Multi-rod shrinking machine

A shrinking machine and shrinking technology, which is applied in the shirring of sausage casings, sausage casings, packaging, etc., can solve the problems of high cost, high sealing requirements, complex structure, etc., and achieve simple structure, high work efficiency, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

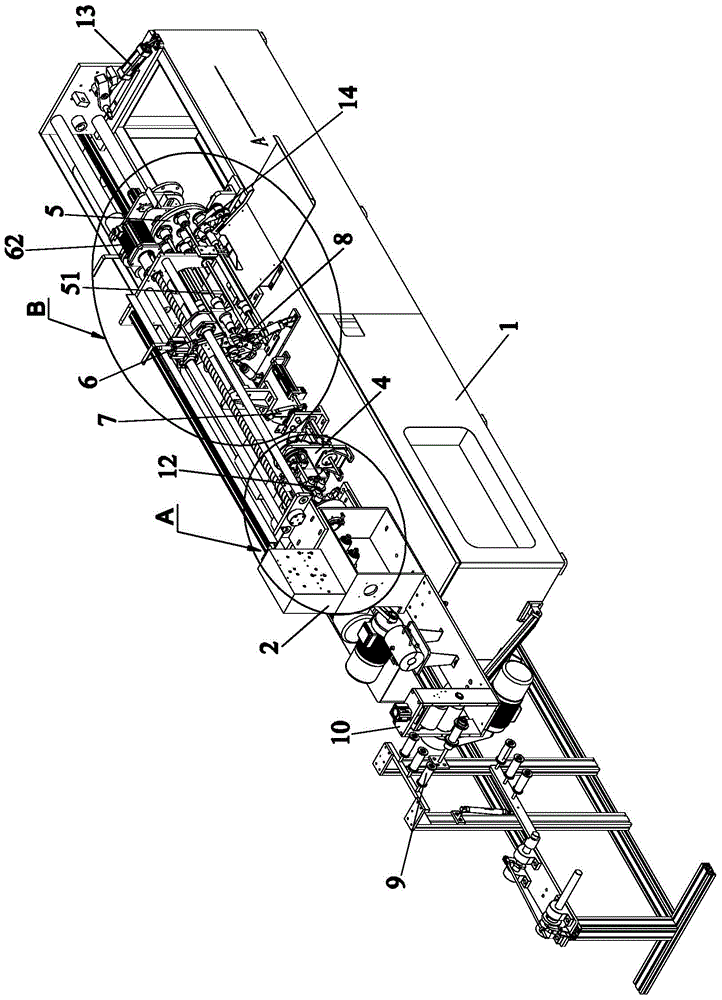

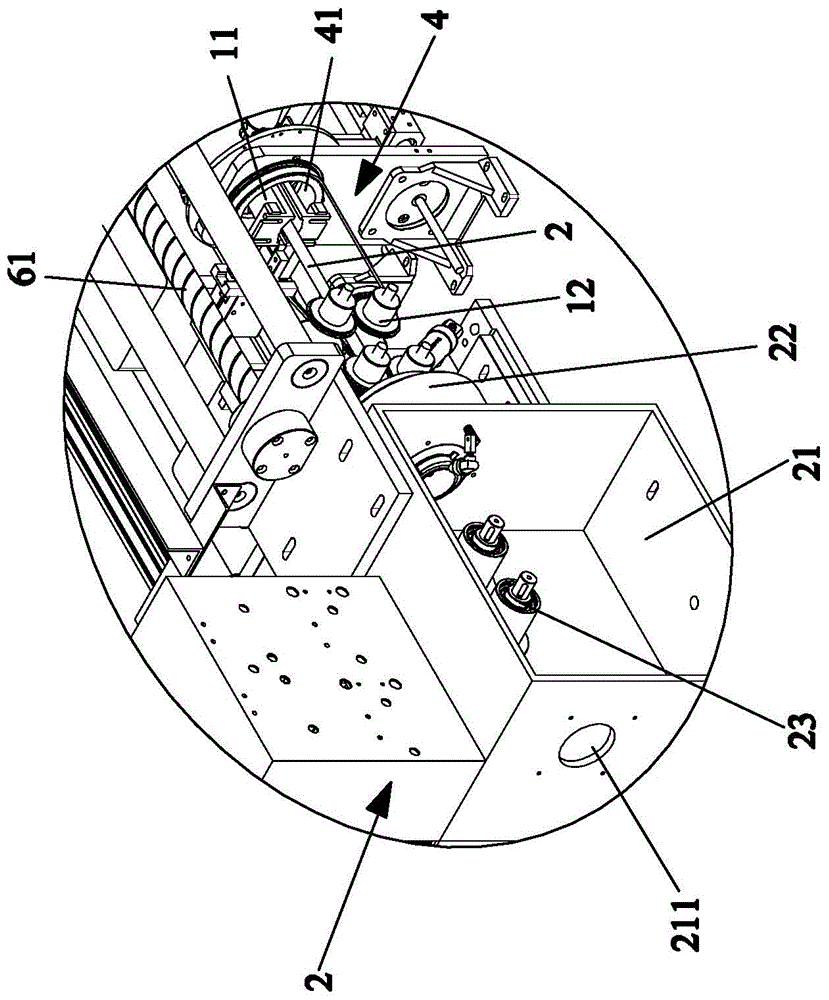

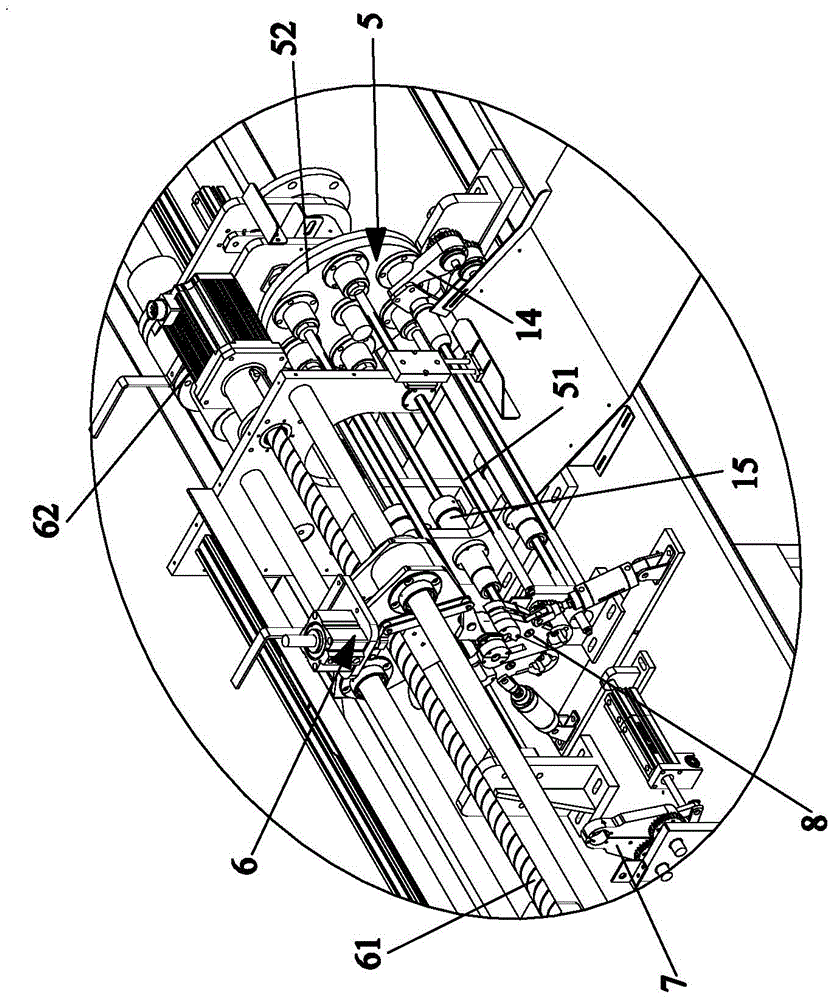

[0039] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 1 and a retractable mechanism 2 installed on the frame 1, a retractable rod 3, a cutting mechanism 4, and a multi-rod receiving mechanism 5 , Mobile clamp 6, first pole clamp 7 and second pole clamp 8.

[0040] Wherein, the telescoping mechanism 2 includes a box body 21 and a telescoping head 22 positioned at the rear of the box body 21, an inlet 211 is provided at the front of the box body 21, and an outlet is provided at the rear of the box body 21 (not shown in the figure). , the inlet 211 and the outlet 212 are used for the passage of the shrinking material. The box body 21 is provided with at least two groups of feed wheel sets 23, and each set of feed wheel sets 23 includes upper rollers and lower rollers arranged in cooperation with each other. The feeding wheel set 23 is used to push the shrinking material into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com