Method for producing metallurgical-grade aluminum oxide by coal ash

A technology for the production of metallurgy and fly ash, applied in the direction of alumina/aluminum hydroxide, solid waste removal, etc. The effect of large consumption, many process links and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

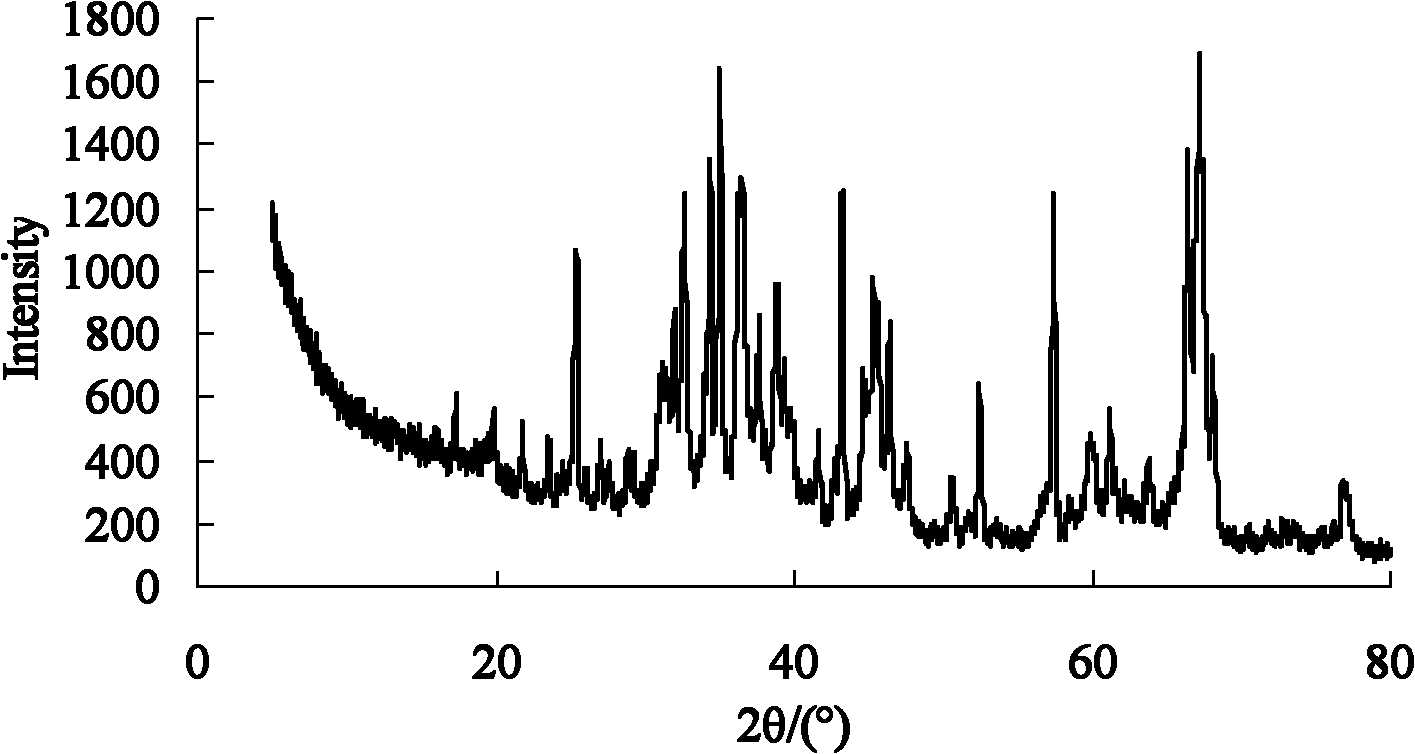

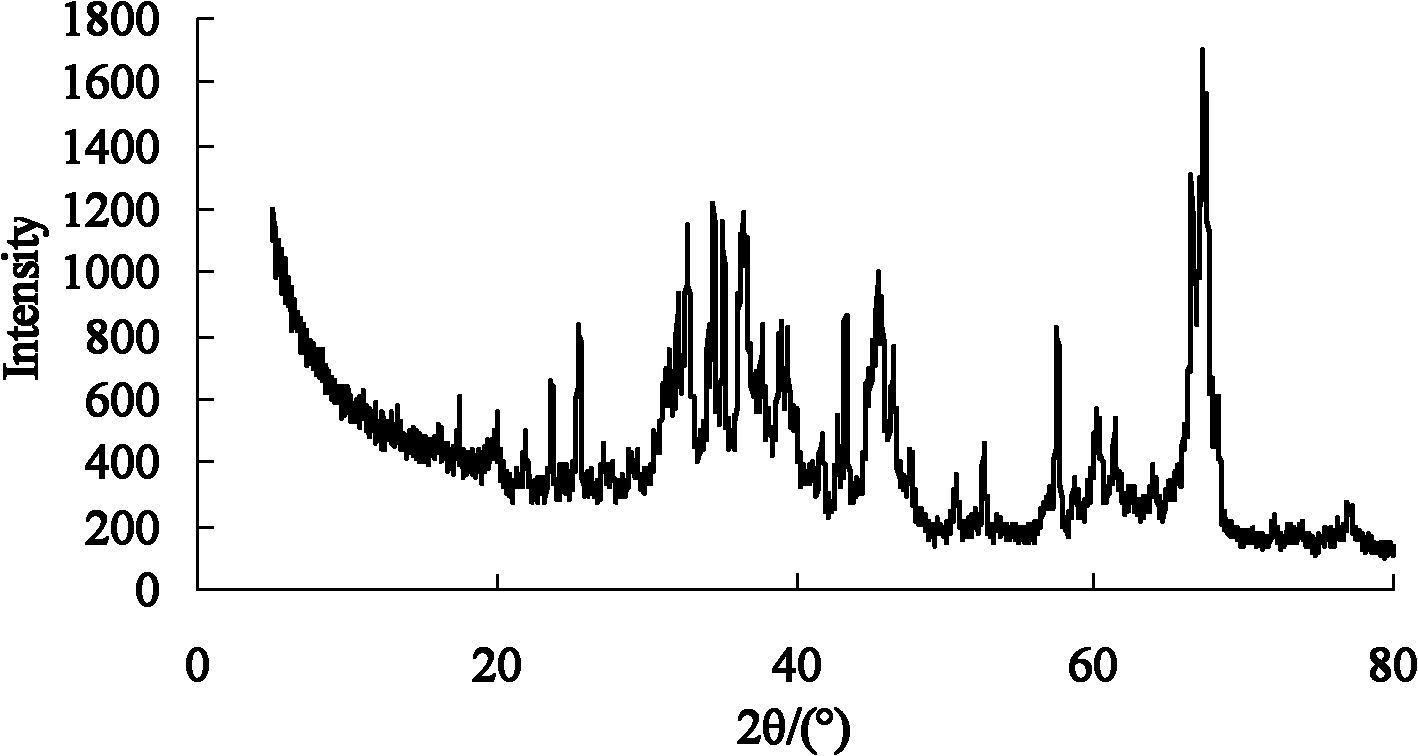

Image

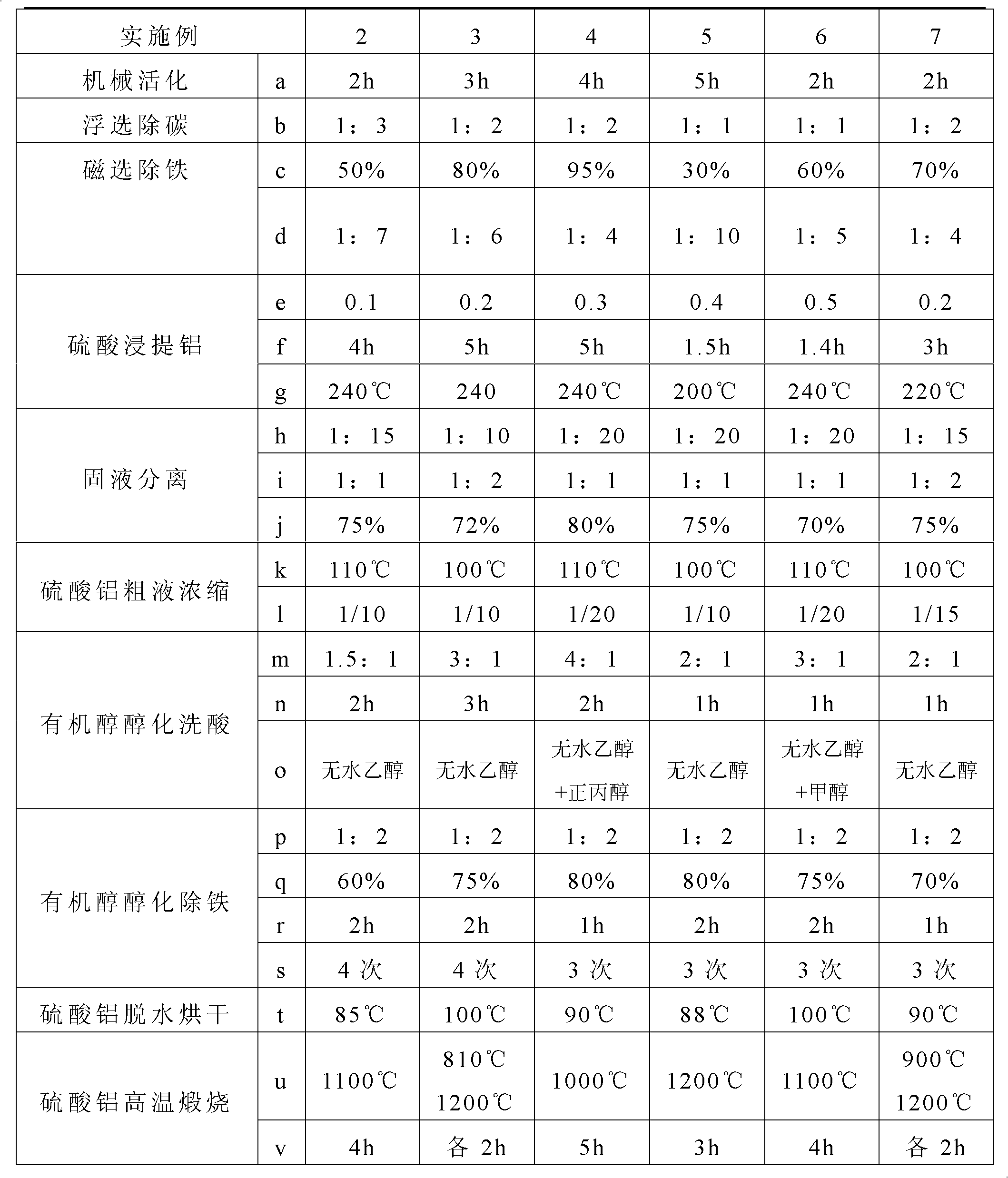

Examples

Embodiment 1

[0046] Embodiment 1: The object of implementation is raw material 1

[0047] (1) Mill the fly ash in a ball mill for 1 hour to perform mechanical activation;

[0048] (2) Add water according to the mass ratio of fly ash and water as 1:3, fully stir, and remove unburned black through flotation;

[0049] (3) remove iron oxide through magnetic separation;

[0050] (4) be made into the mixed solution that the sulfuric acid mass concentration is 40% by the fly ash raffinate and the vitriol oil after flotation carbon, magnetic separation iron, the solid-liquid ratio of control fly ash and mixed solution is 1: 8 ( Mass ratio), heat and pressurize (pressure 0.1MPa) reaction for 3h in the acid-resistant reaction equipment, the maximum temperature of the reaction is 240°C;

[0051] (5) After the reaction cools down, add water according to the mass ratio of fly ash and water as 1: 10, after heating and boiling, suction filter to obtain the filter cake, and wash with water with a mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com