Gallium nitride-based power device epitaxial structure and production method thereof

A technology of epitaxial structures and power devices, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high Al composition in non-gate regions and unsatisfactory Al composition in gate regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

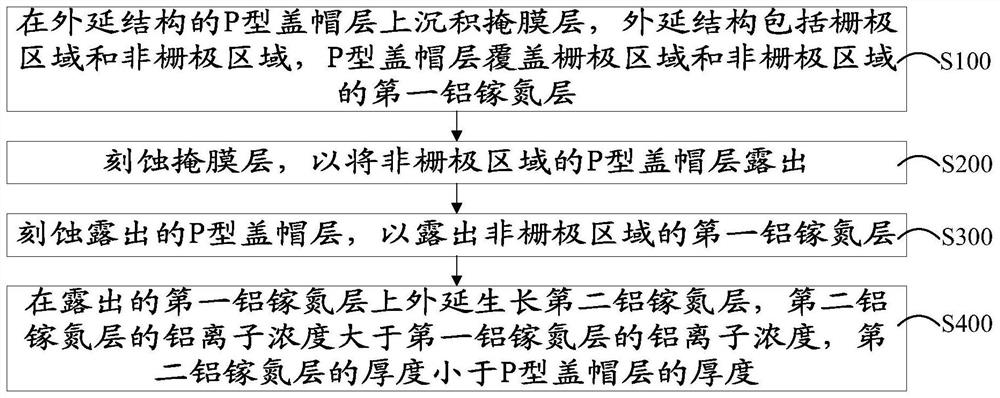

[0042] Please refer to figure 1 , this embodiment provides a method for preparing an epitaxial structure of a gallium nitride-based power device, and the method for preparing the epitaxial structure of a gallium nitride-based power device includes:

[0043] S100, depositing a mask layer 20 on the P-type cap layer 15 of the epitaxial structure, the epitaxial structure includes a gate region and a non-gate region, and the P-type cap layer 15 covers the first AlGaN in the gate region and the non-gate region Layer 14.

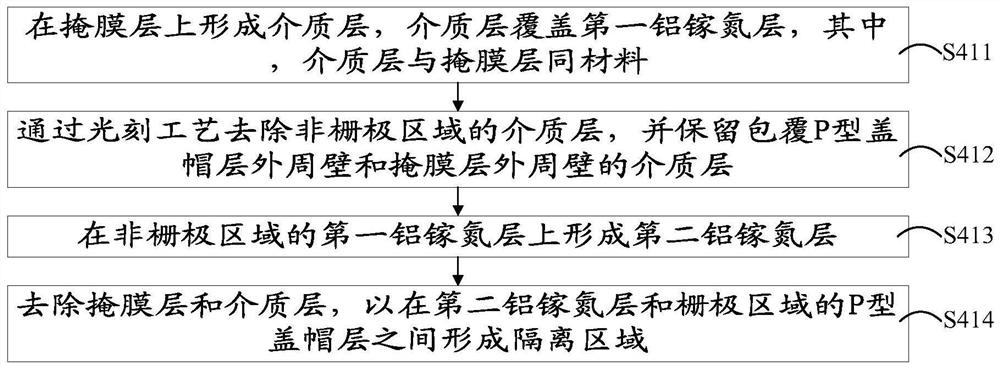

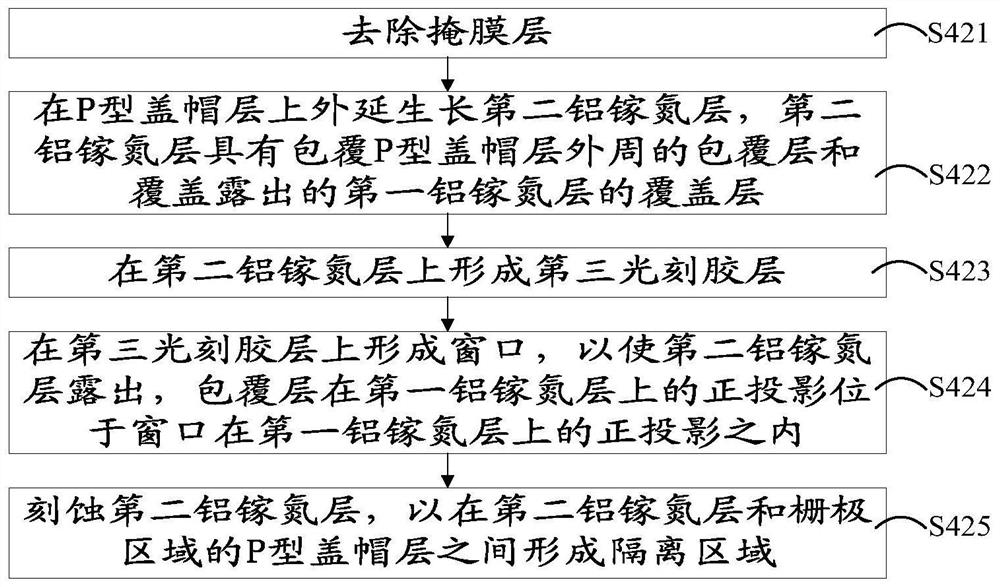

[0044] It should be noted that please refer to Figure 5 As shown, the above-mentioned epitaxial structure includes a substrate 11 , and a nucleation layer, a buffer layer 12 , a channel layer 13 , a first AlGaN layer 14 , and a P-type capping layer 15 sequentially formed on the substrate 11 . Wherein, the above-mentioned substrate 11 can be a silicon substrate, the buffer layer 12 and the channel layer 13 can be a gallium nitride layer, the first aluminum galliu...

no. 2 example

[0091] Compared with the first embodiment, this embodiment differs in that the mask layer 20 is made of SiO 2 layer (or SiN, Al 2 o 3 , HfO 2 Any one of them) is replaced by a photoresist layer. In this way, the method for preparing the epitaxial structure of a GaN-based power device provided in this embodiment will undergo adaptive changes.

[0092] In this way, the method for preparing the epitaxial structure of a gallium nitride-based power device should be prepared according to the following principle: that is, first deposit a photoresist layer on the P-type capping layer 15 of the epitaxial structure, such as Figure 5 shown; and then by exposure and development, remove the photoresist layer in the non-gate region, to expose the P-type capping layer 15 in the non-gate region, as Image 6 shown; and then etch the P-type capping layer 15 to expose the first AlGaN layer 14 located in the non-gate region, as Figure 7 shown; then remove the photoresist layer, and epitaxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com