Patents

Literature

113results about How to "High stripping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

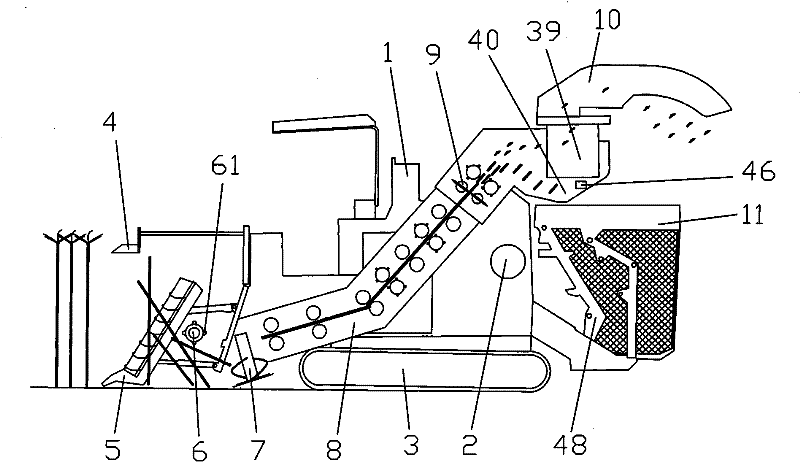

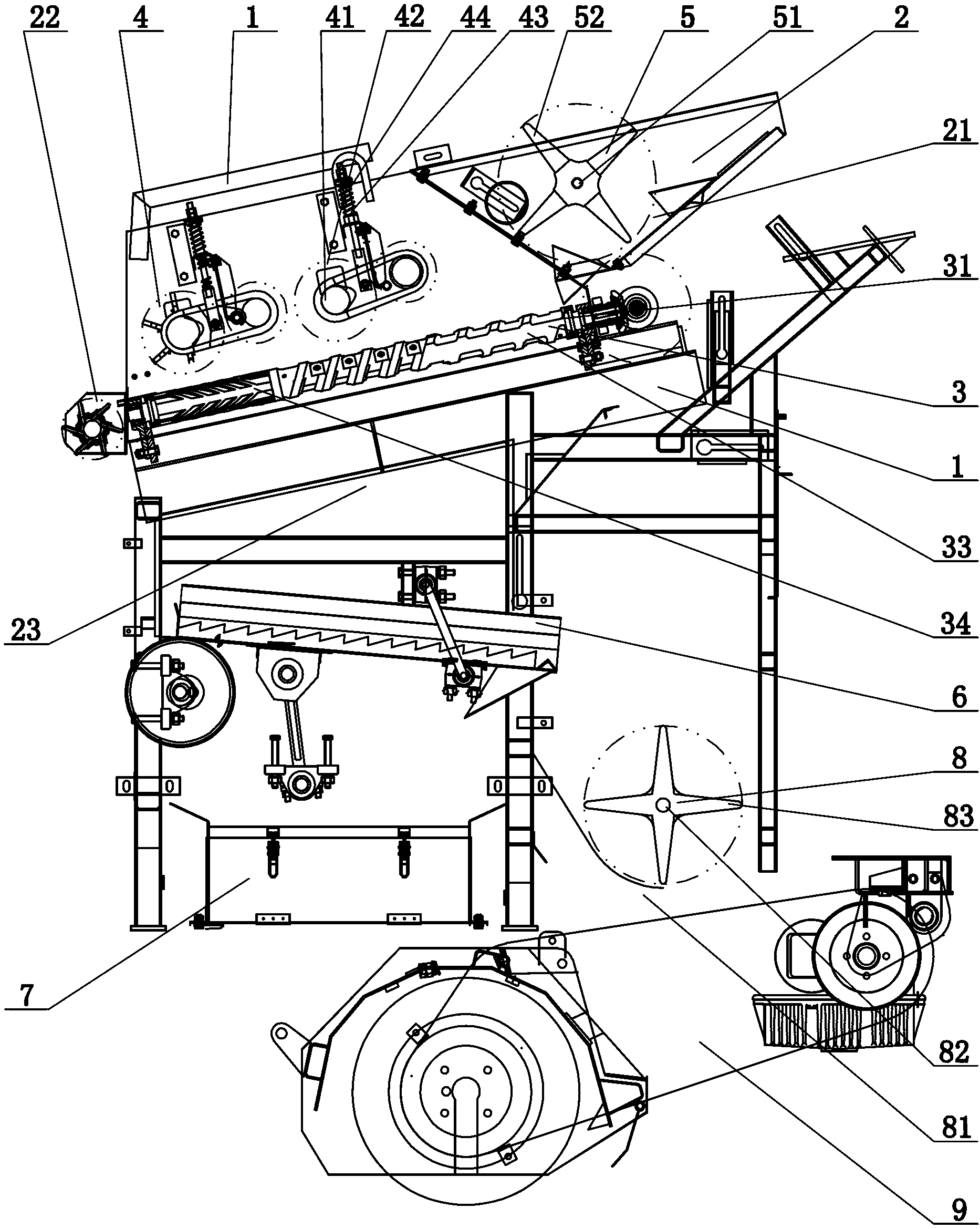

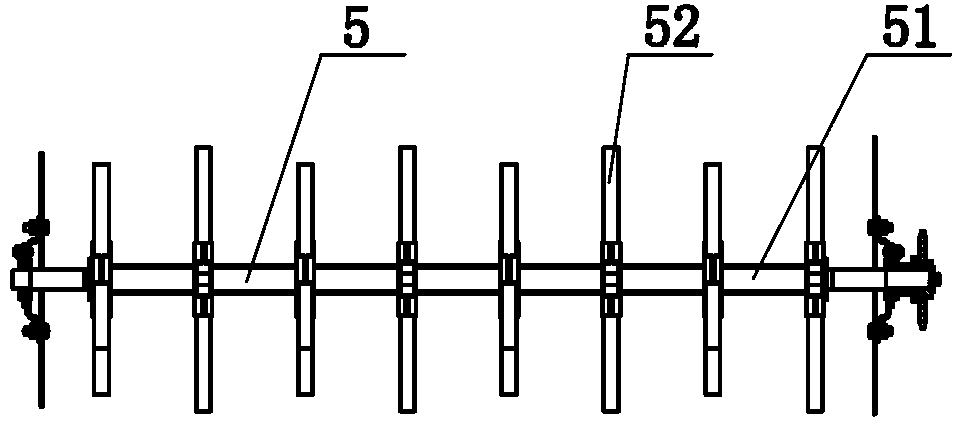

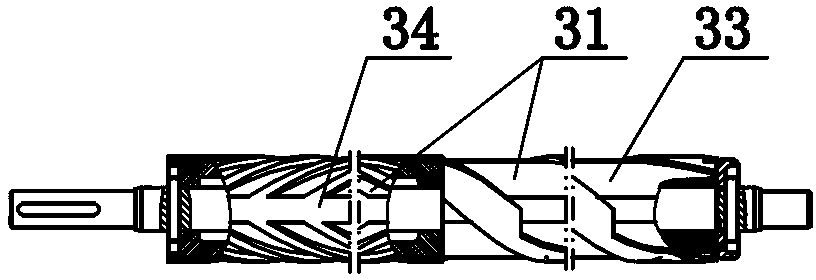

Segmenting type sugar cane combine harvester

InactiveCN101690449AAvoid cloggingReduce cloggingMowersAgricultural lifting devicesControl systemAgricultural engineering

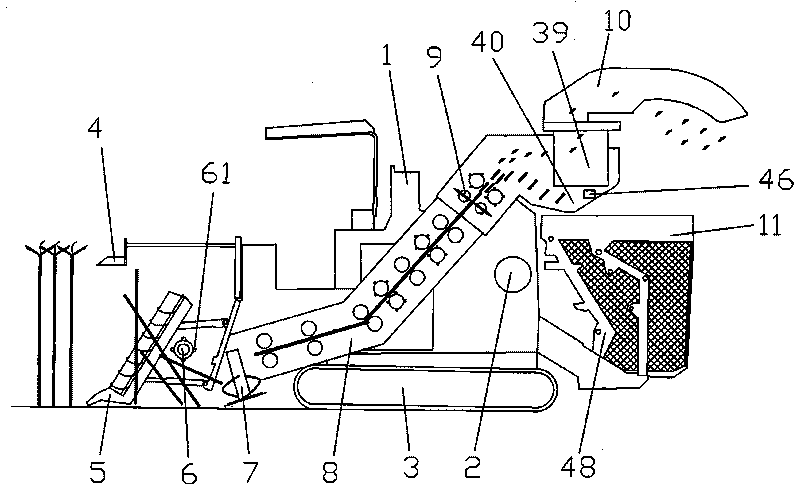

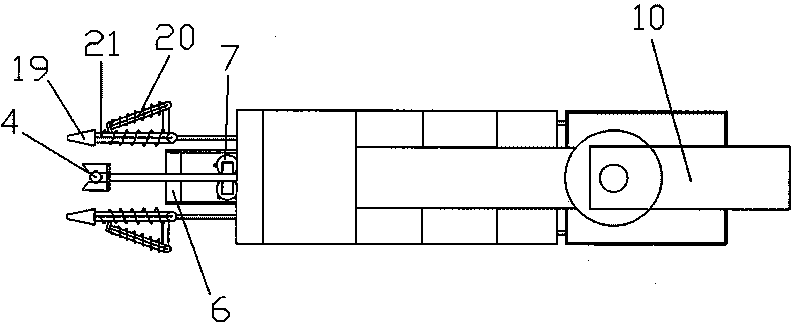

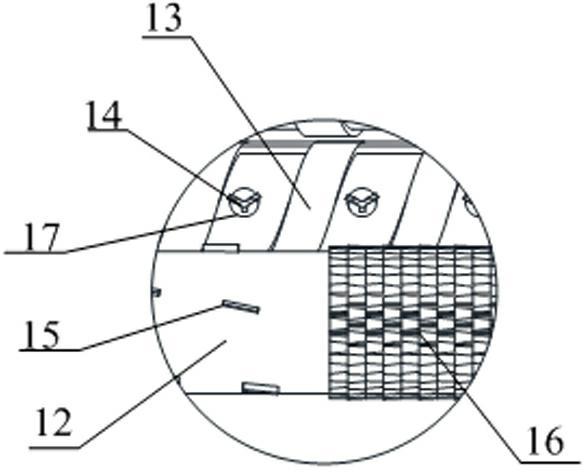

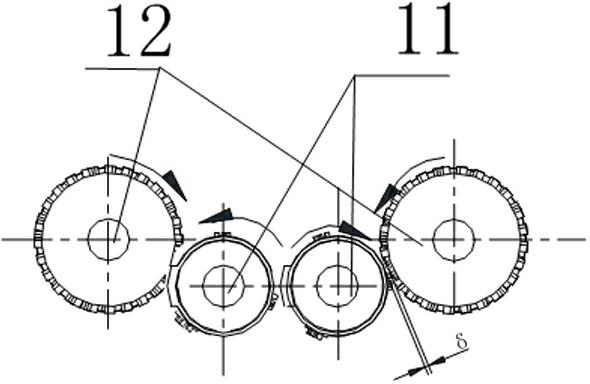

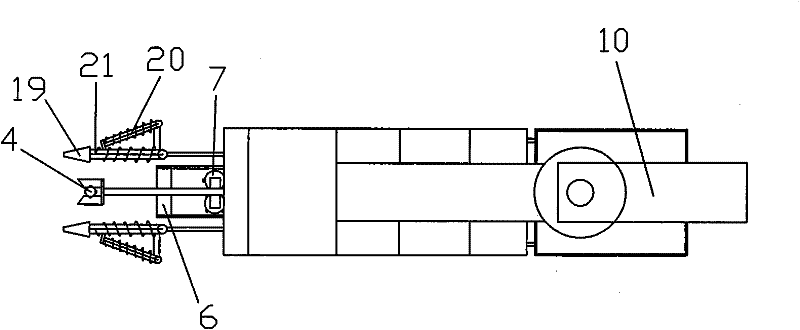

The invention discloses a segmenting type sugar cane combine harvester, which comprises a machine frame, an engine, a crawler type traveling mechanism, a hydraulic power and control system, a sugar cane topper device, a sugar cane supporting device, a sugar cane pressing combing roller, a cutting device, a conveying leaf-removing device, a segmenting device, an impurity discharging device and a collecting device, wherein the cutting device comprises a left set of cutting component and a right set of cutting component, and each set of cutting component comprises a screw conveying rod, a rotary shaft sleeve, a cutter head and a plurality of blades; and the sugar cane supporting device comprises a left set of sugar cane supporting mechanism and a right set of sugar cane supporting mechanism, and each set of sugar cane supporting mechanism is controlled by an independent adjusting mechanism. The segmenting type sugar cane combine harvester has the advantages of having high capability of separating and harvesting sugar canes which are seriously flattened and / or intertwisted, lessening the choking phenomenon occurring in a process of harvesting sugar canes, improving fully removing rate of sugar cane leaves of the harvested sugar canes, reducing the impurity content in sugar cane segments, conveniently collecting sugar cane segments, avoiding the use of a following transport vehicle for collection and storage, along with compact structure, reasonable configuration, convenient travel and use in fields, good harvesting effect, high automation, low manufacturing cost and the like.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

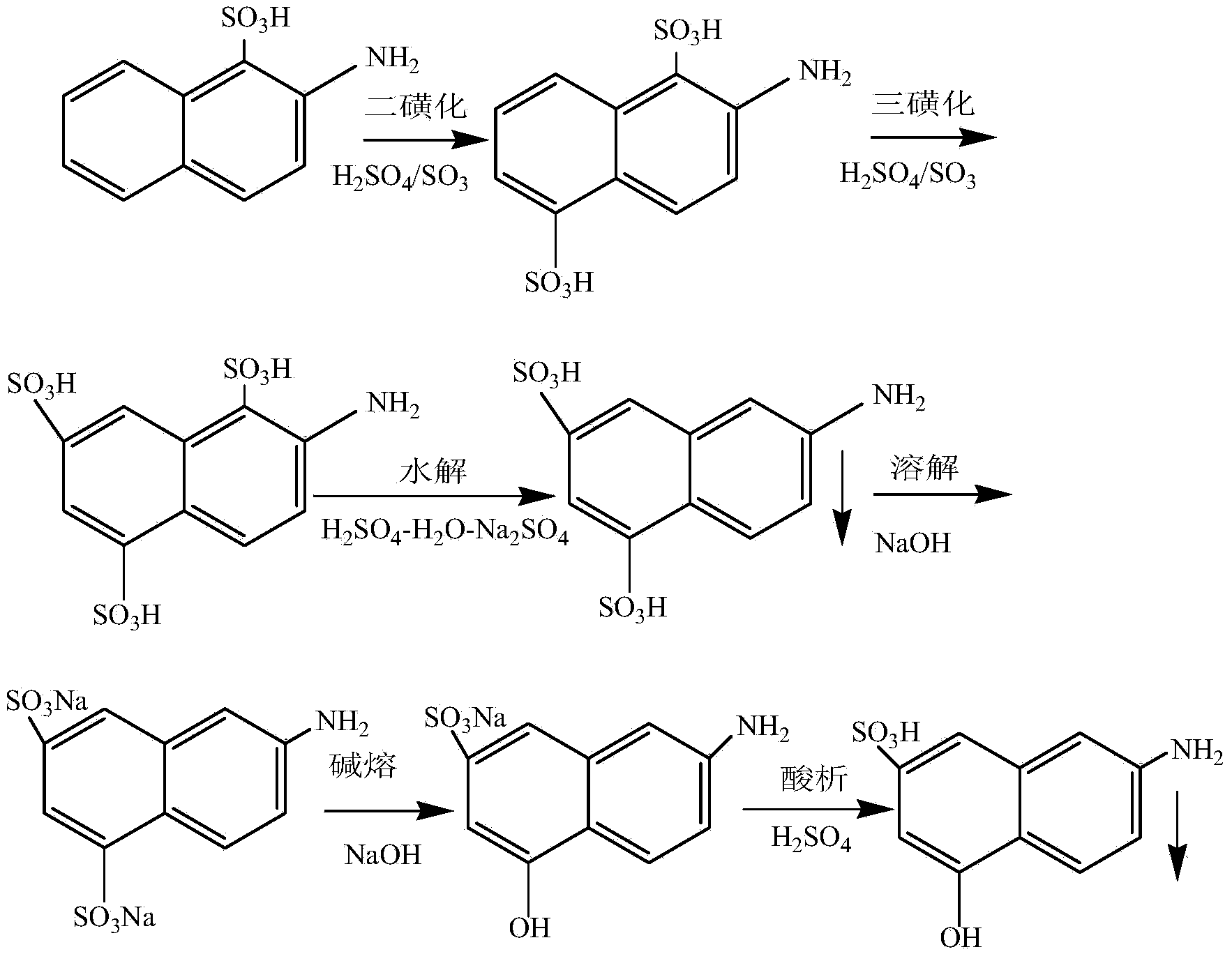

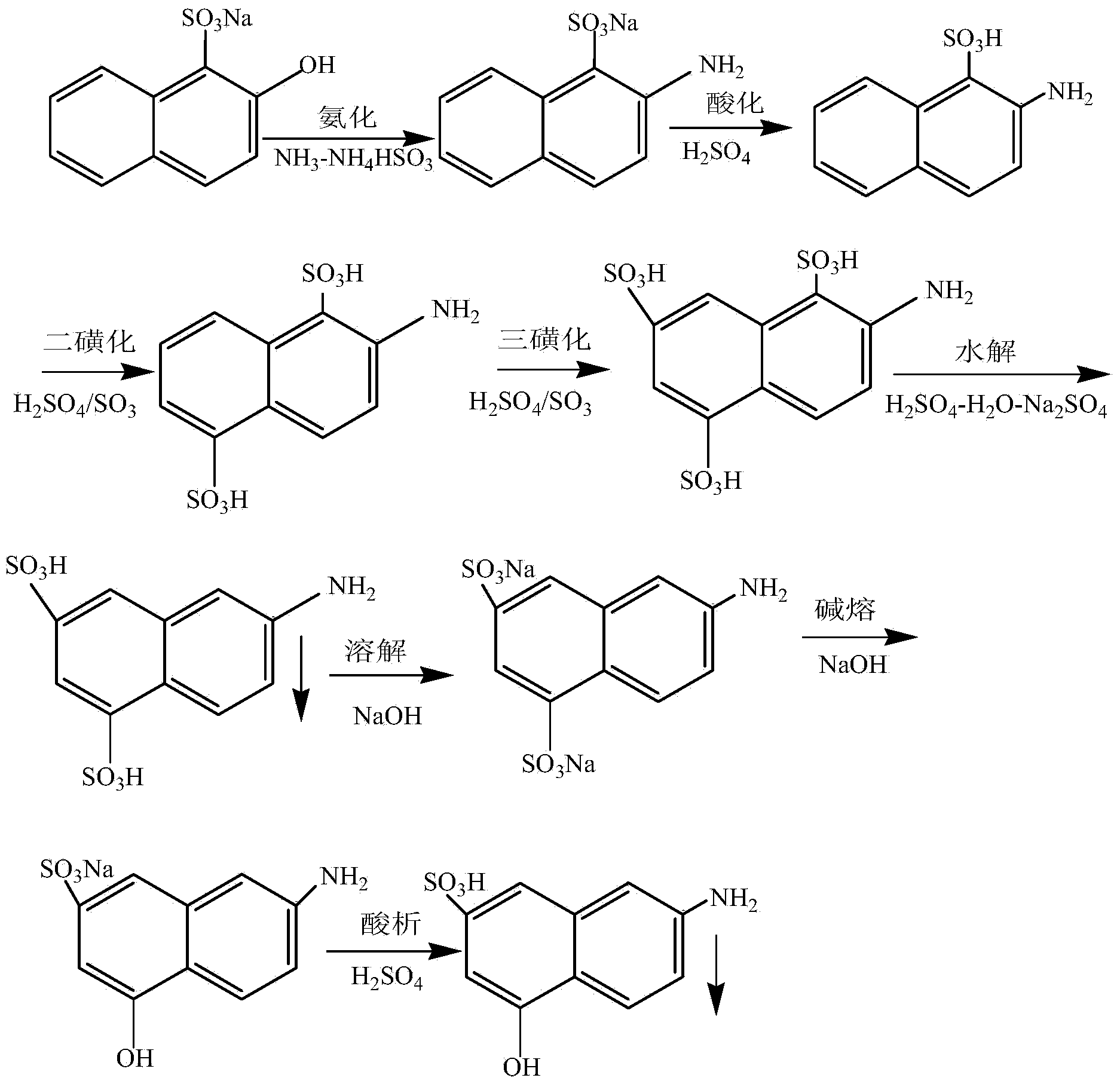

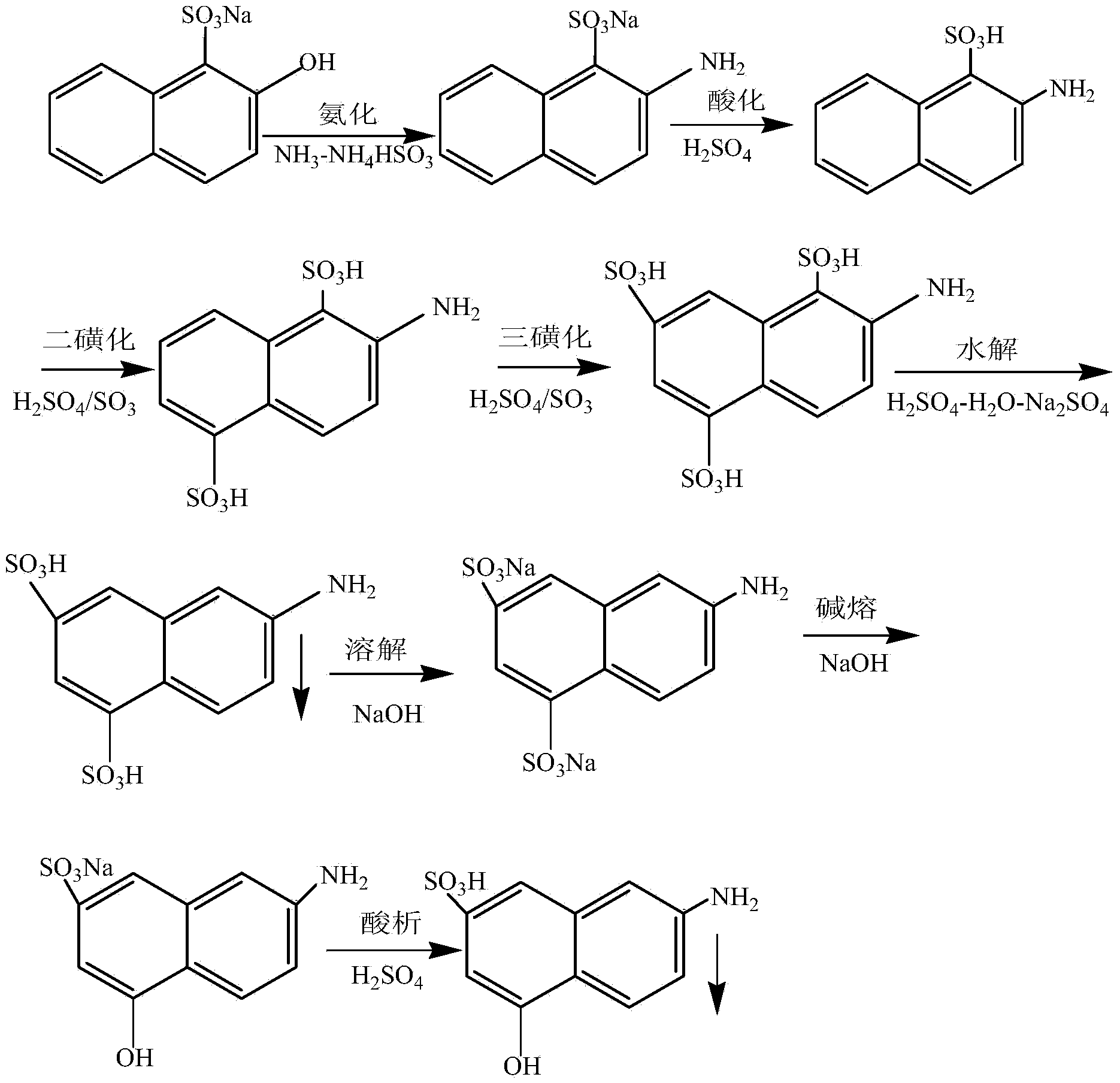

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

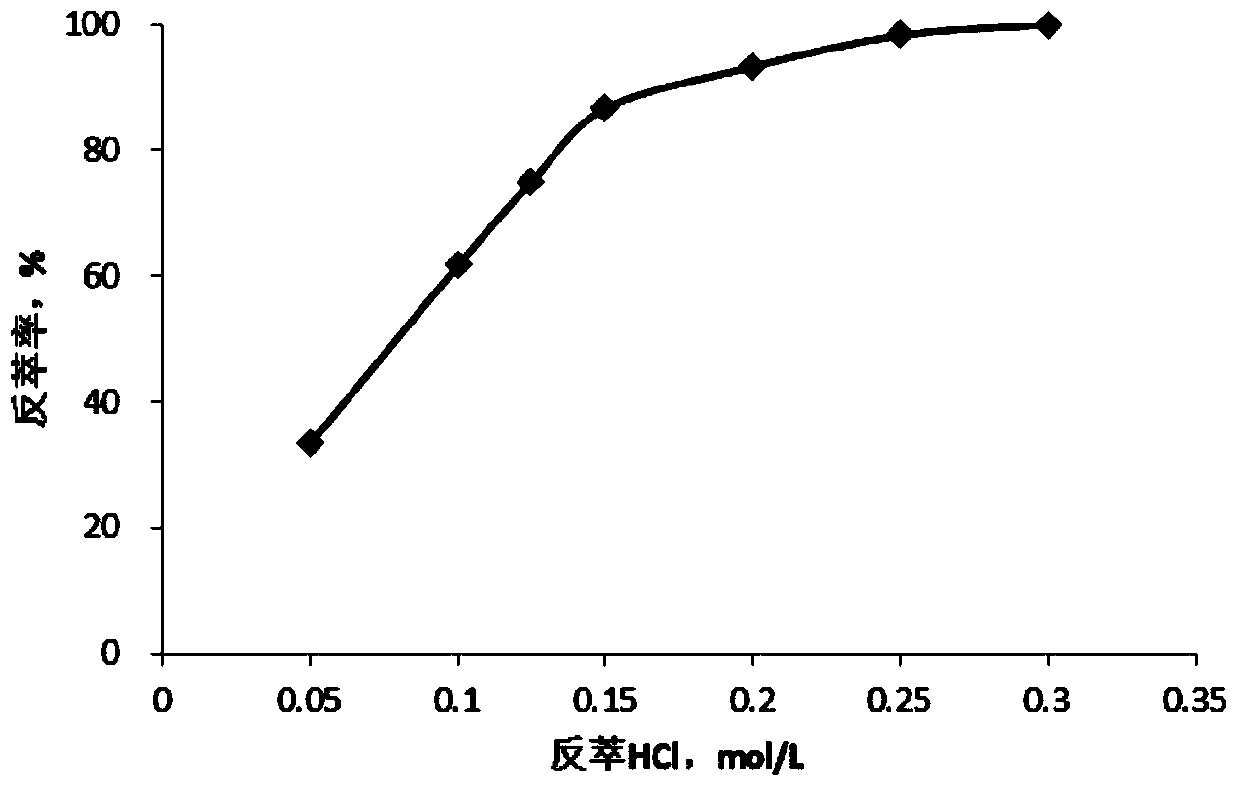

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

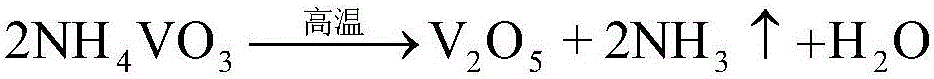

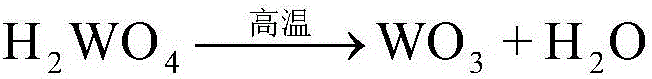

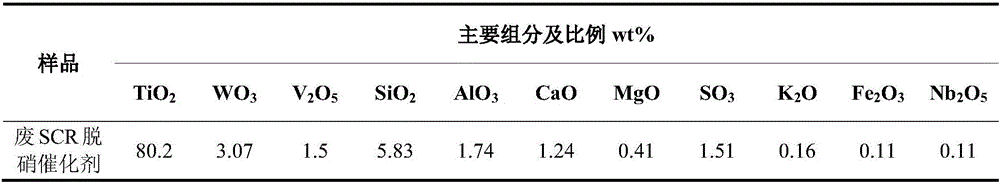

Separating and recovering method for W and V in waste SCR denitration catalyst

ActiveCN106048230AEfficient leachingHigh selectivityProcess efficiency improvementPregnant leach solutionKerosene

The invention discloses a separating and recovering method for W and V in a waste SCR denitration catalyst, and belongs to the technical field of recovery of waste catalysts. The separating and recovering method comprises the specific steps that at first, after being smashed and dried, the SCR catalyst is uniformly mixed with Na2CO3 to obtain a mixture, the mixture is calcined at high temperature to obtain a calcined product, and the calcined product is placed in dilute sulphuric acid to leach W and V; then, W and V in the leachate are extracted with a trioctylamine-isodecanol kerosene solution, and are separated out from an extracted organic phase with NaOH as a back-extractant; next, H2SO4 is added in a back extraction solution to regulate pH, excessive NH4C1 is added to realize vanadium precipitation, and ammonium metavanadate precipitates obtained through filtering are calcined to obtain a V2O5 product; and at last, sulfuric acid is continuously added in a secondary filtrate obtained after vanadium precipitation to regulate pH, excessive CaCl2 is added to realize tungsten precipitation, CaWO4 precipitates obtained through filtering are pickled with hydrochloric acid to obtain a pickled product, and the pickled product is calcined to obtain a WO3 product. The separating and recovering method can realize efficient separation and recovery of W and V in the waste SCR catalyst, the process is simple, the pollution is less, and the separating and recovering method has a relatively high engineering application value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

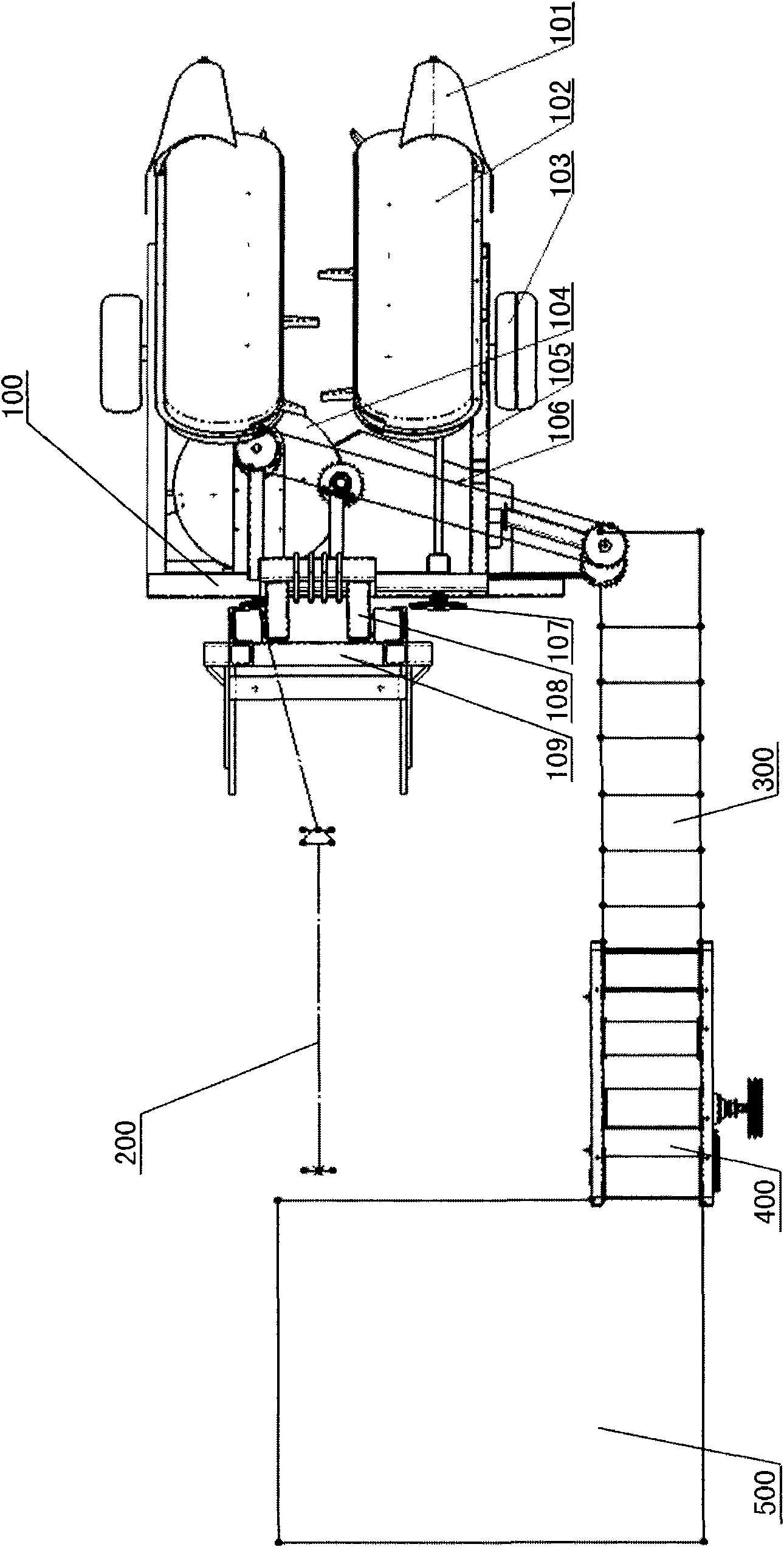

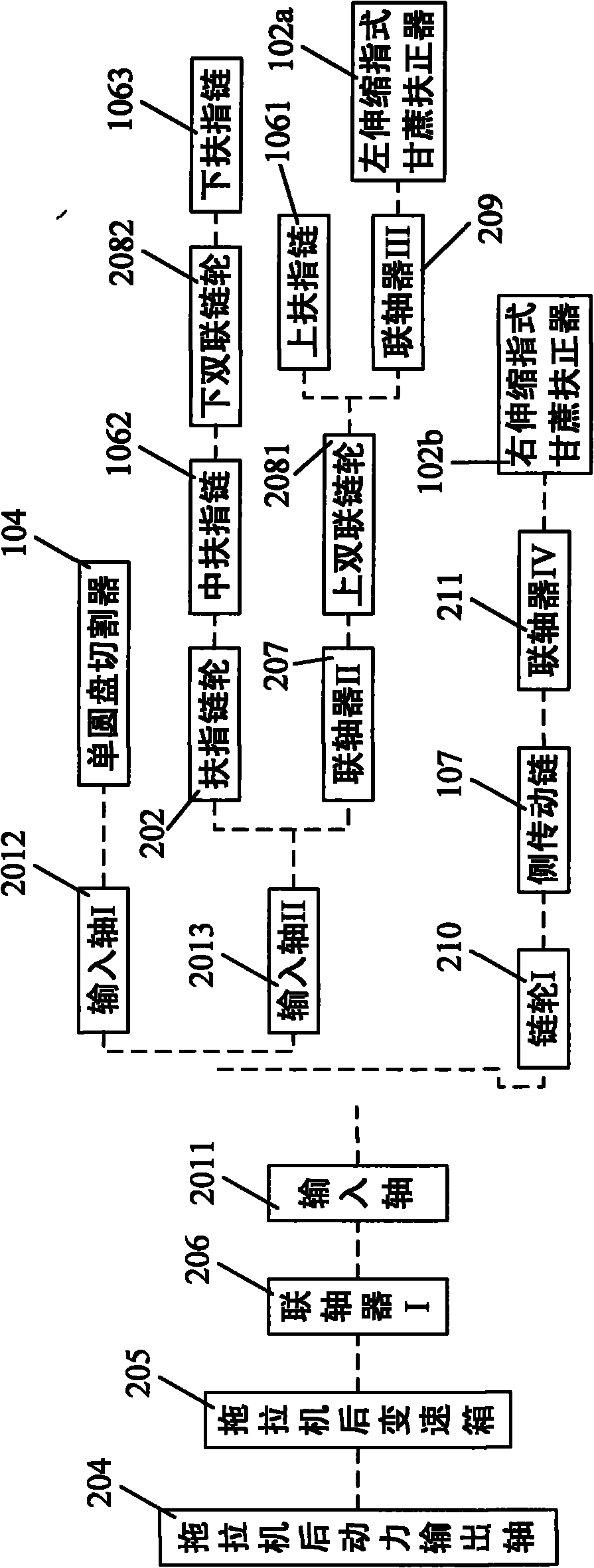

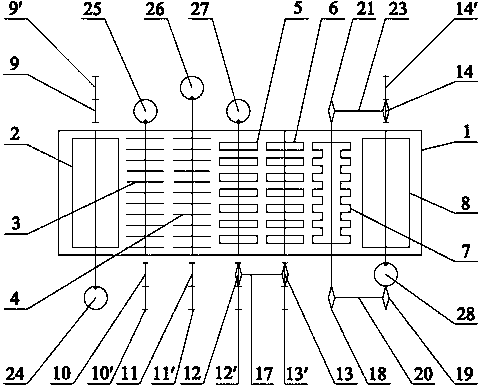

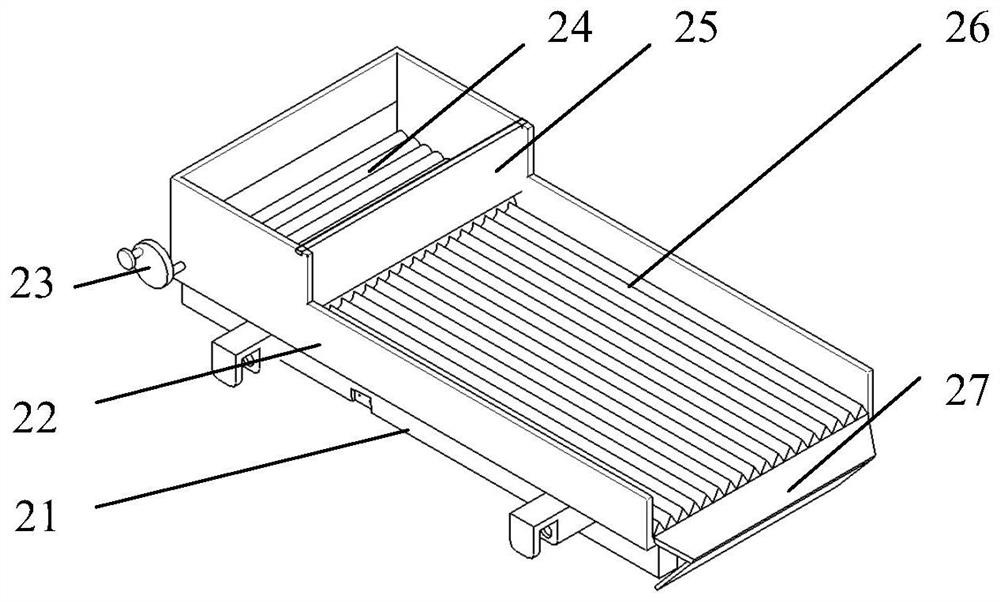

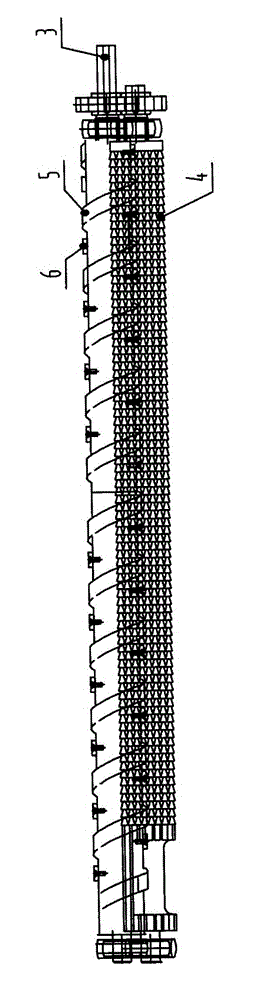

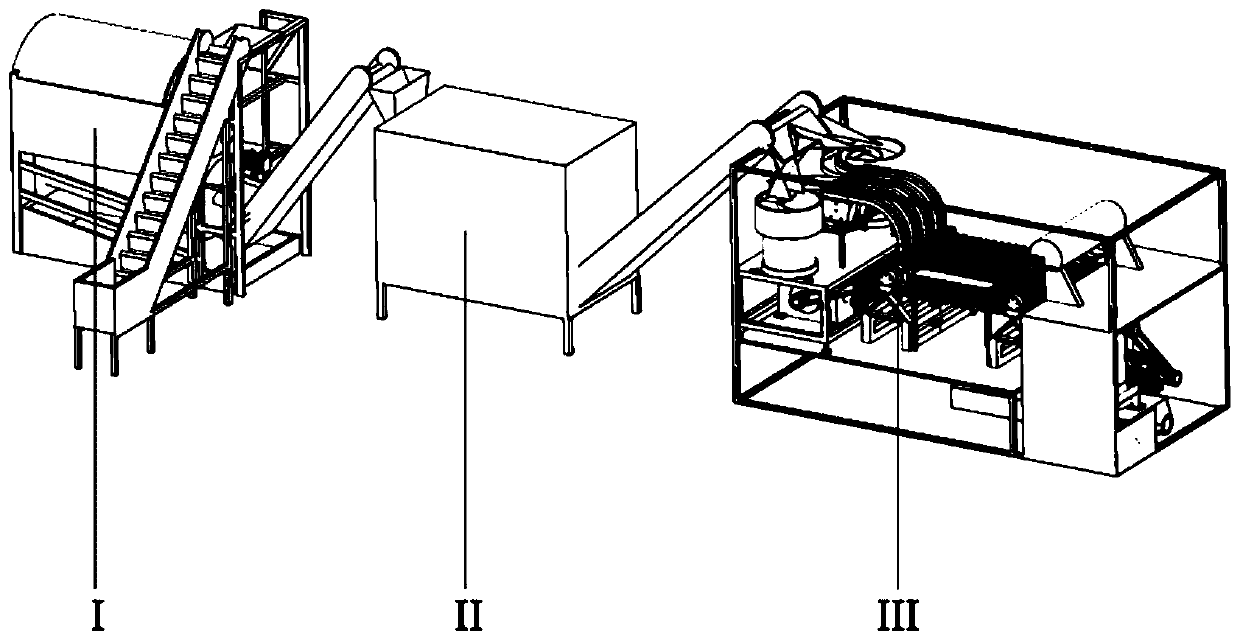

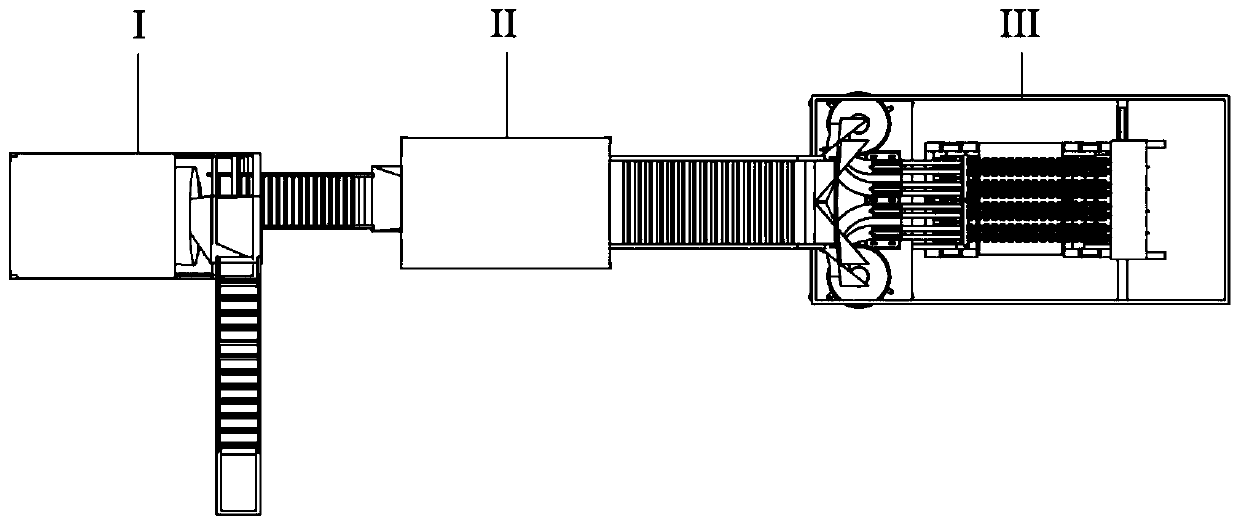

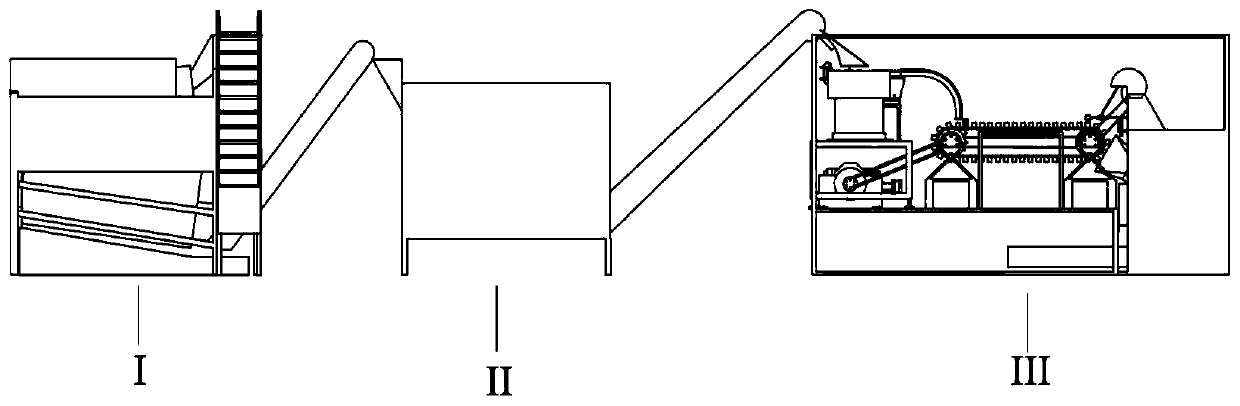

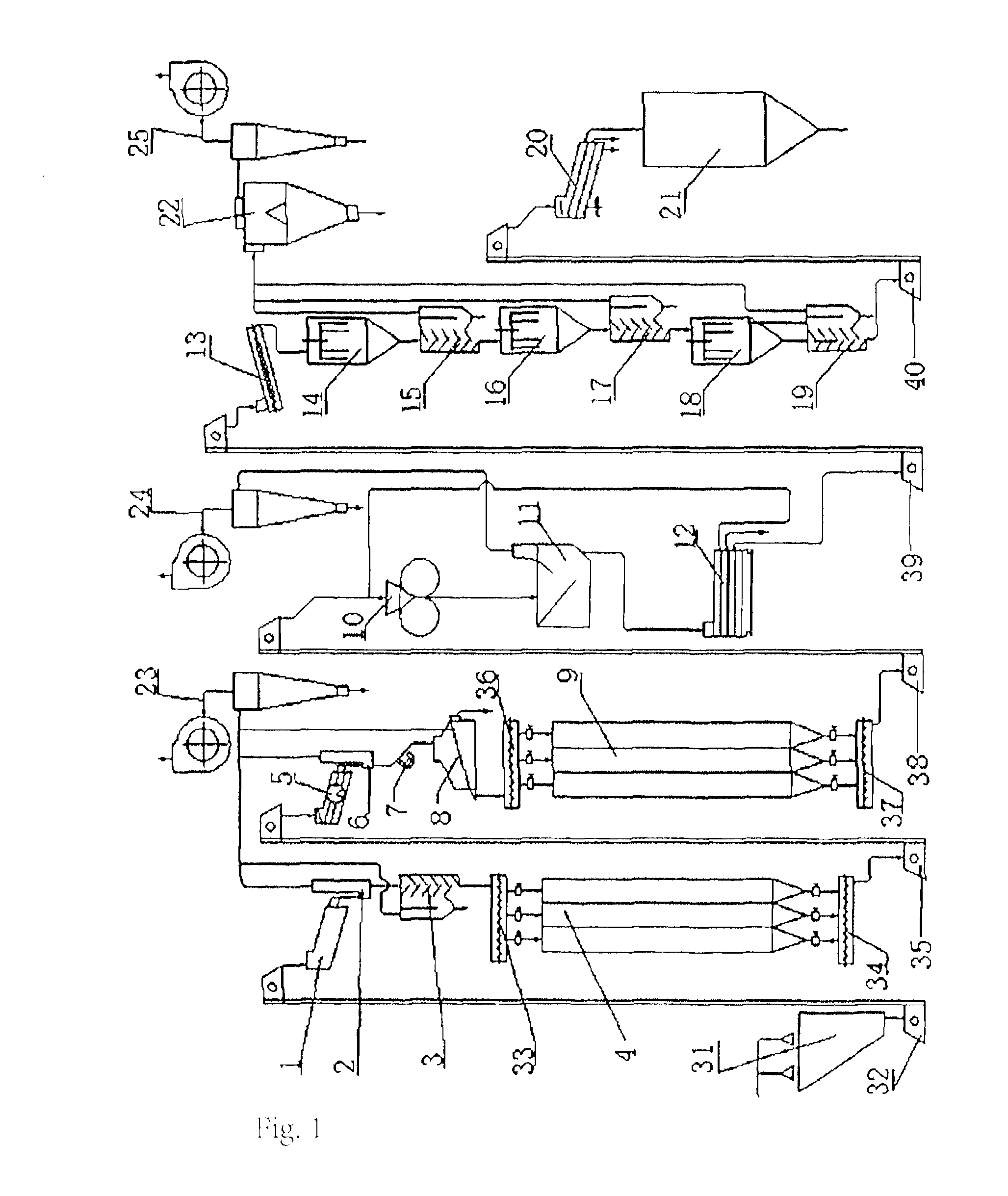

Sugarcane whole stem leaf-peeling device, harvester with same and leaf-peeling method thereof

ActiveCN101836537AReduce power consumptionImprove stripping rateHarvestersVegetable peelingEngineeringDrivetrain

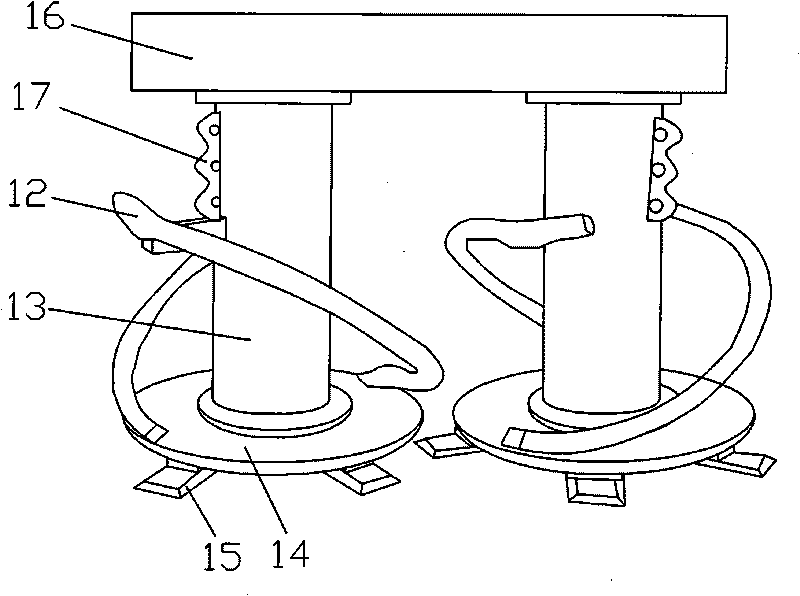

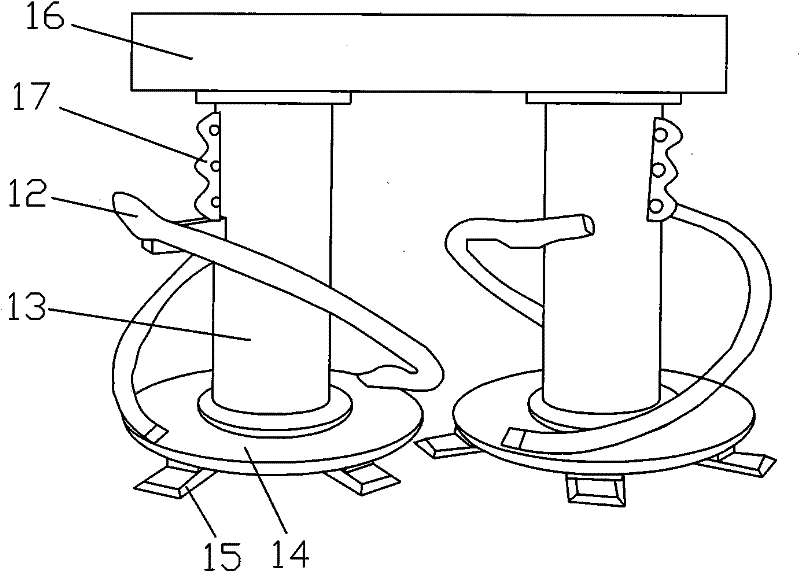

The invention relates to a sugarcane whole stem leaf-peeling device, a harvester with the same, and a leaf-peeling method thereof. The harvester comprises a harvesting device, a power device, a chassis, a side conveying device, a leaf-peeling device and a sugarcane collecting device, wherein the leaf-peeling device comprises a guide cover plate, a pair of tip-cutting rolls, a traverse leaf-peeling roll, a vertical leaf-peeling roll, a speed-limit roll and a power transmission system. A sugarcane is firstly fed into the guide cover plate in a tip-first way, the tip-cutting rolls are oppositely arranged for crushing a growing point of the sugarcane to remove the tip and then fed into the traverse leaf-peeling roll, the transverse leaf-peeling roll and the vertical leaf-peeling roll are fixed with a plurality of rows of lead-peeling brushes, when the sugarcane passes through, leaf-peeling in an upper direction, a lower direction, a left direction and a right direction is completed, and the sugarcane does a certain axial rotation under the drive of the tip-cutting rolls and the speed-limit roll so as to achieve full-direction leaf-peeling. The invention reduces the power consumption, improves the sugarcane whole stem leaf-peeling rate, and can complete integration operations of whole stem buried cutting, transverse and vertical conveying, longitudinal conveying, tip crushing, leaf peeling and pilling placement by one-stop operation.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

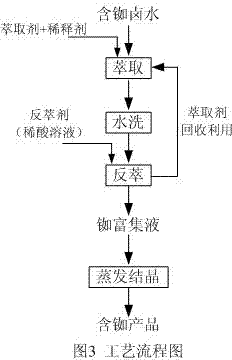

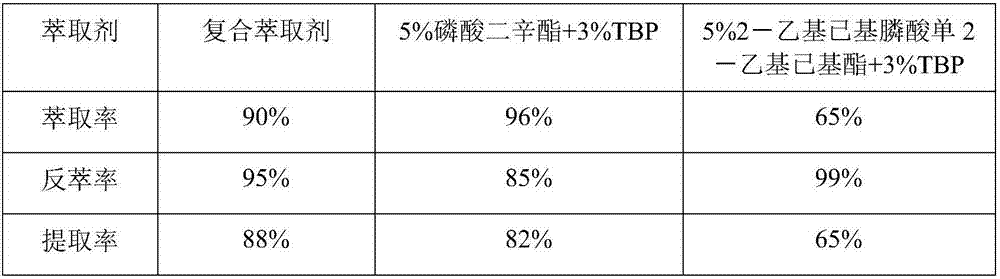

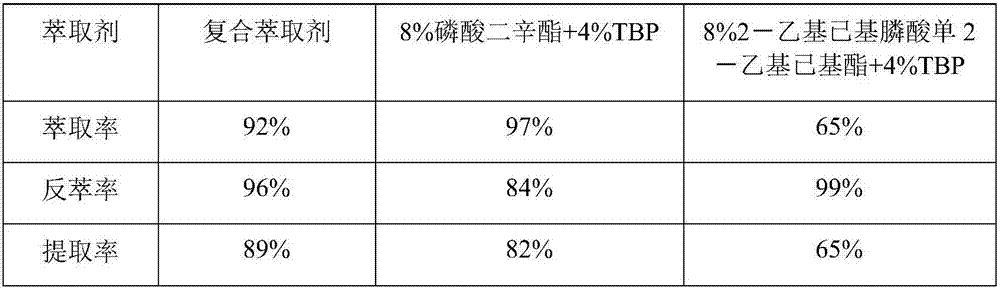

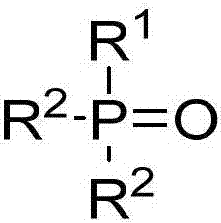

Composite extraction system for extracting lithium from lithium containing bittern and extraction method of composite extraction system

The invention discloses a composite extraction system for extracting lithium from lithium containing bittern and an extraction method of the composite extraction system. The composite extraction system is loaded with 2.5 g / L-10.4 g / L of Fe (III), 10%-60% of an extraction agent A and 10%-30% of an extraction agent B are included, and the balance is diluent, wherein the extraction agent A is a neutral phosphine extraction agent and / or an amides extraction agent, the extraction agent B is an acid phosphine extraction agent, and the percent is the volume percent occupied in the composite extraction system. The composite extraction system can effectively extract lithium from the lithium containing bittern, lithium reverse extraction can effectively conducted especially when the pH ranges from 1.0 to 1.8, the corrosivity to equipment due to peracid reverse extraction is avoided, and lithium is easily recycled in the reverse extraction liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

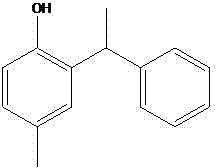

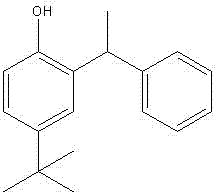

Novel rubidium-potassium separating extracting agent and separating method

InactiveCN103882227AMild extraction conditionsFast phase separationOrganic chemistryOrganic compound preparationPhysical chemistrySolvent

The invention relates to a novel rubidium-potassium separating extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol and a rubidium-potassium separating method. 4-methyl-2-(alpha-methylbenzyl) phenol is taken as the extracting agent, and solvent oil such as D60, and the like, is taken as a diluent for extracting and separating rubidium in alkalescent high-potassium brine, wherein single-stage extraction rate of the rubidium can be over 85%, a rubidium-potassium separating coefficient can be over 30; enriched liquor obtained by reversely extracting an organic phase loaded with rubidium through acid liquor can be evaporated and concentrated to prepare rubidium salt products such as RuCl, RuNO3, and the like. Compared with the normal rubidium extracting agent 4-tertiary butyl-2-(alpha-methylbenzyl) phenol, the novel extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol has the advantages of being high in separating efficiency, simple in synthetic method, low in price, mild in extracting condition, and the like. The extracting agent is applicable to underground brine, salt lake brine and solid ore-decomposed rubidium-containing liquor.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

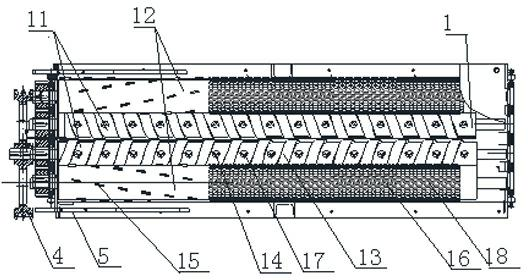

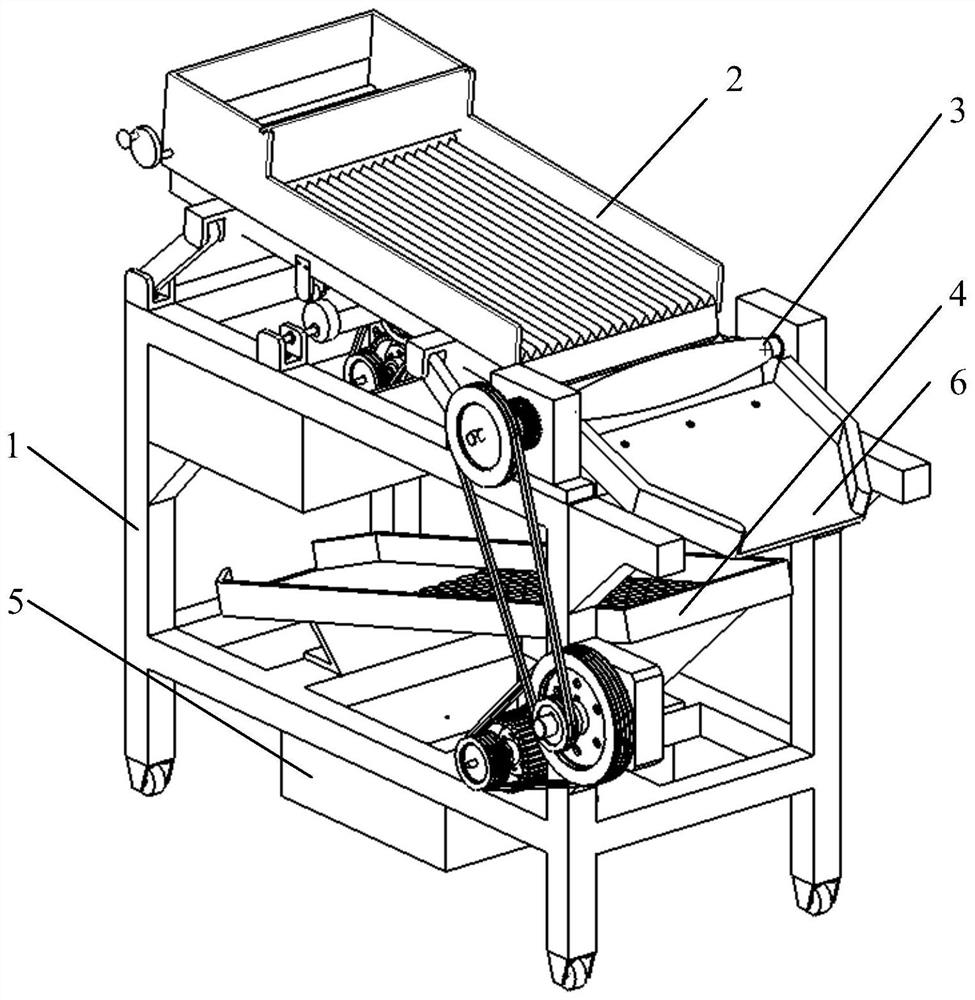

High-efficiency and low-breakage corn ear peeling device

InactiveCN102274771AImprove grip and tear abilityIncrease contact areaGrain huskingGrain polishingWaxy cornMetal strips

The invention relates to agricultural machinery, in particular to a peeling mechanism for removing bracteal leaves from fresh corn ears, in particular to a device for efficiently peeling corn ears at a low smashing rate. The device comprises a feeding hopper, a discharging hopper, a transmission system and a frame, wherein the frame is provided with an engine base; the engine base is provided with a peeling roller device; the peeling roller device comprises at least two pairs of peeling rollers which are meshed in parallel with each other; the peeling rollers consist of fixed peeling rollers and floating peeling rollers; the surface of each fixed peeling roller is provided with metal strip-shaped spiral bumps and inverted V-shaped bracteal leaf cutting teeth; the floating peeling roller close to one side of the feeding hopper is provided with rasp bar-shaped peeling teeth; and the other side is provided with rubber trapezoidal peeling teeth. The device is particularly suitable for fresh corns (such as fruit corns, waxy corns and sweet corns) with high moisture and tight bracteal leaves, fodder corns, corn seeds and the like, and has a good peeling effect, high efficiency and low smashing rate.

Owner:GANSU AGRI UNIV

Rare-earth organic extractant and back-extraction process thereof

InactiveCN103602812AAchieve near-zero emissionsReduce pollutionProcess efficiency improvementKeroseneRare earth

The invention discloses a rare-earth organic extractant and a back-extraction process thereof. The organic extractant contains the ingredients in percentage by volume: 20-35% of cyclohexane, 15-45% of liquid ammonia saponification extractant, 15-35% of N235 and 20-40% of sulfonated kerosene, wherein the liquid ammonia saponification extractant is either P507 or P204. The back-extraction process comprises the steps of preparing loading organic phases containing different rare earth concentrations through extraction, back-extracting and precipitating, thereby obtaining rare-earth oxalate with large grain diameter. A non-saponification extraction system is provided by the invention, and near-zero emission of ammonia nitrogen is realized; the back-extraction process disclosed by the invention has the advantages of high phase separation speed, obvious two-phase boundary and high back-extraction ratio; and a crystal is not deposited on a bottom plate of a back-extraction tank and does not scar on the periphery.

Owner:JIANGXI UNIV OF SCI & TECH

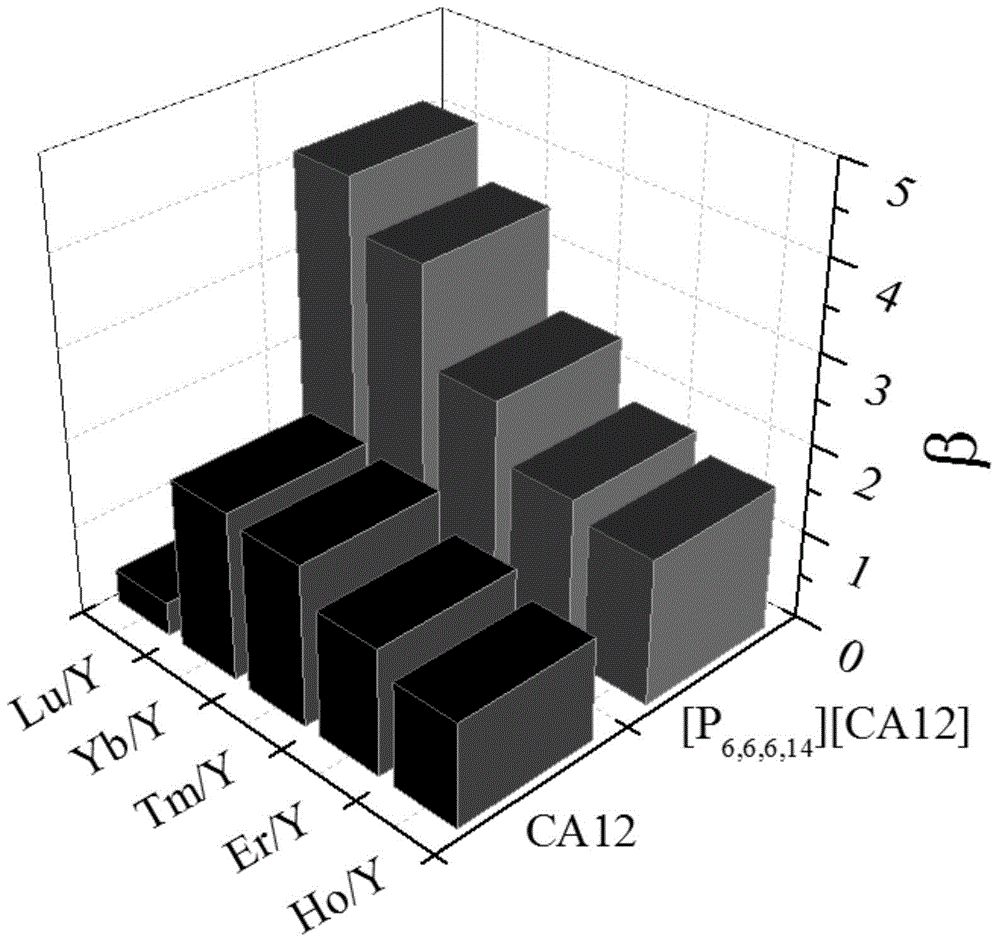

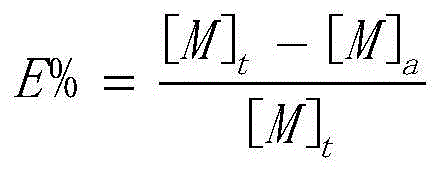

Extraction separation method for heavy rare earth elements

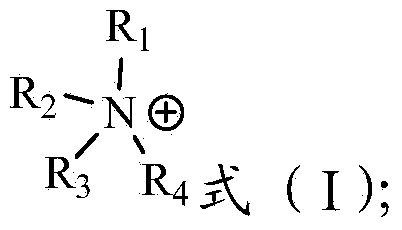

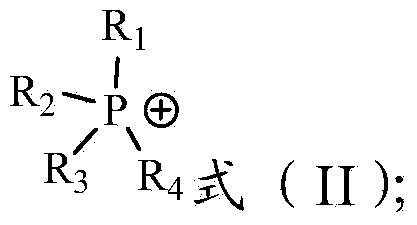

InactiveCN104195336AImprove the extraction separation factorHigh selectivityProcess efficiency improvementRare-earth elementPhosphonium

The invention provides an extraction separation method for heavy rare earth elements. The extraction separation method comprises the following steps: mixing rare earth concentrates with inorganic acid to obtain a raw material liquid; using an organic phase comprising an extraction agent and a thinning agent to extract rare earth elements in the raw material liquid, wherein the extraction agent is a difunctional ionic liquid extraction agent, and the difunctional ionic liquid extraction agent comprises one deprotonated acid phosphine negative ion of quaternary ammonium positive ions and quaternary phosphonium positive ions. According to the method provided by the invention, in the extraction process, due to the fact that the quaternary ammonium positive ions or the quaternary phosphonium positive ions in the difunctional ionic liquid extraction agent are distributed in an organic phase and a water phase, the competitive effect of ionic liquid positive ions and rare earth ions is strengthened, and the extraction separation coefficient of heavy rare earth is improved. Moreover, in the subsequent extraction process, due to specific phase transfer effect of ions, a stripping agent is easier to enter the organic phase, and the reextraction rate is greatly improved.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

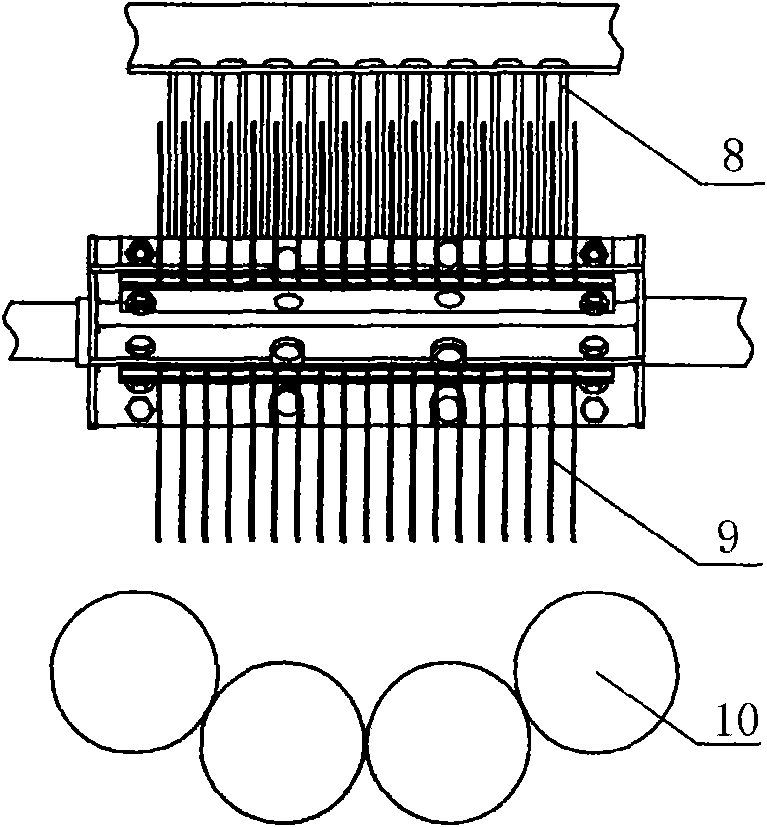

Corn peeling device

The invention discloses a corn peeling device. The device comprises a frame, a peeling roller group, pressure feeders and a husk combing device, wherein the peeling roller group is driven by a power device and rotatably arranged on the frame; the pressure feeders are driven by the power device and rotatably arranged on the frame; at least two groups of the pressure feeders are arranged above the peeling roller group in turn along a fruit cluster conveying direction; and the husk combing device is driven by the power device, arranged on the frame and positioned above the peeling roller group. Fruit clusters are combed, torn out and peeled, so that the peeling rate of the husk is enhanced remarkably; and peeling nails arranged along the axial direction of a rigid roller shaft in the conventional corn peeling device are eliminated, so that seed loss caused by the peeling nails is eliminated and the peeling rate of the husk and the seed loss rate can be balanced.

Owner:LOVOL HEAVY IND

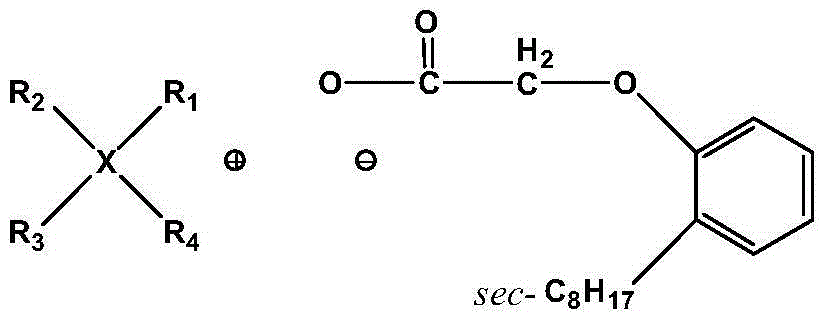

Extractant for yttrium extraction separation and extraction separation method thereof

ActiveCN104946888ASimple ingredientsImprove performanceProcess efficiency improvementRare earthAmmonia

The invention relates to an extractant for yttrium extraction separation and an extraction separation method thereof. The cation of the extractant is quaternary phosphine or quaternary ammonia group, and the anion is sec-octylphenoxy substituted acetate. The extractant is simple in components; and the prepared organic phase has stable performance and can be recycled, and the concentration is not obviously lowered. The organic phase formed by mixing the extractant and diluter can be used for efficiently extracting an yttrium-containing rare-earth solution. Due to the particular phase transition action of the ionic liquid, the back extraction agent can enter the organic phase more easily, thereby greatly enhancing the back extraction rate.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

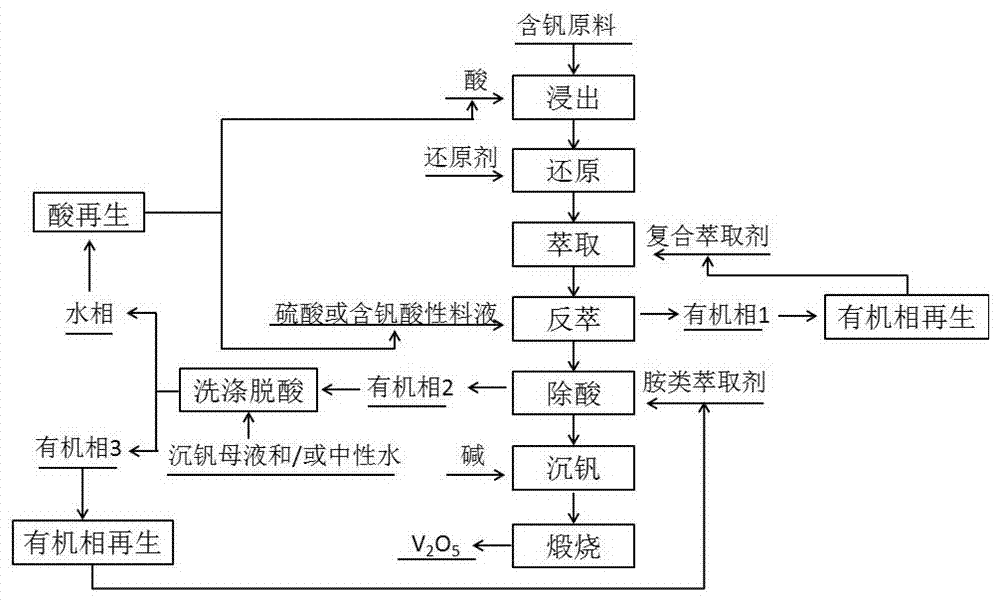

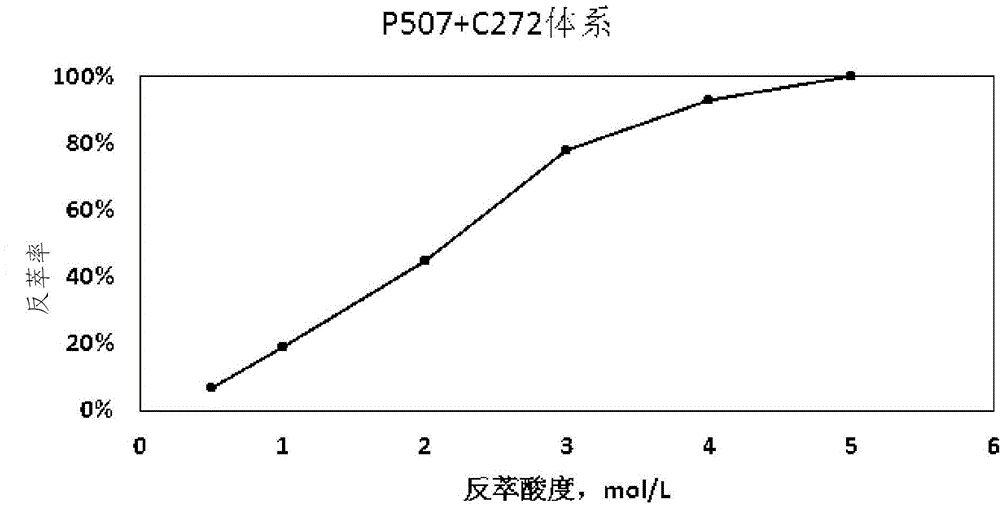

Method for preparing vanadium pentoxide through composite extraction

ActiveCN107226484AHigh extraction rateImprove extraction abilityVanadium compounds preparationVanadium oxidesPhysical chemistryPhosphoric acid

The present invention relates to a vanadium pentoxide preparation method, and provides a method for preparing vanadium pentoxide through composite extraction. The method comprises: (1) leaching; (2) reducing; (3) extracting, wherein a vanadium-containing material liquid is extracted with a composite extractant prepared from a phosphate organic matter and a modifier to prepare a vanadium-containing supported organic phase; (4) carrying out back extraction, wherein the supported organic phase is subjected to back extraction with sulfuric acid or a vanadium-containing sulfuric acid solution to prepare a vanadium-rich liquid; (5) removing acid, wherein the excess acid in the vanadium-rich liquid is extracted; (6) precipitating vanadium; and (7) calcining. According to the present invention, the vanadium is extracted with the composite extractant having strong extraction ability and strong back extraction ability, such that the vanadium extraction rate and the vanadium purity can be improved so as to improve the yield and the product of the vanadium pentoxide product, and the alkali consumption can be reduced so as to reduce the production cost.

Owner:CHONGQING KOOPPER CHEM IND

Extraction composition, extraction system, extraction method and back extraction method

ActiveCN107447108AGood acid and alkali stabilityLow water solubilityProcess efficiency improvementSolubilityOxygen compound

The invention discloses an extraction composition, an extraction system, an extraction method and a back extraction method. The extraction composition comprises an extraction agent and a neutral phosphorus-oxygen compound, and the extraction agent comprises N,N-di-(2-ethylhexyl) acetamide and N,N-di-(2-ethylhexyl) propanamide. The extraction composition provided by the invention is good in pH stability, low in water solubility, density and viscosity, free of complex extraction operation, small in corrosion to equipment and suitable for the industrial operating requirements.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

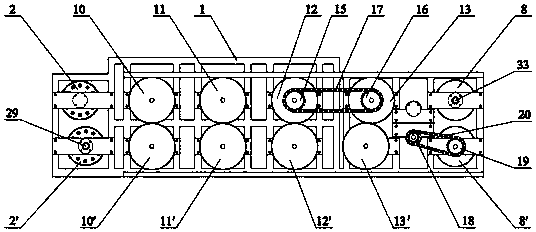

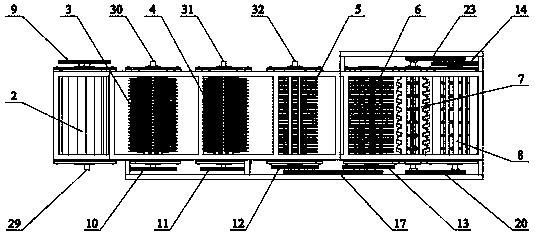

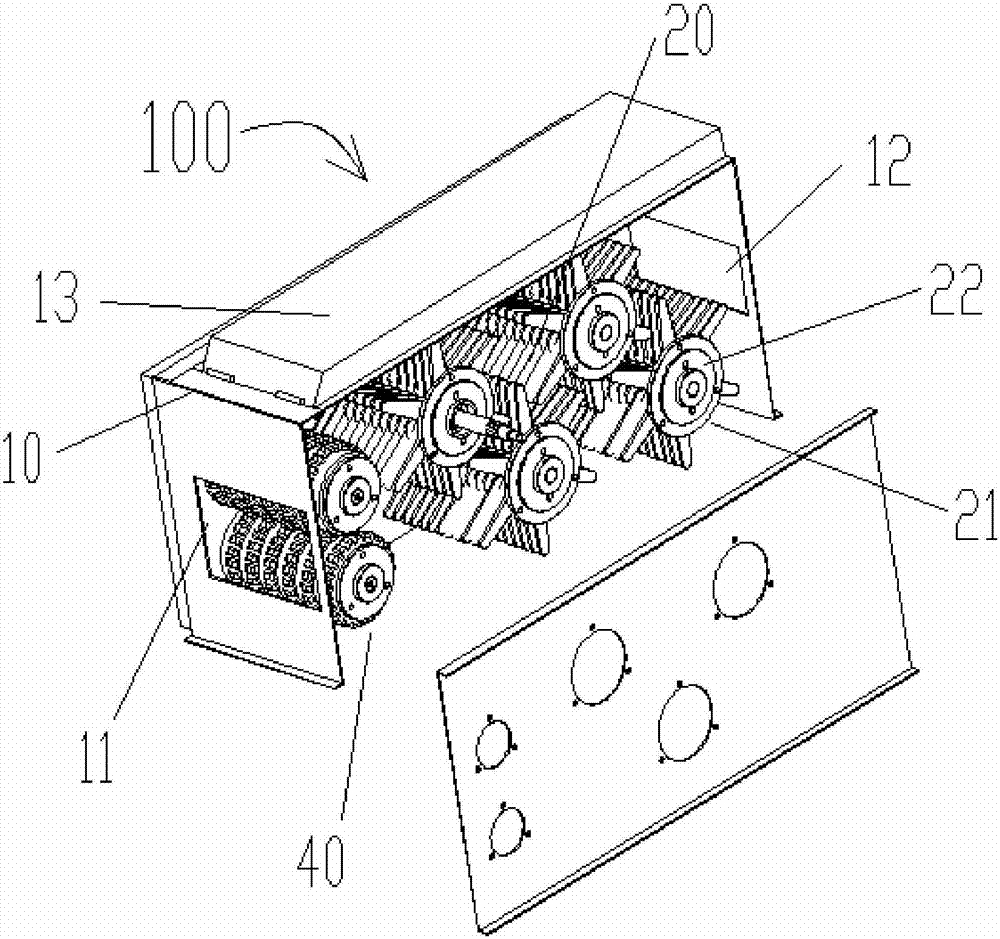

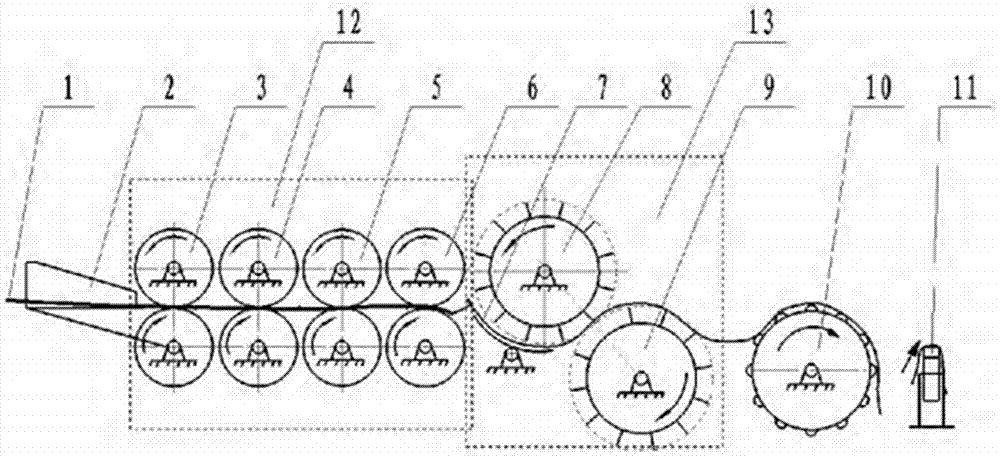

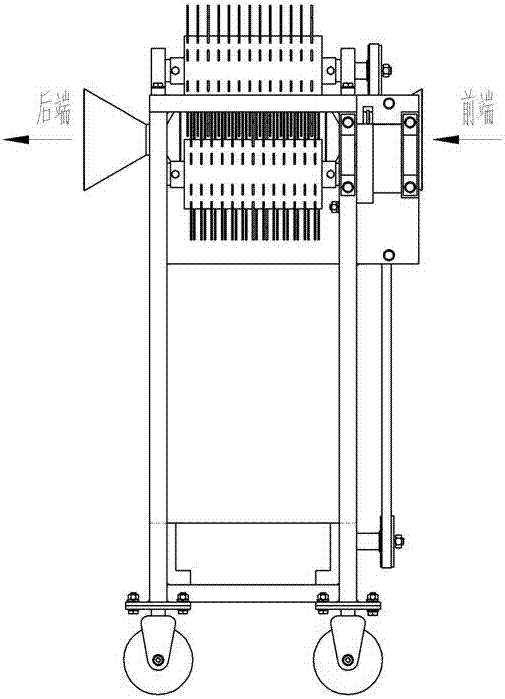

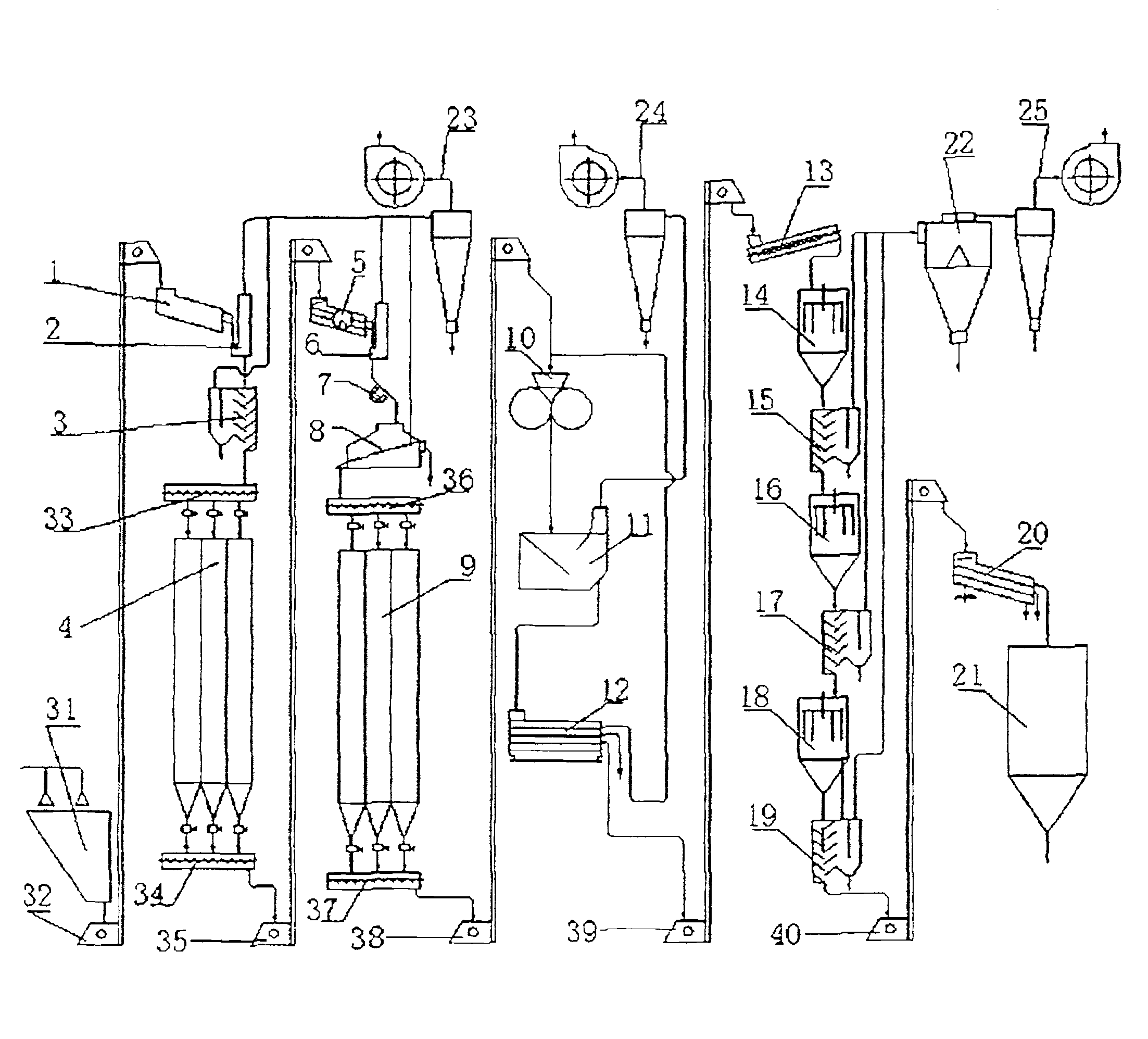

Harvested sugar cane integrated operating system of whole stalk sugarcane harvester

The invention discloses a harvested sugar cane integrated operating system of a whole stalk sugarcane harvester. The harvested sugar cane integrated operating system comprises a frame, a front conveying mechanism, a two-stage leaf smashing mechanism, a two-stage leaf stripping mechanism and a rear conveying tail cutting mechanism. The front portion of the frame is provided with the front conveying mechanism, the middle-front portion is provided with the two-stage leaf smashing mechanism, the middle-rear portion is provided with the two-stage leaf stripping mechanism, and the rear portion is provided with the rear conveying tail cutting mechanism. According to the harvested sugar cane integrated operating system, the front conveying mechanism, the leaf smashing mechanism, the leaf stripping mechanism and the rear conveying tail cutting mechanism are integrated into an operating system, space occupation of the system is reduced; the two-stage leaf smashing mechanism and the two-stage leaf stripping mechanism are arranged, on the conditions that a primary mechanism cannot smash and strip leaves completely, the two-stage mechanisms can complete in an assisting manner, so that complete stripping rate is increased effectively; a front conveying motor, a primary leaf smashing motor, a two-stage leaf smashing motor, a primary leaf stripping motor and a tail cutting motor are all hydraulic driving motors, so that system transmission is stable through hydraulic driving, rapid speed changing and reversing can be implemented without impact, and the system is easy to arrange and operate.

Owner:ZHEJIANG UNIV

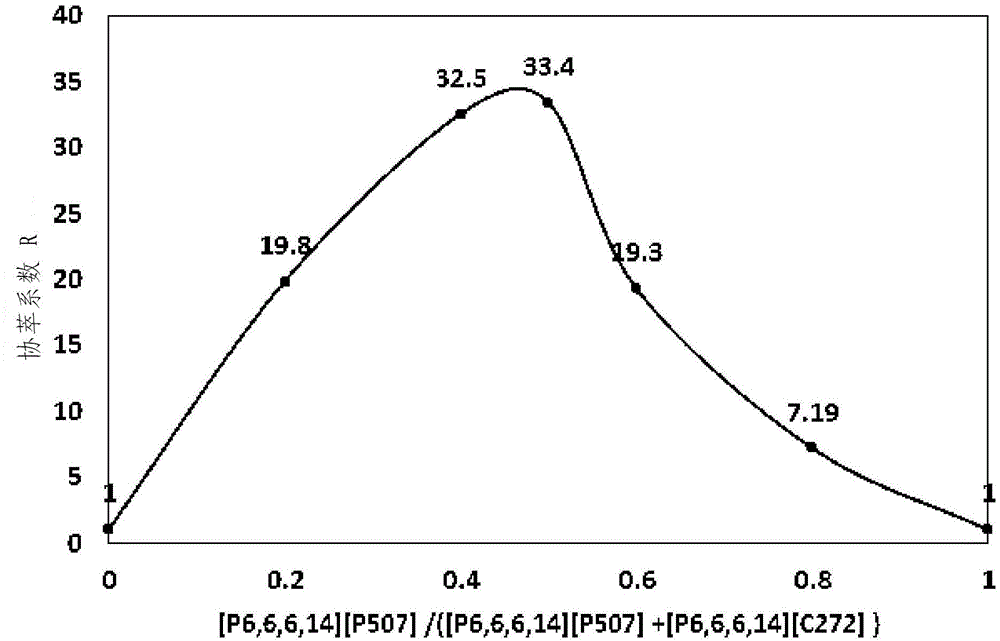

Synergic extraction agent for heavy rare earth elements and extraction separation method of synergic extraction agent

InactiveCN104862504AStrong synergistic extraction effectEasy extractionProcess efficiency improvementRare-earth elementIonic liquid

The invention relates to a synergic extraction agent for heavy rare earth elements and an extraction separation method of the synergic extraction agent. The synergic extraction agent comprises a component (a) and a component (b). The synergic extraction agent and thinner are mixed to form an organic phase to extract a heavy rear earth solution. In the extraction process, due to the fact that the two ionic-liquid-based extraction agents have a quite strong synergic extraction effect on heavy rare earth, the extraction capacity for heavy rare earth is obviously improved. Due to the fact that ionic liquid has a special phase shifting effect, a re-extraction agent more easily enters the organic phase, and the re-extraction rate is greatly increased. Multiple times of circulating saponification are not needed for the ionic liquid, and no ammonia-nitrogen waste water is generated in the extraction process.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

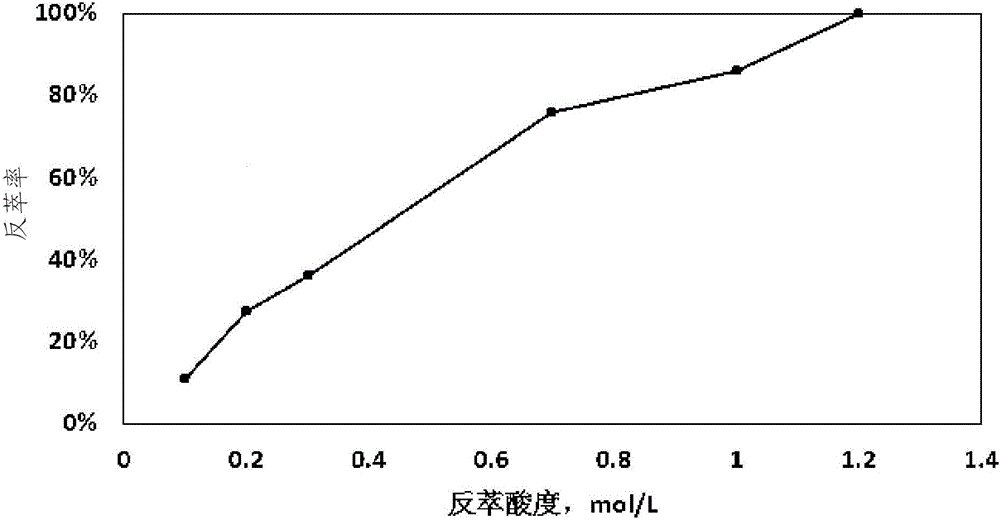

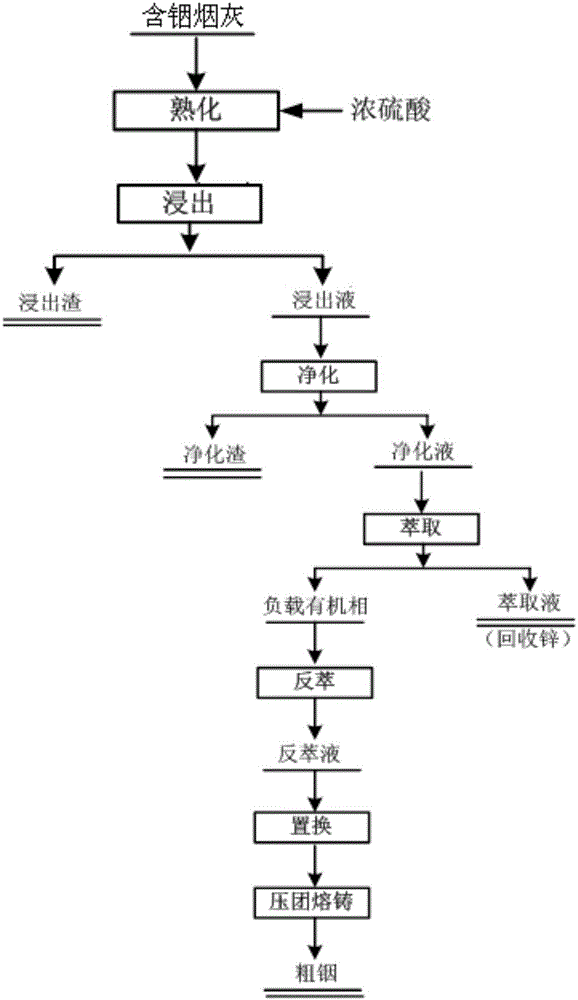

Technique for recovering indium from indium-containing soot

InactiveCN106337134AImprove leaching rateHigh recovery rateProcess efficiency improvementPregnant leach solutionIndium

The invention belongs to the technical field of chemical techniques, and particularly relates to a technique for recovering indium from indium-containing soot. The technique comprises the following steps that firstly, the indium-containing soot is evenly mixed with concentrated sulfuric acid and subjected to sulfuric acid curing roasting, specifically, in the roasting process, 10-20 ml of concentrated sulfuric acid is added into each 20 g of indium-containing soot for sulfuric acid curing roasting, and the sulfuric acid curing roasting time is 1-2 h; secondly, a roasted product obtained through sulfuric acid curing roasting is leached, and leachate and leaching residues are separated; thirdly, the leachate obtained in the second step is purified, and purified liquor and purifying residues are separated; fourthly, the purified liquor obtained in the third step is extracted, so that an extract liquor and a loaded organic phase are obtained; fifthly, the loaded organic phase obtained in the fourth step is eluted, and then reverse extraction is conducted, so that strip liquor is obtained; and sixthly, replacement is conducted on the strip liquor obtained in the fifth step, so that monoplasmatic indium is obtained. According to the technique provided by the invention, the recovery rate of the indium in the indium-containing soot is high, and indium loss and waste are avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing beryllium oxide or high-purity beryllium oxide from beryllium containing solution

ActiveCN103818937ALow grade requirementsImprove qualityBeryllium oxides/hydroxidesO-Phosphoric AcidAlcohol

The invention relates to the technical field of beryllium oxide preparation, and refers to a method for preparing beryllium oxide or high-purity beryllium oxide from a beryllium containing solution. The method comprises the following steps of: 1, weighing and mixing a phosphoric acid extractant, alcohol and sulfonated kerosene in a volume ratio of 10: 10: 75 to 25: 15: 90, then preparing to be an extractant. The method disclosed by the invention is simple and flexible to operate, convenient to realize continuity. The method has low requirements in beryllium containing ore grade and can treat the beryllium containing waste liquid of any concentration. In comparison with the prior art, the recovery rate of beryllium oxide, the back extraction ratio and the one-time precipitation rate of hydrolysis BeO are higher and the quality of beryllium oxide or high-purity beryllium oxide can be effectively guaranteed, so that high-quality beryllium oxide or high-purity beryllium oxide can be obtained. In the process of production, acid waste liquids are mainly produced, and the acid waste liquids can be discharged after a neutralizing treatment is carried out, the waste residue and exhausted air emissions are less, therefore the method is an environment-friendly technology.

Owner:XINJIANG RES INST OF NON FERROUS METALS

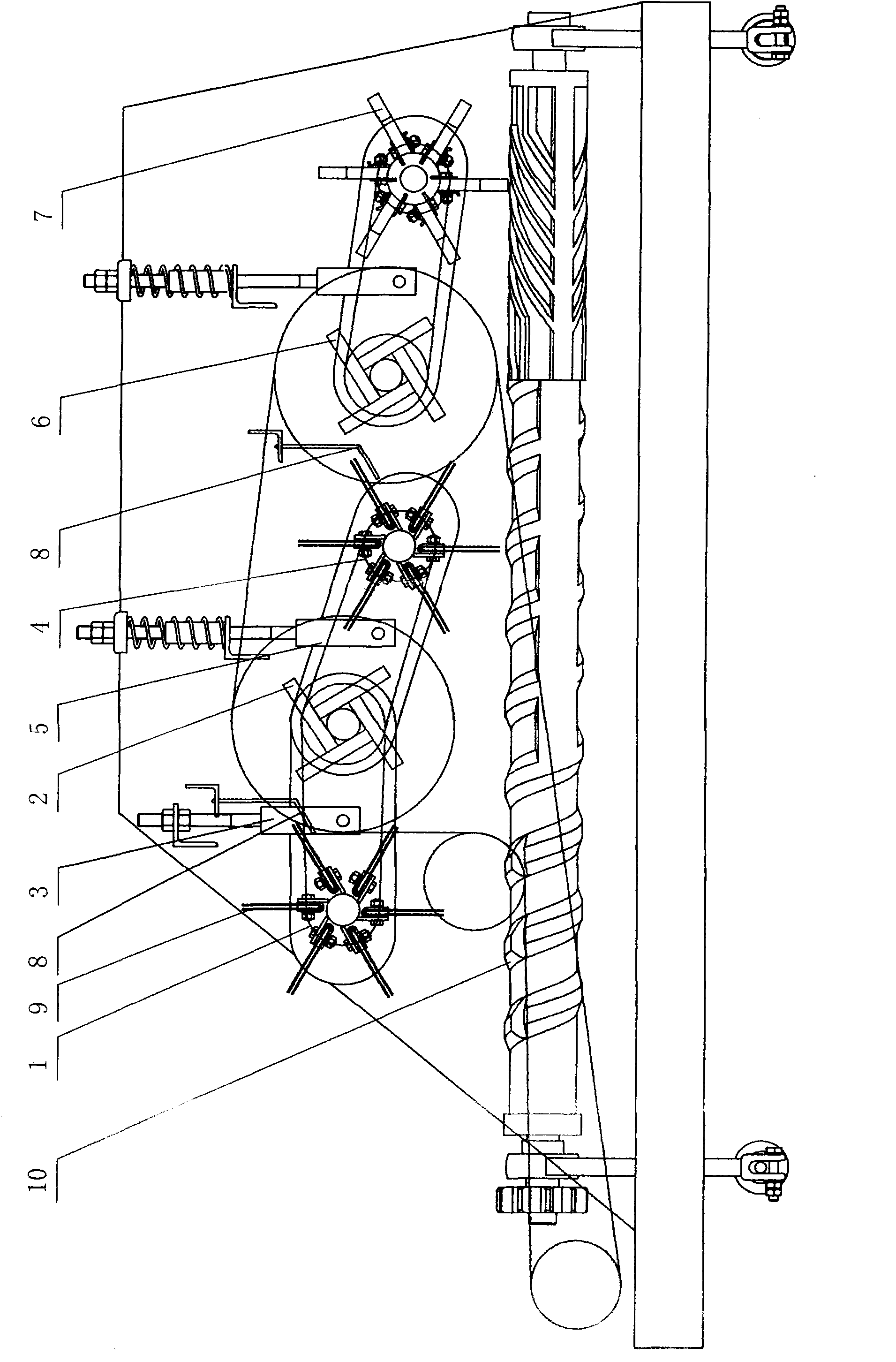

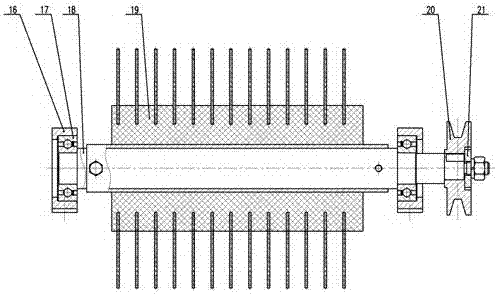

Segmenting type sugar cane combine harvester

InactiveCN101690449BCompact structureReasonable layoutMowersAgricultural lifting devicesControl systemEngineering

The invention discloses a segmenting type sugar cane combine harvester, which comprises a machine frame, an engine, a crawler type traveling mechanism, a hydraulic power and control system, a sugar cane topper device, a sugar cane supporting device, a sugar cane pressing combing roller, a cutting device, a conveying leaf-removing device, a segmenting device, an impurity discharging device and a collecting device, wherein the cutting device comprises a left set of cutting component and a right set of cutting component, and each set of cutting component comprises a screw conveying rod, a rotaryshaft sleeve, a cutter head and a plurality of blades; and the sugar cane supporting device comprises a left set of sugar cane supporting mechanism and a right set of sugar cane supporting mechanism,and each set of sugar cane supporting mechanism is controlled by an independent adjusting mechanism. The segmenting type sugar cane combine harvester has the advantages of having high capability of separating and harvesting sugar canes which are seriously flattened and / or intertwisted, lessening the choking phenomenon occurring in a process of harvesting sugar canes, improving fully removing rateof sugar cane leaves of the harvested sugar canes, reducing the impurity content in sugar cane segments, conveniently collecting sugar cane segments, avoiding the use of a following transport vehiclefor collection and storage, along with compact structure, reasonable configuration, convenient travel and use in fields, good harvesting effect, high automation, low manufacturing cost and the like.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

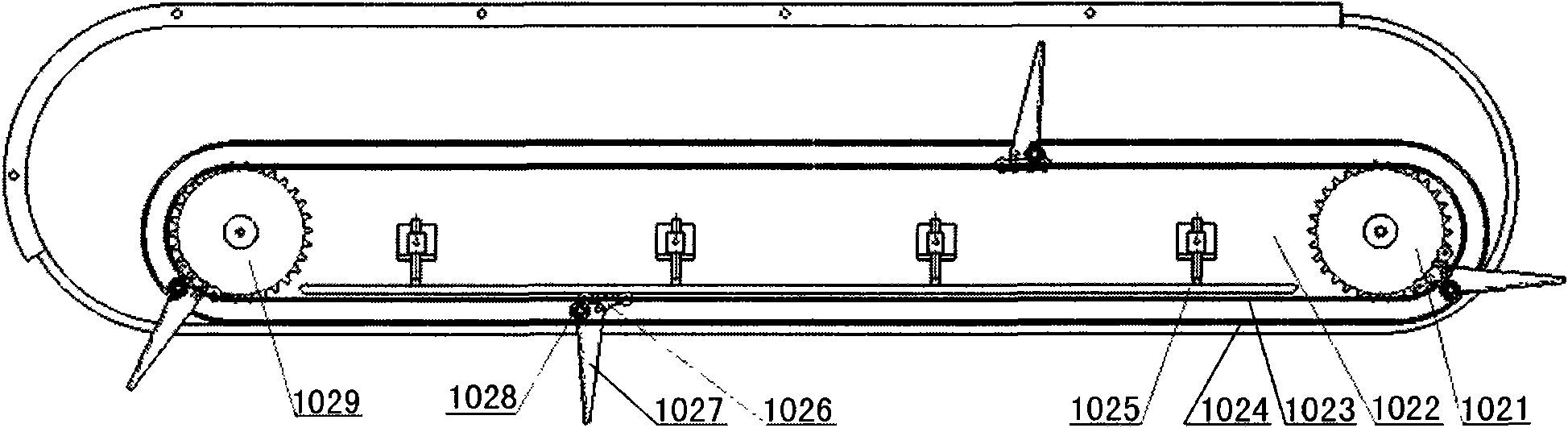

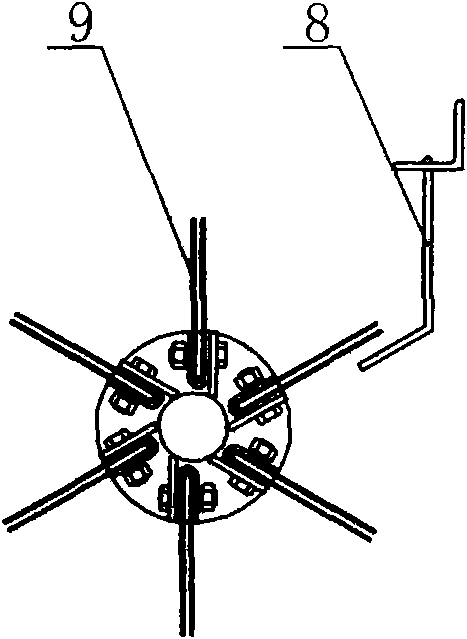

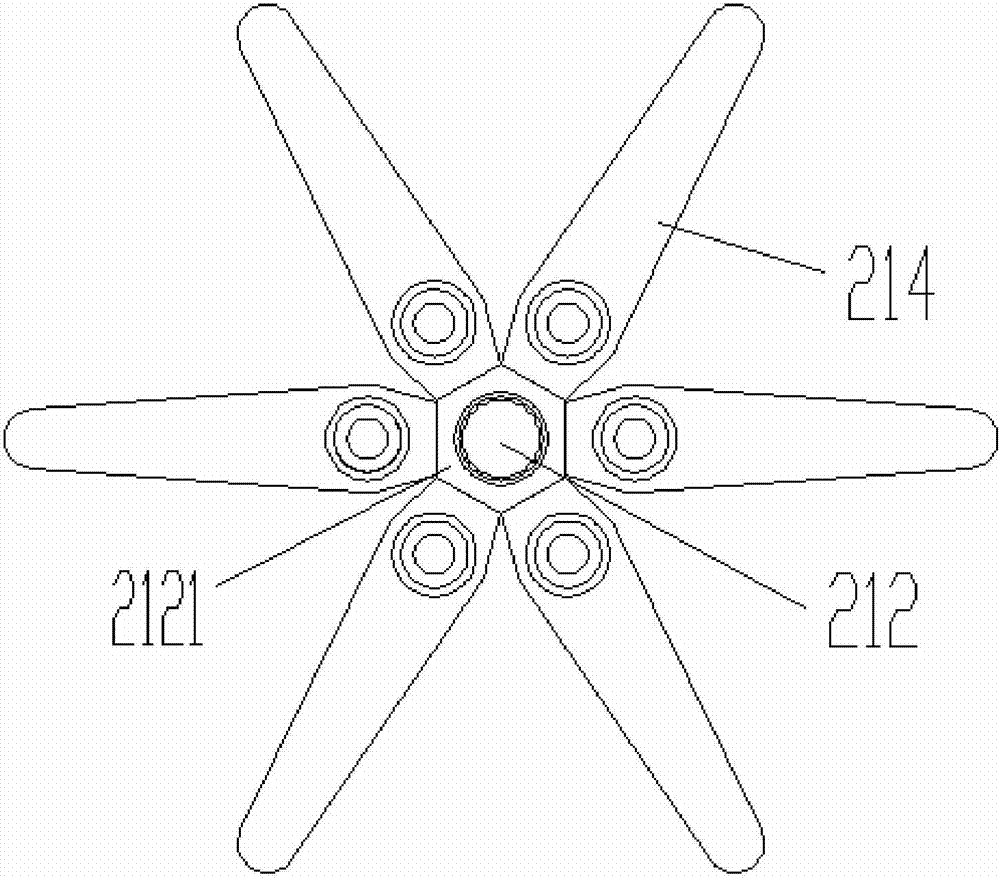

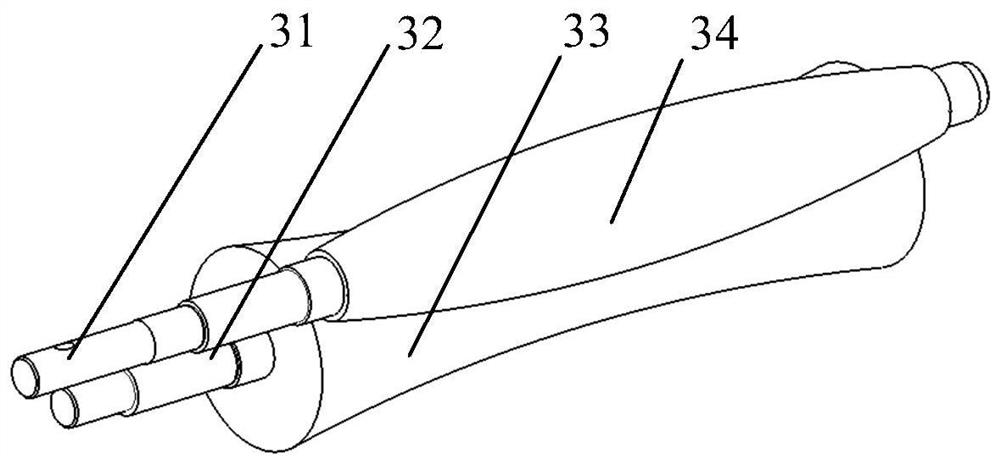

All-pole type sugarcane leaf stripping device

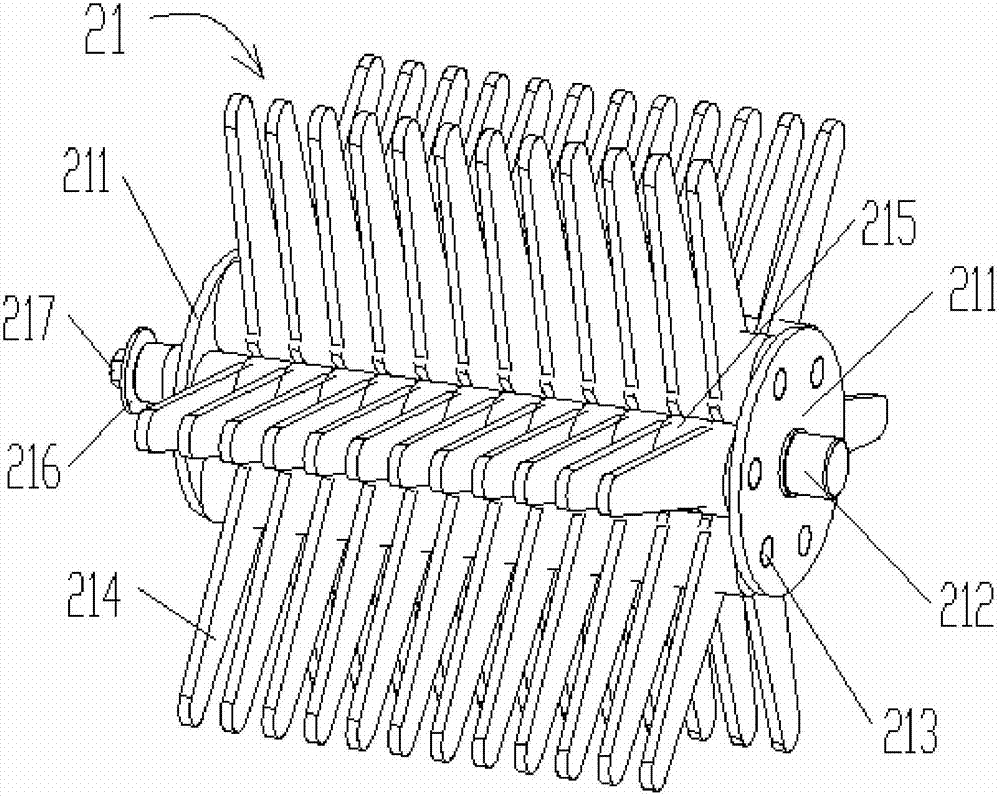

PendingCN107343416AReduce the probability of injuring sugarcaneExtended service lifeHarvestersDrive shaftAgricultural engineering

The invention relates to an all-pole type sugarcane leaf stripping device, comprising an outer frame, a leaf stripping roller system arranged on the outer frame, and a driving system, wherein the leaf stripping roller system comprises upper row of leaf stripping rollers and lower row of leaf stripping rollers which are arranged in parallel, and the leaf stripping rollers in the upper row of leaf stripping rollers and the leaf stripping rollers in the lower row of leaf stripping rollers are arranged in a staggered way; each leaf stripping roller comprises two wheel discs arranged opposite to each other, a main shaft arranged on circle center lines of the two wheel discs, and six blade components arranged between the two wheel discs in a ring-shaped array, wherein the two ends of each main shaft are respectively and fixedly connected with the two corresponding wheel discs, and the cross section of the part, arranged between the two wheel discs, of the main shaft is set as a hexagon; each blade component comprises a driving shaft, and a plurality of leaf stripping blades and adjustable pads which are connected with the driving shaft in a sleeving manner and are arranged at intervals, wherein the end face, facing one side of the corresponding main shaft, of each leaf stripping blade is abutted against and matched with the end face of the main shaft. Due to the reasonable structural arrangement, the all-pole type sugarcane leaf stripping device reduces the probability of hurting sugarcane and increases the stripping rate of sugarcane leaves.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Industrial hemp peeling machine

The industrial hemp peeling machine of the present invention mainly includes a stalk, a feeding hopper, a first pair of crushed stem rollers, a second pair of crushed stem rollers, a third pair of crushed stem rollers, a fourth pair of crushed stem rollers, and a hemp peeling concave plate. Upper peeling roller, lower peeling roller, hemp receiving roller, hemp receiving device, stalk rubbing part, fiber combing part, in which the hemp is fed into the stalk rubbing mechanism through the feeding hopper, and the straight-toothed stem crushing roller crushes and bends the hemp, The skin and bone of the stem are initially separated; then the fresh cannabis stem enters the stem rubbing mechanism, and the cannabis is rolled vertically, and it also has a horizontal rubbing effect, so that the skin and bone of the cannabis are separated more thoroughly, and then the skin and bone enter the combing and separating mechanism, The bone fragments leak out of the concave plate, and the fresh skin is collected by the hemp collecting device; the industrial hemp peeling machine has a high fresh stem peeling rate, a high peeling rate, high production efficiency, low labor intensity, compact structure, and easy to move. Strong bone separation ability and so on.

Owner:田佳聪

Green glycine max husking machine

PendingCN111789276AHigh degree of automationStable jobSievingScreeningProcess engineeringMechanical engineering

The invention discloses a green glycine max husking machine, which comprises a rack, a vibration feeding device, a rolling and husking device, a sieving device and a grain collection box, wherein thevibration feeding device, the rolling and husking device, the sieving device and the grain collection box are all installed on the rack; the rolling and husking device is positioned on a material unloading position of the vibration feeding device, the sieving device is positioned below the rolling and husking device, and the grain collection box is positioned below the sieving device. The green glycine max husking machine has a high automation degree, high production efficiency, a high peeling rate and a low breakage rate and is stable to work.

Owner:YANCHENG INST OF TECH

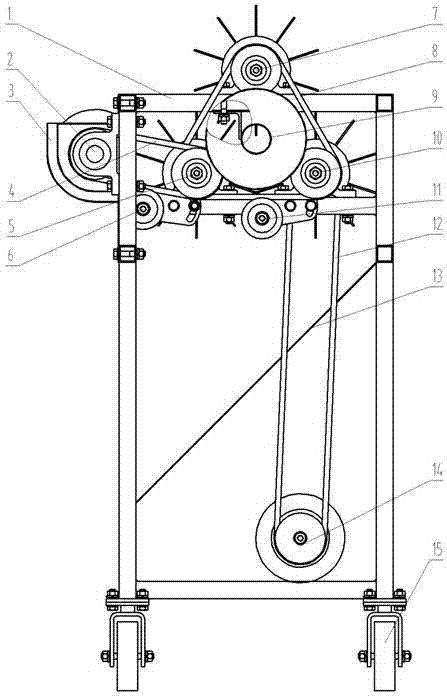

Integral stripping type sugarcane leaf stripping machine

InactiveCN107211649AImprove labor productivityReduce labor intensityHarvestersAgricultural engineeringUltimate tensile strength

The invention belongs to the field of agricultural machinery and relates to an integral stripping type sugarcane leaf stripping machine. The sugarcane leaf stripping machine comprises a supporting frame, a tip cutting part, a tip cutting part cover plate, a belt I, a leaf stripping roller brush part I and the like. The tip cutting part, the leaf stripping roller brush part I, a leaf stripping roller brush part II, a leaf stripping roller brush part III and front and rear guide parts are all connected to the supporting frame. Roller brushes are arranged in the leaf stripping roller brush part I, the leaf stripping roller brush part II and the leaf stripping roller brush part III respectively. An inner belt II is mounted in a belt groove of the leaf stripping roller brush part III and inner belt grooves of the leaf stripping roller brush part I and the leaf stripping roller brush part III. The belt I is mounted in a belt groove of the tip cutting part and an outer belt groove of the leaf stripping roller brush part I. By the sugarcane leaf stripping machine, integral mechanical stripping of sugarcane leaves can be realized, labor productivity can be greatly improved, labor intensity is relieved, production cost is reduced, and market competitiveness of products is improved. In addition, the integral stripping type sugarcane leaf stripping machine has advantages of reasonable structural design, high stripping rate and high operation efficiency.

Owner:KUNMING UNIV OF SCI & TECH

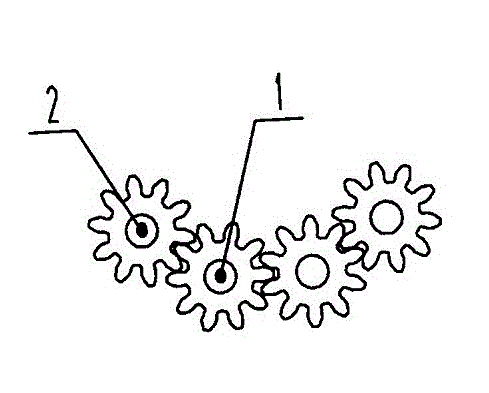

Combined structure of corn husking roller

InactiveCN104412789AHigh stripping rateReduce damage rateThreshersAgricultural engineeringStructural engineering

The invention belongs to the technical field of corn huskers, and in particular relates to a combined structure of a corn husking roller. The combined structure of the corn husking roller comprises two driving husking rollers and two driven husking rollers, wherein the two driving husking roller and the two driven husking rollers are arranged in parallel and respectively located in the same level; the two driven husking rollers are respectively mounted on the tops of ramps of two sides of the two driving husking rollers; each driving husking roller and each driven husking roller comprise mandrels and roller bodies; the driving husking roller bodies are rubber roller bodies, and the driven husking roller bodies are combined roller bodies, wherein each combined roller body comprises an iron roller body section and a rubber roller body section which are mounted on the same mandrel. The combined structure of the corn husking roller has the advantages that the structure is simple, the husking efficiency of corncob is obviously raised, and the damage rate of the corncob and the kernel breaking rate are effectively reduced; and the combined structure of the corn husking roller is suitable for popularization and application.

Owner:蒋爱成

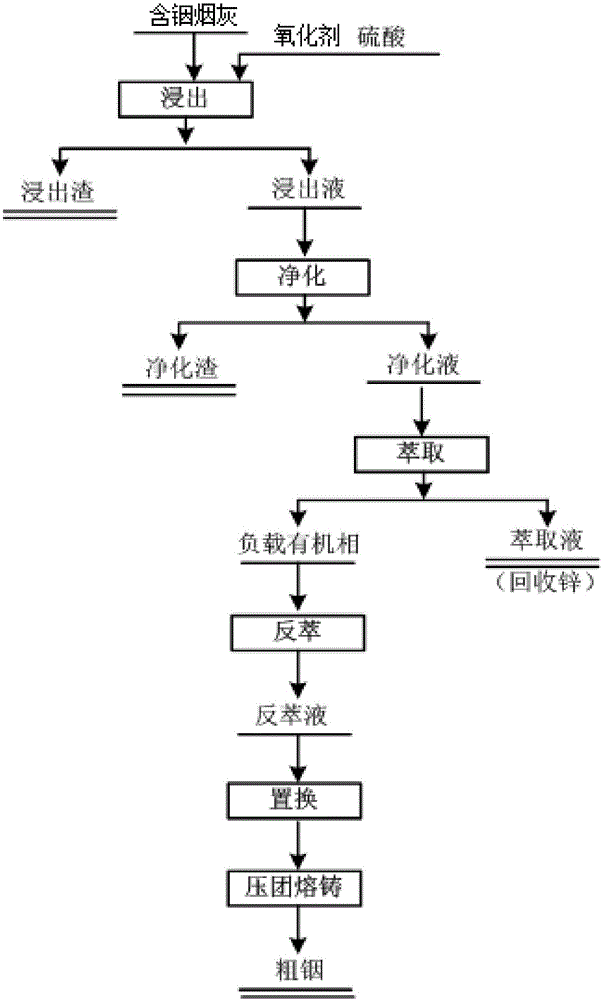

Method for recovering indium from indium-containing soot

InactiveCN106222454AImprove leaching rateHigh recovery rateProcess efficiency improvementPregnant leach solutionWater baths

The invention belongs to the technical field of chemical processes, and particularly relates to a method for recovering indium from indium-containing soot. The method comprises the following steps that step one, the indium-containing soot is leached, and the leaching process comprises the sub-steps that an oxidizing agent and vitriol are added into the indium-containing soot, and stirred for at least 3 hours at the temperature of 50-100 DEG C in a water bath mode, and then leachate is separated from leaching slag, wherein the concentration of the vitriol is 200g / L-400g / L, and the liquid-solid ratio of the vitriol to the indium-containing soot is (3~8):1; step two, the leachate obtained in the step one is purified, and purified liquid is separated from purified slag; step three, the purified liquid obtained in the step two is subjected to extraction, so that extract liquor and loaded organic phases are obtained; step four, the loaded organic phases obtained in the step three are subjected to elution and reverse extraction to obtain strip liquor; and step five, the strip liquor obtained in the step four is subjected to replacement, and the simple substance indium is obtained. According to the method for recovering the indium from the indium-containing soot, the indium recovery rate is high, and indium loss and waste are avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for recycling indium and germanium from chlorination distillation residual liquor containing indium and germanium

ActiveCN108060305AImprove regenerative abilityReduce separation costsProcess efficiency improvementIndiumDistillation

The invention relates to the technical field of hydrometallurgy, in particular to a method for recycling indium and germanium from chlorination distillation residual liquor containing the indium and the germanium. The method comprises the steps that tartaric acid is added to the distillation residual liquor, so that mixed liquor containing InCl4 or InCl6<3> germanium tartrate acid radical anions (Ge(A)3<2>), A representing the tartaric acid) is obtained; indium extraction and germanium extraction are conducted at the same time through a N235-kerosene system extraction agent; and then, indium reverse extraction is conducted through dilute acid, and germanium reverse extraction is conducted through a sodium hydroxide solution. By means of the method, the indium and germanium separation costis lowered; the extraction agent is high in regeneration capacity; the separation difficulty is lowered; the process is easy to implement; and operation is easy and convenient to conduct.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

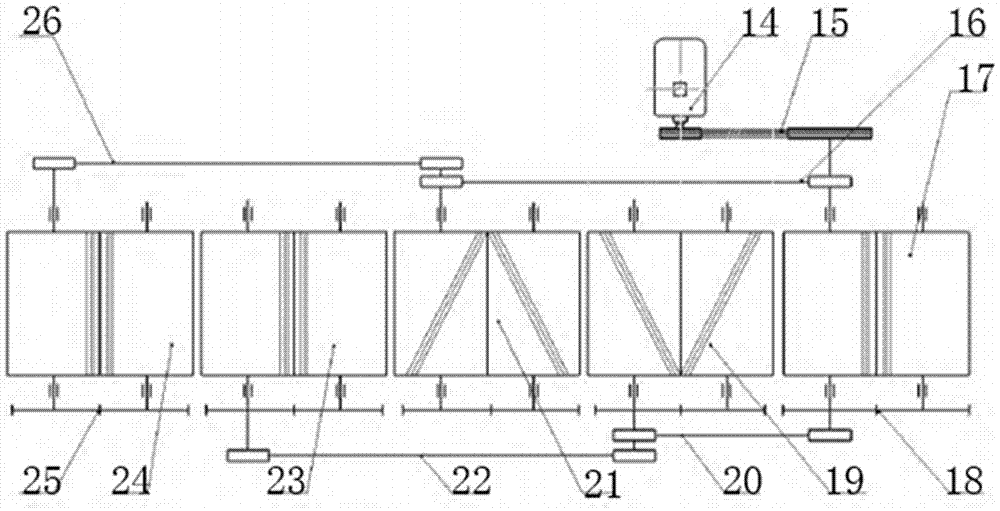

Walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device and method

InactiveCN111567820ARealize processing integrationHigh stripping rateGas current separationHuskingWalnut NutEngineering

The invention discloses a walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device and method. According to the technical scheme, the walnutgreen husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device comprises a green husk removing and cleaning device, a microwave electrothermic drying device and a cracking and kernel extracting device, wherein the green husk removing and cleaning device comprises a green husk stripping device employing an opposite diagonal extrusion mode and a frictional cleaning device at the lower part of the green husk stripping device; a microwave transmitter is arranged in the microwave electrothermic drying device and an air supply heating device is arranged at the bottom of the microwave electrothermic drying device; the cracking and kernel extracting device comprises a feeding positioning device, a cracking device and a husk and kernel separation device; walnuts are discharged through vibration of the feeding positioning device and conveyed to the cracking device through a chain plate feeding device; the cracking device comprises a primary cracking device and a secondary cracking device; the primary cracking device comprises a knocking hammer; the secondary cracking device comprises a helical drum; and the cracked walnuts achieve husk and kernel separation under negative pressure of the husk and kernel separation device. The walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production deviceintegrates the functions, such as walnut feeding, husk removing, cleaning, drying, cracking and kernel extracting into a whole, thereby improving the walnut processing efficiency.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

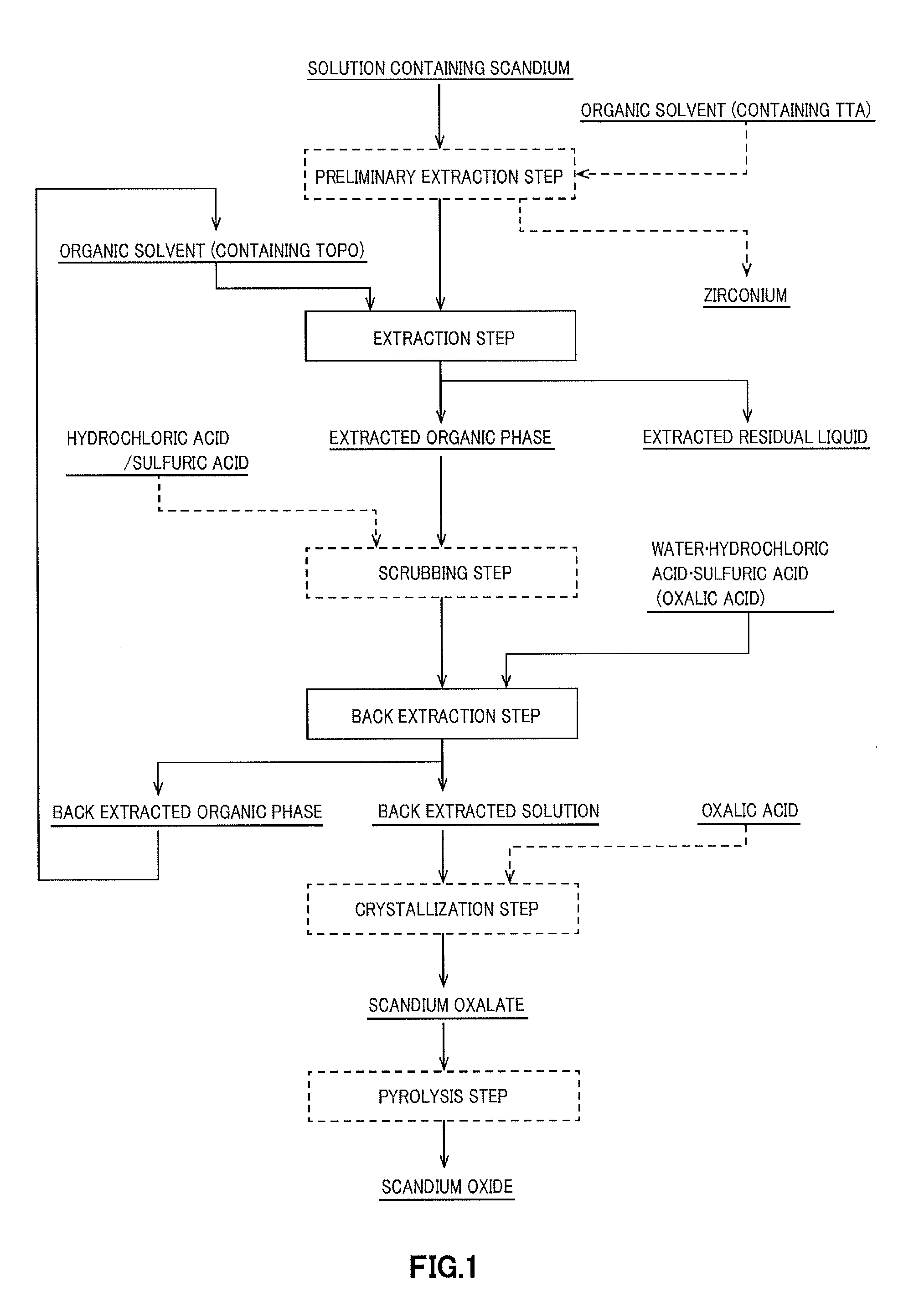

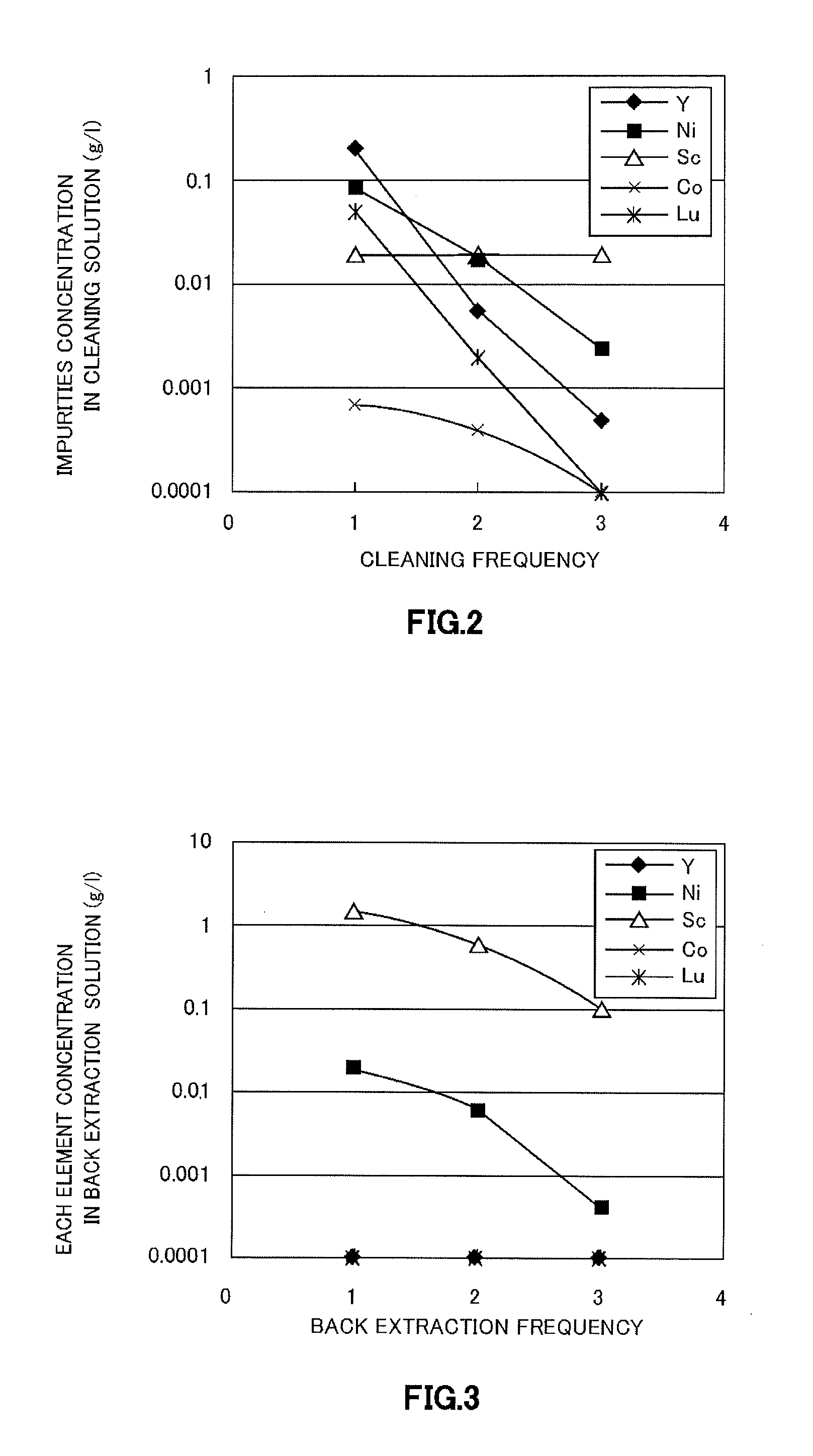

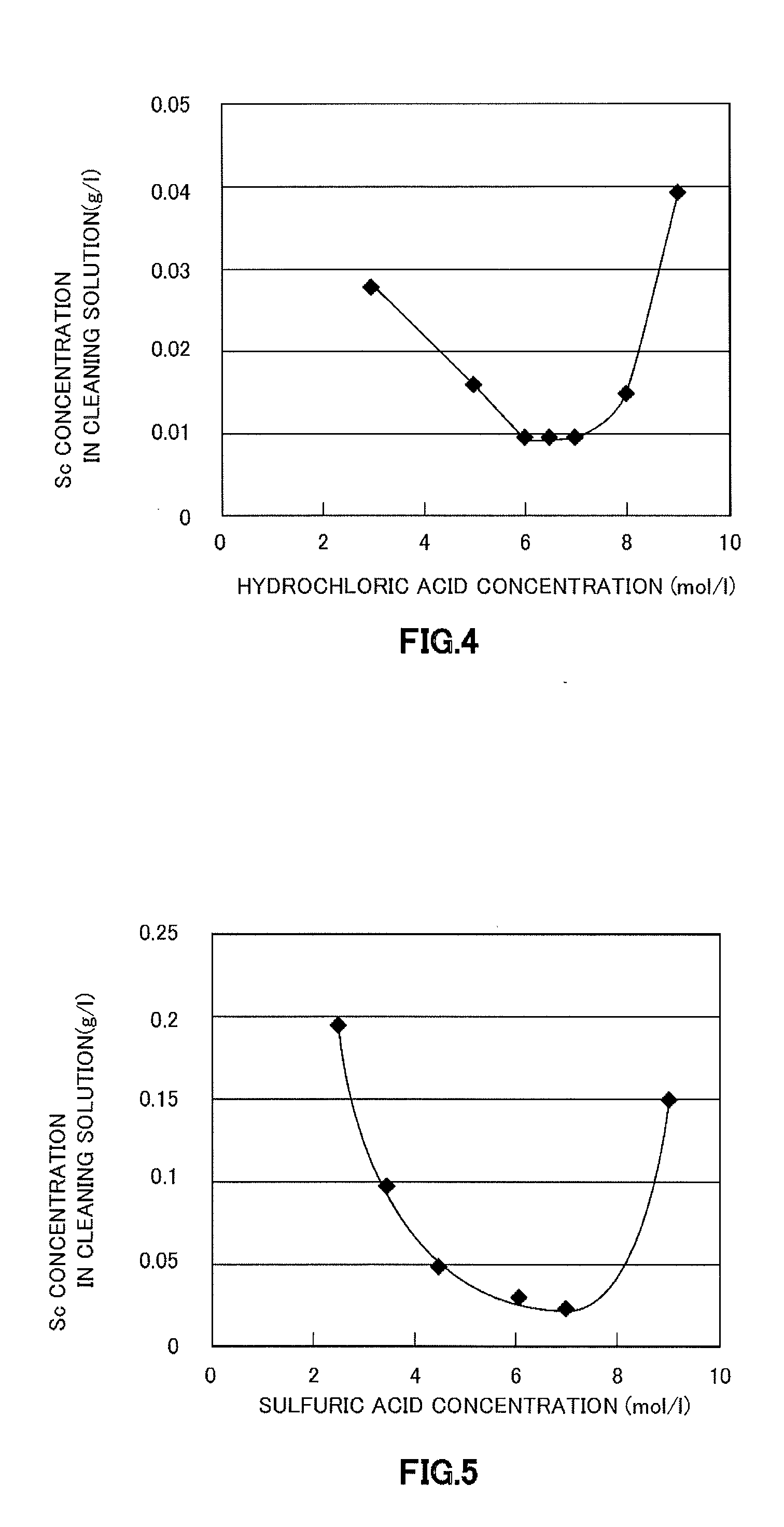

Method for separating and refining scandium

ActiveUS20150184268A1Facilitate strippingHigh stripping rateScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOxalateOrganic solvent

An object of the present invention is to provide a method for separating and refining scandium capable of efficiently separating and refining the scandium from a solution containing the scandium, with improved stripping, while securing separability (selectivity) of the scandium from impurity elements. The method of the present invention involves mixing a solution containing the scandium with an organic solvent containing a trioctylphosphine oxide to extract the scandium into the organic solvent; and mixing the organic solvent with a stripping starting solution containing any one or more of water, hydrochloric acid, sulfuric acid, and oxalic acid to strip the scandium from the organic solvent.

Owner:SUMITOMO METAL MINING CO LTD

Method for extract phase phosphoric acid back extraction in the course of extracting wet-process phosphoric acid by an organic solvent method

InactiveCN101525131AEfficient separationHigh stripping ratePhosphorus compoundsWater bathsOrganic solvent

The invention relates to a method for extract phase phosphoric acid back extraction in the course of extracting wet-process phosphoric acid by an organic solvent method, which comprises steps: in the process of purification, sedimentation, extraction, washing, back extraction and concentration of the wet-process phosphoric acid, surface active agent is taken as stripping agent, the surface active agent is added into the extract phase of organic solvent extracted phosphoric acid to obtain mixing solution and is inversely extracted under stirring, is heated in the temperature range of 30 DEG C to 100 DEG C in water bath and constant temperature with the rotation speed of 100-200r / min and reaction time of 20-40min, stands and delaminated. The back extraction rate of the phosphoric acid obtained by the method is much higher than the back extraction rate of the phosphoric acid without adding non-ionic surface active agent; without adding non-ionic surface active agent, the back extraction rate of the phosphoric acid which is inversely extracted with deionized water is only 50-70%, and generally, 3-5 times of back extraction is carried out. The method reduces concentrated steam consumption, saves energy by more than 30% compared with the traditional technique taking water as stripping agent, simultaneously simplifies technique process and reduces the operation time of back extraction.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Peeling device for corn harvester

ActiveCN103004362AHigh stripping rateAvoid build-up cloggingHarvestersThreshersEngineeringDistributor

The invention discloses a peeling device for a corn harvester, and belongs to the technical field of corn harvesters. The peeling device comprises a peeling box arranged on a machine frame, wherein a plurality of peeling roller groups which are driven by a power device and are arranged in a groove shape are rotatably arranged in the peeling box; at least one pressing device which is driven by the power device is rotatably arranged above the peeling roller groups; a distributor is rotatably arranged on the peeling box at a fruit cluster entrance; the distributor is connected with the pressing device in a transmission way; and the distributor comprises a shifting wheel shaft and a plurality of cross shifting wheels which are fixedly arranged on the shifting wheel shaft. Because the distributor is arranged at the fruit cluster entrance, fruit clusters are uniformly distributed in the peeling roller groups by the distributor when the fruit clusters enter the peeling device from a lifting device; the distribution of the fruit clusters on the peeling roller groups is improved remarkably; the peeling rate of subtending leaves is improved; and moreover, the service life of the peeling roller groups is prolonged.

Owner:GAOMI CHUNYU MACHINERY

Process and device for producing rice from paddy

InactiveUS20140356513A1Debranning resultImprove energy consumptionGrain huskingSievingBroken riceWater temperature

Disclosed is a process for producing rice from paddy. The process comprises a hulling procedure for brown rice, which includes procedures of dampening, and stirred debranning. The dampening procedure involves using a dampener (13) to add water accounting for 0.5-2.5% of the weight of the brown rice material to the brown rice material, with the water temperature being 10-60□; and after the dampening procedure, the brown rice is conveyed to the procedure of stirred debranning within 10 min to be processed. During the procedure of stirred debranning, the height of the brown rice is controlled to be 0.3-2 m, and a stirrer is employed for stirring; and the linear velocity of the stirrer rod of the stirrer is controlled to be 1-6 m / s. The process uses a method of stirred debranning for debranning the brown rice, such that the acting forces on the brown rice grains are relatively small and uniform, thereby improving the removal rate of the hull of the brown rice and reducing the yield rate of broken rice.

Owner:WANG HONGFU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com