Reinforced C30 fly ash ceramsite concrete and preparation method thereof

A technology of fly ash ceramsite and concrete, which is applied in the field of building materials, can solve the problems of poor crack resistance and durability, low compressive and tensile strength, uneven distribution of aggregates, etc., and achieve various performance improvements, thermal insulation Excellent thermal performance and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

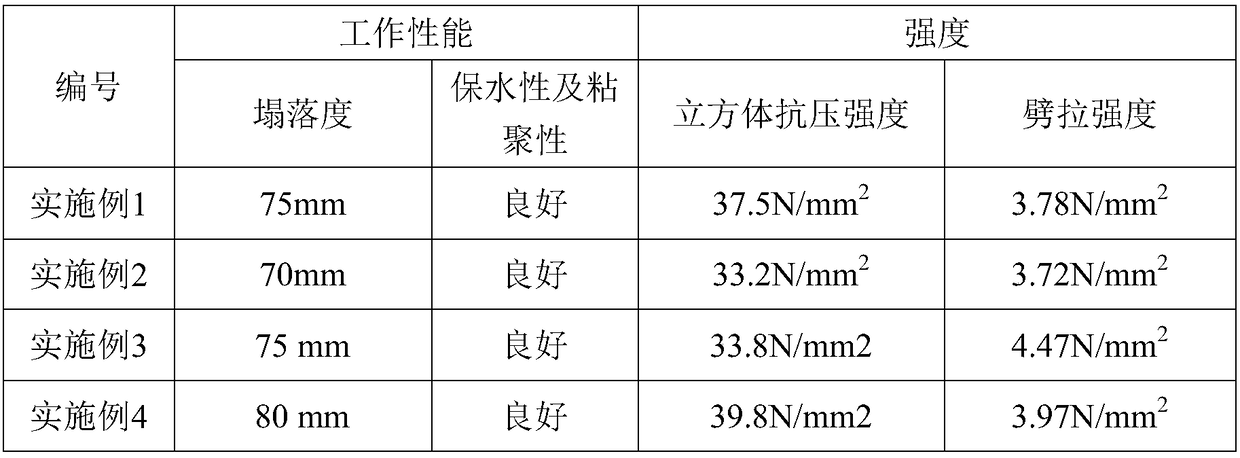

Examples

Embodiment 1

[0032] A reinforced C30 fly ash ceramsite concrete prepared from the following raw materials according to the required weight ratio, cement: steel fiber: basalt fiber: nano-SiO 2 : Fly ash ceramsite: Fine aggregate: Water: The mass ratio of water reducing agent is 1: 0.149: 0.003: 0.012: 0.733: 1.460: 0.476: 0.008.

[0033] Wherein the cement is P.O 42.5 ordinary Portland cement; the steel fiber is shear wave type, its diameter is 0.2-0.5mm, the length is 28-35mm, and the tensile strength of the steel fiber is ≥850N / mm 2 ; The length of the basalt fiber is 3-6 mm, the diameter of the monofilament is 12-16 μm, and the tensile strength is ≥ 4100 N / mm 2 ; The nano-SiO 2 It is white powder, with an average particle size of 30nm, an apparent density of 40-60g / L, a pH value of 5.0-7.0, and a loss on ignition ≤ 1% (mass fraction); wherein the impurity content is <0.5% (impurities account for The mass fraction of the total amount,);

[0034] The bulk density of fly ash ceramsite is...

Embodiment 2

[0039] A reinforced C30 fly ash ceramsite concrete prepared from the following raw materials according to the required weight ratio, cement: steel fiber: basalt fiber: nano-SiO 2 : Fly ash ceramsite: Fine aggregate: Water: The mass ratio of water reducing agent is 1: 0.130: 0.002: 0.010: 0.518: 1.277: 0.416: 0.007.

[0040] Wherein the cement is P.O 42.5 ordinary Portland cement; the steel fiber is shear wave type, its diameter is 0.2-0.5mm, the length is 28-35mm, and the tensile strength of the steel fiber is ≥850N / mm 2 ; The length of the basalt fiber is 3-6 mm, the diameter of the monofilament is 12-16 μm, and the tensile strength is ≥ 4100 N / mm 2 ; The nano-SiO 2 It is white powder, with an average particle size of 30nm, an apparent density of 40-60g / L, a pH value of 5.0-7.0, and a loss on ignition ≤ 1% (mass fraction); wherein the impurity content is <0.5% (impurities account for The mass fraction of the total amount,);

[0041] The bulk density of the fly ash ceramsit...

Embodiment 3

[0047] A reinforced C30 fly ash ceramsite concrete prepared from the following raw materials according to the required weight ratio, cement: steel fiber: basalt fiber: nano-SiO 2 : Fly ash ceramsite: Fine aggregate: Water: The mass ratio of water reducing agent is 1: 0.139: 0.002: 0.010: 0.684: 1.702: 0.444: 0.008.

[0048] Wherein the cement is P.O 42.5 ordinary Portland cement; the steel fiber is shear wave type, its diameter is 0.2-0.5mm, the length is 28-35mm, and the tensile strength of the steel fiber is ≥850N / mm 2 ; The length of the basalt fiber is 3-6 mm, the diameter of the monofilament is 12-16 μm, and the tensile strength is ≥ 4100 N / mm 2 ; The nano-SiO 2 It is white powder, with an average particle size of 30nm, an apparent density of 40-60g / L, a pH value of 5.0-7.0, and a loss on ignition ≤ 1% (mass fraction); wherein the impurity content is <0.5% (impurities account for The mass fraction of the total amount,);

[0049] The bulk density of fly ash ceramsite me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com