Special tool for processing guide sheet casing and method for sleeving guide sheet casing

The technology of a special tool and guide piece is applied in the field of special tools for processing guide piece casings and guide piece casings, which can solve the problems of easy overturning and blocking, easy damage to the casing, inconvenient operation, etc., and achieves low cost, improved efficiency and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

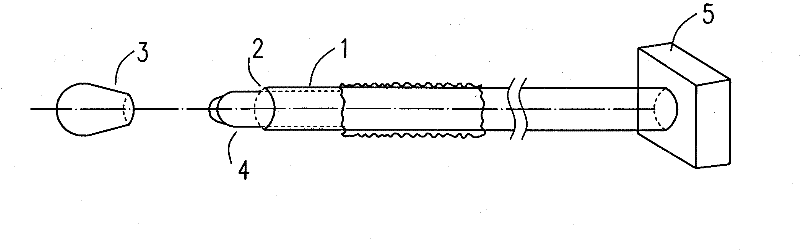

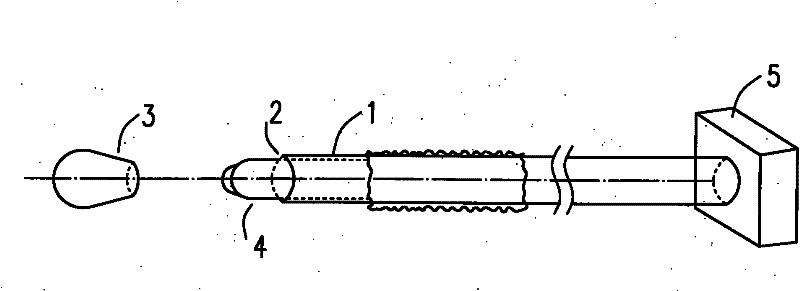

[0018] like figure 1 As shown, an embodiment of the present invention includes a casing tube 1 for casing casings, the casing tube 1 is a thin-walled tube with a lumen that can be inserted into a guide piece, and the operating end of the thin-walled tube is provided with an opening 2 , also includes a plug 3 matching the opening 2. In the prior art, the casing method is to put the openable and closable guide piece on the outer wall of a casing pipe along the length direction, then put the casing on the casing along the casing pipe, and finally remove the casing-covered guide piece from the casing pipe That’s enough, it needs to be flushed and lubricated during the operation, and the guide piece is easy to damage the casing during operation. The special tool of the present invention has a simple structure. The main difference between it and the prior art is that the guide piece 4 can be inserted from the lumen of the casing tube 1, and when the casing in the extended state is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com