Synergic extraction agent for heavy rare earth elements and extraction separation method of synergic extraction agent

The technology of a heavy rare earth element and a separation method, which is applied in the field of rare earth extraction and separation, can solve the problems of saponification of an organic phase, difficulty in back extraction, etc., and achieve the effects of improving extraction capacity, increasing extraction capacity, and improving back extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0057] Synthesis of [P6,6,6,14][P507] and [P6,6,6,14][C272]

[0058] In a 125ml separating funnel, add 0.008mol of tetradecyltrihexylphosphonium chloride (referred to as [P6,6,6,14]Cl) to 60ml of methanol, and then add 75ml of anion exchange resin to obtain hydroxide Tetradecyltrihexylphosphonium (denoted as [P6,6,6,14]OH) solution. Add 0.008mol 2-ethylhexylphosphonic acid-mono-2-ethylhexyl ester (code P507) or bis(2,4,4-trimethylpentyl) to [P6,6,6,14]OH solution base) phosphinic acid (code C272), the resulting mixture was stirred at room temperature for 6h until the solution became neutral, methanol and water were spin-out at 70°C with a rotary evaporator, and the product was dried in a vacuum oven at 70°C After 12h, viscous liquid [P6,6,6,14][P507] or [P6,6,6,14][C272] was obtained. The yields all reached 95%.

Embodiment 3~4

[0060] Synthesis of [N4444][P507] and [N4444][C272]

[0061] In a 125ml separatory funnel, add 0.006mol tetrabutylamine bromide (denoted as [N4444]Br) to 40ml methanol, then add 75ml () anion exchange resin to obtain tetrabutylamine hydroxide (denoted as [N4444]OH) solution. Add 0.006mol P507 or C272 to this solution, and stir the resulting mixture at room temperature for 6h until the solution becomes neutral. Use a rotary evaporator to spin out methanol and water at 70°C, and dry the product in a vacuum oven at 70°C After 12h, viscous liquid [N4444][P507] or [N4444][C272] was obtained. The yields all reached 96%.

Embodiment 5~9

[0063] Preparation of organic phase: [P6,6,6,14][P507] was synthesized according to the method in Example 1, and [P6,6,6,14][C272] was purchased from Cytec Corporation of Canada. [P6,6,6,14][P507] and [P6,6,6,14][C272] of different compositions were mixed with toluene to form 5 ml of organic phase with concentrations of 0.0208 and 0.0052, 0.0156 and 0.0104, respectively , 0.013 and 0.013, 0.0104 and 0.0156, 0.0052 and 0.0208mol / L.

[0064] Preparation of raw material solution: Take 0.0030mol / L Lu(III) solution and add dilute hydrochloric acid to make Lu(III) concentration 4.5×10 -4 mol / L raw material solution, NaCl=0.5 mol / liter, pH=2.09.

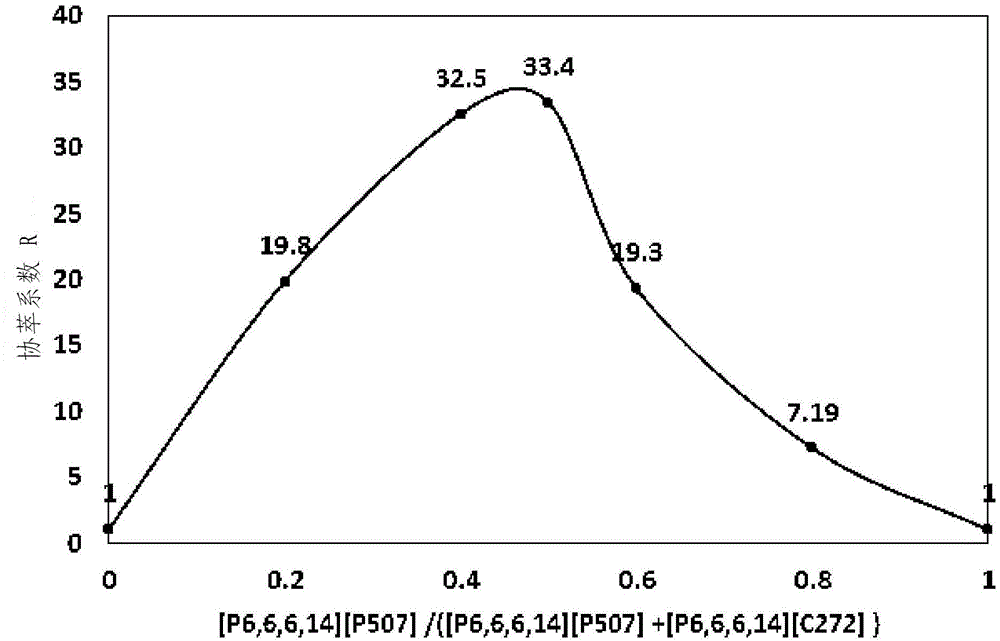

[0065] The organic phase and the raw material solution are mixed at a volume ratio of 1:1, and extracted at room temperature, and the extraction stage is 1 stage. After the extraction was completed, the co-extraction coefficient R was calculated. Such as figure 1 As shown, the distribution ratio of the ionic liquid mixture after mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com