Patents

Literature

242results about How to "Smooth unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

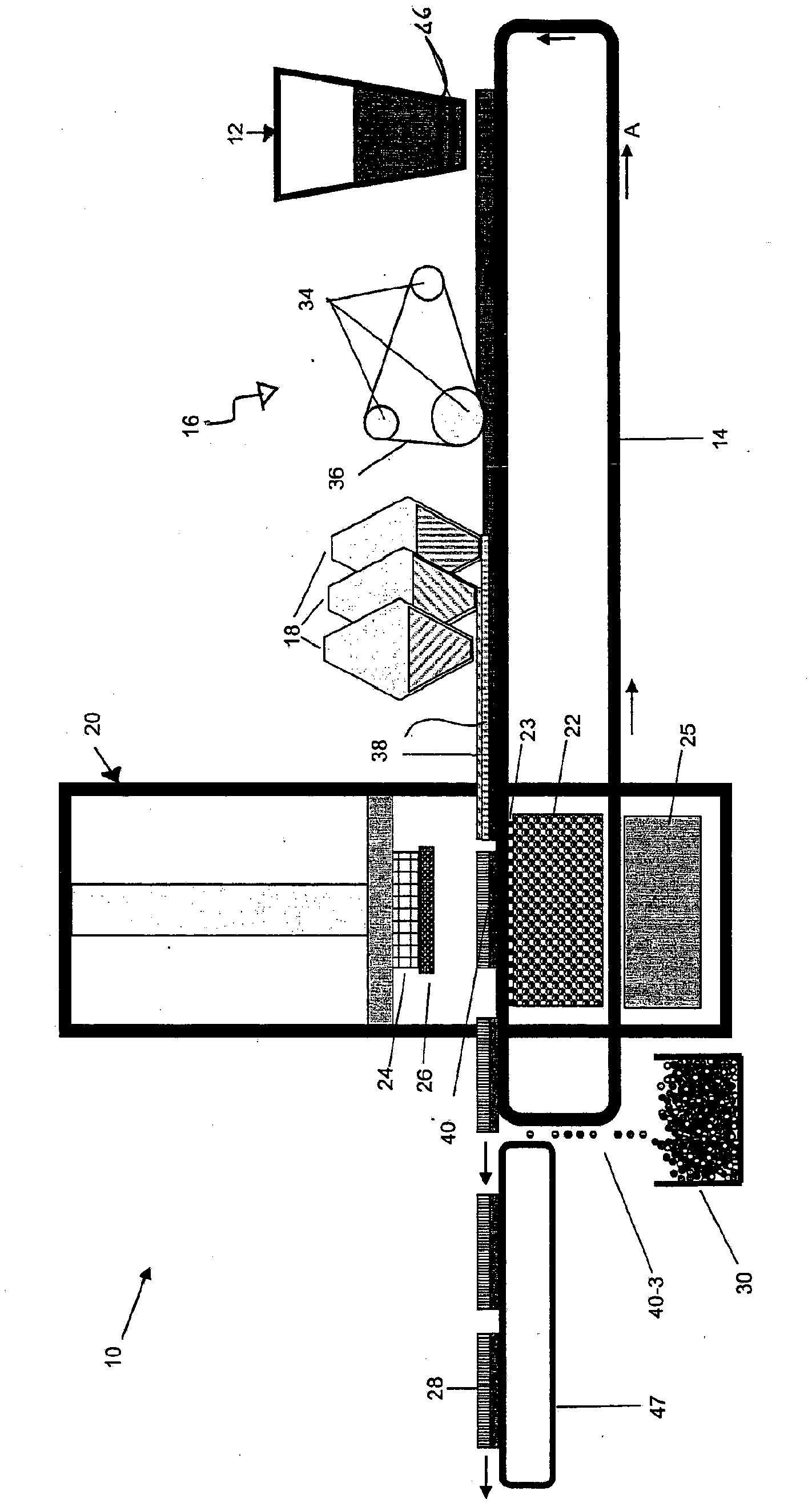

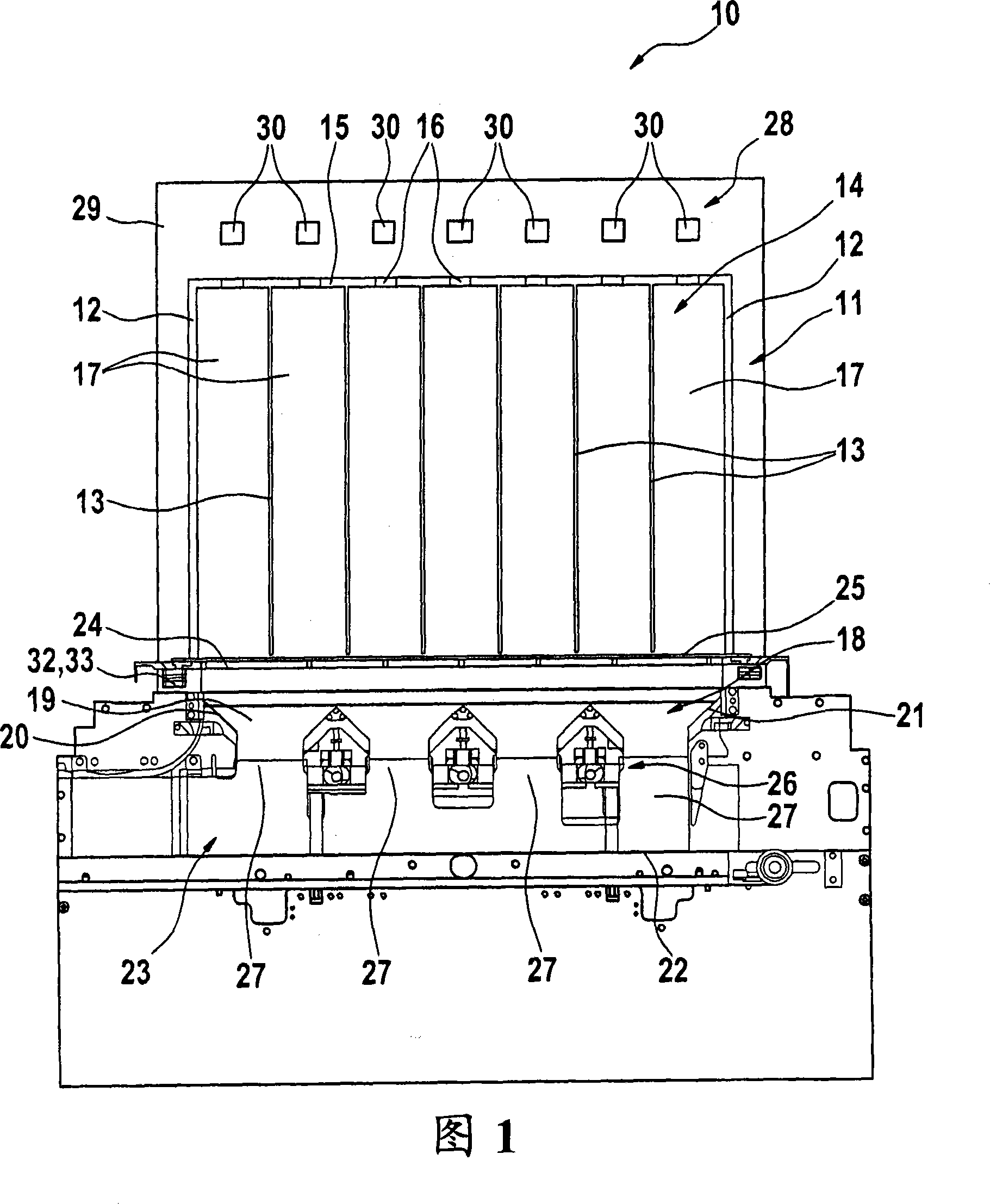

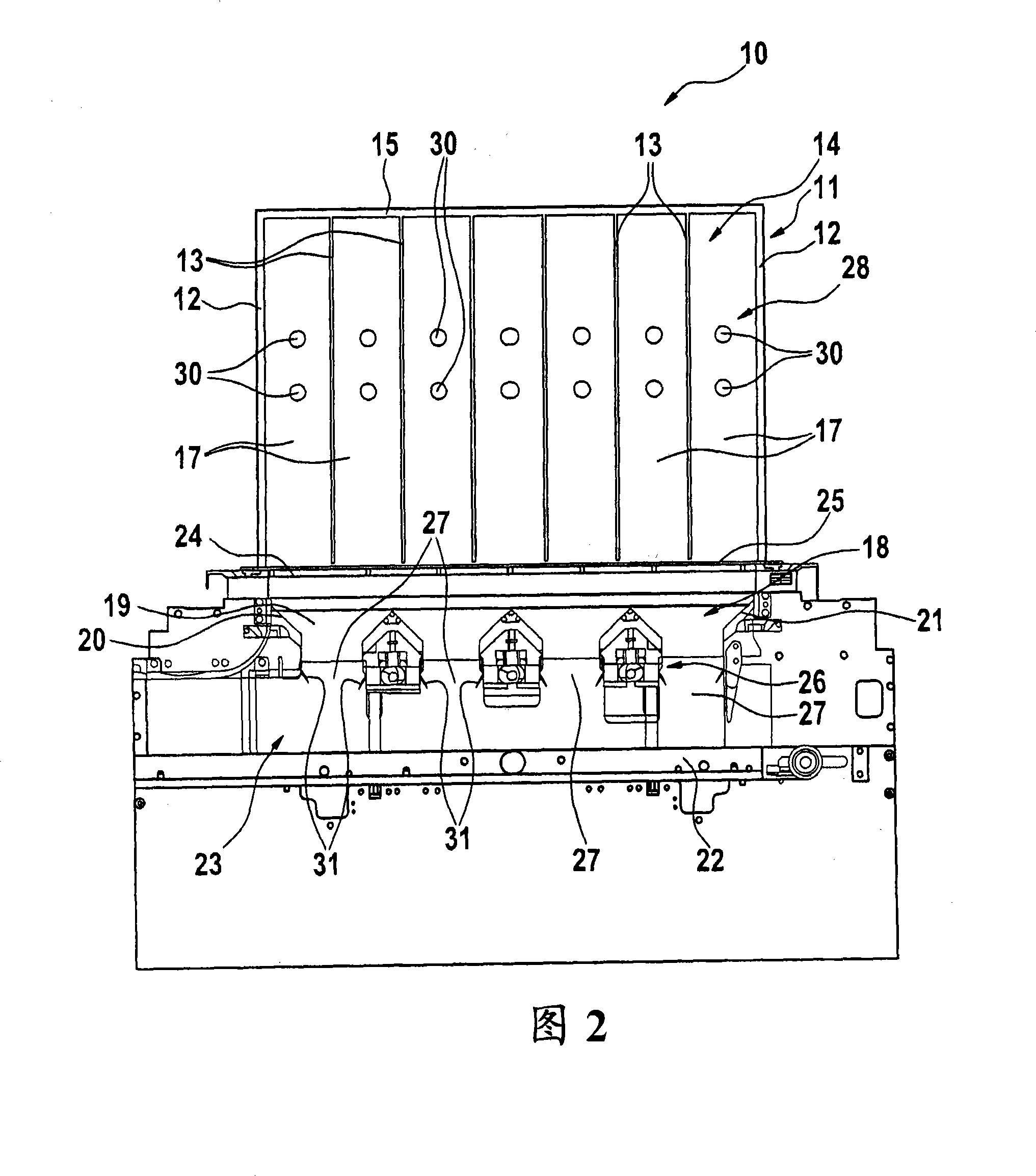

Apparatuses, system and methods for forming pressed articles and pressed articles formed thereby

InactiveCN103635296AImprove efficiencySmooth unloadingPress rollersMould auxillary partsEngineeringMechanical engineering

The invention relates to a method and a system (10) for forming pressed articles by pressing powder or granules, the system comprising the following apparatuses: a powder discharge assembly (12); a no-cavity press assembly (20) including: an bottom plate (22) that is the same size or greater than the pressed articles, a constraining means to isolate a portion of powder, and a top punch (24); and a conveyor (14) to transport the powder and / or pressed articles.

Owner:VECOR IP HLDG +1

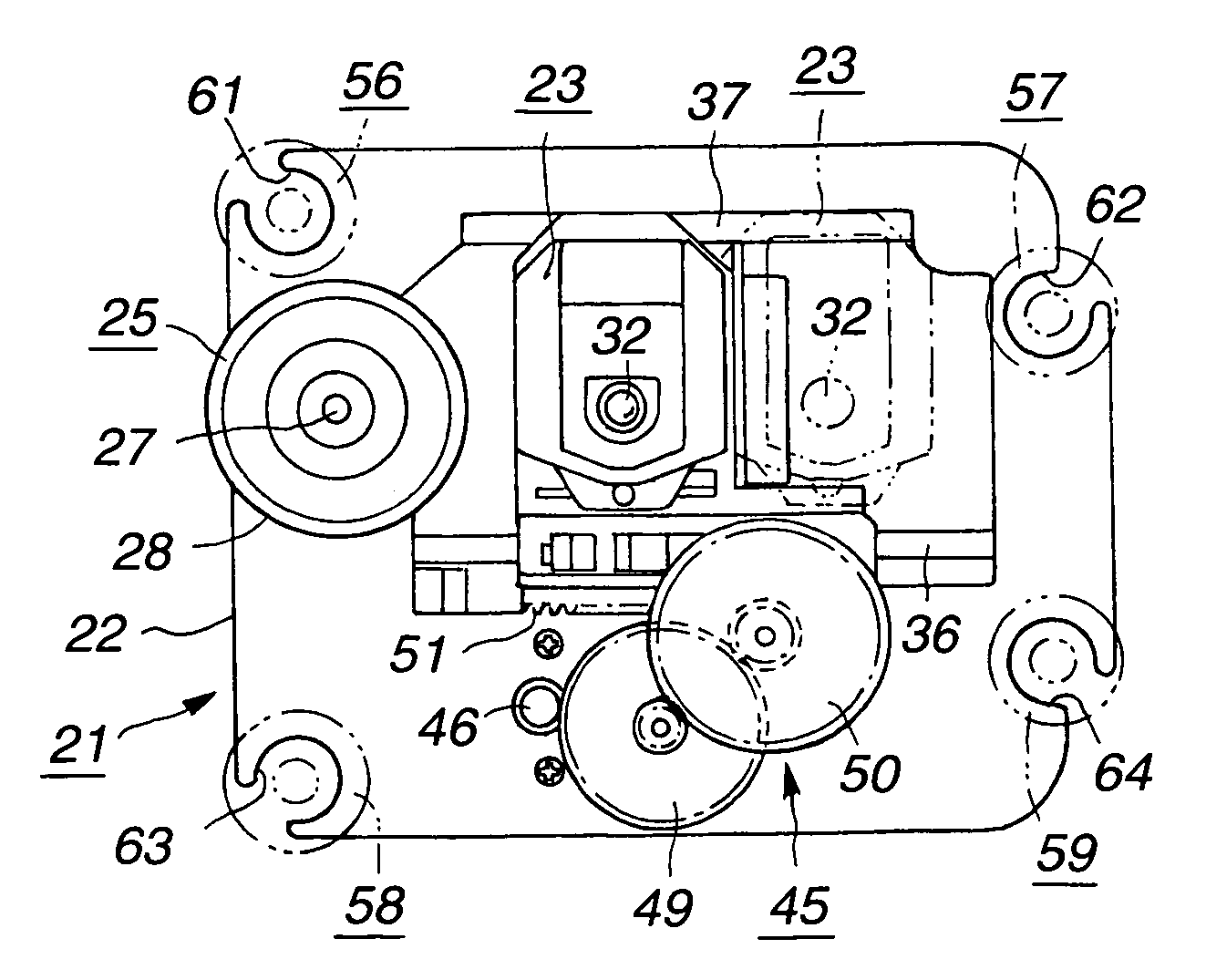

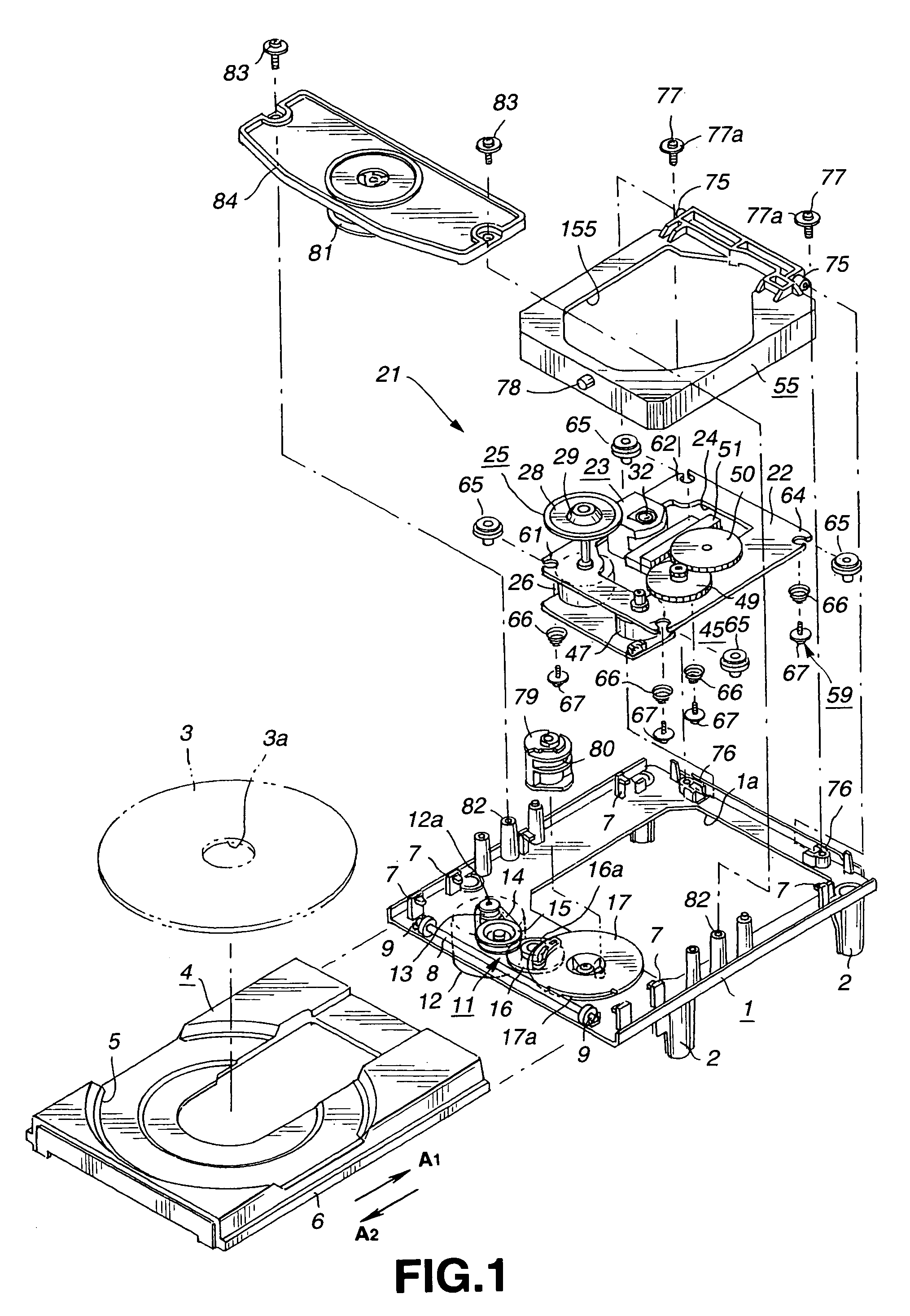

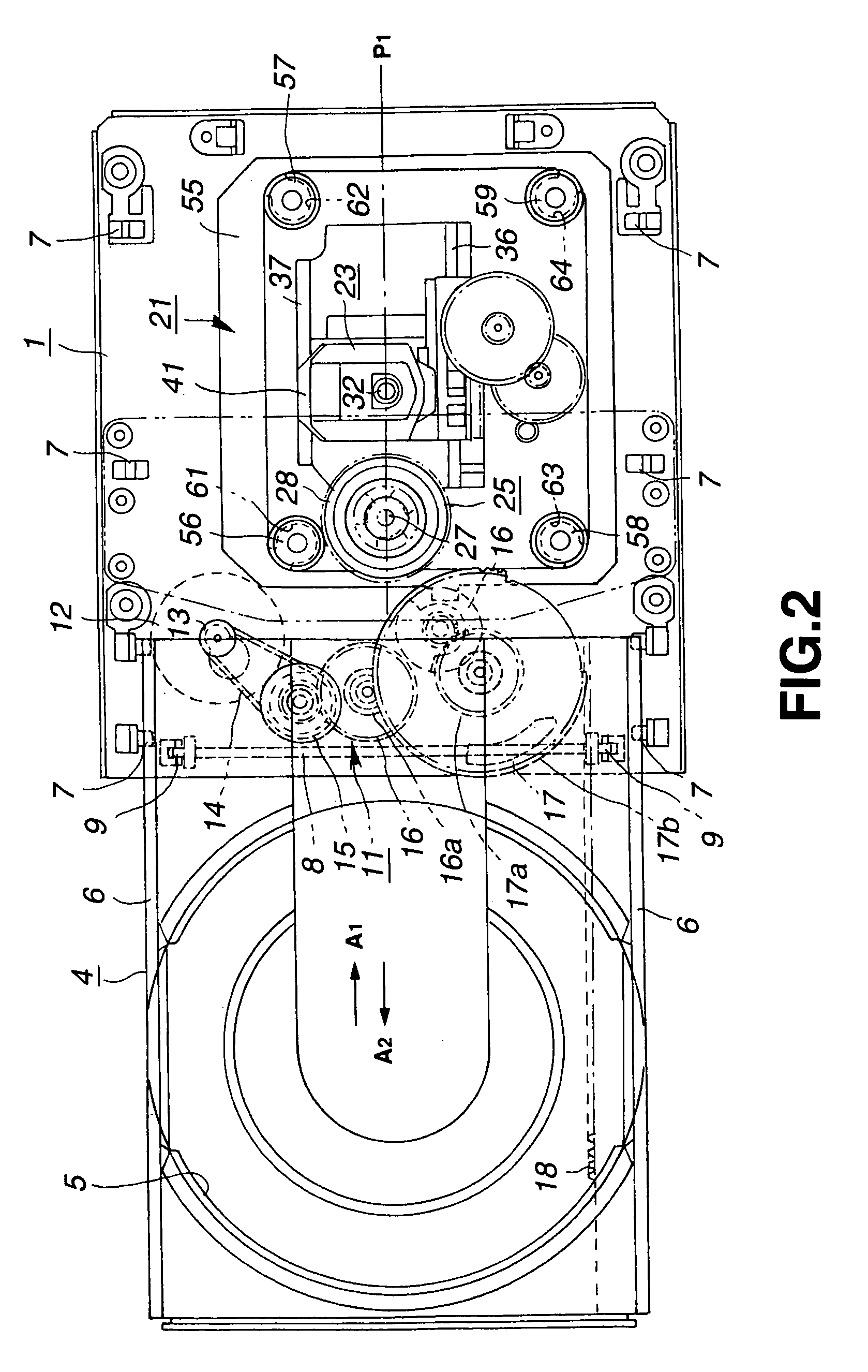

Disc drive and optical disc drive

InactiveUS7120920B1Accurate recordSmooth unloadingCarrier constructional parts dispositionUndesired vibrations/sounds insulation/absorptionWeight shiftOptical pickup

An easily manufacturable optical disc drive that provides for accurate writing and reading of information signals to and from a disc loaded therein by maintaining the horizontal balance of its base during operation, and that provides for smooth loading and unloading of a disc. The optical disc drive includes a base formed of a single metal plate of 1.4–1.8 mm thickness. Major components of the base (i.e., a disc rotation driving mechanism, an optical pickup and a pickup feeding mechanism) are disposed on the base in such a way that the total weight of these components is nearly evenly distributed on the base. The optical pickup is adapted to move across an optical disc between its inner and outer circumferences, while the optical disc is rotated by the disc rotation driving mechanism. The base is supported by a plurality (i.e., at least three) of supporting members, each with an elastic support piece. These supporting members are disposed symmetrically with respect to a center line of the base along the direction of the optical pickup's movement. The symmetrical disposition of these supporting members, together with the vibration absorbing nature of the elastic support pieces and the balanced weight distribution on the base, eliminates weight shifts / imbalance caused by the optical pickup movement, thereby maintaining the horizontal balance of the base at all time during operation of the optical disc drive. The ease of manufacture can be achieved by selecting even numbers (e.g., four) of the supporting members for the base.

Owner:SONY CORP

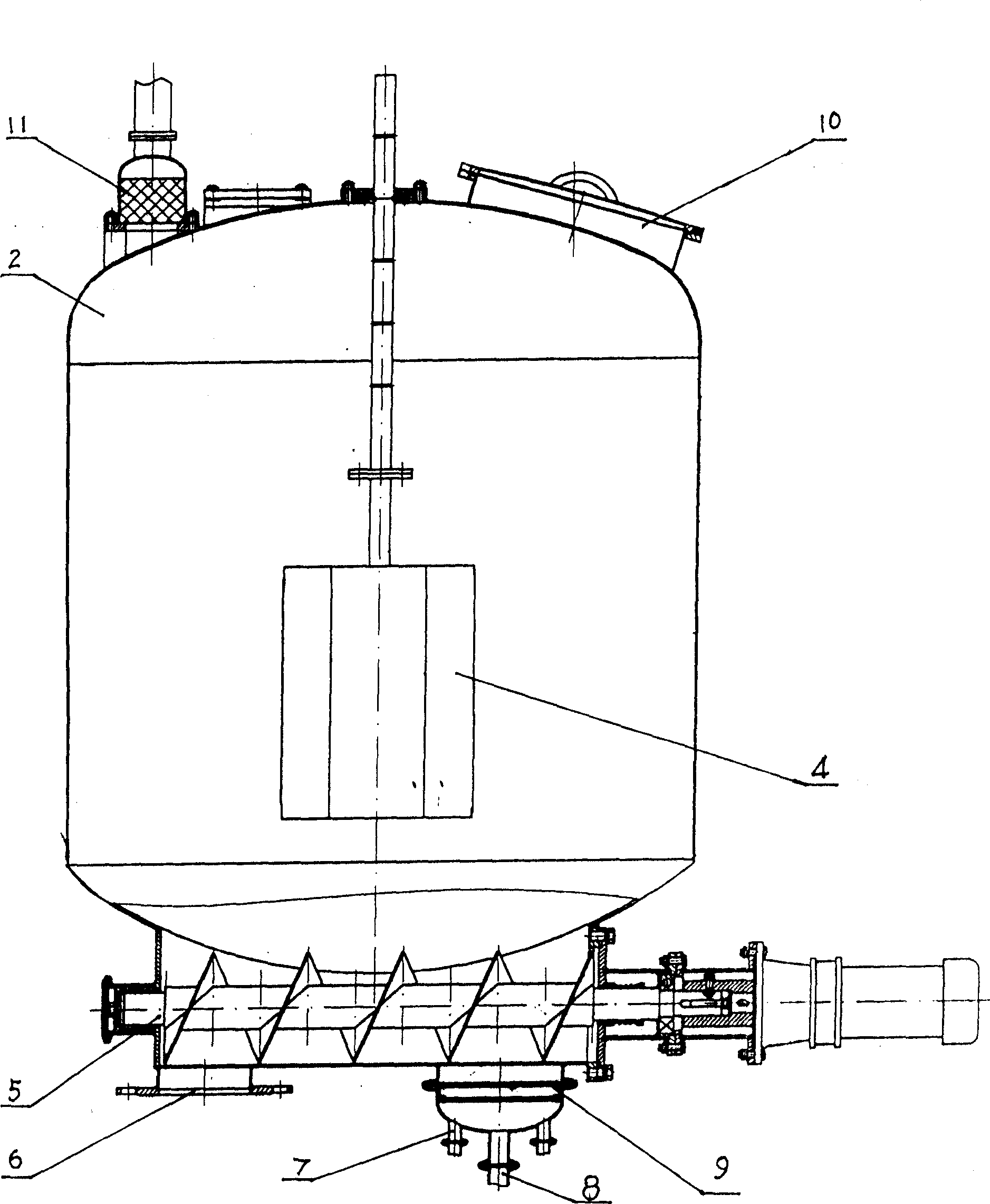

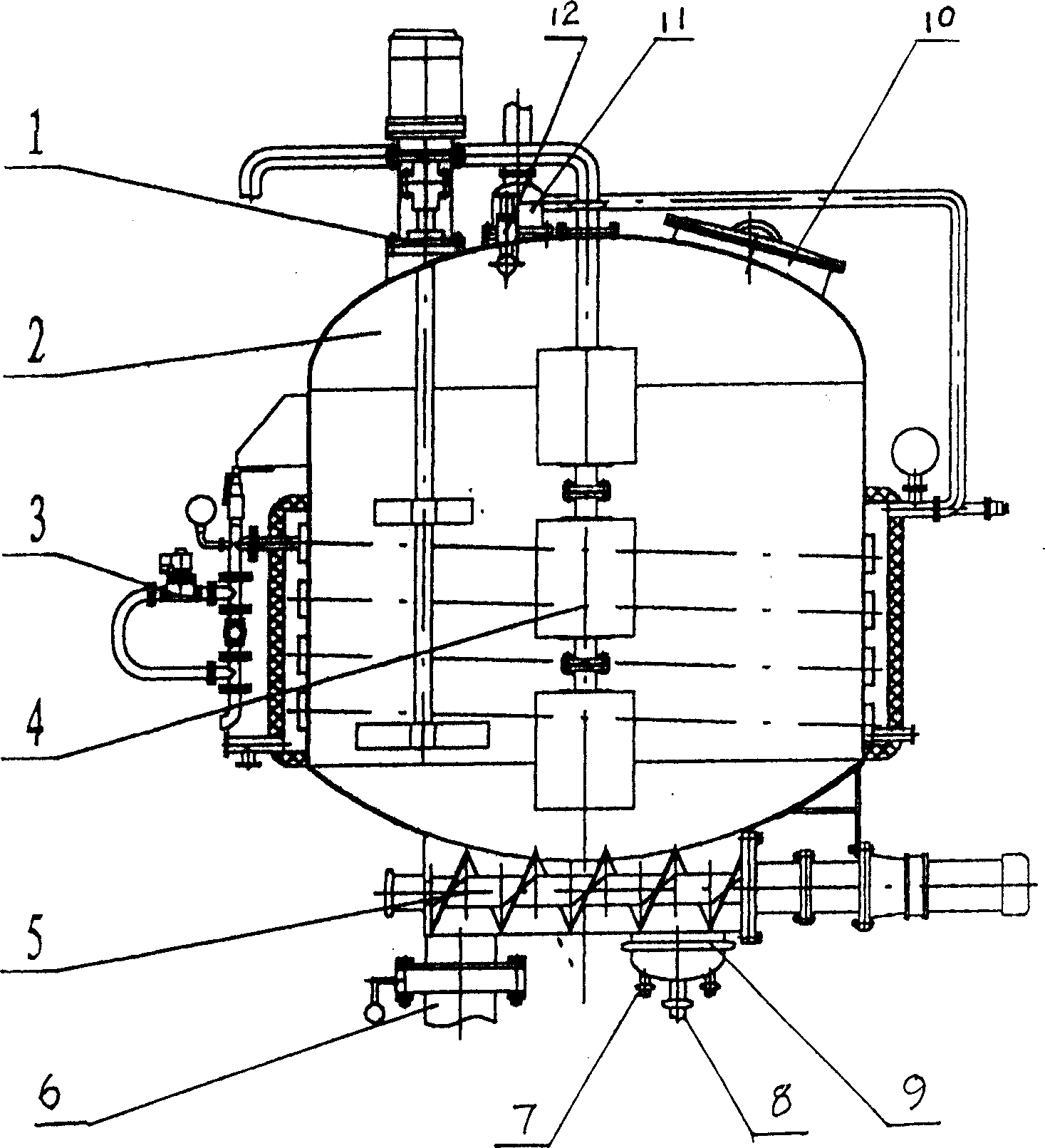

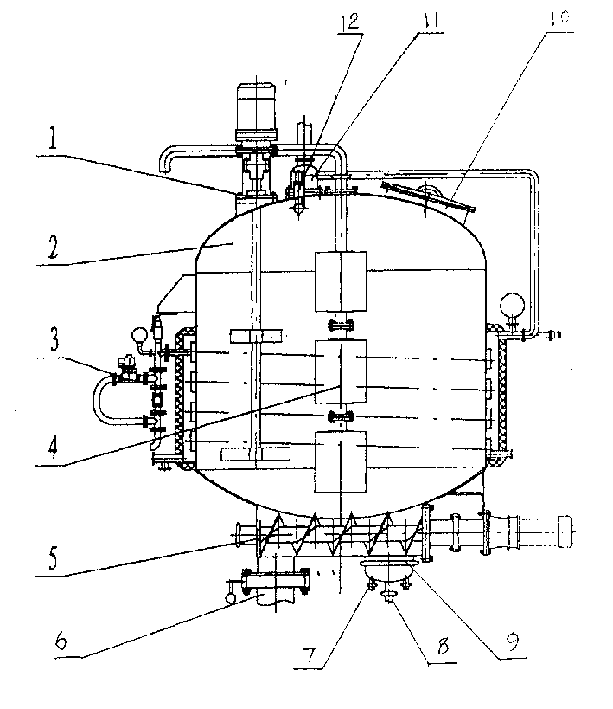

Ultrasonic multifunctional extracting pot

InactiveCN1530159AEasy to unloadSmooth unloadingSolvent extractionPharmaceutical product form changeUltrasonic sensorBiochemical engineering

A multifunctional ultrasonic extractor for preparing Chinese medicine or others is composed of a tank body, an ultrasonic transducer in said tank body, the feed inlet, respirator and washer on the top of tank body, a mechanical dreg discharger on the bottom of tank body, a screw delivering unit, and a solid-liquid separator. Its advantage is the integration of washing, mixing, extracting and solid-liquid separating functions.

Owner:XIANGSHAN MEDICAL PRECISION INSTR

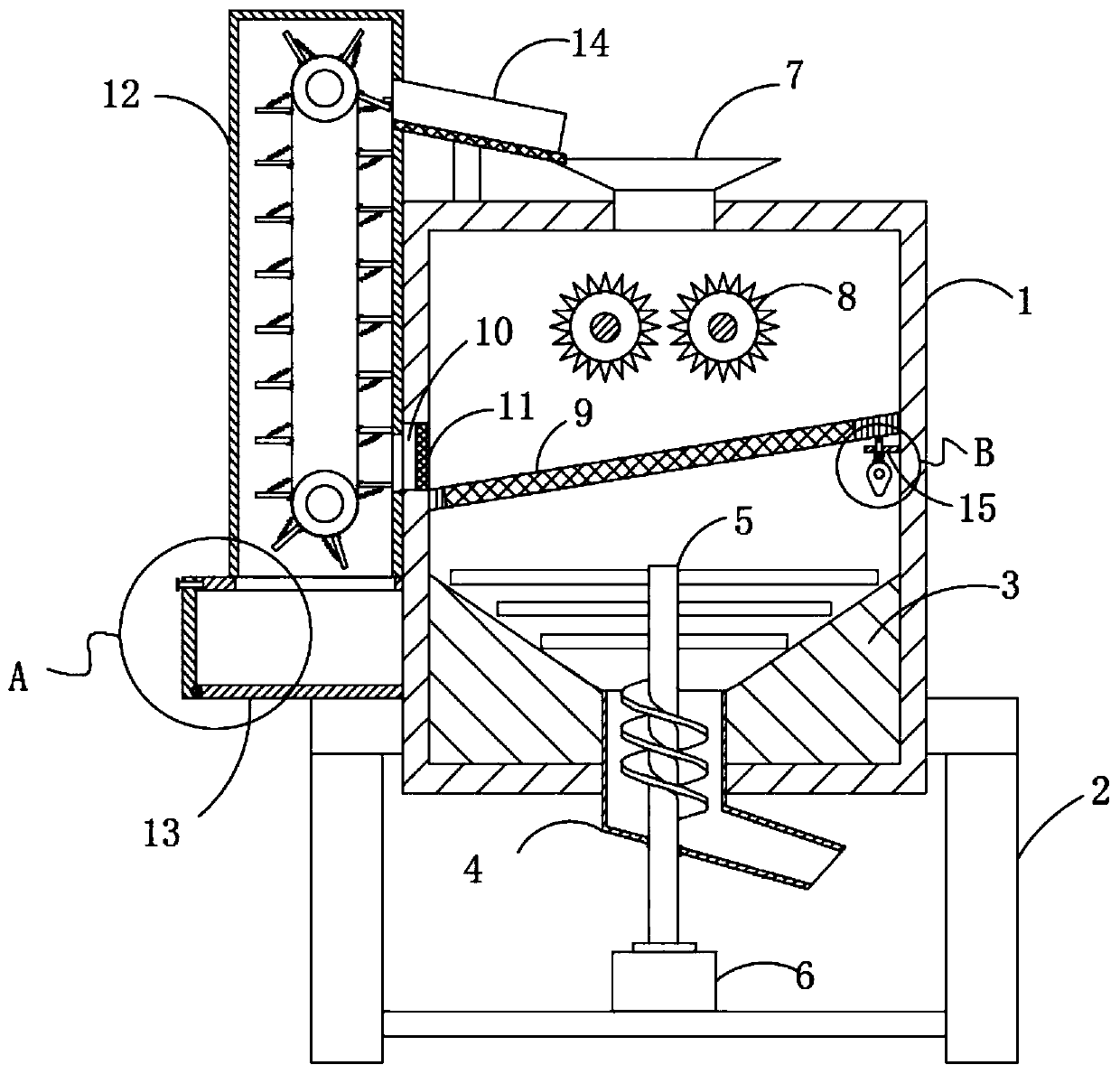

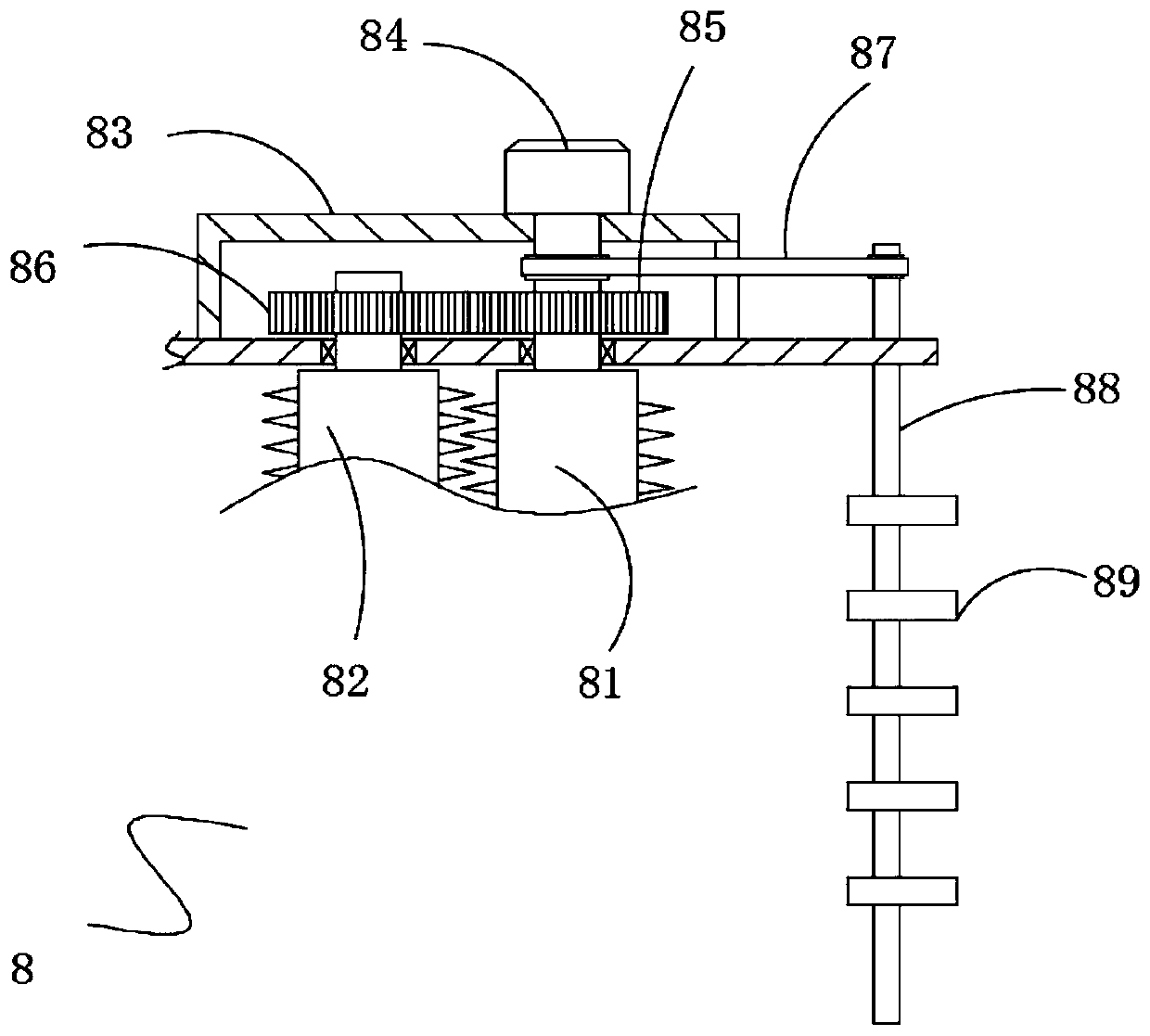

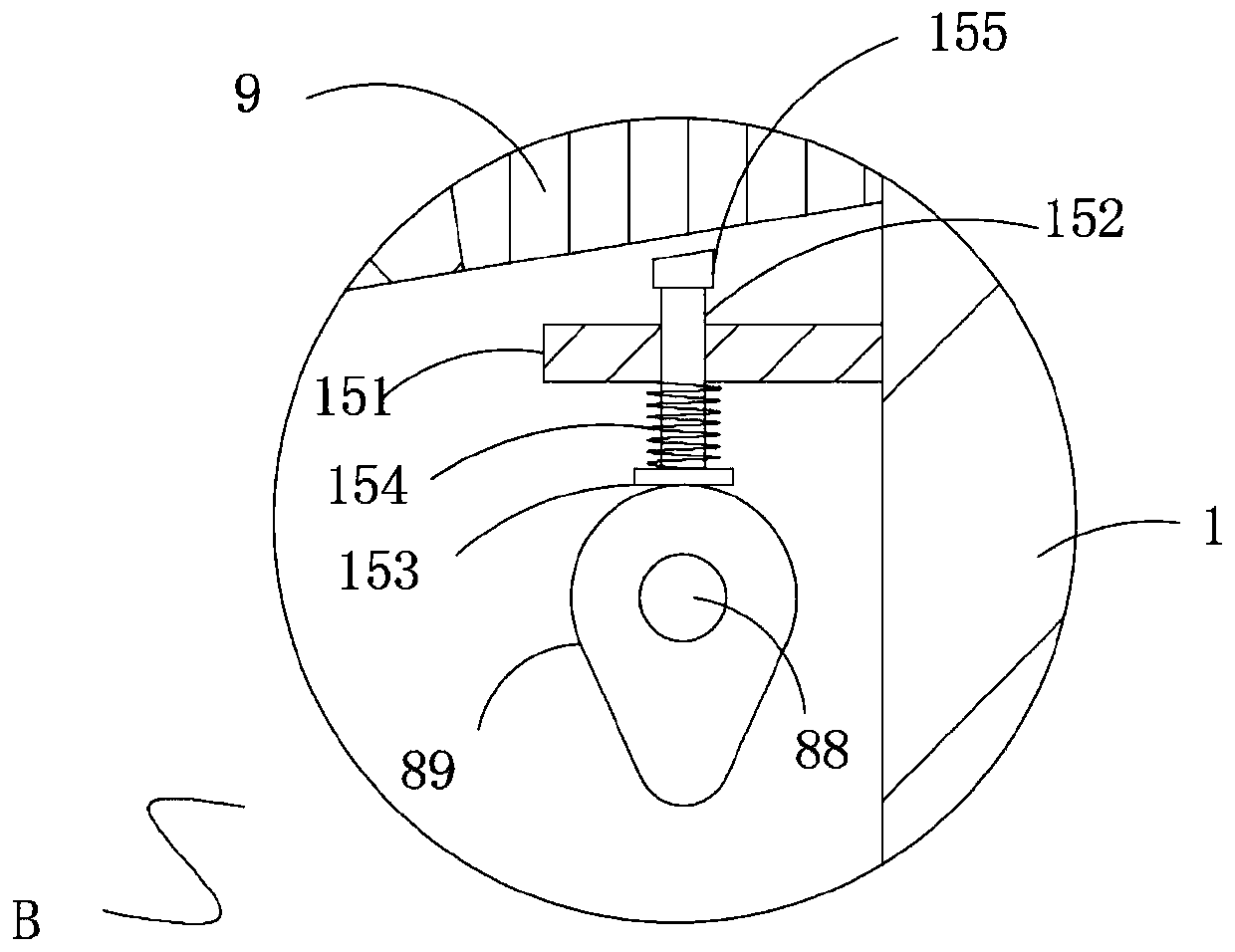

Raw material preparation device for production of refractory material

InactiveCN110773063AImprove the problem of blocked channelsEasy to unloadTransportation and packagingMixer accessoriesElectric machineryRefractory

The invention relates to a raw material preparation device for production of a refractory material. The device comprises a pretreatment box, the bottom of the pretreatment box is provided with a support, the lower part of an inner cavity of the pretreatment box is provided with a discharge hopper, the narrow opening end of the discharge hopper is connected with a discharge inclined pipe, and the lower part of the inner cavity of the pretreatment box is provided with a multifunctional stirring rod; a stirring motor is arranged on the support, and the bottom end of the multifunctional stirring rod penetrates the bottom wall of the discharge inclined pipe to be connected to the output shaft end of the stirring motor; and the top end of the pretreatment box is provided with a feed hopper, theupper part of the inner cavity of the pretreatment box is provided with a crushing mechanism, and an inclined filter net is arranged at the lower side of the crushing mechanism. According to the device, through the technical means that a material return mechanism, the multifunctional stirring rod and a vibration discharge mechanism are arranged, the problems that material blockage easily occur because raw materials that are not sufficiently crushed cannot directly return to a crushing roller for secondary crushing, and multiple crushed raw materials cannot be fully mixed in the prior art are solved.

Owner:浙江长兴振明高科耐火材料有限公司

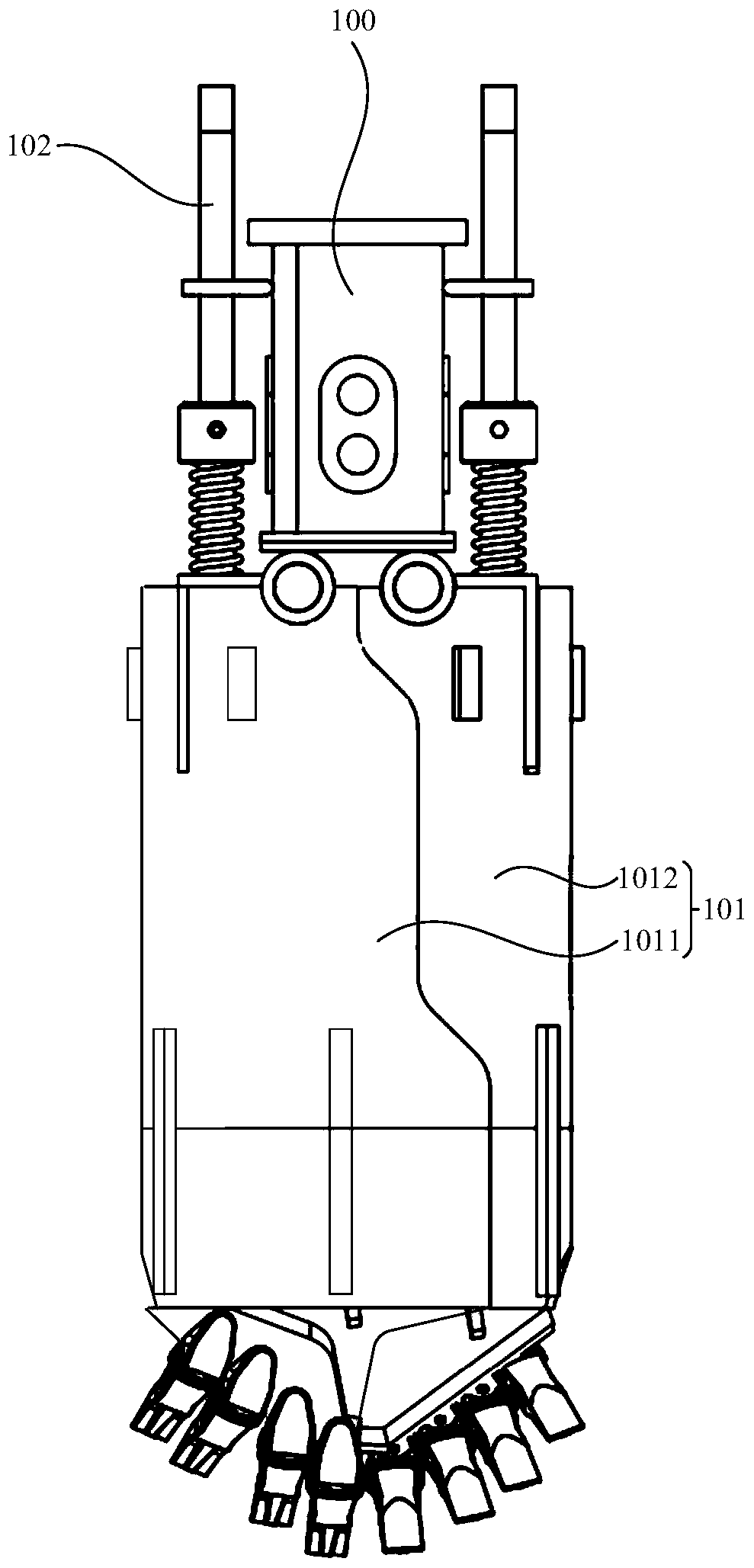

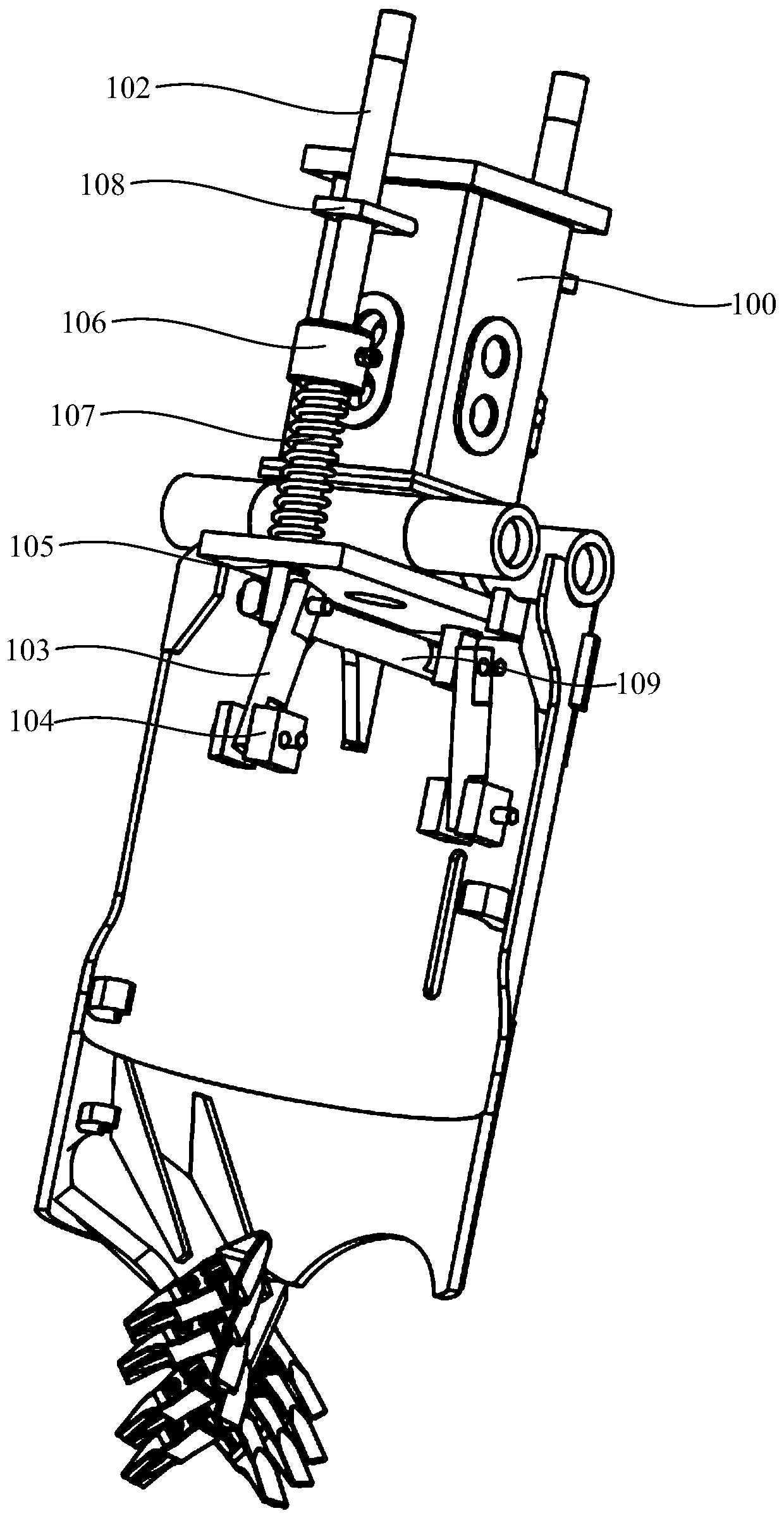

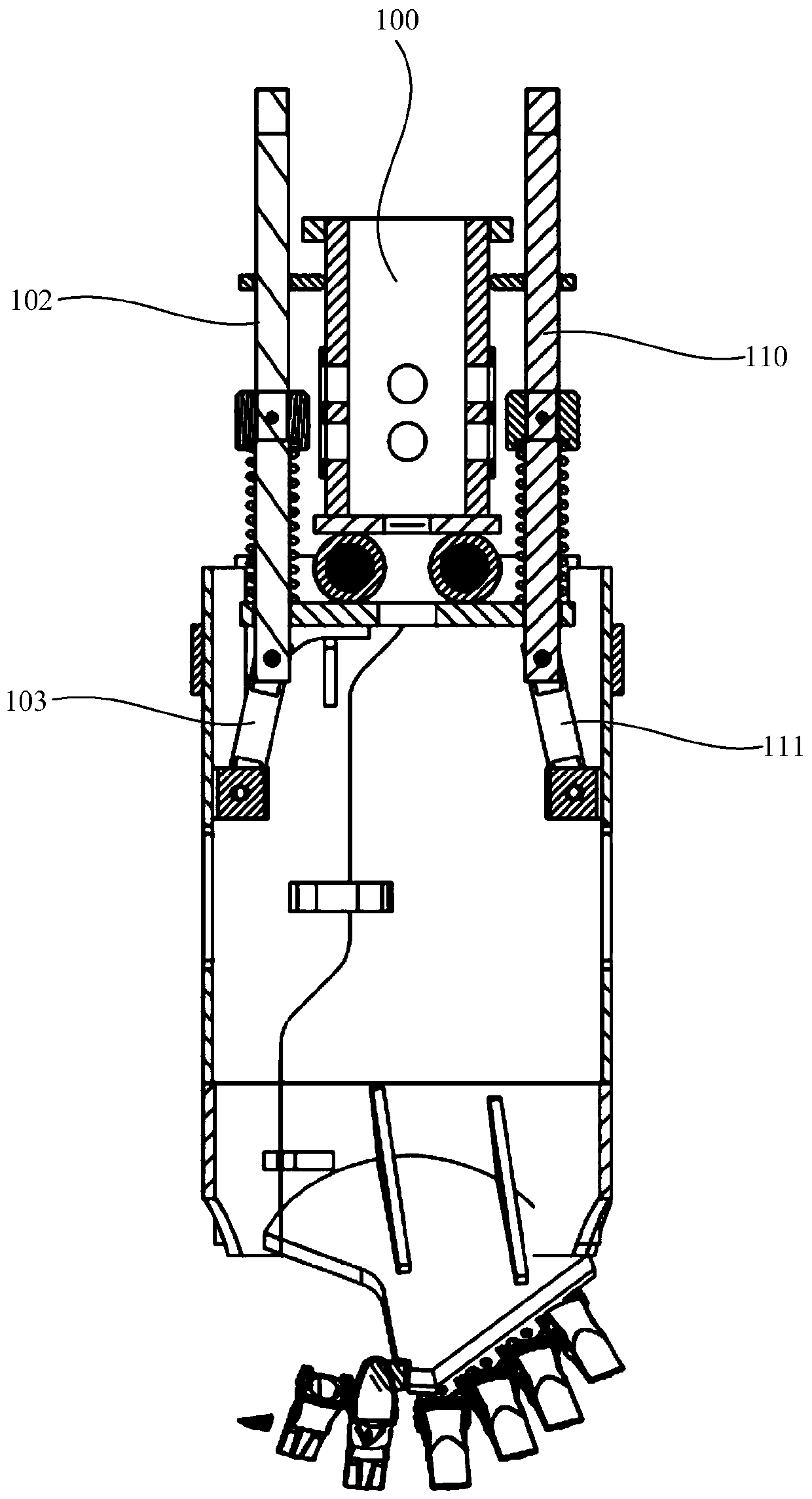

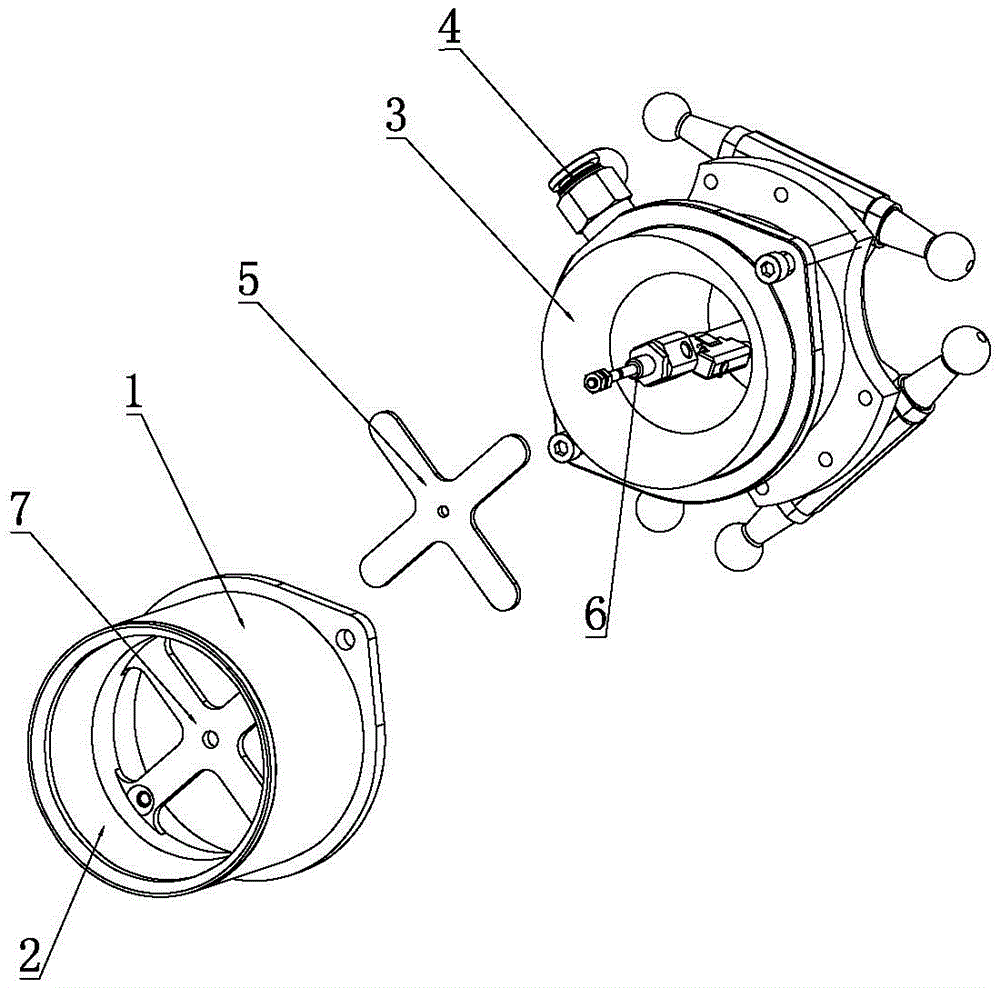

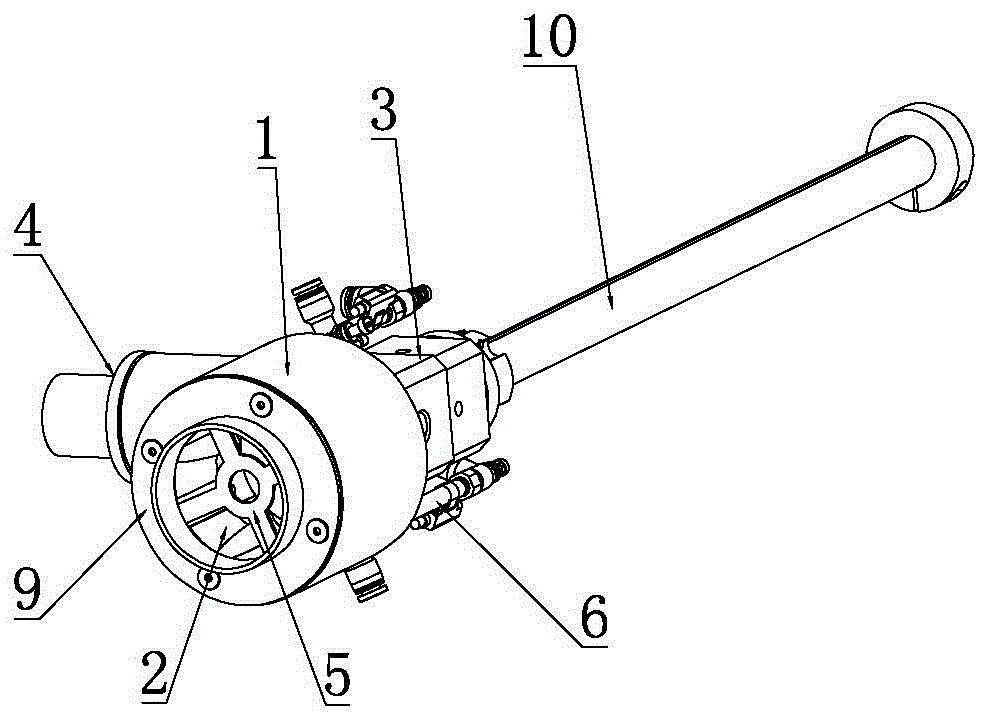

Drilling bucket and rotary drilling rig

PendingCN110566148ASmooth unloadingImprove work efficiencyBorehole/well accessoriesRelative displacementButt joint

The invention provides a drilling bucket and a rotary drilling rig and relates to the technical field of engineering machinery. The drilling bucket comprises a connecting part and a cylinder, whereinthe connecting part is connected with a drill pipe; the cylinder comprises a first half cylinder and a second half cylinder in butt joint with each other; the first half cylinder is hinged to the connecting part; the second half cylinder is connected with the connecting part; a first connecting rod is connected with the end part of a second connecting rod; at the same time, the other end of the first connecting rod is connected with the inner wall of the first half cylinder; the other end of the second connecting rod is connected with a power head pressure plate; that is, the second connectingrod, the first connecting rod and the first half cylinder form a lever structure; and when the power head pressure plate generates displacement relative to the drill pipe, the second connecting rod is driven to generate movement relative to the cylinder to further drive the first connecting rod to move, and the first half cylinder is pushed to rotate towards the direction far away from the secondhalf cylinder so as to unload soil.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

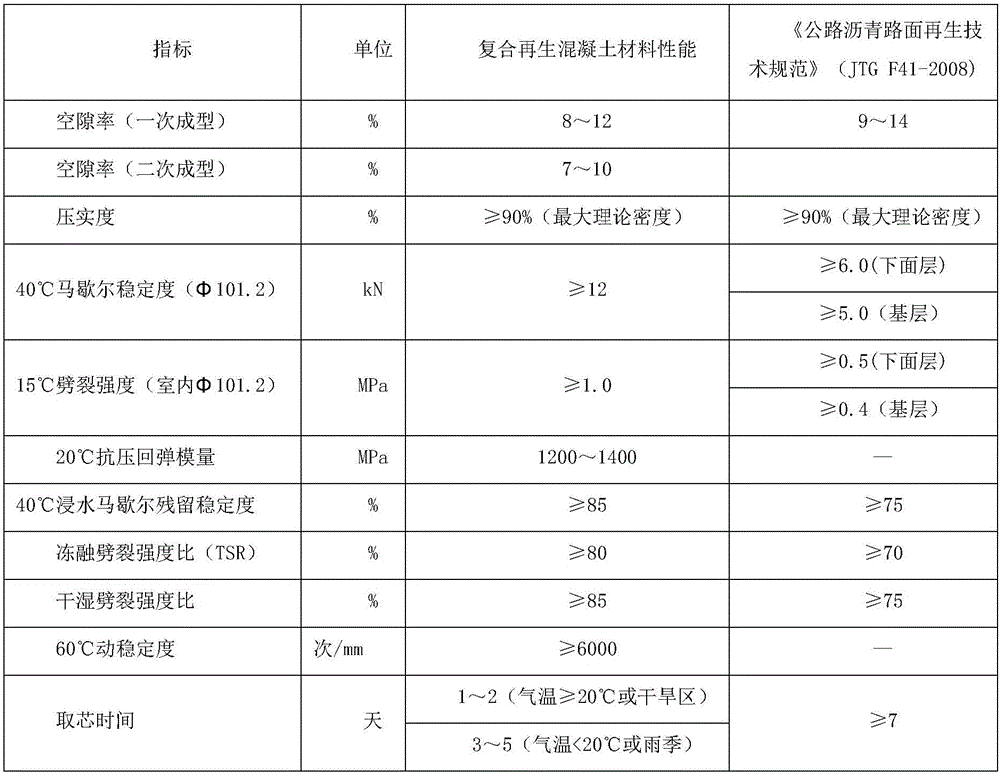

Fiber compound regenerative asphalt concrete

The invention provides fiber compound regenerative asphalt concrete, which is prepared from the following ingredients (by weight): 30 parts of 0-5mm regenerative asphalt concrete RAP, 25 parts of 5-10 mm regenerative asphalt concrete RAP, 28 parts of 10-30 mm regenerative asphalt concrete RAP, 15 parts of 10-30 mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, 1 part of a regenerant and 1.2 parts of glass fiber. The glass fiber of 6 mm long is added to improve material performance of a cold recycled mixture. The glass fiber is obviously better than other fibers. The special fiber has obviously more excellent dispersion effect in the cold recycled mixture than other fibers, and the regenerative mixture is smooth to discharge. The fiber compound regenerative asphalt concrete provided by the invention has obviously more excellent material performance than the code requirements. Tension strength, namely cleavage strength, of the mixture is raised. Material anti-cracking ability is more excellent, reflection crack resistance is stronger, the material is more compact, moisture damage resistance is stronger, and durability is better.

Owner:BEIJING SAINT GROUND HIGHWAY TECH

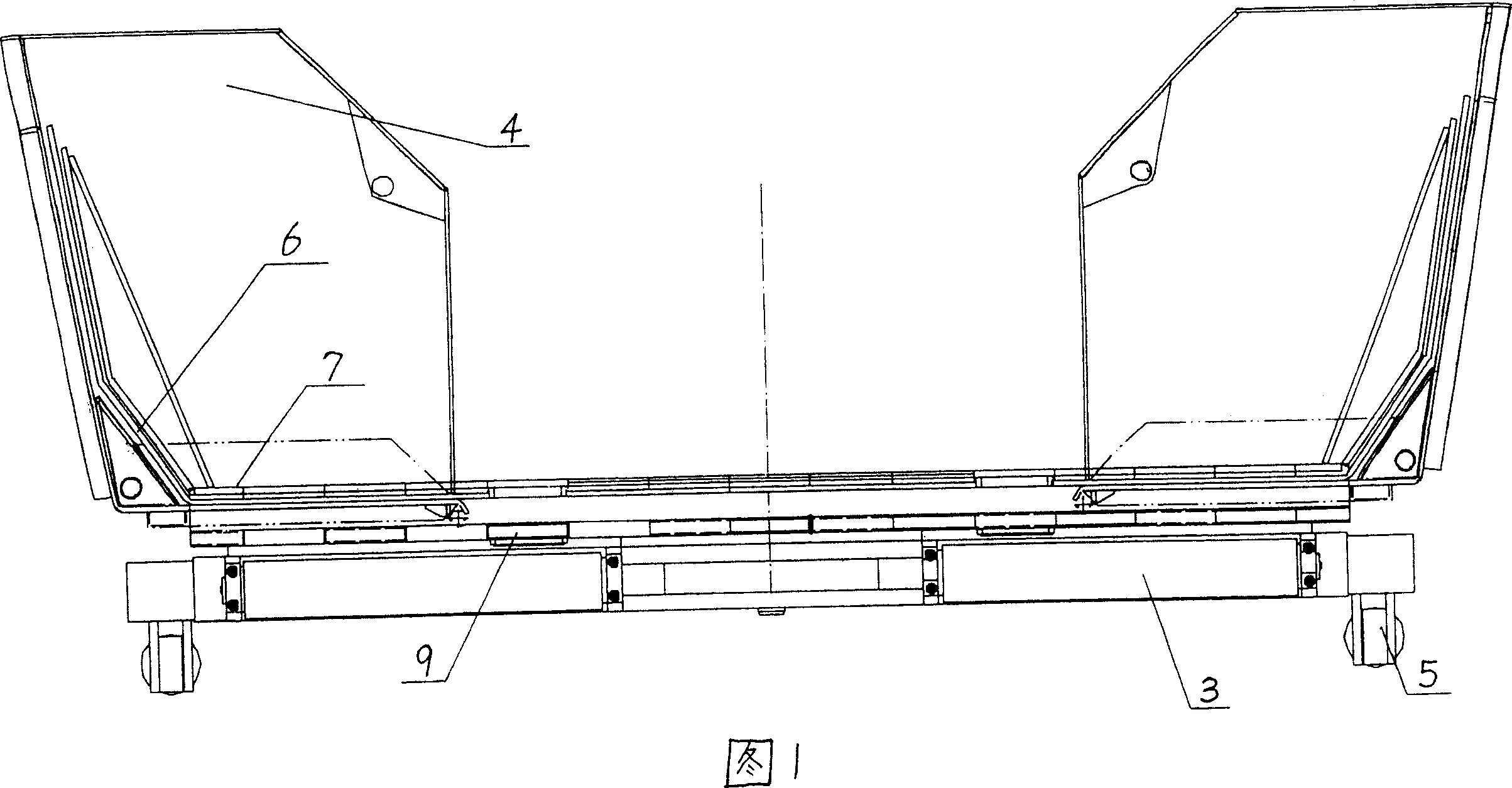

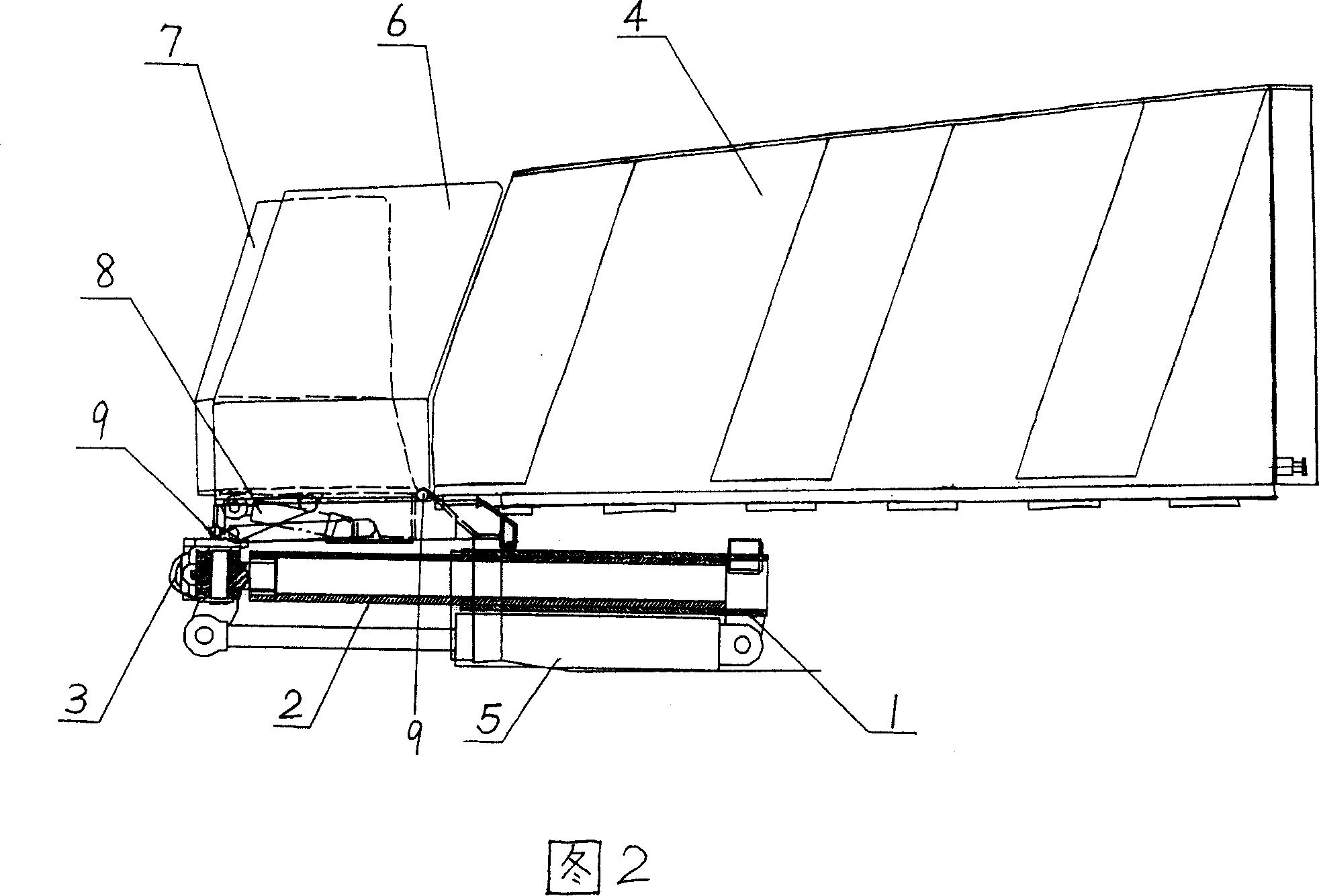

Flex overturning type auxiliary movable hopper for spreading machine

This invention discloses one spreader contract tilting assistant active bunker, which comprises guide channel set on both sides of spreader with one end of slide axis into guide channel and with other end connected to pull assemble fixed with fix bunker and tilt bunker, wherein, the contract cylinder one end is hinged on guide channel and other end hinged onto pull assembly; the active bunker contracts front and back under contract cylinder; the tilt cylinder one end is hinged onto fix bunker and other end connected with tilt with tilt cylinder fixed on middle or both sides of active bunker to realize tilt under tilt cylinder.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

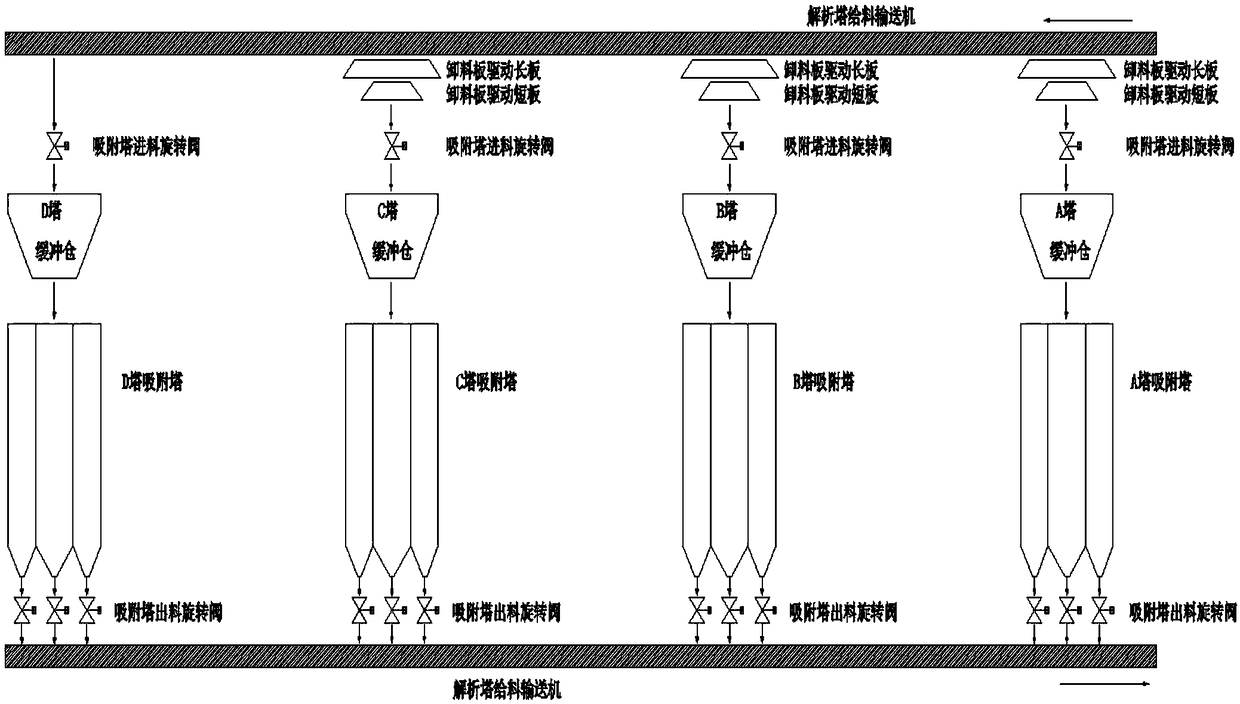

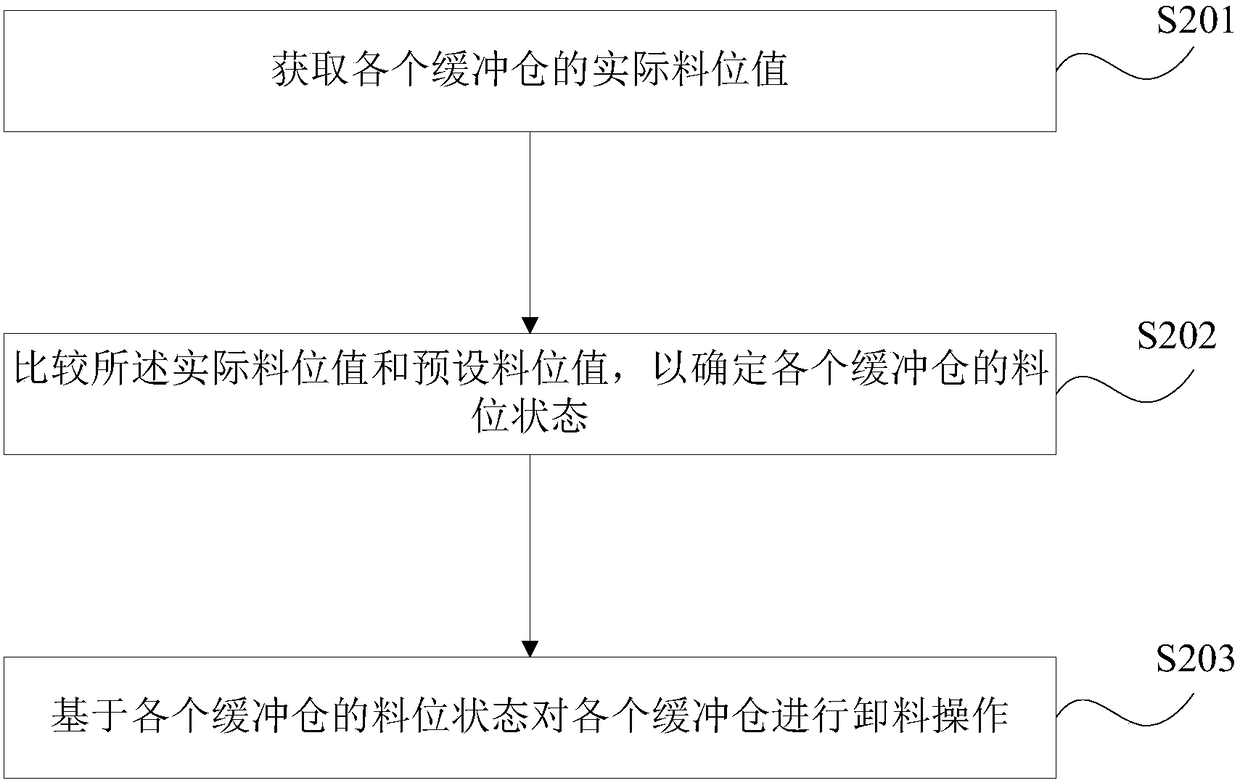

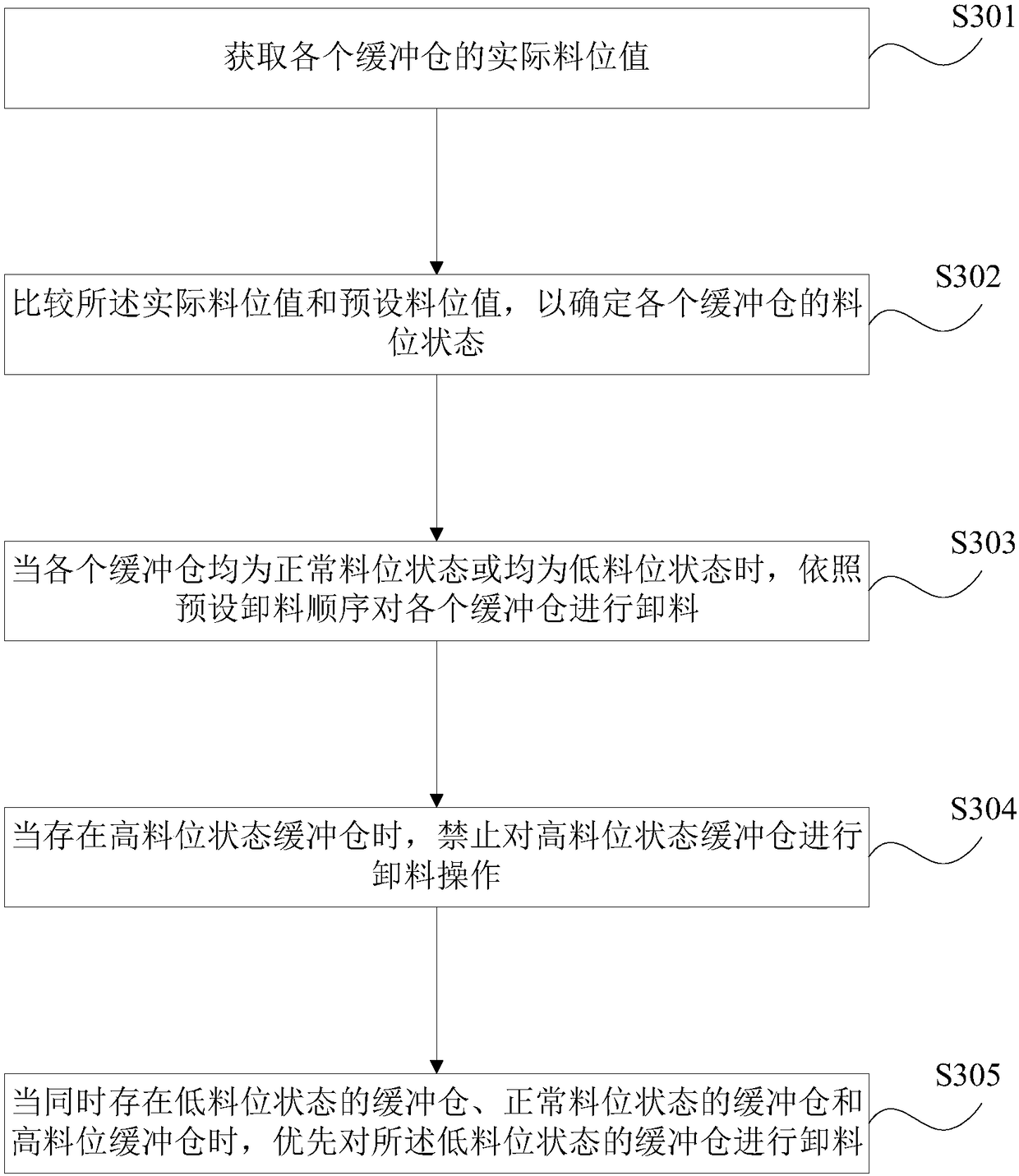

Automatic uniform discharging control method and device

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

Deicing fluid for railway carriage and preparation method thereof

The invention provides a railway carriage antifreezing solution and its preparing method, including the following components in weight precent: anhydrous calcium chloride 20-50%, alcohol 8-10%, and water 40-70%, and it can also adds in antirusting agent sodium nitrite in 1-2%. The preparing method: firstly adding water in a stirring jar, then adding in the anhydrous calcium chloride and stirring to fully dissolving them, eliminating foam, then stirring to the temperature at 19 deg.C-21 deg.C, adding in alcohol, adding in the antirusting agen, stirring for 30 minutes and then ending. It can ensure the vehicle skins do not freeze with the hydrous bulk materials in 10 hours in the open air, and thoroughly solves the freezing problem of the iron mine powder-like hydrous bulk materials in the winter, thus need not defreeze them in defreezing rooms to smoothly discharge, saving energy sources, shortening turnover cycle of railway carriages, reducing labor strength and reducing transport cost.

Owner:辽宁双鞍集团新科工业有限公司

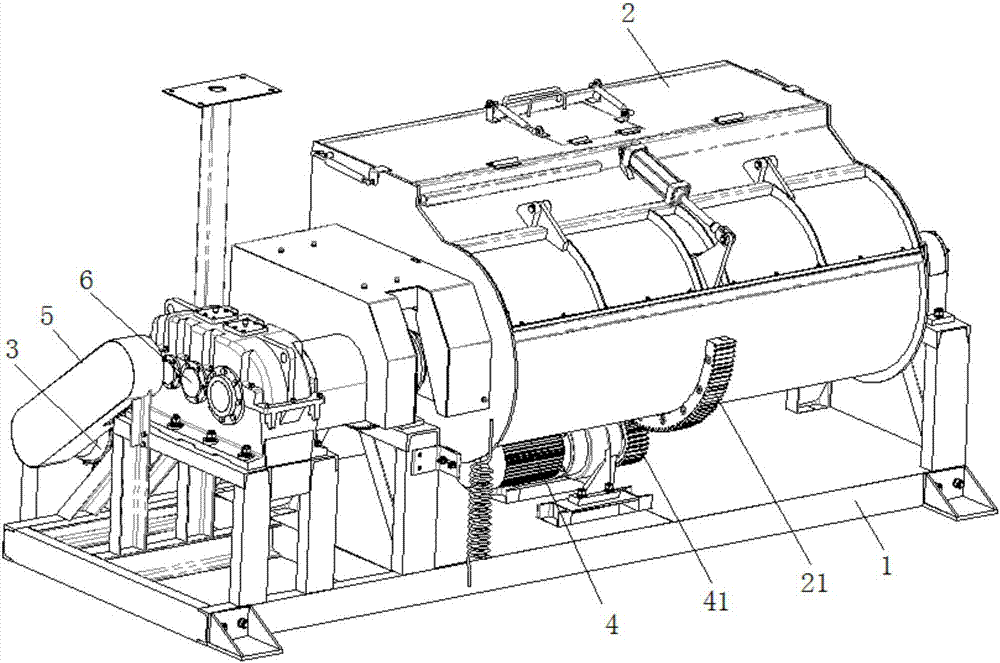

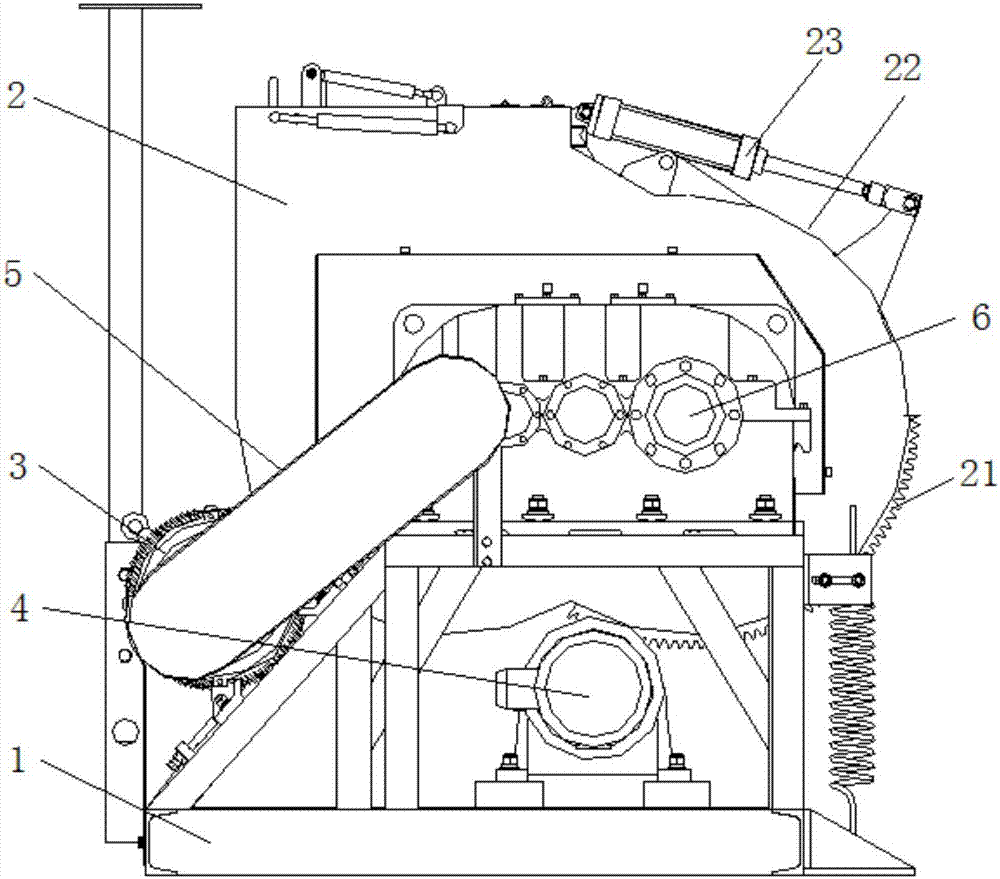

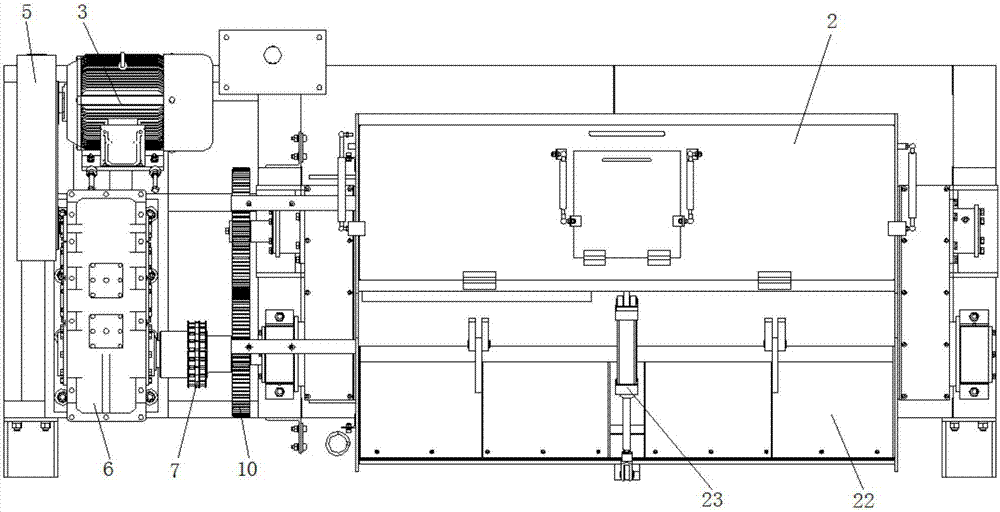

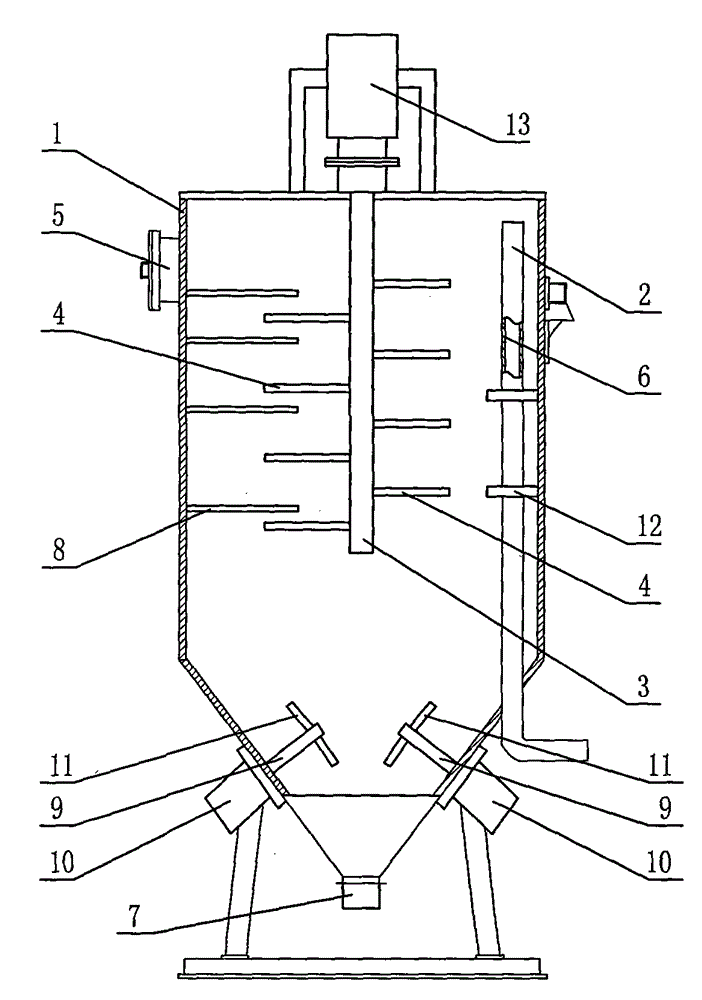

Stirring machine for intermediate materials

PendingCN107413225AExtended service lifeNo dead endsRotary stirring mixersTransportation and packagingMotor driveCoupling

The invention discloses a stirring machine for intermediate materials. The stirring machine comprises a rack, a stirring barrel, a stirring mechanism, a stirring motor and an overturning motor, wherein the stirring barrel is supported on the rack; the stirring mechanism is arranged in the stirring barrel; the stirring motor drives the stirring mechanism; the overturning motor is used for overturning the stirring barrel; the stirring mechanism comprises a driving stirring shaft and a driven stirring shaft; the driving stirring shaft and the driven stirring shaft are connected by a synchronous gear group in a transmission manner; the stirring motor is connected with the driving stirring shaft in the stirring mechanism by a triangular belt, a speed reducing box and a coupling in sequence in a transmission manner; the driving stirring shaft and the driven stirring shaft are respectively provided with stirring blades which are mutually distributed at intervals; the bottom part of the stirring barrel is a curved surface formed by intersection of two semicircular barrel parts, and the radial middle position of the curved surface positioned at the front part is provided with an arc-shaped overturning gear ring; and an overturning gear is arranged at an output shaft of the overturning motor and is meshed with the overturning gear ring. The stirring machine disclosed by the invention has the advantages that no dead corners in the stirring process can be guaranteed, full and uniform stirring is guaranteed, and the stressing in overturning and discharging is uniform, smooth and convenient.

Owner:青岛美中建材机械有限公司

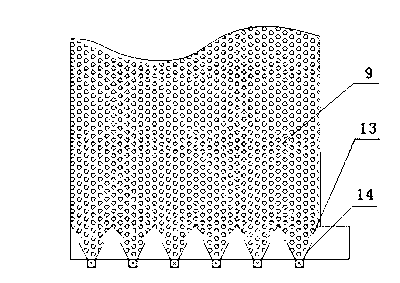

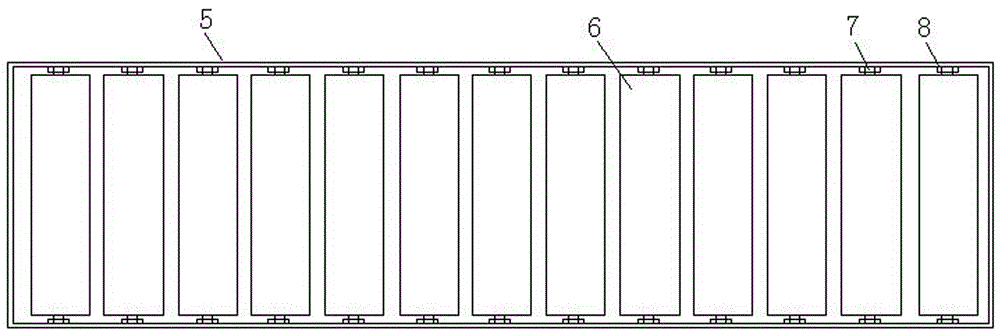

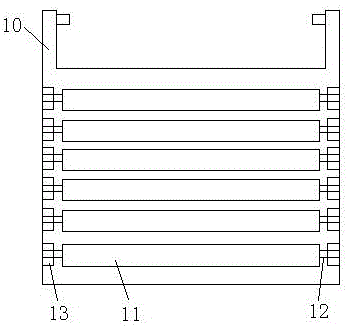

Closed-loop steel sintered red ore cooling device and process method thereof

ActiveCN106123609AIncrease productionGood qualityHandling discharged materialCooling methodsCold air

The invention discloses a closed-loop steel sintered red ore cooling device. The device comprises a device body, a heat exchange cavity arranged in the device body, a feeding inlet formed in the upper end of the device body, a uniform distributor arranged at the lower end of the feeding inlet, a discharging outlet formed in the lower end of the body, a uniform temperature device and at least one fire grate. The uniform temperature device is arranged on the device body and communicates with a cold air outlet. The at least one fire grate is movably installed in the heat exchange cavity. Each fire grate and the heat exchange cavity form an obliquely-downward angle, and the fire grates are parallel to each other. A pushing device is arranged at the front end of each fire grate. A hopper is arranged at the tail end of each fire grate. The device replaces a cooling section of an original sintering machine or a ring cooling machine. Compared with an original cooling mode, the device is high in yield, good in quality and low in energy consumption. Compared with the original cooling mode, the yield of a marching type sintering machine can be increased by 30%-40%, zone firing is increased by 5%-10%, and energy consumption only accounts for about 50% of the original cooling mode.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

Dry-type mixing device

InactiveCN103600415AWell mixedEvenly mixedDischarging apparatusCement mixing apparatusMixing tankWaste management

The invention discloses a dry-type mixing device comprising a mixing tank body, the mixing tank body is connected with a feed pipe which is inserted in an inner chamber of the mixing tank body from the lower part of the mixing tank body, the bottom of the feed pipe is provided with a feed port, a feed pipe section located in the mixing tank body is provided with a plurality of discharge holes from top to bottom, a stirring shaft driven by a power device is in the mixing tank body and is rotationally connected with the mixing tank body, the stirring shaft is connected with stirring blades, the upper part of the side wall of the mixing tank body is provided with a large-grain supply pipe, the lower part of the mixing tank body is shaped as an inverted cone, the bottom of the mixing tank body is provided with a discharge tube, a discharge shaft and a discharge motor are symmetrically arranged on a inverted-cone shaped section of the mixing tank body, the discharge shaft is obliquely upwards stretched out and is driven to rotate by the discharge motor, and the discharge shaft is provided with material-uniforming blades. The dry-type mixing device has the advantages of even feed amount, low tendency to lead feed separation, and even material mixing.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

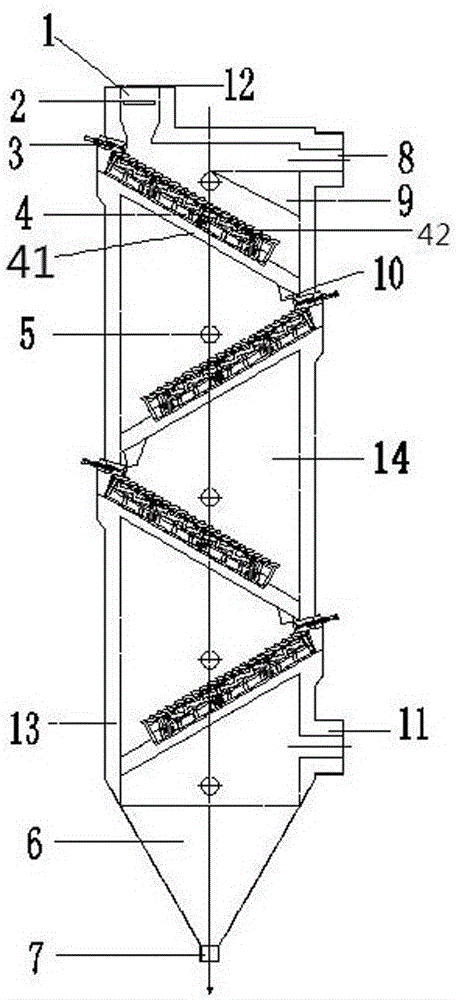

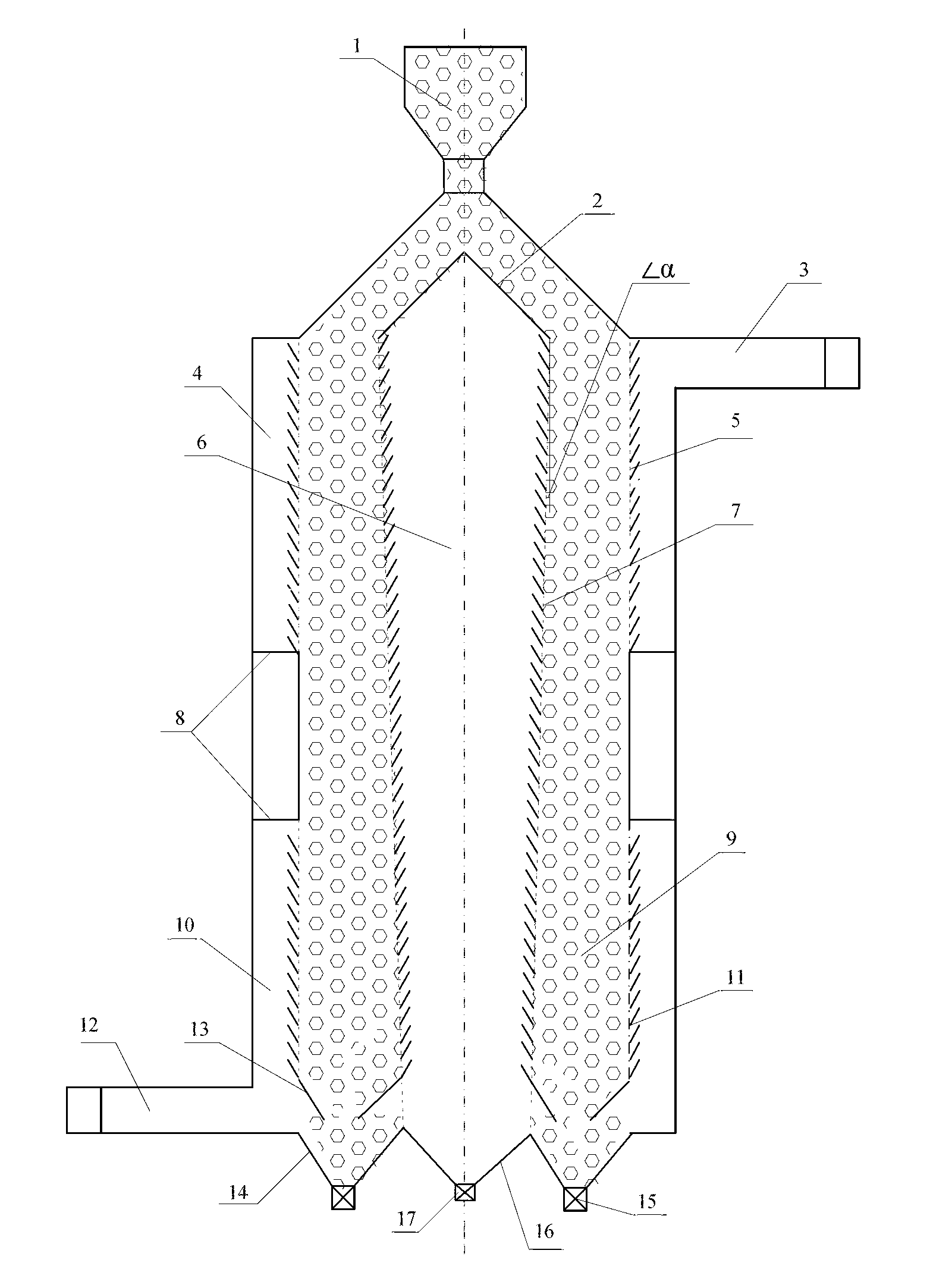

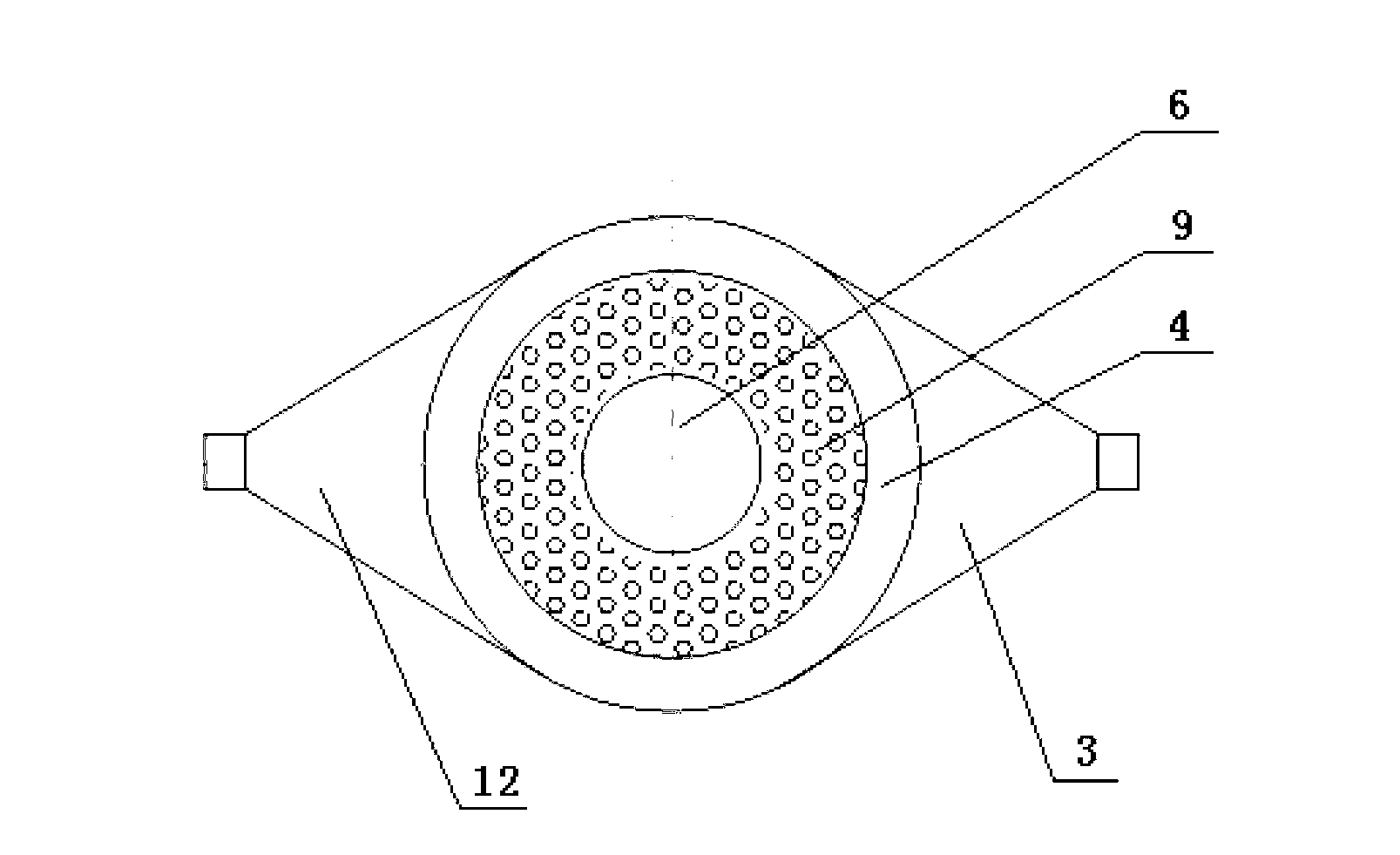

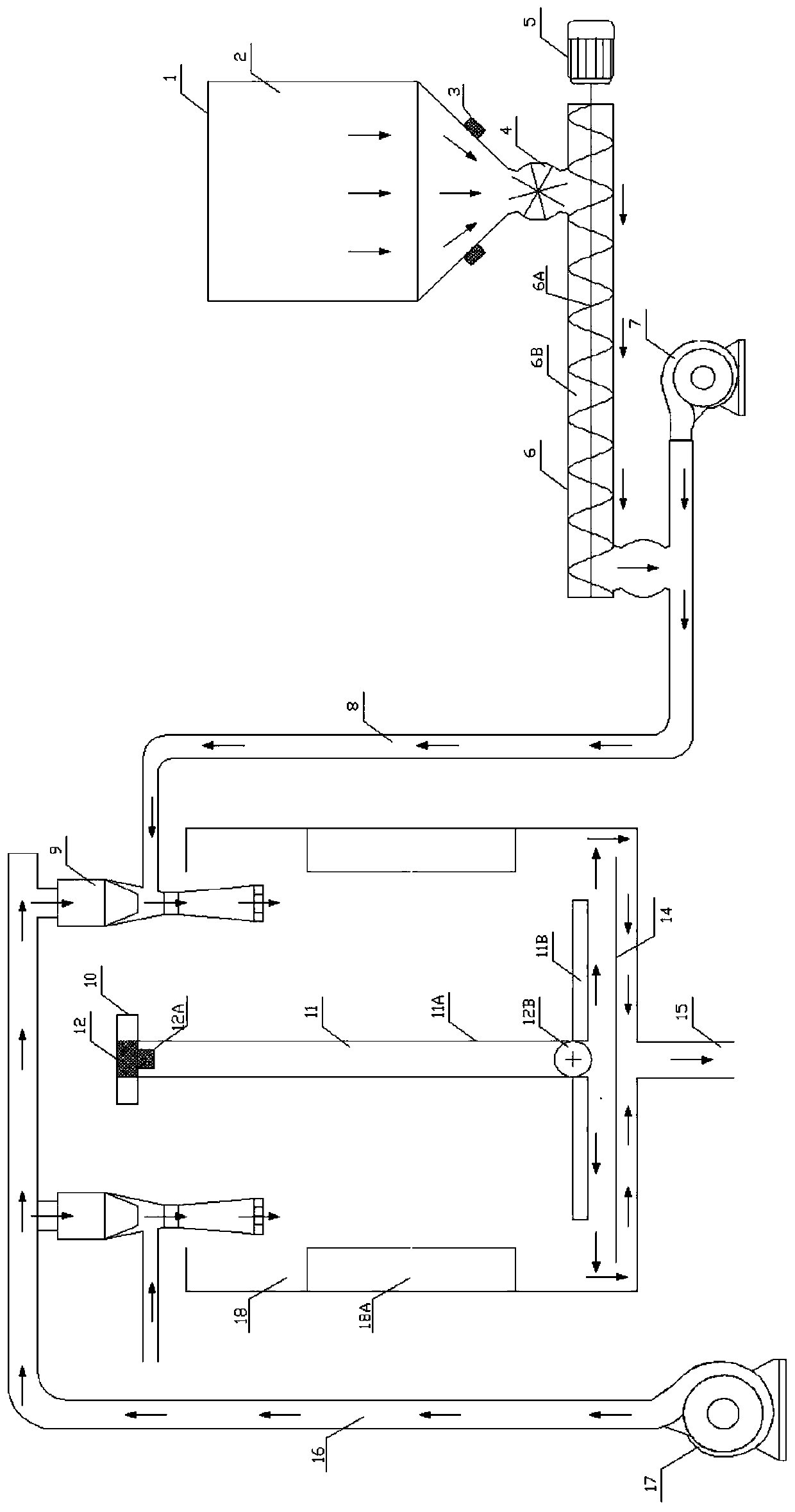

New cross-convective flue gas purification absorption tower

ActiveCN103230724AHigh saturationSimple structureDispersed particle separationFlue gasProcess engineering

The invention discloses a new cross-convective flue gas purification absorption tower. The new fault-convective flue gas purification absorption tower from top to bottom comprises a feeding hopper, a distributing device, an active coke bed layer and a discharging hopper communicated in sequence, wherein a middle flue gas collecting chamber is arranged in the active coke bed layer; the two-layer discharging hopper is arranged at the lower part of the active coke bed layer; the external part of the active coke bed layer is divided into an upper pure flue gas collecting chamber and a lower raw flue gas distributing chamber by a two-layer annular separating plate; an outlet flue is formed in the upper part of the pure flue gas collecting chamber; a raw flue gas inlet flue communicated with the raw flue gas distributing chamber is arranged at the lower part of the raw flue gas distributing chamber; and the active coke bed layer, the middle flue gas collecting chamber, the raw flue gas distributing chamber and the pure flue gas collecting chamber and the cross section of the overall tower body are circular. By adopting the absorption tower disclosed by the invention, the removal efficiency of the pollutant in the flue gas is high; the removal efficiency of SO2 is greater than 96%; the removal efficiencies of SO3, HCl and HF are greater than 98%; the removal efficiency of heavy metal Hg is greater than 90%; and the dust collection efficiency is greater than 80%; and meanwhile, the absorption tower disclosed by the invention also has the advantages of being convenient and uniform in feeding, smooth in blanking, high in utilization rate of the active coke and easy to enlarge.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +2

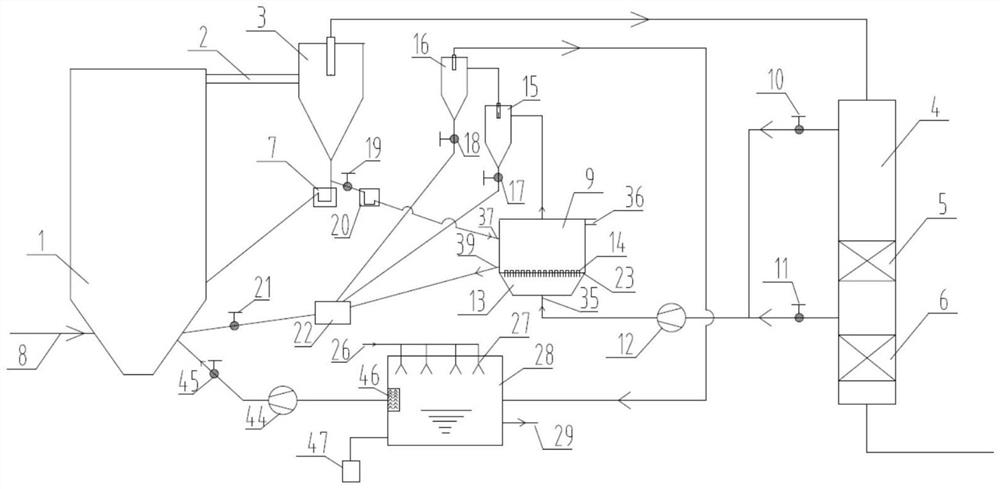

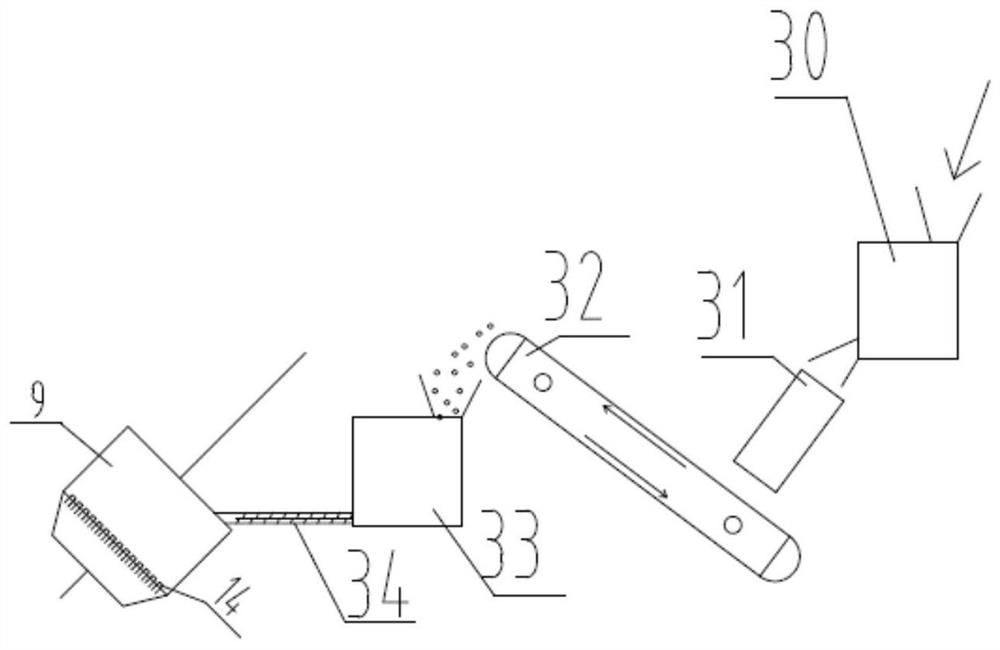

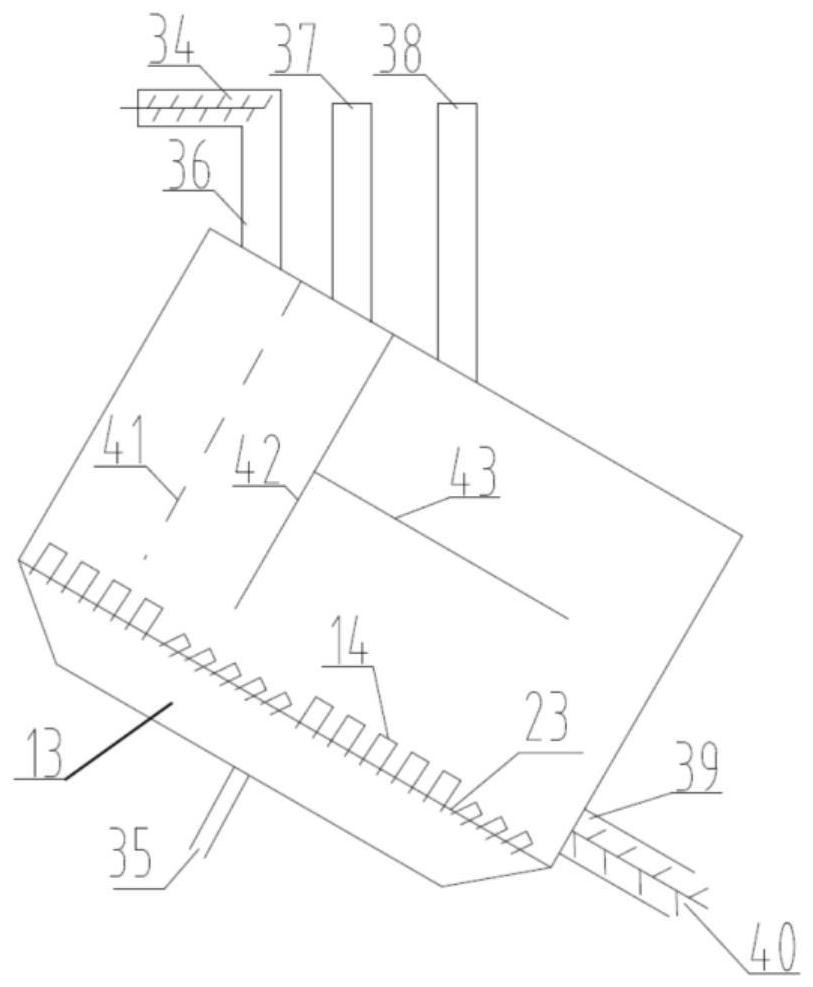

Waste fan blade pyrolysis recovery system and working method thereof

ActiveCN113046107AIndependent and flexible structureHarmlessProductsReagentsFan bladeCirculating fluidized bed boiler

The invention discloses a waste fan blade pyrolysis recovery system and a working method thereof, and belongs to the technical field of resource recovery. The waste fan blade pyrolysis recovery system comprises a crushing system, a circulating fluidized bed boiler system, a pyrolysis reactor, a material collecting and conveying device, a pyrolysis gas-solid separation system and a cracking oil separation system. According to the invention, composite materials in waste blades can be effectively cracked, cracking oil generated by cracking can be recovering, cracking gas is pumped to a hearth to be effectively incinerated, heat value contained in the cracking gas is effectively utilized, pollutants generated in the combustion process can be discharged in a standard reaching mode by means of an environment-friendly device arranged in an original boiler system, and a pyrolysis reaction in a pyrolysis reactor under an anoxic atmosphere effectively avoids the potential problems of dioxin generation and emission, and the like caused by direct incineration of the waste leaves, so that harmless and resourceful treatment of the waste leaves is completely achieved; and before the comprehensive recycling technology of the blade material is mature and utilized on a large scale, the influence of the waste blade on the environment and the like can be effectively solved, and good environmental protection benefits and economic benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

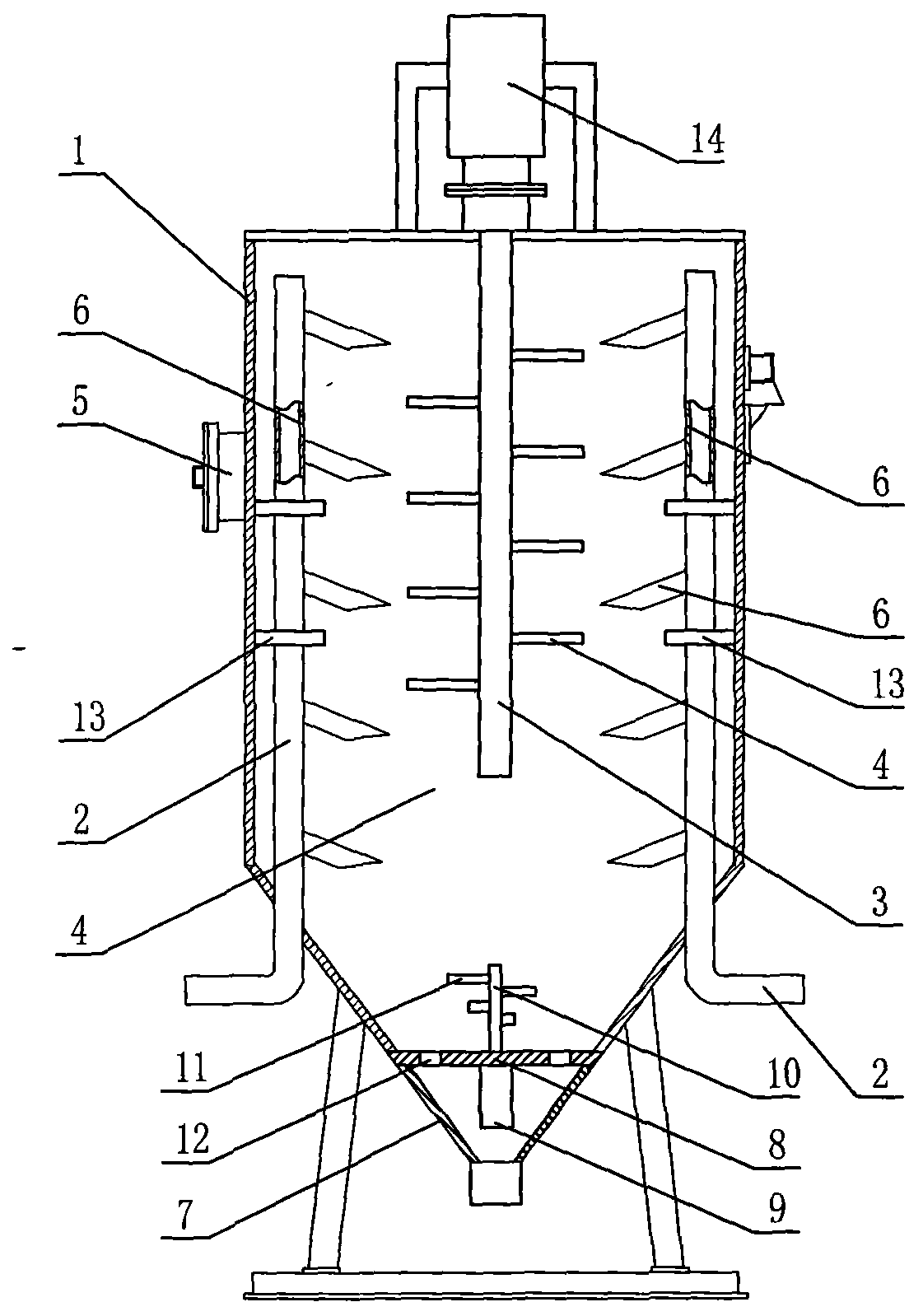

Discharge hopper and method of discharing trays filled with rod-shaped articles

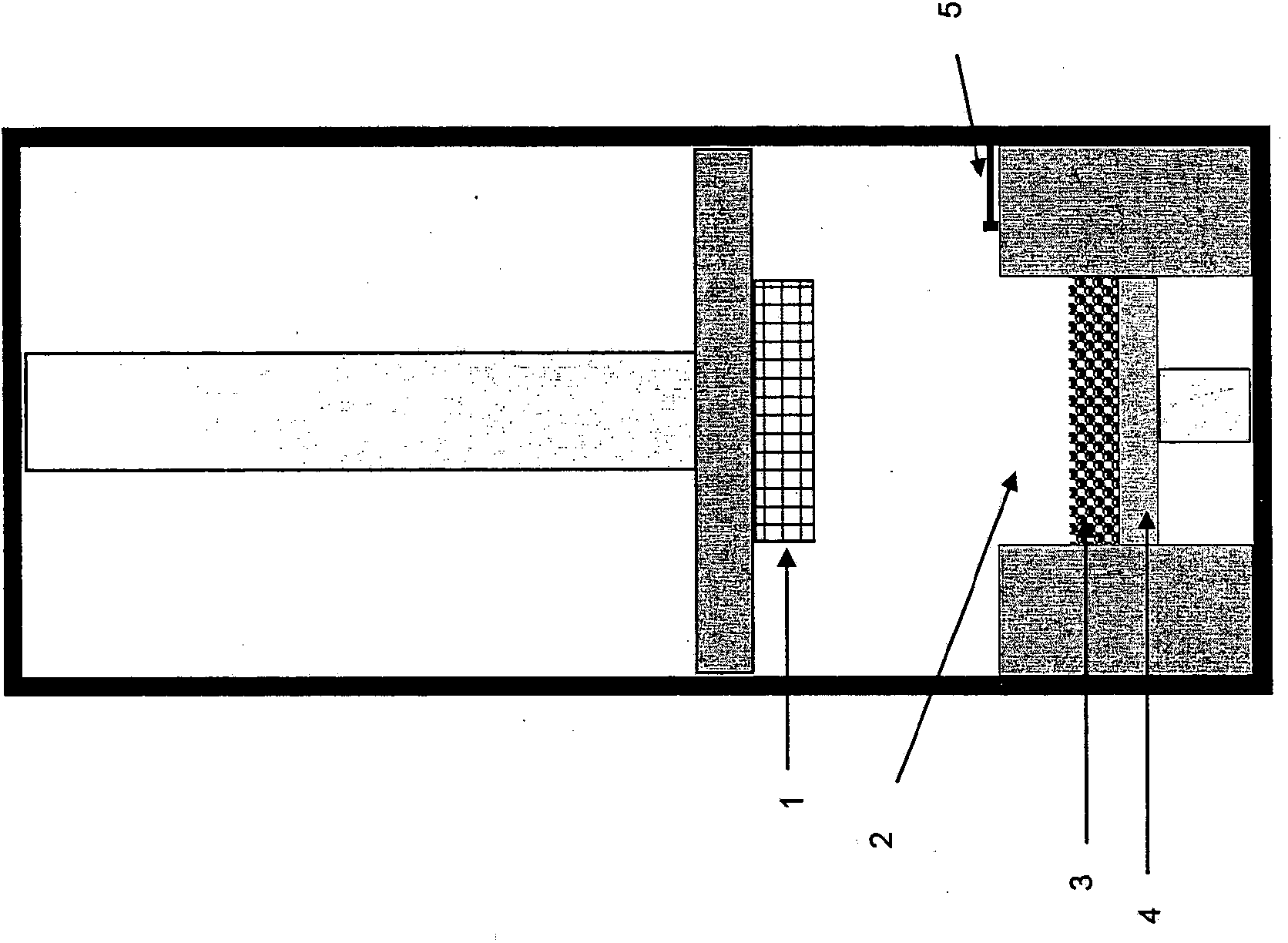

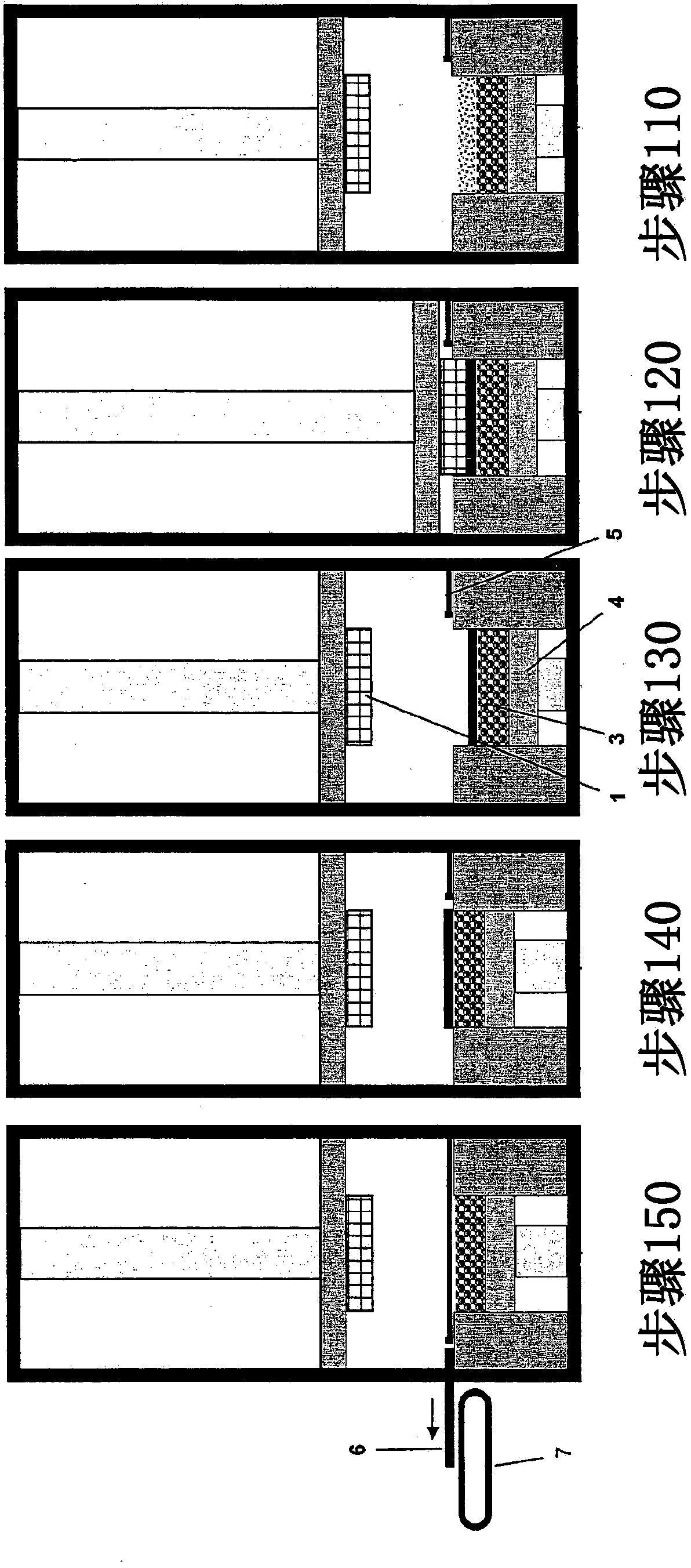

InactiveCN101233955AEffective regulationSmooth unloadingPackaging cigaretteCigarette manufactureEngineeringWellbore

The hopper (10) has a receiving chamber (18) for rod-shaped products flowing from a shaft tray (11), where the chamber includes a top, which opens in a direction of the tray and a bottom comprising a conveying element (22) defining a channel (23) for carrying away the products. Flow regulating elements (26) are located within the chamber to control a flow of the products within the hopper. A monitoring unit (28) is arranged and constructed to detect a level of products within the tray, and operatively connected to the regulating elements for individual control of the regulating elements. An independent claim is also included for a method for discharging a tray inserted in a discharge hopper and filled with rod-shaped products.

Owner:HAUNI MASCHINENBAU AG

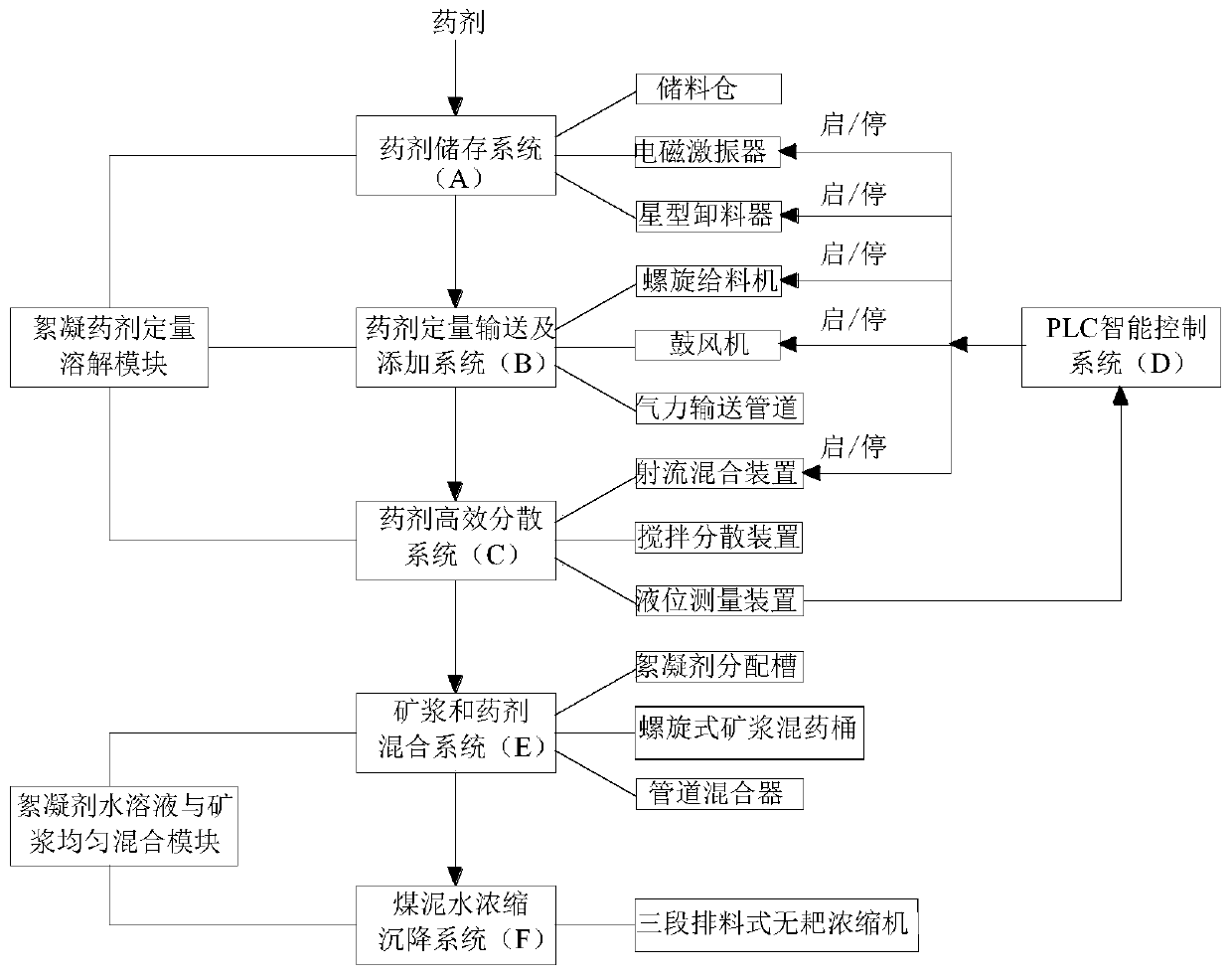

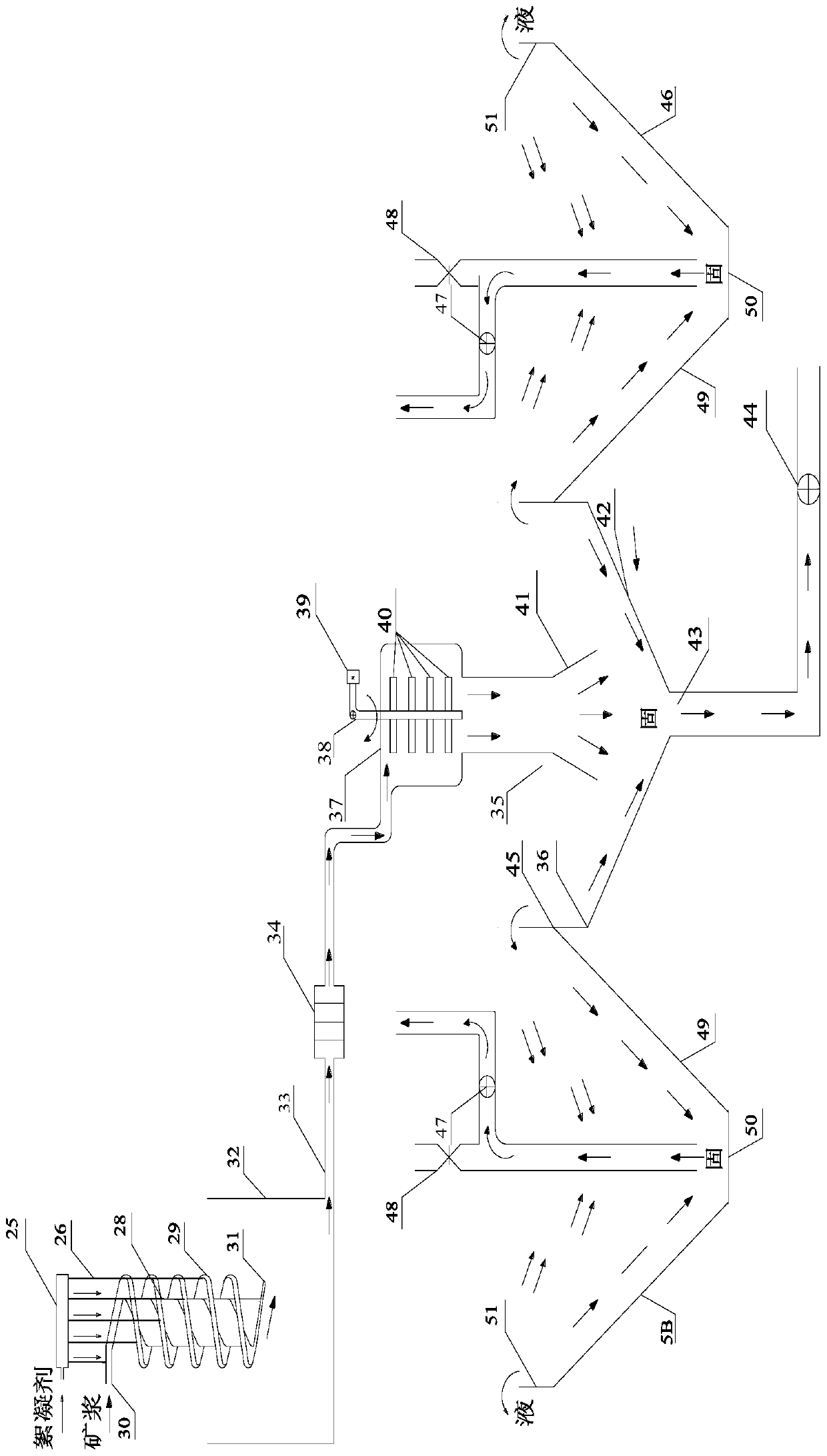

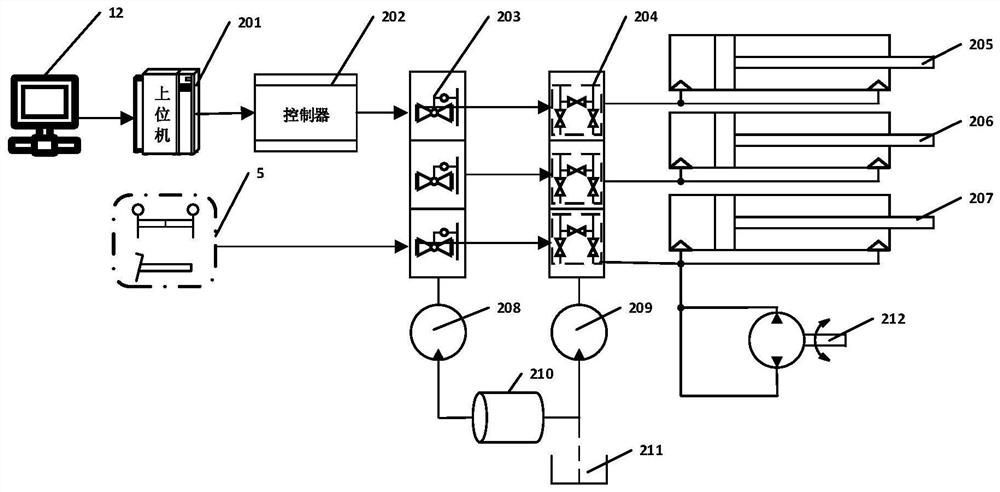

Quantitative dissolution and uniform mixing addition system of flocculation agent

InactiveCN110026123AReasonable system structureHigh degree of automationTransportation and packagingSettling tanks feed/dischargeSettling timeIntelligent control system

The invention relates to the field of concentration treatment of coal slurry water, in particular to a quantitative dissolution and uniform mixing addition system of a flocculation agent. The system comprises an agent storage system, a quantitative agent conveying and addition system, an efficient agent dispersion system, a PLC (programmable logic controller) intelligent control system, an ore pulp and agent mixing system and a coal slurry water concentration and settling system, wherein the agent storage system and the quantitative agent conveying and addition system ensures addition of the powdered agent according to required dose; the efficient agent dispersion system achieves uniform dispersion and quick dissolution of the powdered agent in an aqueous solution; and the ore pulp and agent mixing system promotes uniform mixing of the aqueous solution in which the flocculation agent is dissolved, and the coal slurry water and has a good flocculation settling initial condition. A coredevice of the coal slurry water concentration and settling system is a three-section discharge harrow-less concentrator; the concentrator adopts a 'one-middle and two-sides' discharge mode; thick particles and fine particles are discharged and recovered through different ports; the fine particles have longer settling time; and a whole concentration task has higher concentration efficiency.

Owner:ANHUI UNIV OF SCI & TECH

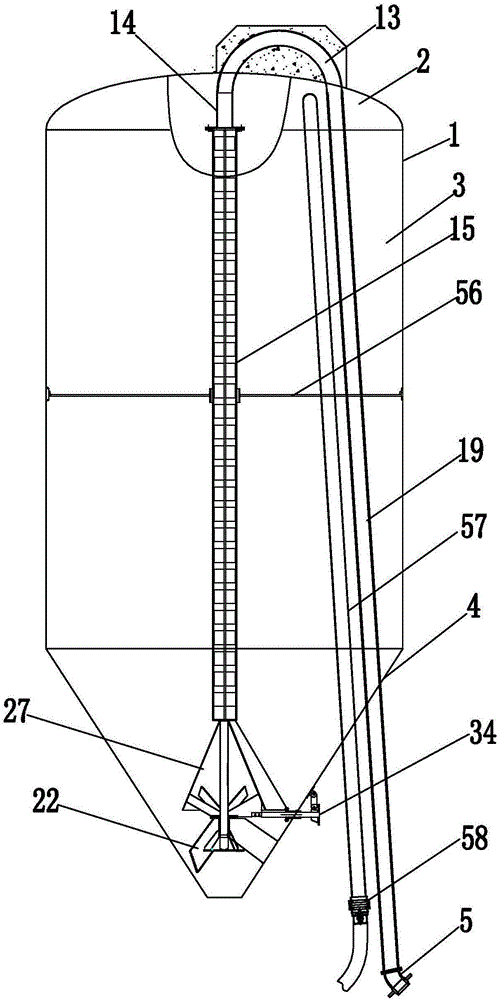

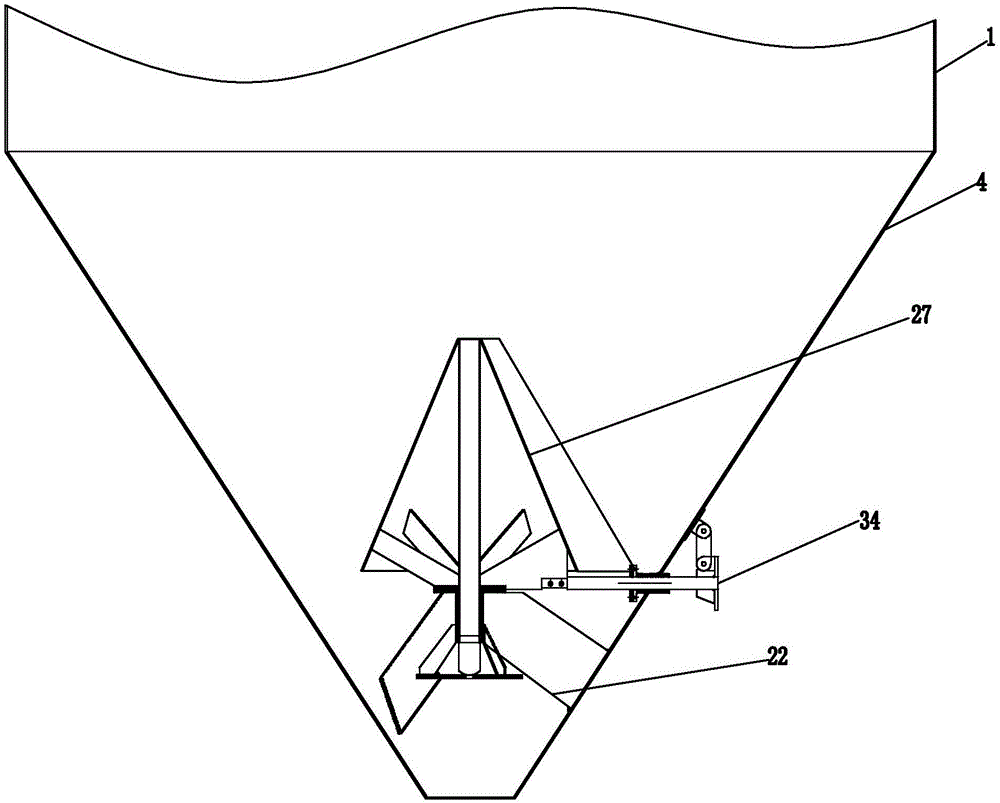

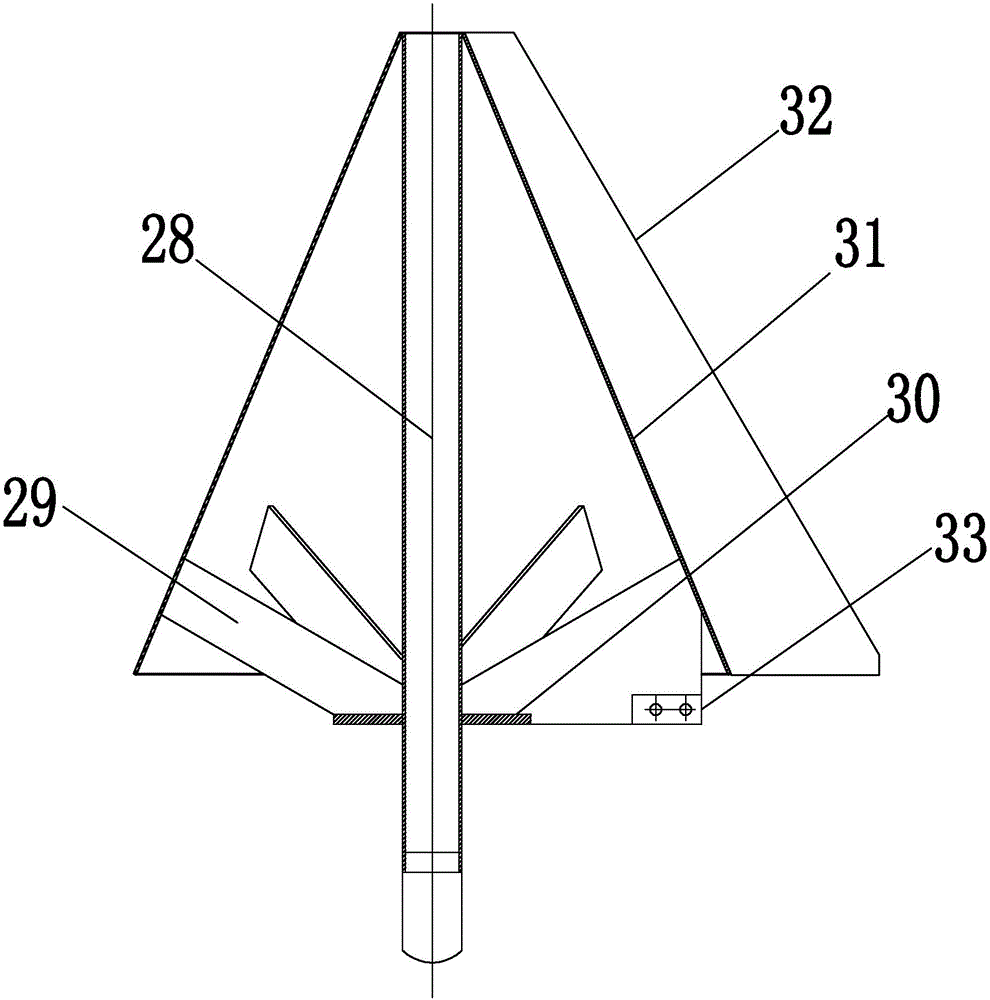

Novel movable silo for dry-mixed mortar

InactiveCN106395172AReduce segregationReduce extrusion pressureLarge containersBulk conveyorsEngineeringSilo

The invention relates to a novel movable silo for dry-mixed mortar. The novel movable silo comprises a movable silo body which is provided with an air-blowing feeding structure, a discharging structure and an air outlet structure. The air-blowing feeding structure comprises a straight feeding pipe; one end of the straight feeding pipe is connected with a steering pipe connection assembly; the other end of the straight feeding pipe is connected with a bend feeding pipe; and the end of the bend feeding pipe is connected with a material guide pipe which is connected with a cage-shaped discharging pipe. The movable silo body comprises a silo cone; the discharging structure comprises a supporting part installed in the silo cone; a conical device is installed on the supporting part and connected with a vibration device which is connected to the side wall of the silo cone; and the conical device is connected with the cage-shaped discharging pipe. The air outlet structure comprises an air outlet pipe which penetrates through the interior of the movable silo body and is connected with a reducing valve. The novel movable silo is simple in structure, convenient to use, durable and convenient to operate, has no vulnerable part and has high practical value.

Owner:浙江益森久城环保设备有限公司 +1

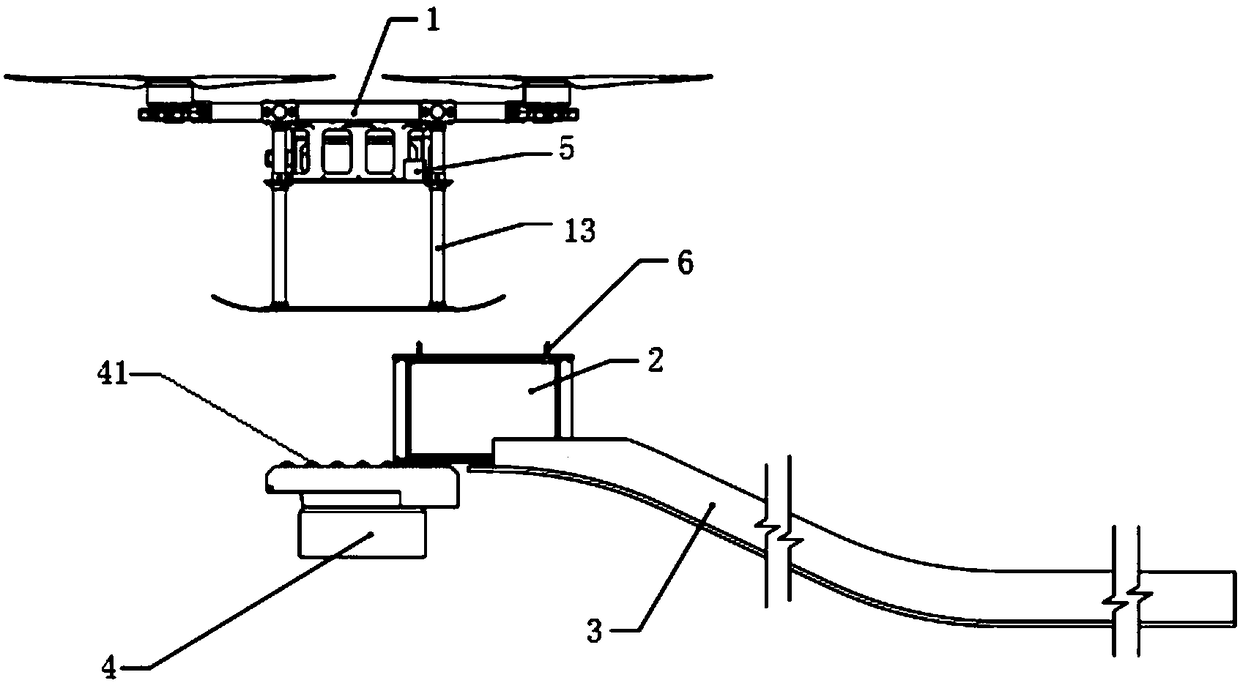

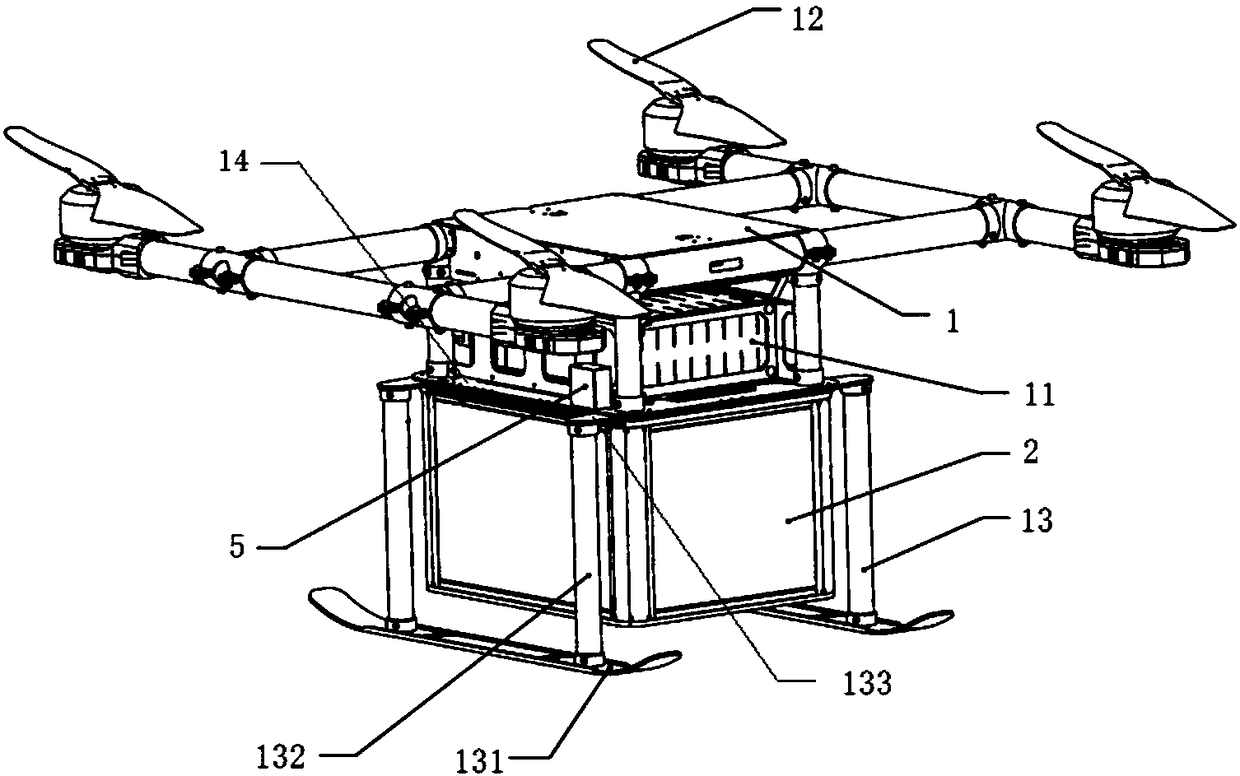

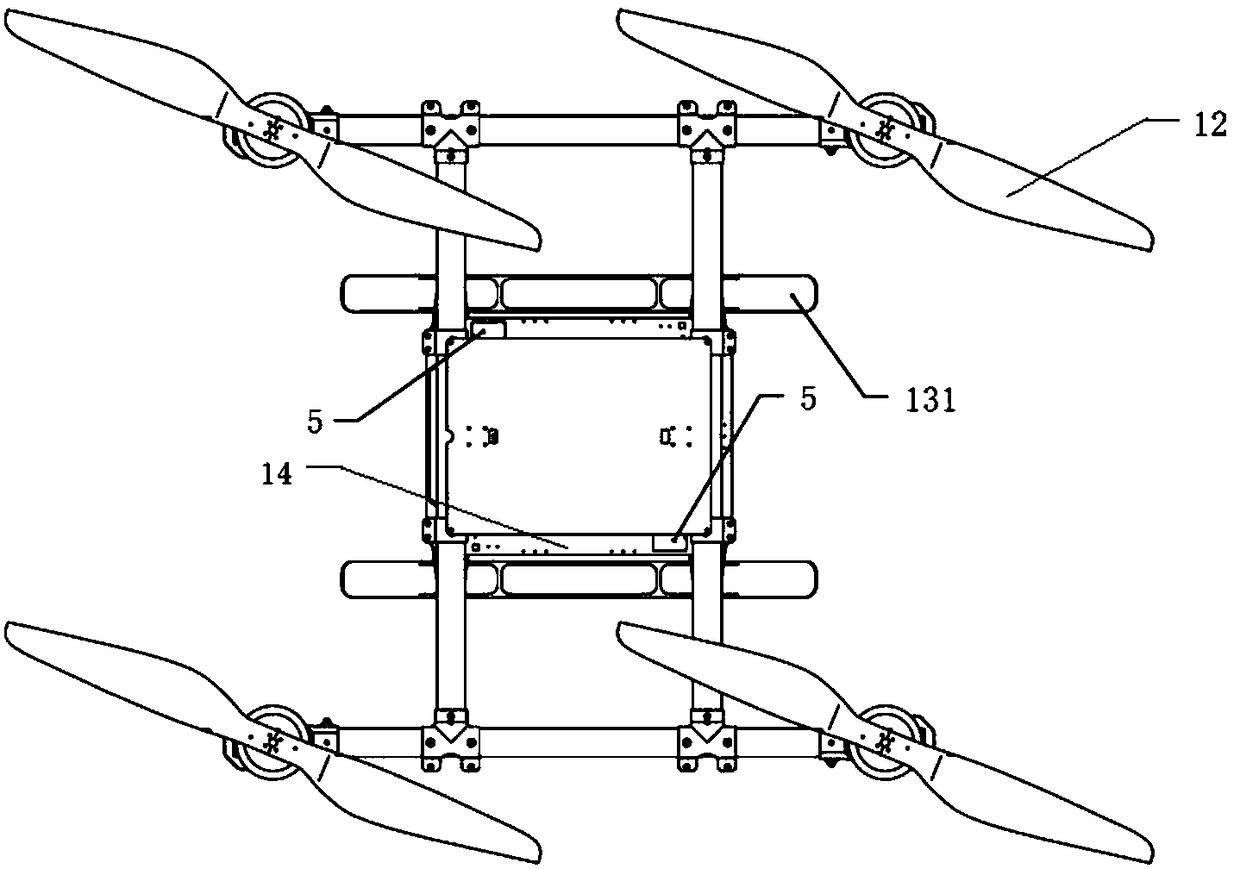

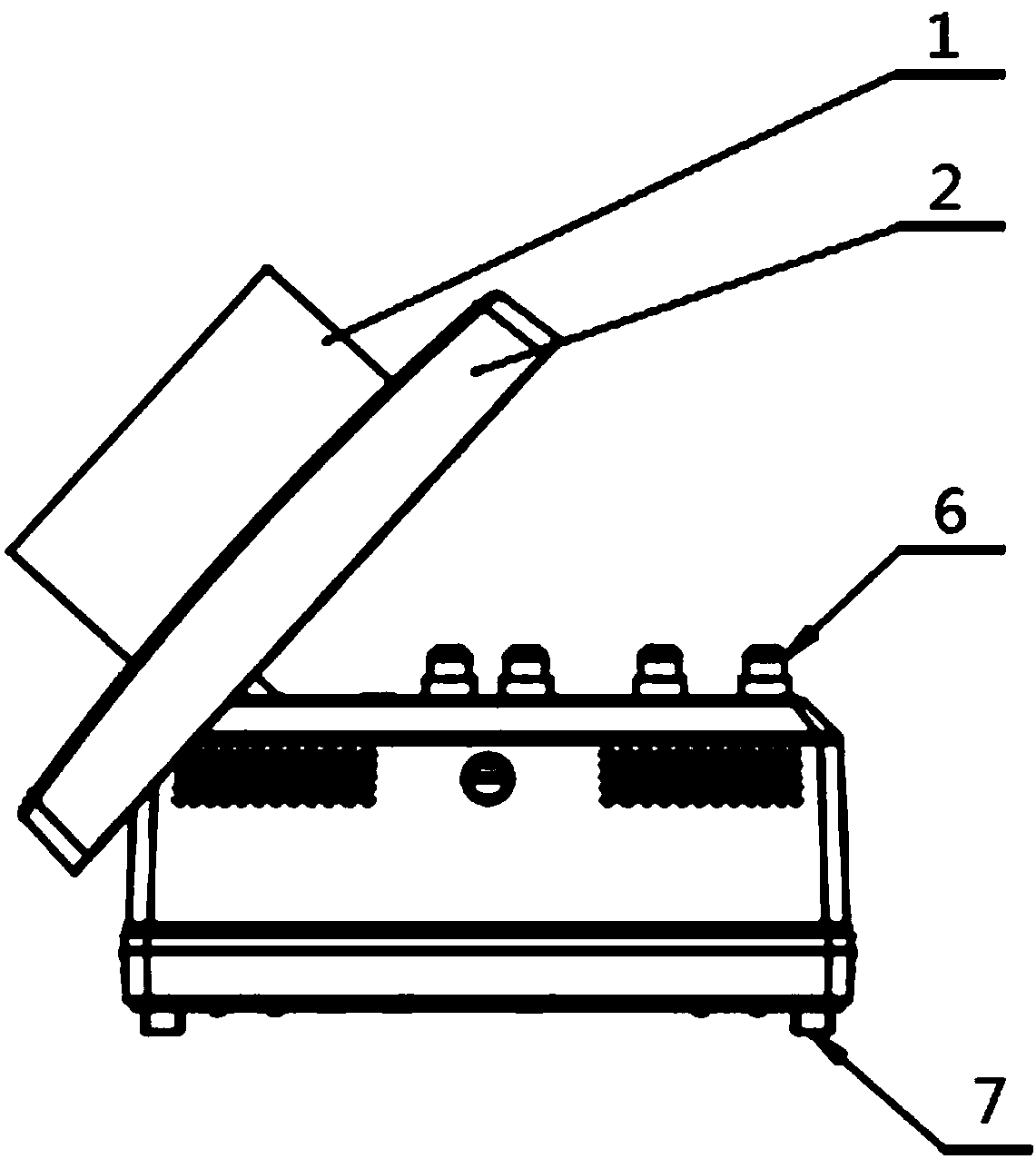

Vertical automatic loading and unloading system device and method

PendingCN108163201AHigh degree of automationSafe mountFreight handlingLaunching weaponsLocking mechanismEngineering

The invention relates to a vertical automatic loading and unloading system device and method. The vertical automatic loading and unloading system device comprises cargo carrying equipment, a cargo case, a conveying rail and a lift. The lift rises and falls in the vertical direction to move the cargo case so as to complete the process of loading the cargo case to the cargo carrying equipment or unloading the cargo case from the cargo carrying equipment to the conveying rail. According to the vertical automatic loading and unloading method, loading and unloading are conducted through the vertical automatic loading and unloading system device. The vertical automatic loading and unloading system device is high in automation degree; the cargo case and the cargo carrying equipment are locked through a locking mechanism so that cargos can be hung on the cargo carrying equipment safely and precisely, steadiness is achieved, and unloading is easy and convenient; and the vertical automatic loading and unloading system device is suitable for automatic cargo carrying tools such as an unmanned aerial vehicle, an unmanned vehicle and a sorting device and especially suitable for loading and unloading operation of the unmanned aerial vehicle.

Owner:丰翼科技(深圳)有限公司

Dry type blender

InactiveCN103612327AInhibition of segregationEvenly mixedDischarging apparatusCement mixing apparatusCharge separationMixing tank

The invention discloses a dry type blender, which comprises a batch mixing tank, the batch mixing tank is connected to an inlet pipe which inserts in the inner chamber of the batch mixing tank from the bottom, a feed inlet is arranged at the bottom of the inlet pipe, a plurality of spigot discharges are provided on an inlet pipe segment in the batch mixing tank from top to bottom, a mixer shaft driven by a power device is connected in the batch mixing tank in a rotation mode, a stirring blade is connected to a mixer shaft, a large granule supply pipe is arranged at the upper part of the sidewall of the batch mixing tank, the bottom part of the batch mixing tank are arranged in an inverted cone shape, and a base plate base plate is arranged on the batch mixing tank, a discharging shaft driven by a discharging motor is connected on a base plate in the rotation mode, several discharging blades are equipped with the discharging shaft, a plurality of discharging apertures distributed around the discharging shaft are arranged on the base plate, and a discharge pipe used for carrying the effluent material from the discharging aperture is equipped on the bottom of the base plate. The dry type blender has the advantages that the charging amount is uniform, charging separation is difficult to generate, and the batch can be uniformly mixed.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

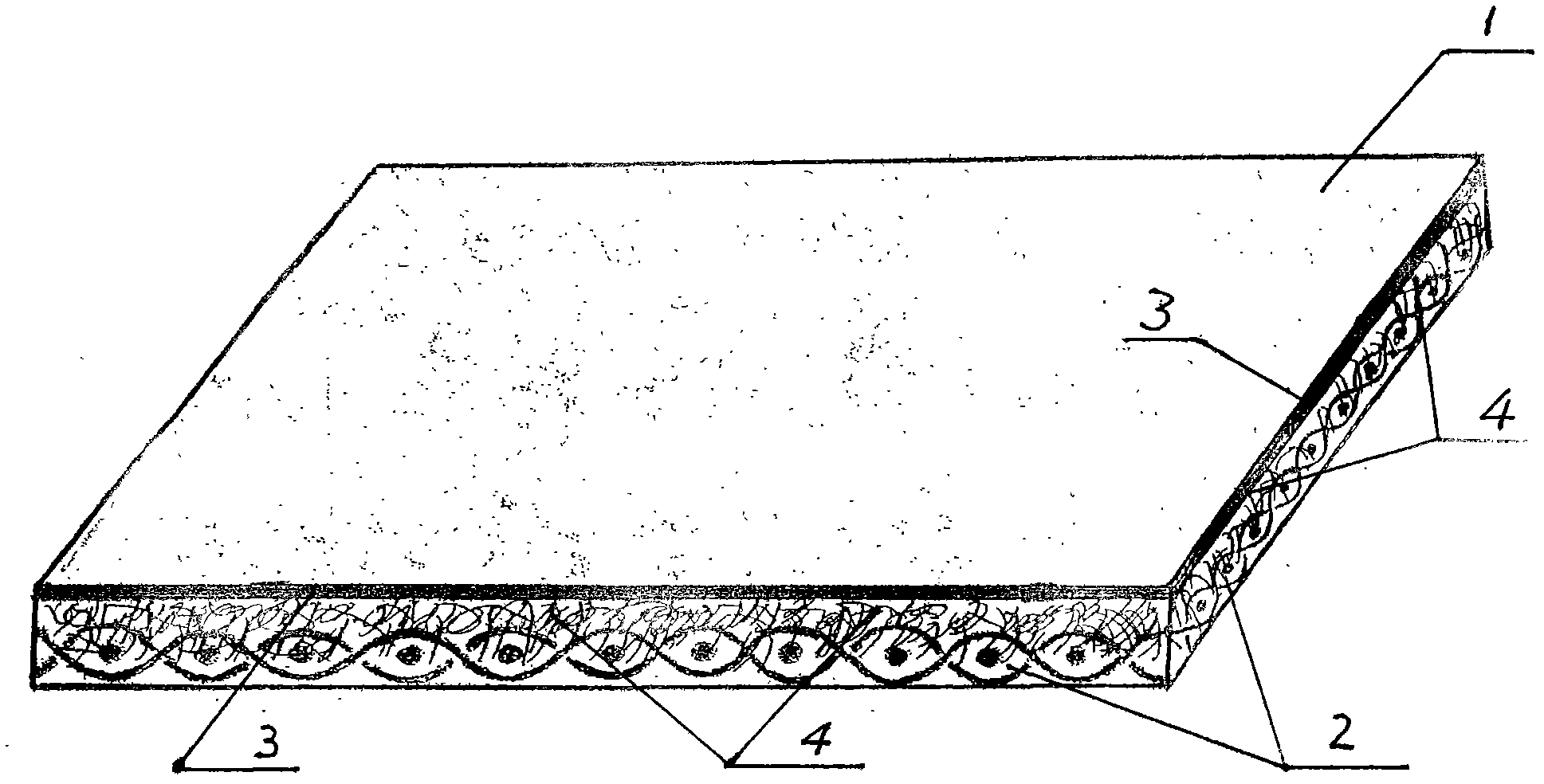

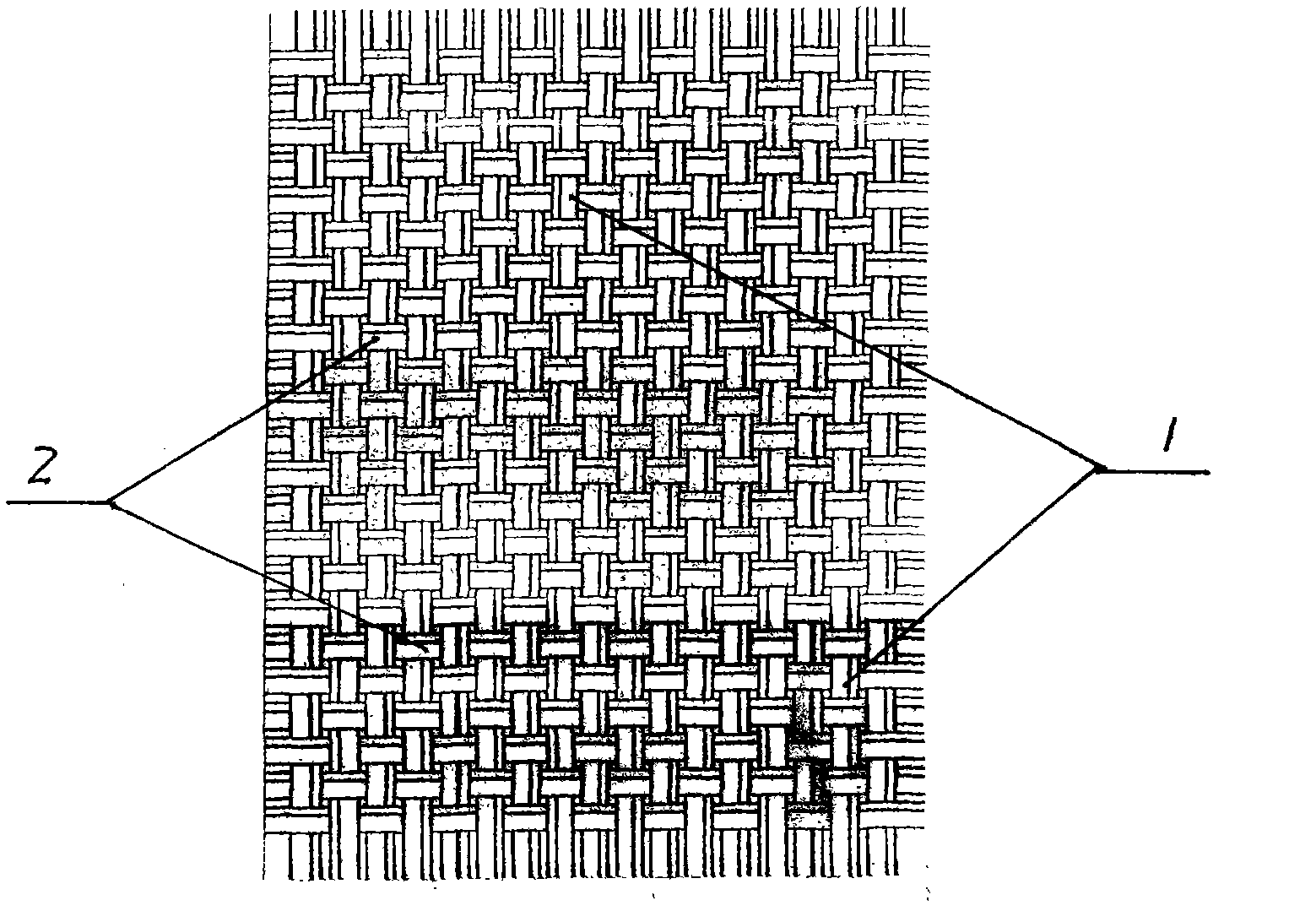

Manufacture method for nonwoven filter cloth

InactiveCN103381315AStrong enoughWill not deformLamination ancillary operationsLaminationBiochemical engineeringNonwoven fabric

A manufacture method for nonwoven filter cloth is characterized by consisting of a two-layer structure comprising a supporting layer and a filter layer. The supporting layer is woven net structure by weaving warps and wefts, and the filter layer is a nonwoven fabric structure formed by needling. According to the manufacture method for the nonwoven filter cloth, the nonwoven fabric formed by needling and the woven net by weaving warps and wefts are combined into a whole through a needling technology and equipment, so that the novel filter cloth is constructed. Meanwhile, the surface of the non-woven fabric of the filtering layer is calendered or sintered, so that the surface is smooth, flat and firm, and a filter cake can be removed smoothly.

Owner:辽宁天泽产业集团纺织有限公司

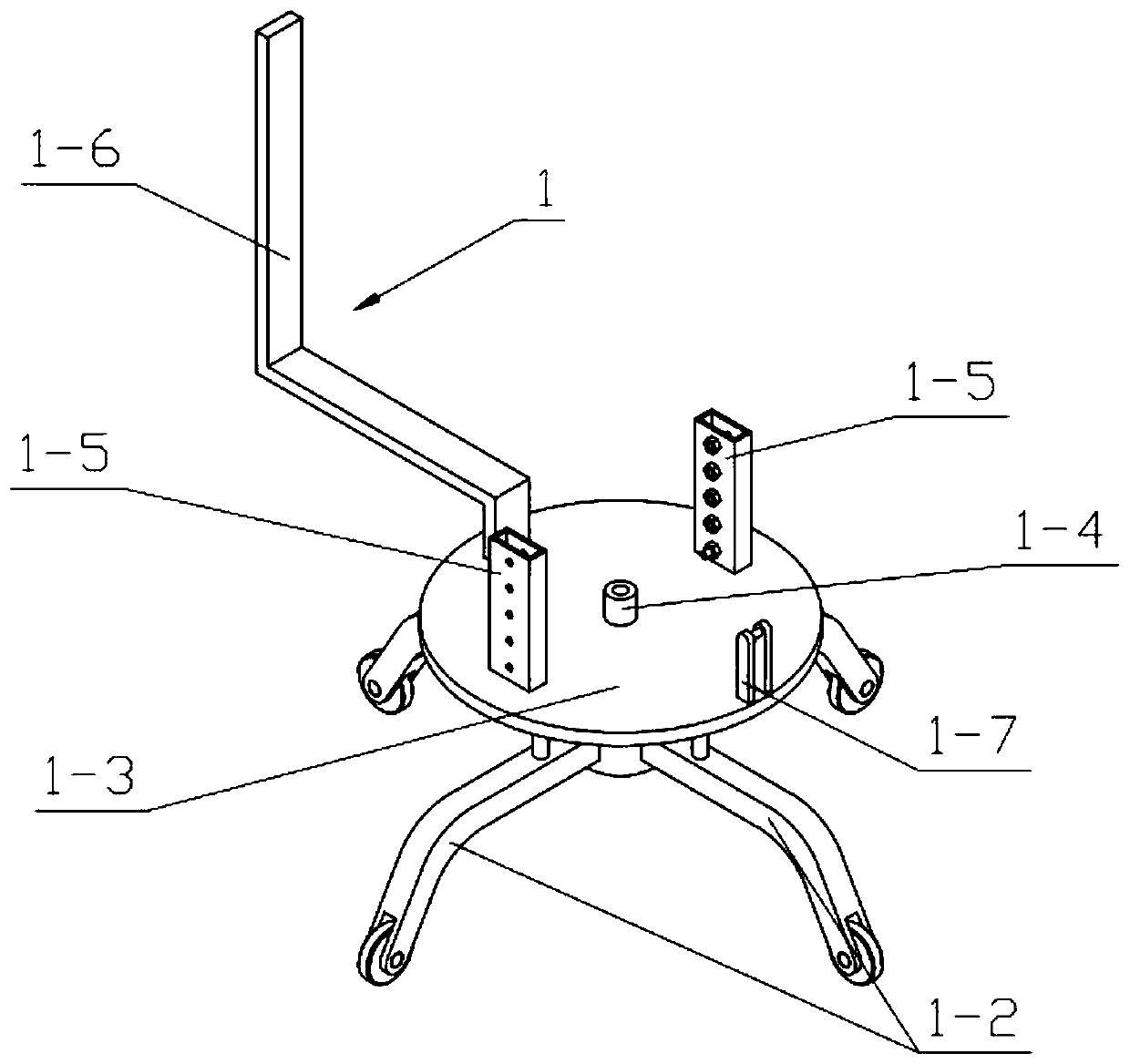

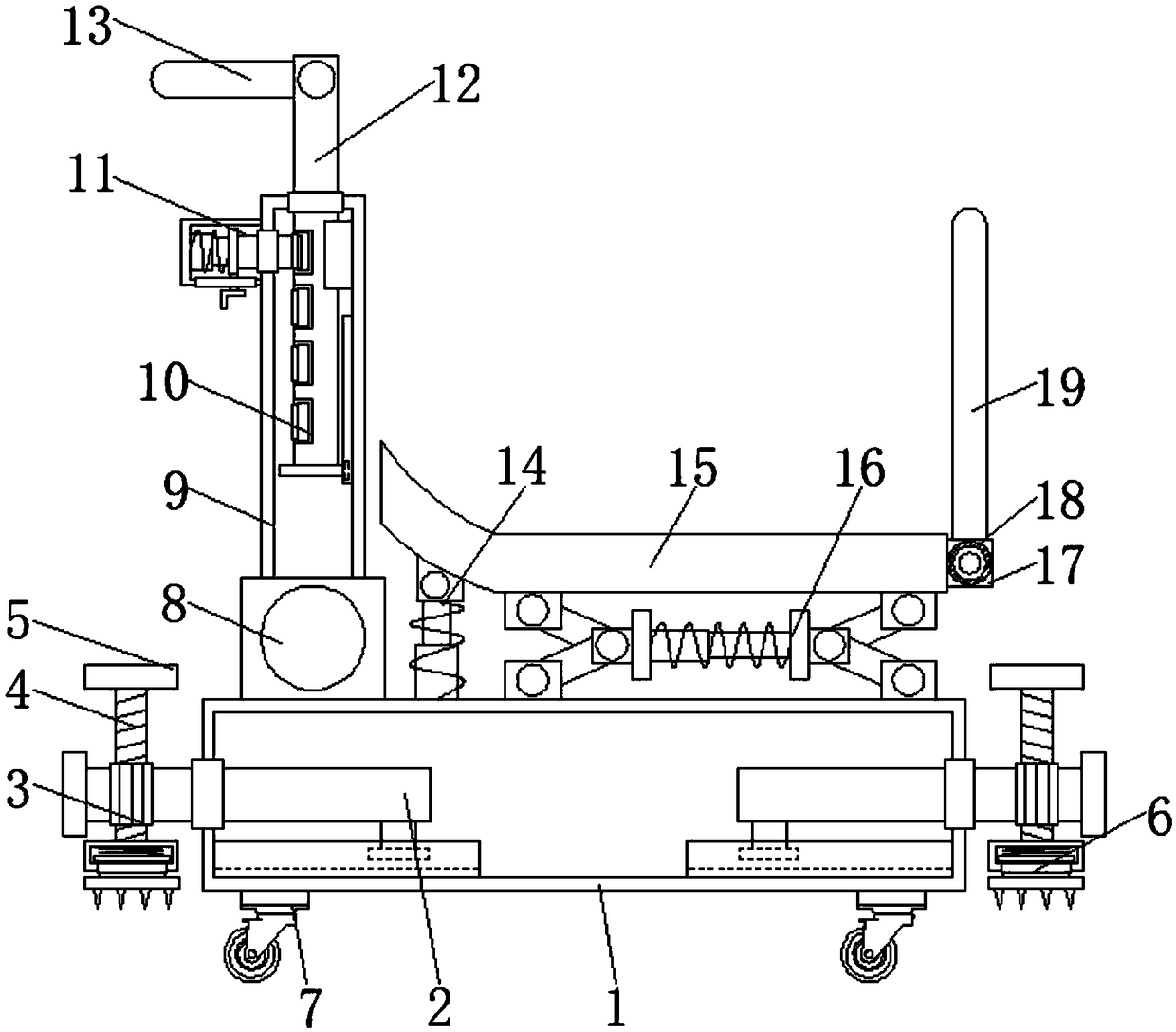

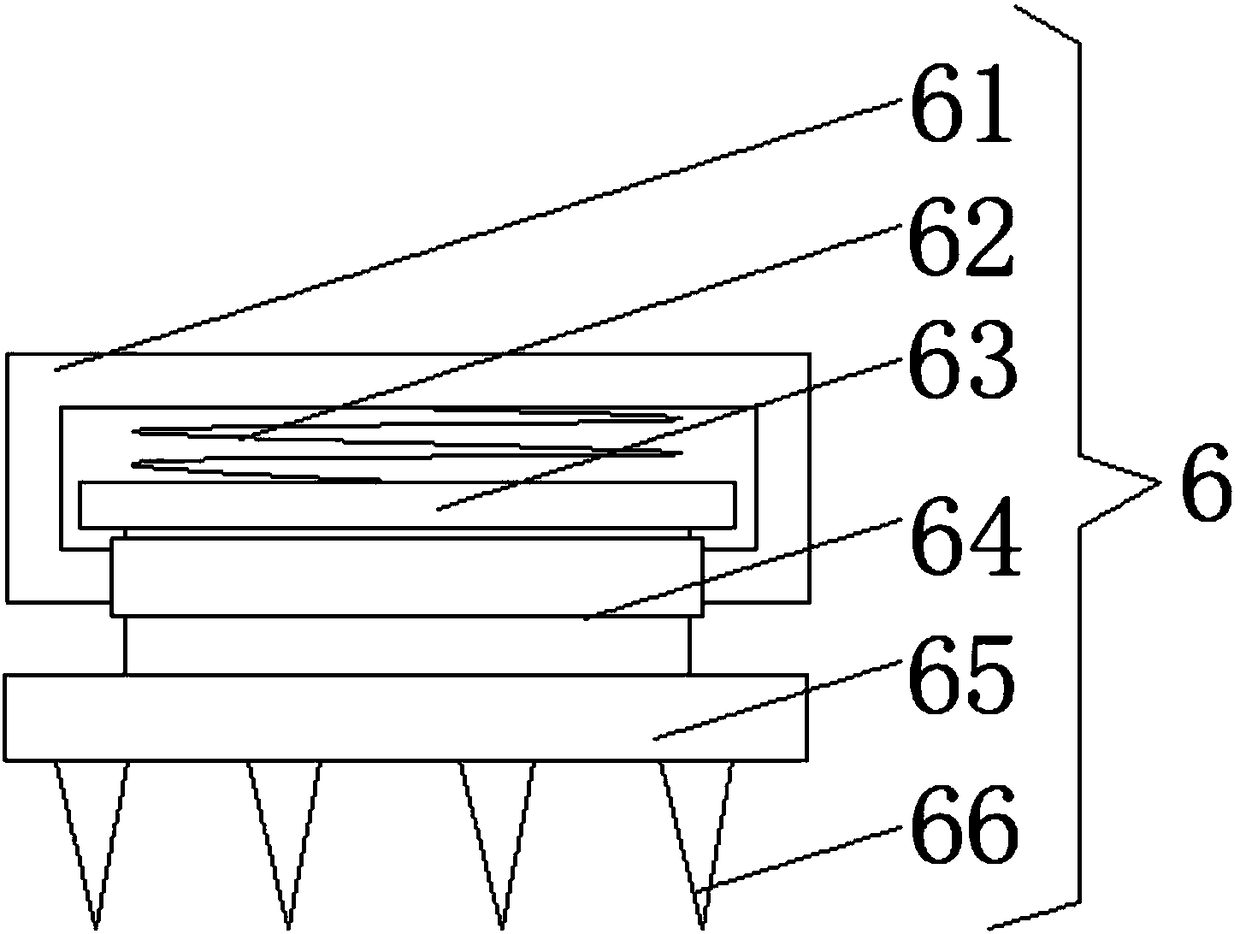

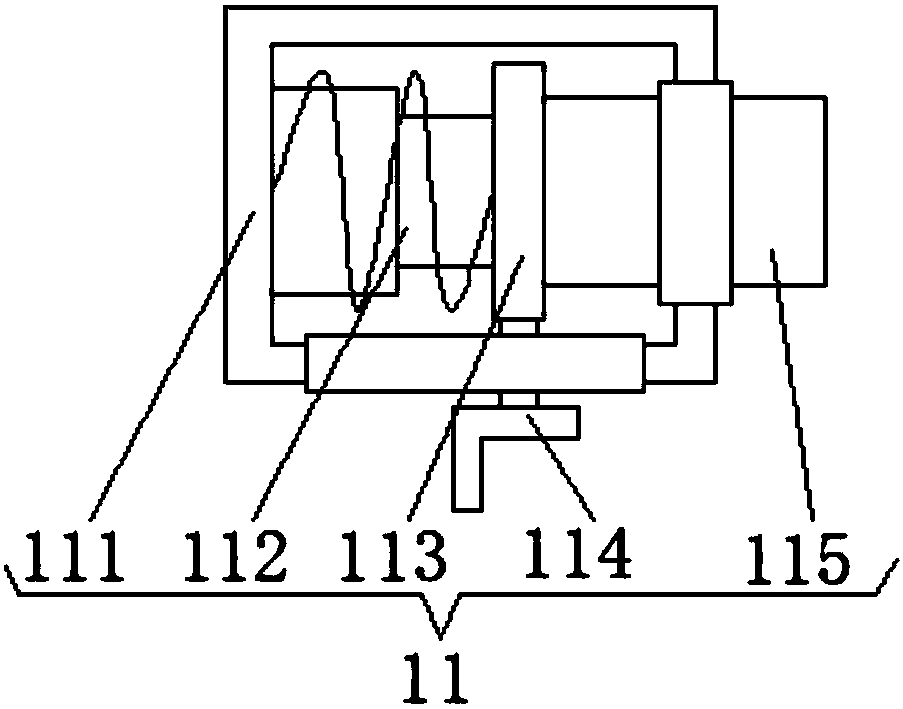

Unloading rack for logistics transportation

The invention relates to an unloading mechanism, in particular to an unloading rack for logistics transportation. The unloading rack comprises a device bracket, a pushing mechanism, a transportation bracket, a limiting bracket, a transportation mechanism, a lifting mechanism, a power mechanism, an unloading bracket and an unloading mechanism. A pushing plate II is in contact with the upper end surface of a cargo needed to be unloaded, and the pushing plate II pushed by the lifting mechanism extrudes a compression spring to push the unloading mechanism to slide on the unloading bracket, so thatthe unloading mechanism and the power mechanism are in friction drive, the power mechanism drives a friction wheel II arranged on the unloading mechanism to rotate, the friction wheel II drives an unloading thread plate to rotate, the unloading thread plate drives four clamping rods to be close to each other to slide through a vortex thread, the lower ends of four bottom supporting rods are in contact with the outer wall of the cargo first, and the four bottom supporting rods pushed by the lifting mechanism slide downward along the outer wall of the cargo to be locked at the bottom of the cargo under the action of a torsional spring to support the cargo.

Owner:云南中通云仓科技有限公司

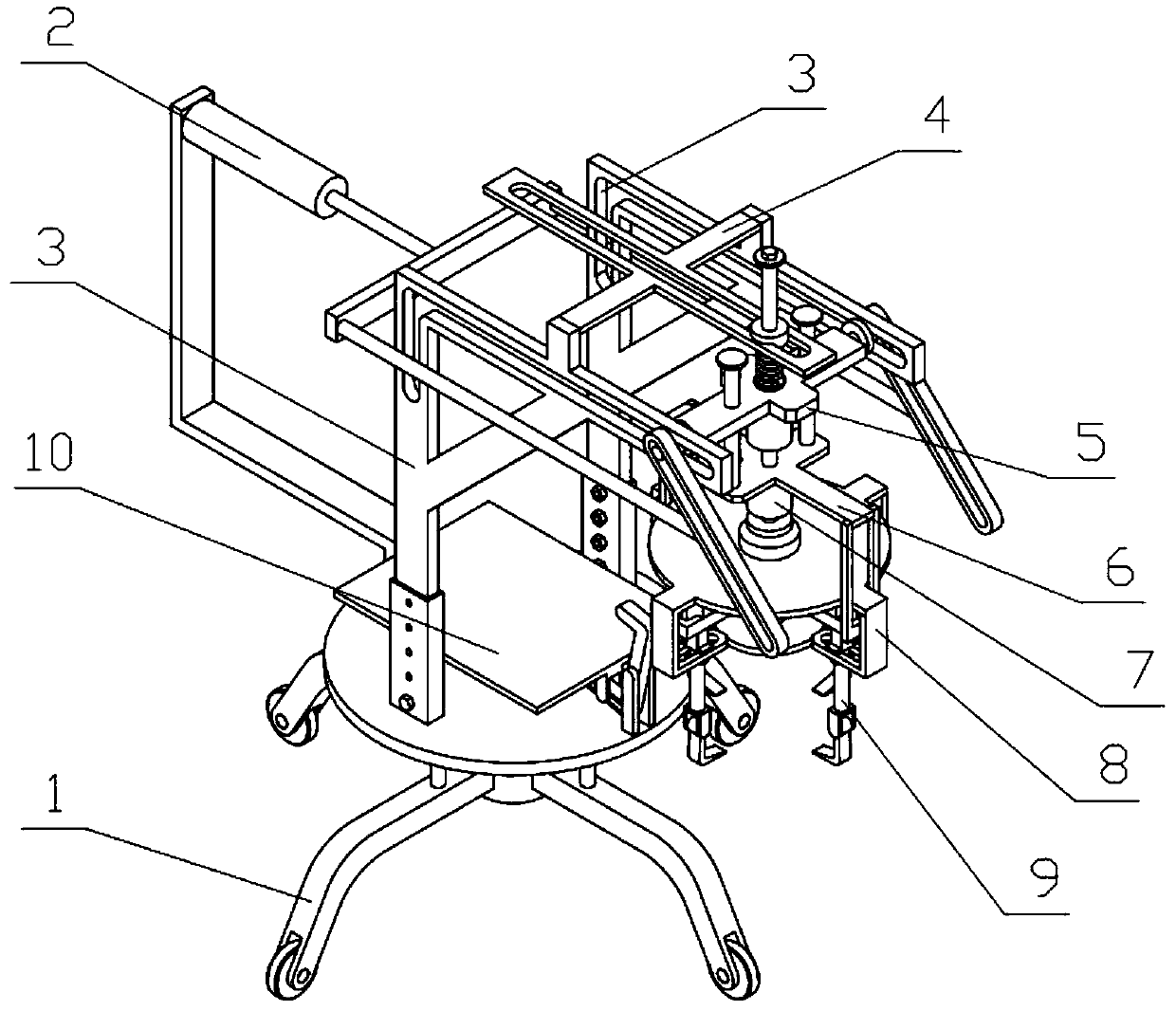

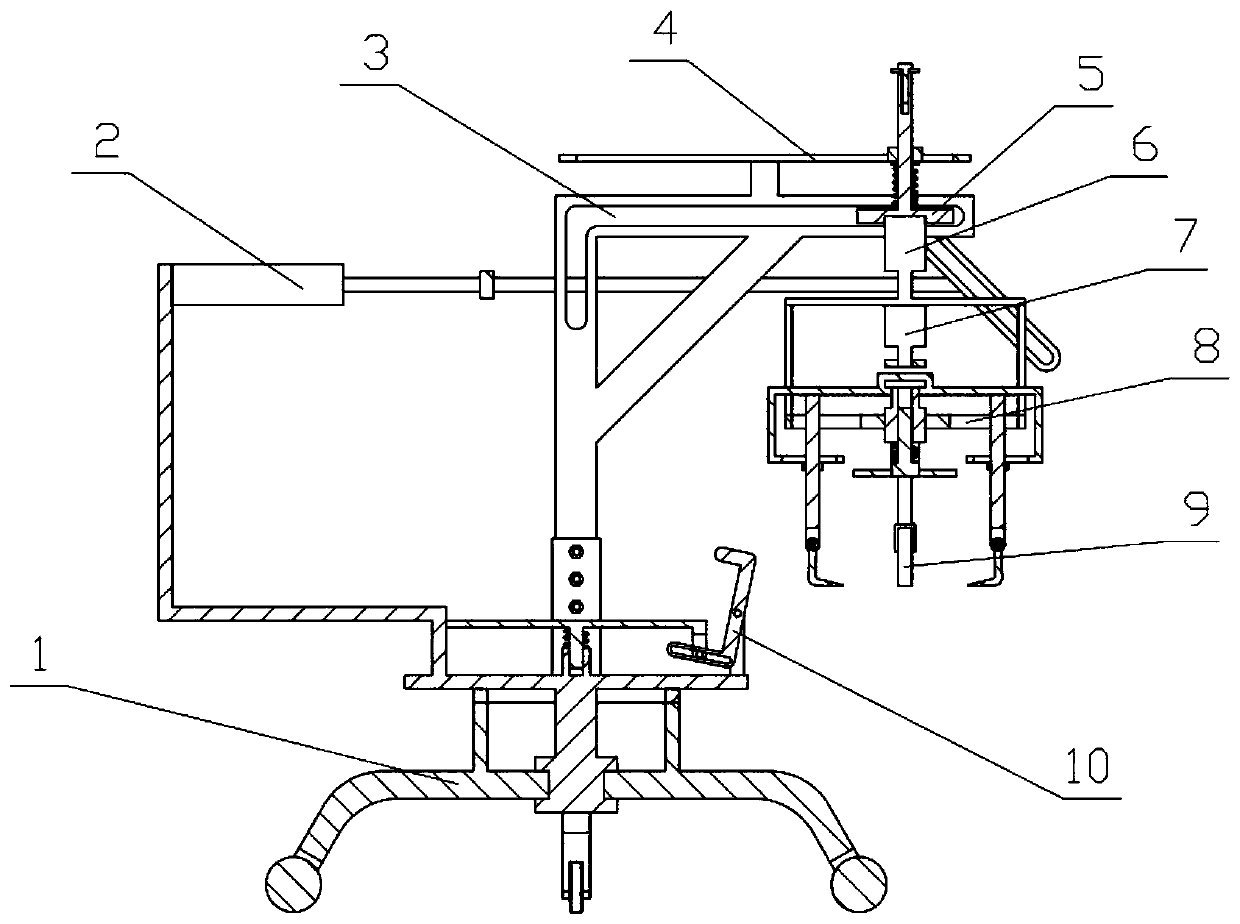

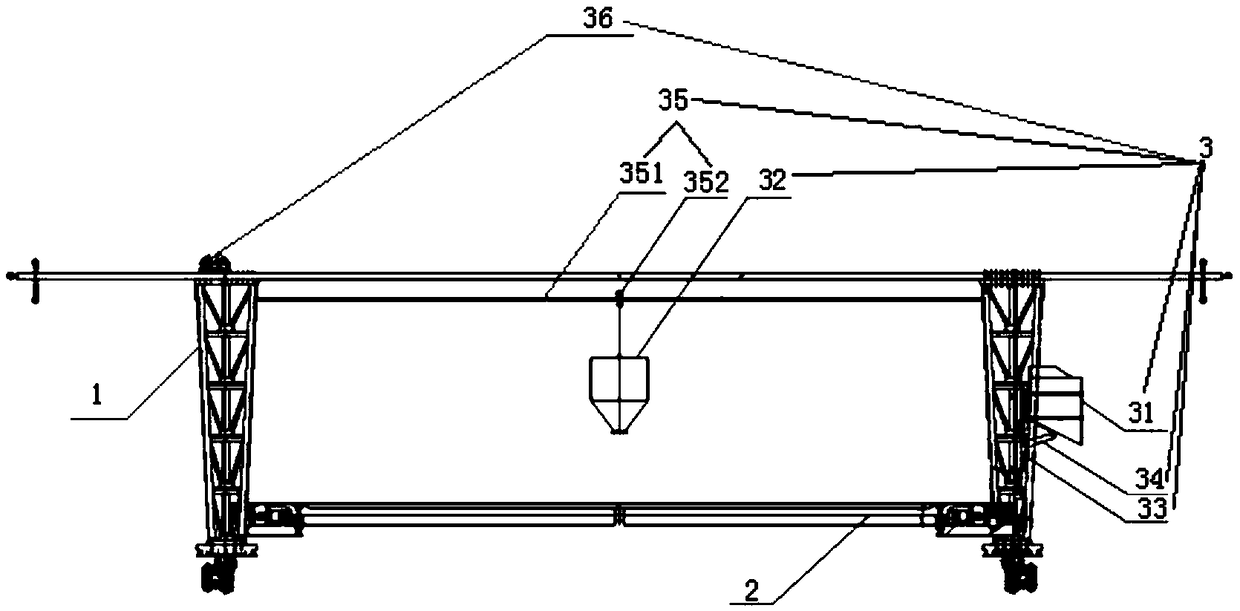

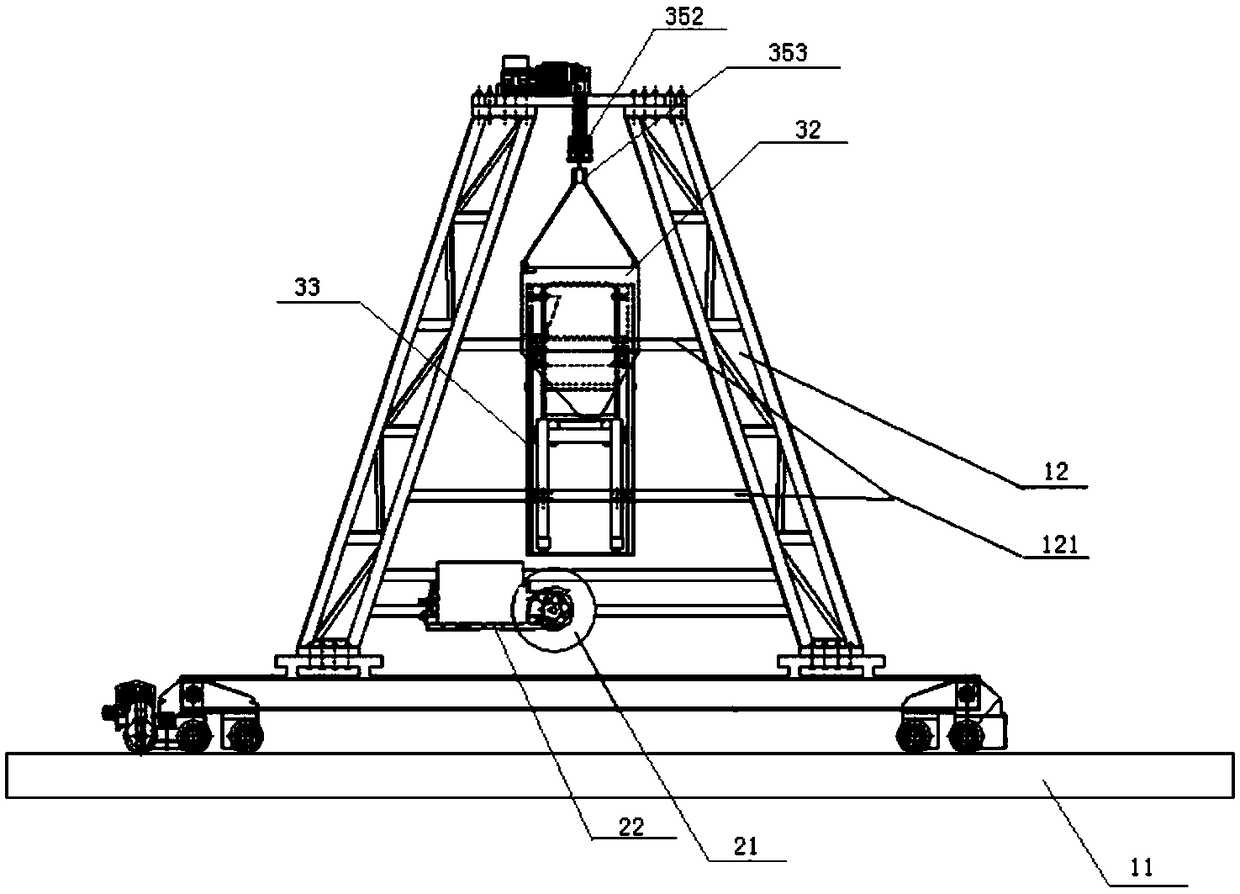

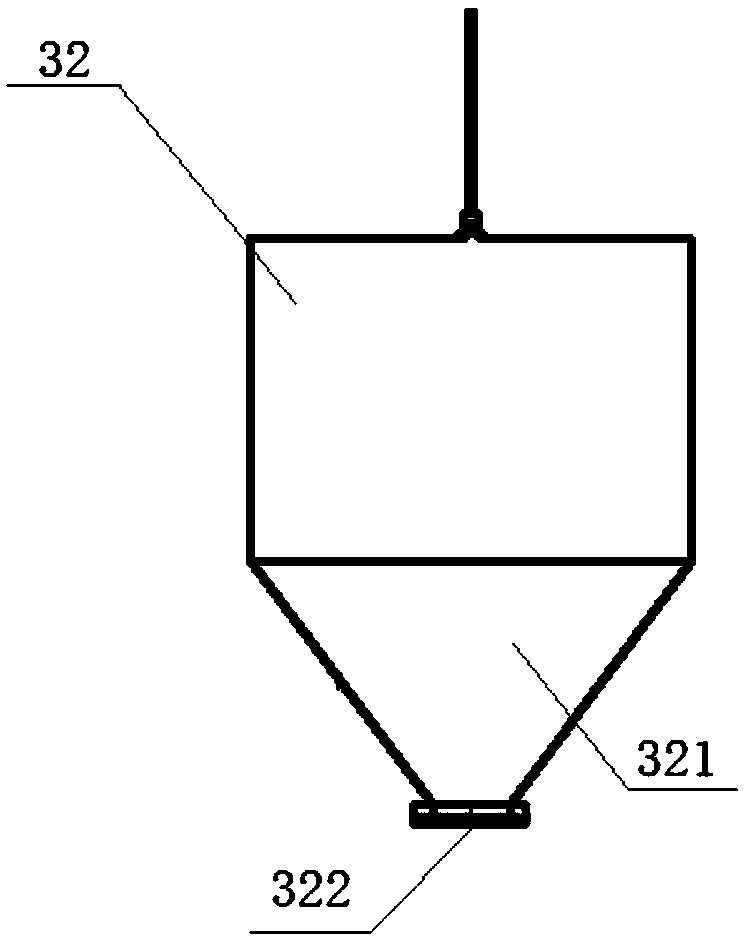

Steel bridge deck prefabricated paving equipment

ActiveCN109306649AReduce construction proceduresReduce the impactBridge structural detailsBridge erection/assemblyBridge deckPortal frame

The invention discloses steel bridge deck prefabricated paving equipment. The steel bridge deck prefabricated paving equipment can change the traditional steel bridge deck pavement construction procedure and technology. The steel bridge deck subjected to sand blasting and anti-rust coat and tack coat spraying can be paved with asphalt concrete in a factory, and is conveyed to a construction site for bridge deck assembling after forming. After assembling, the SMA asphalt mixture and other surface materials can be directly paved on the steel bridge deck. On-site construction procedures are reduced, construction difficulty is lowered, influence on construction by weather is avoided, and steel bridge paving quality and efficiency are effectively improved. The steel bridge deck prefabricated paving equipment comprises a walking machine frame and a paving mechanism, and is provided with a moving material cabin. The walking machine frame comprises a moving portal frame, a guide rail and the like. The paving mechanism comprises a spiral material arranging machine, an ironing plate and an ironing plate lifting device. The moving material cabin comprises a vertical lifting material cabin anda horizontal paving material cabin.

Owner:CHANGAN UNIV

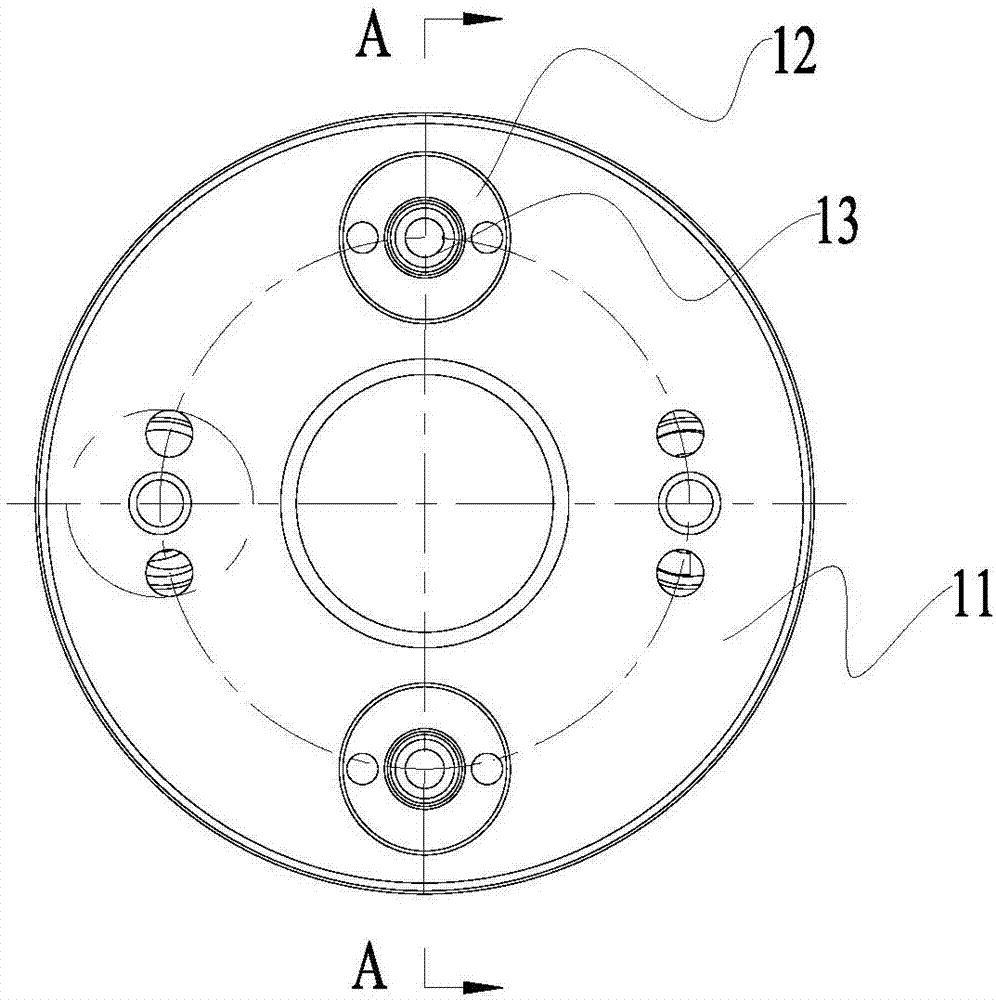

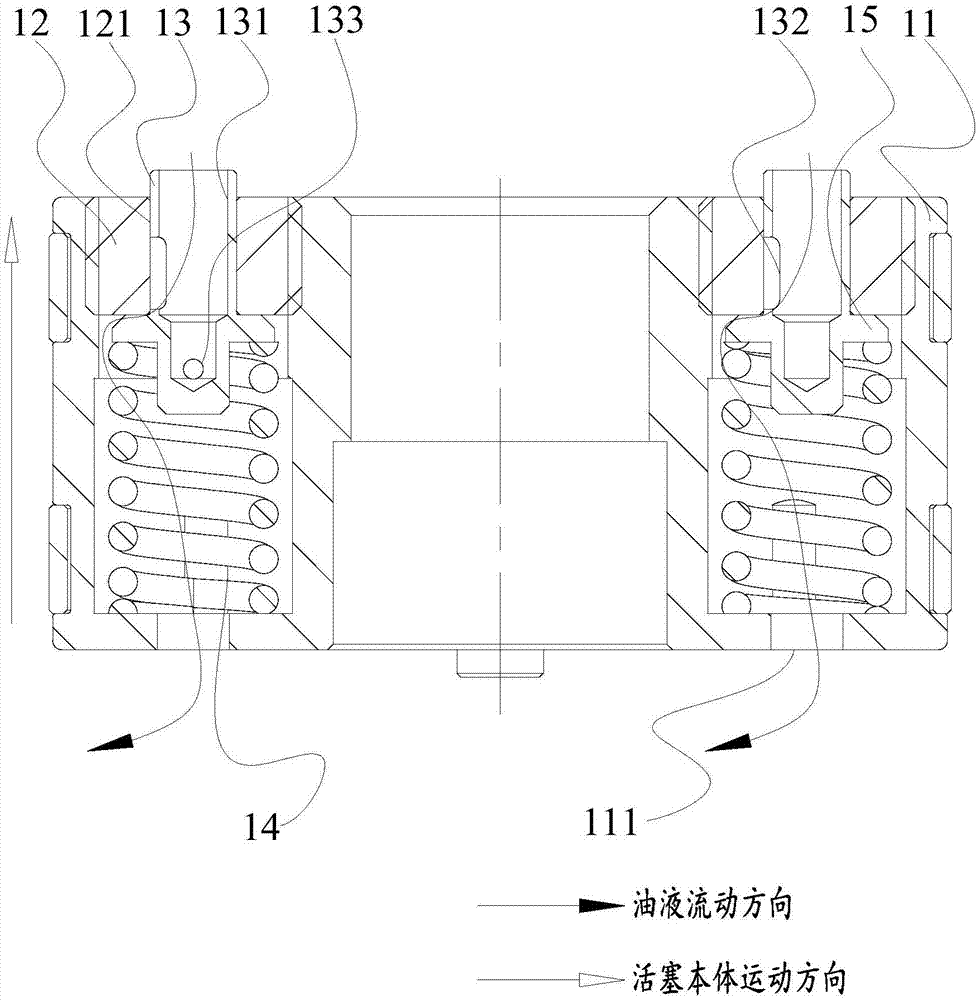

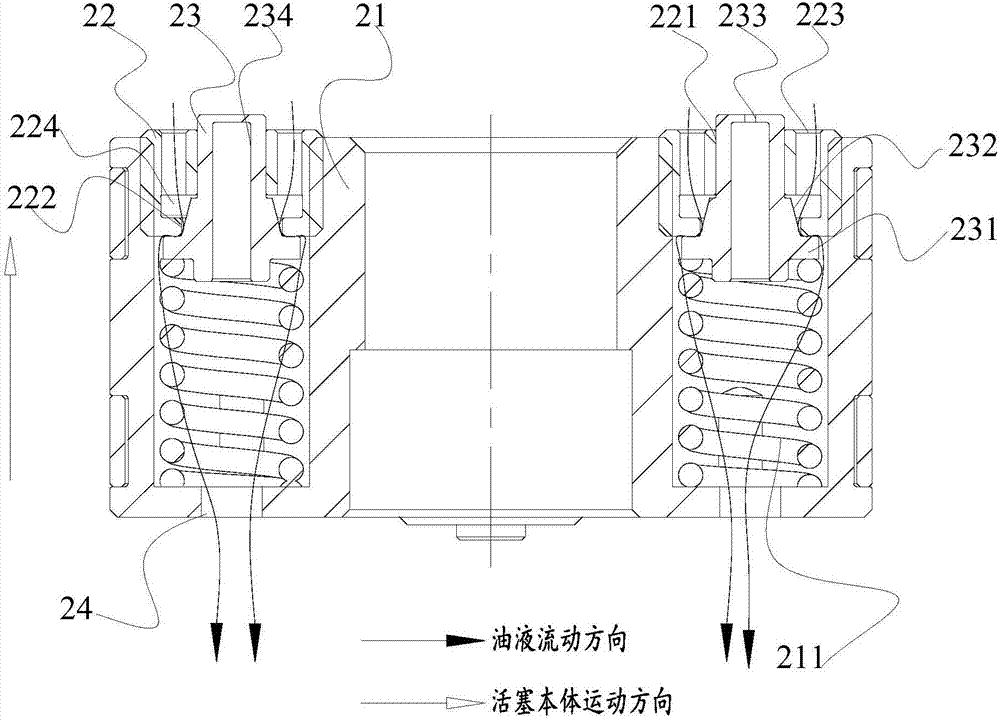

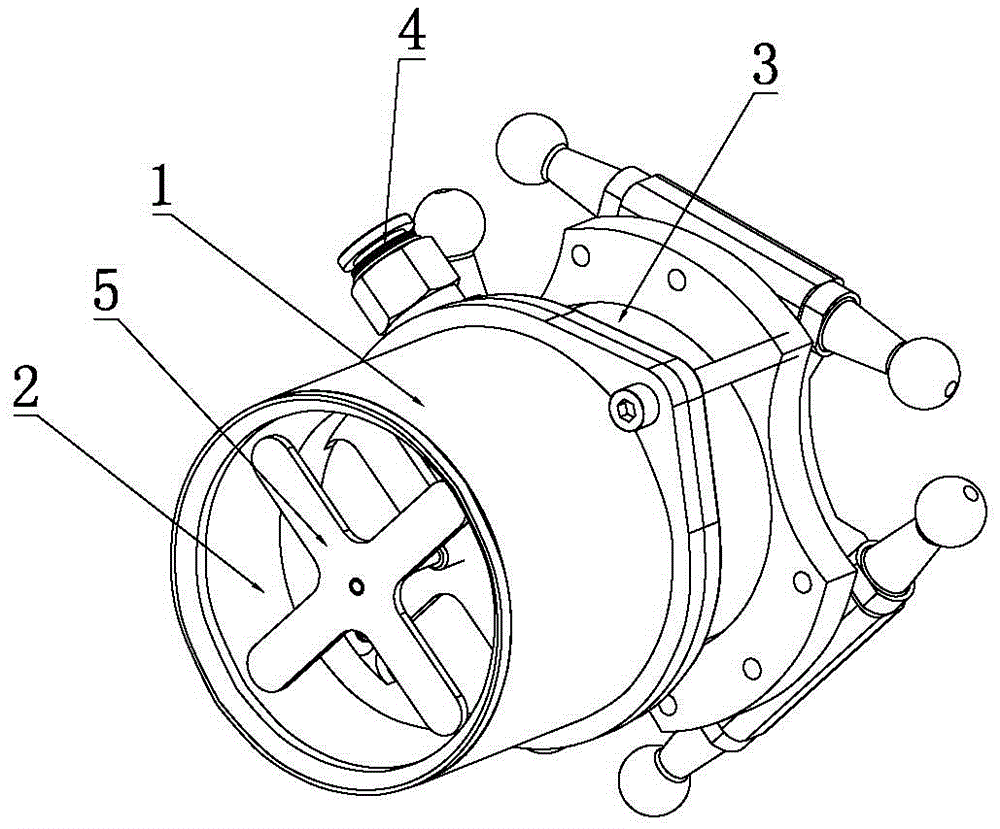

Valve body assembly, piston unit and oil-pressure damper

ActiveCN107143603AQuality improvementImprove accuracySpringsShock absorbersVibration attenuationPiston

The invention provides a valve body assembly. The valve body assembly is arranged on a piston body of an oil-pressure damper. A fluid hole is formed in a valve cover. Oil fluid above the piston body sequentially passes through the fluid hole and a drainage hole, so that the functions of unloading and vibration attenuation are achieved; the situation that in the prior art, the form and location tolerance generated between the valve cover and a valve element when an unloading hole is machined in the side wall of a blind hole of the valve element is affected is avoided; matching precision achieved between the valve cover and the valve element is guaranteed; and furthermore, the valve body assembly is stable in quality and precision performance. The invention further provides a piston unit. The piston unit is applied to the oil-pressure damper and provided with the valve body assembly. The piston unit is stable in quality and precision performance. The invention further provides the oil-pressure damper. The oil-pressure damper is provided with the piston unit and is stable in quality and precision performance.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

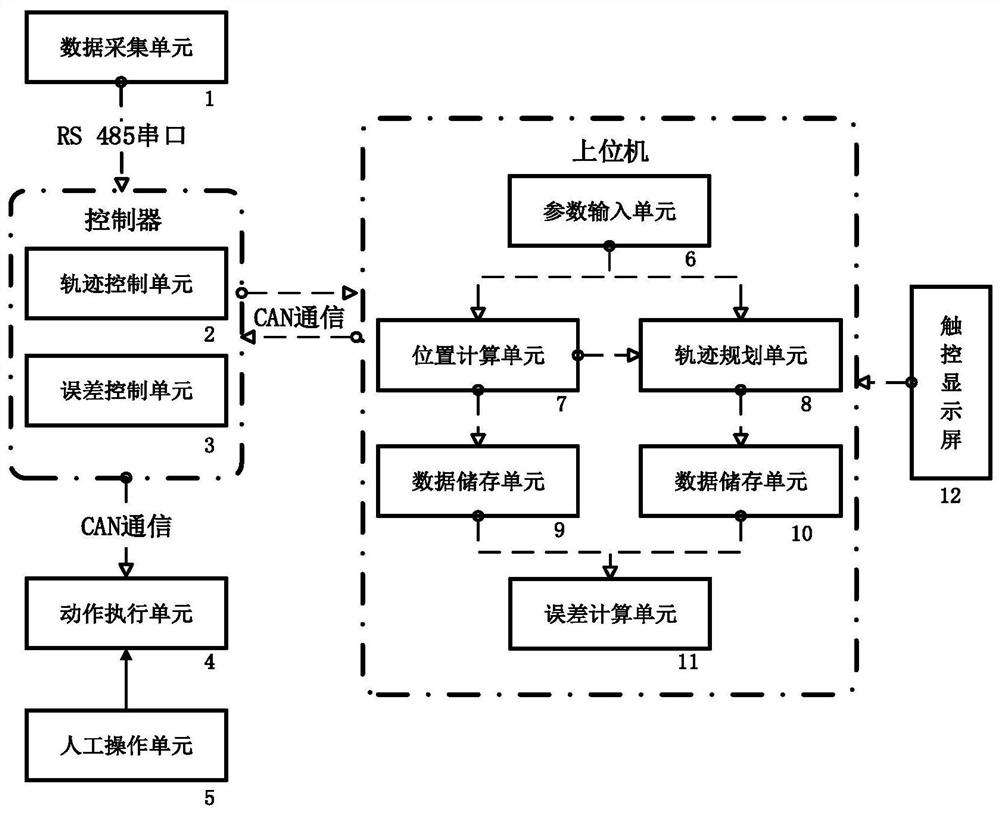

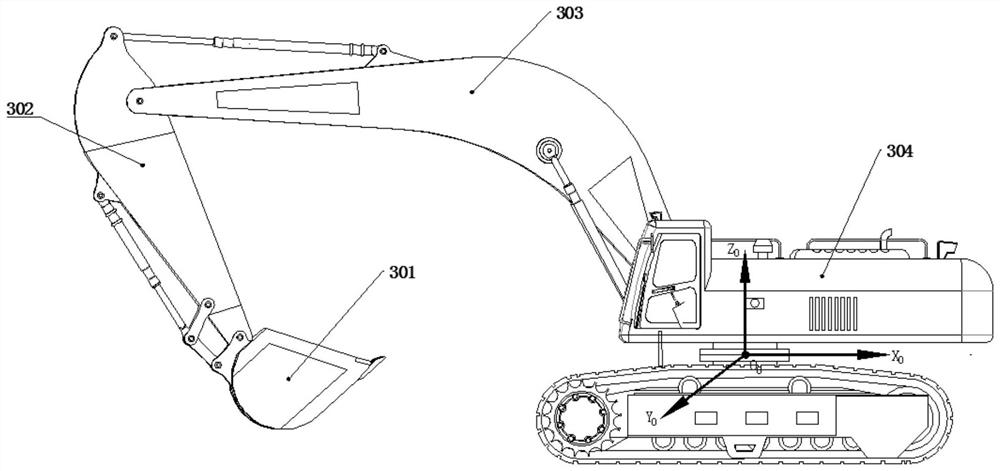

Excavator unloading operation auxiliary system and trajectory planning method

ActiveCN111733918AImprove automationImprove completenessForecastingSoil-shifting machines/dredgersAutomatic controlControl cell

The invention discloses an excavator unloading operation auxiliary system and a trajectory planning method. A data collection unit, a trajectory control unit, an error control unit, an action execution unit, a manual operation unit, a parameter input unit, a position calculation unit, a trajectory planning unit, a data storage unit and an error calculation unit are arranged on the system, whereinthe action execution unit can execute manual operation or automatic control, the trajectory planning method comprises the following steps that (1) a D-H coordinate system is established on an excavator, and the position of a bucket tip of the bucket is determined; (2) a vehicle body coordinate system is established on an unloading vehicle; (3) an unloading track constraint point is established; and (4) an unloading track is planned. Automatic unloading can be achieved through the unloading operation auxiliary system by the excavator, anti-collision factors are considered in unloading trajectory planning, turning point constraints are set, turning points are selected with the shortest path as the target in each path planning, an excavation starting point, the turning points and a target unloading point serve as path constraint points, and an anti-collision unloading trajectory is obtained by adopting an interpolation algorithm.

Owner:JILIN UNIV

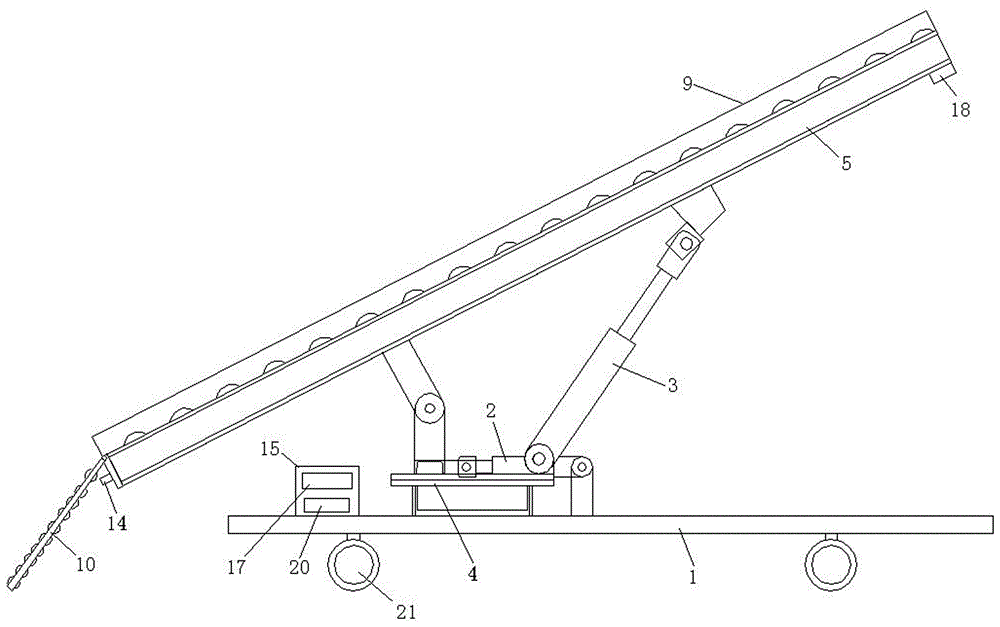

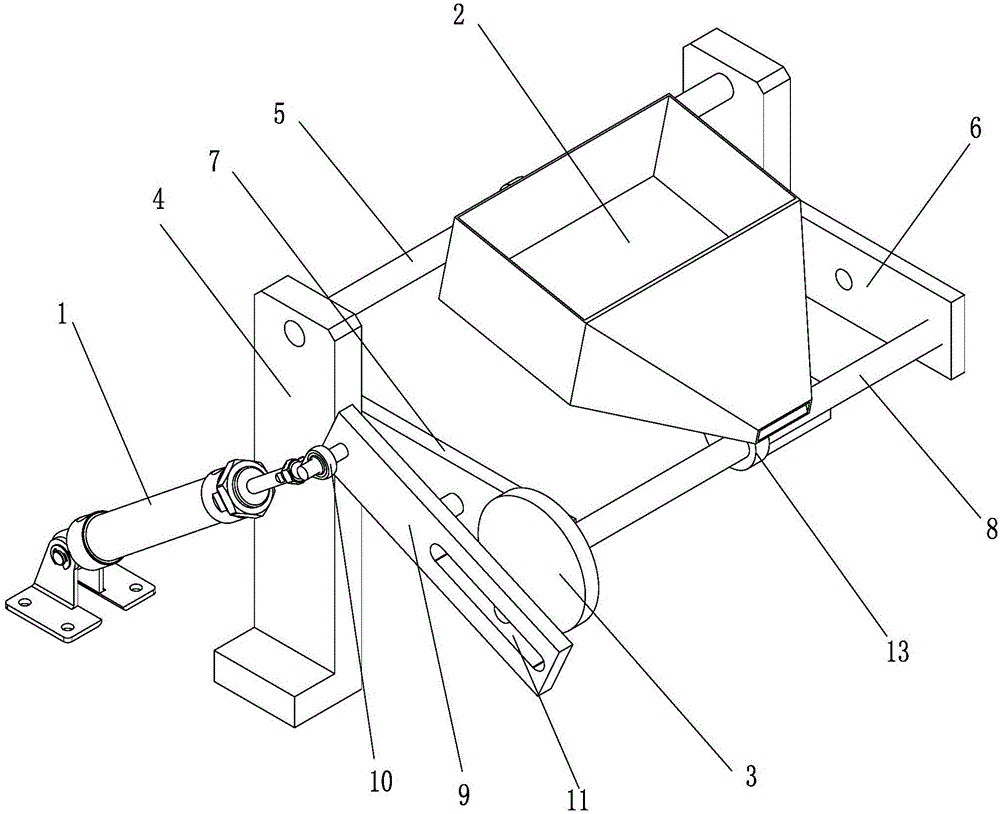

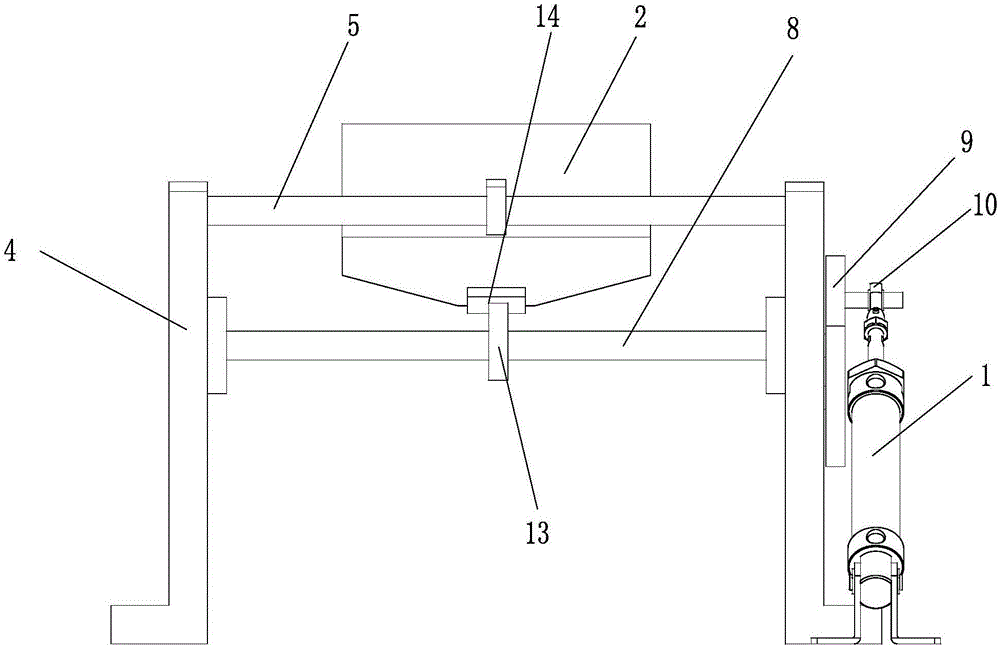

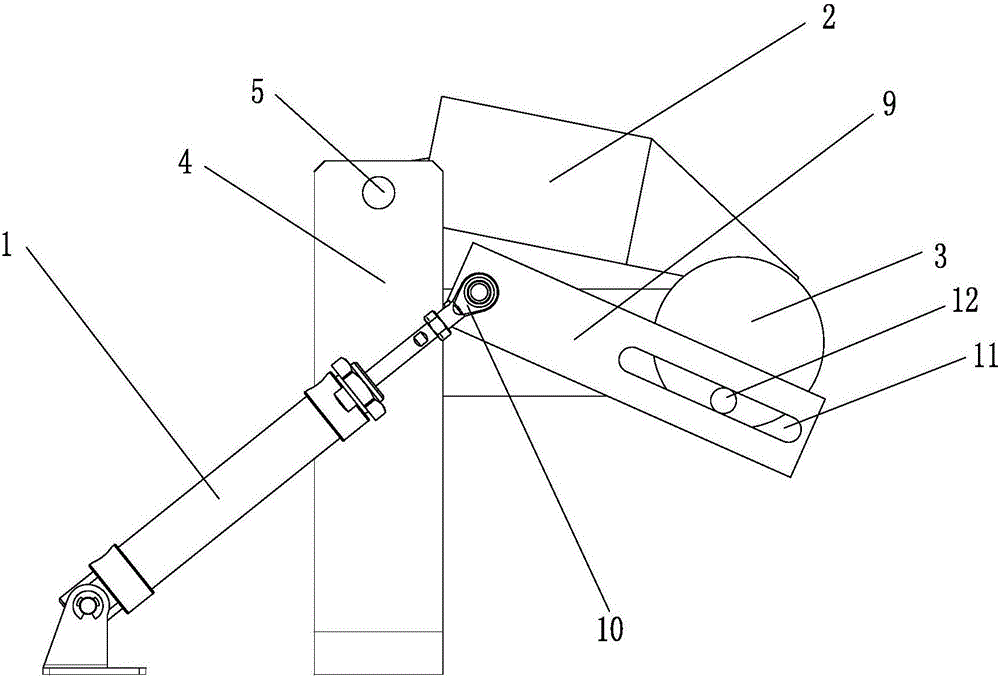

Transportation system for unloading of goods

InactiveCN106241265ARealize deliverySmooth unloadingConveyorsSupporting framesEngineeringMechanical engineering

A transportation system for unloading of goods comprises a baseplate. A turnplate is arranged at one side of the baseplate. A housing of an oil cylinder I is fixedly connected to the baseplate. A retractable rod of the oil cylinder I is hinged to the turnplate. A housing of an oil cylinder II is hinged to the turnplate. A retractable rod of the oil cylinder II is hinged to one side of a transporting plate of a frame-type structure, and the turnplate is hinged to the other side of the transporting plate. Multiple rollers are arranged at intervals in the transporting plate of the frame-type structure and are mounted on a shaft I in a tight fit manner, and two ends of the shaft I are fixed in bearings I on the transporting plate. Two sides of the upper surface of the transporting plate are respectively provided with one baffle for preventing boxed goods from sliding down. The rear end of the transporting plate is hinged to a concave connecting plate. The transportation system for unloading of goods is simple in structure, easy to operate, and can be more steady during unloading of goods; reduction of time in unloading of goods and improvement of the unloading efficiency can be achieved.

Owner:江苏博达生物科技有限公司

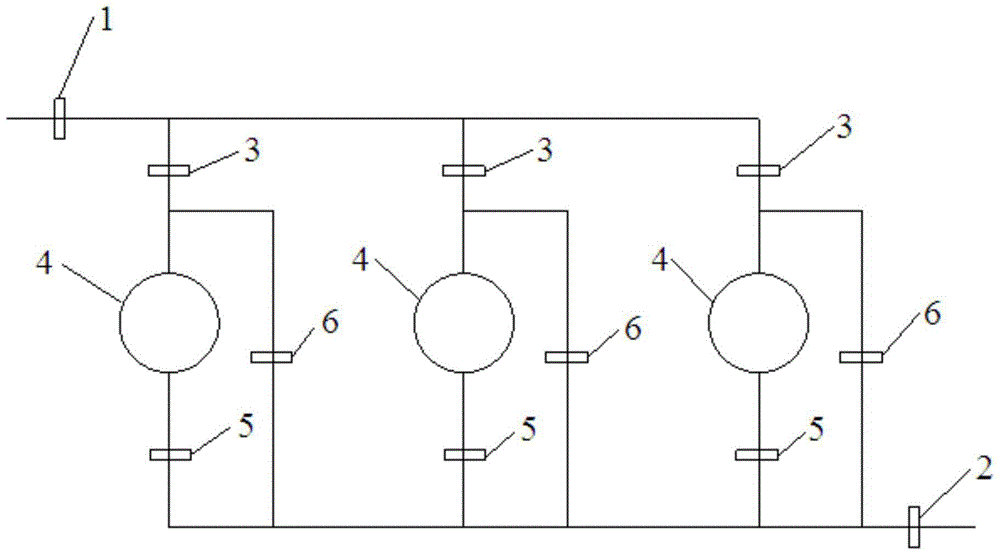

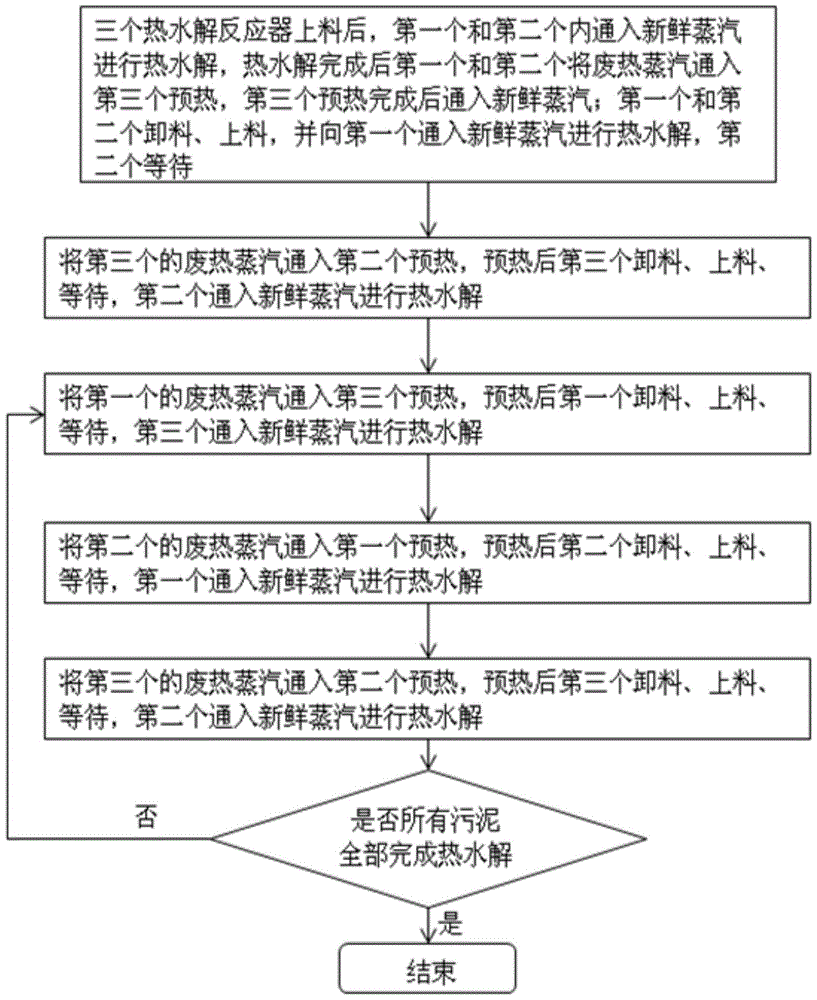

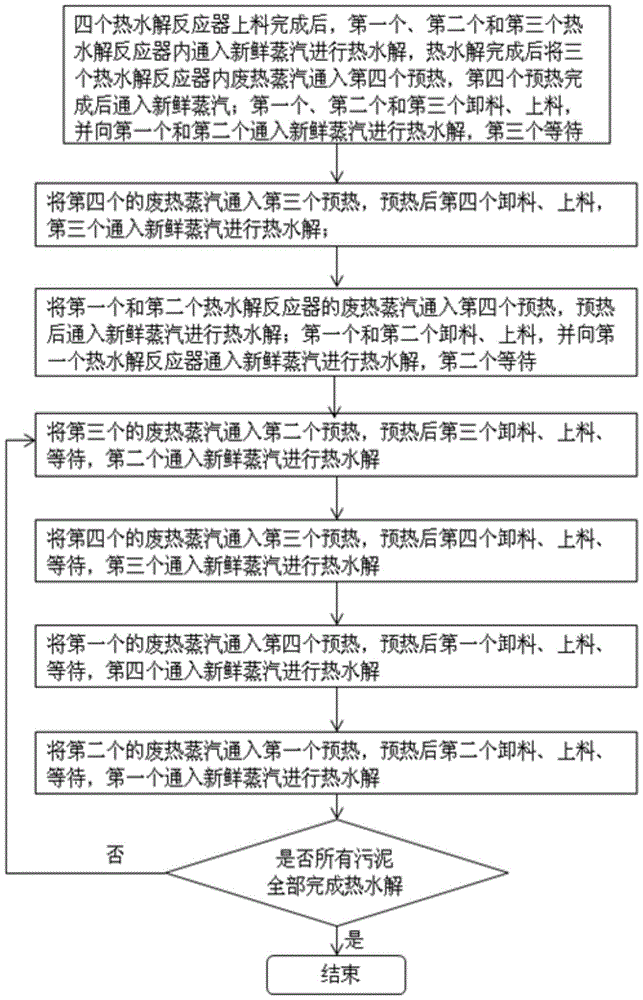

A modular sludge thermal hydrolysis treatment device and method

ActiveCN105016595BReduce consumptionEmission reductionSludge treatment by pyrolysisAutomatic controlSludge

The invention relates to a modular sludge thermal hydrolytic treatment device and method. The device comprises a steam feeding main valve, a steam releasing main valve and three-five hydrolytic modules, wherein the steam feeding main valve is arranged at the inlet of a steam main pipeline, the steam releasing main valve is arranged at the outlet of the steam main pipeline, the inlet of each of the hydrolytic modules is connected with the inlet of the steam main pipeline, and the outlet of each of the hydrolytic modules is connected with the outlet of the steam main pipeline; each hydrolytic module comprises a steam feeding valve, a thermal hydrolytic reactor, a steam releasing valve and a waste steam feeding valve; the inlet of the steam feeding valve is connected with the inlet of the steam main pipeline, the outlet of the steam feeding valve is connected with the inlet of the thermal hydrolytic reactor and the outlet of the waste steam feeding valve in parallel, the outlet of the thermal hydrolytic reactor is connected with the inlet of the steam releasing valve, and the outlet of the steam releasing valve and the inlet of the waste steam feeding valve are connected with the outlet of the steam main pipeline; each thermal hydrolytic reactor is internally provided with a temperature sensor and a pressure sensor, and each temperature sensor and each pressure sensor send collected temperature values an pressure values to an automatic control system.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

Portable unloading device for construction

PendingCN108455323AEasy to fixImprove stabilityLoading/unloadingArchitectural engineeringBuilding construction

The invention discloses a portable unloading device for construction. The portable unloading device for construction comprises a bottom frame; baseplates penetrate through the two sides of the bottomframe; the surfaces, positioned outside the bottom frame, of the baseplates are in threaded connection with screw rods through nuts; the bottom ends of the screw rods are fixedly connected with fixingdevices; the left side of the top of the bottom frame is rotationally connected with a rotating frame through a rotating base; and the device relates to the technical field of related devices of construction engineering. The portable unloading device for construction achieves the purpose of convenient fixation on the ground, improves the stability, prevents shaking in the unloading process, guarantees a smooth unloading process, and facilitates extension of a vertical plate to improve the portability; and meanwhile, the position of a transverse plate can be adjusted according to the height ofa transportation device, so that the portable unloading device for construction is convenient to use by people, the damage to materials in the unloading process is prevented, unnecessary wastes are prevented, the materials are convenient to shift on the ground, the device practicability is improved, and the worker burden is relieved.

Owner:张一天

Sliced food sucking device

The invention discloses a sliced food sucking device and relates to the technical field of food packaging equipment. The sliced food sucking device structurally comprises a sucking head with a containing cavity. Due to the fact that a sliding buffer part is arranged in the containing cavity, the buffer part gets close to a sucking port of the sucking head before food is sucked, in this way, the first slice of food can be tightly attached to the buffer part by moving a quite small distance when food is sucked, side turning of the first slice of food can be prevented, smooth sucking of follow-up food is ensured, collision between the first slice of food and the buffer part is reduced, and then the food breakage probability is reduced. Meanwhile, due to the fact that the buffer part is moved towards the bottom of the containing cavity by the distance of the thickness of at least one slice of food every time the sucking head sucks one slice of food, side turning of follow-up sucked food can be prevented, collision between food can be reduced, and the food breakage probability is further reduced. In the discharge process, the buffer part pushes all food in the sucking head together, and rapid and smooth discharge is achieved.

Owner:QKM TECH (DONG GUAN) CO LTD

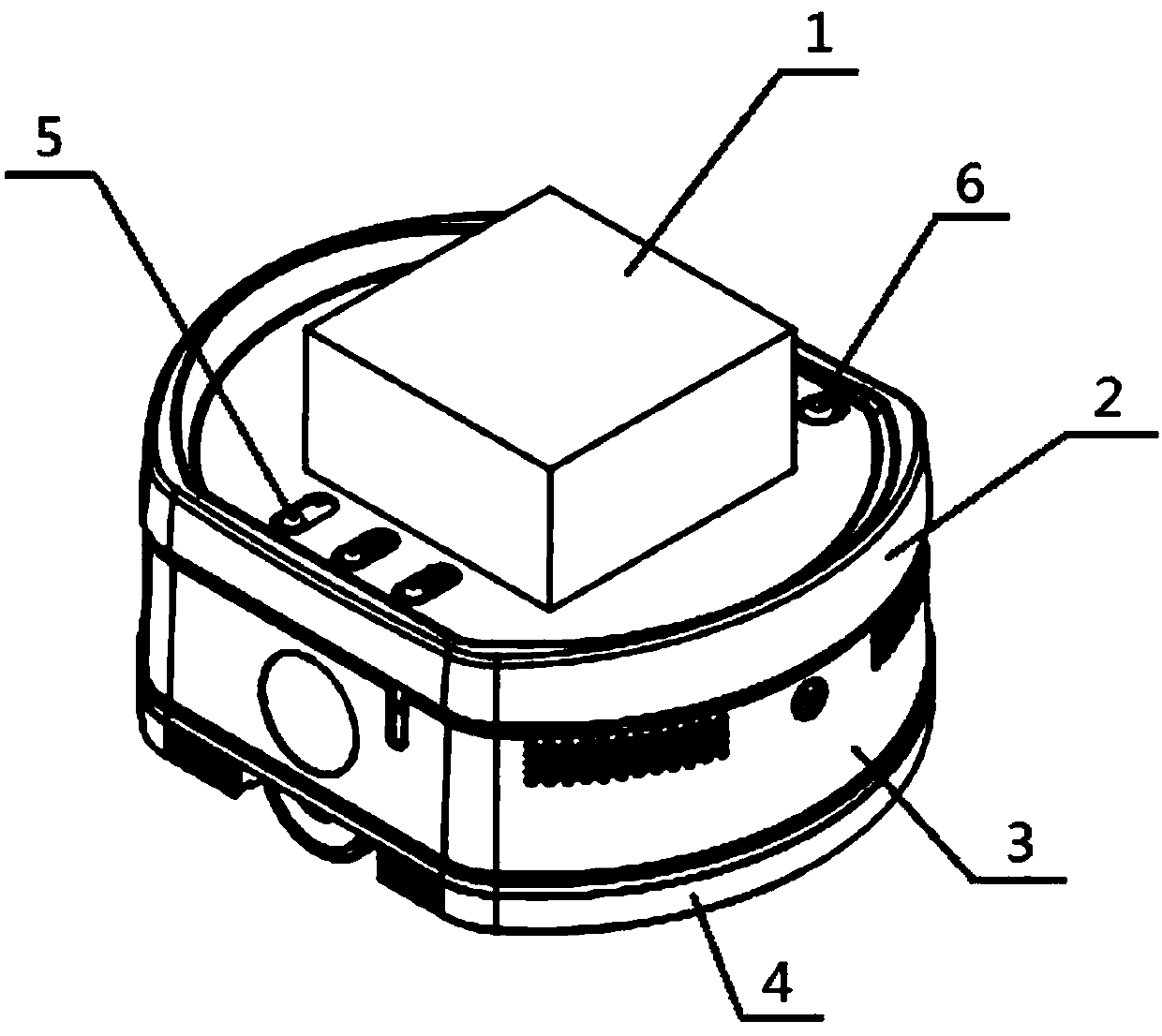

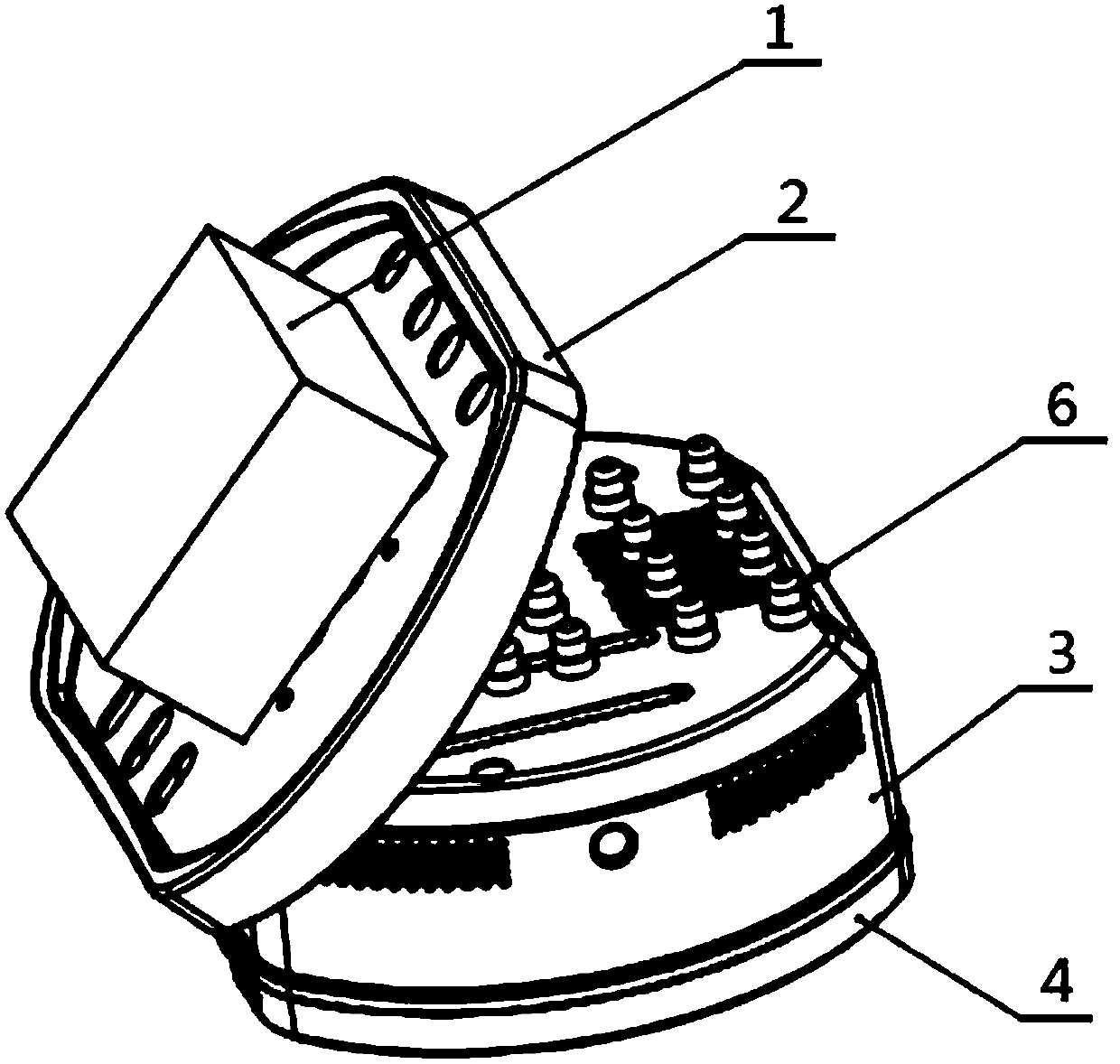

Goods bearing device and sorting AGV

PendingCN110654788AIncrease frictionPrevent slippingConveyor partsMechanical conveyorsFriction forceIndustrial engineering

The invention relates to a goods bearing device and a sorting AGV. The goods bearing device comprises a bearing platform (2) and a movable first antiskid piece (5), the bearing platform (2) is used for placing goods (1), and the goods (1) placed on the bearing platform (2) can be overturned to slide off the bearing platform (2); and the first antiskid piece (5) is used for increasing the frictionforce between the goods (1) and the bearing platform (2) before the bearing platform (2) is overturned, and leaves the antiskid position after the bearing platform (2) is overturned so as to reduce the friction force between the goods (1) and the bearing platform (2). The sorting AGV includes the goods bearing device. According to the goods bearing device and the sorting AGV, by arranging the movable first antiskid piece, the purposes of preventing sliding in the conveying process and ensuring smooth sliding of the goods during unloading can be realized, the safety of the goods in the conveying process can be ensured, and the smooth unloading of the goods can not be influenced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Vibrating discharging device

The invention relates to a vibrating discharging device. The device comprises a rack and is characterized in that a mounting rod is arranged on the rack; a material box is rotationally mounted on the mounting rod; a first mounting plate and a second mounting plate are arranged on two sides of the rack; one end of the first mounting plate and one end of the second mounting plate are mounted on the rack; a rotating wheel mounting shaft is rotationally mounted between the other end of the first mounting plate and the other end of the second mounting plate; a rotating wheel is mounted on the rotating wheel mounting shaft; an eccentric shaft is arranged on the outer end surface of the rotating wheel; a rotating plate is rotationally arranged on the second mounting plate; one end of the rotating plate is rotationally connected with an extending rod of a gas cylinder; a sliding groove is formed in the other end of the rotating plate in the length direction of the rotating plate; the eccentric shaft on the outer end surface of the rotating wheel is arranged in the sliding groove; and a supporting cam is arranged on the rotating wheel mounting shaft and supports the front end of the material box. The device is simple in structure and convenient to operate, and smooth and continuous discharging of viscous materials can be guaranteed.

Owner:WUXI TEHENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com