Iron extracting and removing method of aluminum sulfate solution

A sulfuric acid solution, aluminum sulfate technology, applied in liquid solution solvent extraction, aluminum sulfate, aluminum sulfur compounds and other directions, can solve the problems of shortening extraction time, extraction rate and back-extraction rate, etc., to shorten extraction time, easy to recycle, The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this example, the extraction system of primary amine N-1923 + kerosene + n-octanol is selected, wherein the primary amine N-1923 accounts for 25% by volume of the entire extraction system, and the modifier n-octanol accounts for the volume of the entire extraction system The percentage content is 25%, the volume ratio (O / A) of the organic phase and the water phase in the extraction system is 1:2, and after static extraction for 2-4 minutes, the extraction rate of iron in the aluminum sulfate solution is 100%.

[0026] In this embodiment, sodium chloride solution is selected as the stripping agent, the concentration of the sodium chloride solution is 2.0 mol / L, and the stripping rate is 98.02%.

[0027] In this embodiment, sulfuric acid solution is selected as the stripping agent, and when the concentration of the sulfuric acid solution is 4.0 mol / L, the stripping rate is 98.67%.

Embodiment 2

[0029] In this example, the extraction system of primary amine N-1923 + kerosene + n-octanol is selected, wherein the primary amine N-1923 accounts for 25% by volume of the entire extraction system, and the modifier n-octanol accounts for the volume of the entire extraction system The percentage content is 10%, the volume ratio (O / A) of the organic phase and the water phase in the extraction system is 1:2, and after static extraction for 5-10 minutes, the extraction rate of iron in the aluminum sulfate solution is 100%.

[0030] In this embodiment, sodium chloride solution is selected as the stripping agent, the concentration of the sodium chloride solution is 2.0 mol / L, and the stripping rate is 94.84%.

[0031] In this embodiment, sulfuric acid solution is selected as the stripping agent. When the concentration of the sulfuric acid solution is 4.0 mol / L, the stripping rate is 95.30%.

Embodiment 3

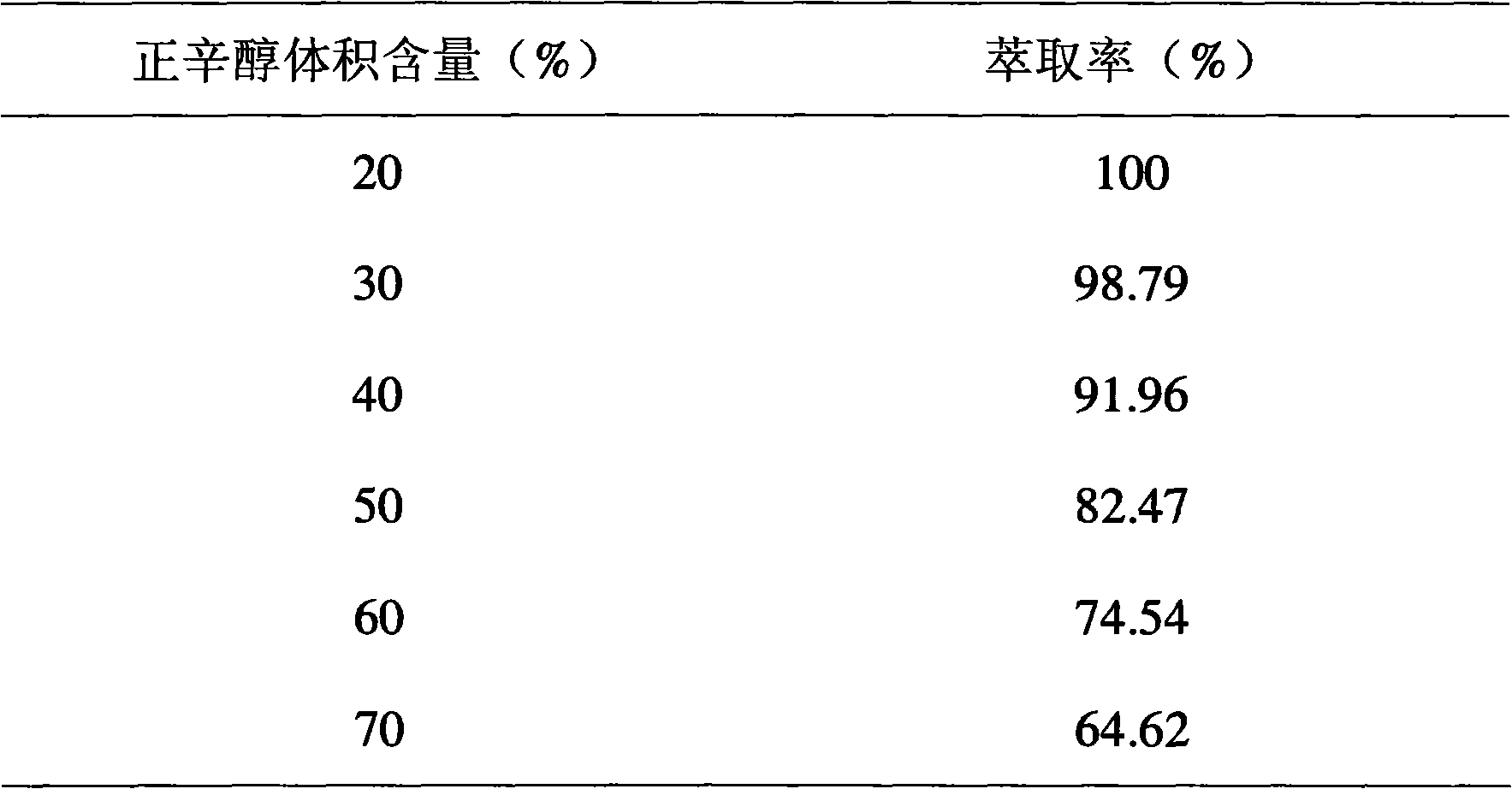

[0032] Example 3 Effect of n-octanol on extraction system

[0033] In this example, the effect of n-octanol on the entire extraction system is studied by comparing the addition of n-octanol and the absence of n-octanol in the extraction system.

[0034] 1. The extraction system does not add n-octanol

[0035] The extraction system is primary amine N-1923+kerosene, wherein primary amine N-1923 accounts for 25% of the total volume of the entire extraction system, and kerosene accounts for 75% of the total volume of the entire extraction system.

[0036] The extraction system was used to stand still to extract the aluminum sulfate solution, and it was found that the water phase and the oil phase were cloudy and could not be separated.

[0037] 2. Add n-octanol to the extraction system

[0038] The extraction system is primary amine N-1923 + n-octanol + kerosene, wherein primary amine N-1923 accounts for 25% of the total volume of the entire extraction system, kerosene accounts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com