Waste sintered brick recycled C25 concrete and preparation method thereof

A technology for waste sintered bricks and concrete, applied in the field of construction engineering materials, can solve the problems affecting the resource utilization of waste sintered bricks, low strength grade of recycled concrete, and low aggregate density of waste sintered bricks, etc. The effect of improved performance and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

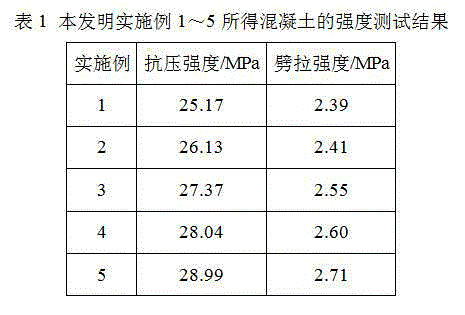

Examples

Embodiment 1

[0028] A recycled C25 concrete from waste fired bricks is prepared from cement, recycled coarse aggregate from waste fired bricks, fine aggregate, and water at a mass ratio of 1:1.96:1.15:0.46.

[0029] Described cement is P.O 42.5 ordinary portland cement.

[0030] The bulk density of the waste sintered brick regenerated coarse aggregate is 1609 kg / m 3 , the crushing index is 31.6%, the water absorption rate is 29%, and the particle size is d 1 Mass distribution: 5 mm≤d 1 ≤10mm is 25%, 10mm1 ≤16mm is 30%, 16mm1 ≤20 mm is 25%, 20 mm1 ≤25mm is 20%.

[0031] The fine aggregate is river sand with an apparent density of 2536 kg / m 3 , moisture content 3%, particle size d 2 Range: 0.15 mm~2.36 mm, particle size distribution: 0.15 mm≤d 2 ≤0.3 mm is 10%, 0.3 mm2 ≤0.6 mm is 30%, 0.6 mm2 ≤1.18mm is 30%, 1.18mm2 ≤2.36mm is 30%.

[0032] According to GB / T50080-2002 "General Concrete Mixture Performance Test Method Standard" to test the working performance of the waste fired brick ag...

Embodiment 2

[0034] A recycled C25 concrete from waste fired bricks is prepared from cement, recycled coarse aggregate from waste fired bricks, fine aggregate, and water at a mass ratio of 1:1.91:1.17:0.45.

[0035] Described cement is P.O 42.5 ordinary portland cement.

[0036] The bulk density of the waste sintered brick regenerated coarse aggregate is 1623 kg / m 3 , the crushing index is 30.7%, the water absorption rate is 27%, and the particle size is d 1 Mass distribution: 5 mm≤d 1 ≤10mm is 25%, 10mm1 ≤16mm is 35%, 16mm1 ≤20 mm is 20%, 20 mm1 ≤25mm is 20%.

[0037] The fine aggregate is machine-made sand with an apparent density of 2591kg / m 3 , moisture content 3.3%, particle size d 2The range is: 0.15 mm to 2.36 mm, and the particle size and mass distribution is: 0.15 mm≤d 2 ≤0.3 mm is 20%, 0.3 mm2 ≤0.6 mm is 20%, 0.6 mm2 ≤1.18mm is 30%, 1.18mm2 ≤2.36mm is 30%.

[0038] According to GB / T50080-2002 "General Concrete Mixture Performance Test Method Standard" to test the working pe...

Embodiment 3

[0040] A recycled C25 concrete from waste fired bricks is prepared from cement, recycled coarse aggregate from waste fired bricks, fine aggregate, and water at a mass ratio of 1:1.85:1.19:0.44.

[0041] Described cement is P.O 42.5 ordinary Portland cement.

[0042] The bulk density of the waste sintered brick regenerated coarse aggregate is 1645kg / m 3 , the crushing index is 29%, the water absorption rate is 27%, and the particle size is d 1 Mass distribution: 5 mm≤d 1 ≤10mm is 20%, 10mm1 ≤16mm is 40%, 16mm1 ≤20 mm is 20%, 20 mm1 ≤25mm is 20%.

[0043] The fine aggregate is river sand with an apparent density of 2611 kg / m 3 , moisture content 3.9%, particle size d 2 The range is: 0.15 mm to 2.36 mm, and the particle size and mass distribution is: 0.15 mm≤d 2 ≤0.3 mm is 20%, 0.3 mm2 ≤0.6 mm is 25%, 0.6 mm2 ≤1.18mm is 25%, 1.18mm2 ≤2.36mm is 30%.

[0044] According to GB / T50080-2002 "General Concrete Mixture Performance Test Method Standard", the working performance of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com