Patents

Literature

523results about "Aluminium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

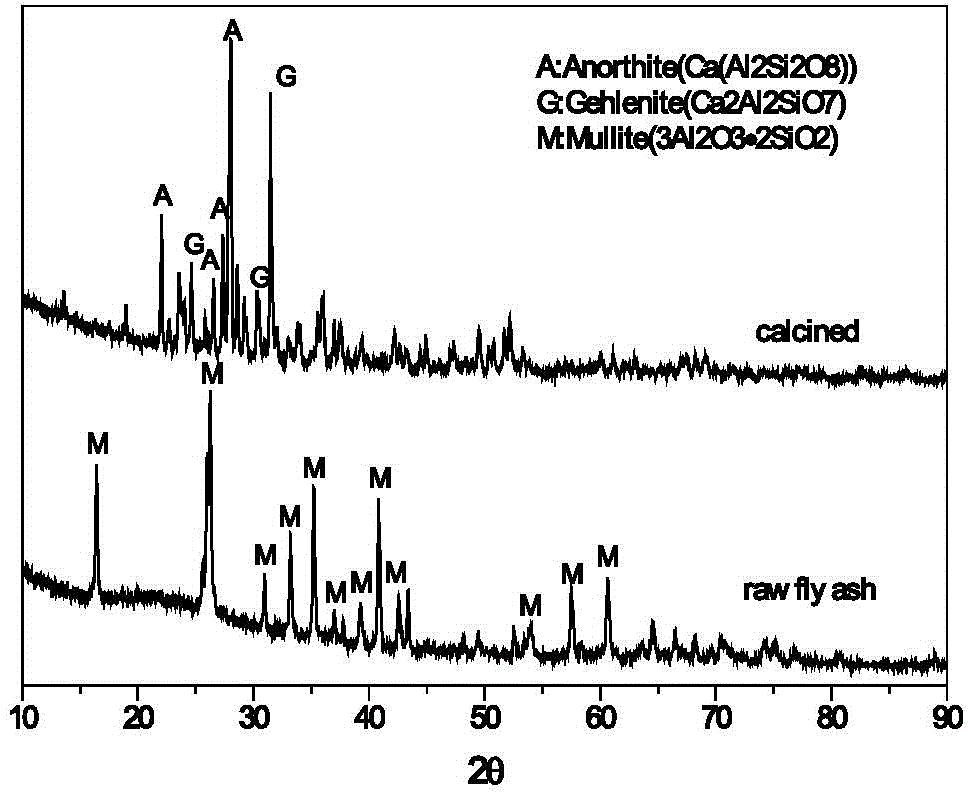

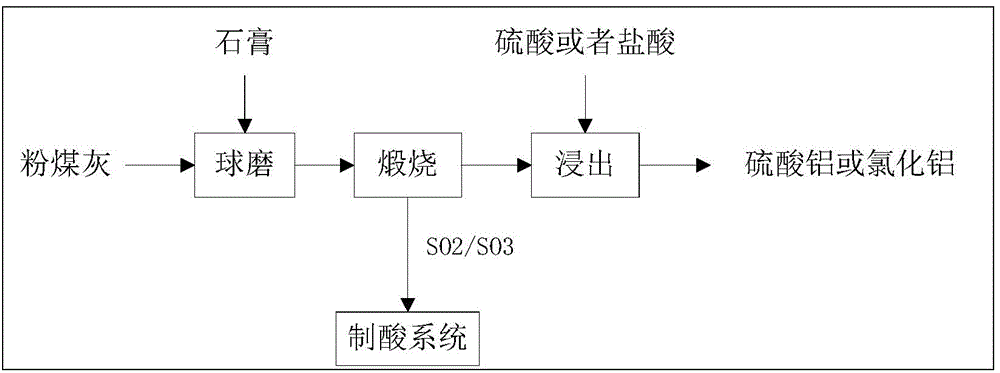

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

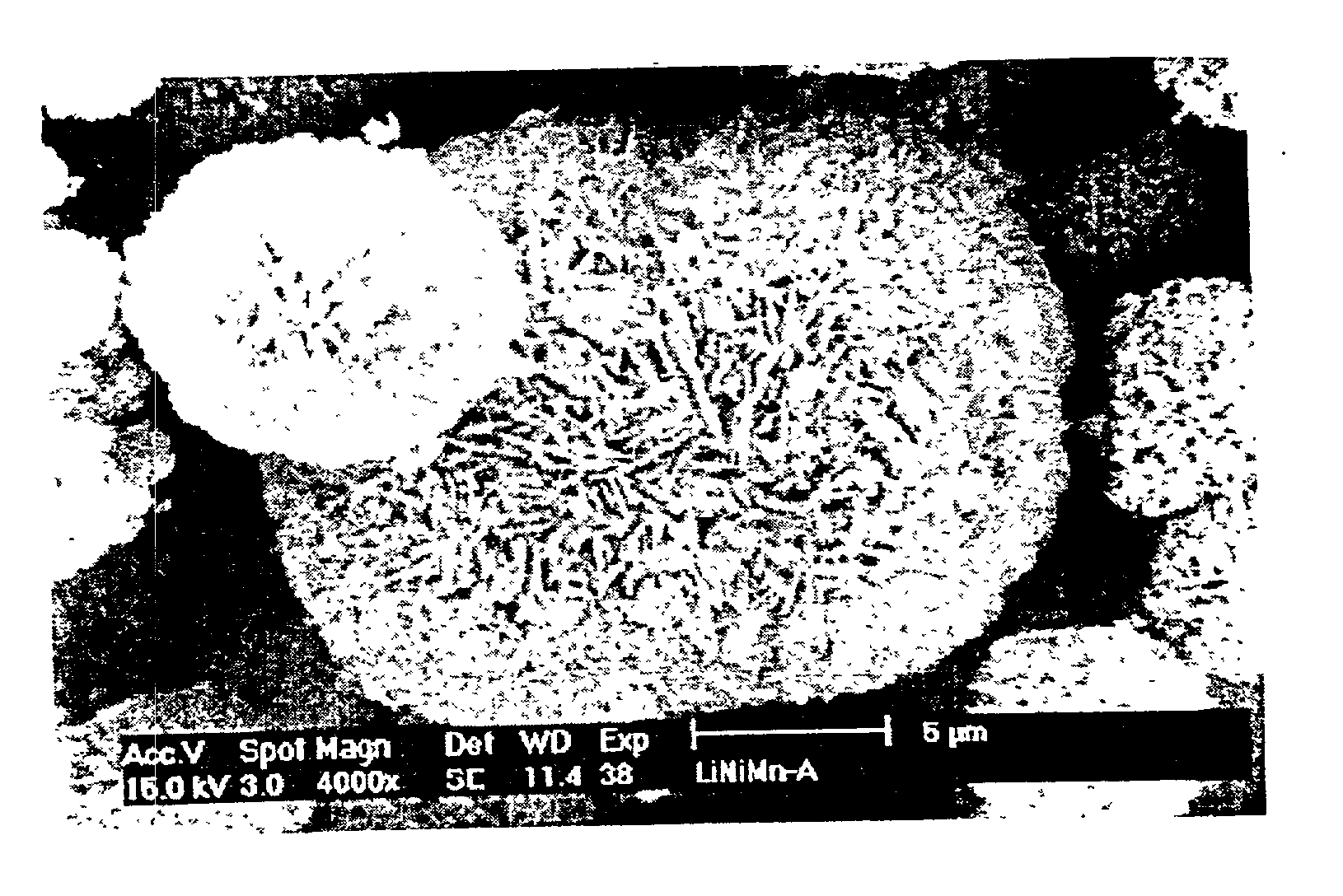

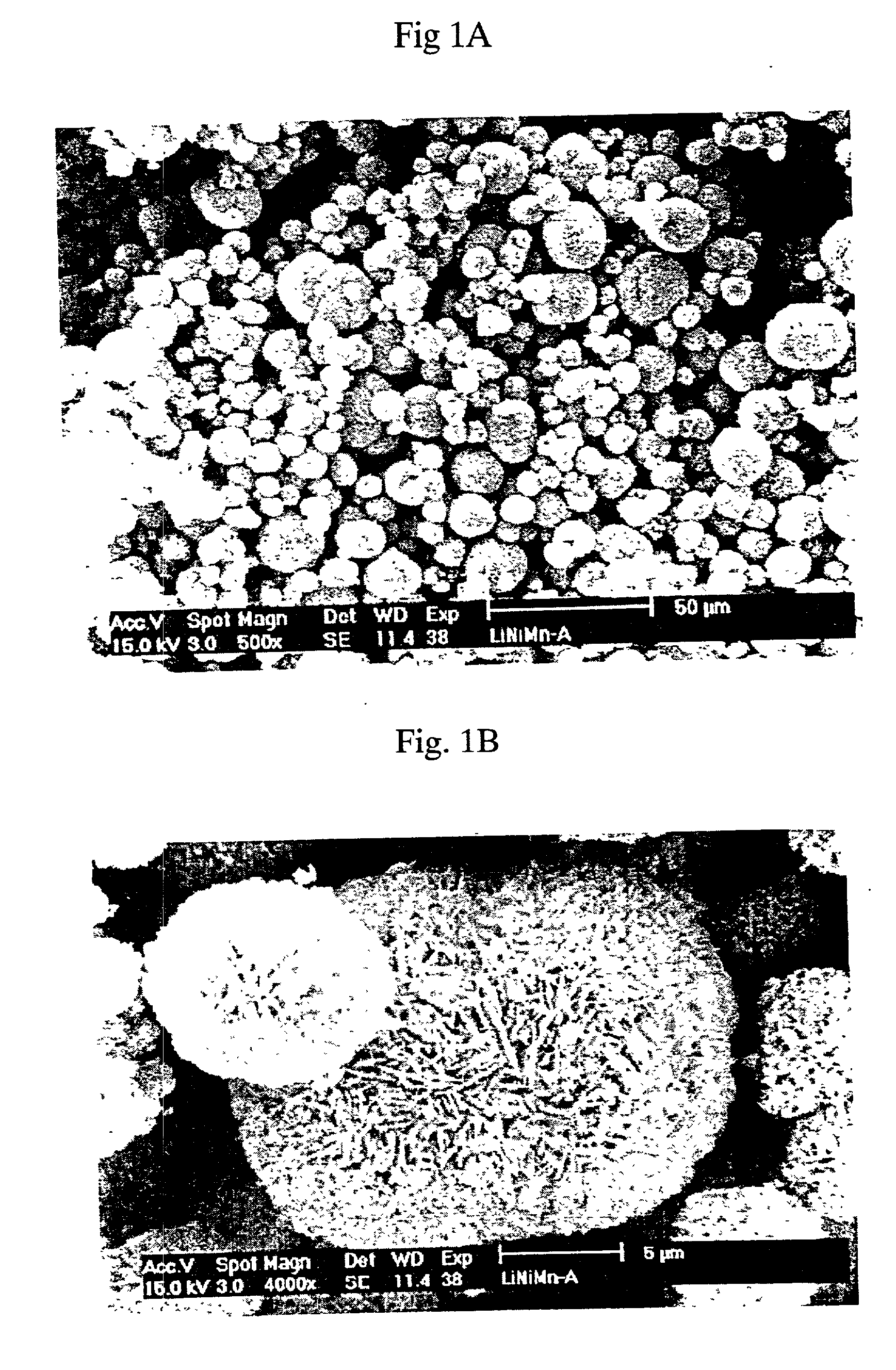

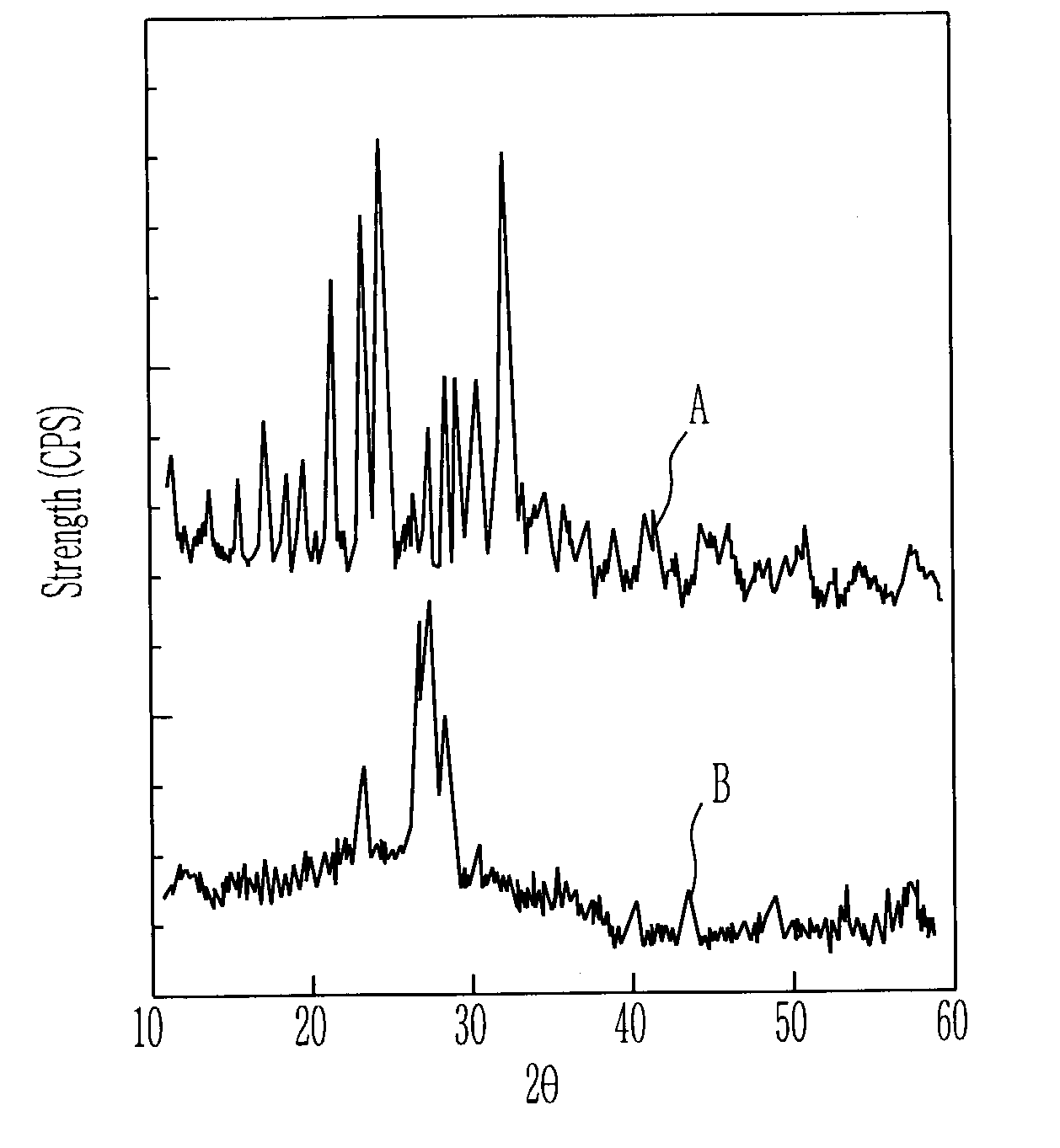

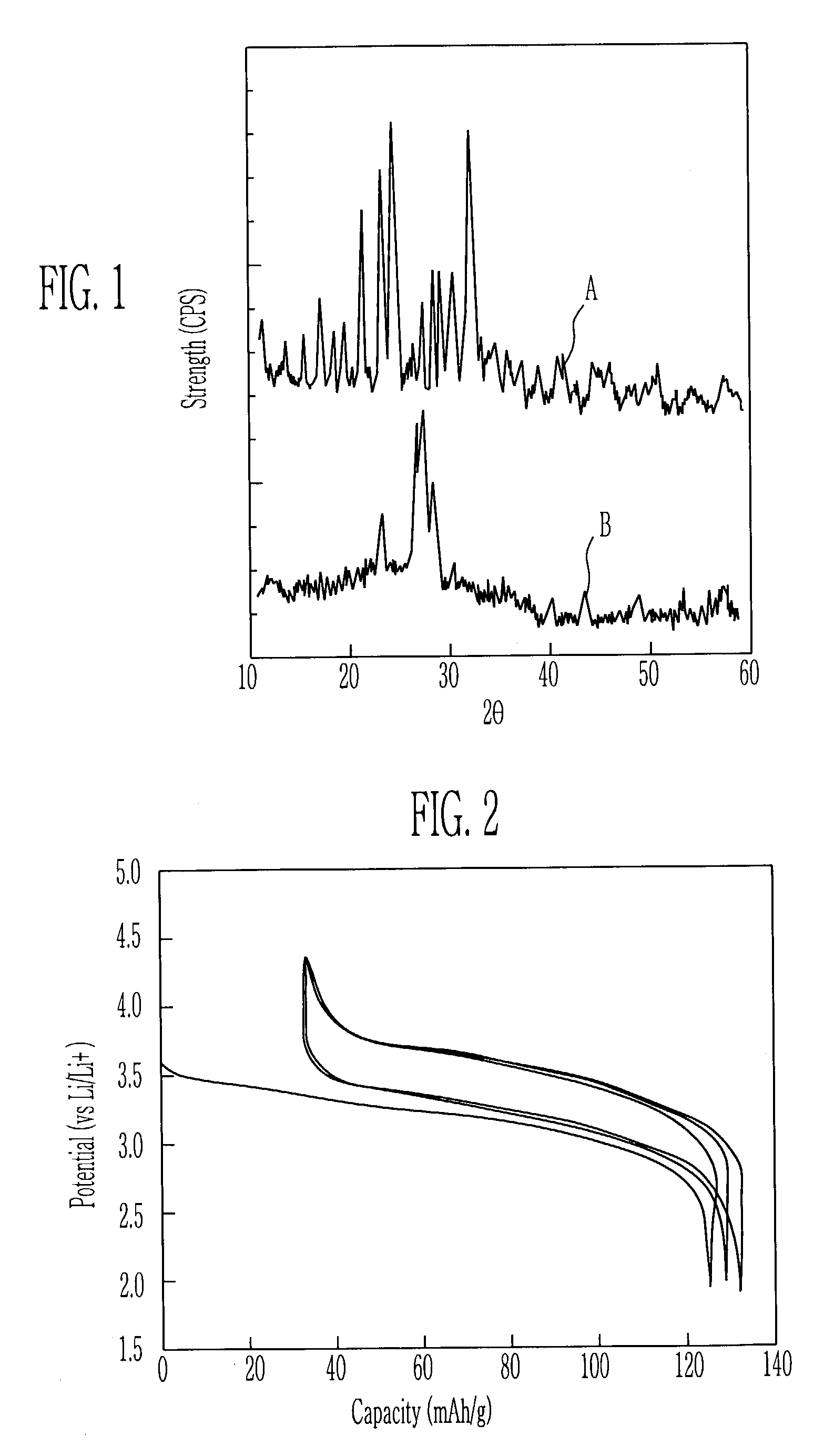

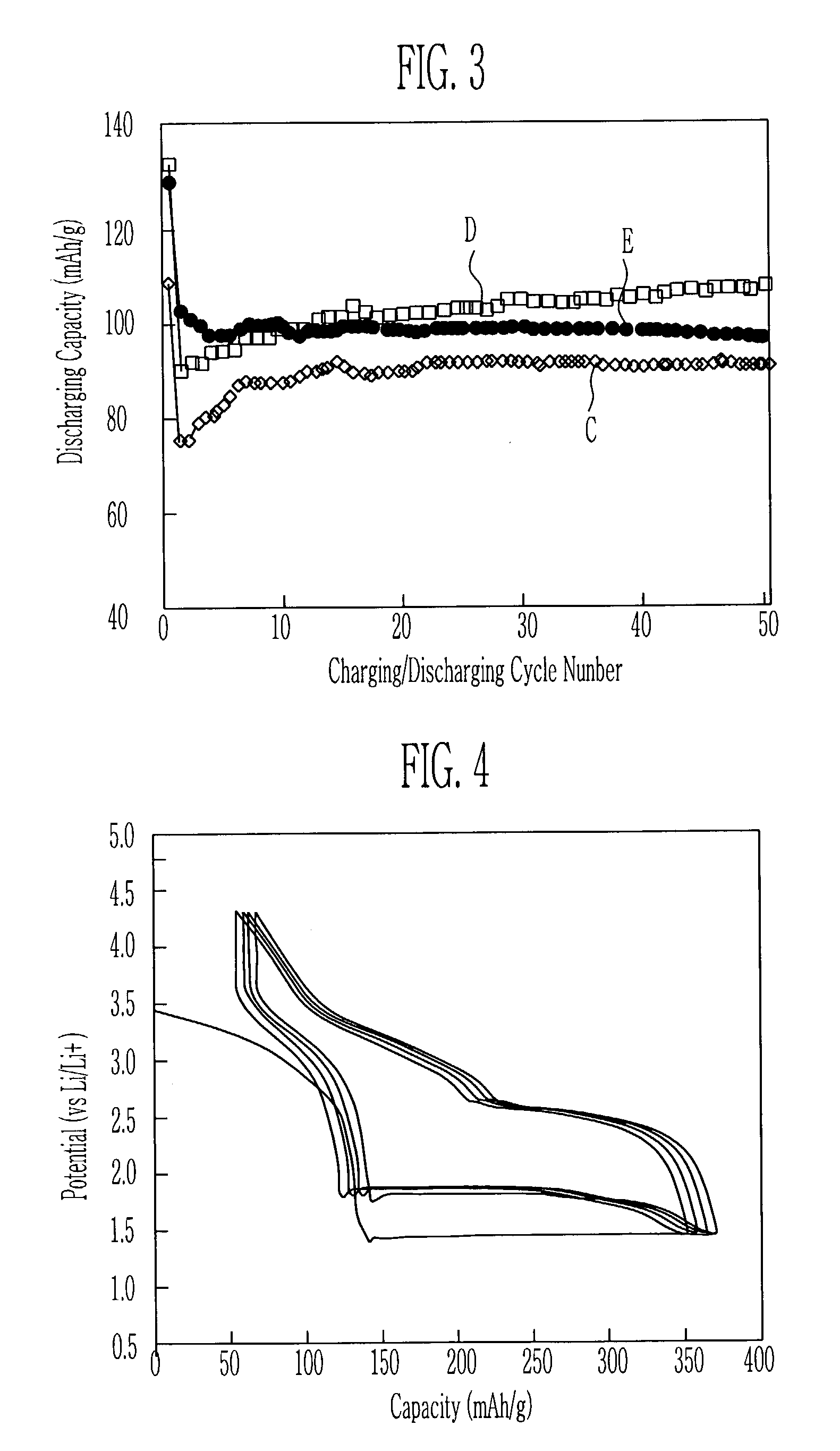

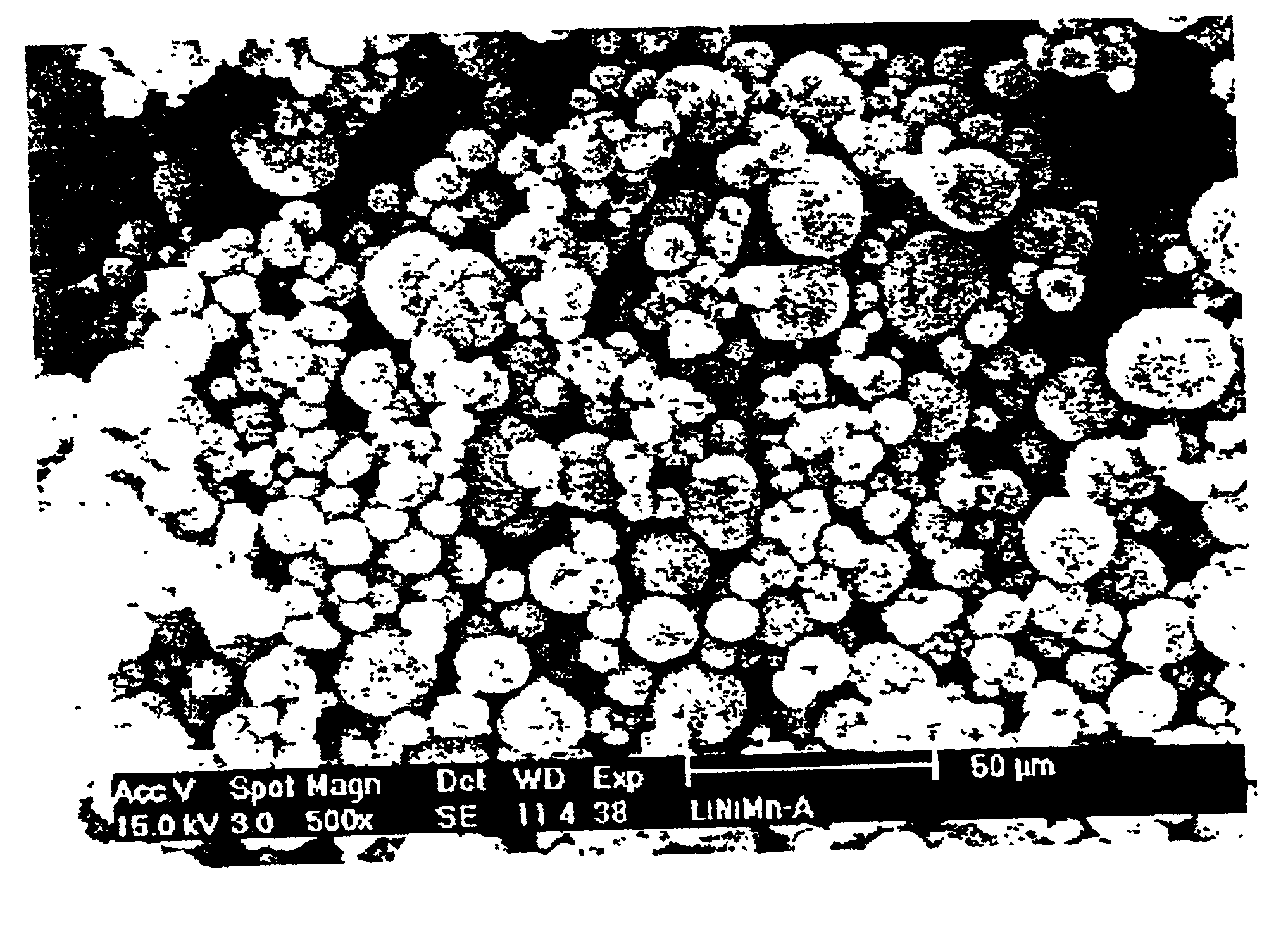

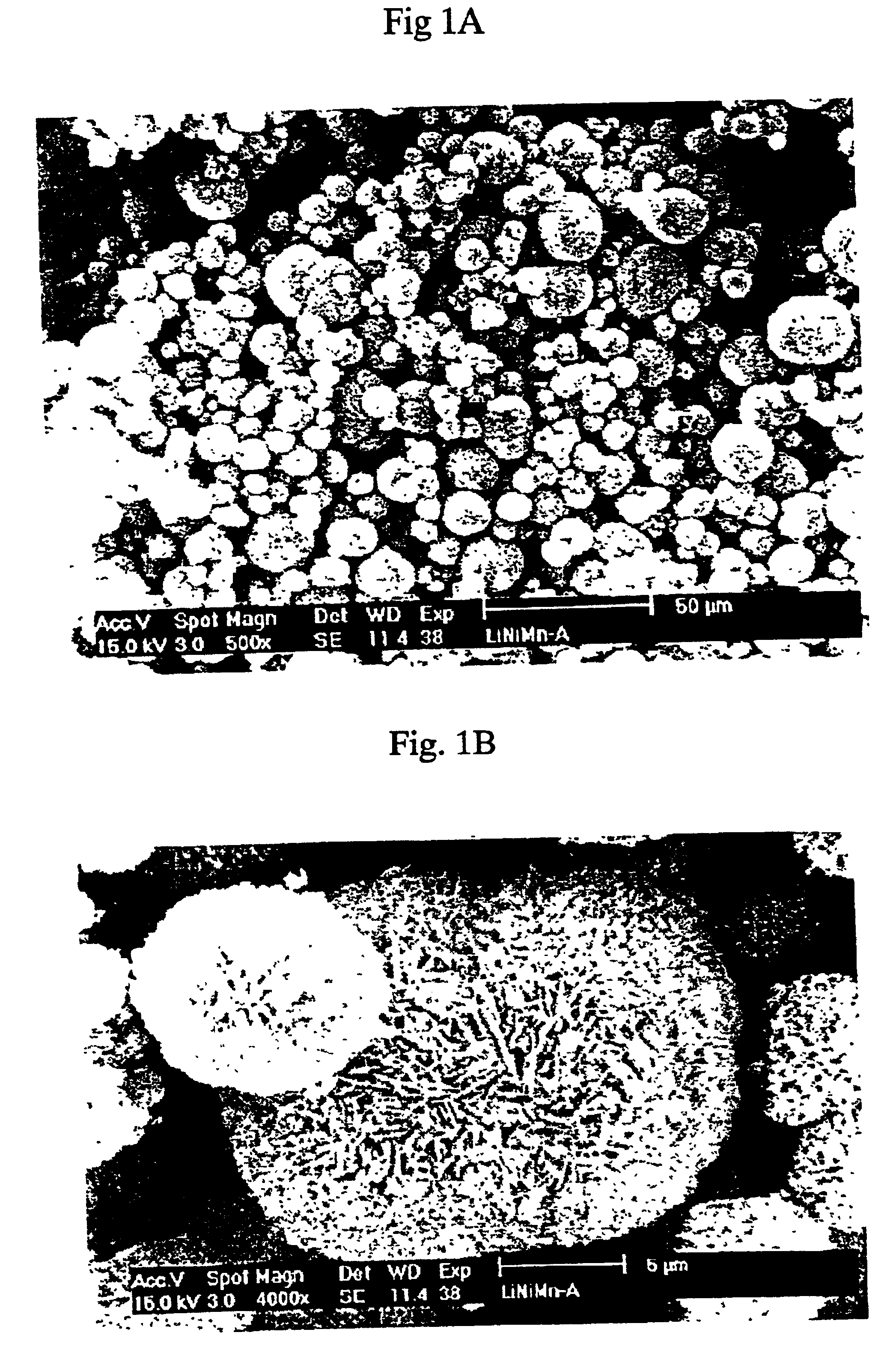

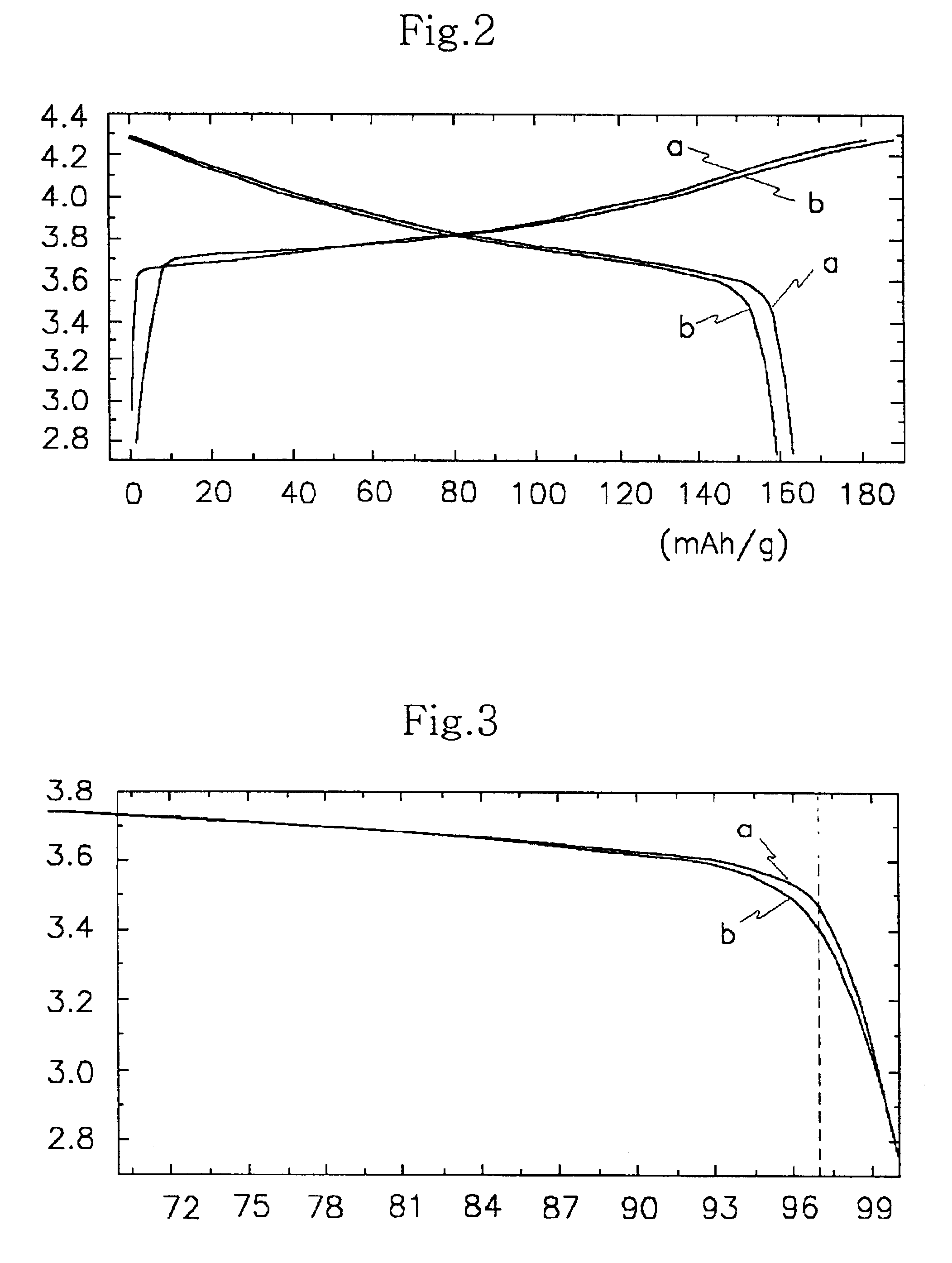

Positive active material for rechargeable lithium battery and method of preparing same

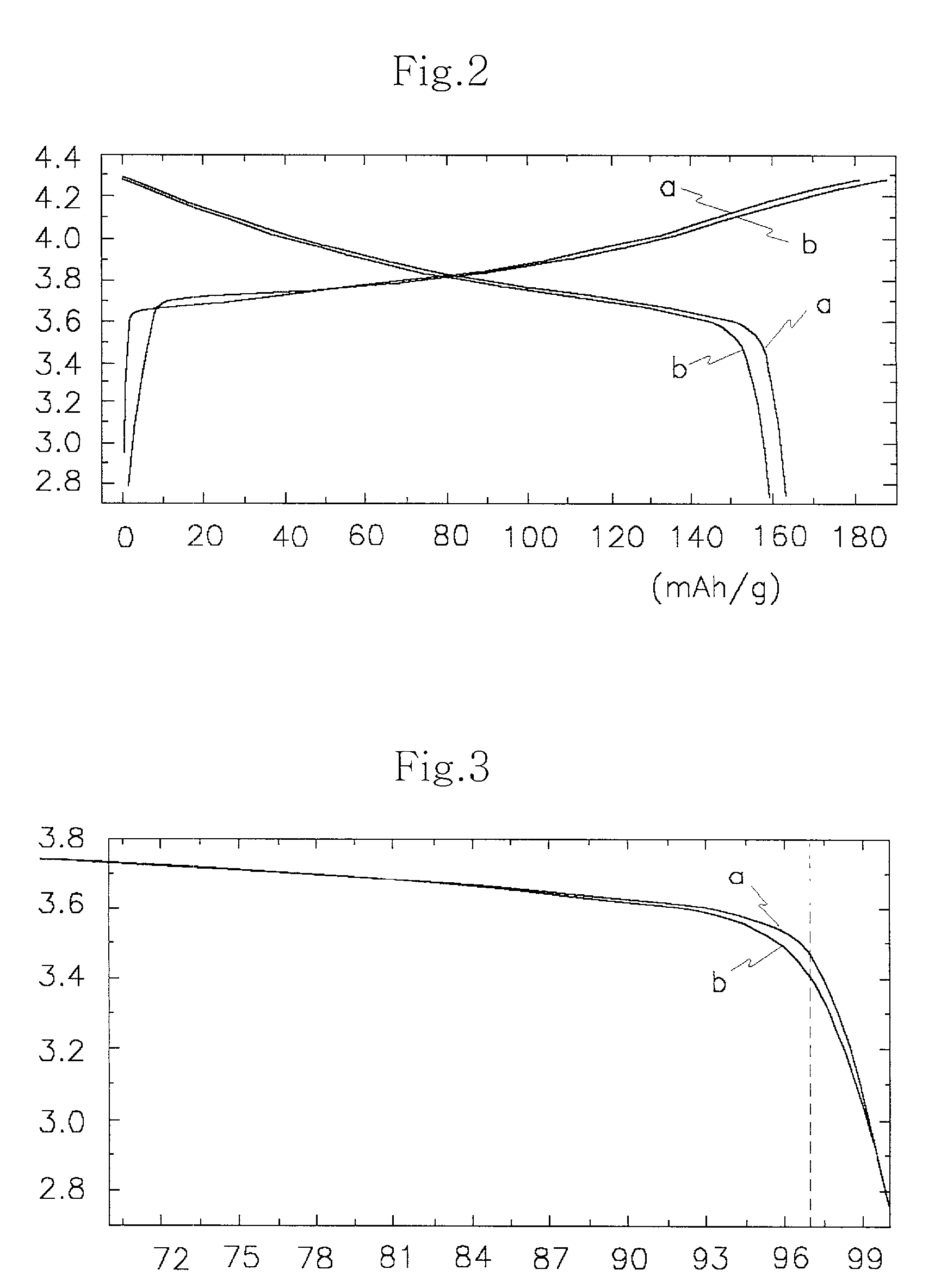

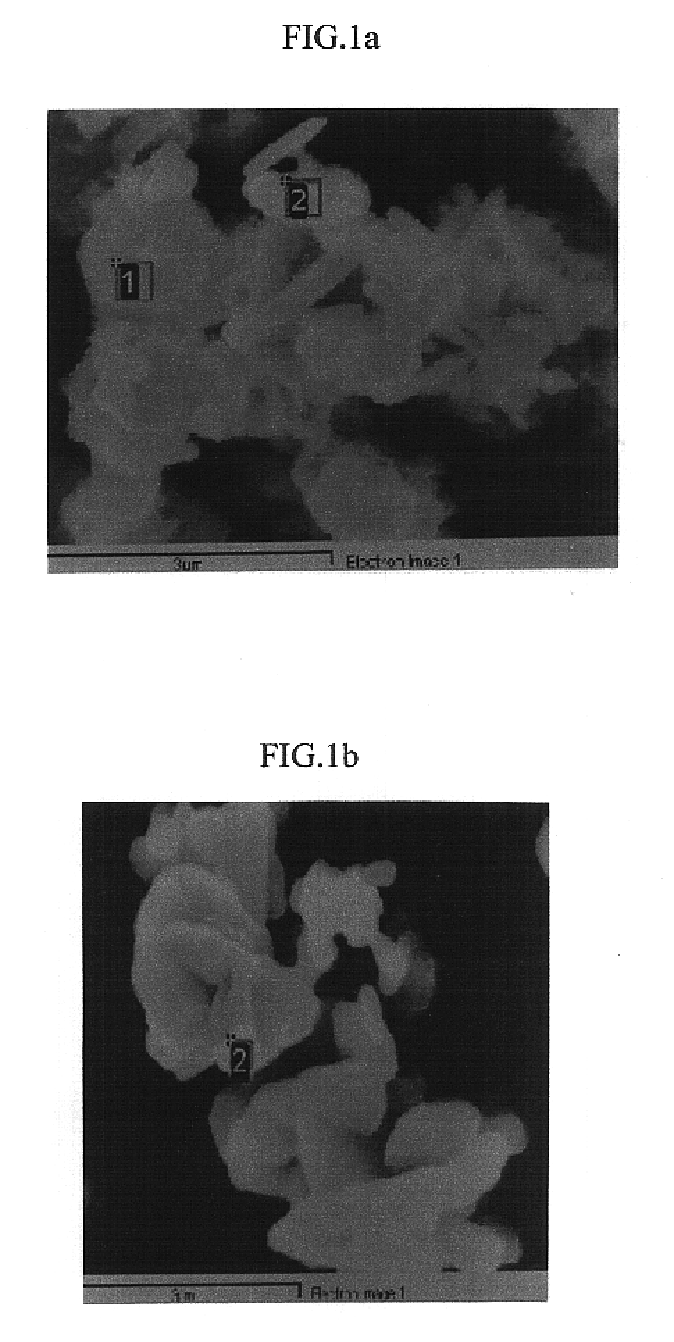

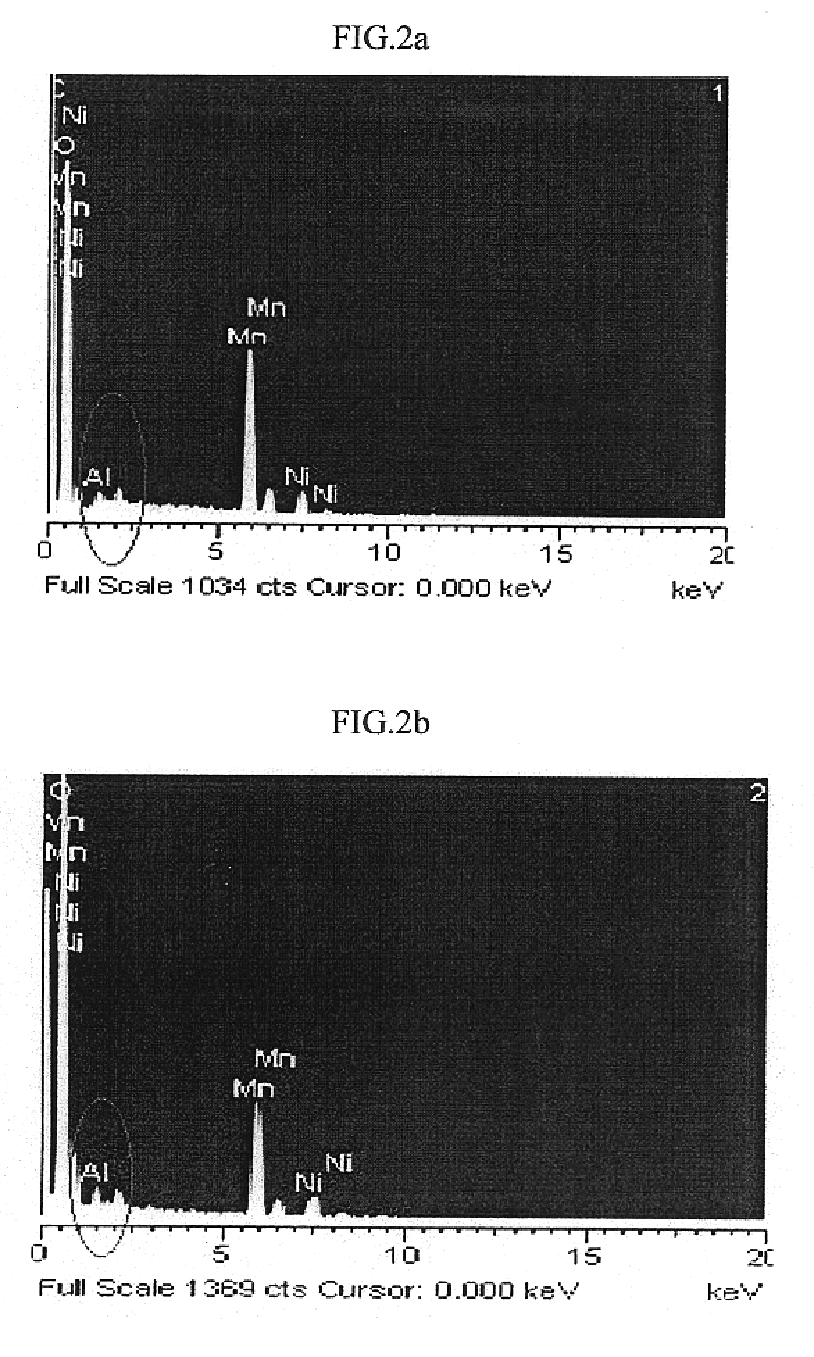

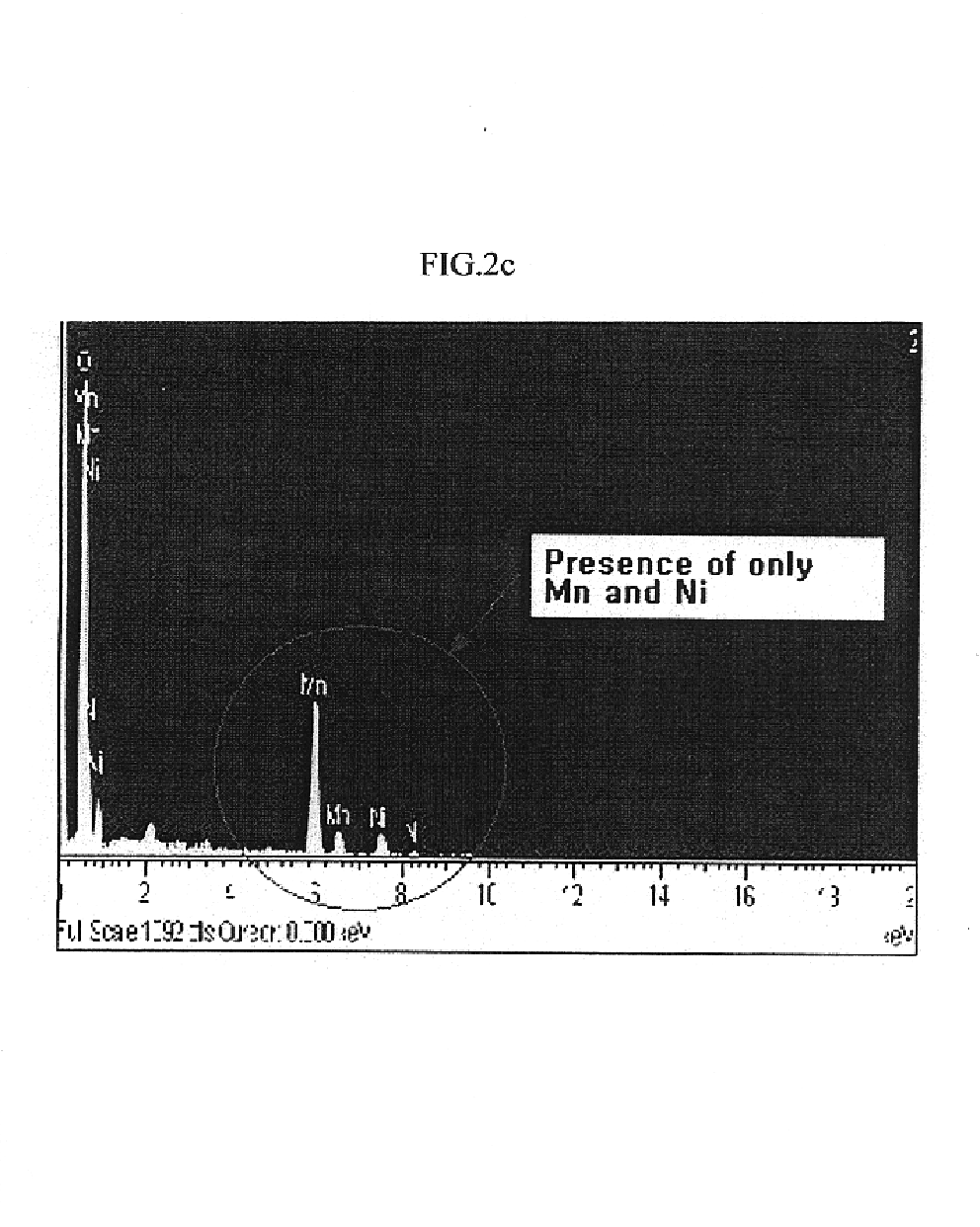

InactiveUS20020055042A1Improve thermal stabilityElectrode manufacturing processesZirconium compoundsPhysical chemistryLithium battery

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 andl a metal oxide or composite metal oxide layer formed on the compound. <table-cwu id="TABLE-US-00001"> <number>1< / number> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="OFFSET" colwidth="42PT" align="left" / > <colspec colname="1" colwidth="77PT" align="left" / > <colspec colname="2" colwidth="98PT" align="center" / > <row> <entry>< / entry> <entry>< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyF2< / entry> <entry>(1)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-yMnyS2< / entry> <entry>(2)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aFa< / entry> <entry>(3)< / entry> < / row> <row> <entry>< / entry> <entry>LixNi1-y-zMnyMzO2-aSa< / entry> <entry>(4)< / entry> < / row> <row> <entry>< / entry> <entry namest="OFFSET" nameend="2" align="center" rowsep="1">< / entry> < / row> < / tgroup> < / table-cwu> (where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, IPu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<=y<=0.99, 0<=,z<=0.5, and 0<=a<=0.5)

Owner:SAMSUNG SDI CO LTD

Method of preparing positive active material for rechargeable lithium batteries

InactiveUS6949233B2Improved cycle life characteristicsHigh discharge rateElectrode manufacturing processesPhosphatesPhysical chemistryHeat treated

Owner:SAMSUNG SDI CO LTD

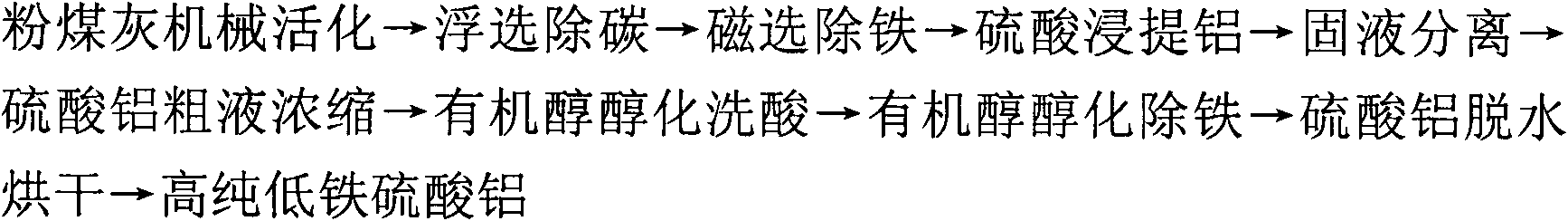

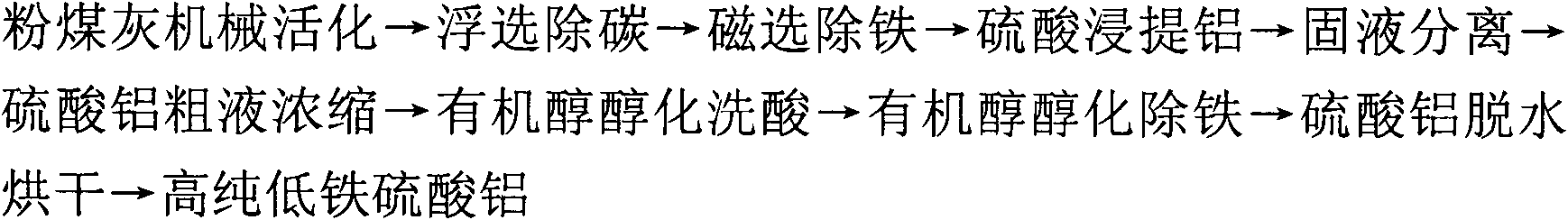

Technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing coal ash

InactiveCN102101689AEasy industrial iron removalLow costPigmenting treatmentSolid waste disposalBiological activationCoal

The invention discloses a technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing the coal ash, comprising the following steps of: carrying out mechanical activation, flotation decarburization, magnetic separation for deferrization, aluminum extraction with sulfuric acid, solid-liquid separation, concentration of aluminum sulfate crude liquor, organic alcohol alcoholization for acid rinse, organic alcohol alcoholization for deferrization and aluminum sulfate dewatering and drying on the coal ash to obtain the high-purity low-iron aluminum sulfate with low Fe content. The invention solves the problems on impurity removal and purification of the aluminum sulfate in the recycling process of the coal ash, simplifies the process flow, reduces the energy consumption, solves the technical problem of overlarge accumulation of secondary residue quantity, achieves high extraction ratio of aluminum contained in the coal ash, and realizes the recycling of organic alcohol and sulfuric acid and the comprehensive utilization of side products including unburnt black, magnetic iron powder, iron-containing aluminum sulfate crystals, high-silicon-dust active mineral blending materials or novel silicon-magnesium cement, and the like. The technological method has the advantages of simple process, short flow, easiness for control of a production process, high aluminum extraction ratio, low impurity content of products and stable quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

Method of preparing aluminum sulphate by utilizing fly ash

The invention relates to a method of preparing aluminum sulphate by utilizing industrial solid waste, in particular to a method of preparing aluminum sulphate by utilizing fly ash. The method comprises the following steps: mechanically activating the fly ash; mixing the mechanically activated fly ash with water according to a weight ratio of 1: 0.5-2.5; adding concentrated sulfuric acid at a weight ratio of 0.3-2.2 : 1 to the fly ash to a reaction kettle to generate basic aluminum sulphate at a temperature of 120 to 230 DEG C kept for 1-8h and a pressure of 0.11 to 0.50 MPa; cooling the basic aluminum sulphate after a reaction, separating solid and liquid, adding sulfuric acid to the basic aluminum sulphate liquid, adjusting the system to have the basicity of 0.1 to 0.4 and the pH value of 3 to 4 and converting the basic aluminum sulphate liquid into an aluminum sulphate solution; and evaporating and concentrating the aluminum sulphate solution to 110 to 120 DEG C and cooling and crystallizing the aluminum sulphate solution to separate aluminum sulphate crystals.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for recovering and preparing alum from activated clay production waste liquid

InactiveCN101671048ANo secondary pollutionReduce manufacturing costWater/sewage treatment by flocculation/precipitationAluminium sulfatesPotassiumWastewater

The invention discloses a method for recovering and preparing alum from activated clay production waste liquid, comprising the following steps of using sulfuric acid, aluminum sulfate in the activatedclay production waste liquid to react with aluminum hydroxide and stronger ammonia water or potassium hydroxide, filtering, evaporating to obtain ammonium alum or potassium alum, purifying, removingimpurities to obtain ammonium alum or potassium alum products with more than 99% of purity. The invention solves the problem existing in the management and recycling method of the activated clay production waste liquid, lowers cost for preparing alum in industry and has the advantages of environment protection, energy conservation and the like.

Owner:HEFEI UNIV OF TECH +1

One step synthesis of polymerized aluminum-iron sulfurate from industrial waste slags

InactiveCN1583593AGood suspensionEasy to separateWater/sewage treatment by flocculation/precipitationAluminium sulfatesAluminium sulfateIron salts

This invention relates to production of aggregate aluminium sulphate iron. Industrial waste residue used as raw material, flying ash as auxiliary agent, a one-step synthesizing method achieves to yield the macromolecule flocculant. The macromolecule flocculant has the characteristic of aluminium salt and iron salt flocculant. And it can cleanse water and many other uses, specially, good for environment.

Owner:刘启旺

Harmless and comprehensive utilization method for vanadium-extraction liquid leached residue

The invention relates to a harmless and comprehensive utilization method for vanadium-extraction liquid leached residue (in particular, low-sodium roasted vanadium-extraction liquid leached residue). The method is characterized by comprising the following steps of: taking the vanadium-extraction liquid leached residue as a raw material, extracting the valuable elements, such as vanadium, aluminum, ferrum, phosphorus and the like by carrying out a series of treatments, such as acid leaching, ion exchange, stripping liquid purification, ammonium polyvanadate precipitation, ammonium polyvanadate pyrolysis, and aluminum-ferrum-phosphorus precipitation for a solution obtained after carrying out ion exchange, wherein the liquid leached residue can be harmless and can have chemical stability; and then, mixing the chemical stability with a limestone crushed material and cement, grinding, moistening by using water, then, briquetting, stripping and carrying out natural curing to form a baking-free brick which meets the requirements of the GB6566-2001 on decorative materials.

Owner:HUAIHUA HONGFA RESOURCE COMPREHENSIVE UTILIZATIONTECH

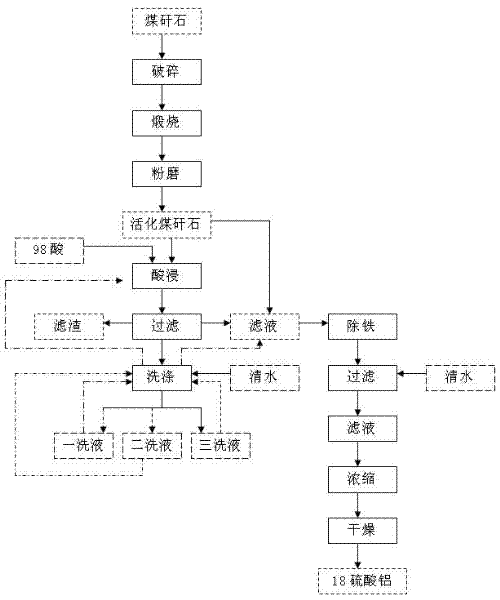

Method for preparing aluminium sulphate, sodium silicate, and derivative products from coal slack

This invention relates to a method for producing aluminum sulfate, sodium silicate and their derivatives from gangue. The method comprises: crushing the gangue by a jaw crusher, torrefying to remove organic substances, pulverizing by a ball mill till 80% powder are 200 mesh or finer, placing the gangue powder in a reaction kettle, adding 46-60% sulfuric acid and reacting to obtain aluminum sulfate solution, filtering, sending into a refinery tank, adding BaS to remove iron, adding silicon dioxide residue and liquid alkali into a reaction kettle, reacting at 120-160 deg.C under 0.7-0.8 MPa for 3-5 h, and filtering to obtain liquid sodium silicate. The method does not produce harmful substances, thus is not pollutive to the environment.

Owner:刘希林

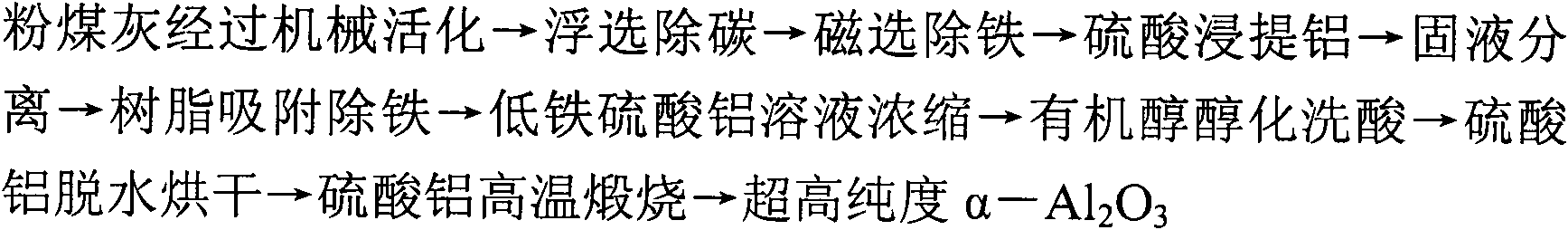

Cathode active material for lithium secondary cell and method for manufacturing the same

ActiveUS6986968B2Good electrochemical propertiesEasy to getPhosphatesSulfur compoundsChemical treatmentLithium

A cathode active material for a lithium secondary cell used in a cellular phone is disclosed. The cathode active material for the lithium secondary cell and the method the same having a high capacity and a long lifetime, different from LiCoO2 and LiMn2O4, Li(Ni, Co)O2, and V-system oxide that has been researched as the active material for substituting LiCoO2 are provided. The cathode active material for the lithium secondary cell in the next formula 1 is obtained by heating or chemically treating diadochite [Fe2(PO4)(SO4)(OH).6H2O] that is the mineral containing PO43−, SO42−, and OH−.LiaFebMc(PO4)x(SO4)y(OH)z (1)In the formula, M is at least one element selected from a radical consisting of Mg, Ti, Cr, Mn, Co, Ni, Cu, Zn, Al, and Si, with 0≦a, c≦0.5, 1≦b≦2, 0.5≦x, y, z≦1.5.

Owner:ELECTRONICS & TELECOMM RES INST

Method for preparing iron-free aluminium sulfate and superfine active carbon white utilizing aluminium first-class ore

InactiveCN1850607AConcentration easyDo not reduce the concentrationSilicaAluminium sulfatesSurface-active agentsActive particles

The invention discloses a method for preparing iron-free aluminum sulfate and superfine active white carbon black with bauxite, crushing the bauxite and removing dissociative iron source by magnetic separation, and then reacting with vitriol; adding in dithiocarbamate with medium and high molecular weights and multiple functionalities to remove iron ions by solid phase reaction, and filtering, where the filtrate is iron-free aluminum sulfate; washing filter residue with alkaline water solution, surface active agent water solution, and tap water, respectively, to neutralize it, then after reacting with alkali, filtering, making filtrate, inorganic acid and active particles react mutually, filtering, water-washing, and drying to obtain the superfine active white carbon black. And the method has simple process, and low cost, applied to industrialized production, where the iron content of the prepared aluminum sulfate is less than 15 ppm, and the grain size, specific surface area, tensile strength, added value of the superfine white carbon black are 0.5-5 mum, greater than 200 m2 / g, higher than 17.0 MPa, and high, respectively.

Owner:杭州百事特实业股份有限公司

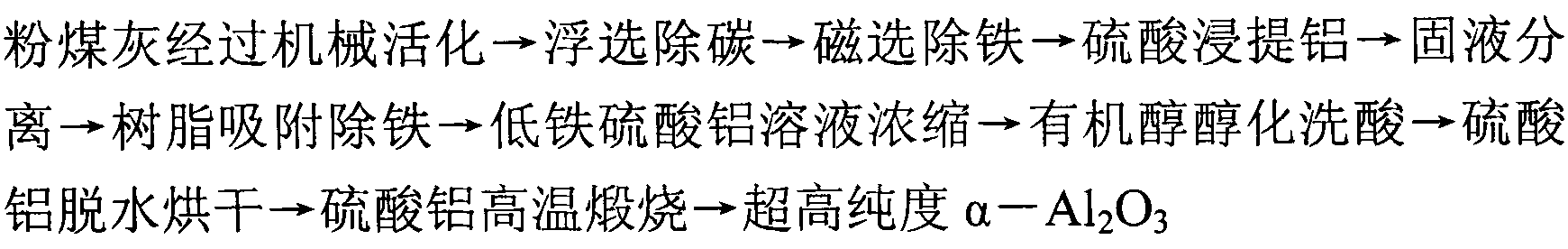

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

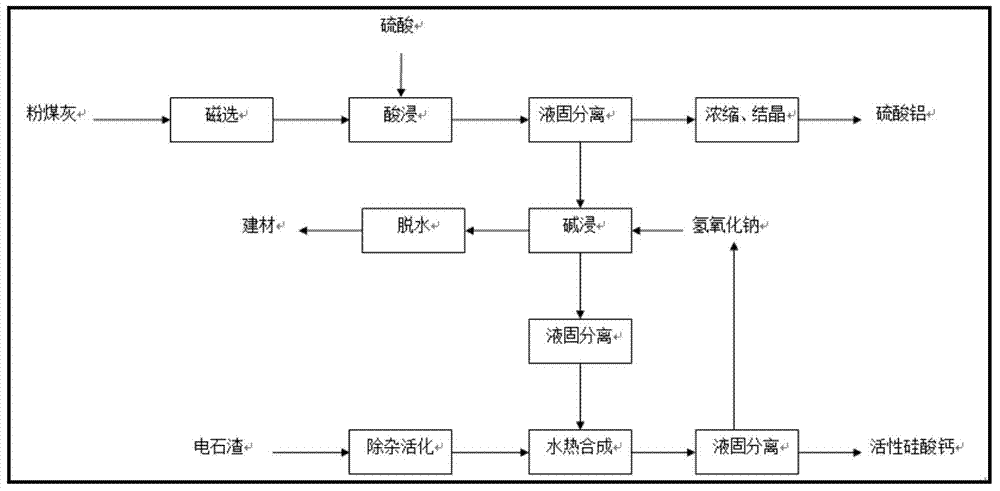

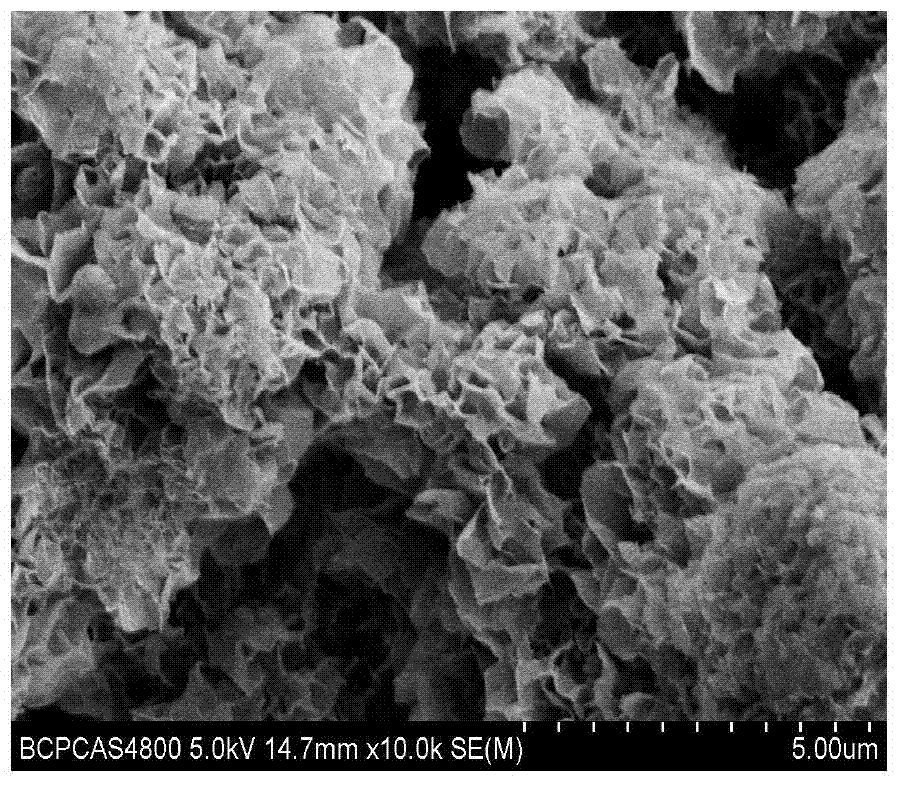

Method for synergic resource utilization of acetylene sludge and coal ash

ActiveCN104495899AShort processZero emissionAlkaline-earth metal silicatesCement productionCalcium silicateResource utilization

The invention provides a method for synergic resource utilization of acetylene sludge and coal ash. The method comprises the following steps: carrying out magnetic separation, acid leaching and filtering on coal ash to obtain an aluminum sulfate solution and acidic leaching residues, carrying out evaporative concentration and cooling crystallization on filtrate to obtain an aluminum sulfate crystal; carrying out alkaline leaching and filtering on the acidic leaching residues to obtain a sodium silicate solution and alkaline leaching residues, and carrying out cleaning and activation on the acetylene sludge to prepare lime milk which is subjected to hydro-thermal synthesis with the sodium silicate solution, and drying and dehydrating to prepare active calcium silicate powder, wherein the alkaline leaching residues can be directly used for preparing building materials after being dehydrated. According to the invention, by adopting the method for producing aluminum sulfate co-production active calcium silicate through synergic resource utilization of the acetylene sludge and coal ash, high-value utilization of large quantity of industrial solid wastes can be realized, and the production added value is high; all byproducts can be recycled, zero discharge is realized, energy consumption is low, and economical efficiency and environmental protection are achieved.

Owner:陕西龙湘科创节能环保科技有限公司

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS6737195B2Improve thermal stabilityElectrode manufacturing processesZirconium compoundsMaterials scienceMetal

Disclosed is a positive active material for a rechargeable lithium battery. The positive active material includes at least one compound represented by formulas 1 to 4 and a metal oxide or composite metal oxide layer formed on the compound.(where M is selected from the group consisting of Co, Mg, Fe, Sr, Ti, B, Si, Ga, Al, Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ac, Th, Pa, U, Np, Pu, Am, Cm, Bk, Cf, Es, Fm, Md, No and Lr, 0.95<=x<=1.1, 0<y<=0.99, 0<=z<=0.5, and 0<=A≤0.5).

Owner:SAMSUNG SDI CO LTD

Method for producing low iron aluminum sulfate by utilization of coal gangue

InactiveCN102311136AGood slag activityUnderburn noneWaste processingSolid waste disposalSlagAluminum sulphate

The invention relates to a method for producing low iron aluminum sulfate by the utilization of coal gangue and belongs to the technical field of coal solid waste resource utilization. The method provided by the invention comprises the following steps of: carrying out calcination activation on coal gangue at the temperature of 785-850 DEG C, adjusting the pH of an aluminum sulfate solution by directly using the activated coal gangue, oxidizing divalent iron ions into trivalent ions, removing iron precipitate and a few gel in the aluminum sulfate solution by the utilization of the adsorption property of the coal gangue, producing low iron aluminum sulfate, recycling the removed iron slag, and terminating the recycling operation when the removed iron slag amount is greater than 120% of the acid-leach residue amount or the mass ratio of aluminium to iron in an iron-removing liquid is less than 160. The temperature of the calcinated coal gangue satisfies the operation condition for the boiling of a circulating fluidized bed. No addition of an auxiliary agent helps heat recovery. The activity of the coal gangue cinder is good, the grinding requirement is not high and the energy consumption is low. Hydrogen peroxide or ozone, air and variable valence element-containing hypervalent compounds KMnO4, MnO2 oxidizing agents are adopted to remove iron with less loss of aluminium. The ratio of Al2O3 to Fe in the product is greater than 160 and the quality of the product is high. The acid leaching reaction is carried out at normal pressure. And the production is easy to operate at low cost.

Owner:KUNMING UNIV OF SCI & TECH

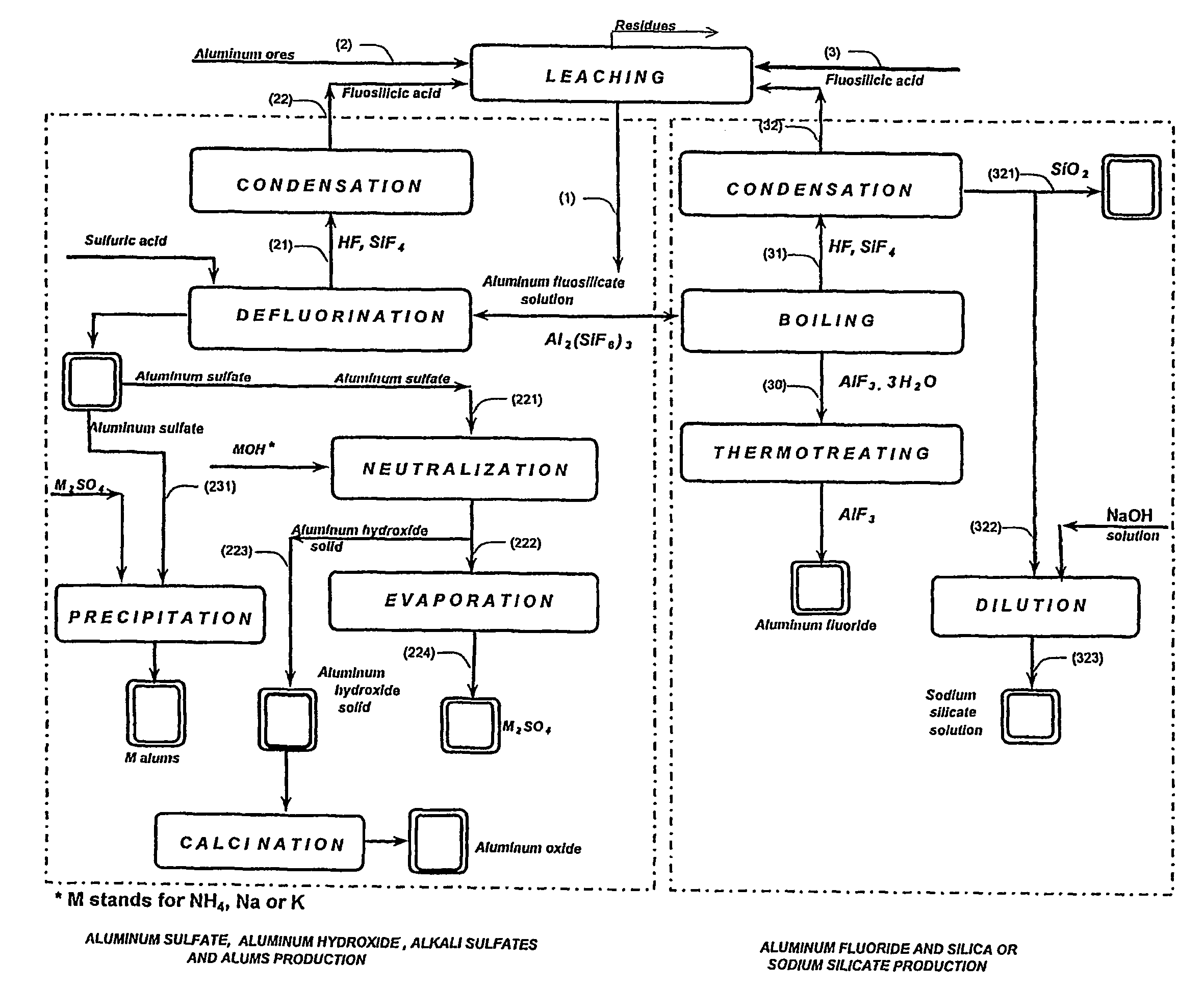

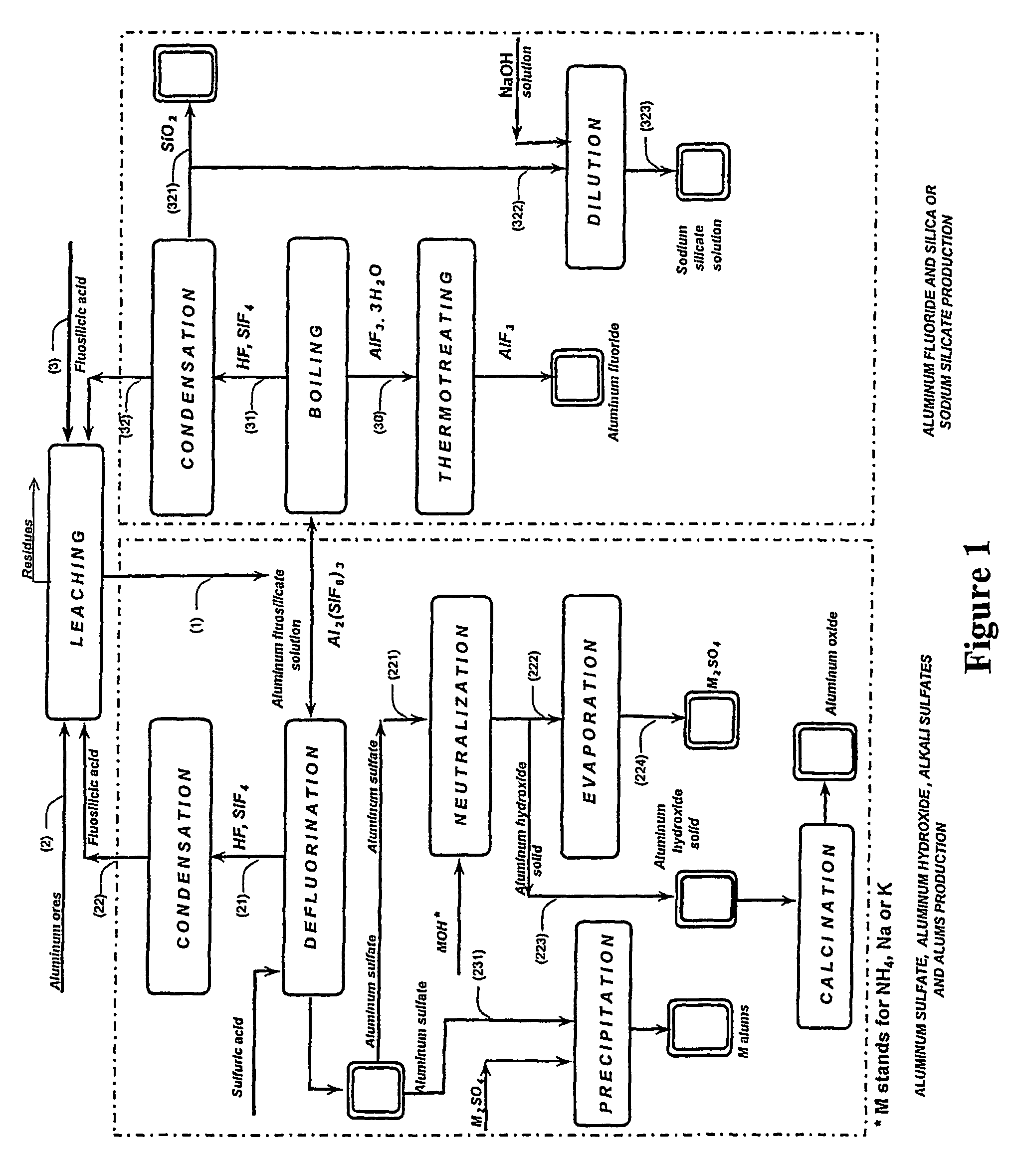

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

Process for production of sodium borohydride from sodium aluminum hydride with recycle of byproducts

A process for production of sodium borohydride. The process comprises the steps of: (a) combining a boric acid ester, B(OR)3 and sodium aluminum hydride to produce sodium borohydride and Al(OR)3; and (b) combining Al(OR)3 and sulfuric acid to produce alum and ROH.

Owner:ROHM & HAAS CO

Novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica

InactiveCN102139894AImprove utilization efficiencyReduce the impactCell electrodesLithium carbonates/bicarbonatesRubidiumNiobium

The invention provides a novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica. The method is characterized by comprising the following steps of: crushing lithium mica powder until granularity is 100 to 200 meshes, adding the crushed lithium mica powder and 30 to 70 percent sulfuric acid solution in a solid and liquid mass ratio of 1:(2-8) into a reaction device, reacting at the temperature of between 60 and 200 DEG C for 3 to 10 hours to obtain the sulfuric acid solution which contains Li<+>, and separating to remove fluorine-containing solution; performing filtering separation on the sulfuric acid solution which contains the Li<+>, and fully washing the filter residue with water to remove the filter residue and obtain filtrate which serves as mother liquor 1; changing the temperature of the mother liquor to be between 10 and 100 DEG C with stirring, separating solids, namely rubidium, caesium and alum, performing filtering separation, washing the filter residue, and recovering the filtrate as mother liquor 2; adding calcium hydroxide into the mother liquor 2, and controlling the pH value of the solution to between 2 and 7 to obtain solid and liquid mixed solution of neutralization reaction; performing filtering separation on the solid and liquid mixed solution, washing and filtering the filter residue, and recovering the filtrate as mother liquor 3; performing evaporation concentration on the mother liquor 3, controlling the concentration of the Li<+> in the solution to be between 40 and 65g / l, and filtering to obtain the filtrate serving as mother liquor 4; and blowing carbon dioxide into the mother liquor 4 at the temperature of between 95 and 105 DEG C under 2 atmospheres and performing lithium-sinking reaction for 40 to 100 minutes, filtering and mechanically separating to obtain lithium carbonate, washing with water, and drying to obtain the battery grade lithium carbonate product.

Owner:宜春银锂新能源有限责任公司

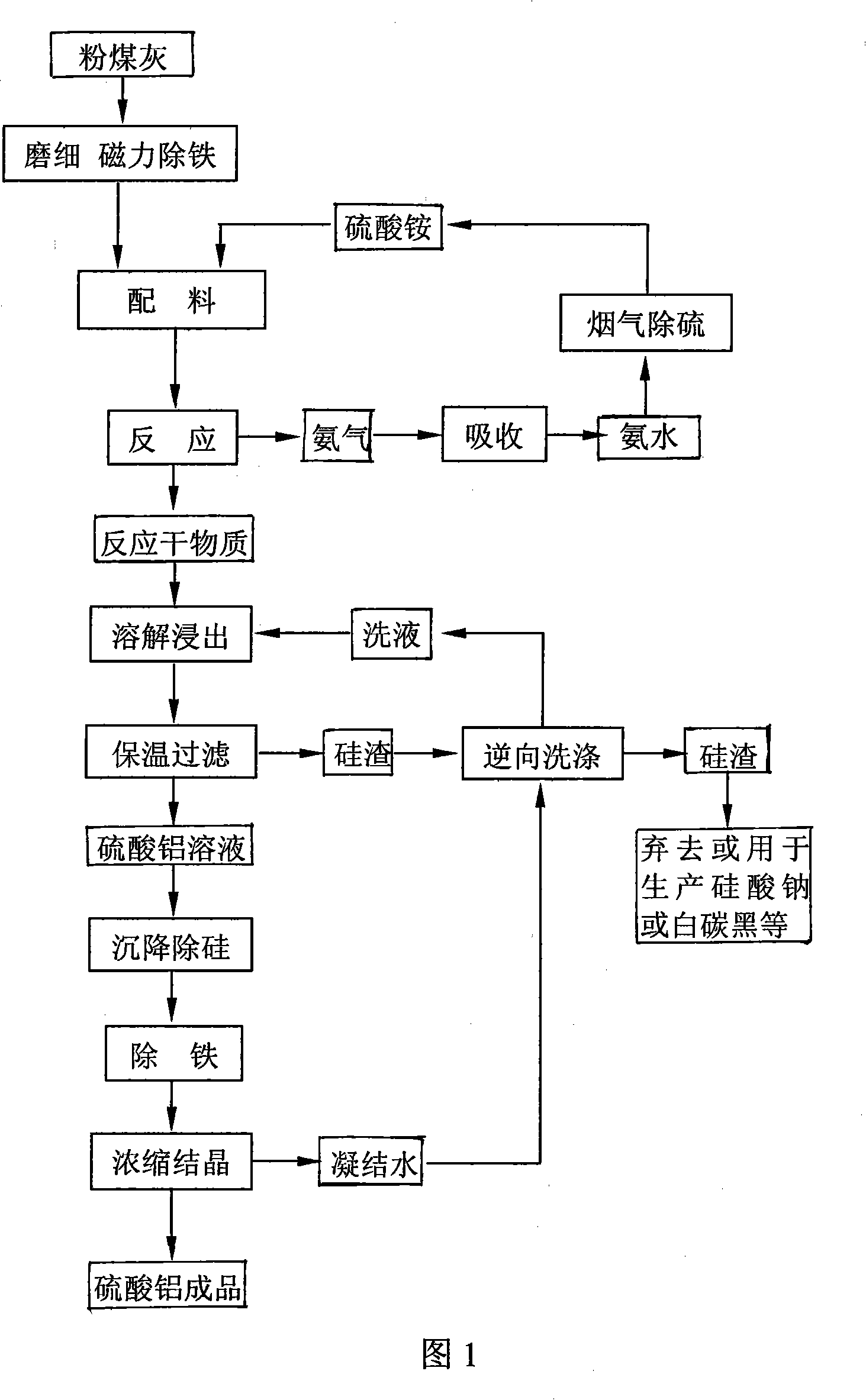

Comprehensive utilization method of ammonium sulfate and pulverized coal ash produced by thermal power plant ammonia process

InactiveCN101157456AAchieve recyclingEmission reductionAmmonia preparation/separationAluminium sulfatesChemical industryPulverized fuel ash

The invention relates to a processing technic for emission produced during burning coal in a heat-engine plant, in particular to a multipurpose use method of ammonium sulphate and pulverized fuel ash produced during the ammonia process of desulfurization in the heat-engine plant. The invention solves the problems that evacuated rejectamenta produced in the heat-engine plant pollutes the environment in the prior art. The invention has the following steps: the pulverized fuel ash is milled and activated, proportioning feeding and action are performed, ammonia gas is recycled and lixiviated, silicon is removed from filtrate, and pearl alum and / or aluminium ammonium sulfate are / is produced after being crystallized. The invention has the fundamental principle that the ammonium sulphate produced by the ammonia process of desulfurization is mixed with the pulverized fuel ash, the ammonium sulphate and the pulverized fuel ash perform a solid state reaction to produce the pearl alum and release the ammonia gas. The pearl alum is used as a commodity to sale, the ammonia gas returns to a stack gas desulfurization process for periodic duty. The stack gas desulfurization and the multipurpose use method of the pulverized fuel ash are combined with each other, basic products of the chemical industry such as the pearl alum and the aluminium ammonium sulfate is produced, thereby realizing the periodic duty of the ammonia gas and the multipurpose use of the pulverized fuel ash, effectively reducing the discharging of the injurant produced in a coal-fired power plant, and having obvious economic benefit and social benefit.

Owner:李禹

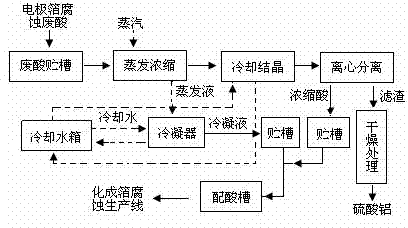

Recycling process of waste sulfuric acid from corrosion of electrode foil

ActiveCN103935966ALow concentration of aluminum ionsAchieve recyclingSulfur-trioxide/sulfuric-acidAluminium sulfatesAluminum sulphatePolymer

The invention discloses a recycling process of waste sulfuric acid from corrosion of an electrode foil, and the specific steps are as follows: preheating, evaporating, cooling, condensing and crystallizing, performing centrifugal separation and drying. According to the recycling process disclosed by the invention, steam-saving three-effect evaporation is adopted for concentrating the waste sulfuric acid, basic conditions for enabling aluminum sulfate in the waste acid to form a colloid are created, and sulfuric acid-containing steam which is evaporated out is condensed and recovered; and the aluminum sulfate in the concentrated sulfuric acid is further crystallized at certain temperature for facilitating centrifugal separation of the concentrated sulfuric acid and an aluminum sulfate polymer, the effective recovery of the sulfuric acid and the aluminum sulfate is realized, the purpose of reducing the emission is achieved, and the cost of a corrosion process of the electrode foil is further effectively reduced, thereby greatly assisting in upgrading of market competitiveness of an electrode foil product.

Owner:NANTONG VOCATIONAL COLLEGE +2

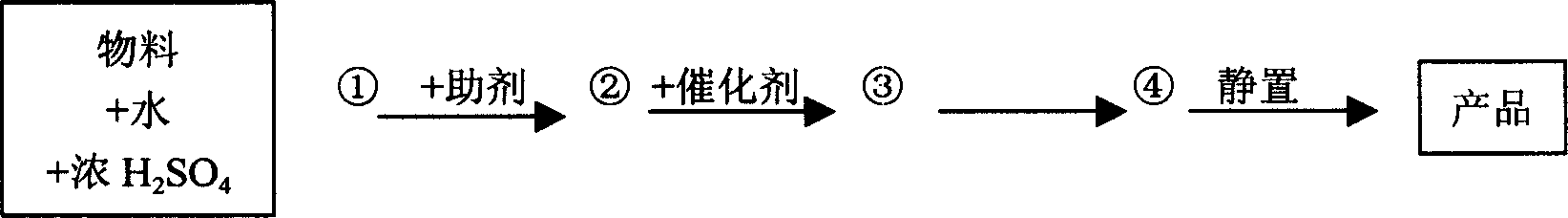

Production process of aluminium iron sulfate polymer as composite water purifying agent

InactiveCN1337356AReduce manufacturing costSimple processSulfate preparationWater/sewage treatment by flocculation/precipitationIron sulfateCleansing Agents

The production process of compound water-cleaning agent aluminium iron polysulfate uses the iron oxide contained offscum produced after production of sulfuric acid in sulfuric acid plant as raw material, and adopting the folloiwng steps: according to the chemometric, adding water, offscum and sulfuric acid into reactor in turn to make reaction, then adding isometric water to make dilution, and discharging diluted reactant into settling tank, adding small quantity of flocculant to make natural settling and solid-liquid separation, pumping said clear liquor into polymerization container, addingH2O2 and making it and the clear liquor to implement quick oxidation and polymerization to obtain the invention finished product liquor, evaporating and dewatering to obtain its natural crystal, thenbreaking it into granular or powdered material to obtain the invented solid aluminium iron polysulfate. It can obtain good sewage treatment effect.

Owner:邓中杰

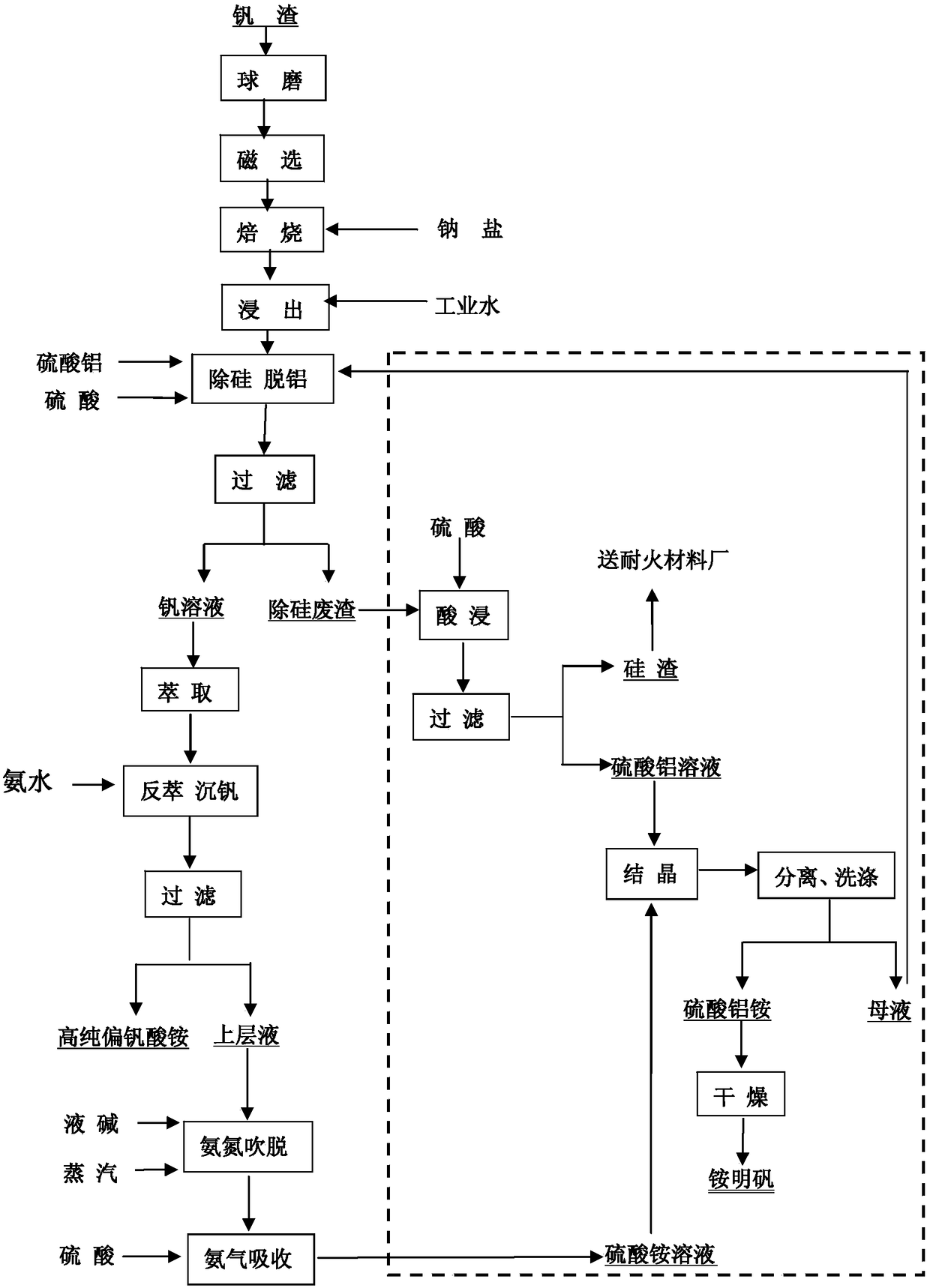

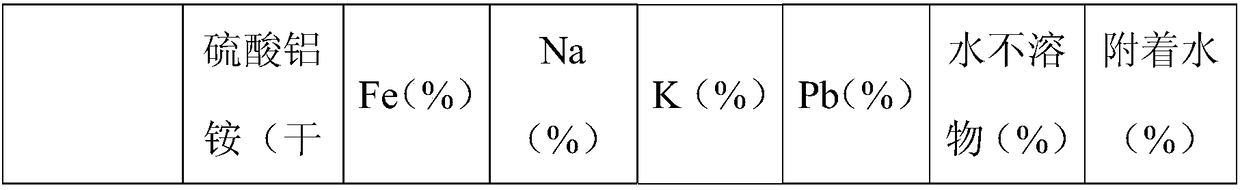

Preparation method of vanadium containing solution

ActiveCN108359815AHigh recovery rateSolve the pollution of the environmentVanadium oxidesCeramic materials productionResource utilizationAluminum ammonium sulfate

The invention provides a preparation method of a vanadium containing solution. The preparation method comprises the following steps that vanadium containing lixivium is subjected to silicon removal and dealumination to obtain the vanadium containing solution and silicon removal waste residues; the silicon removal waste residues are leached through concentrated sulfuric acid to obtain an acid leaching solution; after the acid leaching solution is precisely filtered, silicon residues and an aluminum sulfate solution are obtained; and the aluminum sulfate solution and an ammonium sulfate solutionare mixed, recooling crystallization is carried out after reacting, aluminum ammonium sulfate crystals and crystallization mother liquor are obtained through second solid-liquid separation, and the crystallization mother liquor is used for replacing part or all of aluminum salt to be mixed with a silicon-chrome-silicon containing solution for silicon removal. According to the method, the siliconremoval waste residues can be subjected to resource utilization, and an aluminum ammonium sulfate product high in additional value can be obtained; meanwhile, the consumption of the aluminum salt canbe reduced, high-purity ammonium metavanadate can be prepared continuously and stably, and therefore a high-purity vanadium pentoxide product with the purity not smaller than 99.9% is prepared, and the vanadium recovery rate is increased; and the process is simple, the cost is low, and energy consumption is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

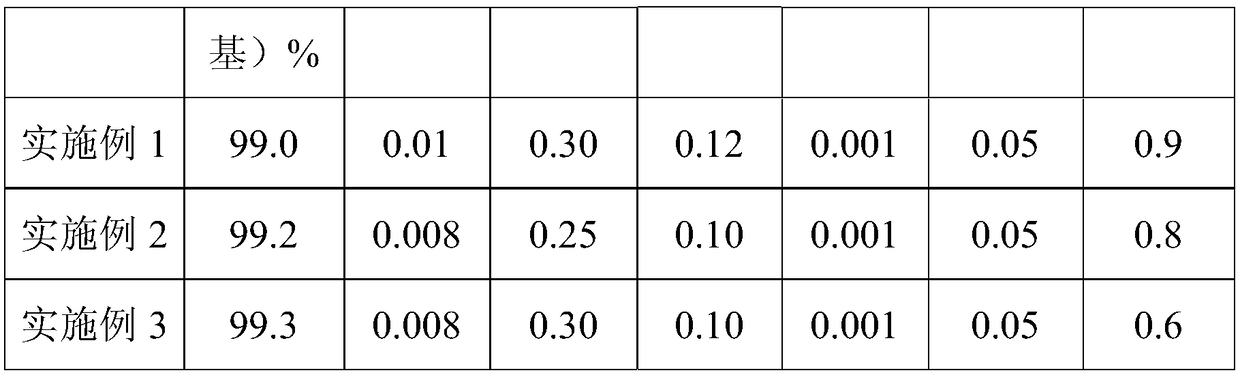

Fly ash decomposition method

The invention discloses a fly ash decomposition method. The method comprises the following steps: sending fly ash powder to an acidolysis process, adding sulfuric acid or hydrochloric acid or nitric acid to carry out a multistage acidolysis reaction with fluorite or industrial calcium fluoride as an activator in order to convert aluminum and iron elements in the fly ash powder into corresponding soluble salts entering a liquid phase, filtering, and separating to obtain an acid leachate containing aluminum salt and iron salt; washing acidolysis residues, mixing the acidolysis residues with water, adding sodium hydroxide to carry out an alkaline hydrolysis reaction, and filtering to prepare high modulus water glass; and washing alkaline hydrolysis residues, filtering, and sending the obtained acid leachate to a fore acidolysis process in order to be used for burdening. The decomposition rates of alumina and iron oxide in the fly ash reach above 90% and above 85% respectively; the modulus of the water glass is controlled between 3.2 and 3.8, the device investment is reduced, and the energy consumption and the raw material cost are reduced; and the method realizes recycling of decomposition residues, eliminates influences of secondary waste residues on environment, and lays a foundation for the preparation of aluminum, iron and silicon compounds.

Owner:NANYANG ORIENTAL APPL CHEM RES INST

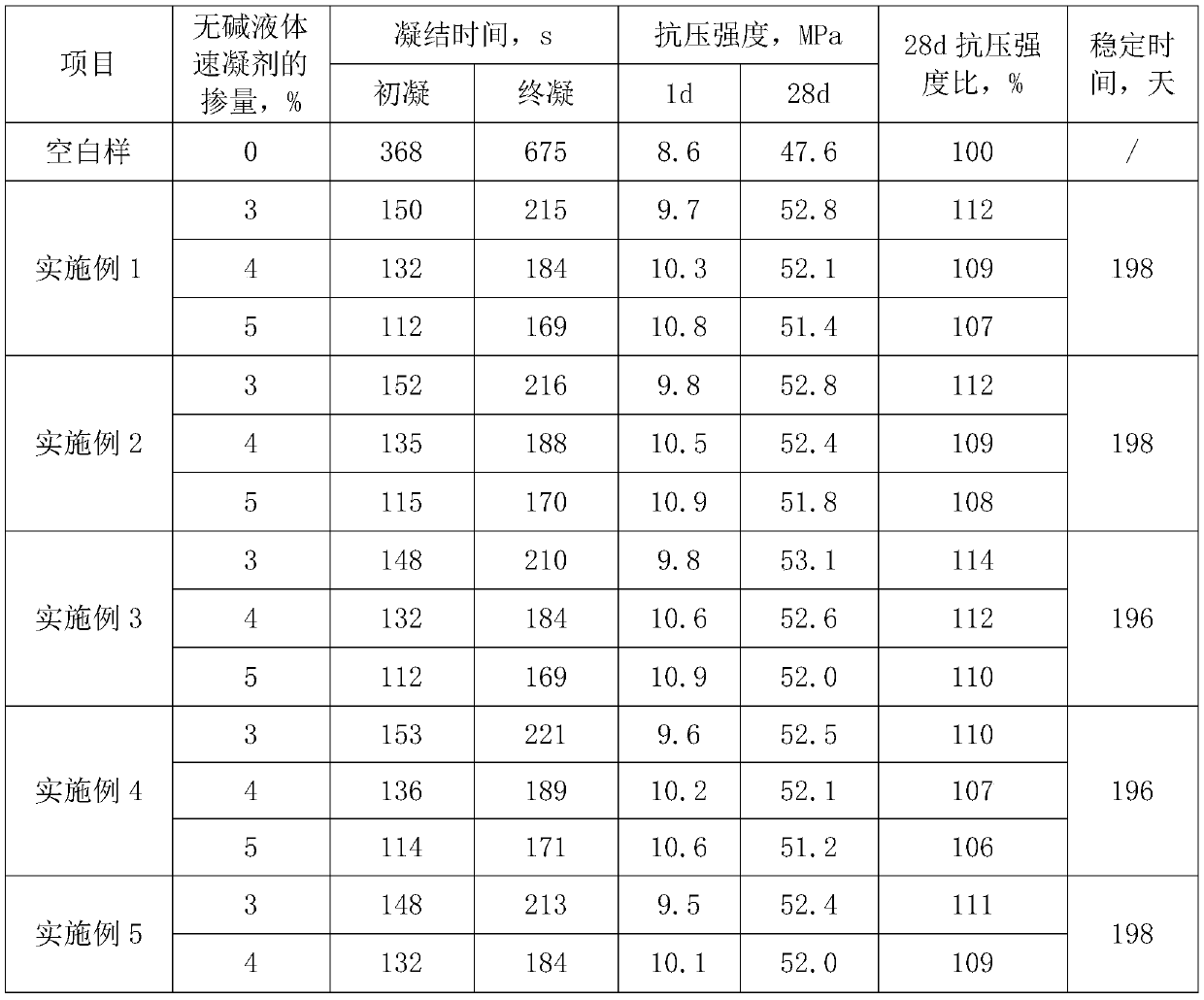

Alkali-free liquid accelerator and preparation method thereof

ActiveCN110451844AHigh solid contentGood quick setting effectAluminium sulfatesAluminium sulfateOrganic acid

The invention discloses an alkali-free liquid accelerator and a preparation method thereof, and relates to the technical field of concrete admixtures. The technical solution main point is that the alkali-free liquid accelerator comprises the following components in parts by weight: 45-55 parts of polyaluminium sulfate, 3-5 parts of an organic acid, 0.5-1 part of an inorganic acid, 2-4 parts of a stabilizer, 1-2 parts of an early strength agent, 1-2 parts of a thickener, and 40-50 parts of water. By combination of polyaluminium sulfate with the organic acid, the inorganic acid and the stabilizer, the prepared accelerator has the advantages of low blending amount, good quick-setting effects and low strength loss.

Owner:重庆腾治科技有限公司

Comprehensive utilization method of serpentine and device used by method

Owner:NANYANG ORIENTAL APPL CHEM RES INST +1

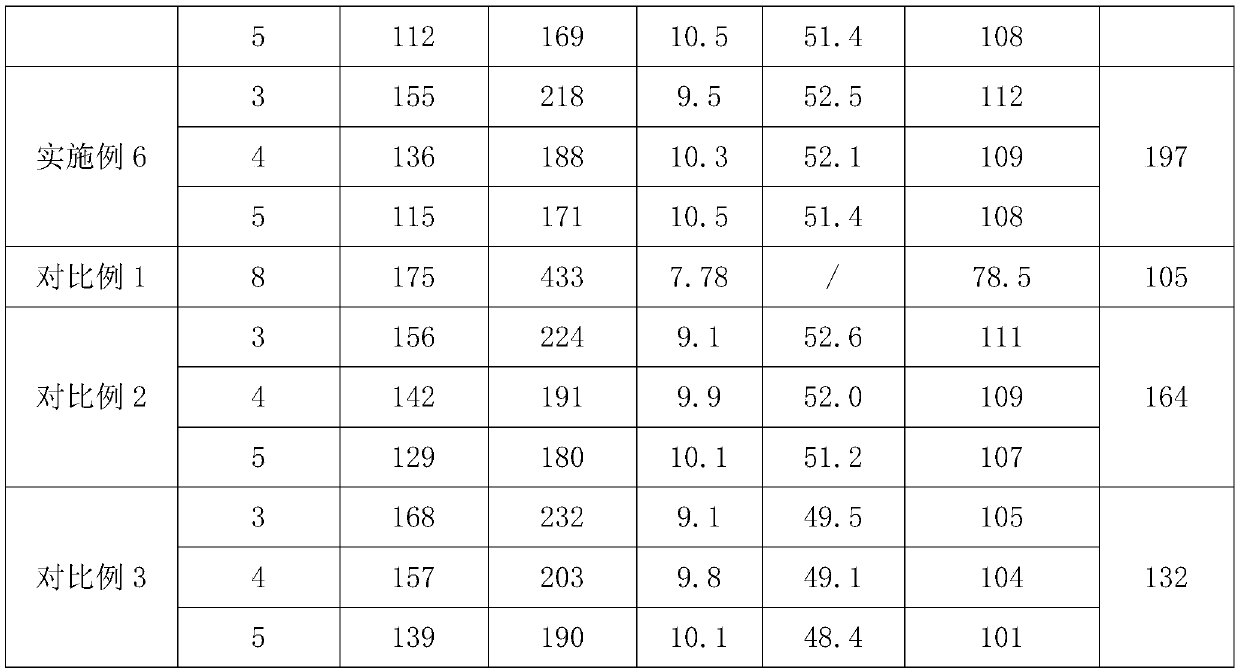

Iron extracting and removing method of aluminum sulfate solution

InactiveCN101659438AHigh extraction rateSolve the problem of extraction and phase separationLiquid solutions solvent extractionAluminium sulfatesAluminium sulfateAlcohol

The invention discloses a iron extracting and removing method of aluminum sulfate solution. The extraction system of the invention is composed of primary amine N-1923, kerosene and n-caprylic alcohol,wherein, the n-caprylic alcohol accounts for 5-30% of the whole extraction system in percentage by volume. The invention also comprises a re-extraction system taking sodium chloride solution or sulfuric acid solution as a re-extraction preparation. The invention is characterized in that n-caprylic alcohol is added in primary amine and kerosene extraction systems, which can effectively solve the problem of extracting phase-splitting and shorten extracting time. The invention optimizes the using amount of n-caprylic alcohol, sodium chloride solution concentration and sulfuric acid solution concentration so as to improve extraction efficiency and re-extraction efficiency. The extraction system of the invention can effectively extract iron in industrial aluminum sulfate solution, and non-ironaluminum sulfate products obtained by extraction conform to low-iron requirement on aluminum sulfate for industries, such as papermaking, printing, dyeing and the like, so that the invention has verygreat significance for practical industrial application.

Owner:JINAN UNIVERSITY

Method for dissolving aluminum out of circulating fluidized bed coal ash

ActiveCN102153120AIncrease profitSimple processSolid waste disposalAluminium chloridesFluidized bedAcid dissolution

The invention relates to a method for dissolving aluminum out of circulating fluidized bed coal ash. The method includes the steps of mixing the circulating fluidized bed coal ash with acid according to a certain ratio for acid dissolution reaction, and conducting solid-liquid separation and washing on a product produced after acid dissolution reaction to obtain acid leaching liquor, namely the aluminum is thus dissolved out of from the coal ash. In the method, the circulating fluidized bed coal ash is taken as a raw material and the acid dissolution method is utilized for dissolving out the aluminum; the dissolution rate of the aluminum is above 80%; and the method is simple in technology, saves energy, reduces waste, greatly improves the utilization rate of the coal ash and lowers pollution.

Owner:CHINA SHENHUA ENERGY CO LTD

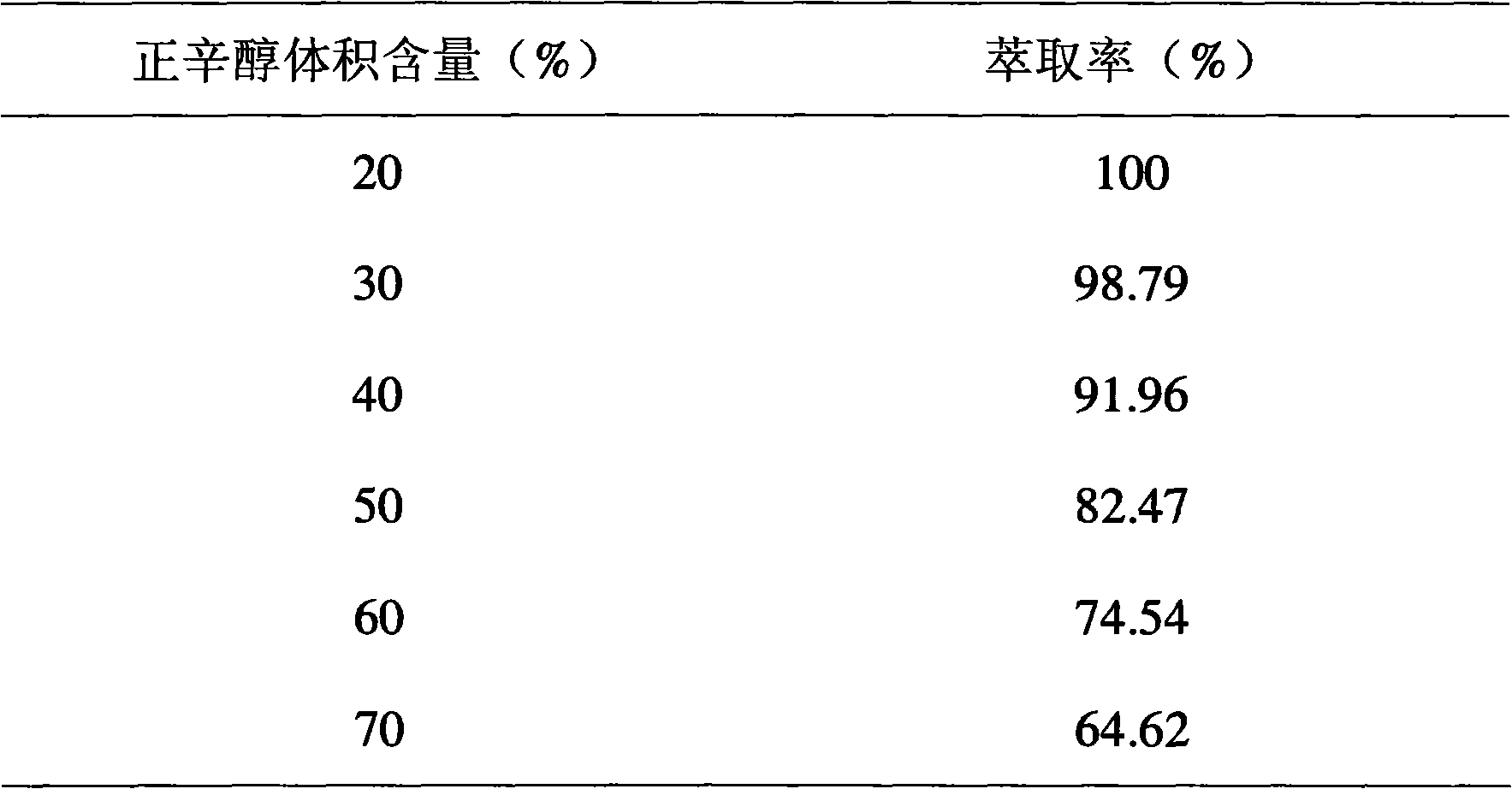

Method for producing polyaluminium sulfate by using red mud slag

ActiveCN103588235AQuality improvementGreat advantageWater/sewage treatment by flocculation/precipitationAluminium sulfatesSlagRed mud

The invention provides a method for producing polyaluminium sulfate by using a red mud slag. The method comprises the following steps: iron in the red mud is recovered, wherein the red mud is a solid waste produced in the production of aluminium oxide, the slag is blended with concentrated sulfuric acid after the recovery of iron to conduct sulfurizing roasting, then water leaching is implemented to obtain an aluminum sulfate solution containing rare metals like rare earth, the rare metal slag is extracted through extraction, the raffinate is added into lime milk to conduct an alkalized polymerization reaction, the pH value and the temperature of the raffinate are controlled, the impurities like titanium and iron are separated through hydrolysis, a stabilizing agent is added at the low basicity, then lime milk is added to conduct an emulsion reaction, the solution is subjected to filter pressing when the basicity reaches a preset value, the filter residue is a titanium-rich slag, the liquid subjected to the filter-pressing is put into an aging vat and aged to obtain a high-concentration polyaluminium sulfate product. The method has the advantages of simple process and feasible operation, the comprehensive utilization of the red mud is achieved, the correlative charge for the stockpiling of the red mud is reduced, and meanwhile, the influence caused by the stockpiling of the red mud to the environment and the accident potential are also eliminated.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for producing aluminium sulfate using aluminium hydroxide mud

InactiveCN101070176ATo achieve the purpose of comprehensive utilizationImprove hygieneSludge treatmentAluminium sulfatesAluminium sulfateSludge

The invention relates to a kind of method producing aluminum sulfate using Riopone, which belongs to technique field of sewage disposal. Put solution dilute sulfuric acid or abandoned sulfuric acid or oil of vitriol into reaction tank, add Riopone mud gradually, mix them make them activate at room temperature, make Riopone mud activate to dissolve gradually and form liquid aluminum sulfate; heat them in the autoclave, heat and vacuumize liquid aluminum sulfate to concentrate it; cool liquid aluminum sulfate to form massive aluminum sulfate at room temperature which is crushed to form solid aluminum sulfate. It can reclaim and reuse Riopone mud in this invention, which regards recrement as treasure, not easy to form the secondary pollution, propitious to environmental sanitation, not waste recourses of land; it can debase the production coat and need not increase production equipment, the fabricate craft is simple, liquid aluminum sulfate or solid aluminum sulfate which is used by many sewage treatment plants can totally reach the disposing request.

Owner:童益

Alkali/Transition Metal Halo-And Hydroxy-Phosphates And Related Electrode Active Materials

InactiveUS20100276632A1Increase capacityImprove cycle performancePhosphatesFluoride preparationHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(SO4)2Zd.

Owner:VALENCE TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com