Patents

Literature

59results about How to "Increased splitting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-impact-resistance acrylate structural adhesive

ActiveCN105713543AHigh strengthImprove impact resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHigh resistanceMethacrylate

The invention belongs to the technical field of adhesives, and particularly relates to a high-impact-resistance acrylate structural adhesive. The high-impact-resistance acrylate structural adhesive contains rigid functional groups provided by hydrogenated bisphenol A and methacrylate functional groups which can enhance the curing pull strength and impact resistance. The toughening resin is added to greatly enhance the impact resistance. The high addition percent of the curing agent in the component B can ensure the whole system to quickly perform reaction and curing. After room curing is performed for 3-5 minutes, 70-DEG C hot pressing only takes 60 seconds. The high-impact-resistance acrylate structural adhesive has high impact resistance, can pass the disk knife test, and can still keep high bonding power after being cut a little. The structural adhesive has high forward pull strength, and the pull force test proves that the pull force at the copper nail is generally required to be greater than 20kg or the copper nail can shed. The structural adhesive has high temperature resistance and high humidity resistance, and the strength does not obviously decrease when the structural adhesive is at 60 DEG C under the 90% humidity condition for 7 days.

Owner:信泰永合(烟台)新材料有限公司

Composite concrete agent

The invention discloses a concrete complexing agent as additive in the architectural material technical domain, which comprises the following parts: 48-55% silica, 27.5-45% fluorite, 2.5-8% sodium cetylsulfate, 4-9% hydroxy carboxyl acid and 0.5-1% aliphatic hydroxy sulfonate high-effective dehydragent. The complexing agent improves particle bond of concrete aggregate, which saves cement quantity by 10-20%.

Owner:王衡

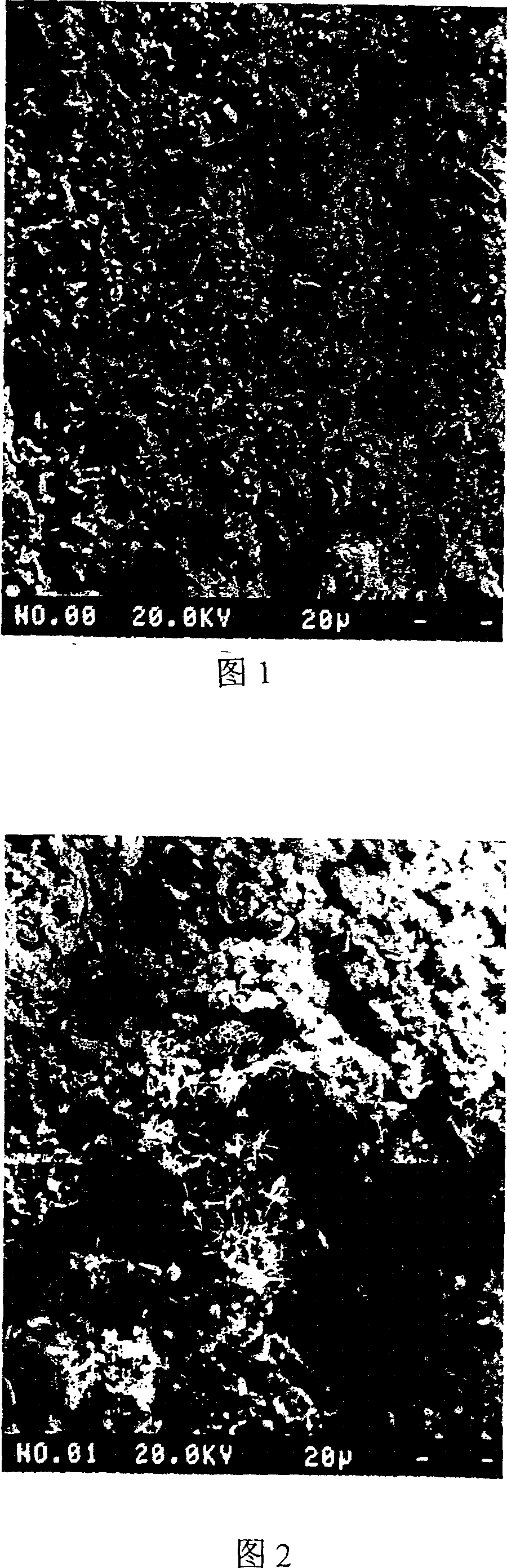

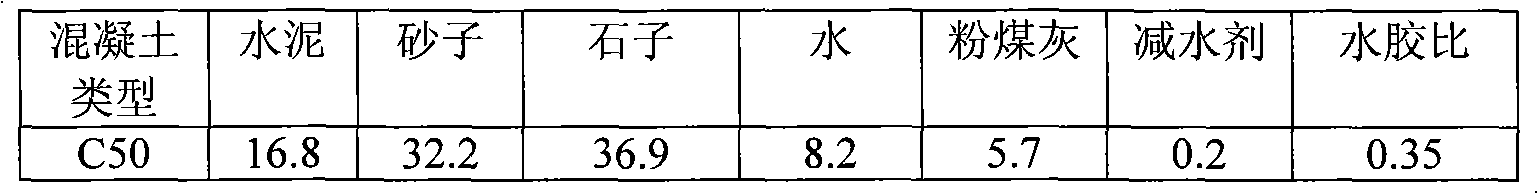

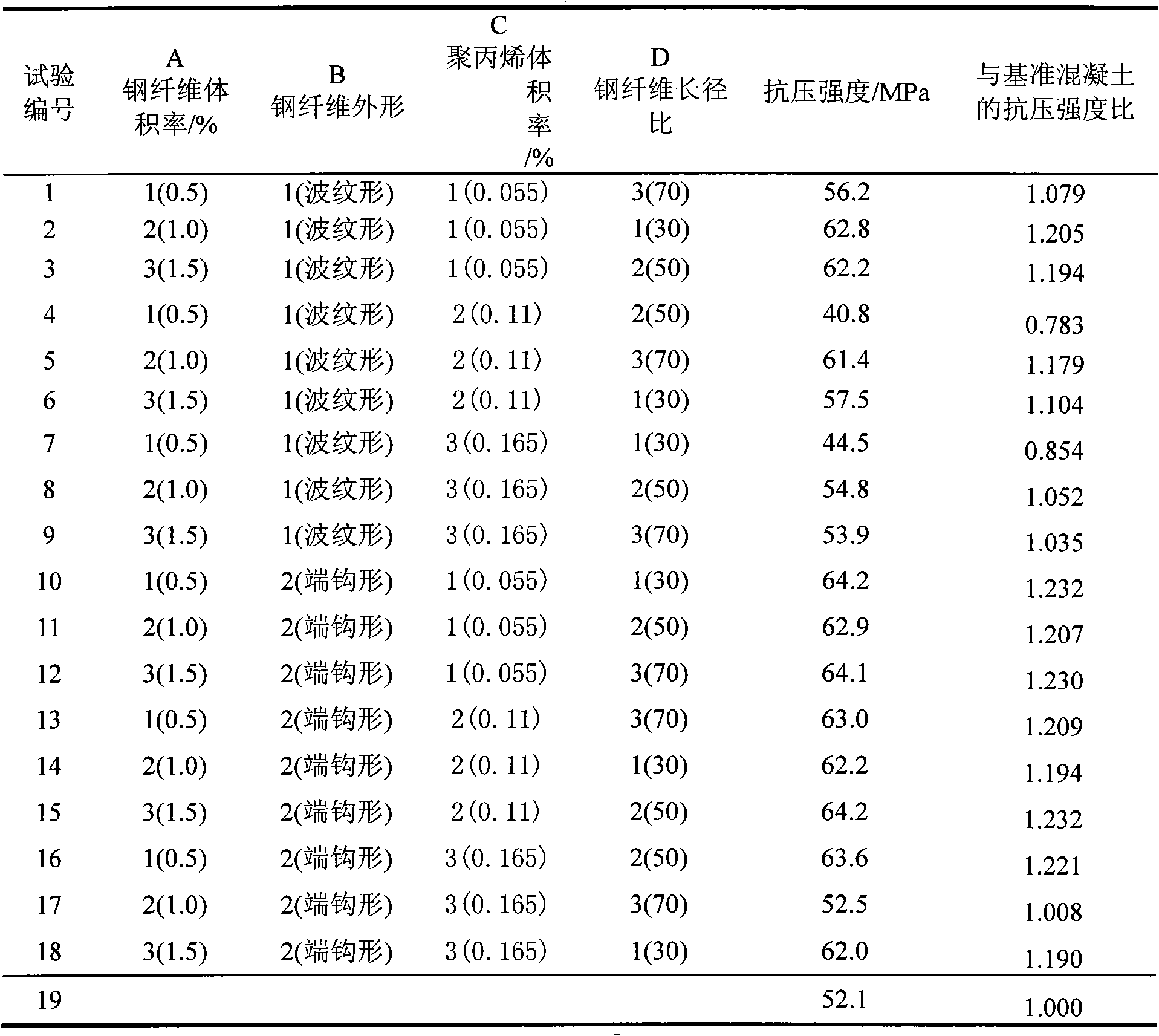

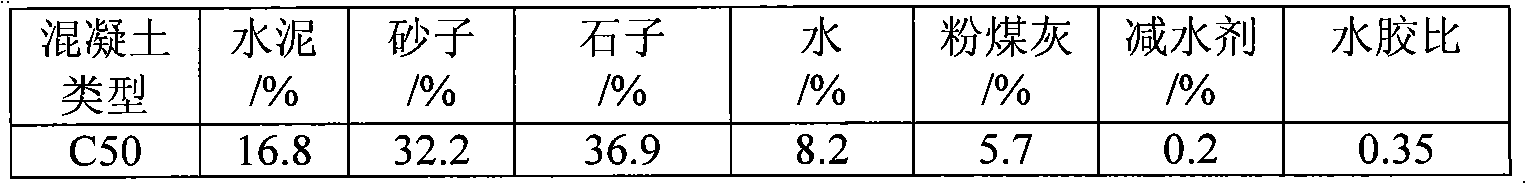

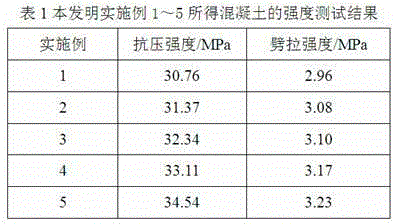

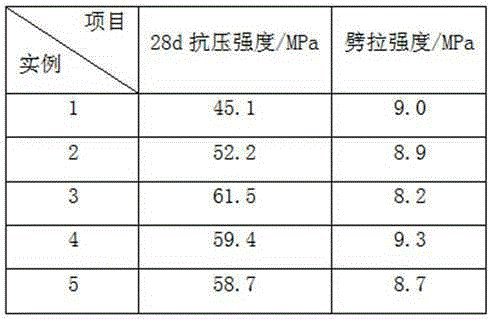

High performance steel-polypropylene hybrid fiber concrete

InactiveCN101880138AHigh compressive strengthIncreased splitting strengthSolid waste managementUltimate tensile strengthWater reducer

The invention designs novel high performance fiber concrete in the field of building materials. Steel fibers and polypropylene fibers with low mixing quantity are added in original concrete. The volume ratio range of the steel fibers is 0.5-1.5 percent, and the volume ratio of polypropylene is 0.055-0.165 percent. Cement in the original concrete is C50, and the original concrete comprises the following components in percentage by weight: 16.8 percent of the cement, 32.2 percent of sands, 36.9 percent of pebbles, 8.2 percent of water, 5.7 percent of fly ash and 0.2 percent of water reducer. By adding the polypropylene, at the early stage, crack developing of the concrete is limited, and an internal structure of the concrete is improved; and the steel fibers limit and delay the occurrence and the development of a macroscopic crack at the later phase, are connected with parts of developed cracks and efficiently strength the intensity of the concrete. In addition, through coordination work of the three of the steel fibers, the polypropylene fibers and the original concrete, the positive hybrid effect is generated, the ductility, the toughness, the impermeability, the fatigue performance, the shrinkage and the creep of the concrete can be better improved, and excellent working performance is generated.

Owner:周健民

Multi-strength regeneration brick aggregate fiber concrete and preparing method thereof

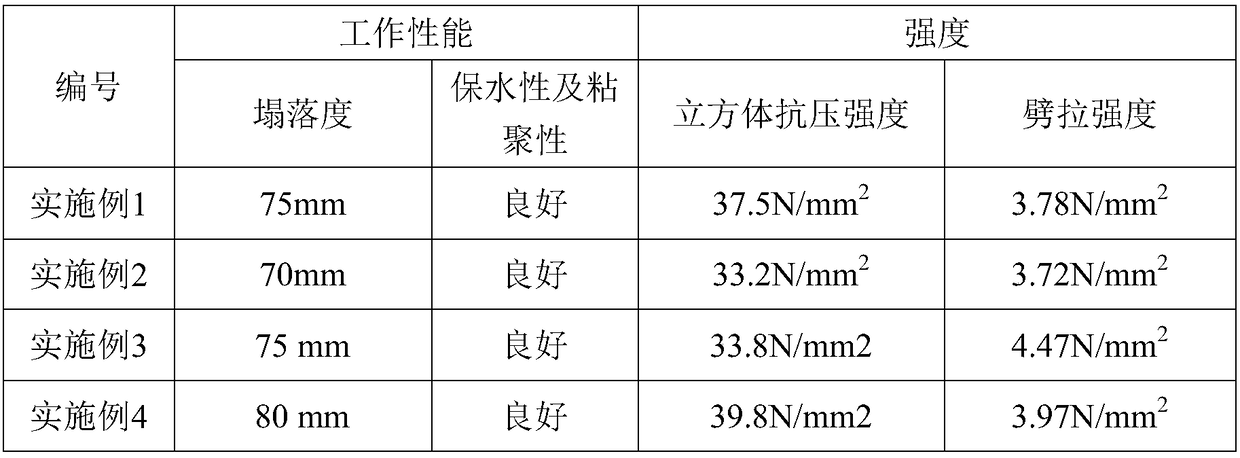

The invention relates to multi-strength regeneration brick aggregate fiber concrete and a preparing method thereof. The multi-strength regeneration brick aggregate fiber concrete is prepared from cement, fine aggregate, natural coarse aggregate, regeneration brick coarse aggregate, polyolefin fiber, steel fiber and water according to the weight ratio of 1: (0.780-1.309) : (0-1.830) : (0.390-1.568) : (0-0.019) : (0-0.161) : (0.33-0.48). The regeneration brick aggregate fiber concrete with the target strength grade of CF30-CF50 can be prepared by means of the raw materials, strength grade is high, and application range is wide. The obtained regeneration brick aggregate fiber concrete has high working performance including peaceability and water-retaining property, compressive strength and splitting-tension strength are high, the preparing process is simple and environmentally friendly, and construction is easy.

Owner:ZHENGZHOU UNIV

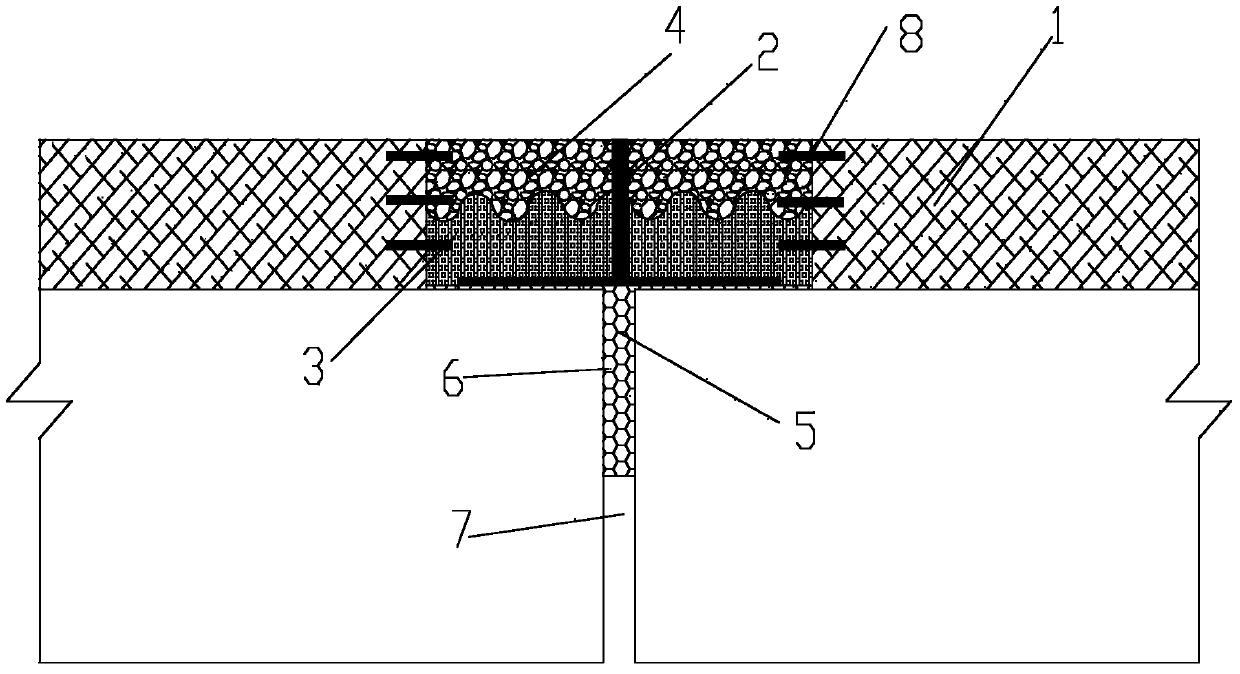

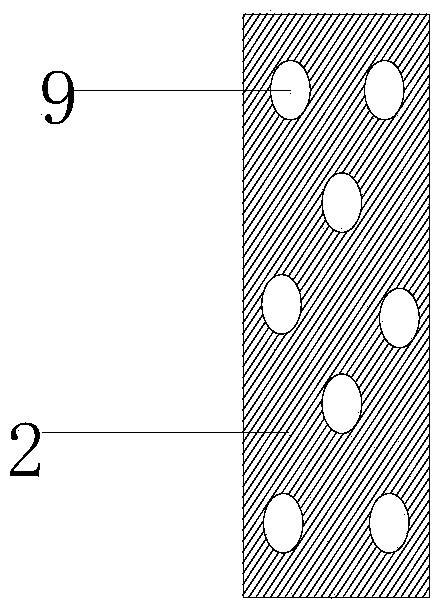

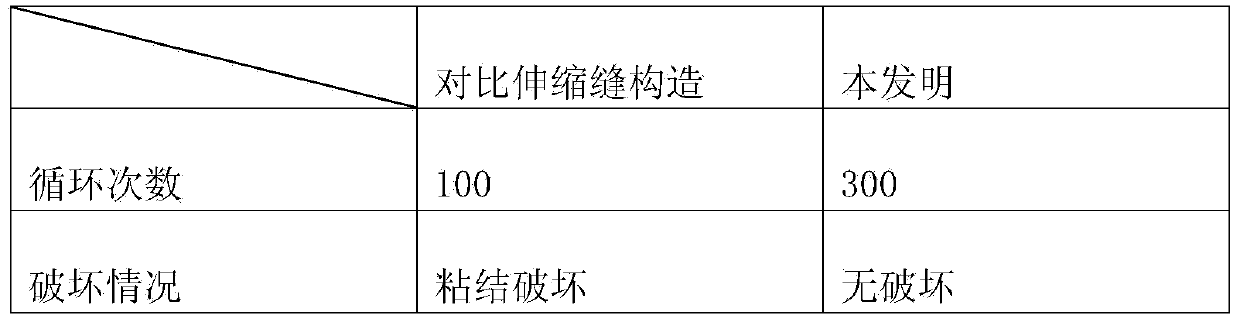

Road and bridge expansion joint structure

InactiveCN103669202AEasy constructionReasonable designBridge structural detailsStress conditionsIn vehicle

The invention discloses a road and bridge expansion joint structure. The road and bridge expansion joint structure comprises an inverted-T-shaped plate component with the bridge longitudinal cross section being in an inverted T shape. Two wing plates of the inverted-T-shaped plate component transversely extend into a base body of a bridge pavement layer. A web extends upwards to be flush with the upper surface of the bridge pavement layer. Each wing plate is sequentially provided with a cushion layer and a protection wear-resisting layer from bottom to top in a laying mode and is longitudinally connected with the bridge pavement layer. An expansion joint notch and the two sides of the expansion joint notch are filled with elastic layers to be sealed. The road and bridge expansion joint structure has the advantages of being convenient to construct, reasonable in design, high in efficiency, good in vehicle load bearing performance, good in elasticity, smooth and attractive in surface, and good in waterproofing, anti-aging, anti-fatigue, shock resistance and corrosion resistance. In accordance with the characteristics of an expansion joint, three materials of different components and matching ratios are adopted, layered pavement is conducted according to different stress conditions and states, good durability is achieved, construction is rapid and simple, and the expansion joint performance requirement can be well met.

Owner:孟献春

Waste sintered brick recycled C30 concrete and preparation method thereof

ActiveCN104529333AImprove uniformityImprove quality and tightnessSolid waste managementCompressive resistanceBrick

The invention relates to waste sintered brick recycled C30 concrete and a preparation method thereof. The waste sintered brick recycled C30 concrete is prepared from cement, a waste sintered brick recycled coarse aggregate, a fine aggregate, water and a water reducing agent at a weight ratio of 1 to (1.679-1.737) to (0.653-0.817) to (0.367-0.397) to (0.006-0.01). The C30 concrete prepared by the method disclosed by the invention is qualified and stable in strength, high in compressive strength and split and tensile strength, good in working performances such as workability, fluidity and water retention property, simple and environmentally friendly in preparation process and easy to implement.

Owner:ZHENGZHOU UNIV

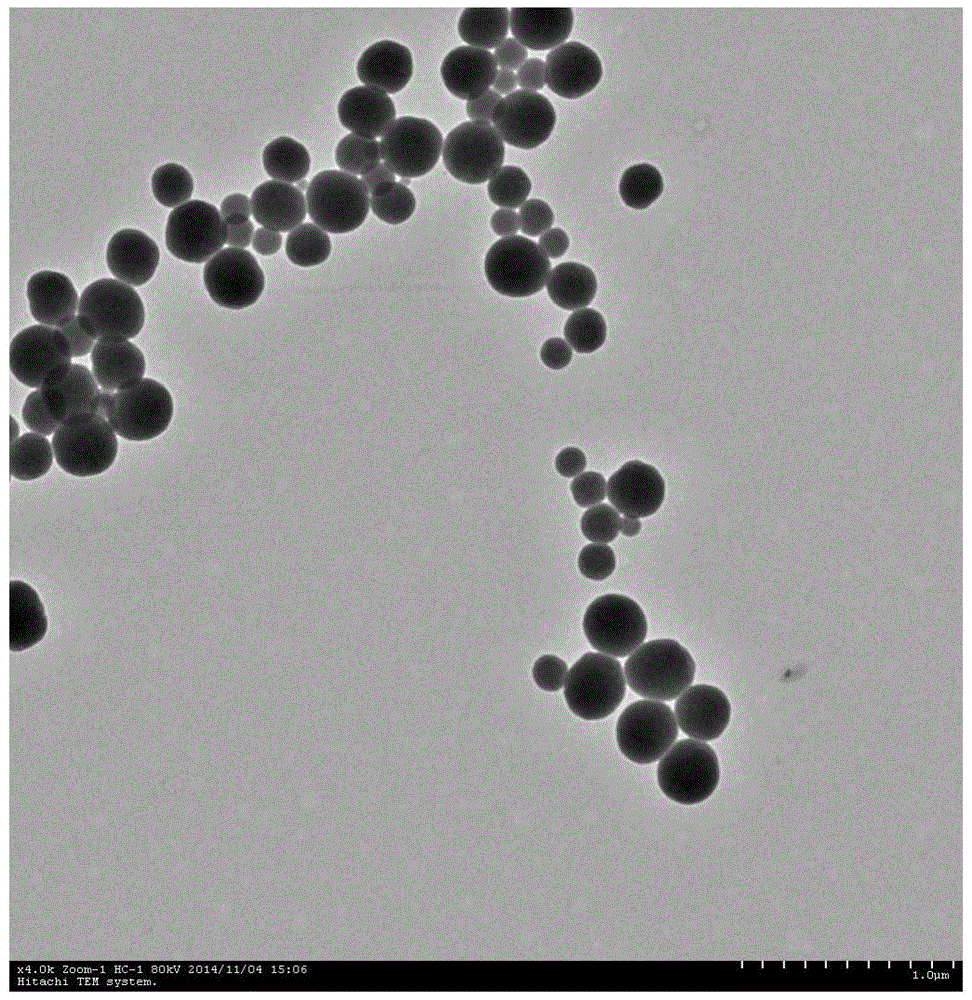

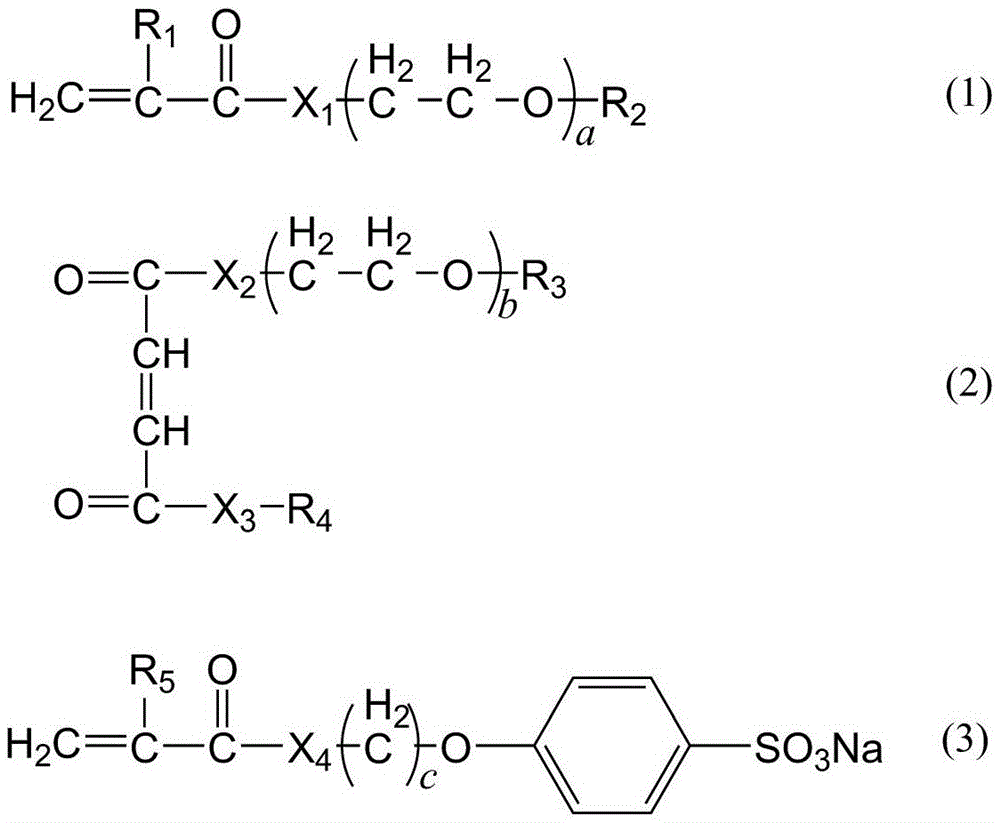

Admixture for improving mechanical properties of cement-based materials and preparation method of admixture

The invention discloses an admixture for improving mechanical properties of cement-based materials. The admixture is aqueous dispersion of organic-inorganic hybrid particles, the organic-inorganic hybrid particles account for 5-40% of the aqueous dispersion, and each particle is in a two-layer structure including an inner layer and an outer layer. The inner layers comprise organic components and inorganic components, wherein no covalent bond exists between the organic components and the inorganic components, and the inorganic components and the organic components are respectively connected through covalent bonds to form a polymer network. Each outer layer is a layer of electronegative organic polyelectrolytes with long side chains. The admixture for improving the mechanical properties of the cement-based materials is beneficial to improvement of compressive strength of the cement-based materials, and the more the admixture is doped, the more evidently the mechanical properties of the cement-based materials are improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

High performance concrete containing composite fiber

The invention discloses high performance concrete containing composite fiber. The problems in the existing high performance concrete of being large in fiber adding amount and poor in mechanical performance, stretching toughness and bend ductility are solved. The technical scheme is that the high performance concrete comprises the concrete and the composite fiber. Based on 100% of volume of the concrete, mixing rate of the composite fiber is 0.8-1% of the concrete volume, and the composite fiber is composed of steel fiber, plastic steel fiber and polypropylene monofilament fiber. The concrete is good in comprehensive mechanical performance of concrete crushing strength, splitting tensile strength, toughness, bend ductility and the like, low in fiber adding amount and wide in application range.

Owner:HUBEI UNIV OF TECH

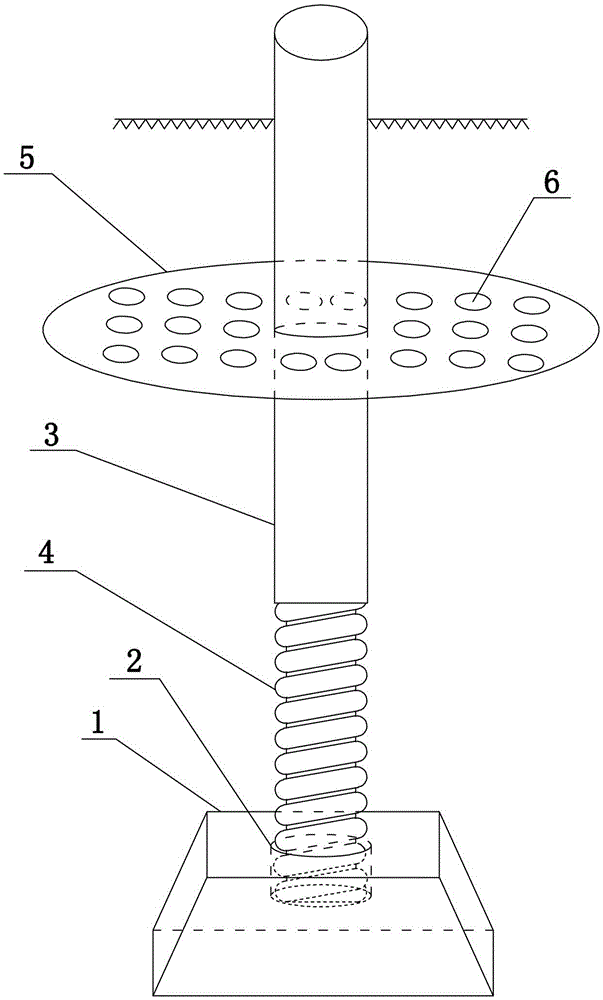

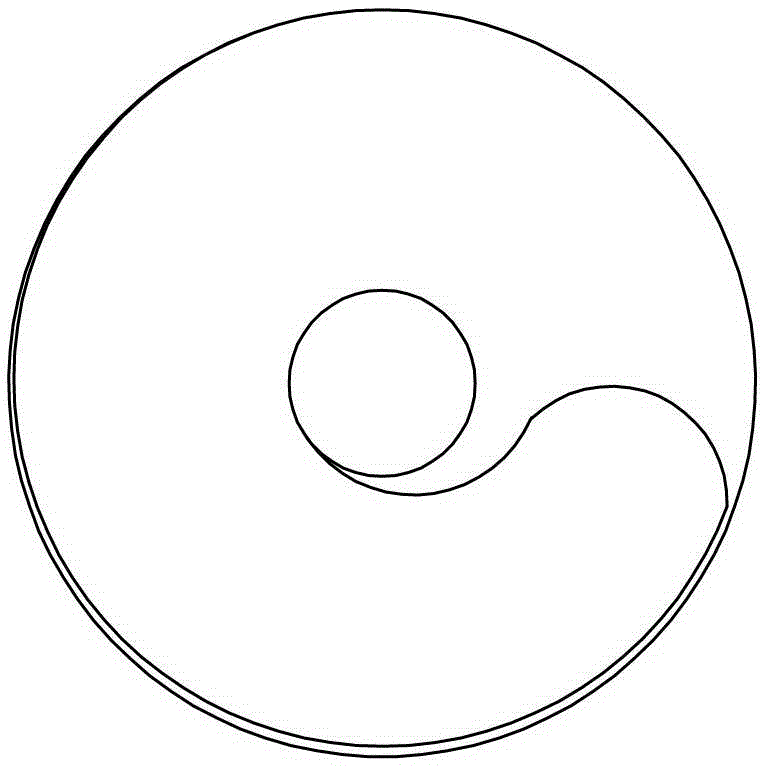

Pole shock-resistant mechanism of

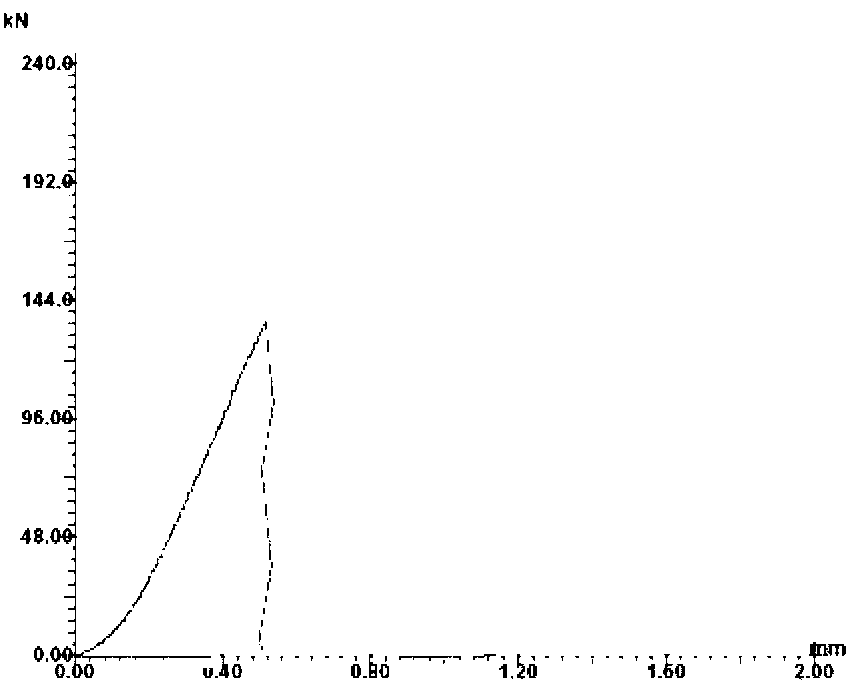

ActiveCN105347758AHigh compressive strengthImprove crack resistanceTowersTransverse shearBearing capacity

The invention belongs to the technical field of power transmission line construction projects and particularly relates to a pole shock-resistant mechanism. The pole shock-resistant mechanism provided by the invention comprises a base, wherein a positioning groove is formed on the upper end face of the base; a vertically oriented spiral pressure spring is arranged between the bottom of the pole and the positioning groove to close the bottom of the pole and the base; a disc loop is arranged around the pole; isometric round holes are formed on the disc loop; and the base and the disc loop are poured by concrete. The pole shock-resistant mechanism provided by the invention can effectively improve the ductility, the transverse shearing capacity and the bending bearing capacity of the pole, so that the reliability of the pole is improved, and the safety and stability of power transmission lines are ensured.

Owner:STATE GRID HENAN TONGBAI POWER SUPPLY CO

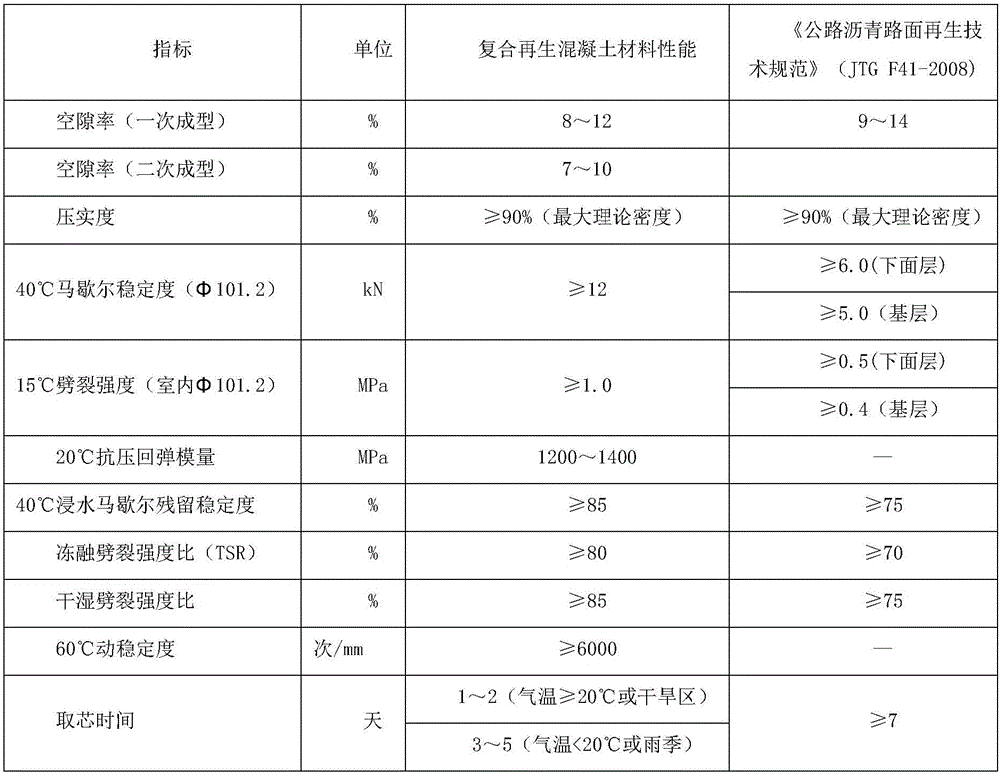

Fiber compound regenerative asphalt concrete

The invention provides fiber compound regenerative asphalt concrete, which is prepared from the following ingredients (by weight): 30 parts of 0-5mm regenerative asphalt concrete RAP, 25 parts of 5-10 mm regenerative asphalt concrete RAP, 28 parts of 10-30 mm regenerative asphalt concrete RAP, 15 parts of 10-30 mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, 1 part of a regenerant and 1.2 parts of glass fiber. The glass fiber of 6 mm long is added to improve material performance of a cold recycled mixture. The glass fiber is obviously better than other fibers. The special fiber has obviously more excellent dispersion effect in the cold recycled mixture than other fibers, and the regenerative mixture is smooth to discharge. The fiber compound regenerative asphalt concrete provided by the invention has obviously more excellent material performance than the code requirements. Tension strength, namely cleavage strength, of the mixture is raised. Material anti-cracking ability is more excellent, reflection crack resistance is stronger, the material is more compact, moisture damage resistance is stronger, and durability is better.

Owner:BEIJING SAINT GROUND HIGHWAY TECH

Full-light high-strength concrete for fabricated prefabricated part and preparation method thereof

The invention relates to full-light high-strength concrete for a fabricated prefabricated part. The full-light high-strength concrete comprises the following components in parts by weight: 45-55 partsof cement, 45-55 parts of ceramsite, 38-55 parts of pottery sand, 15.5-17.5 parts of fly ash, 9-35 parts of steel fibers, 22-44 parts of high-performance fibers and 1.0-1.5 parts of a water reducingagent. Compared with the prior art, the prepared concrete is uniform in distribution; the weight is light, the strength is high, and the self-heat-preservation performance is good; the concrete has good tensile deformation resistance and light specific gravity, so that the full-light concrete has toughness, various properties of the concrete are effectively improved, the volume weight of the concrete is greatly reduced, the compressive strength is ensured, the full-light high-strength concrete is simple in preparation process, environment-friendly and easy to construct, and the concrete has good popularization value.

Owner:汝州市东江建筑工业科技有限公司

Waste sintered brick recycled C25 concrete and preparation method thereof

ActiveCN104556905ARealize recyclingIncrease profitSolid waste managementBrickUltimate tensile strength

The invention relates to waste sintered brick recycled C25 concrete and a preparation method thereof. The C25 concrete is prepared from cement, waste sintered brick recycled coarse aggregate, fine aggregate and water at a mass ratio of 1: (1.76-1.96): (1.15-1.23): (0.42-0.46). The prepared concrete has qualified and stable strength as well as good working performance such as workability, fluidity, water-retaining property and the like, the preparation process is simple and environment-friendly, and construction is easier.

Owner:ZHENGZHOU UNIV

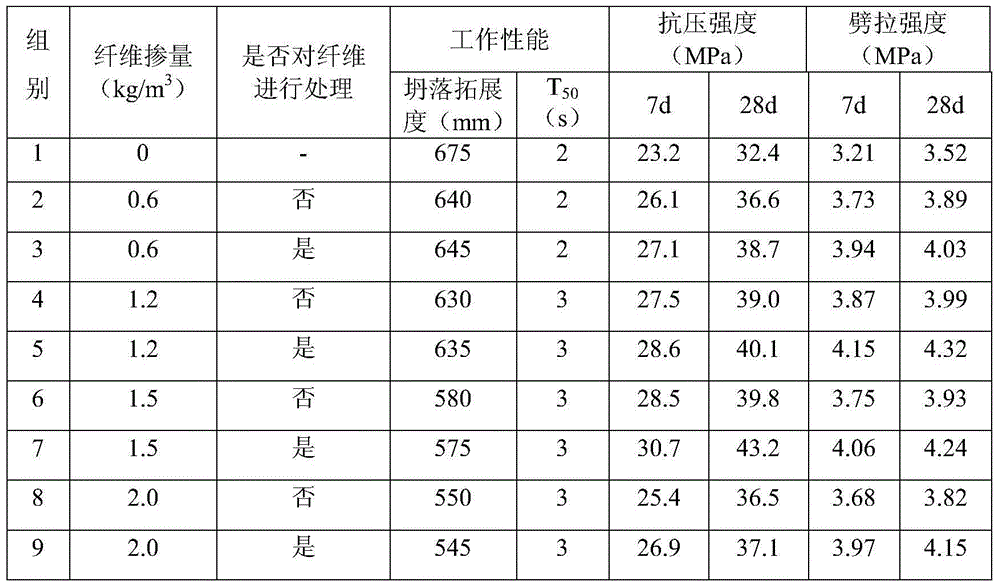

High-crack-resistant palm fiber self-compacting concrete

The invention discloses high-crack-resistant palm fiber self-compacting concrete. The high-crack-resistant palm fiber self-compacting concrete comprises cement, pulverized fuel ash, river sand, limestone, water, a water reducing agent and palm fibers, wherein the content of the cement is 320-380kg / m<3>; the content of the pulverized fuel ash is 170-230kg / m<3>; the content of the river sand is 780-860kg / m<3>; the content of the limestone is 920-980kg / m<3>; the content of the palm fibers is 0.6-1.5kg / m<3>; the content of water is 175-240kg / m<3>; the content of the water reducing agent is 10-12.5kg / m<3>. By virtue of the adoption of the design, the palm fibers are doped into the existing the concrete, so that the compressive strength, the splitting tensile strength and the crack resistance of the concrete are effectively improved; the integrated performance of the concrete is improved; meanwhile, the high-crack-resistant palm fiber self-compacting concrete is low in cost and has good market prospect and good popularization value.

Owner:SHENZHEN UNIV

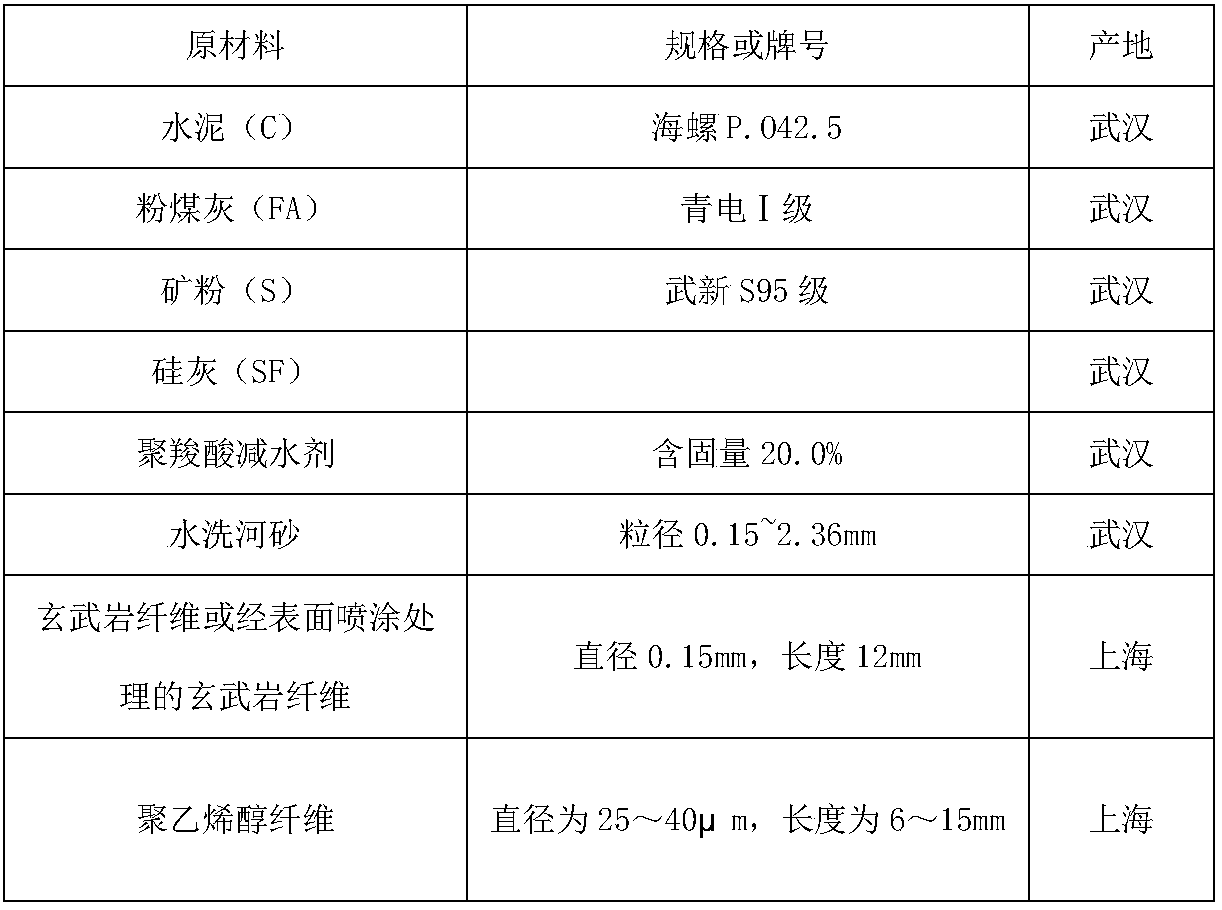

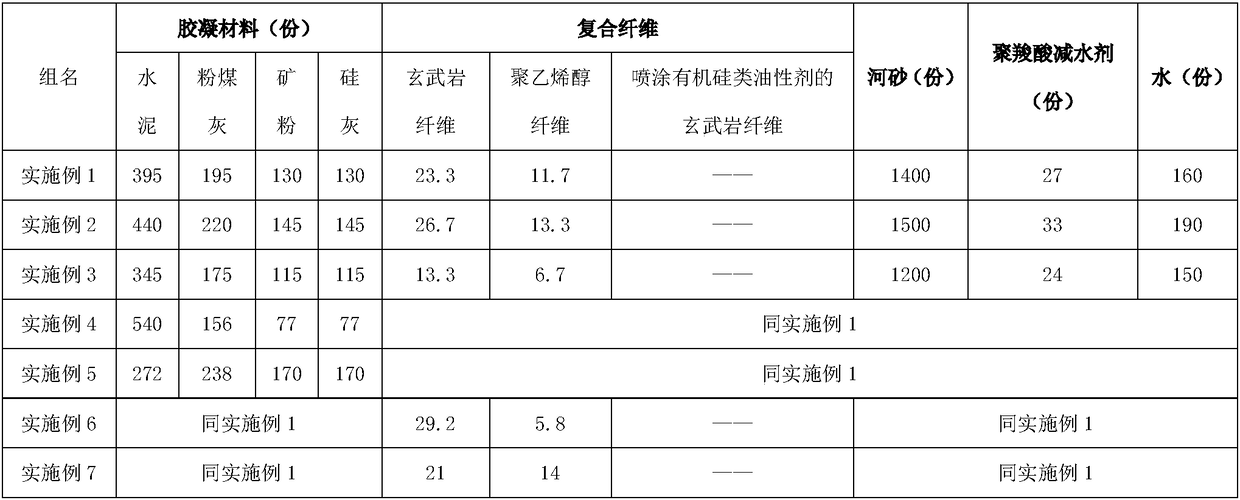

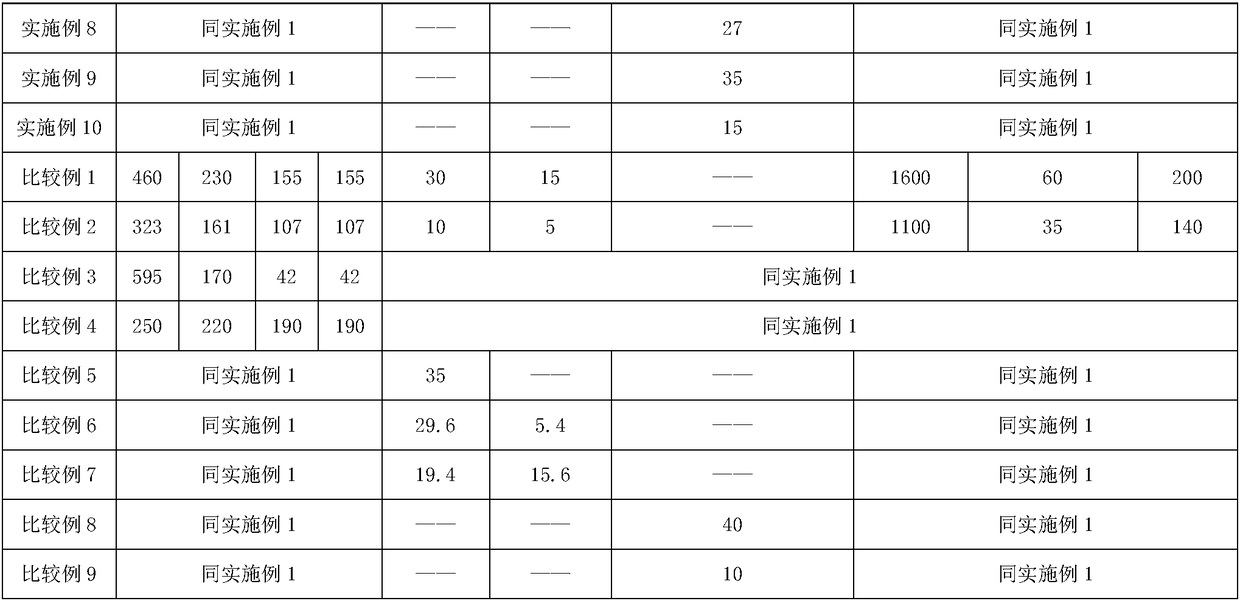

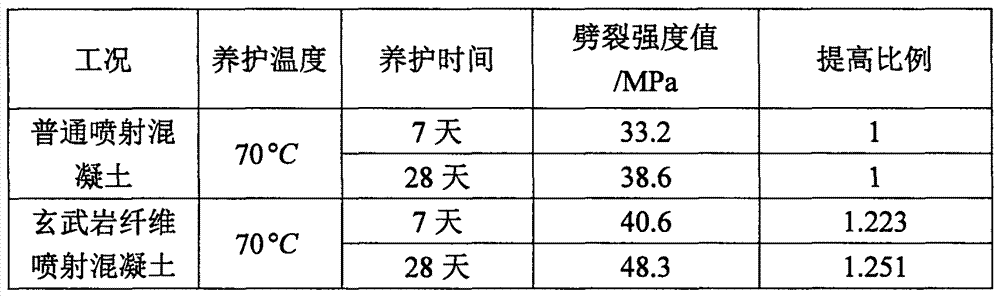

River-sand basalt-fiber active powder concrete and preparation method thereof

InactiveCN108059414AHigh compressive strengthIncreased splitting strengthWeather resistancePolyvinyl alcohol

The invention discloses river-sand basalt-fiber active powder concrete and a preparation method thereof. The river-sand basalt-fiber active powder concrete is prepared from the following components inparts by weight: 750 to 950 parts of cementing material, 1,200 to 1,500 parts of river sand, 40 to 55 parts of water reducer, 150 to 190 parts of water and 20 to 40 parts of composite fiber or 15 to35 parts of basalt fiber subjected to surface spraying treatment, wherein the cementing material is prepared from cement, pulverized fuel ash, mineral powder and silica fume, which are further in a weight ratio of (4 to 7) to (2 to 3.5) to (1 to 2.5) to (1 to 2.5); the composite fiber is prepared from a basalt fiber and a polyvinyl alcohol fiber; the basalt fiber subjected to the surface sprayingtreatment refers to a basalt fiber treated by using an organic silicon oiliness additive. The invention also provides the preparation method of the active powder concrete. A finished product is prepared through soaking the fiber, pre-homogenizing the cementing material, curing with water and thermally curing with steam. The finished product is obviously improved in main mechanical performance, hasfavorable corrosion resistance, high and low temperature resistance and weather resistance at the same, is stable in performance, is green and environmentally friendly, and is low in cost.

Owner:WUHAN YUANJING READY MIXED CONCRETE CO LTD

Reinforced C30 fly ash ceramsite concrete and preparation method thereof

The invention discloses reinforced C30 fly ash ceramsite concrete and a preparation method thereof. The concrete is prepared from cement, steel fibers, basalt fibers, nano SiO2, fly ash ceramsite, fine aggregate, a water reducing agent and water according to a required weight ratio. In the presence of the fly ash ceramsite and through the synergistic effect between the fly ash ceramsite and otherraw materials, the prepared concrete is low in mass and high in strength, and has excellent heat preservation and insulation performance, the structure is dense, and the strength, toughness and durability of the concrete are remarkably improved. Waste can be recycled, the concrete with the remarkably improved performance is obtained under the condition that a small quantity of additive exists, andgood application prospects are achieved.

Owner:ANYANG NORMAL UNIV

Preparation of slag polypropylene fiber concrete

InactiveCN101348356AImprove performanceImprove impact resistanceSolid waste managementSocial benefitsSlag

The invention discloses a method for preparing slag polypropylene fibre concrete. The sand and stones are mixed according to the mass ratio of 1:1.61, and cement, slag, polypropylene fibre, polyocarboxy acid superplasticizer and water are weighed up, wherein the cement content in concrete is between 0.17 to 0.32 percent; the slag content in concrete is between 0.17 to 0.32 percent; the polypropylene fibre is added according to the volume ratio of polypropylene fibre and concrete of between 0.2 to 0.6 percent; the adding quantity of the polyocarboxy acid superplasticizer is between 3.52 to 11.55ml / kg; the water content in concrete is between 0.17 and 0.22 percent; the concrete of the invention can be directly applied to concrete engineering in fields such as water conservancy, traffic and urban construction, etc., particularly the concrete structure engineering having requirements on tensile stress bearing, repeated dynamic load and anti-fatigue. Because a large amount of slag is added, the cement consumption is reduced, and the polyocarboxy acid superplasticizer is introduced in the preparation of the concrete, under the condition of reducing the manufacturing cost of concrete, the durability of concrete is improved, so that the application of the slag polypropylene fibre concrete can generate bigger economic and social benefits and more obvious ecological benefits.

Owner:NORTHWEST A & F UNIV

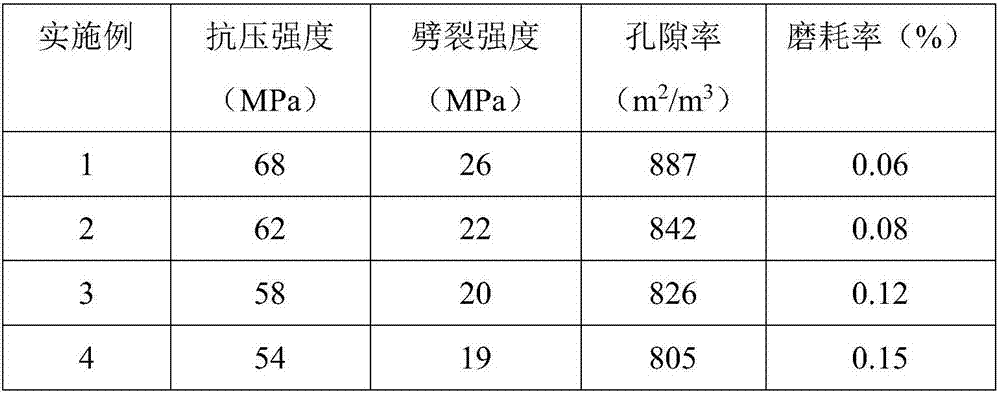

Strong-strength denitration catalyst and preparation method for same

InactiveCN107138152AHigh compressive strengthIncreased splitting strengthHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPolyesterFiber

The invention discloses a strong-strength denitration catalyst and a preparation method for the same. The denitration catalyst is prepared from the following raw materials in parts by weight: 80 to 100 parts of titanium dioxide, 20 to 35 parts of silicon dioxide, 8 to 16 parts of tungsten trioxide, 3 to 8 parts of vanadium pentoxide, 1 to 6 parts of expanded perlite, 2 to 7 parts of attapulgite, 1 to 3 parts of hollow glass beads and 1 to 3 parts of polyester fibers. The preparation method for the denitration catalyst comprises preparation of a catalyst substrate, impregnation and adsorption with mixed liquor, and drying and calcination. The denitration catalyst disclosed by the method is strong in compressive strength and cleavage strength, moderate in porosity, low in pulverization and cracking rate, high in catalytic efficiency and long in service life, the using amount is greatly reduced, a preparation process is simple and controllable, and the energy consumption is reduced.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

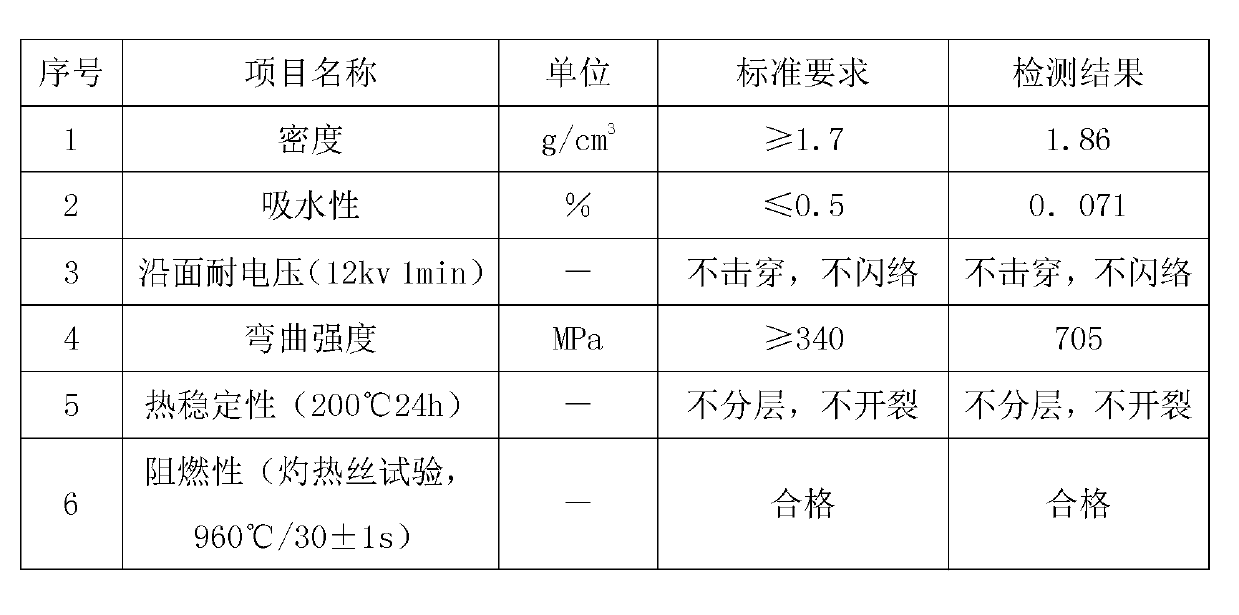

Glass fiber reinforcement polyester resin motor slot wedge and preparation method thereof

The invention discloses a glass fiber reinforcement polyester resin motor slot wedge which comprises the following raw materials, by weight, 10-15% of unsaturated polyester resin, 50-55% of twistless glass fiber roving, 15-20% of bamboo powder, 5-10% of modified limestone, 2-3% of aluminum hydroxide, 4-6% of yellow dextrin, 1-2% of hardening agent, 0.5-1.5% of internal releasing agent 352. The slot wedge prepared through the method has high mechanical strength and dielectric property, and good heat-resistant property and moisture-resistant property. Moreover, an insulation grade of the slot wedge is F, the resistant high temperature reaches 150 DEG C to 160 DEG C, high split-resistant strength maintained at the high temperature can reach over 900 MPa / 10mm, and operation requirements of motors are completely met.

Owner:YUEXI COUNTY SHUDA BAMBOO

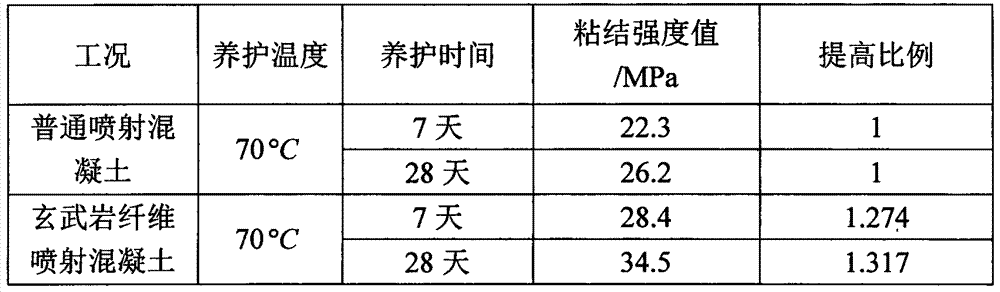

Basalt-fiber shotcrete for thermal-damage tunnel construction

The invention relates to a new type of shotcrete, that is, basalt fiber shotcrete, in which a certain amount of basalt fiber and fly ash are added on the basis of the original shotcrete, and is especially suitable for the construction of thermal damage tunnels. Make full use of the advantages of basalt fiber and concrete, improve the splitting strength and bonding strength of shotcrete, and realize the composite material design concept of "superimposition of performance and economic effect".

Owner:汪耀

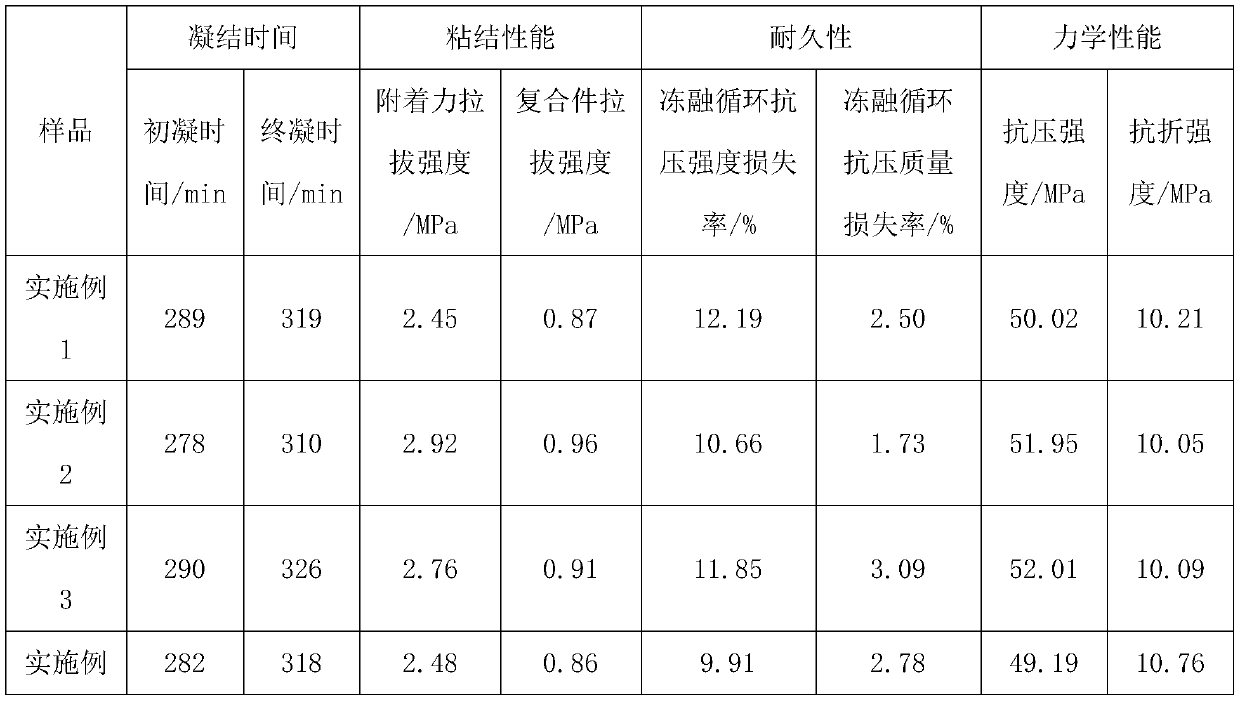

New and old pavement base splicing interface treatment material and preparation method thereof

The invention discloses a new and old pavement base splicing interface treatment material, belongs to the field of road engineering, and aims to provide a new and old pavement base splicing interfacetreatment material for highway reconstruction and extension engineering. The new and old pavement base splicing interface treatment material comprises, by weight, 50-100 parts of an organic silicon modified polyurethane emulsion, 1-3 parts of organic modified rectorite, 100-200 parts of cement, 0.5-1.5 parts of a water reducer, 20-50 parts of water and 0.5-2.5 parts of a composite retarder. The new and old pavement base splicing interface treatment material is used for solving the problems of existing base splicing interface materials, and has the advantages of simple preparation process, stable performances, high bonding strength and good splicing effect.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

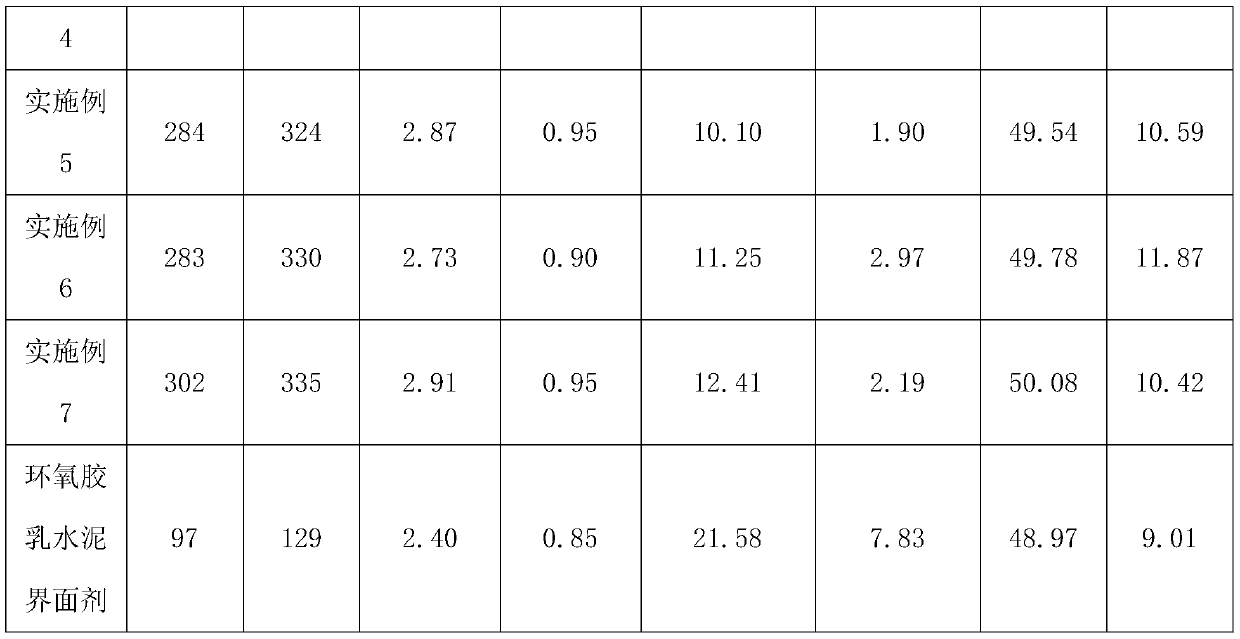

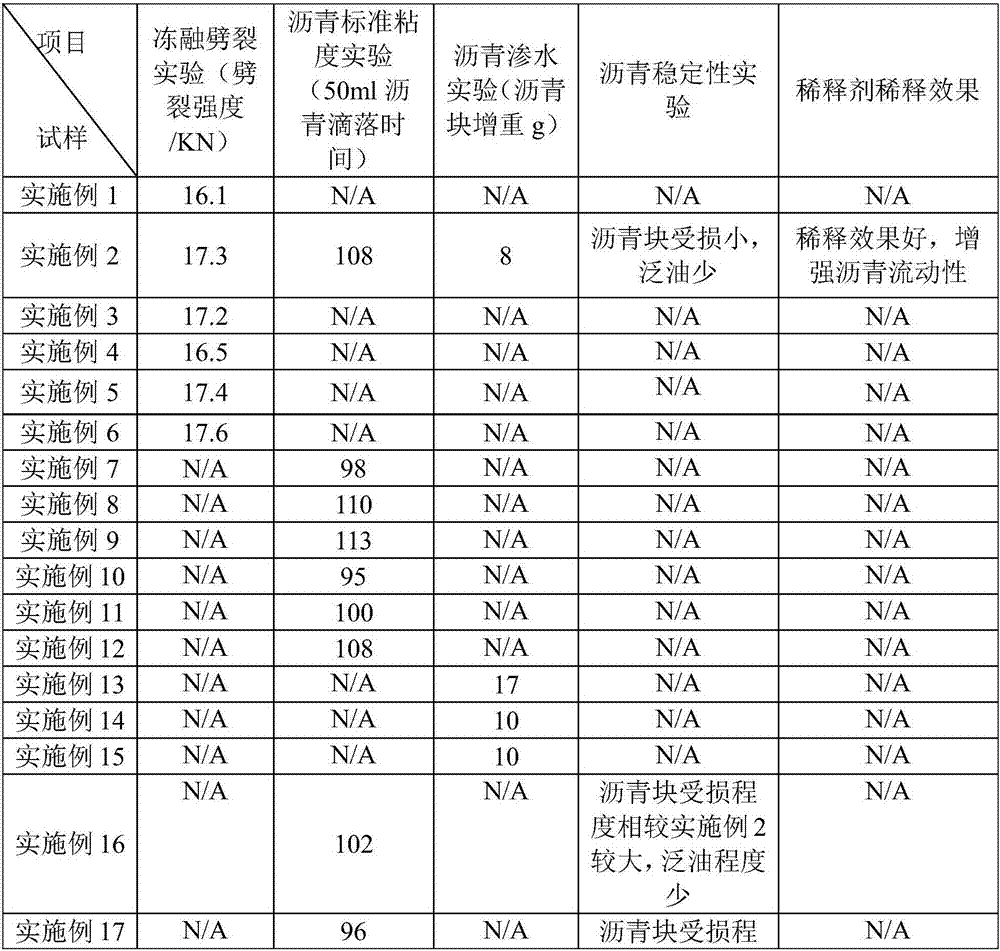

Antifreezing asphalt pavement

ActiveCN107244836AIncreased splitting strengthImprove frost resistanceIn situ pavingsDiluentRoad surface

The invention discloses an antifreezing asphalt pavement. The antifreezing asphalt pavement comprises a base layer and an asphalt pavement layer, wherein the asphalt pavement layer is prepared form materials in parts by mass: 60 to 83 parts of asphalt, 5 to 15 parts of polyurethane, 13 to 20 parts of resin, 18 to 40 parts of diluent, 0.8 to 2 parts of additive, 0.5 to 2 parts of polyimide / montmorillonoid nanocomposite and 0.1 to 0.7 part of stabilizer. The antifreezing asphalt pavement has the advantages of good antifreezing performance, more safety and prolonged service life.

Owner:南通市市政工程设计院有限责任公司

Bidirectional glass fiber drawing groove wedge and production method thereof

ActiveCN101552506AWith latitude and longitude two-way strengthHigh mechanical strengthWindingsGlass fiberFiber

The invention discloses a bidirectional glass fiber drawing groove wedge and the production method thereof. The bidirectional glass fiber drawing groove wedge is characterized in that: the finished product contains 52-64% of alkali free glass fiber packing, and 36-48% of cured resin. The production method comprise: preparing glue; impregnating alkali free glass fiber; cutting the shaped groove wedge and grinding head; washing and drying in air; performing surface treatment and drying in air; inspecting finished products; sorting and packaging. The invention is characterized in that: a glass fiber woven sleeve is disposed out of the alkali free glass fiber after the first impregnation before the second impregnation; and the alkali free glass fiber and the glass fiber woven sleeve after the second impregnation are moulded by pultruding. The bidirectional glass fiber drawing groove wedge has both longitudinal strength and latitudinal strength, and better thermal state performance; the production method includes two impregnations; and the glass fiber packing is combined by a plurality of structures; thereby, the solidification is more completely, and the solidified groove wedge has better integrity.

Owner:浙江博菲电气股份有限公司

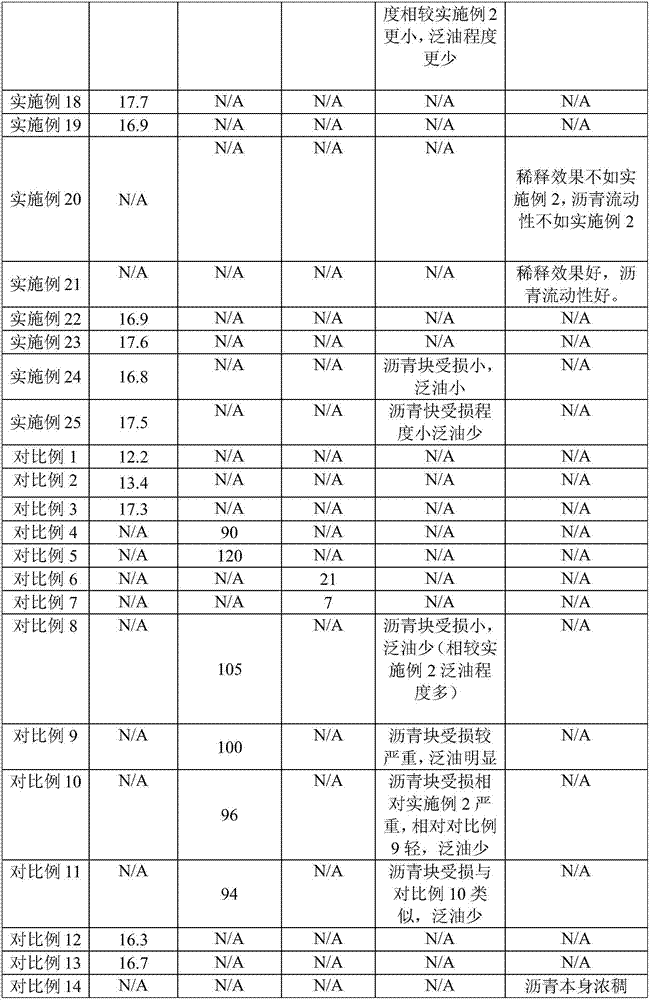

Composite material for preparing crack-free cement stabilized macadam and preparation method of composite material

The invention discloses a composite material for preparing crack-free cement stabilized macadam and a preparation method of the composite material, and belongs to the technical field of road buildingmaterials. The composite material comprises micro-expansion moisture-preserving anti-cracking mineral powder and anti-cracking fibers, and the weight ratio of the micro-expansion moisture-preserving anti-cracking mineral powder to the anti-cracking fibers is 100:(8-20). The preparation method comprises the following steps: 1) adding micro-expansion moisturizing anti-cracking mineral powder into astirrer; 2) adding anti-cracking fibers while stirring; and 3) conducting full stirring, bagging and packaging. Compared with an existing semi-rigid base layer, the invention effectively solves the problem of cracking of a semi-rigid base layer. The preparation method is simple, quality control is convenient, the anti-cracking capacity of the semi-rigid base layer can be effectively improved, cracks are avoided, and therefore the purposes of improving the durability of the semi-rigid base layer and an asphalt pavement and prolonging the service life of the pavement are achieved.

Owner:SOUTHEAST UNIV

Extraction slot wedge for high intensity glass fiber cloth

InactiveCN101826765AIncreased transverse mechanical strengthImprove mechanical propertiesWindingsManufacturing dynamo-electric machinesGlass fiberAlkali free

The invention provides an extraction slot wedge for high intensity glass fiber cloth, comprising the following compositions in percentage by weight: 32-34 percent of alkali-free glass cloth and alkali-free glass fibers and 66-68 percent of adhesive. Because the alkali-free glass cloth is introduced, the adhesive is improved and the transverse mechanical strength of the slot wedge is increased, the slot wedge has excellent mechanical property and solvent and chemical medicine resistance under high temperature and particularly keeps stronger split resistance under high temperature, wherein the split resistance can achieve above 3000N / 10mm. The invention can completely satisfy the running requirement of a motor.

Owner:浙江博菲电气股份有限公司

Magnetic motor slot wedge and preparation method thereof

InactiveCN108329670AImprove flexural strengthHigh permeabilityTert-butyl peroxybenzoateElectric generator

The invention relates to the technical field of motor, and in particular, relates to a magnetic motor slot wedge and a preparation method thereof. The invention provides the magnetic motor slot wedgecomprising the raw materials by the weight percentage: 16%-20% of unsaturated polyester resin, 0.2%-0.6% of an internal demoulding agent, 0.5%-0.9% of tert-butyl peroxybenzoate, 0.3%-0.6% of dibenzoylperoxide, 35%-43% of a reduced iron powder, 17%-23% of alkali-free glass fibers, 1.5%-3.5% of an iron-cobalt alloy powder, 3%-5% of an iron-silicon alloy powder and the like. The invention also provides the preparation method of the magnetic motor slot wedge. The prepared magnetic motor slot wedge has the characteristics of high magnetic conductivity, high splitting strength and high bending strength, can make the temperature rise and the noise reduce in operation of an electric generator, improves the efficiency and service life of a motor, and reduces the maintenance cost.

Owner:安徽省旌德县江南机电配件有限公司

Motor stator slot portion insulation structure

ActiveCN105245048ALower potentialIncreased splitting strengthWindings insulation shape/form/constructionSlot insulationInstability

The invention relates to a motor stator slot portion insulation structure. The structure comprises a stator core (1), the stator core (1) is provided with a stator slot (2), a coil (3) is disposed in the stator slot (2), a slot insulation structure (4) and a coil fixing structure (5) are disposed between the coil (3) and the stator slot (2), the slot insulation structure (4) comprises an insulation glue layer (41), a low-resistance paint layer (42),a rubber layer (43) and low-resistance cloth (44), and fixing materials used in the coil fixing structure (5) are 3241 semiconductor cushion strip. A practical application shows that a motor set adopting the stator slot portion structure runs well in a high-altitude area, set discharging, burnout and other accidents do not occur, set running safety can be effectively guaranteed, and the service life of the set is prolonged; and the whole insulation structure adopts homemade materials, economic cost is low, independent research, development and innovation of science and technology in our county are facilitated, and dependency and instability of imported foreign materials are reduced.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

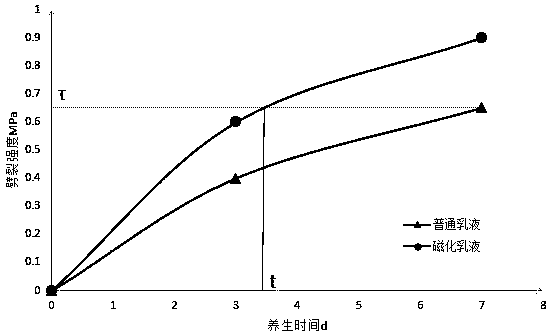

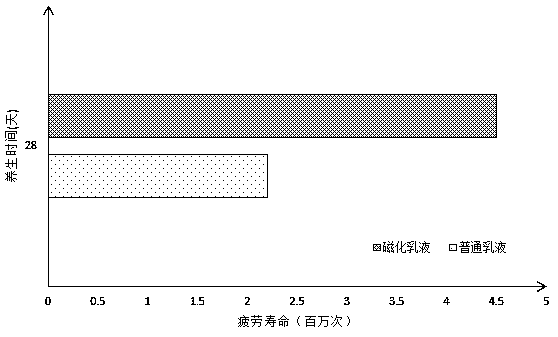

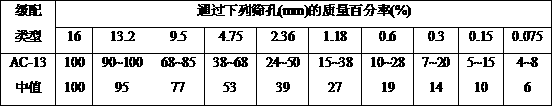

High-performance cement-emulsified asphalt mixture and preparation method thereof

InactiveCN111056771AImprove ease of constructionReduce the mixing water consumption of the mixtureMineralogyMining engineering

The invention belongs to the technical field of road engineering, and discloses a high-performance cement-emulsified asphalt mixture and a preparation method thereof. The high-performance cement-emulsified asphalt mixture comprises coarse aggregate, fine aggregate, emulsified asphalt, a mineral filler, an additive and water. The preparation method comprises the following steps: fully mixing waterfor mixing, the emulsified asphalt, the mineral aggregates, the filler and the additive in a mixing device, uniformly stirring, carrying out magnetization treatment on the obtained mixture through a magnetic field with a preset intensity according to a certain discharge rate, and carrying out paving molding through a paving machine. The asphalt mixture prepared by adopting the preparation method and the optimized material blending proportion shows excellent construction workability and pavement effect; and compared with a traditional cold-mixed asphalt mixture, the mixture of the invention hasthe following advantages: the strength forming time is short, the splitting strength of the mixture is obviously improved, and the fatigue life of the mixture is obviously prolonged.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

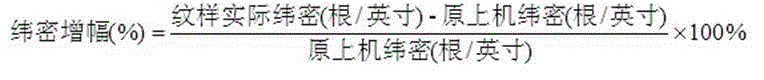

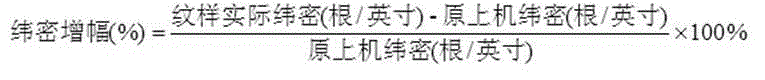

Method for improving sparse grain and dense grain of crammed clipped fabric and fabric woven through method

InactiveCN104153184AEliminate thin linesEasy to operateSevering textilesEngineeringVolumetric Mass Density

The invention discloses a method for improving sparse grain and dense grain of crammed clipped fabric and the fabric woven through the method. The amplification of the weft density of the pattern portion of the fabric is calculated, and weaving is carried out by adjusting the weft density according to the arrangement of ground weft and pattern weft. According to the method, under the condition of not changing original equipment, the effect of eliminating the sparse grain and the dense grain on the surface of the crammed clipped fabric is achieved by adjusting technological parameters, the operation is easy, the variety adaptability is good, and the method is suitable for the crammed clipped fabric of various pattern effects. The appearance quality of the fabric meets requirements, meanwhile, the internal quality of the fabric is improved by adjusting the weft density, and the splitting strength of the fabric is improved.

Owner:JIANGSU SHUNYUAN NEW MATERIAL TECH CO LTD

Road base mixture and preparation method thereof

PendingCN111574121AIncreased splitting strengthHigh strengthSolid waste managementHydration reactionSlag

The invention discloses a road base mixture. The road base mixture comprises the following components in parts by weight: 1-2 parts of cement; 2-10 parts of coal ash; 5-15 parts of furnace slag; 30-45parts of gravels; 0.5-1 part of silica fume; and 1-2 parts of excitant. In the road base mixture, the main components of the furnace slag are SiO2 and Al2O3; the main component of the silica fume isSiO2; the furnace slag and the silica fume can react with Ca (OH) 2 generated by hydration reaction of the cement, so that C-A-H and C-S-H gelling substances with stable chemical properties can be generated, so that the mixture has higher strength. On the premise of ensuring that various performance indexes meet the requirements, the utilization rate of the fly ash and the furnace slag is increased as much as possible, cement consumption is reduced, economic benefits are maximized, and various performance indexes are optimized. According to the road base mixture of the invention, the fly ash and the furnace slag are applied to road infrastructure construction, so that the pollution to the surrounding environment caused by accumulation of a large amount of industrial wastes is reduced, theconsumption of natural gravels can be reduced, and the purposes of changing wastes into valuables and realizing sustainable development are achieved.

Owner:NINGXIA UNIVERSITY +1

Concrete for road construction and preparation method of concrete

InactiveCN111574120AImprove stress resistanceExcellent quality control rateCement mixing apparatusPlant fibreArchitectural engineering

The invention relates to the technical field of concrete. The concrete for road construction is prepared from the following materials in parts by weight: 40 to 60 parts of cement; 30 to 40 parts of sand; 20 to 30 parts of mineral powder; 50 to 67 parts of stone; 18 to 32 parts of water; 1 to 3 parts of plant fiber; 0.5 to 2 parts of a water reducing agent; and 2.5 to 4 parts of montmorillonite. The concrete provided by the invention has the advantages of excellent compression resistance and high splitting strength.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com