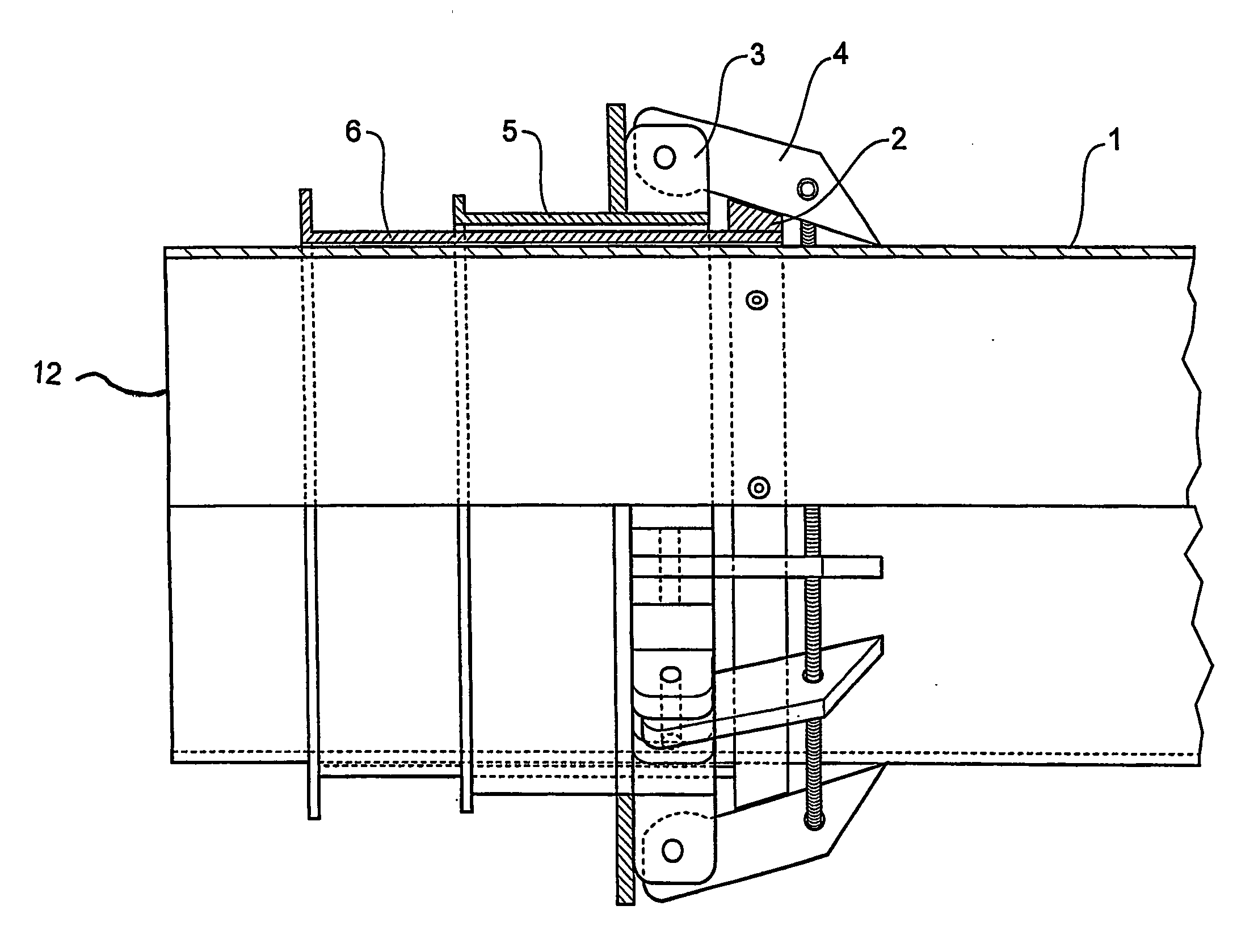

Hand operated shirring machine

A hand-operated machine for shirring casing onto a stuffing tube (1) includes a body through which the stuffing tube (1) covered in casing may pass. The shirring machine has casing engaging means (4) that engages the casing as the machine is pushed along the stuffing tube (1) from the discharge end (12) so that the casing is drawn onto the stuffing tube. The casing engaging means (4) also disengages the casing when it is pulled in the opposite direction. The shirring machine also includes grasping means (11) to manually move it back and forth along the stuffing tube (1).

Owner:MEATECH

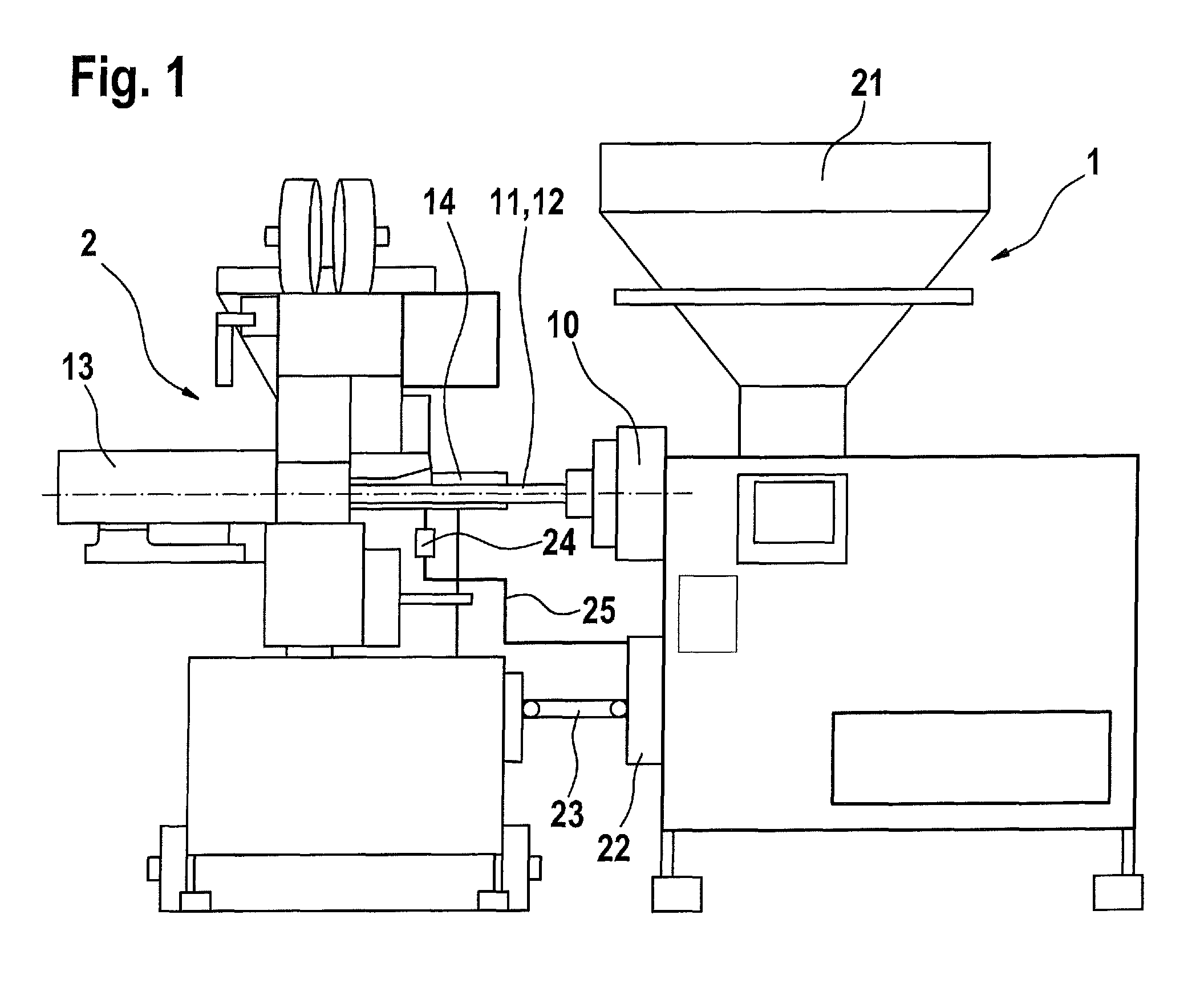

Device for filling packing wrappers with stuffing

ActiveUS7997045B2Oral administration deviceWrapper twisting/gatheringMechanical engineeringEngineering

A packing wrapper filling device includes a filling machine (1) having at least one pivotable filling tube (11) on rotary plate (10). A gathered packing wrapper (14) is fitted onto the filling tube. The invention includes a closing mechanism (2) and store (3) for gathered packing wrappers. The closing mechanism (2) closes both sides of filled wrapper sections. Control device (22) interconnects filling machine (1), closing mechanism (2), store (3), and rocking arms (16). The lateral wall(s) of store (3) include a longitudinal flap (16) in the lower section, pivotable by rotary articulation (20) via rocking arms (15). The control device (22) controls individual envelope (14) removal from store (3). Transport devices (5, 6, 7, and 8) and deflection rollers (9) arranged along feed belt (4) transport envelope (14) along the feed belt (4) from store (3) to filling tube (11 or 12).

Owner:KALLE AG

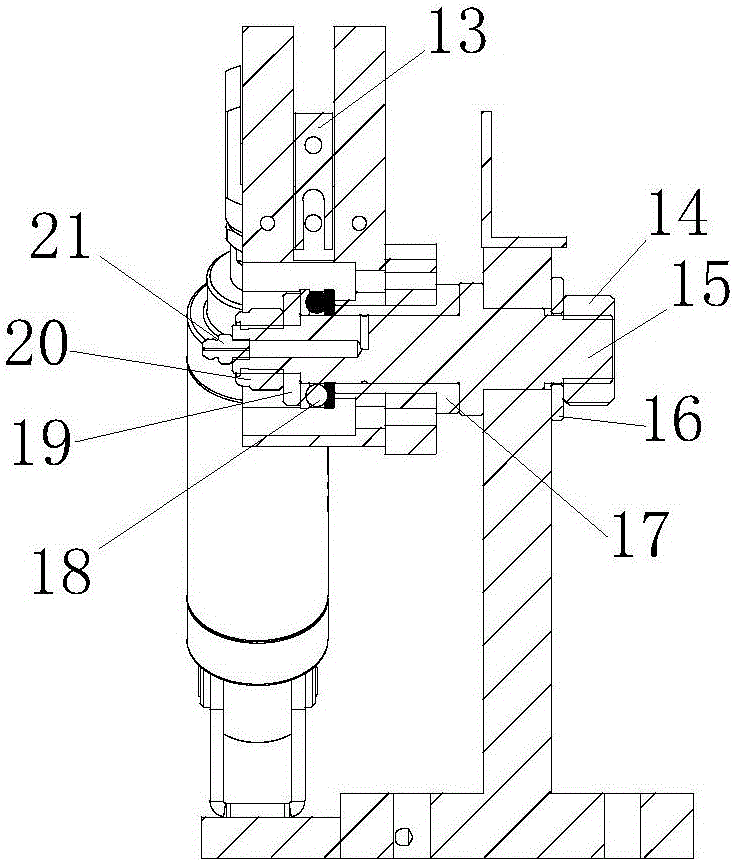

Clamping hand device for casing sleeve shrinkage continuous production and automatic casing sleeve shrinkage machine

ActiveCN106305952AStable air pressureThe overall impact is smallSausage casing shirringEngineeringAtmospheric pressure

The invention discloses a clamping hand device for casting continuous sleeve shrinkage production and an automatic casing sleeve shrinkage machine. The clamping hand device comprises a cylinder baseplate, a clamping seat B and a cylinder seat are arranged at the top of the cylinder baseplate, a gear is mounted on the clamping seat B through a gear shaft, a left swing arm and a right swing arm are arranged on the gear, an air replenishing clamp rotating pin and an air replenishing clamp limiting plate are arranged on each of the left swing arm and the right swing arm, an approach switch seat is arranged on the other sides of the left swing arm and the right swing arm, and a first clamping piece and a second clamping piece are arranged at the tops of the left swing arm and the right swing arm. When a cylinder pushes the left and right swing arms to close through a Y-shaped joint, an air replenishing clamping arm is driven to close, a groove exactly aligns at a circle of ventilation holes in the side wall of a piston valve so as to fill a sleeve shrinkage rod with air without leaking, stability in air pressure inside a casing is ensured, the sleeve shrinkage rod is firmly clamped, the side wall of a piston is annularly sealed, and a circle of small holes in the side wall of the piston are inflated without air leaking.

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

Stuffing apparatus and casing breakage detecting device for stuffing apparatus

ActiveUS8231441B2Increase freedomPrevent materialSausage filling/stuffing machinesSausage casing shirringFilling materialsEngineering

Owner:HITEC

Textured non-porous barrier transfer casing

ActiveUS20200037623A1Sufficient barrier effectPreventing contamination of environmentThermoplastic sausage casingsOrganic chemistryPolymer sciencePolyolefin

The present invention provides a functional additive transferring (co)extruded thermoplastic food casing having a water vapor barrier and / or oxygen barrier effect wherein an inside surface of the thermoplastic food casing has a textured surface which forms a three-dimensional pattern of higher and lower retaining capacity for a functional additive, wherein the thermoplastic food casing having a textured surface in case of a monolayer casing or an inner layer comprising the inside surface having a textured surface in case of a multilayer casing comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides, (co)polyolefins, (co)polyester and vinylidenchloride (co)polymers, wherein the (co)extruded thermoplastic food casing does not comprise a net and / or a material forming a net or any other three dimensional structure on its outside surface, wherein the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity is in a range of from 1 to 100 μm, wherein the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 191 to 2000 μm, provided that the thickness difference between the average thickness in the areas having higher retaining capacity and the average thickness in the areas having a lower retaining capacity is in a range of from 160 to 1950 μm and that a ratio of the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity and the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 0.002 to 0.25.

Owner:VISCOFAN

Ruckers capable of rucking fixed diameter coverings and associated devices, methods, systems and computer program products

InactiveUS20070022712A1Wrapper twisting/gatheringSausage makingStructural engineeringMechanical engineering

Methods, apparatus and associated devices for rucking sleeves of covering material onto a chute body include a translating member disposed in a housing having an axis of movement configured to reciprocally translate a chute body about the axis of movement; and at least one gripping member disposed in the housing in cooperating alignment with the translating member. Each at least one gripping member has a gripping edge portion that defines a gripping surface. The at least one gripping member configured to reciprocally translate substantially orthogonal to the axis of movement. In operation, the at least one gripping member has an automated stroke cycle whereby the at least one gripping member is configured to travel inwardly a distance sufficient to snugly abut an outer surface of the chute body while the chute body travels in a first direction about the axis of movement and to travel outwardly a sufficient distance to prevent contact with the chute body while the chute body travels in a second opposing direction about the axis of movement.

Owner:TIPPER TIE

Packaging Equipment for Continuous Automatic Net Sleeving of Casing, Shirring Machine and Packaging Method

PendingUS20200288728A1Improve efficiencyRealize integrated processingSkinless sausage makingSausage casing manufactureReciprocating motionPinch grip

The present disclosure relates to packaging equipment for continuous automatic net sleeving of a casing, a shirring machine and a packaging method. The packaging equipment is provided with a shuttle; a first gripper, capable of being opened or closed to release or clamp and fix the shuttle; a second gripper, capable of driving an open end of the net bag to make reciprocating motion between a first position and a second position on the shuttle when being closed, and capable of allowing the net bag to move freely in a net bag conveying direction when being opened; a third gripper, configured to clamp the open end of the net bag and pull the net bag to sleeve a whole shirred casing in a penetrating mode; and a fourth gripper, configured to pull the net bag, and designed to be capable of moving with the third gripper.

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com