Recycling process of waste sulfuric acid from corrosion of electrode foil

A technology for recycling and processing waste sulfuric acid, applied in aluminum sulfate, sulfur trioxide/sulfuric acid, aluminum sulfur compounds, etc., can solve the problems of waste of resources, high cost, affecting the filtration speed, etc., achieving no secondary pollution and a wide range of applications , the effect of high environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples and figures. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

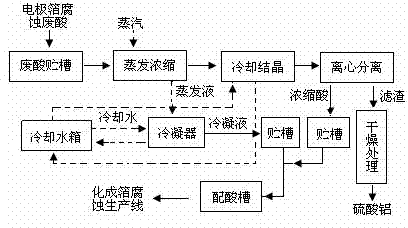

[0023] Such as figure 2 Shown: a recovery treatment process of electrode foil corrosion waste sulfuric acid, the specific steps are as follows:

[0024] Step 1. Preheating: the electrode foil corrosion waste sulfuric acid from the waste sulfuric acid storage tank is pumped into the preheater for preheating, and the uncondensed steam generated by the three-effect evaporator and the concentrated high-temperature sulfuric acid are used as the preheating heat source;

[0025] Step 2. Evaporation: The preheated waste sulfuric acid enters the three-effect evaporator to evaporate, and the sulfuric acid content reaches 40%-70% through the control of the acid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com