Alcoholization removing method of impurity iron in aluminum sulfate solution

A technology of aluminum sulfate and low-iron aluminum sulfate, applied in the direction of aluminum sulfate, aluminum sulfur compounds, etc., can solve the problems of harsh operating conditions, complicated process, high energy consumption, etc., and achieve the effect of low cost, simple operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

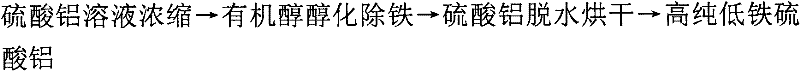

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the aluminum sulfate solution that will contain sulfuric acid with sulfuric acid leaching fly ash is evaporated and concentrated at 100 ℃ to become the aluminum sulfate concentrated solution that concentration is 40%, cooling, according to the volume ratio of ethanol and aluminum sulfate concentrated solution is 1: 1 Add absolute ethanol, stir thoroughly for 2 hours, and obtain an aluminum sulfate filter cake after filtering; according to the mass ratio of aluminum sulfate filter cake and water as 1:2, add water to dissolve the filter cake, continue to add ethanol, and control the volume of ethanol in the mixed solution system The fraction is 50%, stir well for 2 hours, dissolve the ferric sulfate in it, and precipitate aluminum sulfate, and obtain aluminum sulfate filter cake after filtration. Repeat the above-mentioned alcoholization and iron removal process 3 times to remove iron impurities to the maximum extent, and finally obtain a low-iron aluminum su...

Embodiment 2

[0028] Embodiment 2: the aluminum sulfate solution containing sulfuric acid that will be leached bauxite with sulfuric acid is evaporated and concentrated at 110 ℃ to become the aluminum sulfate concentrated solution that concentration is 50%, cooling, according to the volume ratio of ethanol and aluminum sulfate concentrated solution is 1.5: 1 Add absolute ethanol, stir thoroughly for 2 hours, and obtain an aluminum sulfate filter cake after filtering; according to the mass ratio of aluminum sulfate filter cake and water as 1:2, add water to dissolve the filter cake, continue to add ethanol, and control the volume of ethanol in the mixed solution system The fraction is 60%, stir well for 2 hours, dissolve the ferric sulfate, and precipitate aluminum sulfate, and filter to obtain aluminum sulfate filter cake. Repeat the above-mentioned alcoholization and iron removal process 4 times to remove iron impurities to the maximum extent, and finally obtain a low-iron aluminum sulfate ...

Embodiment 3

[0030] Embodiment 3: the aluminum sulfate solution containing sulfuric acid that will be leached coal gangue with sulfuric acid is evaporated and concentrated at 100 ℃ to become the aluminum sulfate concentrated solution that concentration is 45%, cooling, according to the volume ratio of ethanol and aluminum sulfate concentrated solution is 3: 1 Add absolute ethanol, stir thoroughly for 3 hours, and filter to obtain an aluminum sulfate filter cake; according to the mass ratio of aluminum sulfate filter cake and water as 1:2, add water to dissolve the filter cake, continue to add ethanol, and control the volume fraction of ethanol in the mixed solution system 75%, fully stirred for 2 hours, dissolved the ferric sulfate, and precipitated aluminum sulfate, filtered to obtain aluminum sulfate filter cake. Repeat the above-mentioned alcoholization and iron removal process 4 times to remove iron impurities to the maximum extent, and finally obtain a low-iron aluminum sulfate filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com