Patents

Literature

144 results about "Spin out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corporate spin-off, also known as a spin-out, or starburst, is a type of corporate action where a company "splits off" a section as a separate business.

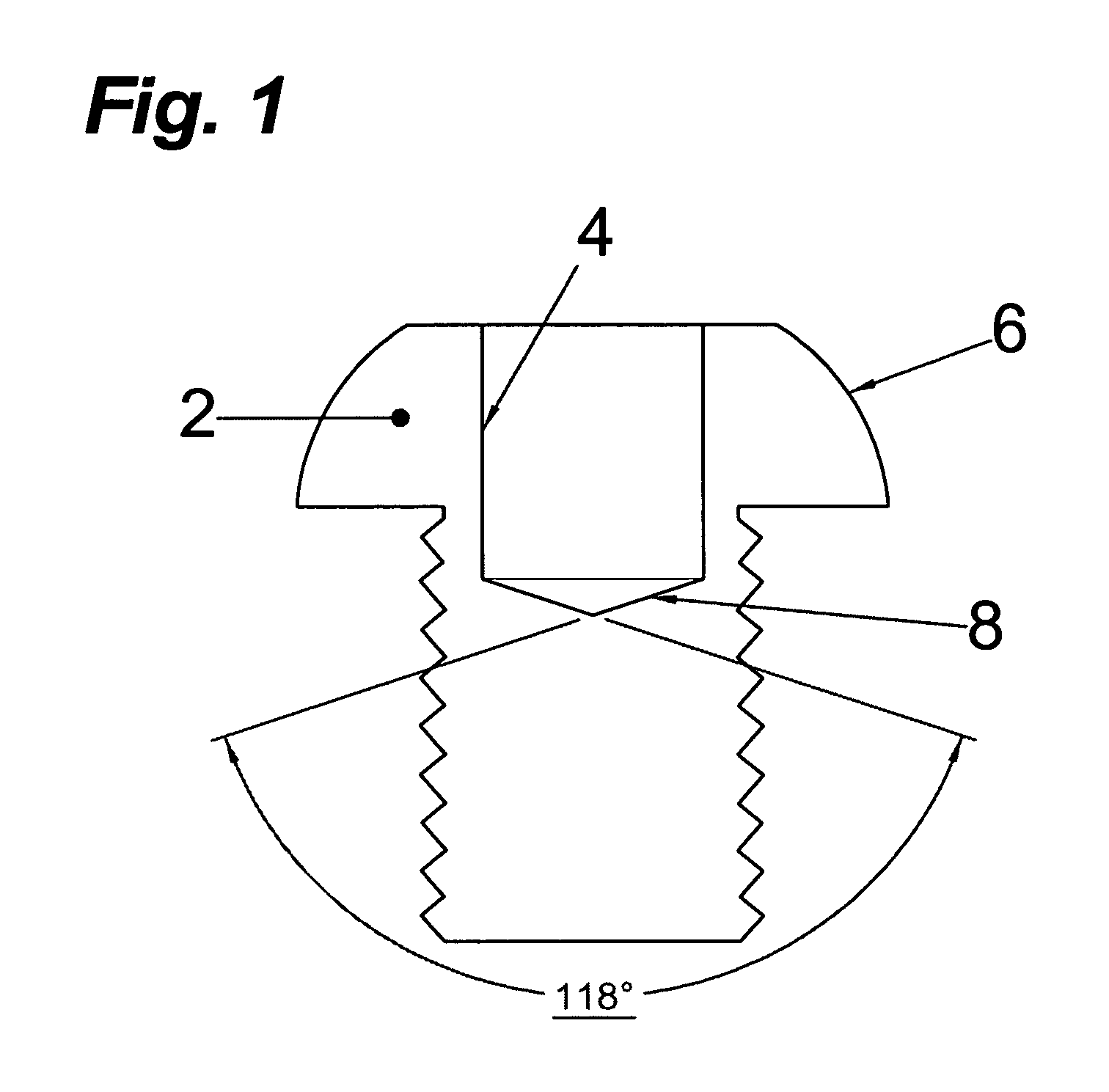

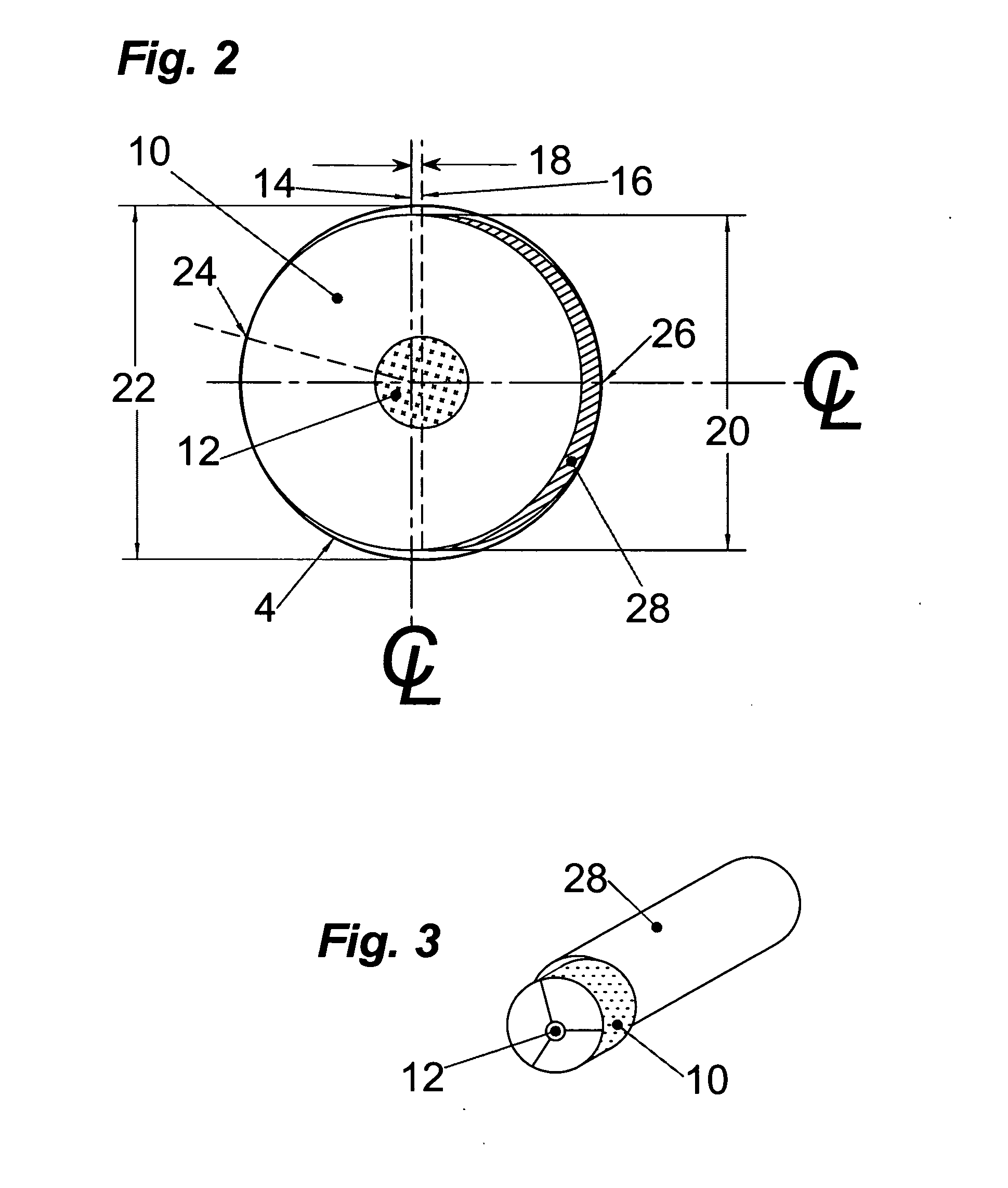

Torque-setting, tamper-resistant fastener and method and tool for use with same

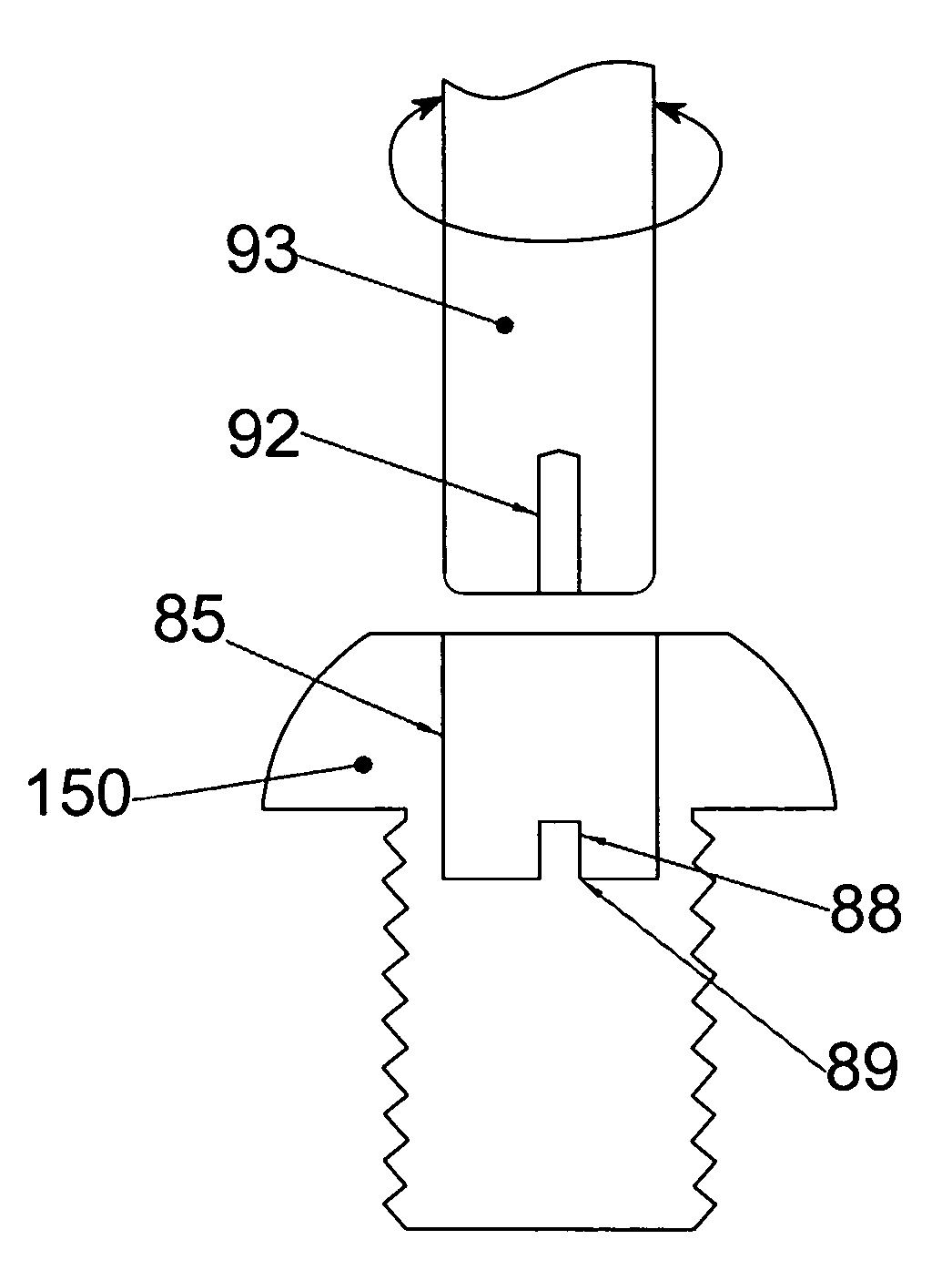

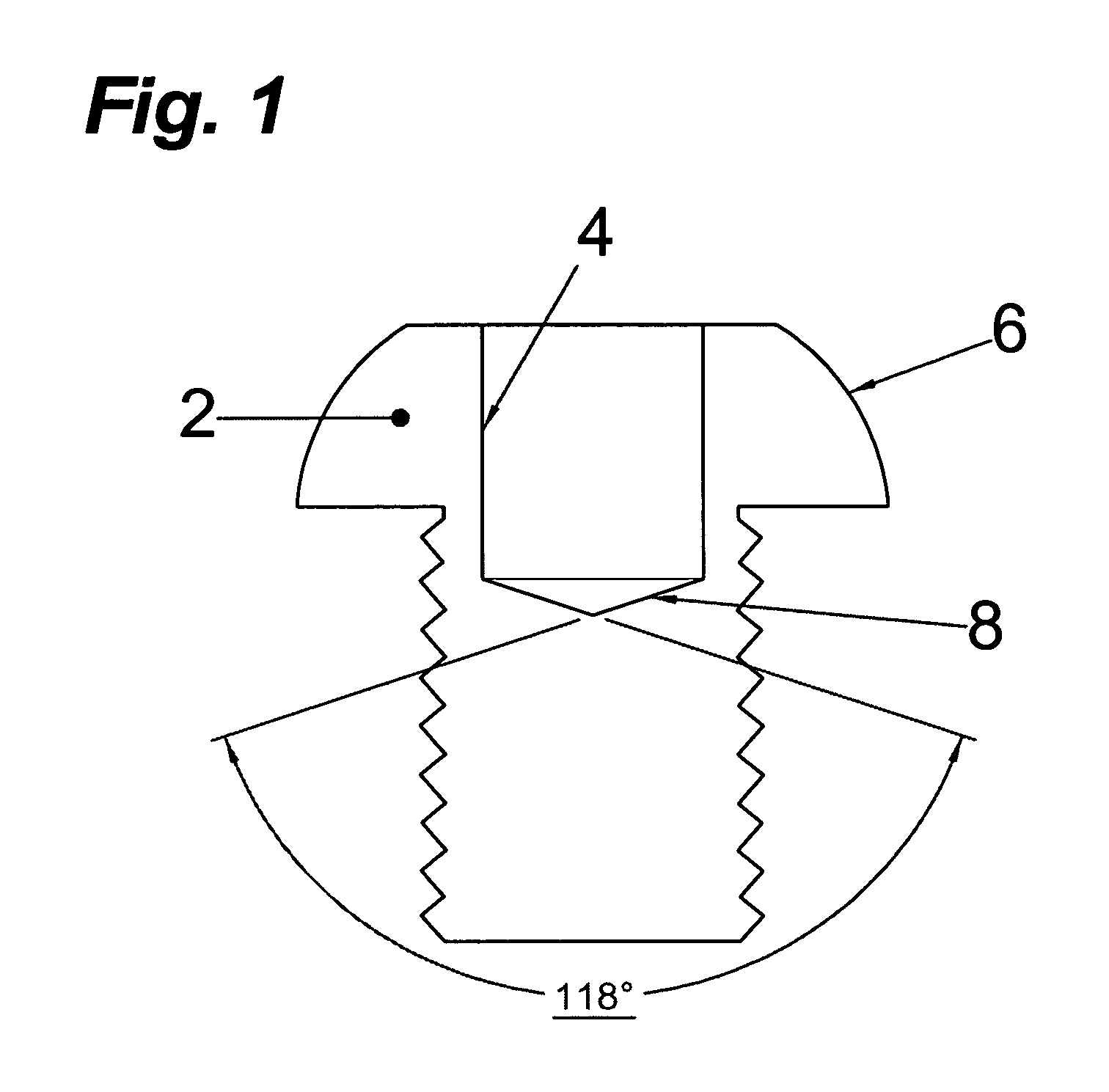

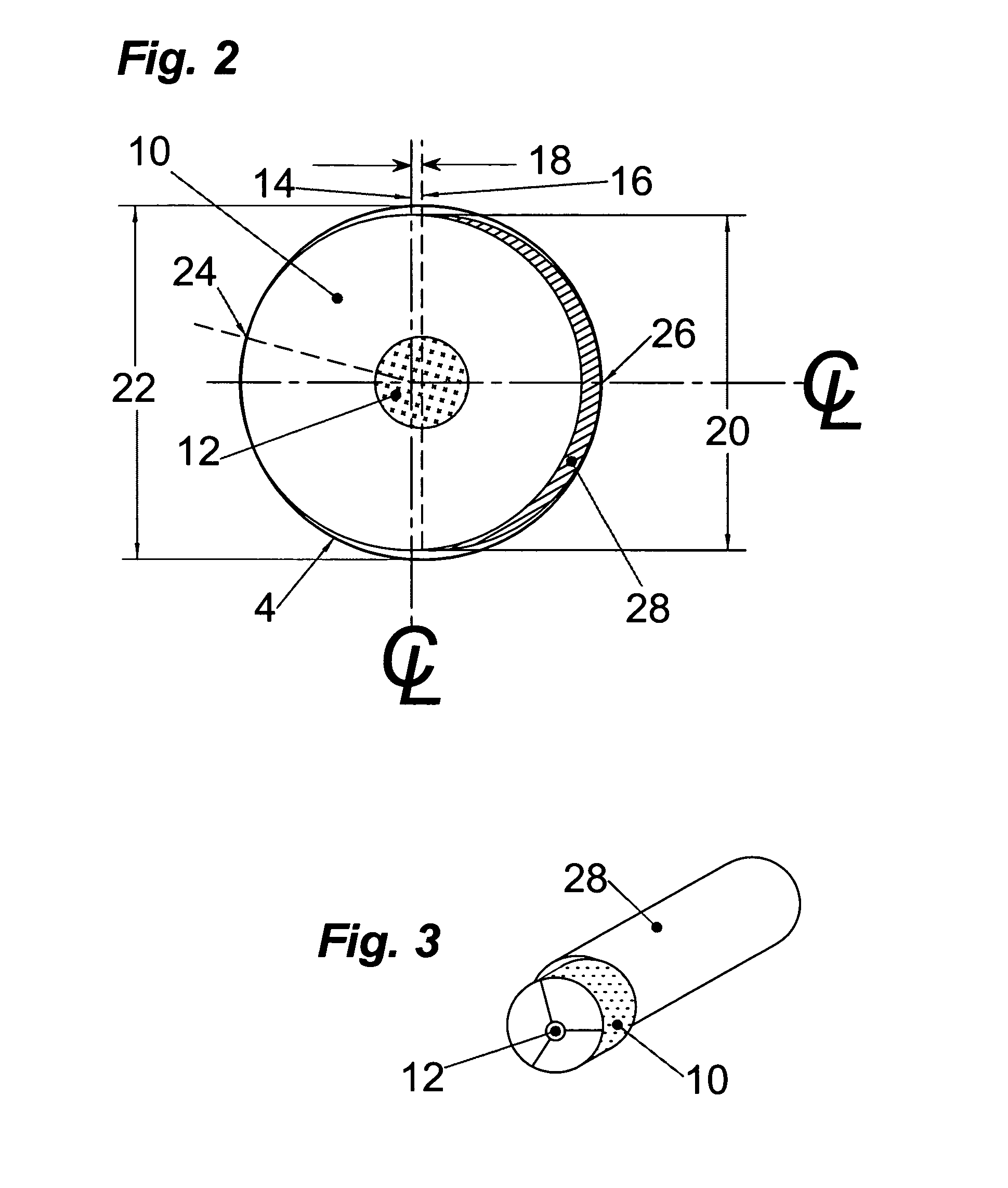

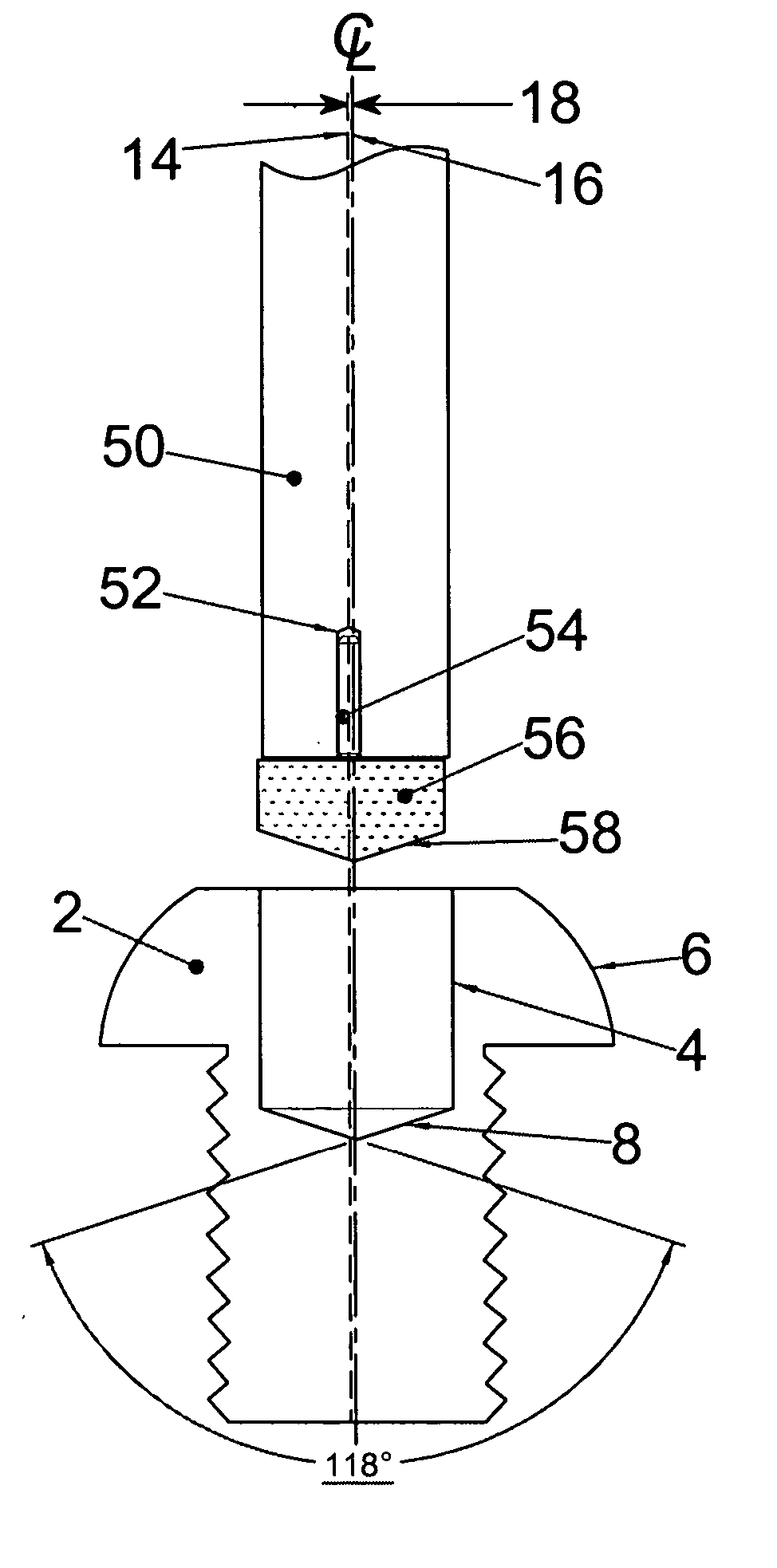

A fastener includes a round, blind hole or pocket in its head. Installation and removal of the fastener is accomplished with a tool containing an eccentric segment on the end of a shaft. When rotated within the pocket, the eccentric segment displaces laterally relative to the shaft to provide a friction grip to the lateral wall of the pocket. The strength of the grip is proportional to the applied torque. Eccentric displacement allows rotation but prevents the tool from spinning out of the fastener thereby eliminating cam-out and surface damage resulting from contact with a spinning tool tip. The eccentric head of the tool can be made disposable and to shear off when a predetermined torque is reached. The smooth-sided round hole offers no purchase for commonly available tools; making the fastener tamper-resistance. In another embodiment, the fastener includes a raised portion in the pocket. A tool having a complementary opening shears off the raised portion at a predetermined torque.

Owner:FLESHER ROBERT W

Tamper-resistant fastener and method and tool for use with same

A fastener includes a round, blind hole or pocket in its head. Installation and removal of the fastener is accomplished with a tool containing an eccentric segment on the end of a shaft. When rotated within the pocket, the eccentric segment displaces laterally relative to the shaft to provide a friction grip to the lateral wall of the pocket. The strength of the grip is proportional to the applied torque. Eccentric displacement allows rotation but prevents the tool from spinning out of the fastener thereby eliminating cam-out and surface damage resulting from contact with a spinning tool tip. The eccentric head of the tool can be made disposable and to shear off when a predetermined torque is reached. The smooth-sided round hole offers no purchase for commonly available tools; making the fastener tamper-resistance. In another embodiment, the fastener includes a raised portion in the pocket. A tool having a complementary opening shears off the raised portion at a predetermined torque.

Owner:FLESHER ROBERT W

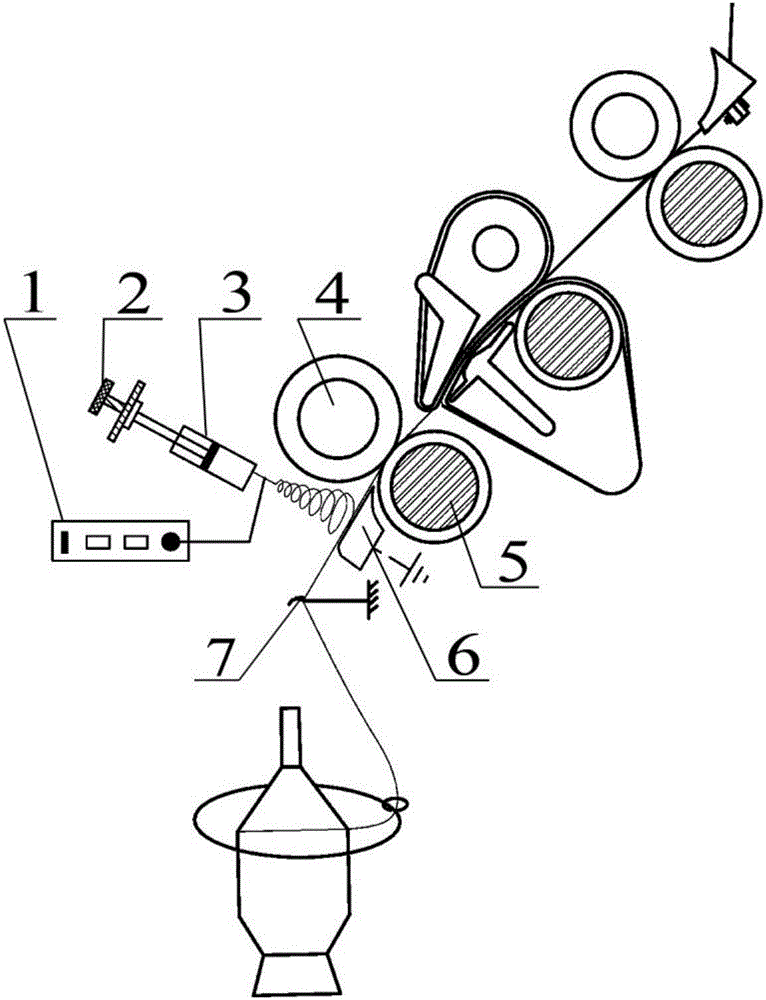

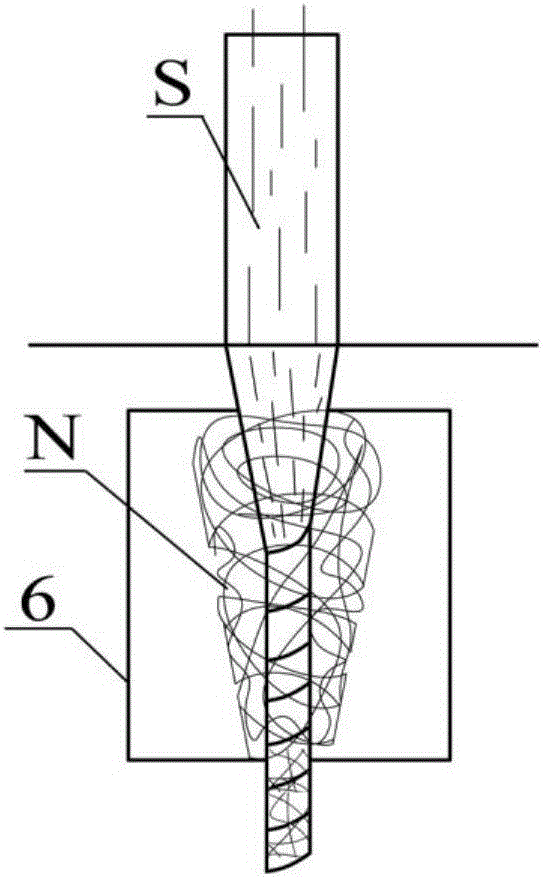

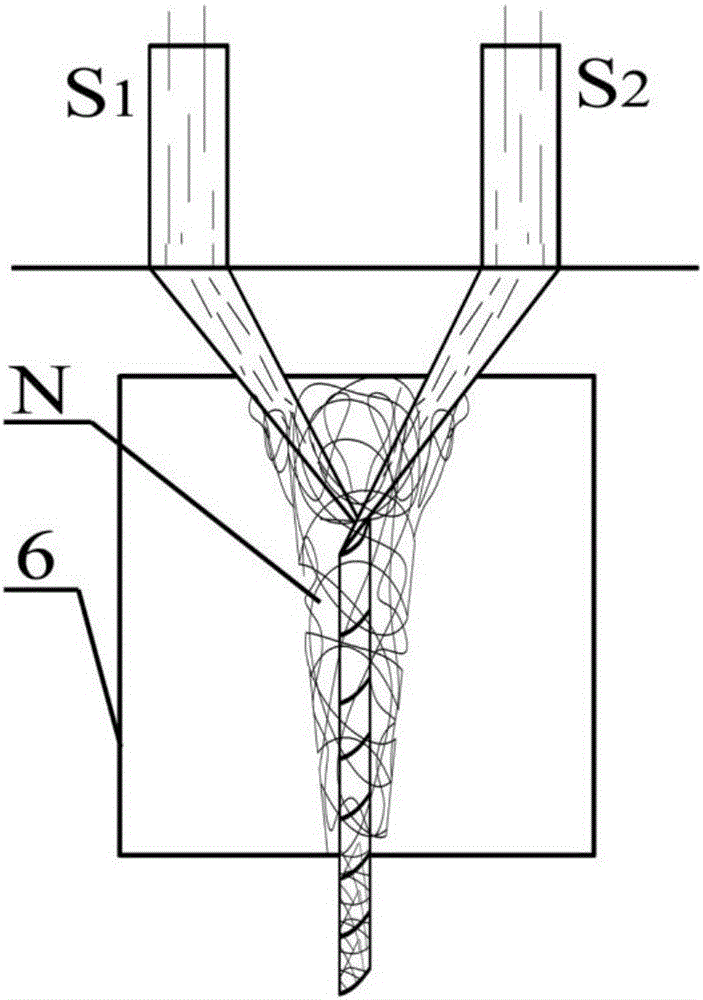

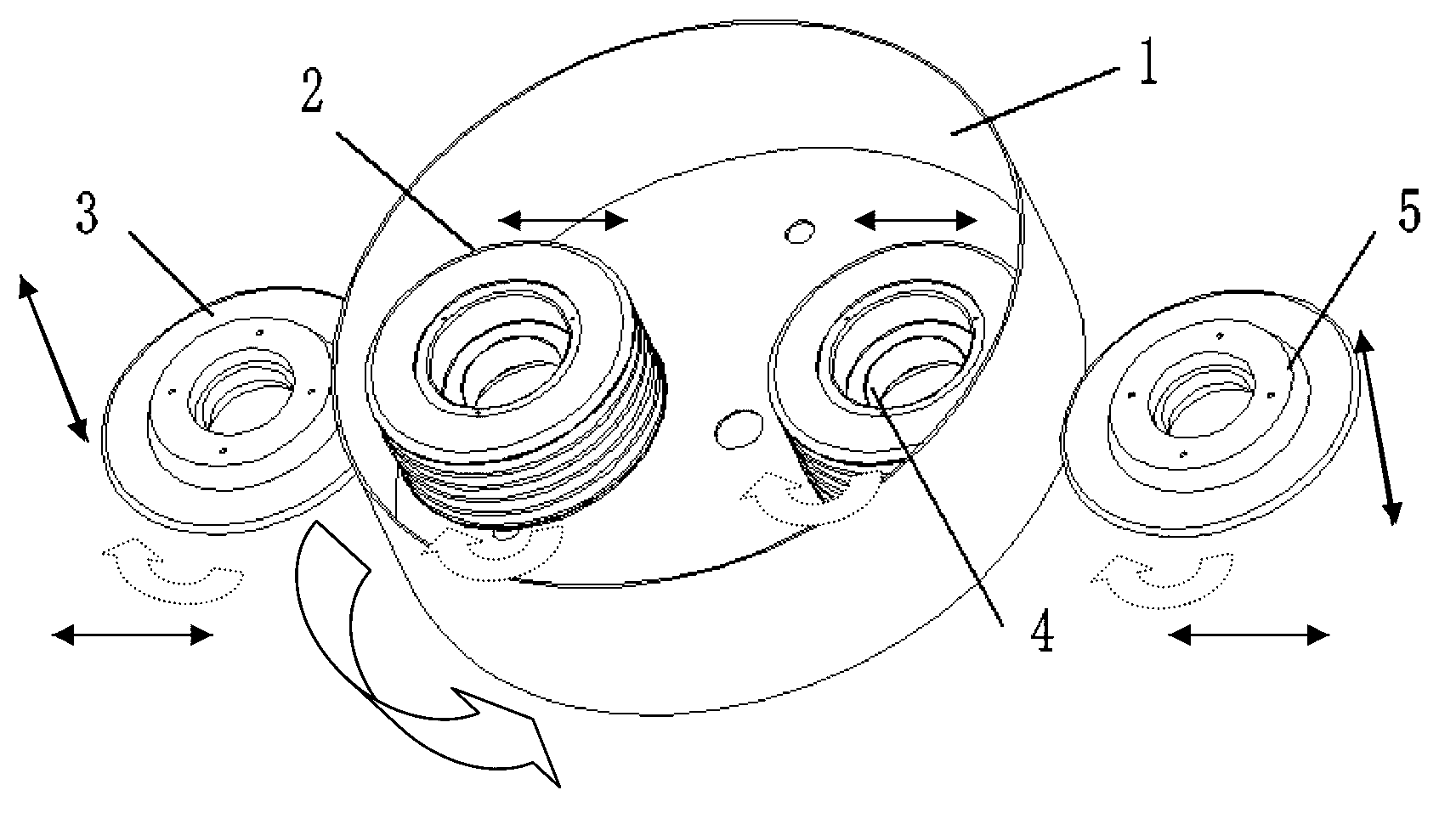

Nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method

The invention relates to a nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method, and belongs to the technical field of textile processing. The method comprises the following steps: arranging an electrostatic spinning apparatus between each yarn guide hook of a ring spinning frame and a front roller jaw formed by a front roller corresponding to the yarn guide hook and a front rubber roll, enabling a receiving surface of the electrostatic spinning apparatus to stay on a same plane with a public tangential surface of a front leather roll and the front roller at the front roller jaw, forming an electrostatic spinning area between an electrostatic spray head and a receiving surface of a receiving plate, and combining and twisting a nano fiber net spun out from the electrostatic spray head and staple fiber strands passing by the receiving surface of the receiving plate. According to the method, the electrostatic spinning and a conventional ring spinning are reasonably integrated, so that the high-speed successful production of nano fiber yarns is guaranteed, the naon fiber net effectively captures exposed fibers and improves the winding tightness, and the yarn forming structure and performance quality of the nano fiber wrapped blended yarns can be greatly improved. Equipment involved in the method is universal, and the operation and the use are convenient.

Owner:WUHAN TEXTILE UNIV

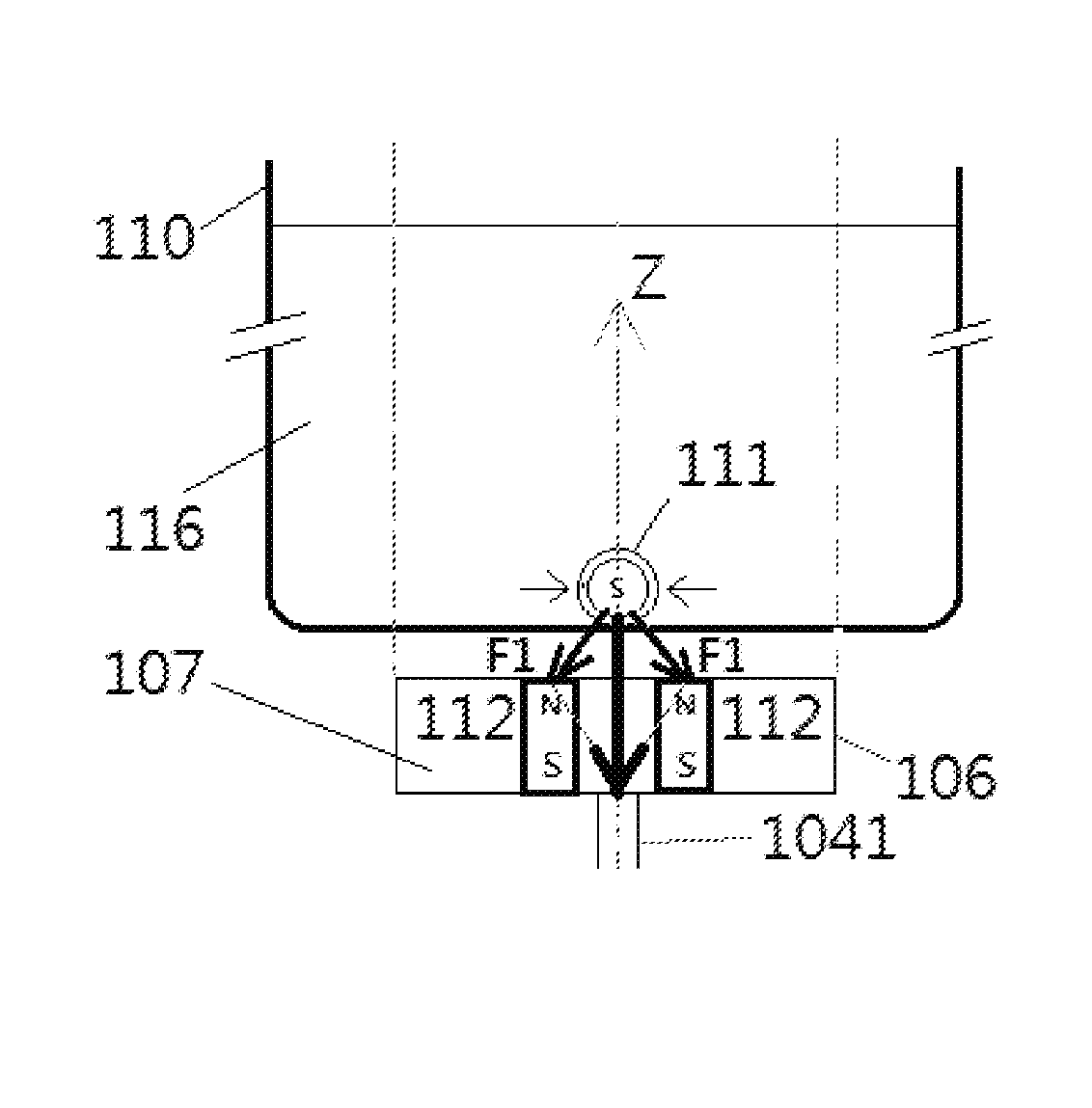

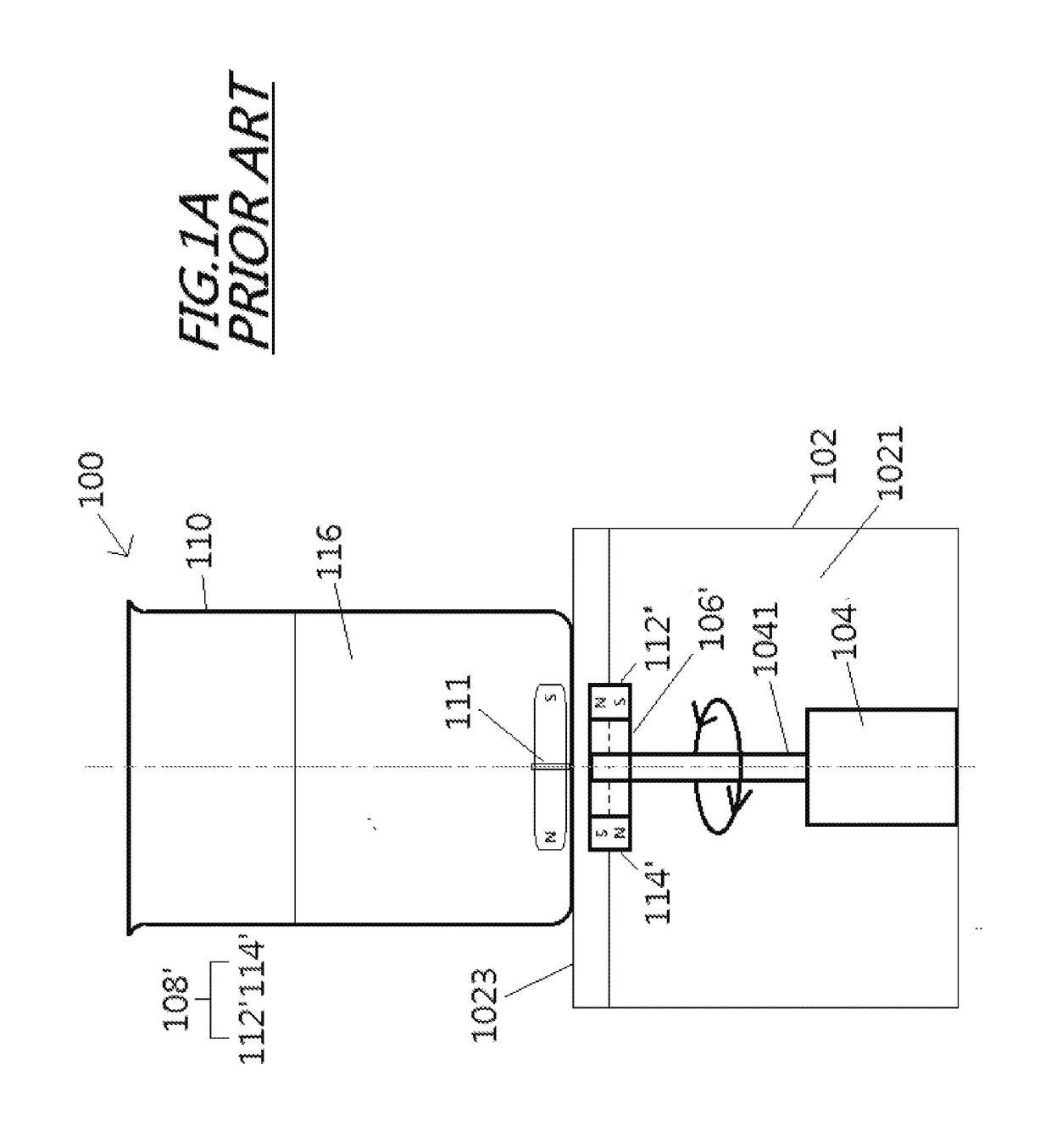

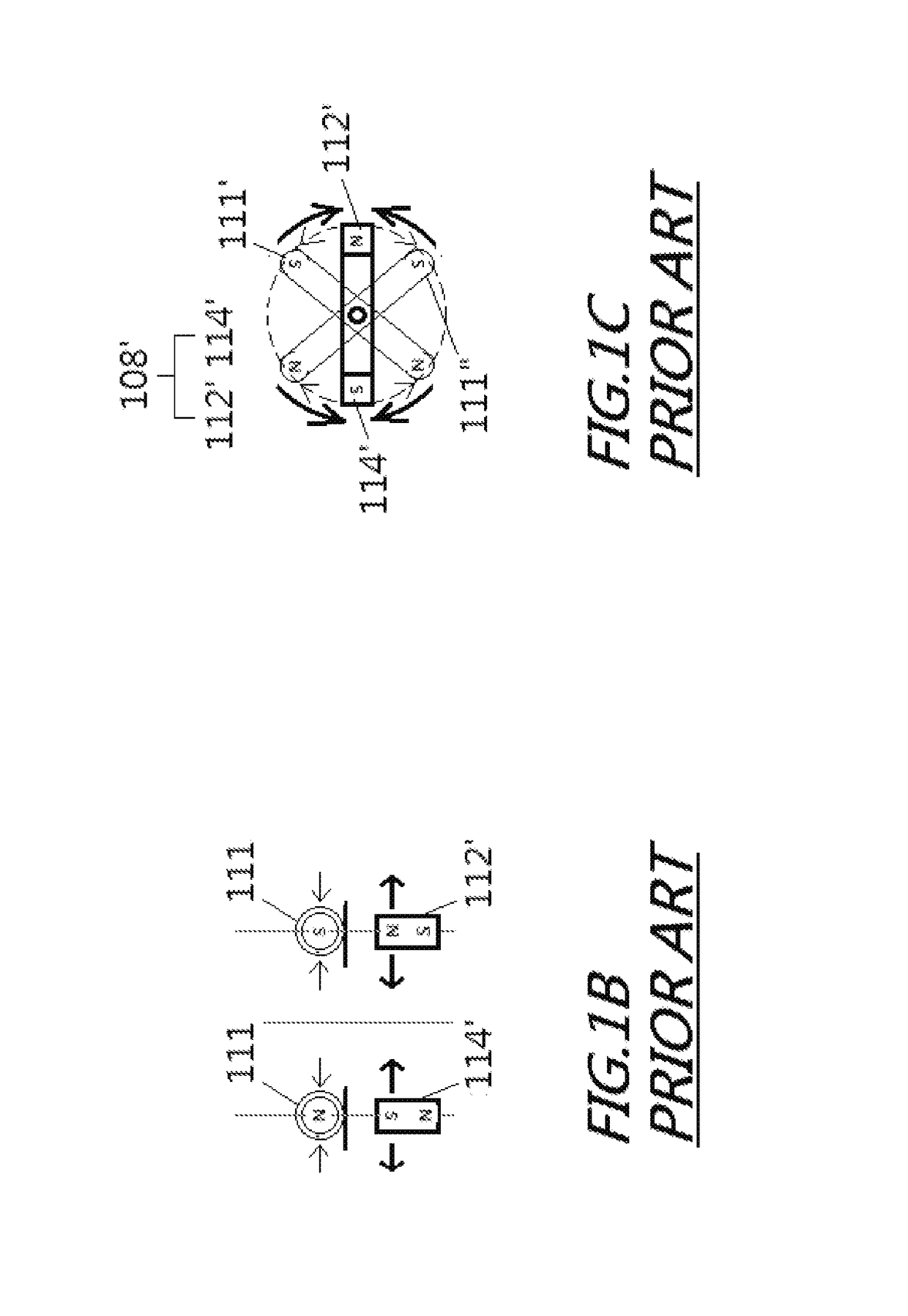

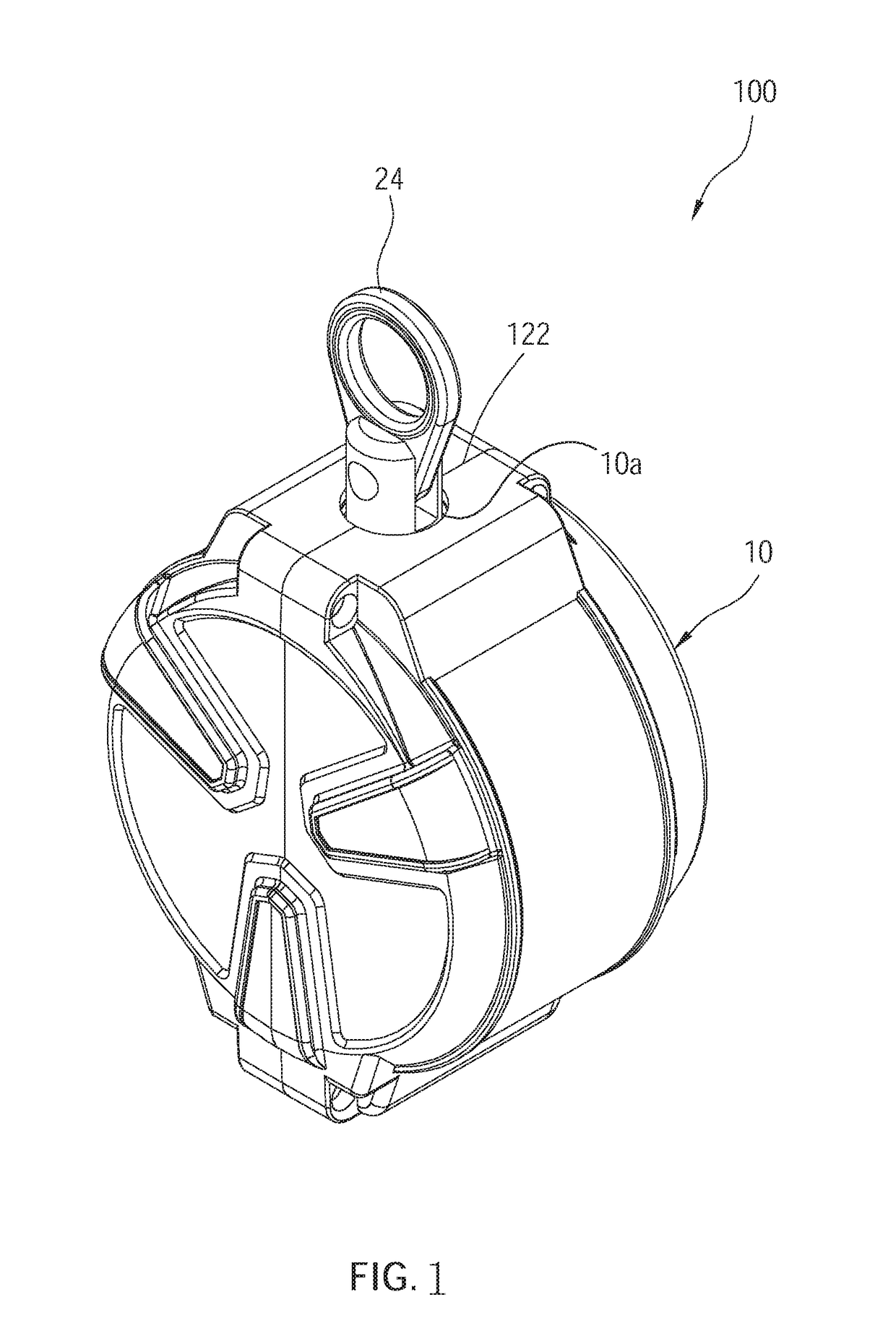

Magnetic coupling assembly for coupling stir bar in magnetic stirrer mixer and magnetic stirrer mixer using the same

ActiveUS20180141011A1Well mixedIncrease powerDynamo-electric brakes/clutchesTransportation and packagingSpin outCoupling

A magnetic coupling assembly for a magnetic stirrer includes a non-magnetic disc embedded with two or more pairs of magnets. The two magnets of each pair are oriented with opposite magnetic poles pointing in the upward direction. When the magnetic coupling assembly is driven to rotate, it can bind one or more axially magnetized stir bar in a mixer at a relatively higher speed to achieve better mixing result without causing spin-out or jumping-flea phenomena, compared to when only one pair of magnets is used.

Owner:MOU DUEN GANG

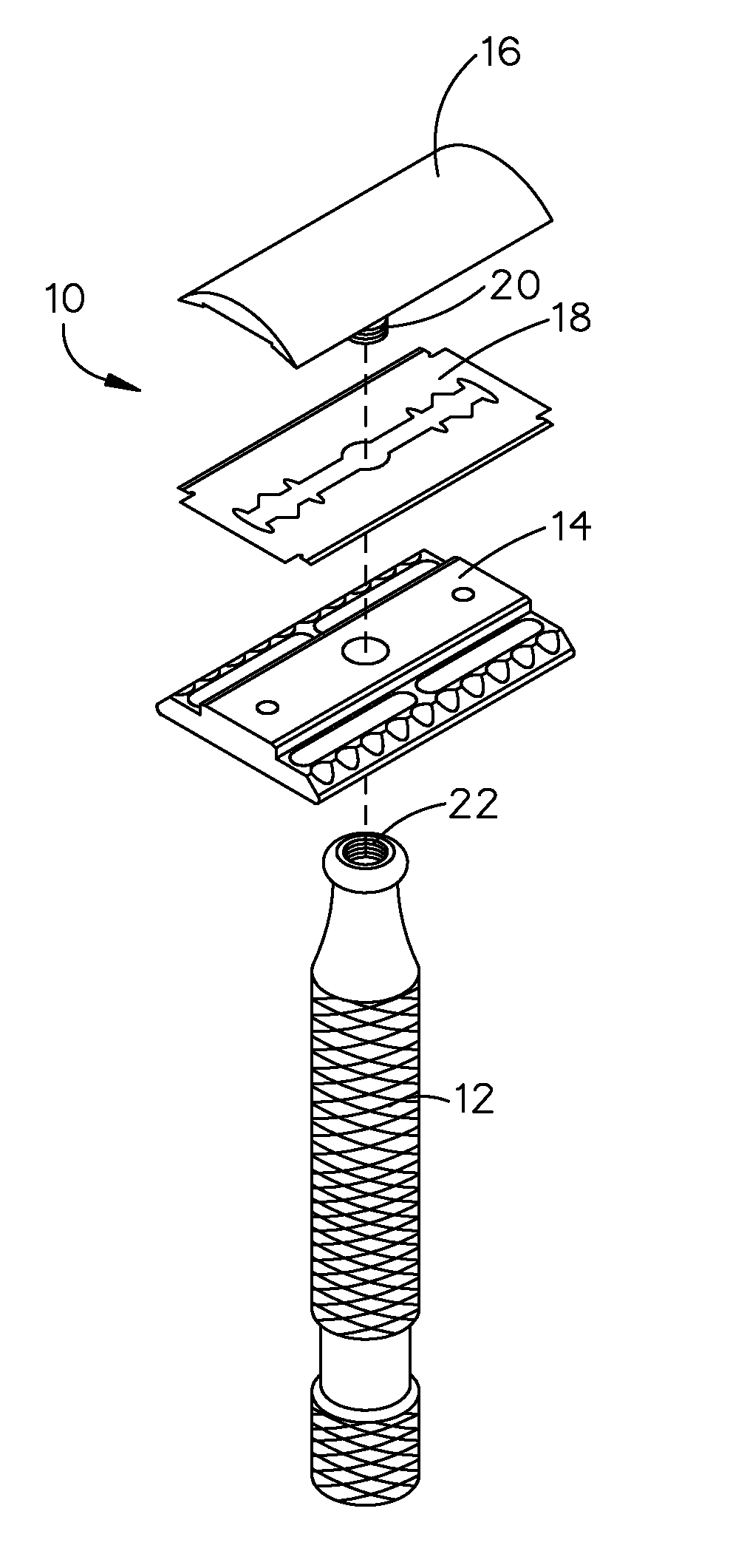

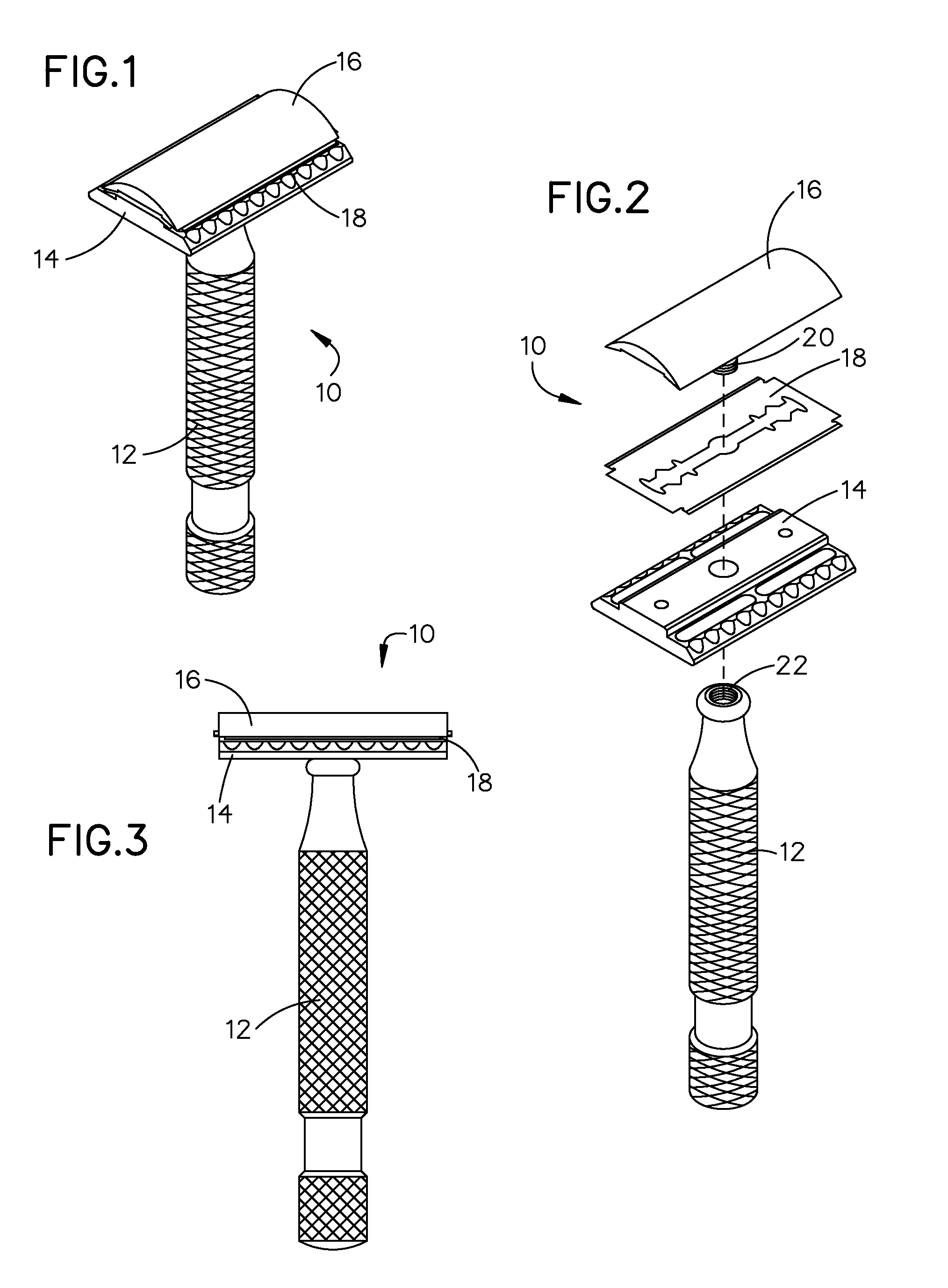

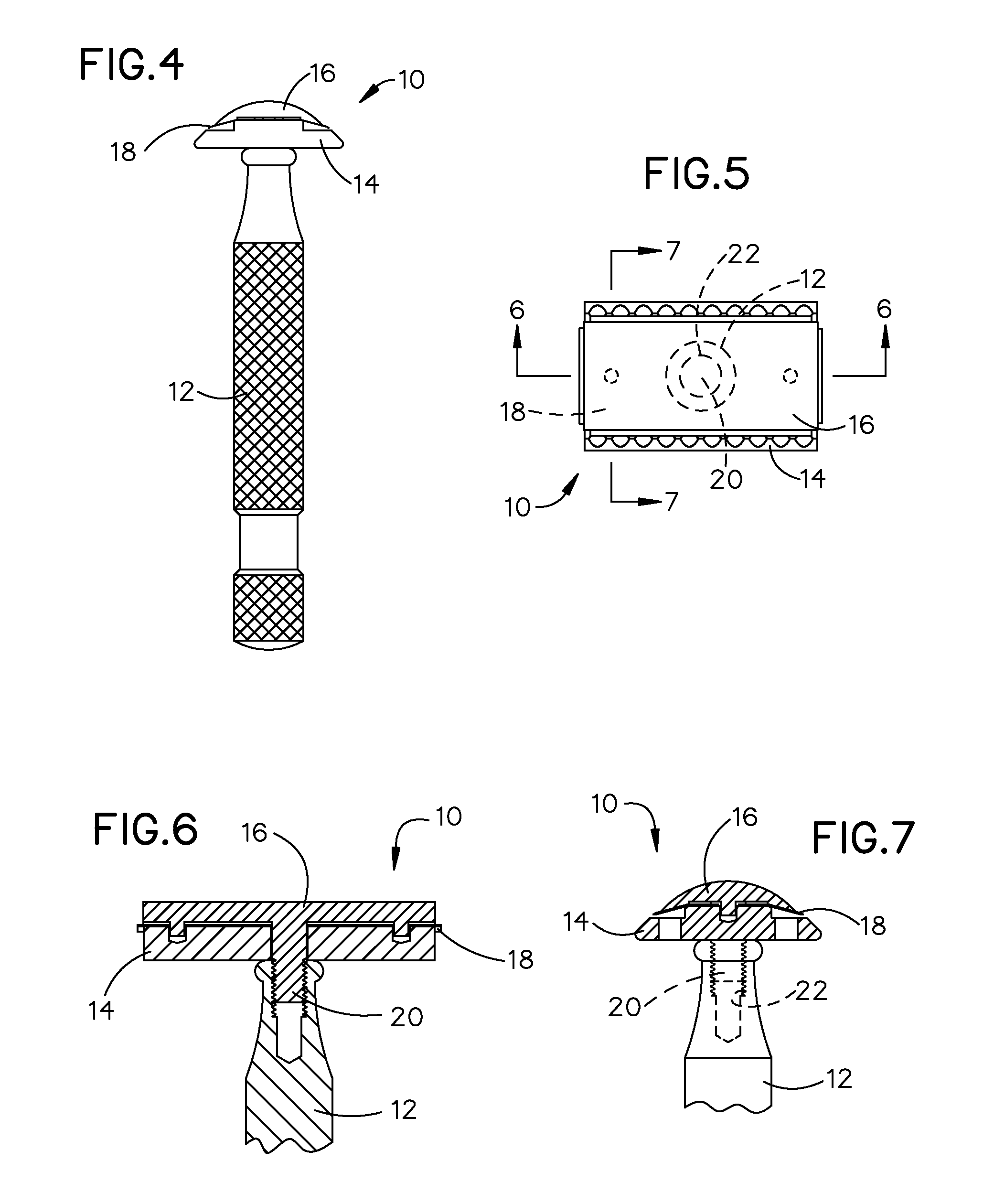

Double edge safety razor with razor blade alignment

A double edge razor assembly with a razor blade alignment is provided. The double edge razor includes a head with a cap and a base. A post and at least one pin may protrude for the inner surface of the cap. The post and the at least one pin may snuggly fit within a channel through the razor. The post may fit through an aperture in the base, and the pin may fit within a pin hole in the base. The pin may align the razor in between the cap and the base, and prevent the razor from spinning out of alignment. The post may then attach to a handle to complete the double edge razor assembly.

Owner:HICKAM STANLEY LEE

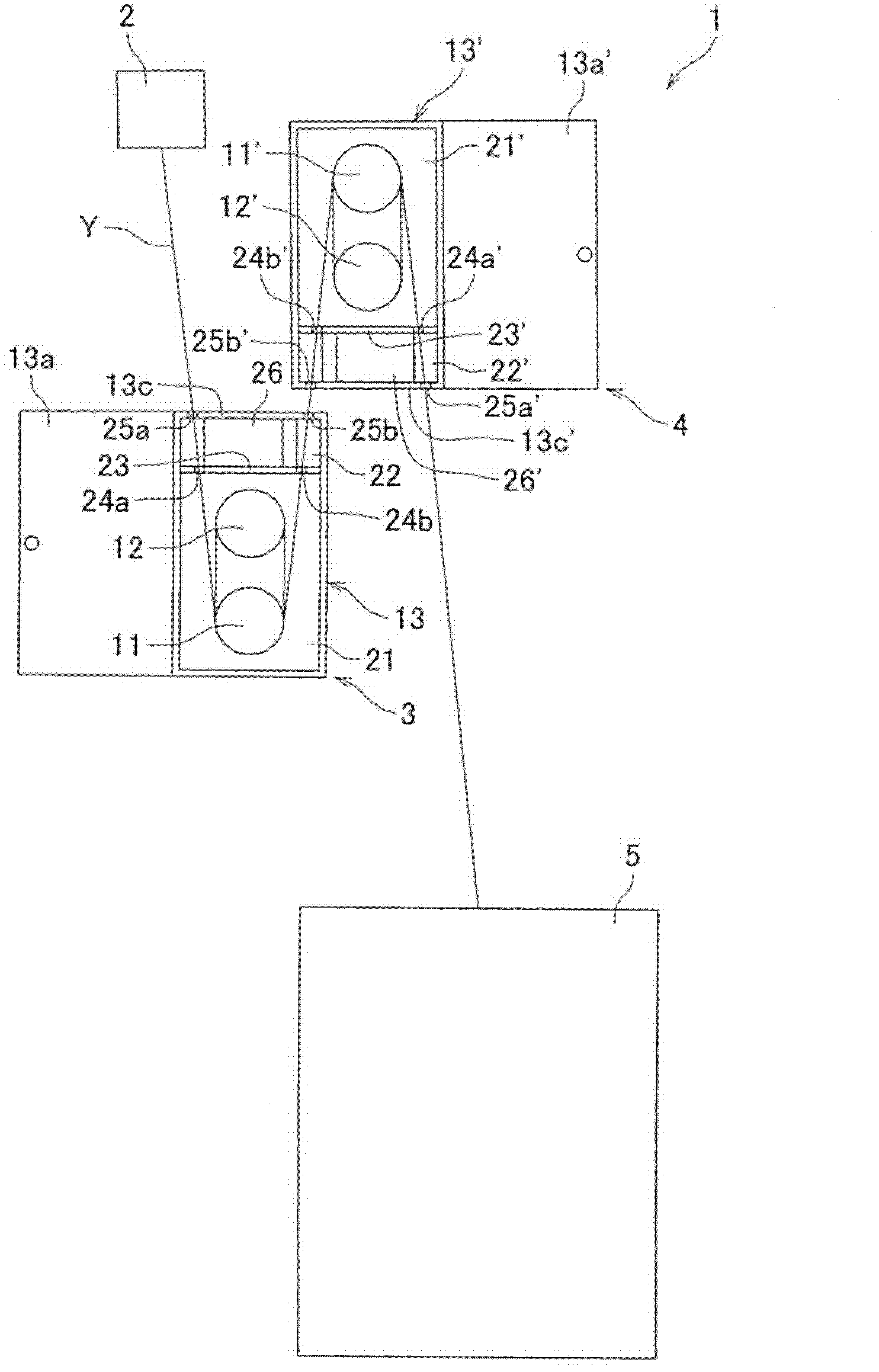

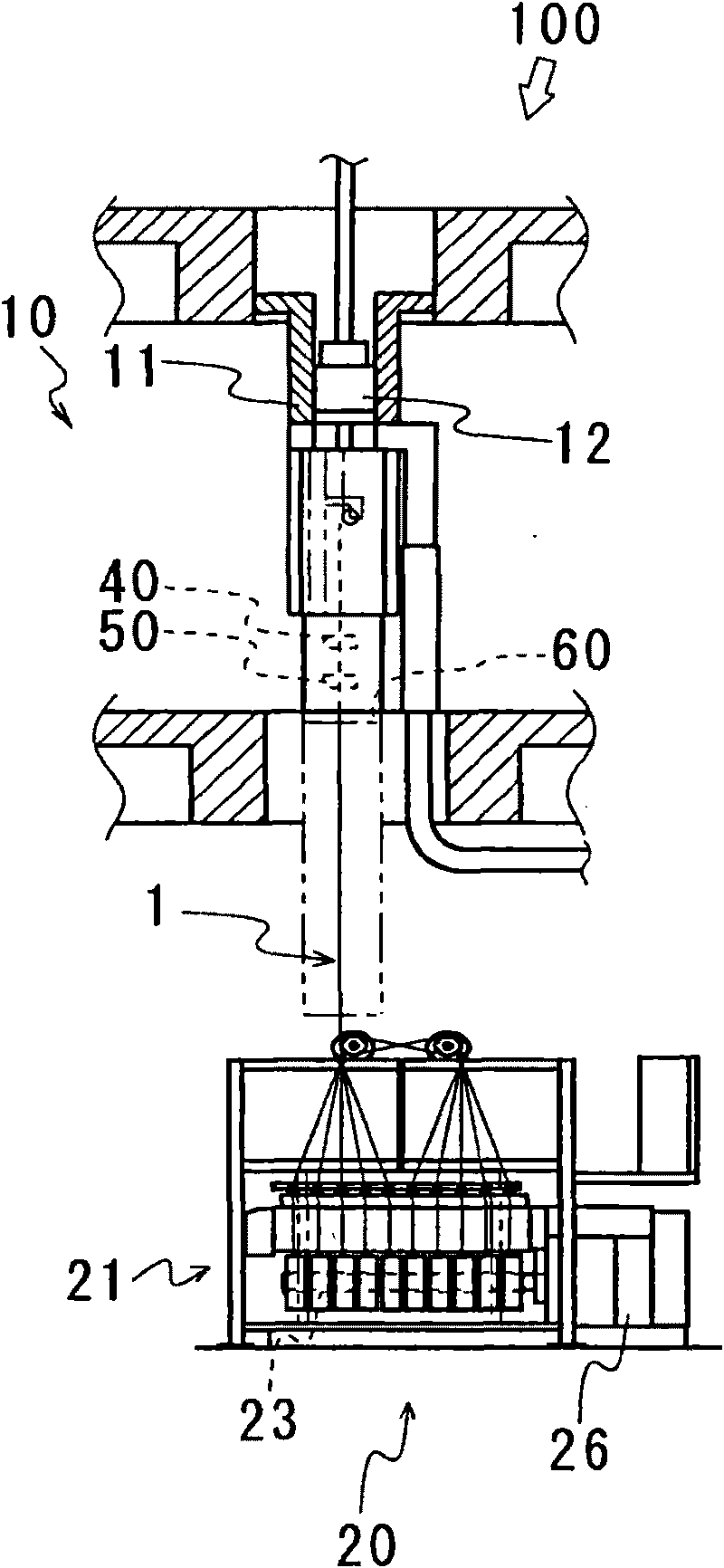

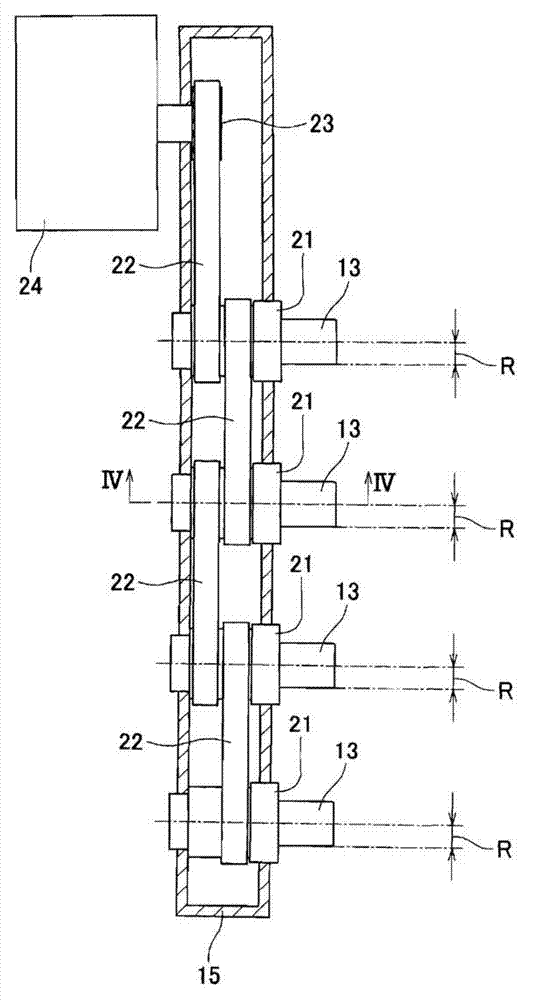

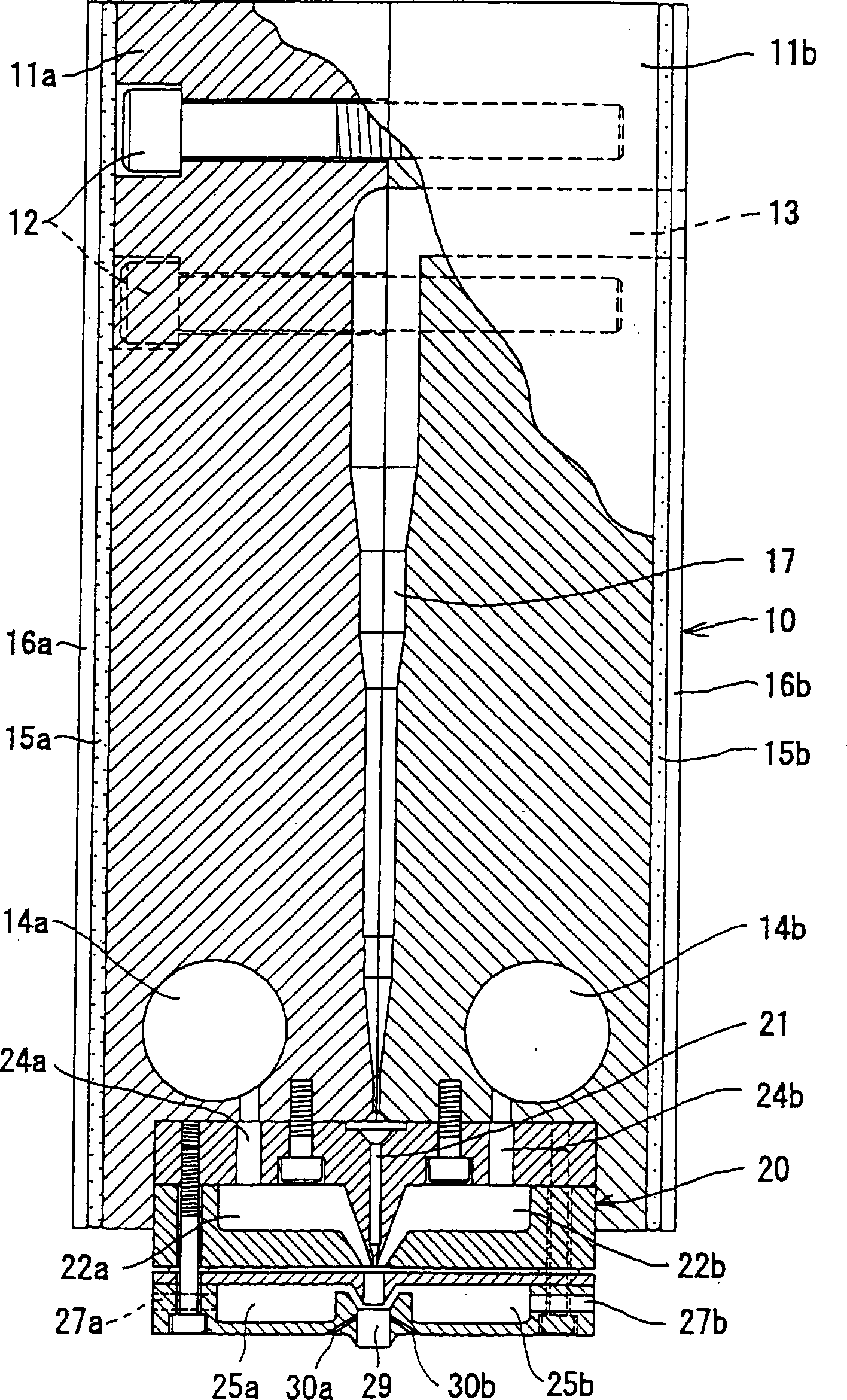

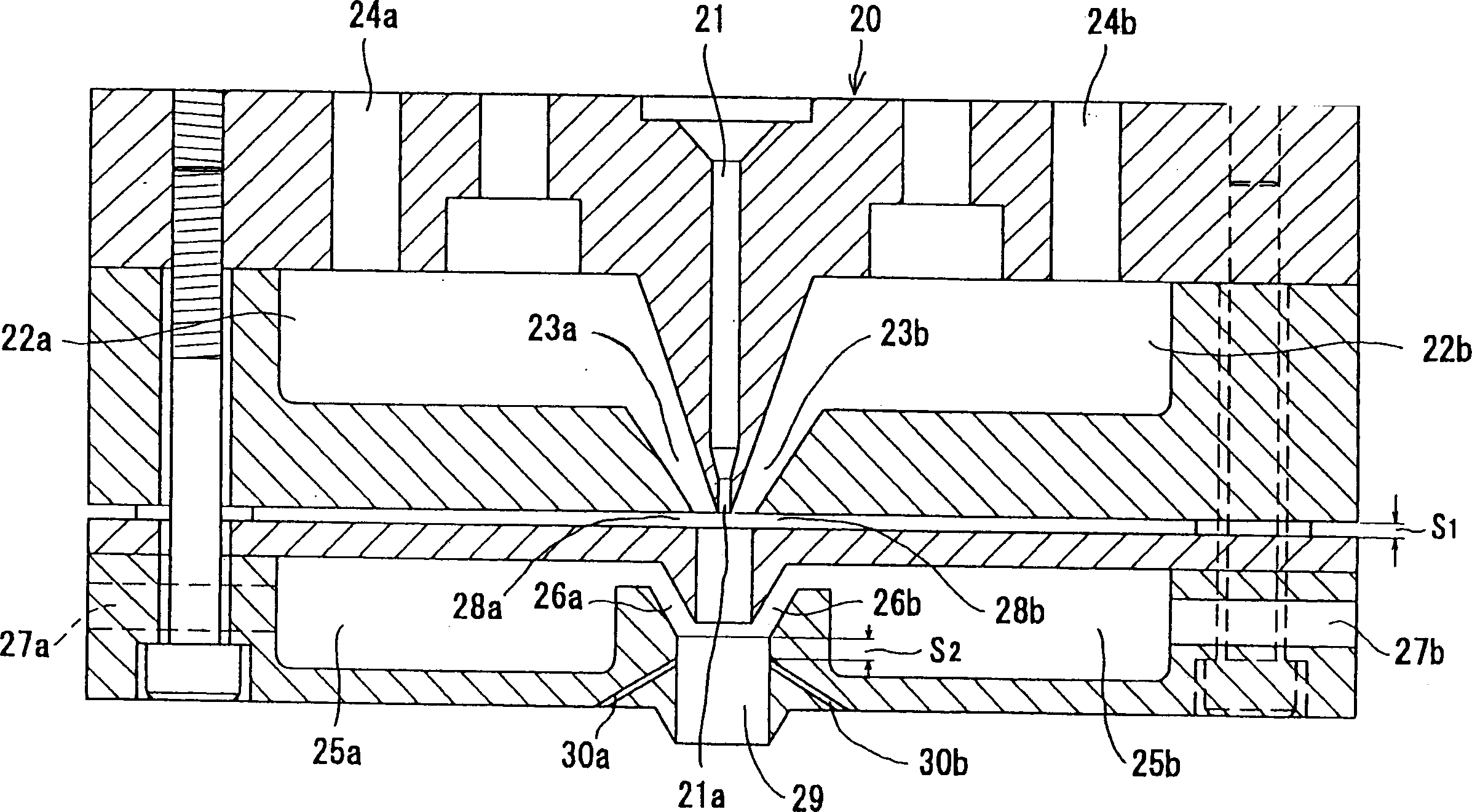

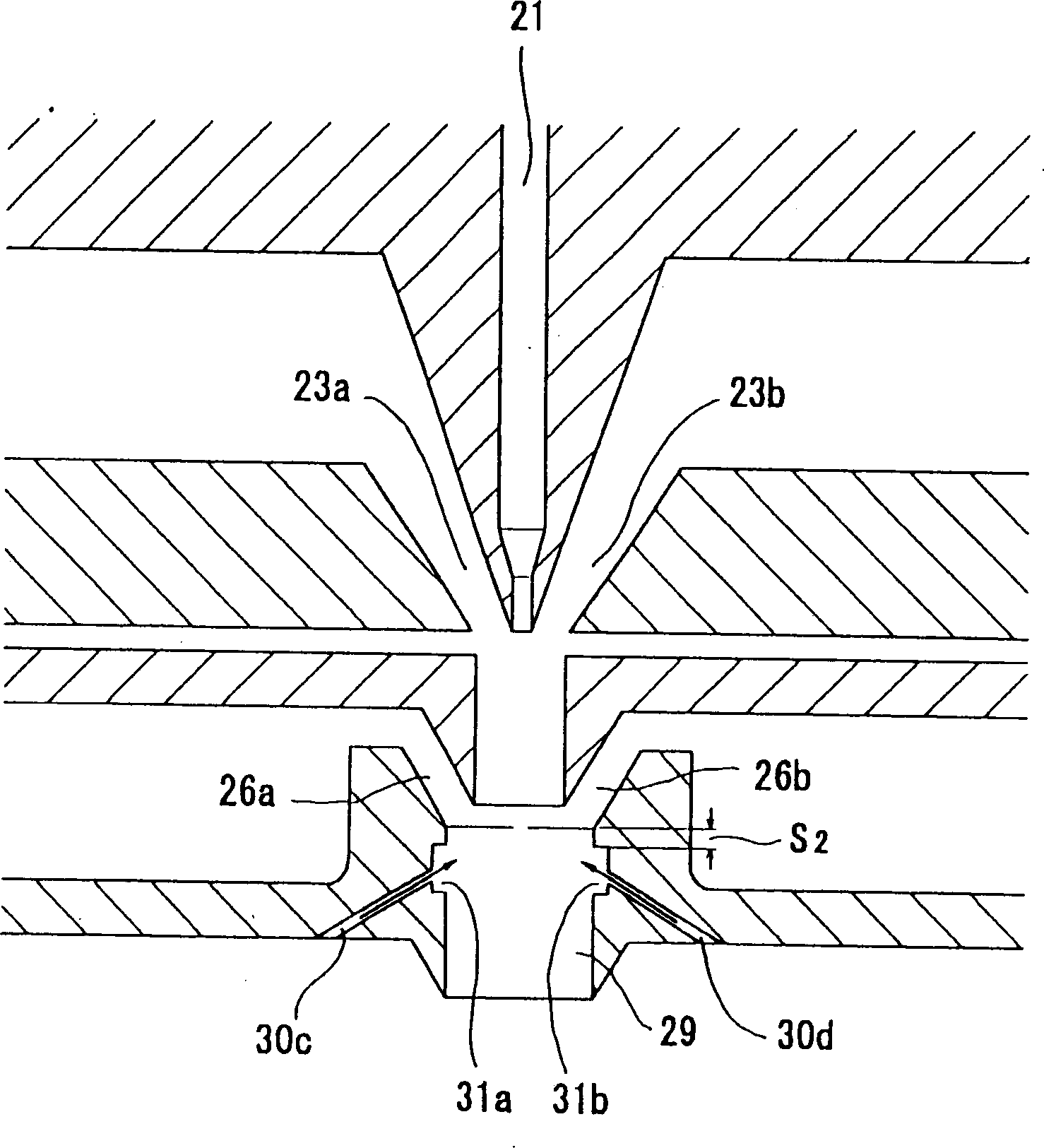

Yarn heating apparatus

ActiveCN102373525AReduce the temperatureReduce power consumptionArtificial thread manufacturing machinesArtificial filament heat treatmentYarnSpin out

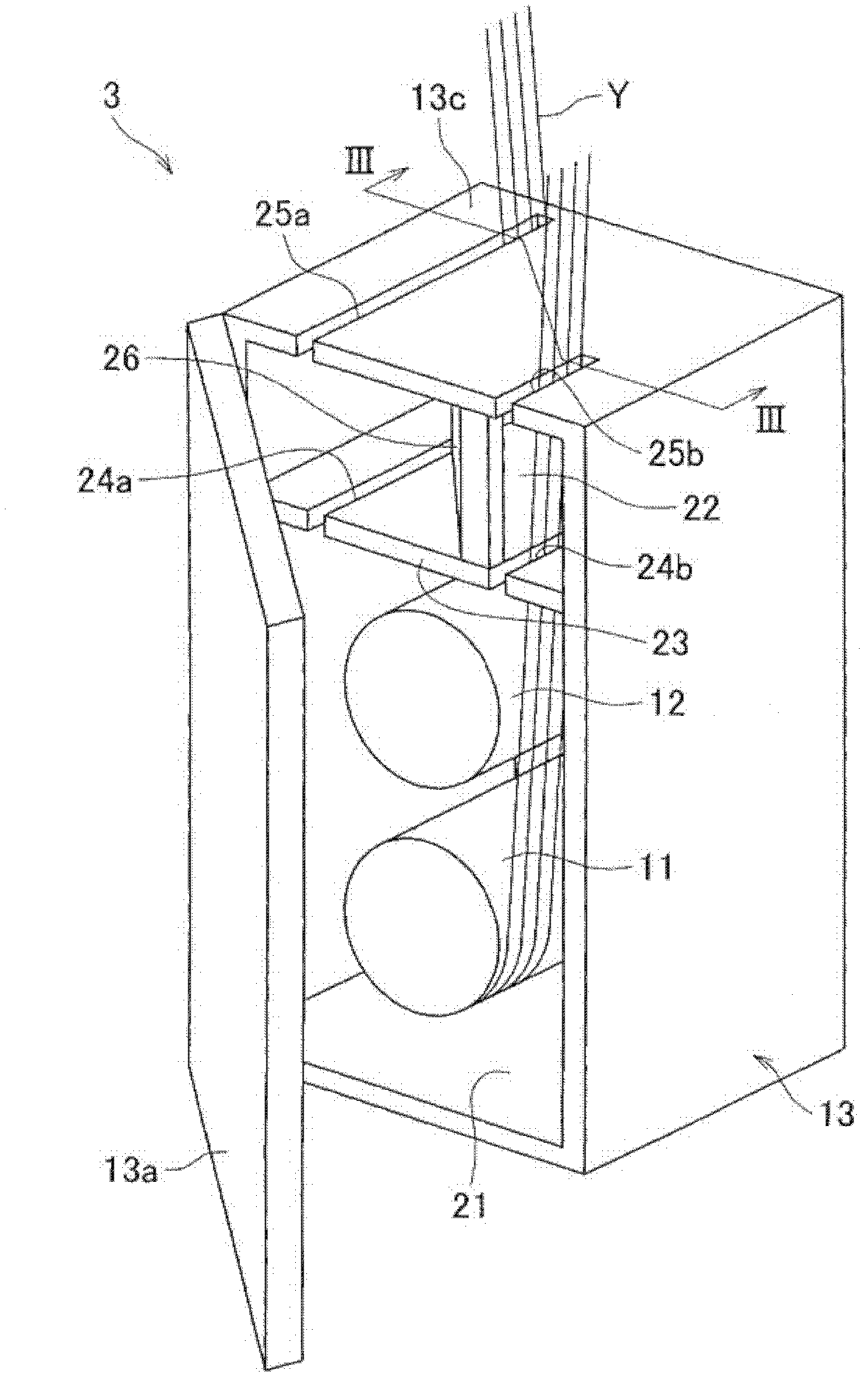

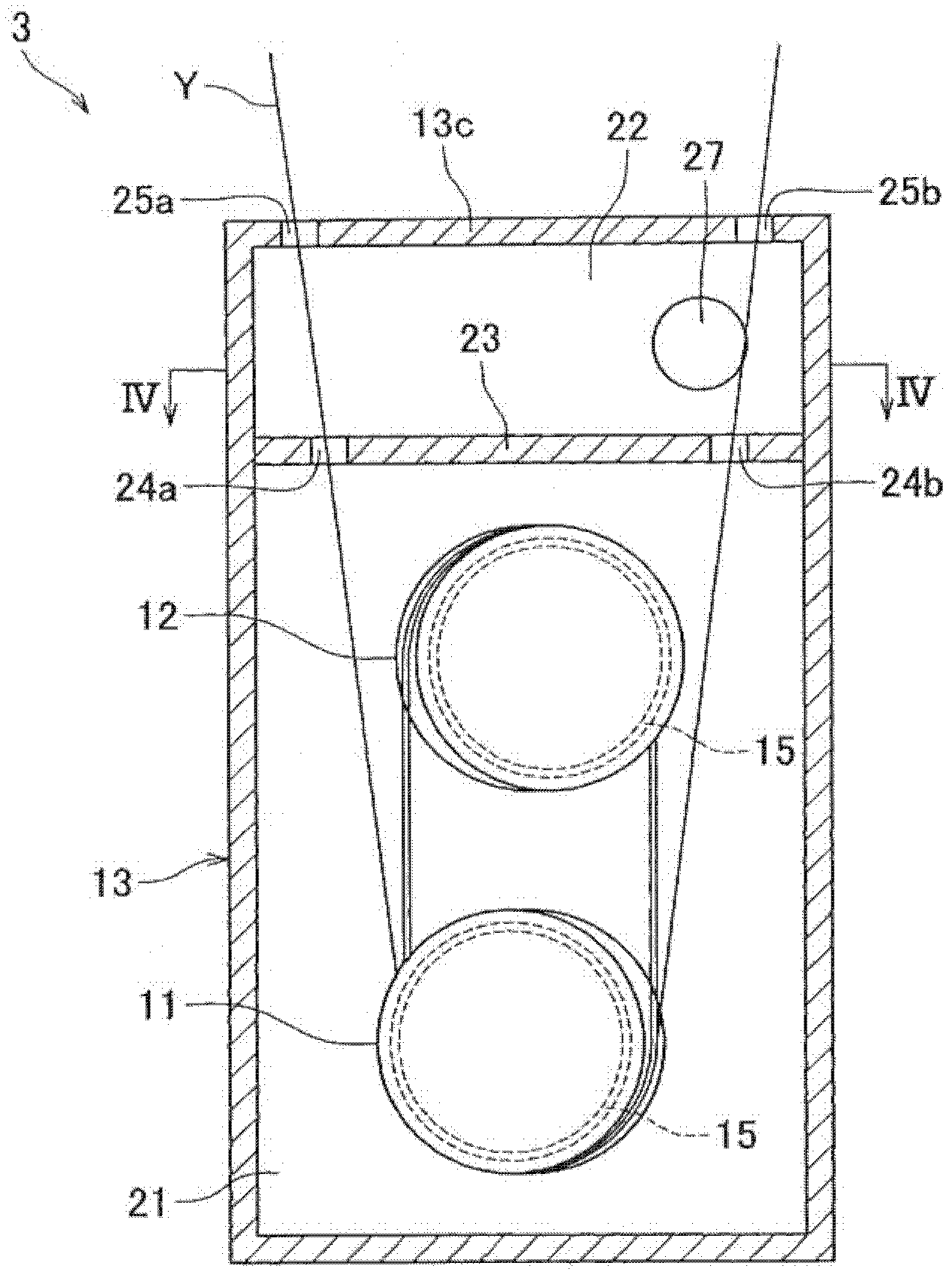

The invention provides a yarn heating apparatus with a reduced power consumption for heating yarns fed by a yarn feeding roller. In a thermal insulation box (13), above a thermal insulation space (21) in which a godet roller (11) and a separate roller (12) each having a heater (15) are provided, a connecting space (22) separated from a thermal insulation space by a wall (23) is provided. Yarns (Y) spun out from a spinning machine enter the thermal insulation space after passing through a slit (25a) at an upper wall (13b) of the thermal insulation box (13), the connecting space, and a slit (24a) on the wall, reciprocate between the rollers (11) and (12) plural times, and then go out from the thermal insulation space to the outside of the thermal insulation box through a slit (24b) of the wall (23), the connecting space, and a slit (25b) of the upper wall (13b). In so doing, an accompanied flow generated around the running yarns (Y) causes a part of air having flown out from the thermal insulation space through the slit (24b) to return to the thermal insulation space through the connecting space and the slit (24a).

Owner:TMT MACHINERY INC

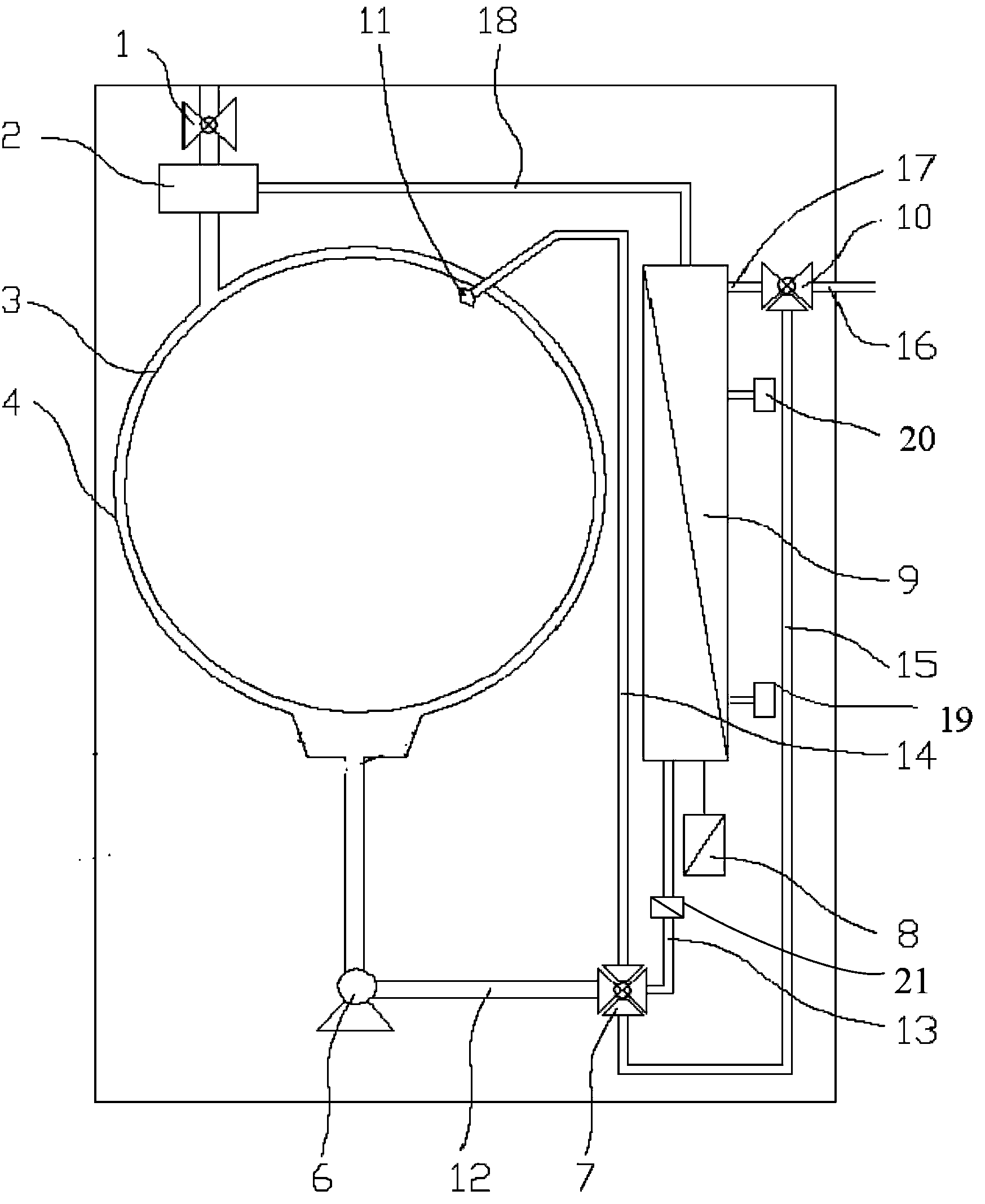

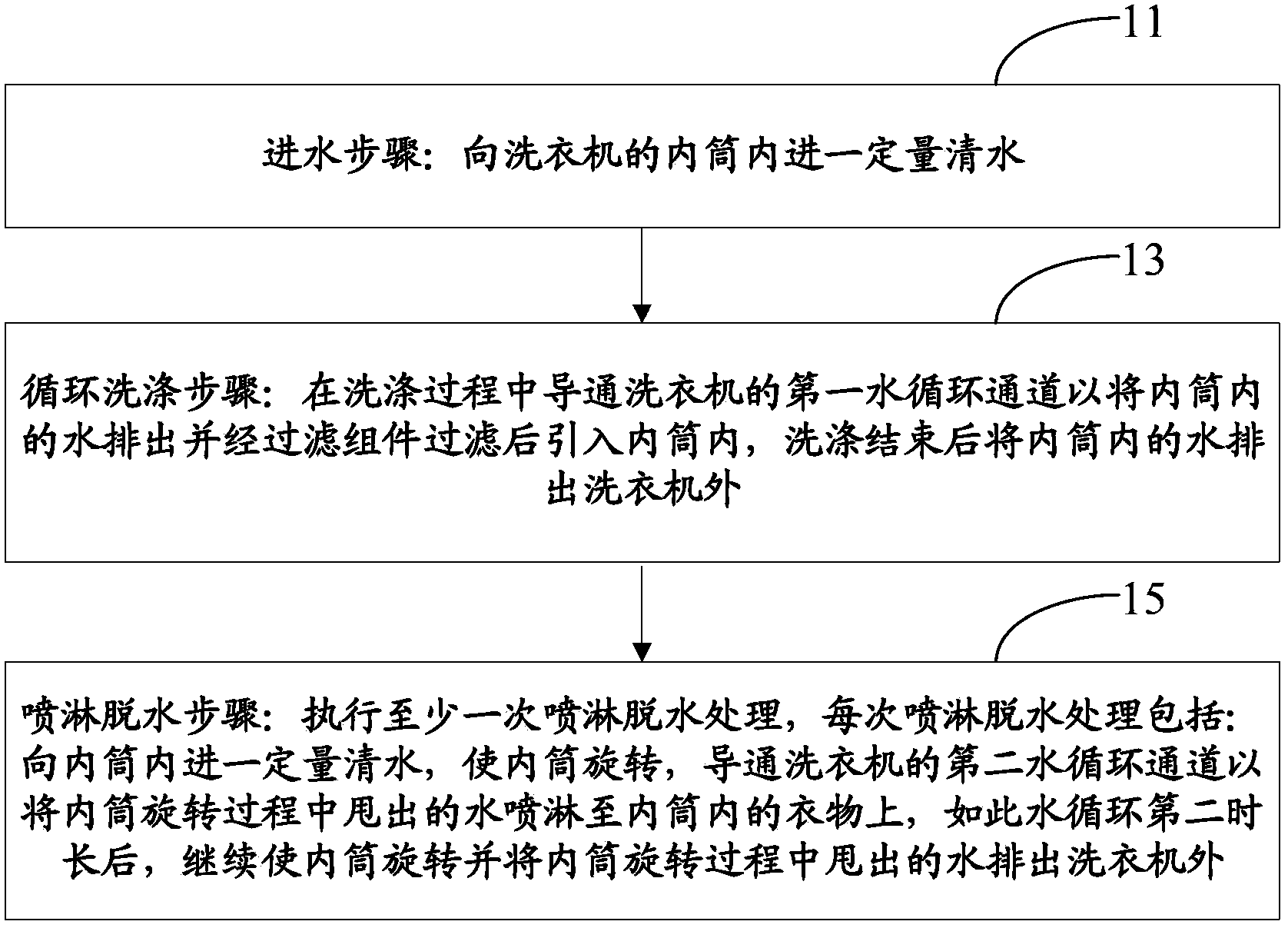

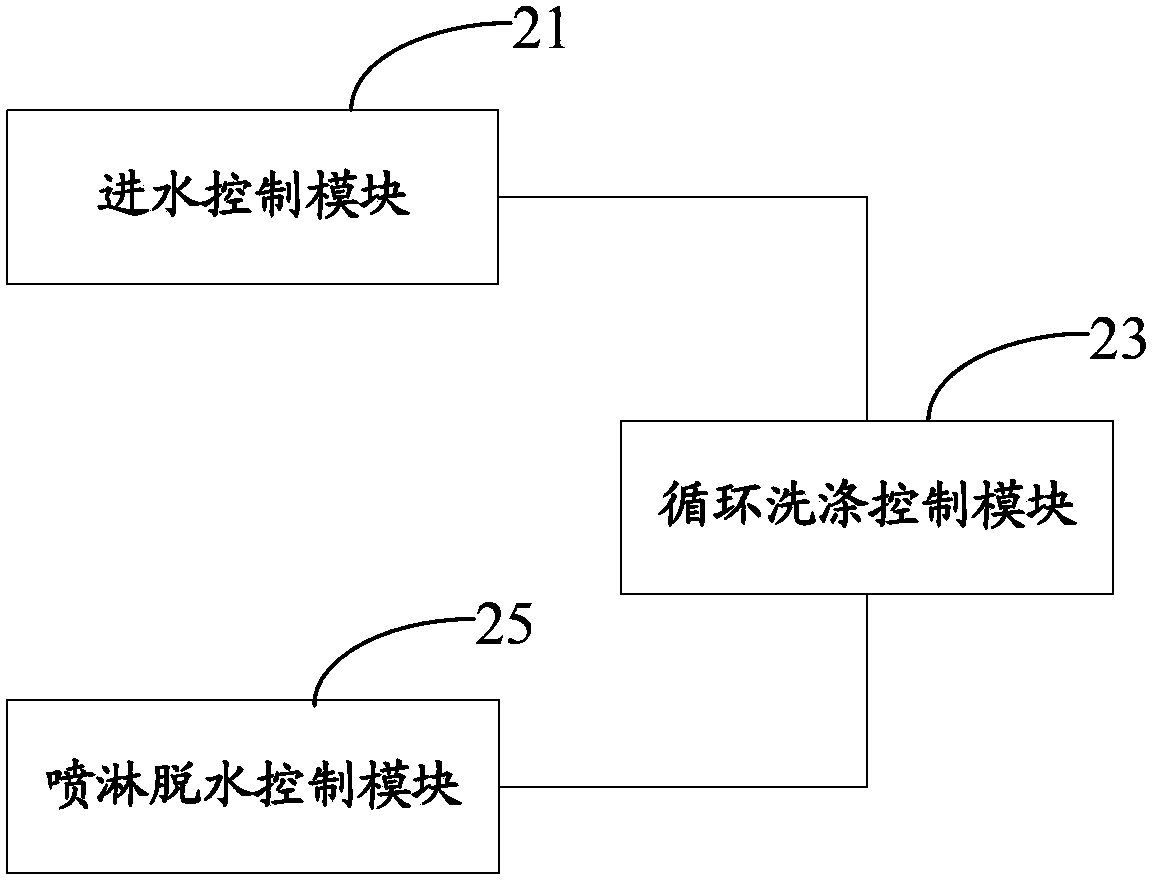

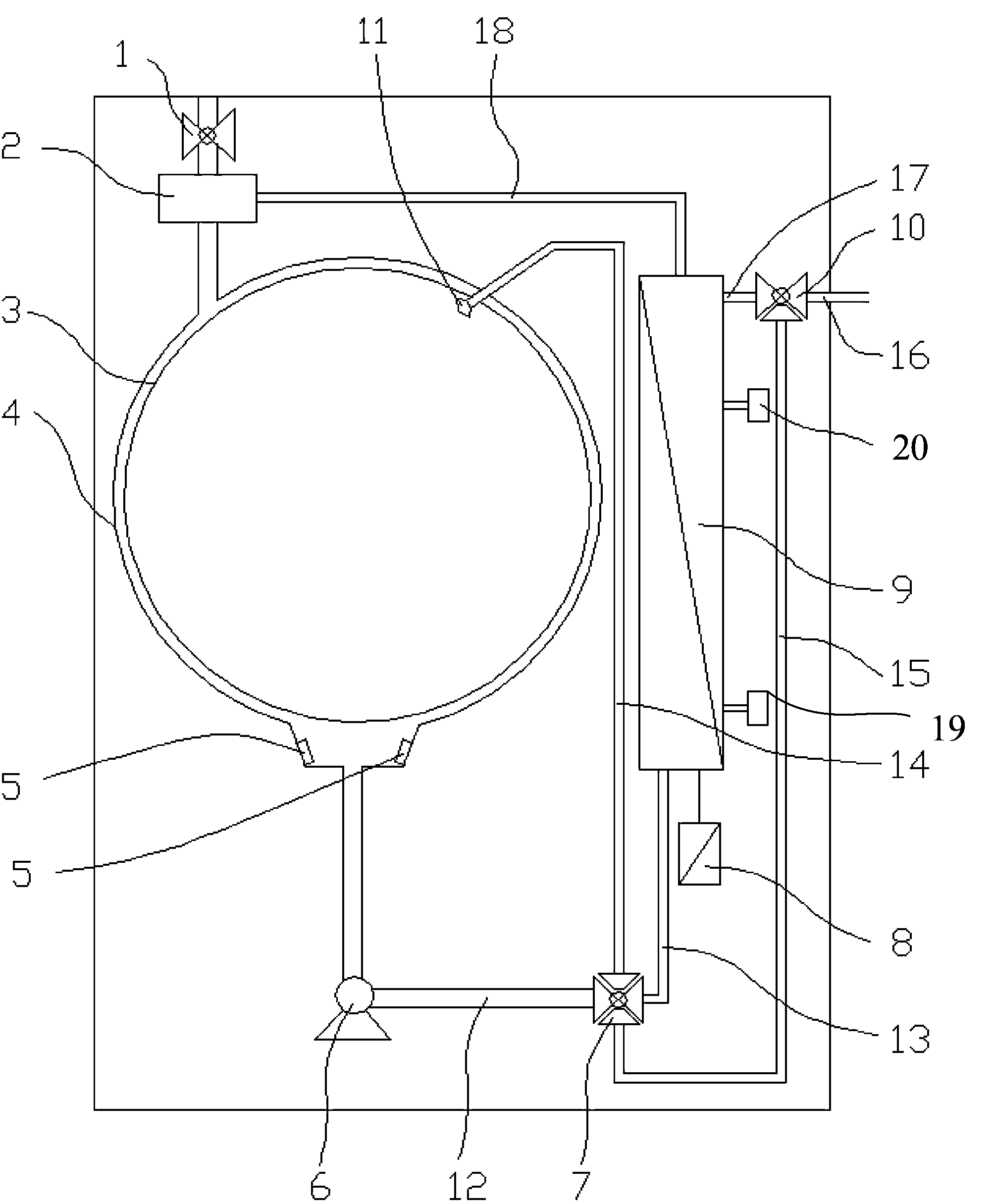

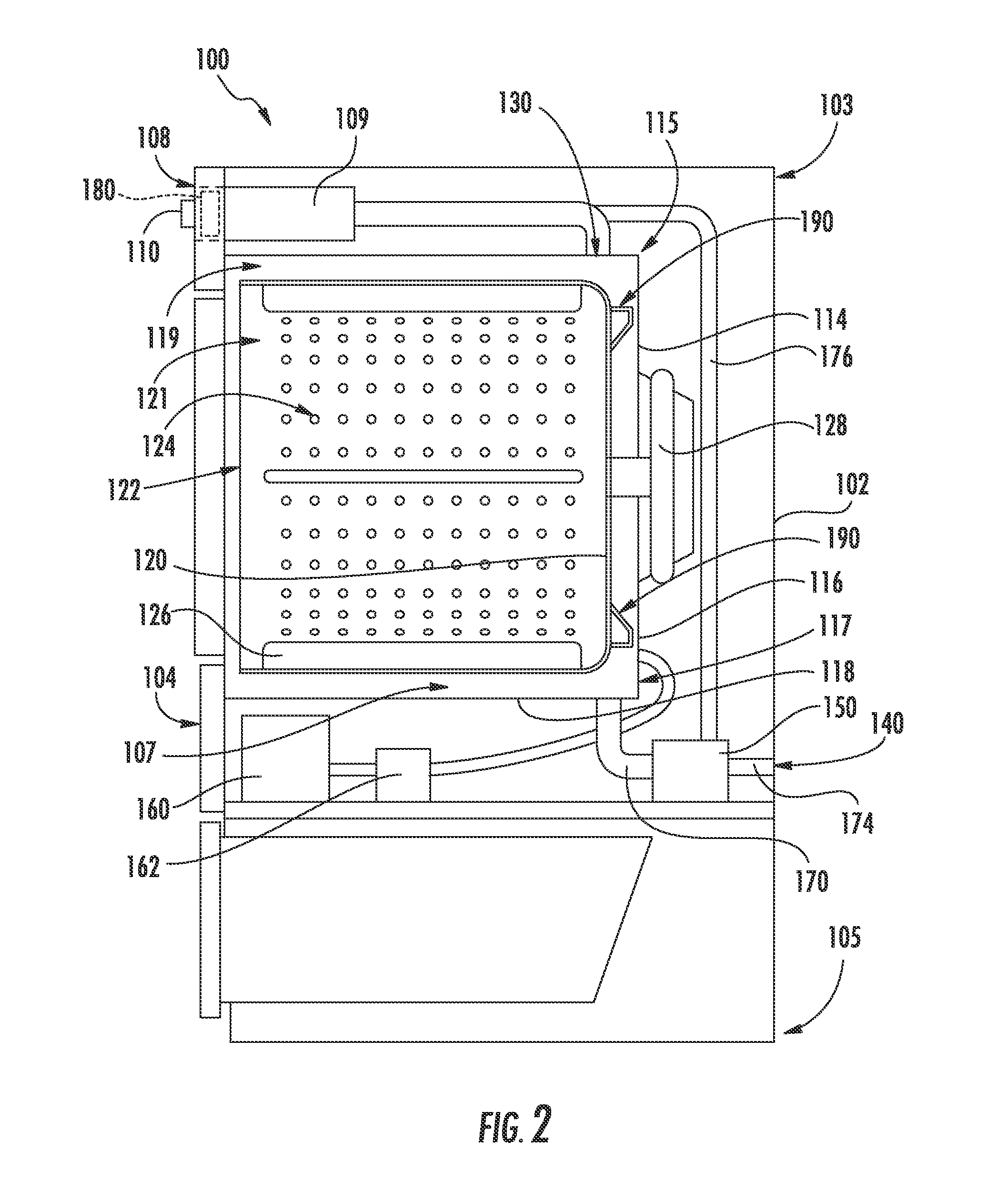

Washing control method and washing machine

ActiveCN104294530AIncrease profitMeet cleanlinessOther washing machinesControl devices for washing apparatusWater useSpin out

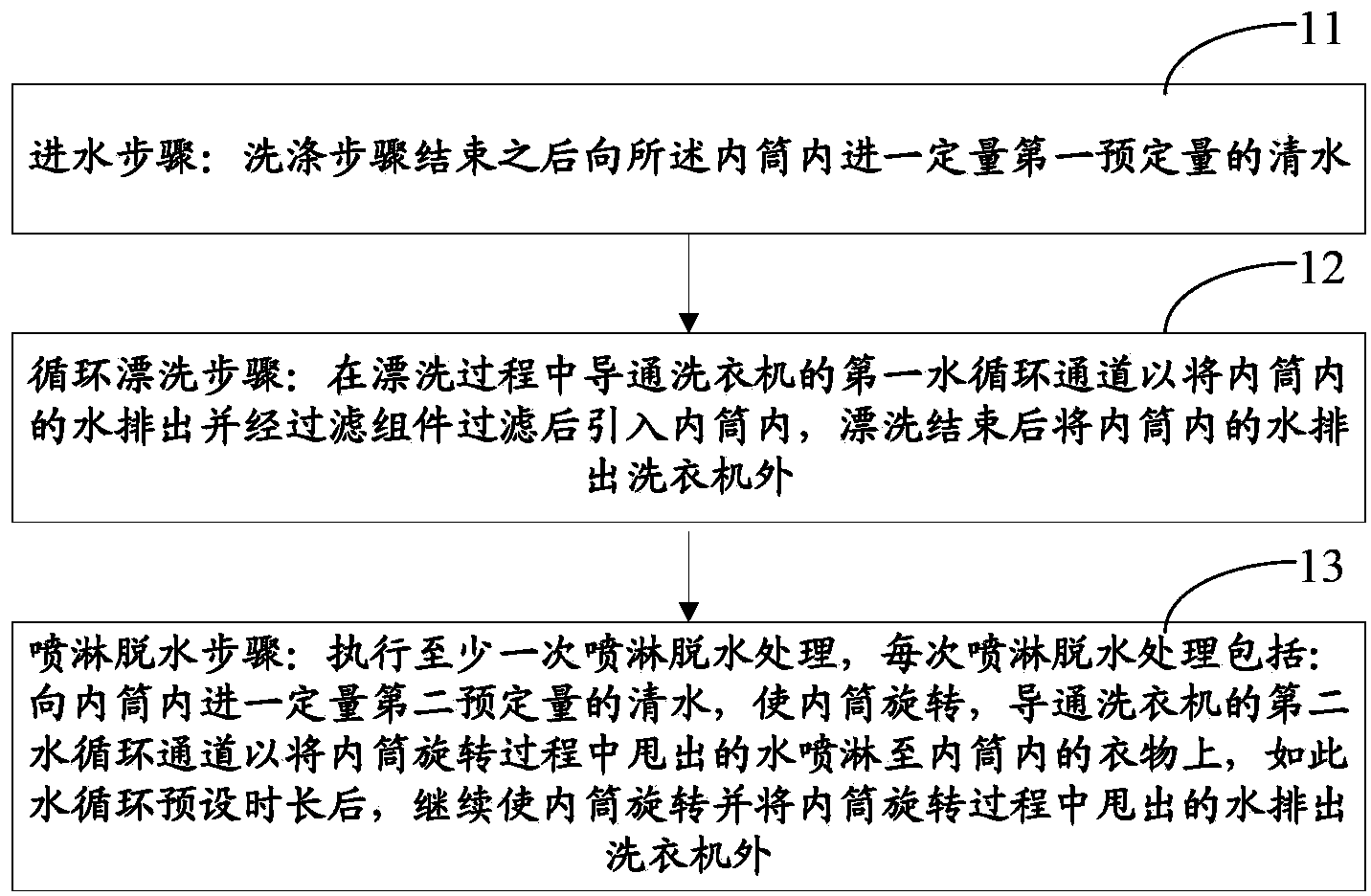

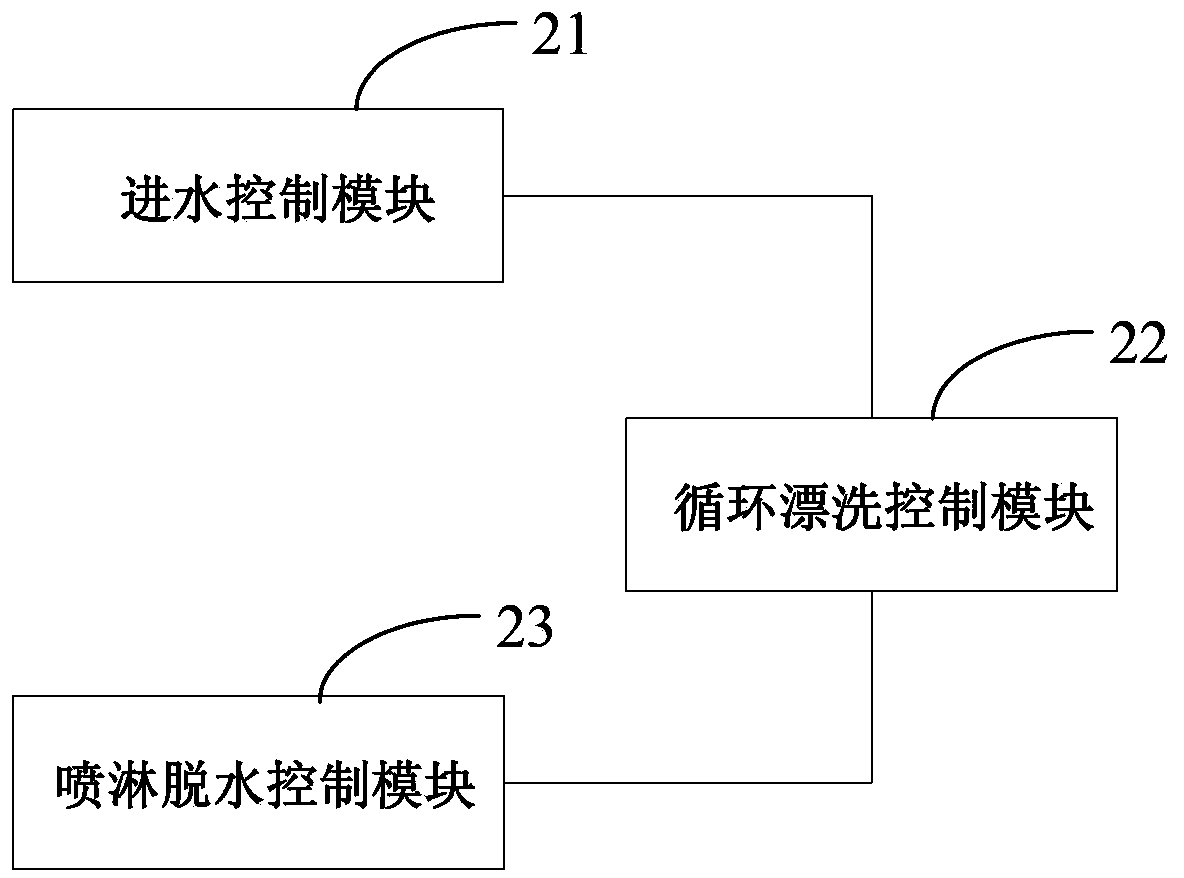

Disclosed are a laundry control method and a washing machine. The method comprises: after a washing step has been concluded, introducing a first predetermined amount of clean water into an inner drum (3) of the washing machine; circulating and rinsing: during the rinsing process, guiding through a first water circulation channel of the washing machine to discharge water from inside the inner drum and introducing the water into the inner drum (3) after filtering same through a filter component, and after rinsing has concluded, discharging the water from inside the inner drum (3) out of the washing machine; spraying and water-removal: performing at least one spraying and water-removal process, each spraying and water-removal process comprising: introducing a second predetermined amount of clean water into the inner drum (3), making the inner drum (3) rotate, guiding through a second water circulation channel of the washing machine to spray water which was spun out during the rotation of the inner drum (3) onto clothing inside the inner drum (3), and after a second length of time for such water circulation, continuing to rotate the inner drum (3) and discharging the water which was spun out during the rotation of the inner drum (3) out off the washing machine, thereby saving water used for laundry, reducing the residual amount of washing substance in the clothing and keeping costs relatively low.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

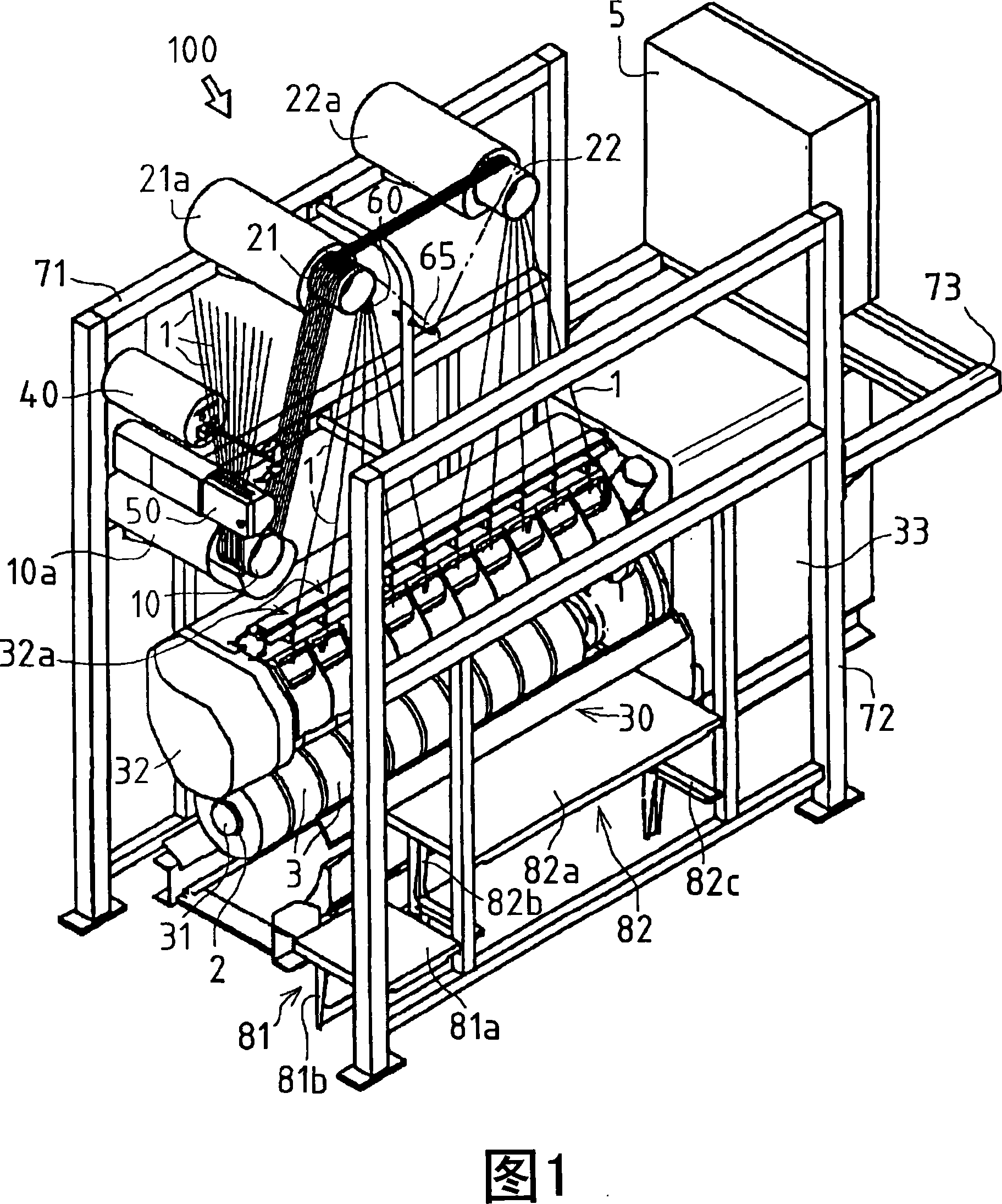

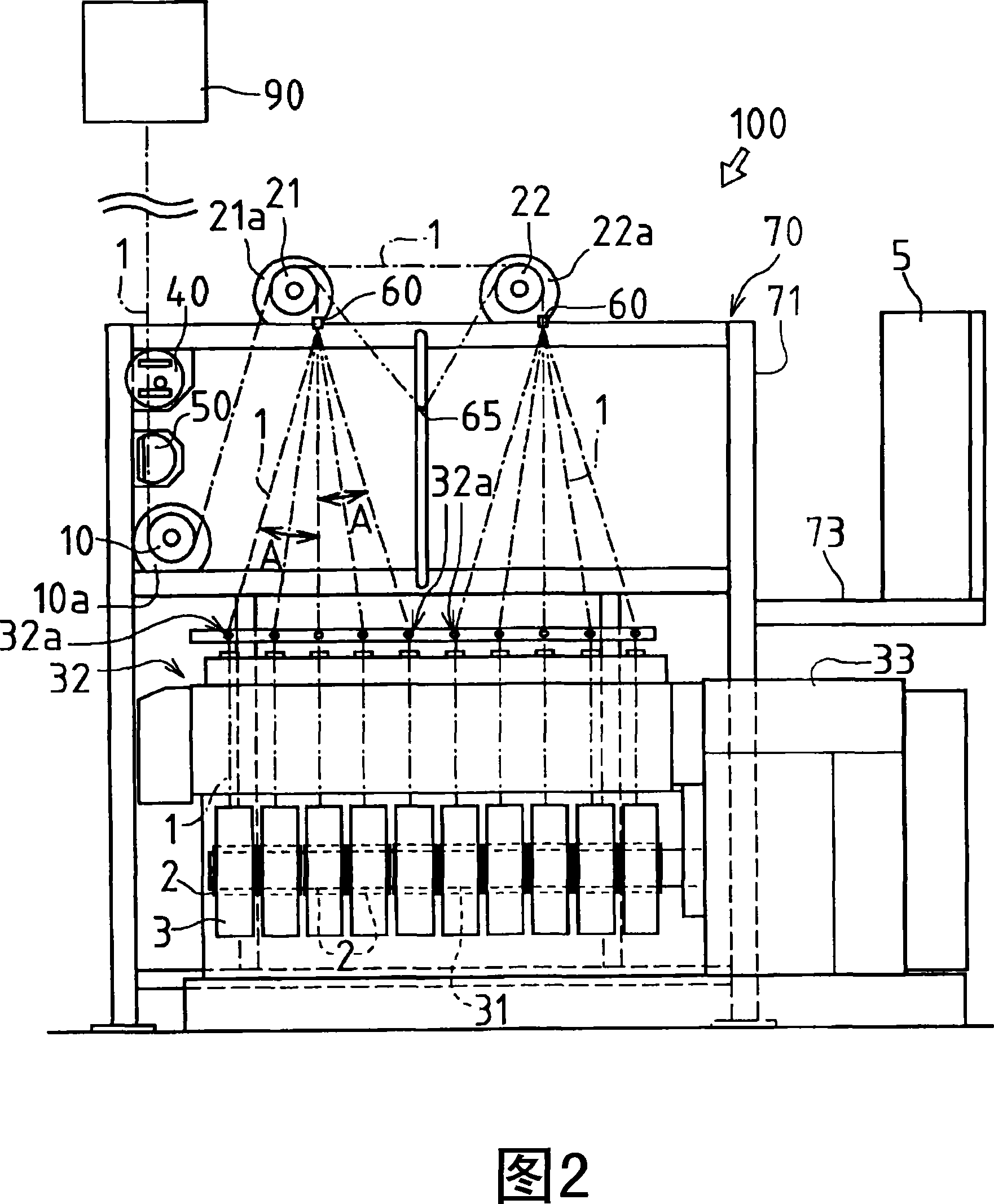

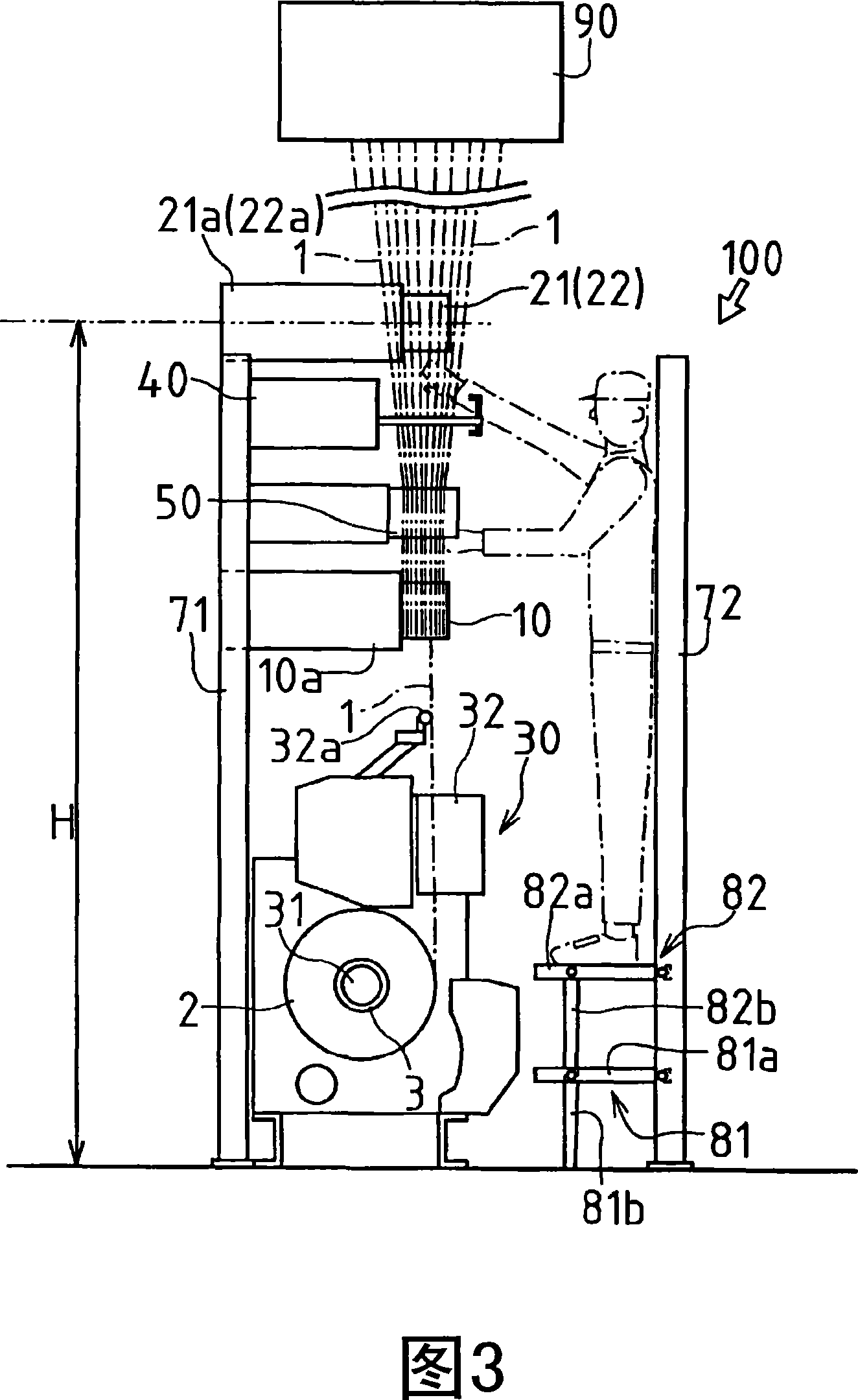

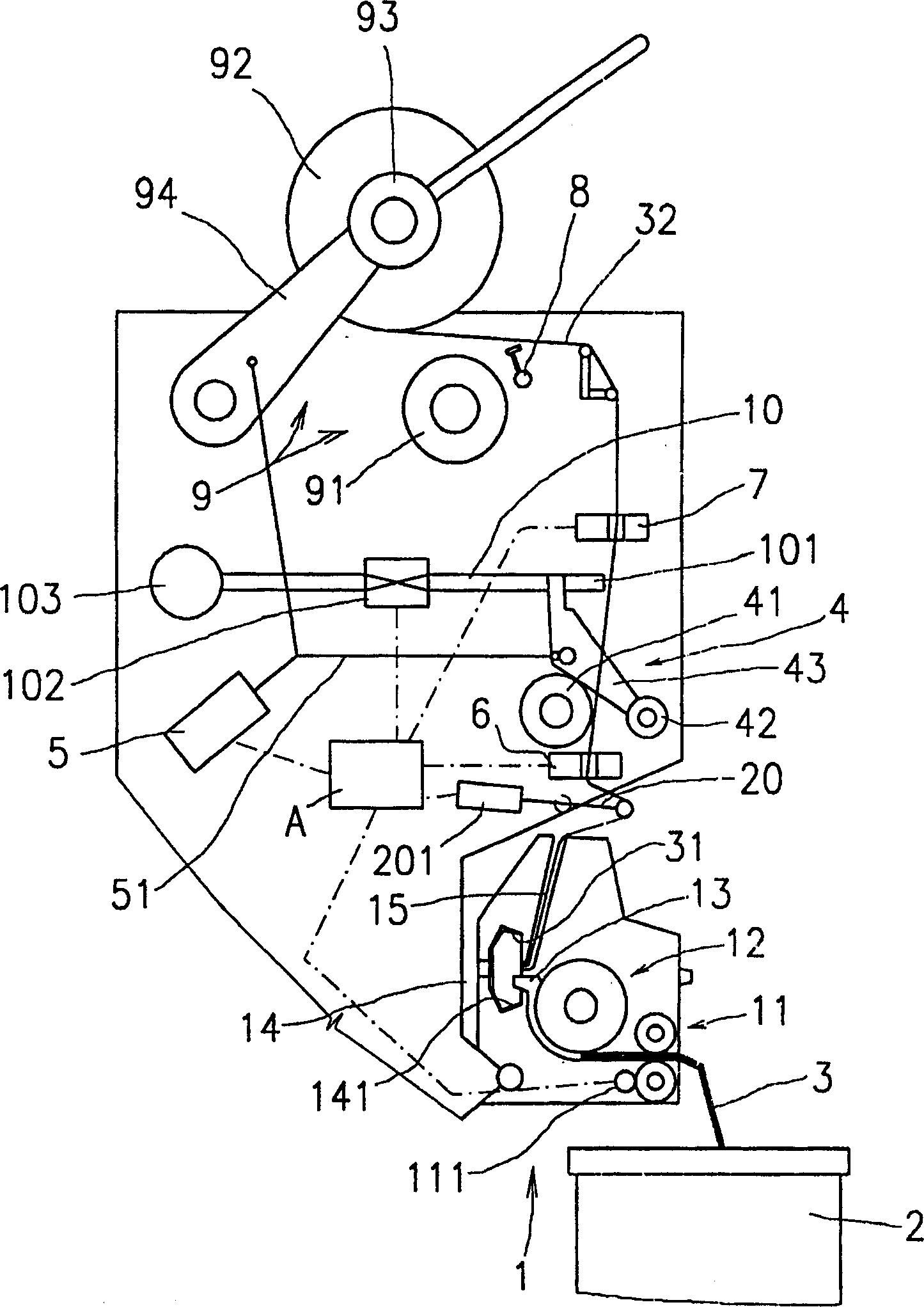

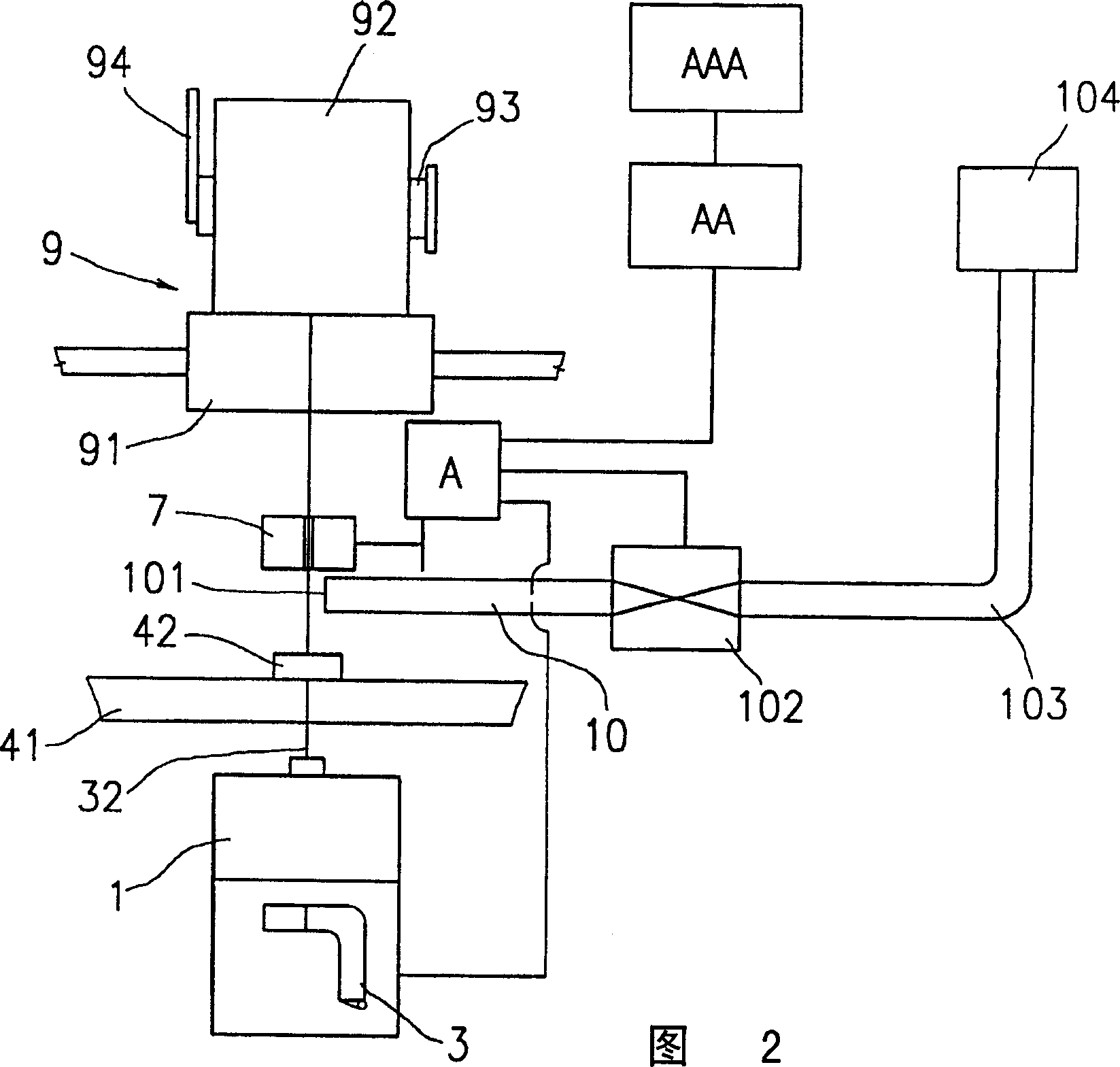

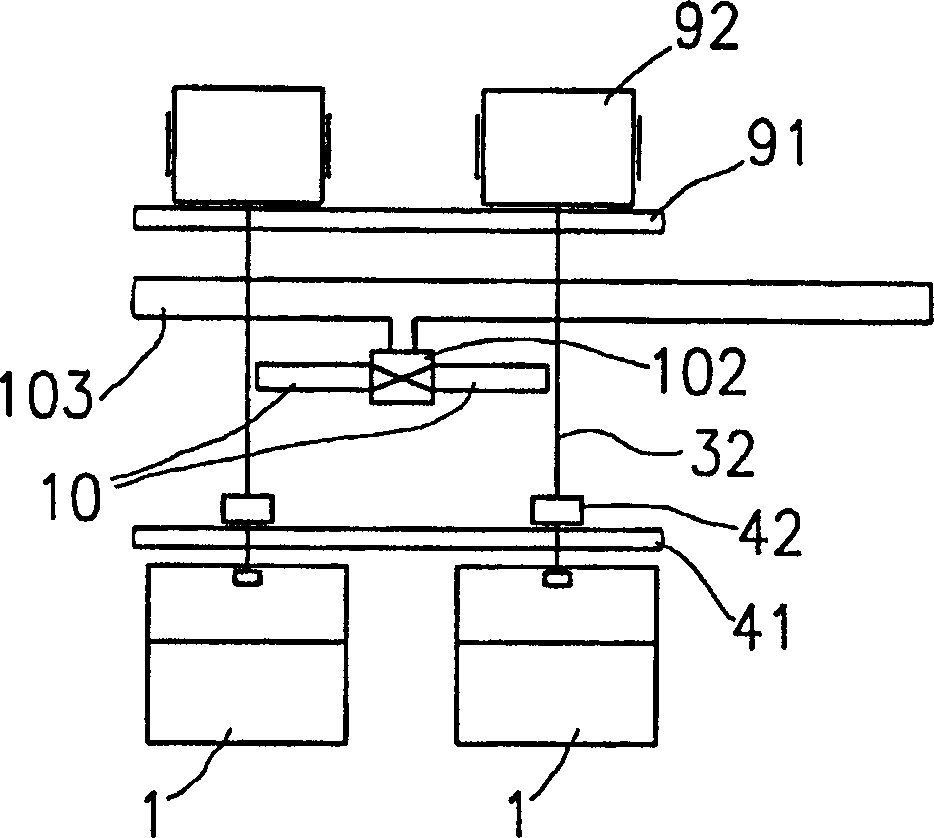

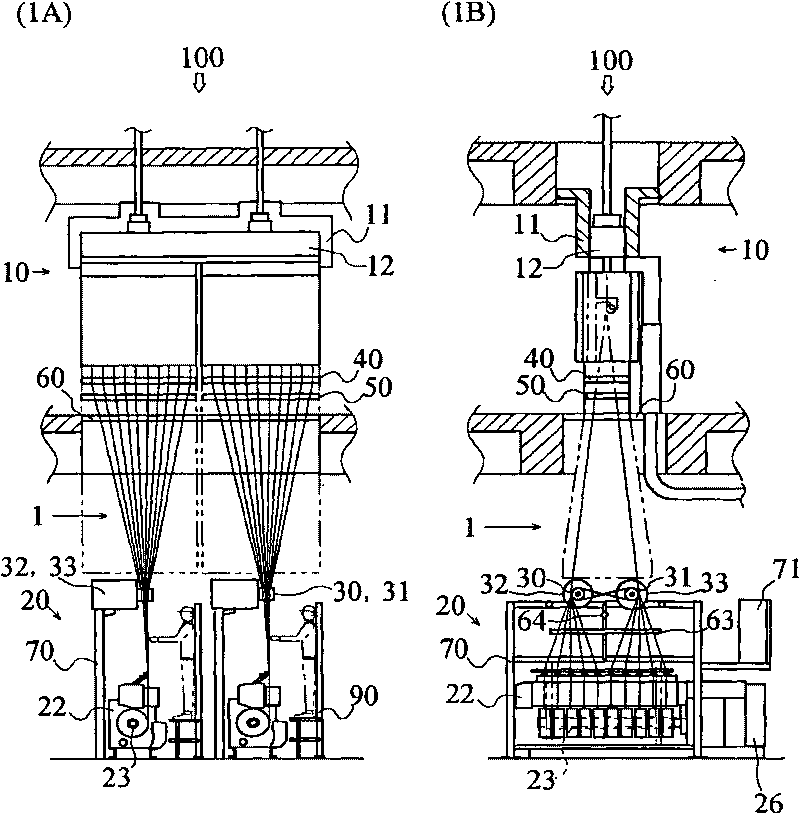

Spun yarn taking-off apparatus

A spun yarn taking-off apparatus (100) for POY, wherein ten pieces of yarns (1) spun out from a spinning head (90) are fed from an upper side to a lower side through a yarn feed roller (10) for conveyance on a first stage and last yarn feed rollers (21) and (22) on a second stage and concurrently wrapped around ten bobbins (2) installed on one winder (30). These ten pieces of yarns (1) are distributed to the plurality of last feed rollers (21) and (22) in unit of five pieces and then divided into pieces and led to the bobbins (2). The total circumferential lengths of the yarns (1) applied to the last yarn feed rollers (21) and (22) are the same.

Owner:TMT MACHINERY INC

Method for production of island type composite industrial yarn

InactiveCN1844506ASolve the interface peeling problemGood mechanical propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

This invention provides a production of island-type compound industrial silk. It uses polyester as island component, polyamide as sea component, the compositing proportion of the polyester and polyamide is their weight proportion, and the polyamide takes up 25-70% of the weight proportion. After the polyester with island component and polyamide with sea component are dried, then they are melted and extruded out from their own screw extrusion press, then they are computed by computing pump and then sent to the compound spinning machine, and then the integral boss type island compound spinning assembly spinning out the island type compound silk, and then the silk is made into island-type compound industrial silk through one step technology or two steps technology. The product in this invention has high intensity, better cohesive, and better fatigue resistance.

Owner:SINOSELEN HI TECH

Method and device for end forming of yarn in jet spinning machine

InactiveCN1384229AQuality improvementAvoid formingContinuous wound-up machinesOpen-end spinning machinesYarnSpin out

A method for spinning-in a yarn on an open-end spinning machine, wherein the yarn (32) between the pulling-off mechanism (4) and the winding device (9) begins to be stressed at the latest at the beginning of pulling-off of the yarn. The negative pressure sucks the yarn (32) coil in the process of entering the negative pressure tube (10) of the working mechanism. After the normal working yarn winding speed is restored, the coils of the yarn (32) in the negative pressure tube (10) are consumed and the negative pressure on the yarn (32) is stopped. This method can be used for all air spinning machines, and also for such devices, the principle of which is that each On the working mechanism, a yarn suction hole (101) of the negative pressure tube (10) for temporarily storing the spun-out yarn (32) after spinning is arranged. The negative pressure tube (10) is a part of the working mechanism of the air spinning machine and is connected to the negative pressure source (1014) in a controllable manner.

Owner:RIETER CZ AS

Synthetic fibre for reinforced concrete with rust prevention function and method for preparing same

The invention relates to rustproof concrete used synthetic fiber, which is prepared with the following components: 1.0 percent to 20 percent of a vapour-phase inhibitor and 80.0 and 99.0 percent of a polymer. The preparation method of the rustproof concrete used synthetic fiber comprises the steps that : 1) the solid vapour-phase inhibitor mixture is mixed uniformly and is mixed together with the polymer before the mixture is granulated, thus getting polymer master batches; 2) the polymer master batches are mixed with a fresh polymer without solid vapour-phase inhibitor, and fiber precursor is spun out; 3) the liquid vapour-phase inhibitor is beaten and mixed in a spinning finish before the mixture is emulsified into stable back spinning oil solutions which are applied on fiber; 4) the fiber applied with the oil solutions is drawn, thermoformed and cut off before the fiber is packed. The inhibitor contained in the rustproof concrete used synthetic fiber can be released slowly during the use of concrete, and protects steel bars well after the released inhibitor arrives at the surface of the steel bars through the capillary bores in the concrete. When the fiber is stretched or broken under stress, the inhibitor can be released quickly; in this way, the fiber is rustproof when the inhibitor inhibits the concrete from cracking.

Owner:JIANGSU SOBUTE NEW MATERIALS

Spinning method for ultra-high molecular weight polyethylene/black polyester staple fiber blending rough gray yarn

The invention discloses a spinning method for ultra-high molecular weight polyethylene / black polyester staple fiber blending rough gray yarns. The blending rough gray yarns are formed by blending raw materials of ultra-high molecular weight polyethylene staple fibers and black polyester staple fibers in proper blending ratio through a compact siro spinning technology. The main steps comprise raw material pre-processing, blowing, cotton carding, drawing, roving, spun yarns, spooling, and other procedures to spin the ultra-high molecular weight polyethylene / black polyester staple fiber blending rough gray yarns. Through different blending ratios of the ultra-high molecular weight polyethylene staple fibers and the black polyester staple fibers, various kinds of rough gray yarns in different gray levels can be spun out. Special performance of high-strength, wear resistance, cutting prevention of ultra-high molecular weight polyethylene staple fibers is fully developed, and weakness of poor dyeing property of the staple fibers is overcome. The yarn has high wearing-resistance and a cotton yarn style, and can be used for production of protection fabrics, gloves, and sports socks in special industries, a later dyeing processing procedure of the product can be removed, thereby achieving an energy-saving environmentally-friendly green production requirement.

Owner:NANTONG WEILUN TEXTILE

Method for preparing celluloses and modified biodegradable polymer blend fibers

InactiveCN103276473AImprove melting effectImprove spinnabilityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberCellulose

The invention provides a method for preparing celluloses and modified biodegradable polymer blend fibers. The method is characterized by comprising the concrete steps: step one, vacuum-drying biodegradable polymers, and blending 80-90 weight percent of the vacuum-dried biodegradable polymers, 9.8-19.9 weight percent of active small molecules and 0.1-0.2 weight percent of initiating agent and then adopting a double-screw extruder to extrude to obtain graft-modified biodegradable polymers; step two, vacuum-drying celluloses and the graft-modified biodegradable polymers obtained in the step one, blending 20-30 weight percent of the vacuum-dried celluloses, 40-60 weight percent of ionic liquid and 20-30 weight percent of the vacuum-dried graft-modified biodegradable polymers and then adopting the double-screw extruder to extrude, and spinning out through a spinneret plate of a spinning pack; and washing off the ionic liquid of the obtained fibers through a water tank, then stretching and winding through the spinning pack, and finally obtaining the celluloses and the modified biodegradable polymer blend fibers. According to the method, the materials have good processing properties and biological properties.

Owner:DONGHUA UNIV

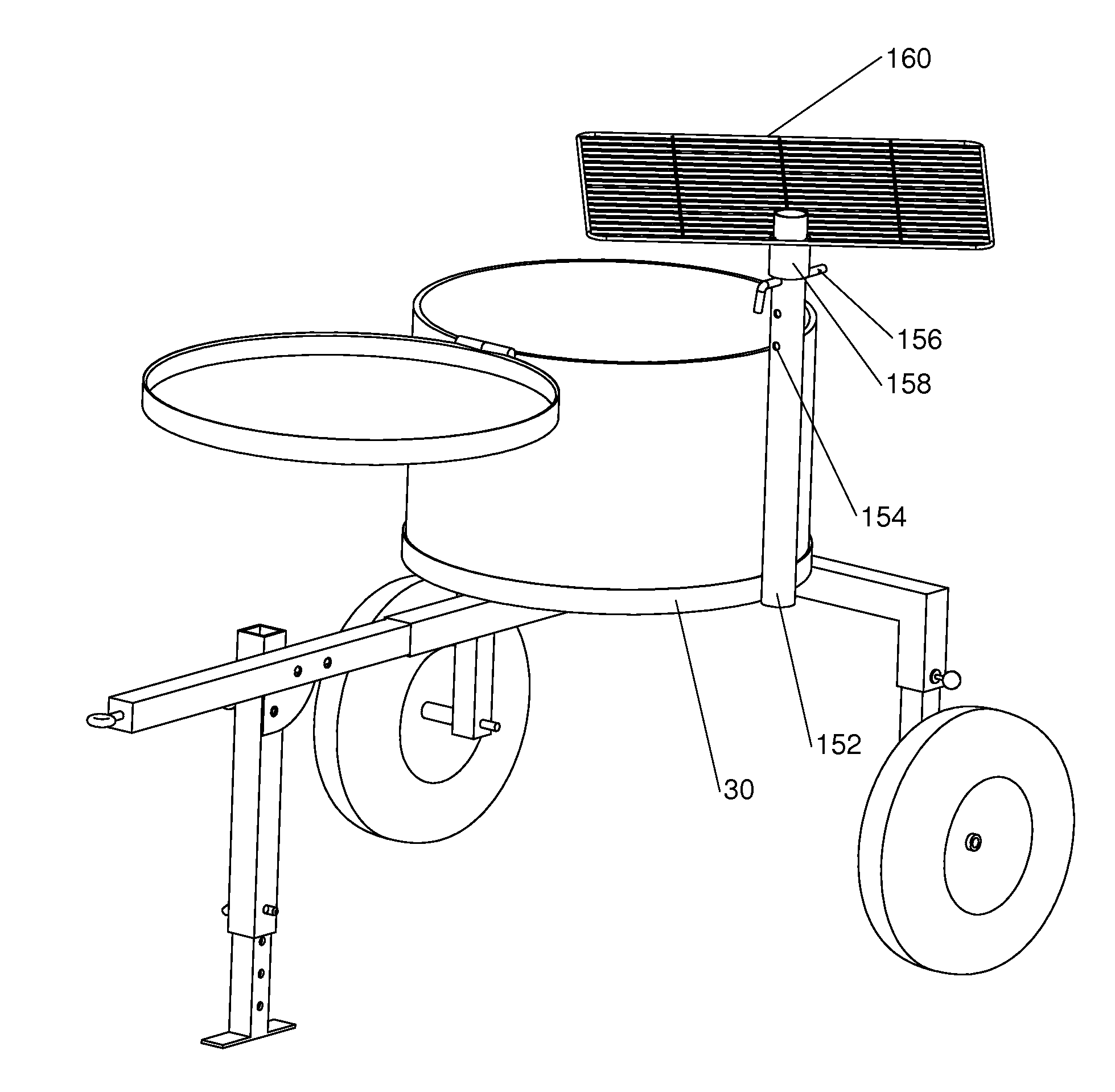

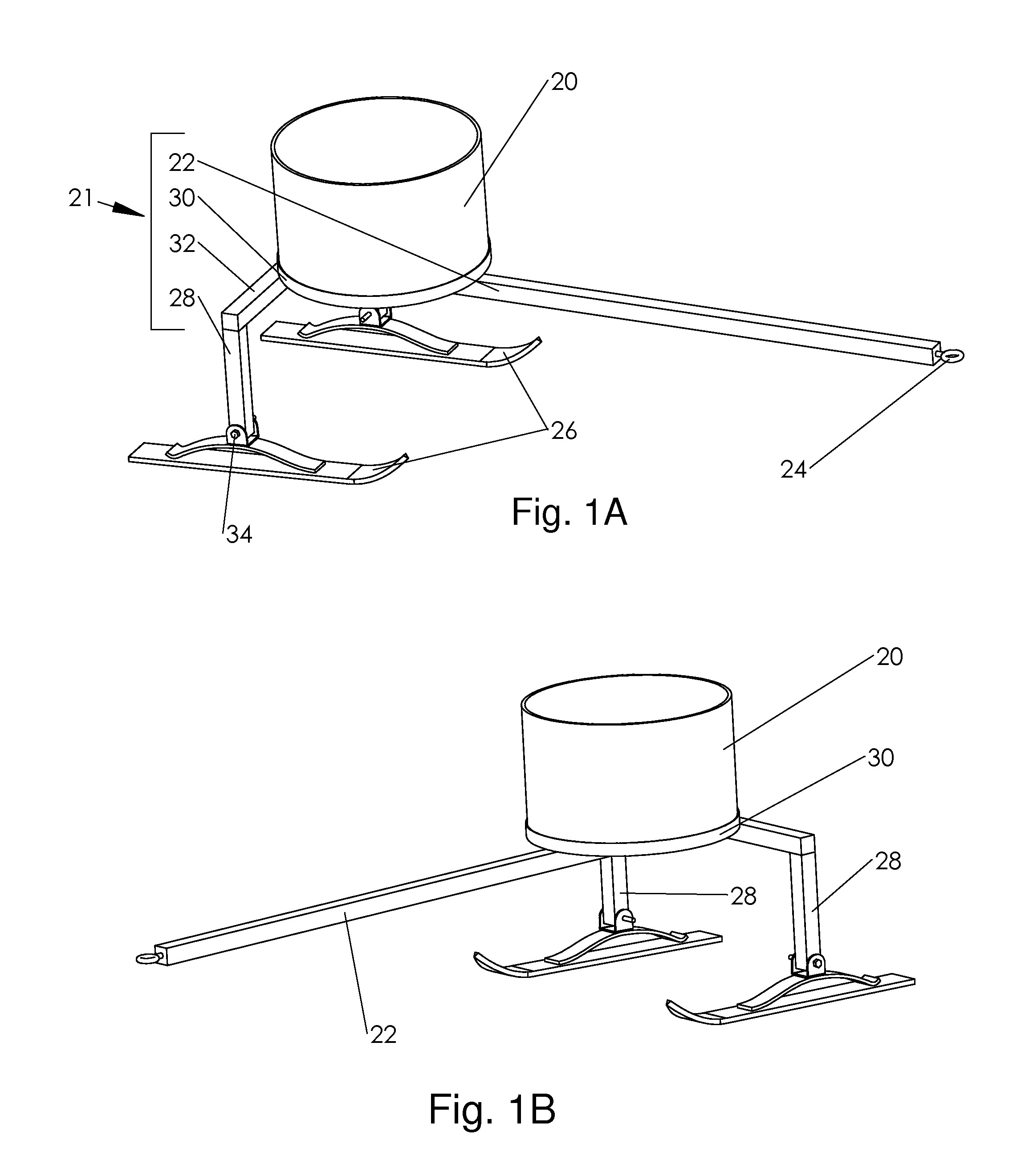

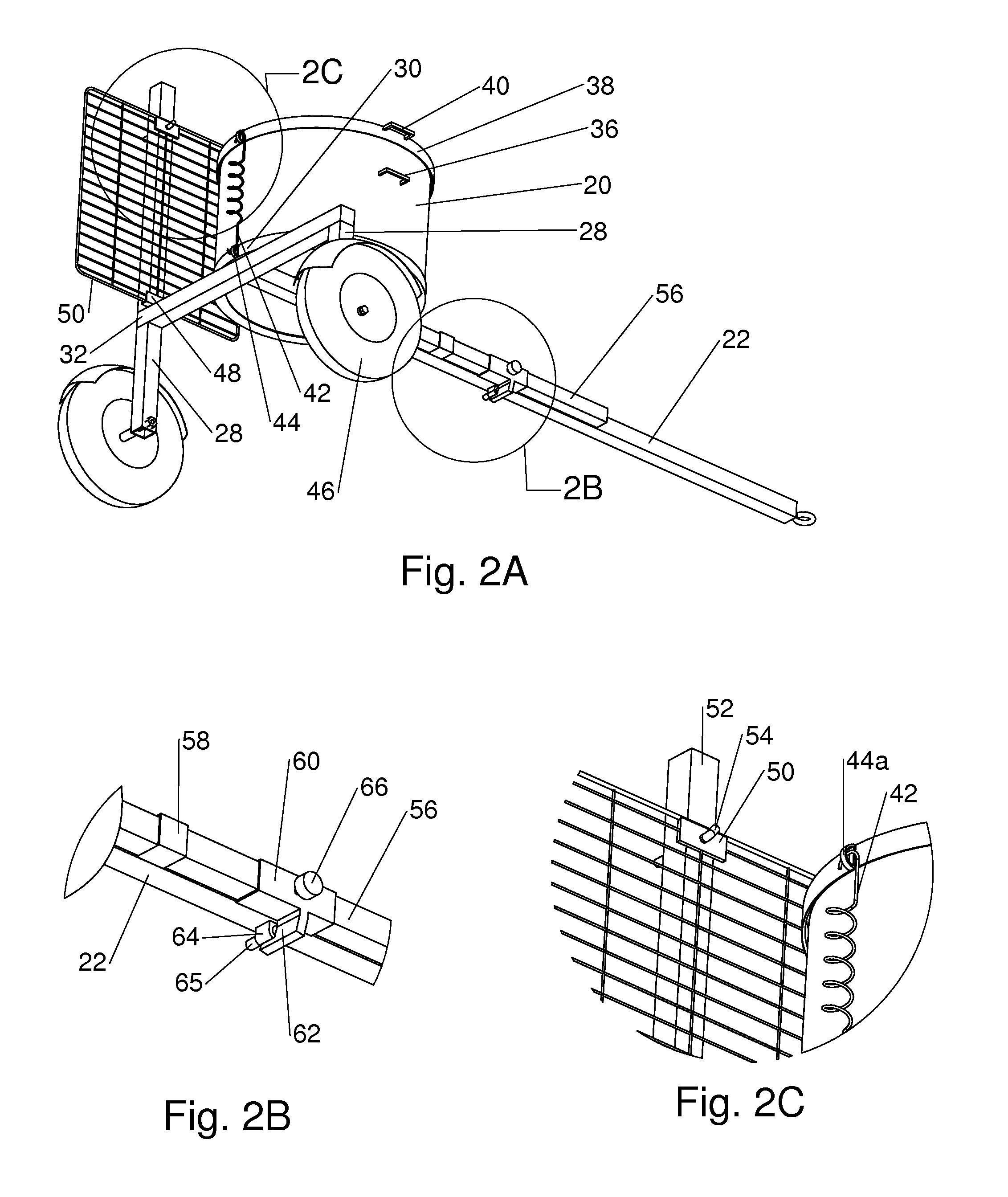

Portable towable stove for outdoor use

A portable stove for outdoor enthusiasts has, in one embodiment, a tow bar (22) to be connected to a towing vehicle such as an all-terrain-vehicle or snowmobile. The tow bar is connected to a crossbar (32), that together support a base (30). The base holds a fire compartment (20) in which solid, liquid, or gaseous fuel can be burned. Wheels (46) or skis (26) can be connected to tow the stove over a variety of terrains. A cover (38) encloses the fire compartment during transport and spins out to serve as a table while cooking or heating. A grill (50) can be adjusted in height to vary the cooking temperature, and can be spun out away from the fire compartment to give clear access to the fire compartment or to remove the food from the heat. Other embodiments are described and shown.

Owner:MICHAUD MARCEL ALBERT

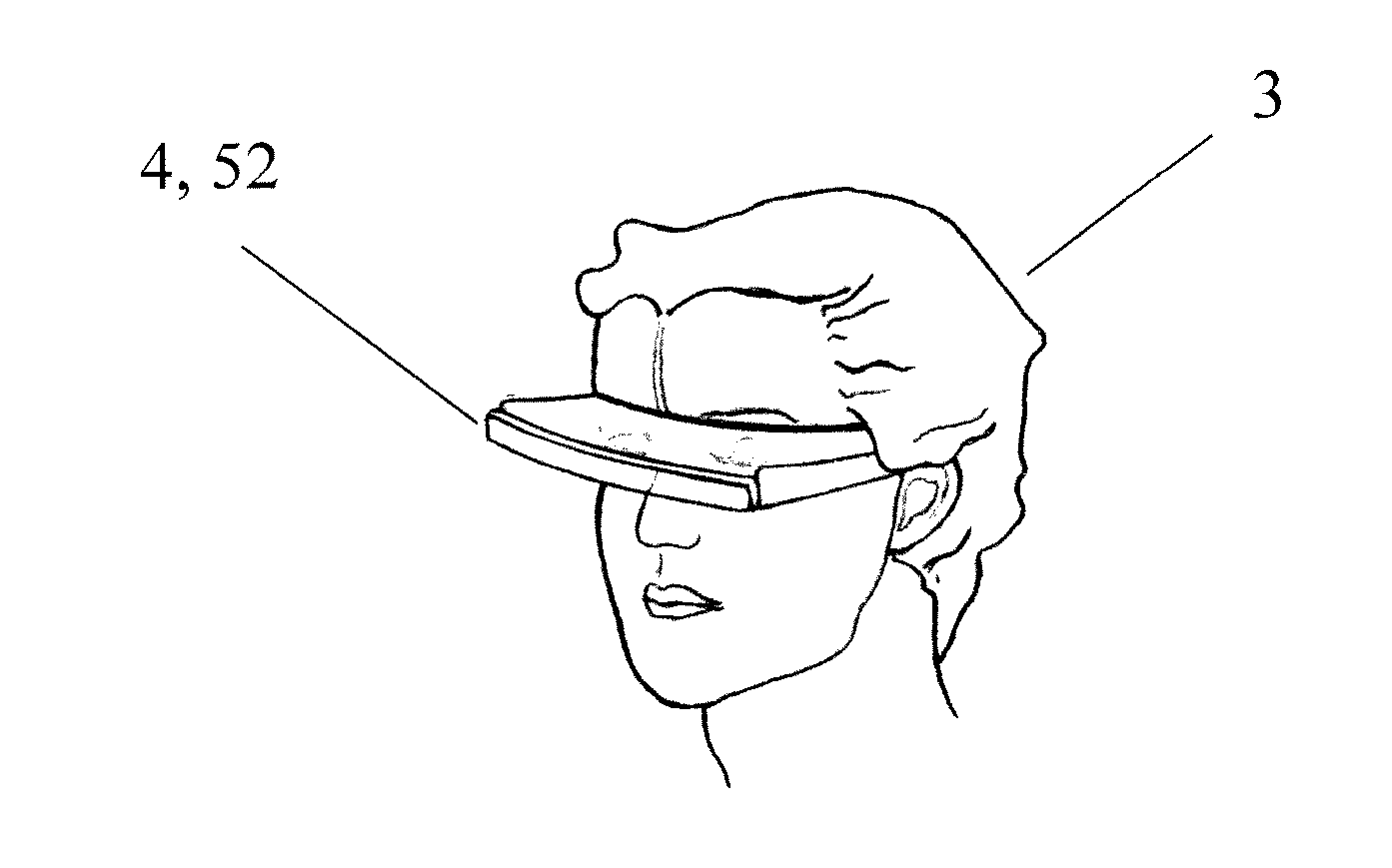

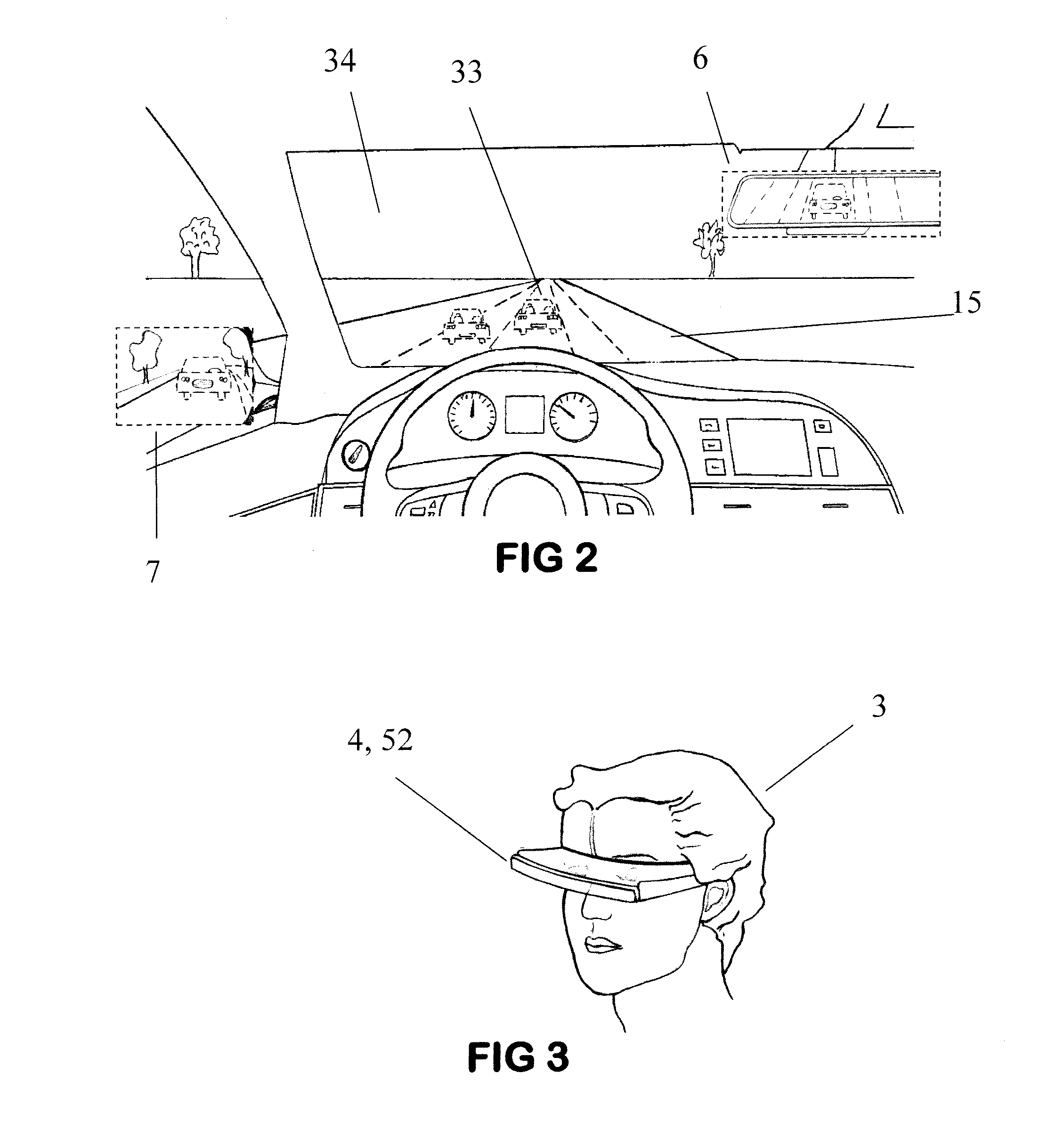

Driver Education and Training System and Method for Training Drivers in Simulated Emergencies

InactiveUS20160321940A1Control be loseDecrease available timeCosmonautic condition simulationsSimulatorsSpin outUnexpected events

The “Real Driving” driver education system combines specifically prepared surfaces of an outdoor driving training area preferably extending a length of approximately 600 feet and computer-generated, “augmented reality” images. This system requires the use of the actual vehicle owned by the trainee and / or used in his / her employment. Several field devices and sensors integral to the prepared area send signals to a portable computer, which can generate a variety of augmented and real driving hazards, including “water curtains,” to a head-mounted display worn by the driver. The driver / trainee will drive his / her vehicle through various stages and simulations, thus exposing him / her to challenging driving situations. Failing to perform proper maneuvers will result in losing control over the vehicle and probable spin-outs or sliding. Applying adequate steering, braking, and / or acceleration corrections will result in successful execution of each scenario.

Owner:BANGA IVAN

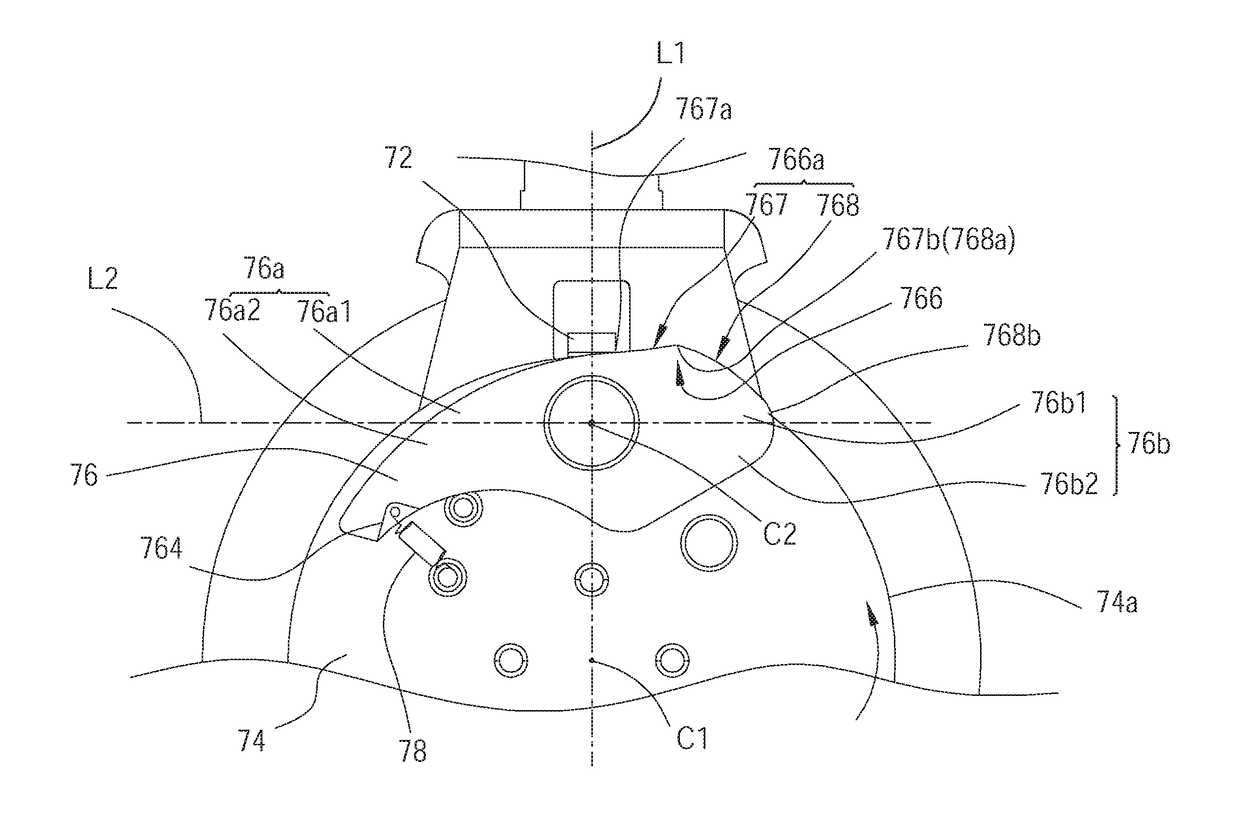

Fall protection device

A fall protection device includes a frame, a rotation unit, a safety belt, and a braking unit. The rotation unit is rotatably disposed in the frame; the safety belt is wound up on the rotation unit, and adapted to be pulled to drive a rotation of the rotation unit. The braking unit includes a braking plate, a braking block, and a stopper. The braking plate is connected to the rotation unit, rotates with the rotation unit coaxially. The braking block is pivotally connected to the braking plate, and includes a stopping part. The stopping part of the braking block can be spun out by a centrifugal force produced by a rotation of the braking plate, and abuts against the stopper to limit the rotation of the rotation unit. The braking block includes an abutted part. The stopper is disposed in a movement path of the abutted part.

Owner:YOKE INDAL CORP

Washing control method and washing machine

ActiveCN104060435AIncrease profitMeet cleanlinessOther washing machinesControl devices for washing apparatusSpin outProcess engineering

A laundry control method and a washing machine. The method comprises: water-filling; cycled wash: during a washing process, a first water circulation channel of the washing machine is conducted to have water inside an inner tub (3) discharged, filtered, and introduced into the inner tub (3), and, when the washing is completed, the water inside the inner tub (3) is discharged to the external of the washing machine; spray-and-drying: a spray-and-drying process is executed at least once, where each spray-and-drying process comprises: a certain amount of clean water is filled into the inner tub (3), the inner tub (3) is rotated, a second water circulation channel of the washing machine is conducted to have water that is spun out when the inner tub (3) is rotating sprayed onto clothes inside the inner tub (3), and, when the water is circulated as such for a second duration, the inner tub (3) is made to continue to rotate while the water that is spun out when the inner tub is rotating is discharged to the external of the washing machine. The present invention conserves laundry water, reduces residual amount of a laundry substance in the clothes, and is of reduced costs.

Owner:HAIER GROUP TECHN R&D CENT +1

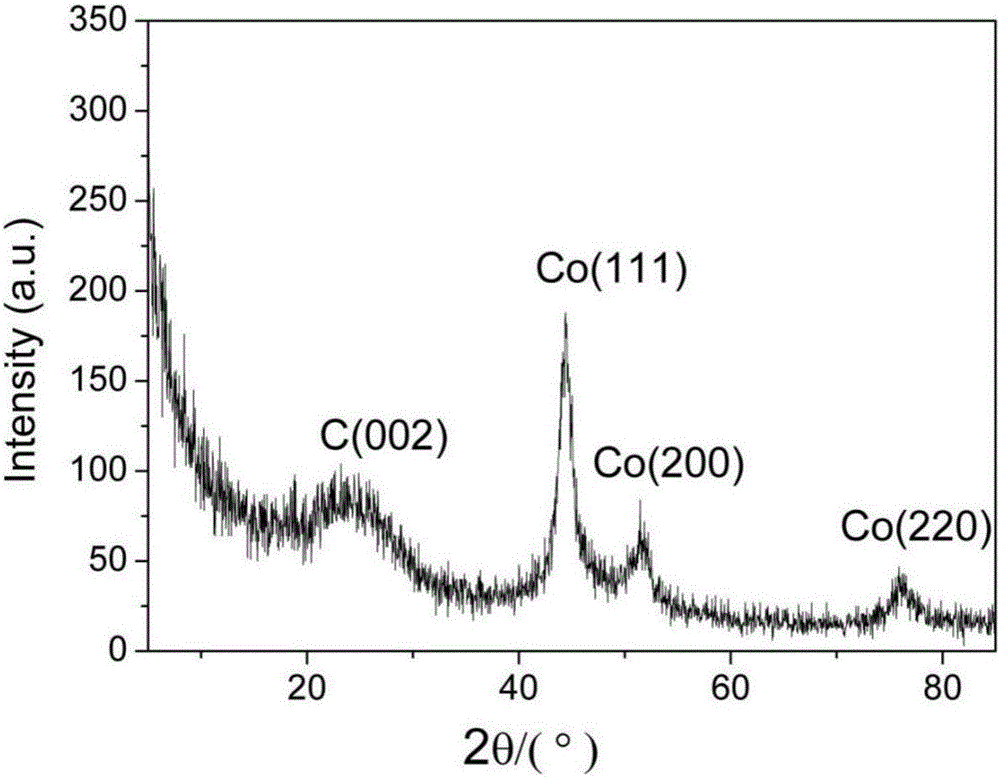

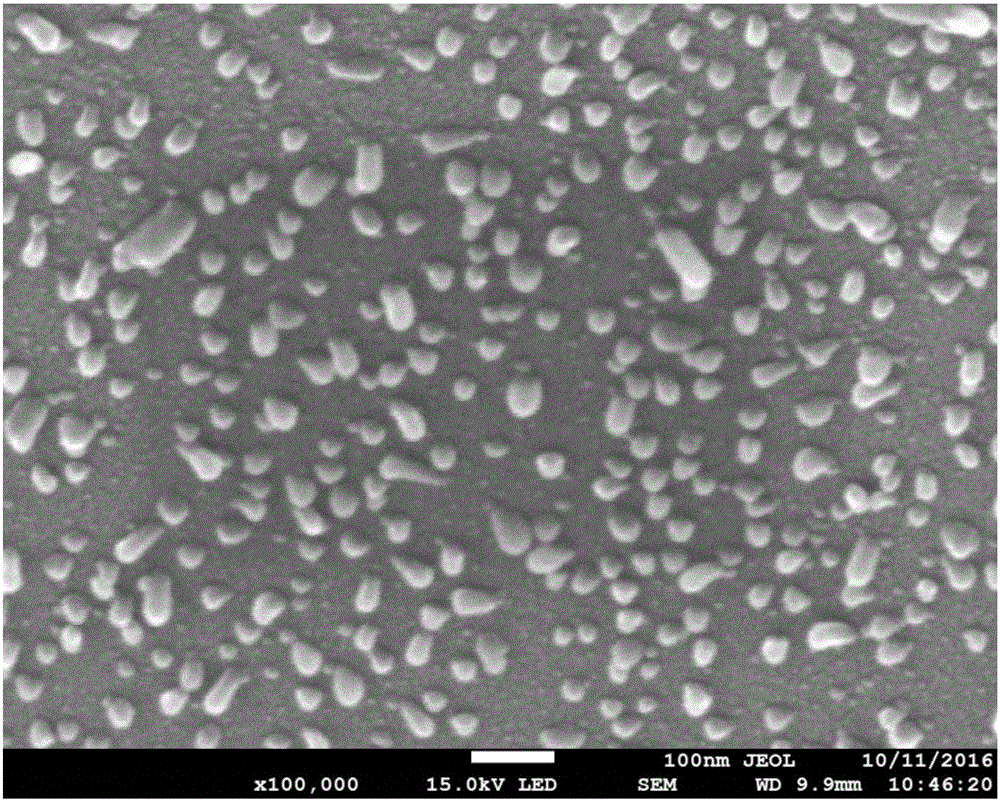

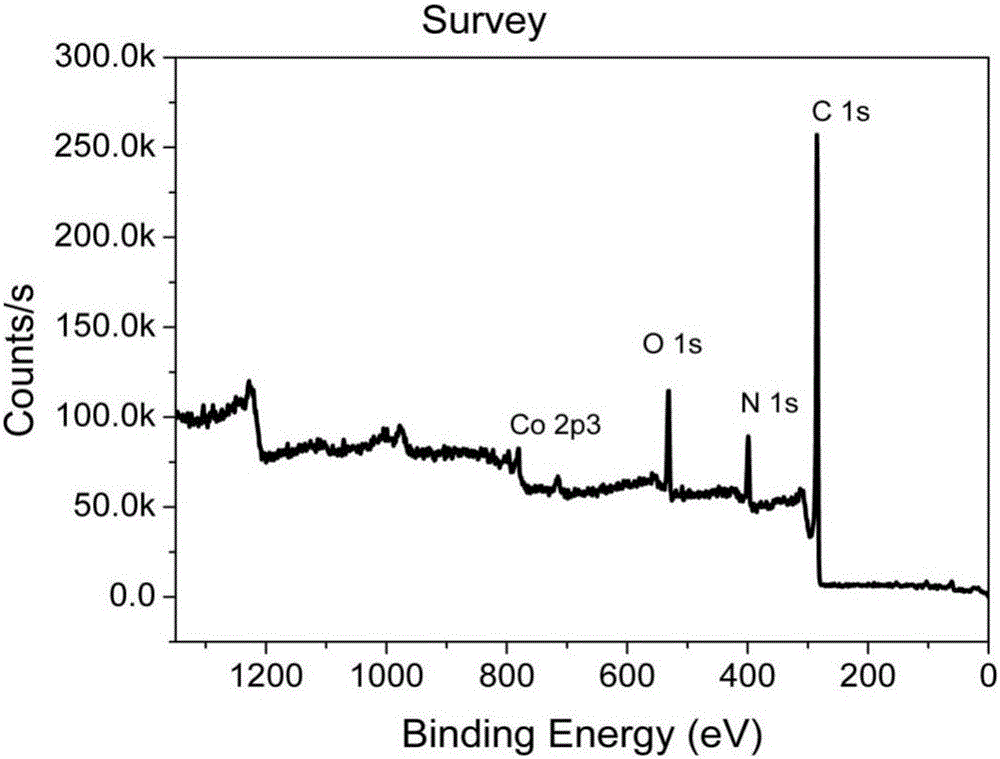

Preparing method of Nitorgen-doped carbon nano-material modified by metal cobalt

ActiveCN106694019AEasy to operateIncrease surface areaOrganic chemistryPhysical/chemical process catalystsEthylenediamineRotary evaporator

The invention discloses a preparing method of Nitrogen-doped carbon nano-material modified by metal cobalt. The preparing method comprises the first step of adopting Ethylene glycol-bis-(2-aminoethylether)-N,N,N',N'-tetraacetic acid or ethylenediaminetetraacetic acid as a carbon source and adding the carbon source into a beaker; the second step of stirring the carbon source and using a nitrogen source to adjust the ph value of a solution to be neutral till the carbon source is completely dissolved; the third step of adding water into cobalt nitrate or cobalt acetate to dissolve cobalt nitrate or cobalt acetate, putting dissolved cobalt nitrate or cobalt acetate into the solution of which the pH value is already adjusted; the fourth step of stirring the solution and afterwards again adjusting the pH value to be neutral, and putting the prepared solution into a rotary evaporator to spin out moisture; the fifth step of placing the solution to an electrothermal blowing dry box to dry the solution and obtaining a solid body; the sixth step of grinding the obtained solid body into fine powder and placing the fine powder into a porcelain boat, under the condition of the protection of nitrogen, placing the porcelain boat in a vacuum tube type high-temperature sintering furnace to be subjected to heating and roasting to prepare the Nitrogen-doped carbon nano-material modified by metal cobalt. According to the preparing method of the Nitrogen-doped carbon nano-material modified by metal cobalt, the steps of synthesis of carbon nano-materials, doping of nitrogen, and modification of metal ion cobalt are integrated into one, thus the obtained catalyst is large in superficial area, stable in structure and property, and is applicable to heterogeneous catalysis such as epoxidation of alkene.

Owner:美迪森(荆门)生物医药科技有限公司

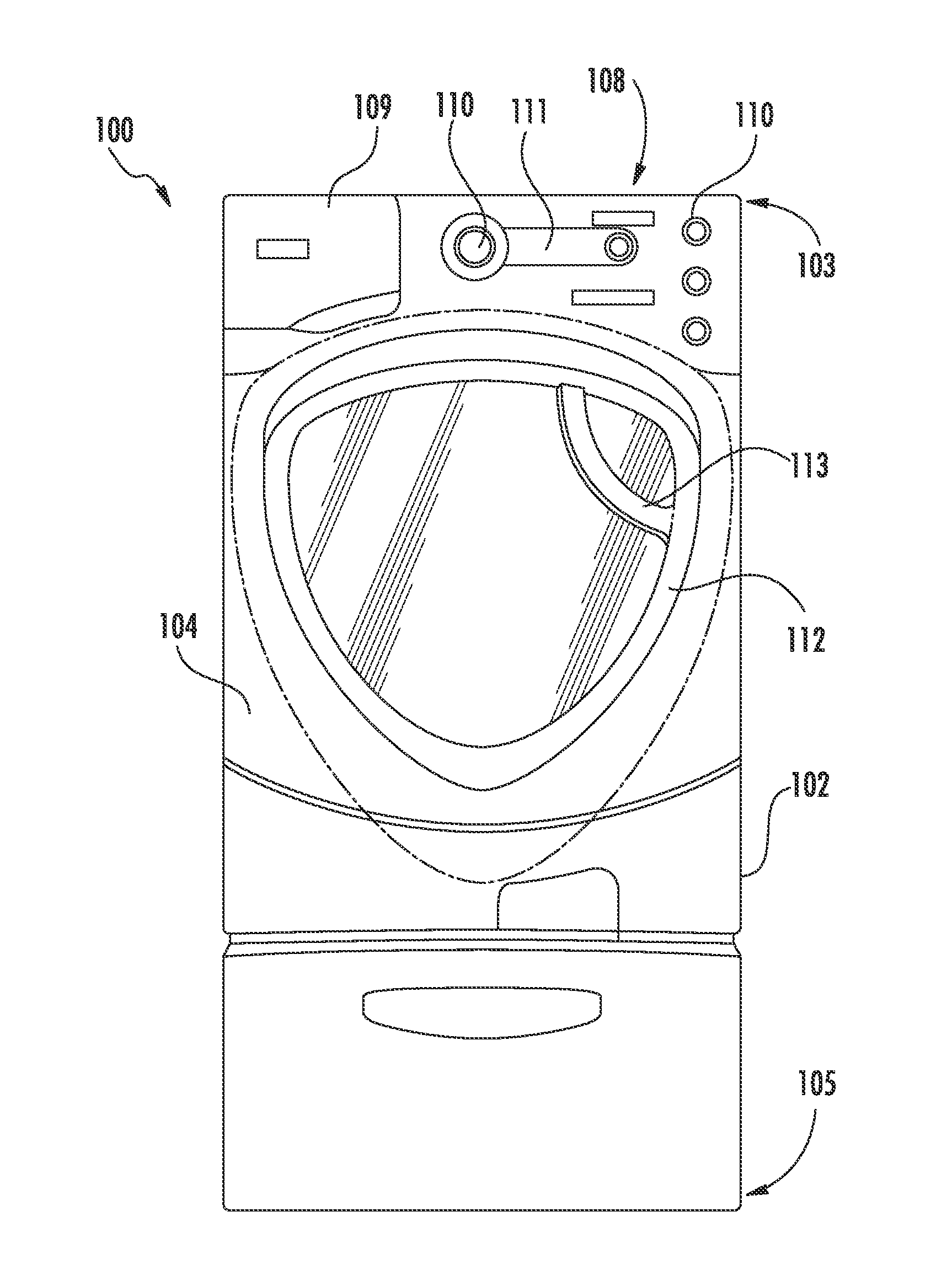

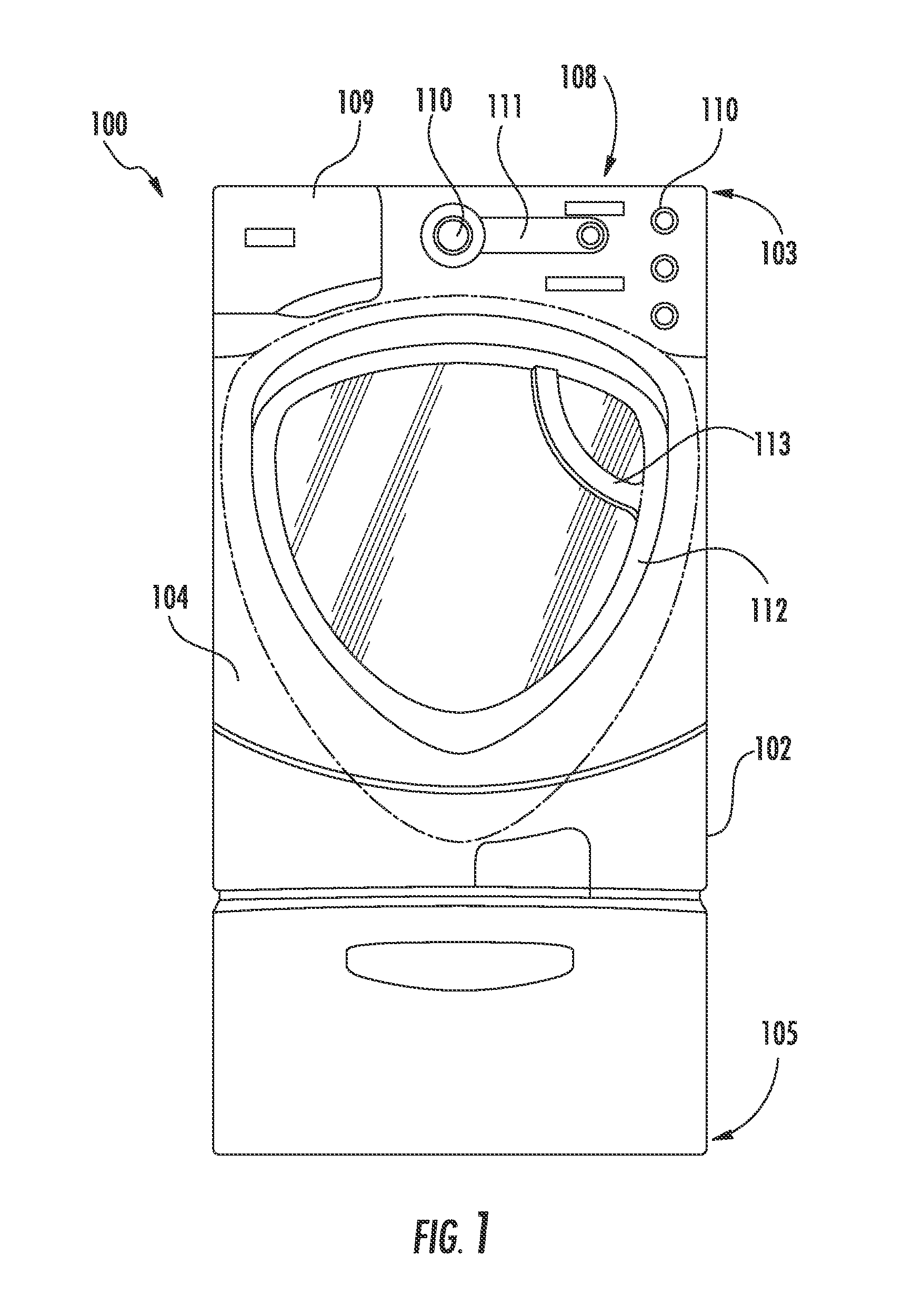

Systems and Methods for Detecting an Imbalanced Load in a Washing Machine Appliance Having a Balancing Apparatus

An exemplary washing machine appliance includes a cabinet, a tub positioned within the cabinet, a drum rotatably mounted within the tub, a balancing apparatus configured to offset an imbalance created by articles in the drum, and a motor in mechanical communication with the drum. The motor is configured for selectively rotating the drum within the tub. The washing machine appliance includes a controller configured to perform operations. The operations include receiving a signal indicative of a speed of the motor. The operations include determining a deviation of the speed of the motor from a target motor speed and comparing the deviation to one or more threshold values. The operations include determining whether to perform a rebalancing process or a spin out process based on the comparison of the deviation to the one or more threshold values.

Owner:HAIER US APPLIANCE SOLUTIONS INC

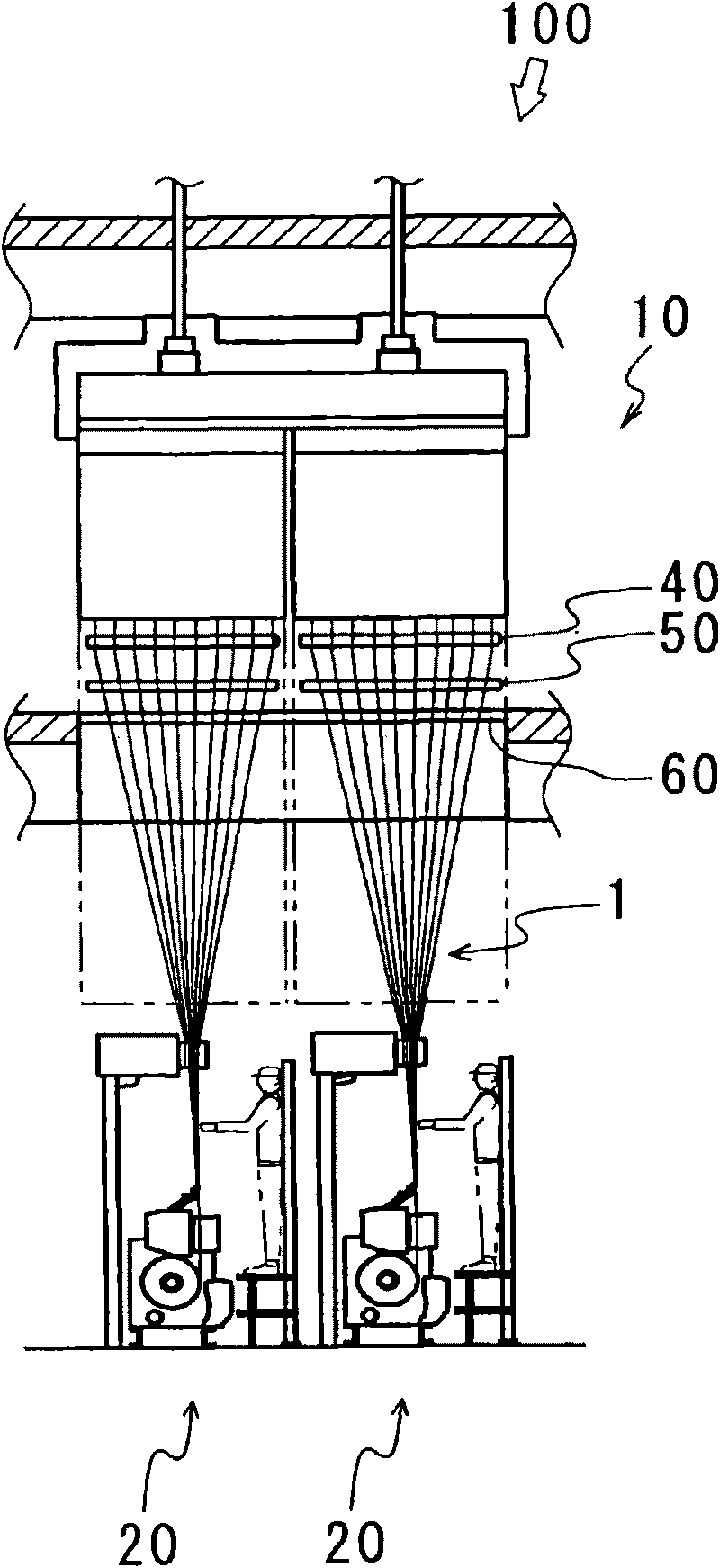

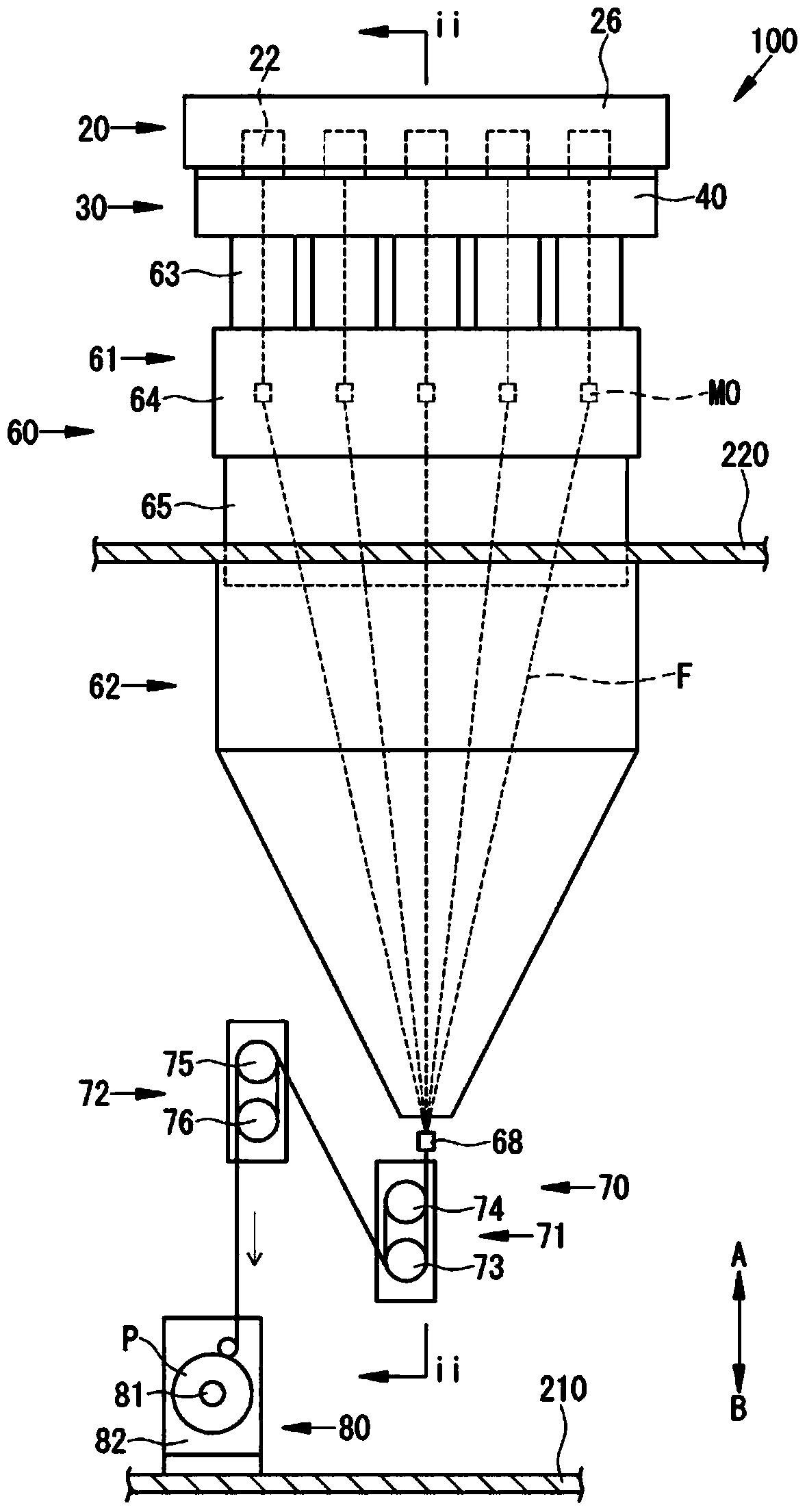

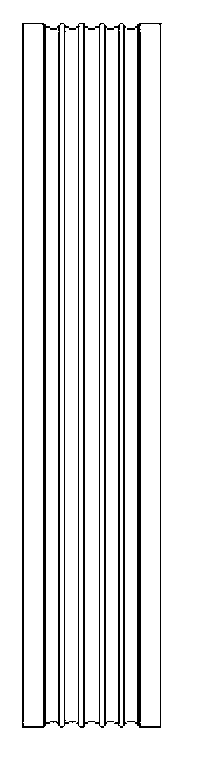

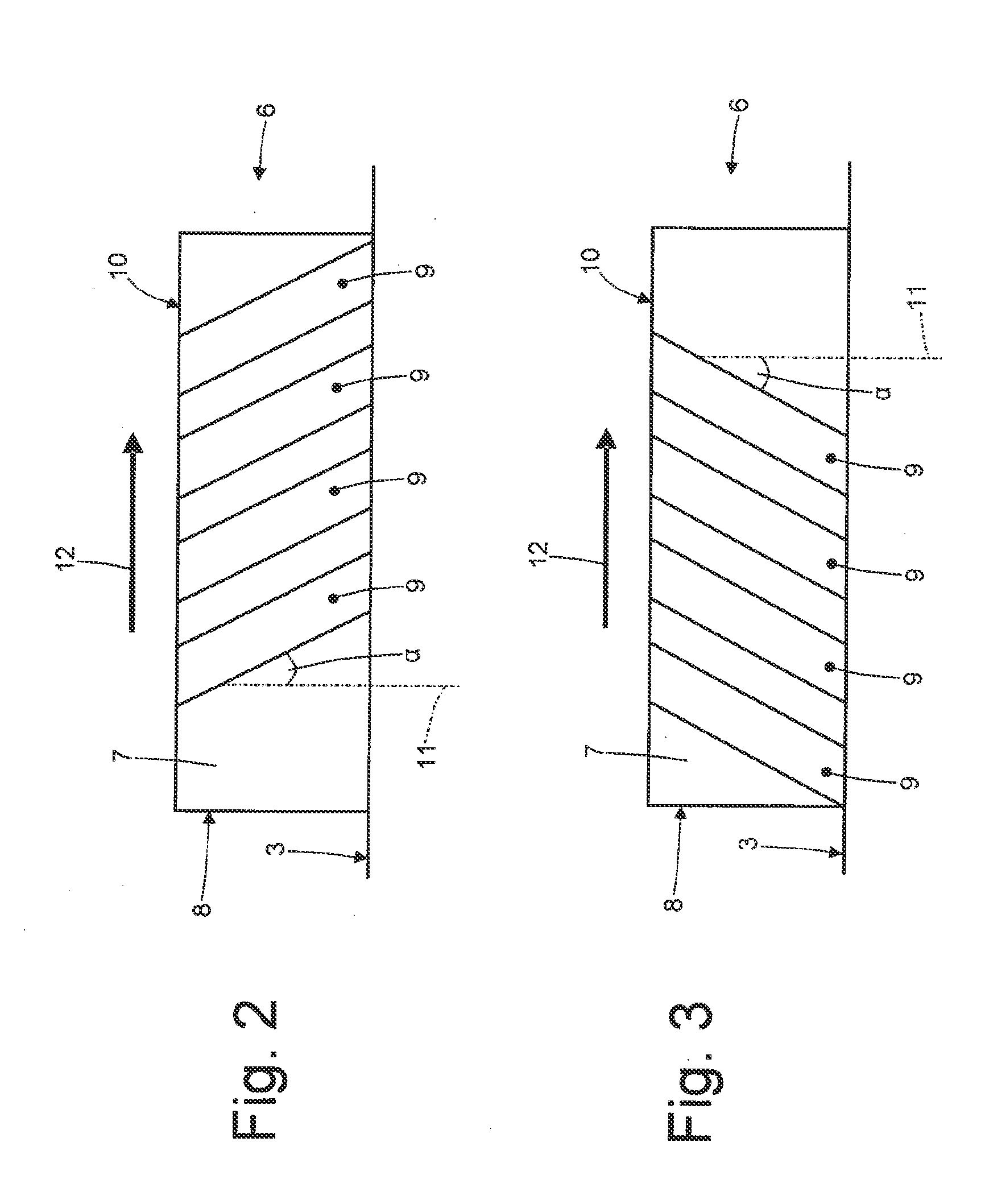

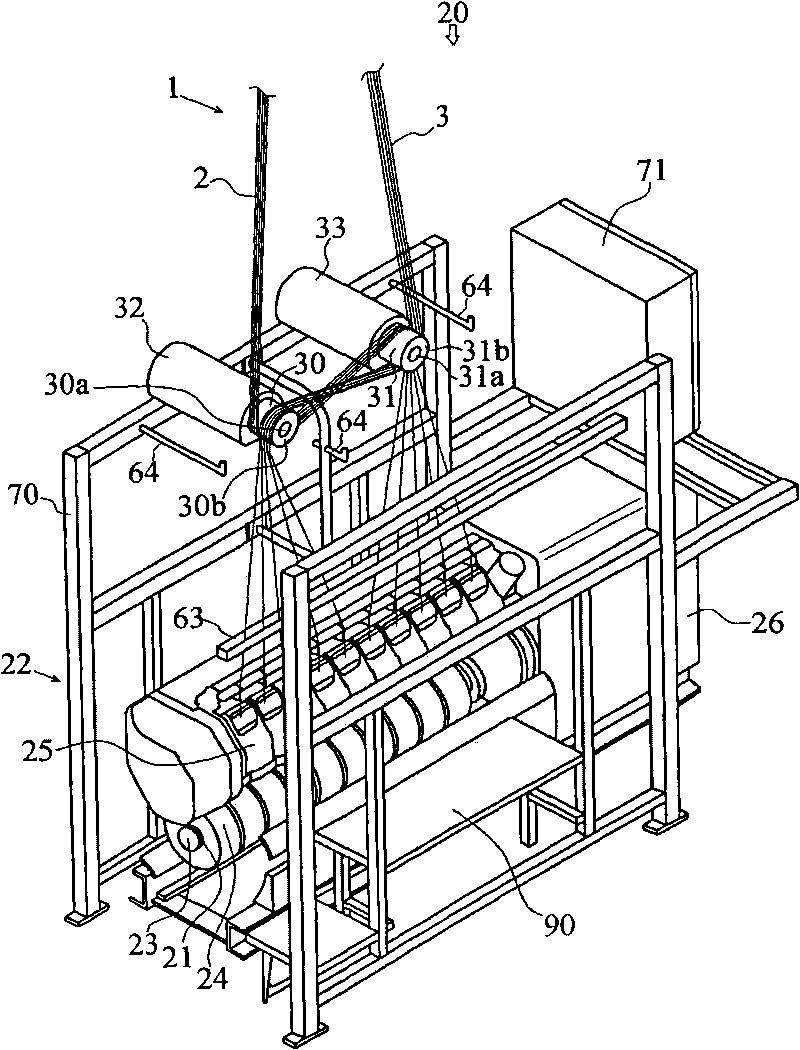

Take-up winding facility

ActiveCN101736421AWind evenlyImprove qualityNew-spun product collectionArtificial thread manufacturing machinesWinding machineBobbin

An object of the present invention is to provide a take-up winding facility having a simple structure and which can be miniaturized. The present invention provides a take-up winding facility 10 feeding a plurality of filament yarns 1 spun out by a spinning machine 10, from above to below to simultaneously wind the plurality of filament yarns 1 around respective plural bobbins 22 installed on a bobbin holder shaft 23 in one take-up winding machine, wherein a plurality of yarn feeding rollers 31, ... are arranged above the take-up winding machine 21, and one of the plurality of yarn feeding rollers 31, ... takes off all of the plurality of filament yarns and winds around the respective bobbins 22 via the said yarn feeding roller and other yarn feeding rollers.

Owner:TMT MACHINERY INC

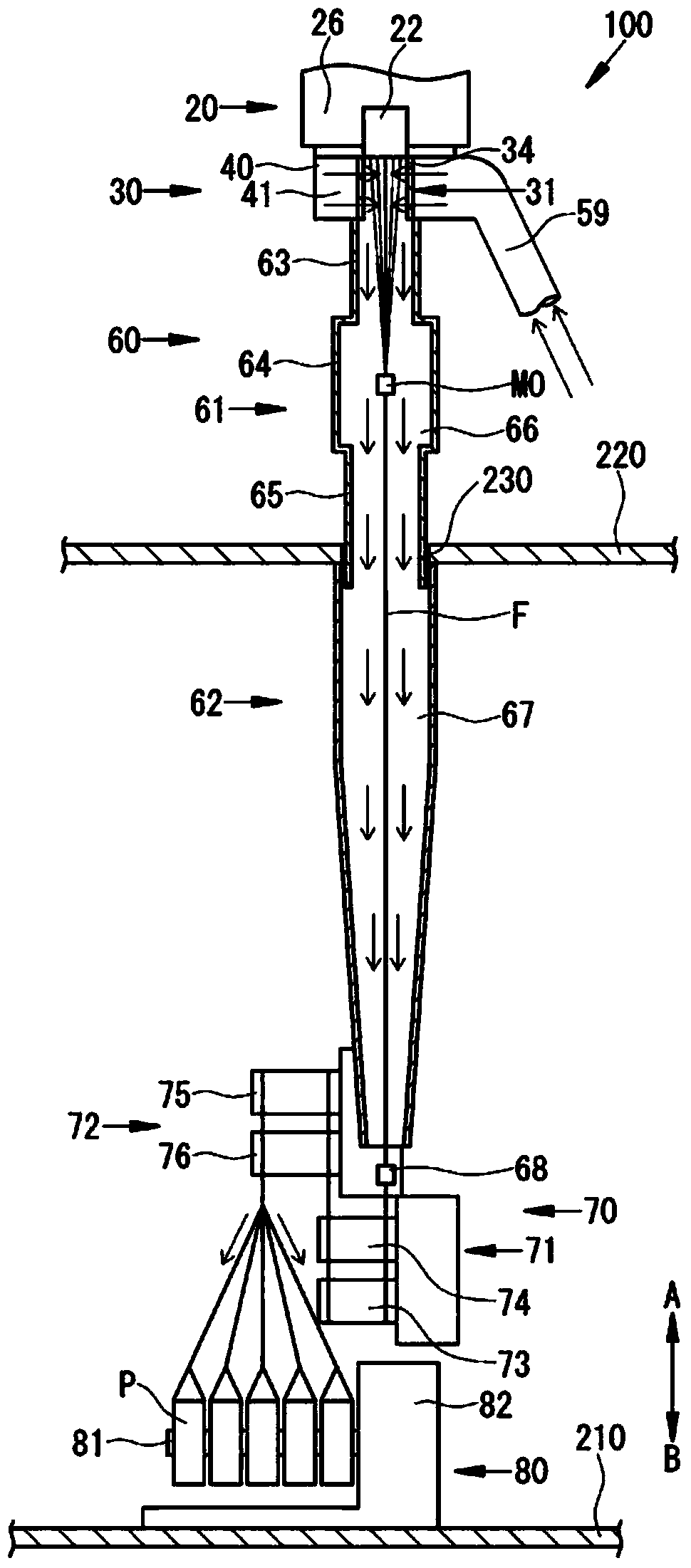

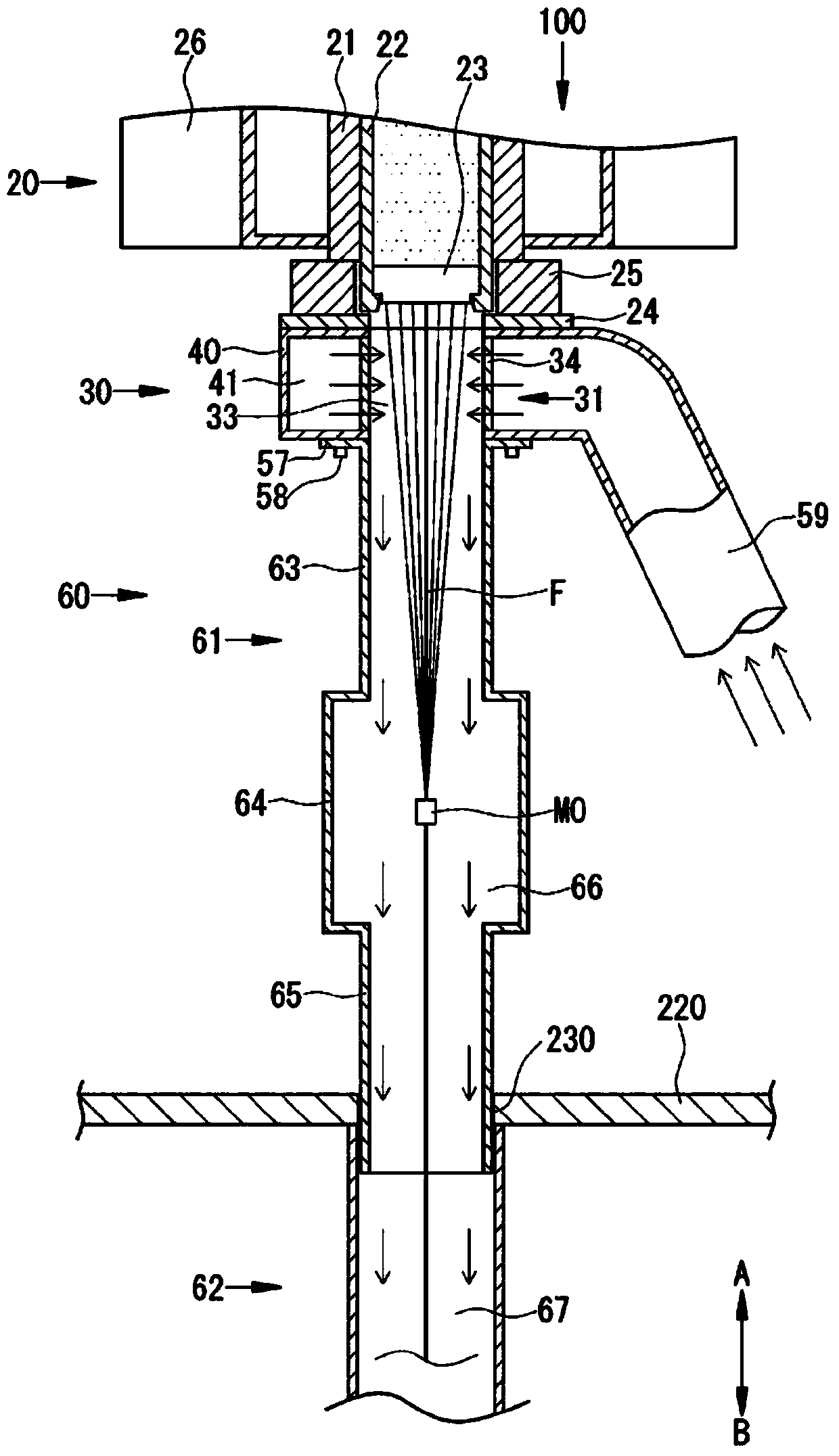

Spinning winding device

ActiveCN103966679AReduce the temperatureReduce temperature changesNew-spun product collectionStretch-spinning methodsSpin outFiber bundle

The invention aims to provide a spinning winding device which, by inhibiting temperature drop of a fiber bundle in a path from a cooling device to a heating stretching device and enabling the temperature of the fiber bundle in front of the heating stretching device to be higher than before, can shorten contact time with a heating roller and contact length required by heating the fiber bundle to above a specified temperature (glass transition point temperature). Specifically, the spinning winding device includes a spinning device which spins out a plurality of fiber bundles from fused material, a cooling device for fiber bundles spinned out by an air cooling spinning device, a heating stretching device which heats at a downstream side of a traveling direction of the fiber bundles of the cooling device and stretches the fiber bundles, and a winding device which winds the fiber bundles at a downstream side of the traveling direction of the fiber bundles of the heating stretching device; and the spinning winding device has a traveling space for the fiber bundles to travel from the cooling device to in front of the heating stretching device, and an attemperator which guides air used by the cooling device for cooling the fiber bundles to inside the traveling space.

Owner:TMT MACHINERY INC

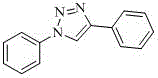

Method for synthesizing 1,2,3-triazole compound through one-pot two-step method

InactiveCN106588788AThe post-processing process is simpleHigh yieldOrganic chemistryIodideFiltration

The invention discloses a method for synthesizing 1,2,3-triazole compound through a one-pot two-step method. An iodo-aryl compound, sodium azide, 1,8-diazabicyclo[5.4.0]-11-carbon-7-alkene and a catalyst cuprous iodide are added into a reaction container containing a solvent dimethyl sulfoxide, the reaction mixture is stirred and react at the temperature of 95 DEG C, and TLC tracking detection is carried out till reacting is complete; after the reaction temperature is reduced to room temperature, a phenylacetaldehyde compound or a terminal-based alkyne compound is added into the reaction container, after the reaction is completed, water and ammonium hydroxide are added into the reaction mixture, the extraction is carried out with dichloromethane three times, washing is carried out with saturated salt water once, drying and suction filtration are carried out, a solvent is spun out, column chromatography purification is carried out, and the target product is obtained. The method is simple in process, convenient to operate, mild in reaction condition, short in reaction time and high in target product yield.

Owner:HENAN NORMAL UNIV

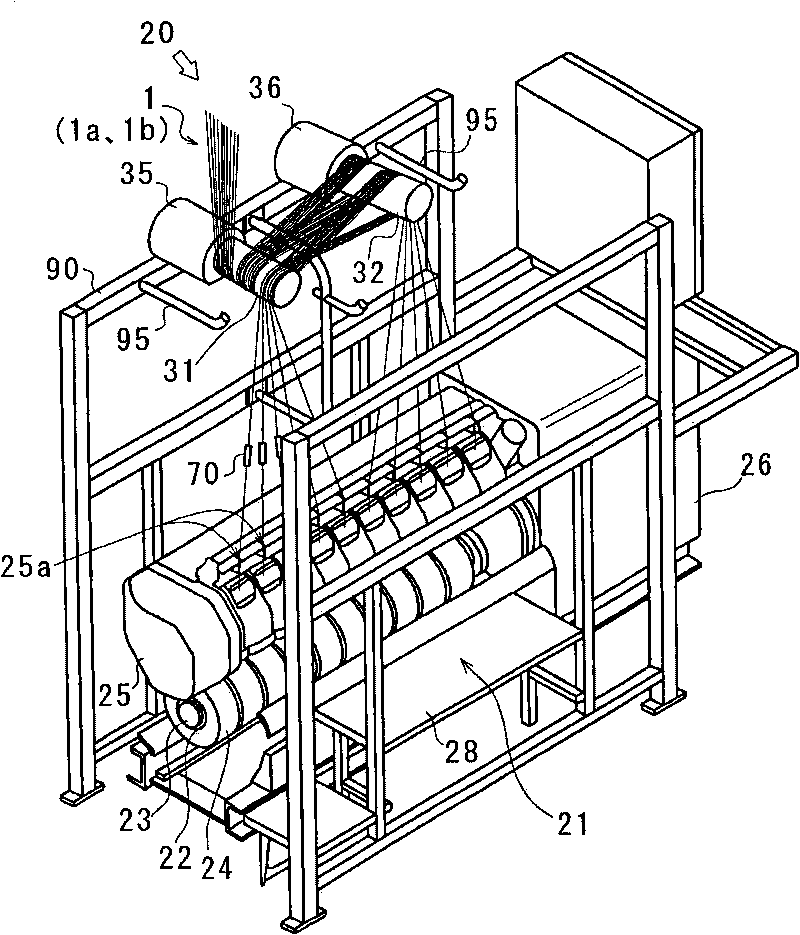

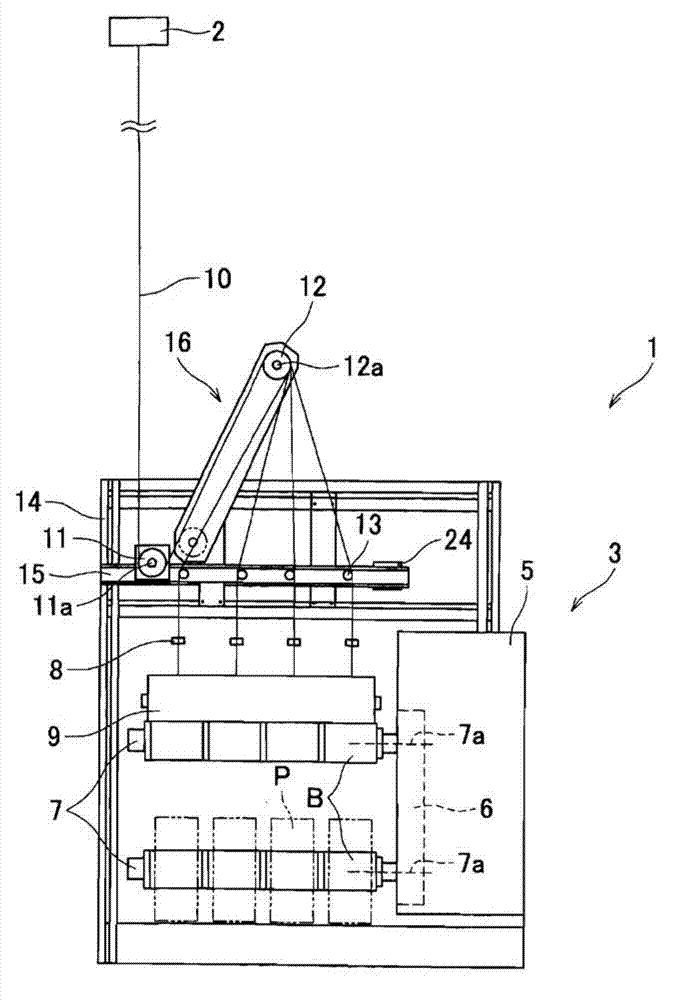

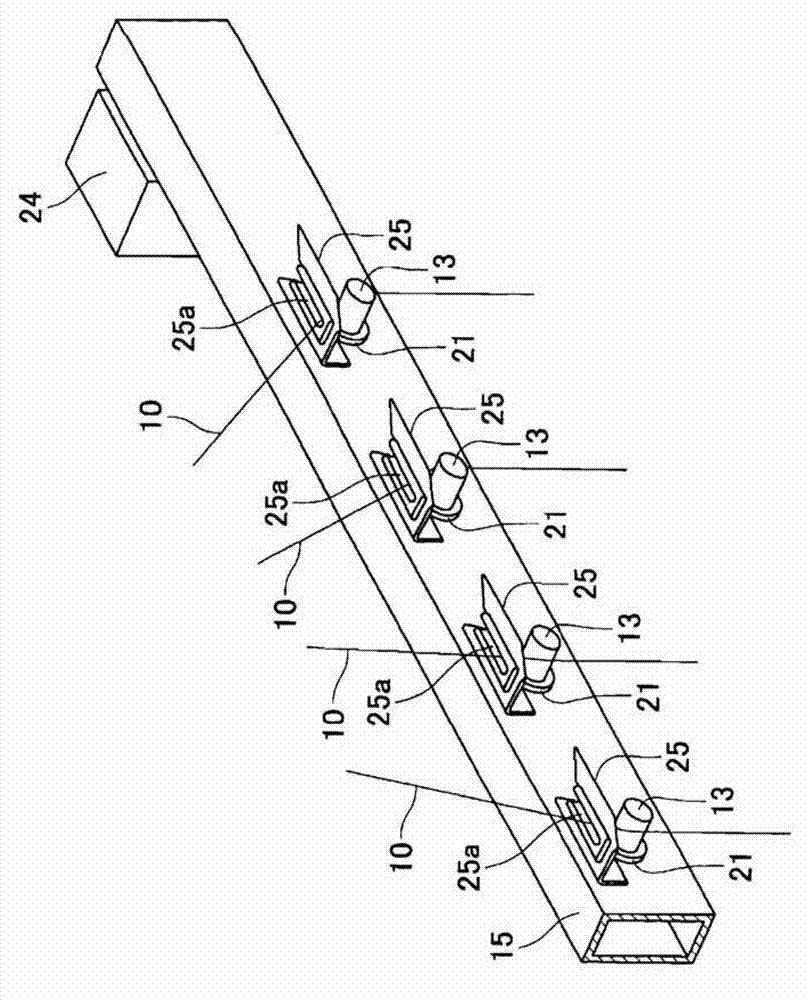

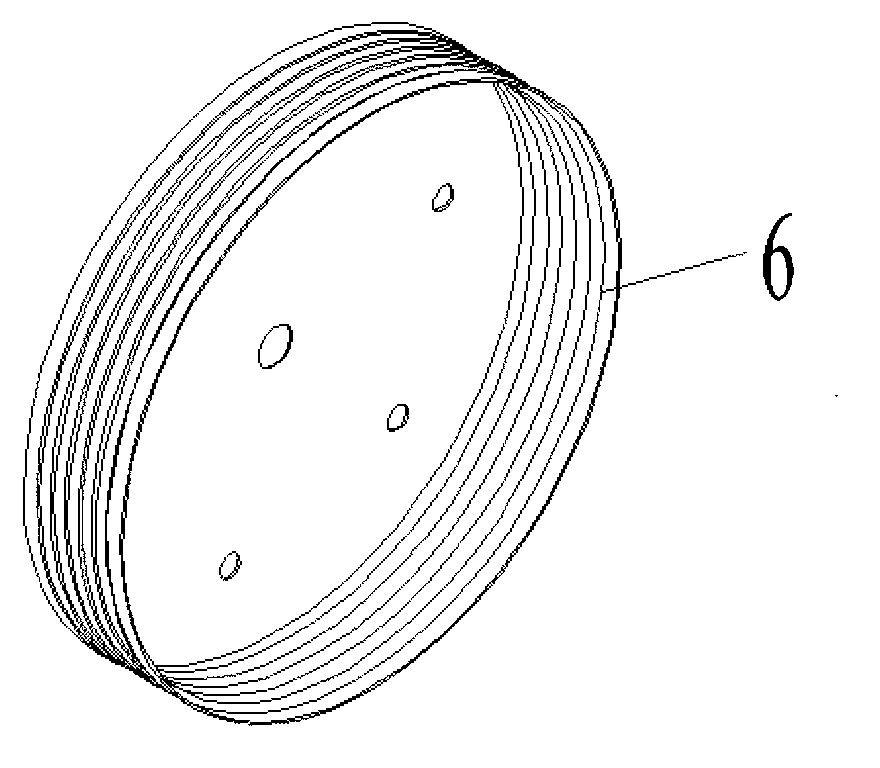

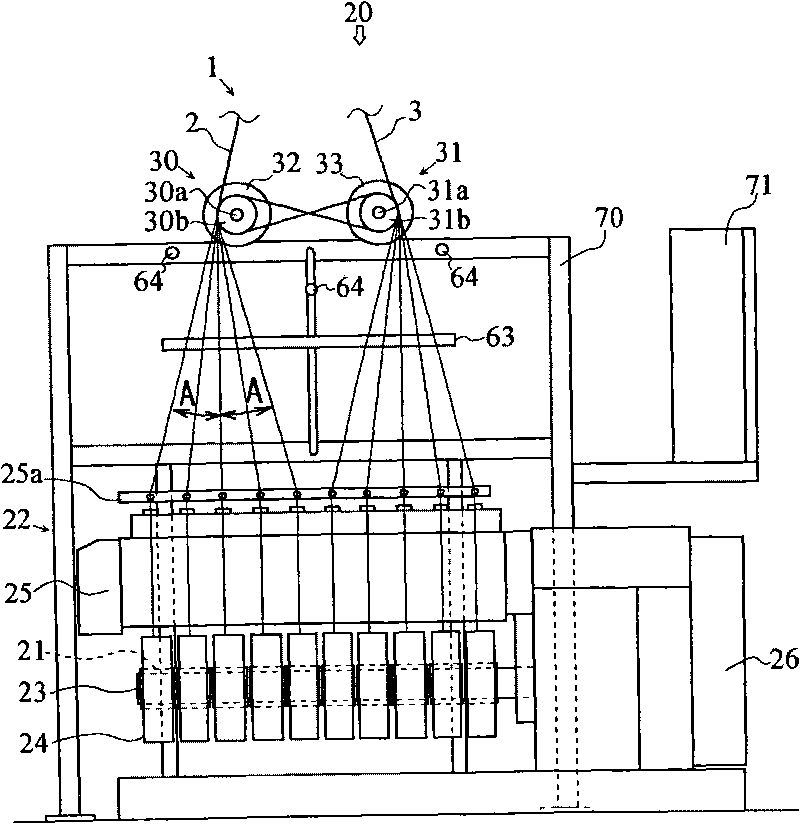

Spinning winder

ActiveCN102888667ANo frequent maintenanceLarge bending angleNew-spun product collectionFilament handlingYarnSpin out

Damage on yarns is restrained while allowing the bending angles of the yarns at distribution guides by which the yarns spun out from a spinning unit are distributed to be large. Yarns 10 serially spun out and supplied from a spinning machine are conveyed to a winding unit below by two godet rollers, and in a winding unit the yarns 10 are distributed by fulcrum guides 13 and then wound onto bobbins attached to a bobbin holder. Each fulcrum guide 13 is a column having a radius of not shorter than 3mm and not longer than 8mm, and the yarn 10 is threaded on the outer circumference of the fulcrum guide 13. By rotating the fulcrum guide 13, the sliding position between the fulcrum guide 13 and the yarn 10 is changed. Furthermore, the movement of the yarn 10 threaded on the fulcrum guide 13 is restrained in the axial directions of the fulcrum guide 13, because the yarn 10 is arranged to pass through a slit 25a made through a restraining guide 25 which is provided above the fulcrum guide 13.

Owner:TMT MACHINERY INC

Two-wheel flexible spinning technology applicable to steel plate welding wheels with grooves

Disclosed is a two-roller flexible spinning technology applicable to steel plate welded wheels with grooves. Two mandrels provided with grooves identical with target workpieces and two spinning wheels complementary with single grooves are used, and belt wheel grooves are machined in a mode that the spinning wheels spin out of the grooves one by one from bottom to top. According to the two-roller flexible spinning technology, large equal-wall-thickness belt wheels can be machined conveniently, the adaptability is high, the machining range can be expanded without replacing the mandrels and the spinning wheels, and the working efficiency is high.

Owner:XI AN JIAOTONG UNIV

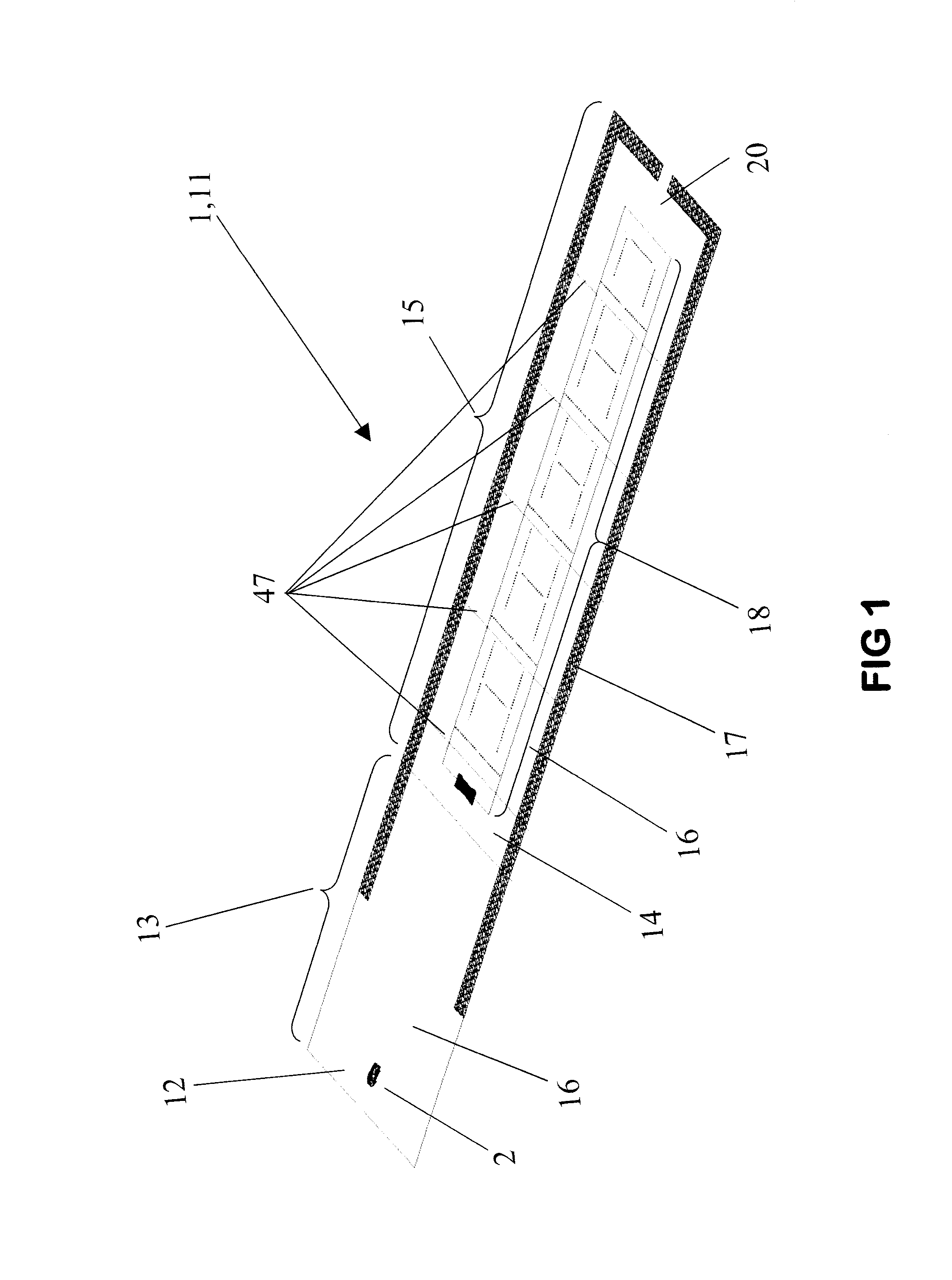

Spinning plate used in non-woven fabric production

This present invention provides a spinning die for a melt-blow type nonwoven fabric, capable of spinning out a smooth fiber having a minute diameter, and capable of reducing an energy cost. This spinning die has a pair of hot air-jetting slits arranged at the vicinity of the tip of a nozzle for extruding a molten polymer, a pair of cold air-jetting slits arranged at the downstream thereof, and ventilation slits formed at the spinning opening. The pair of the slits are regulated so that a large amount of the cold air may be blown to draw the molten polymer extruded from the nozzle by the negative pressure. The ventilation slits reduce the whirlpool caused by the rapid jetting of the cold air to enable the fiber with the smooth surface to be spun.

Owner:SUETOMI ENG

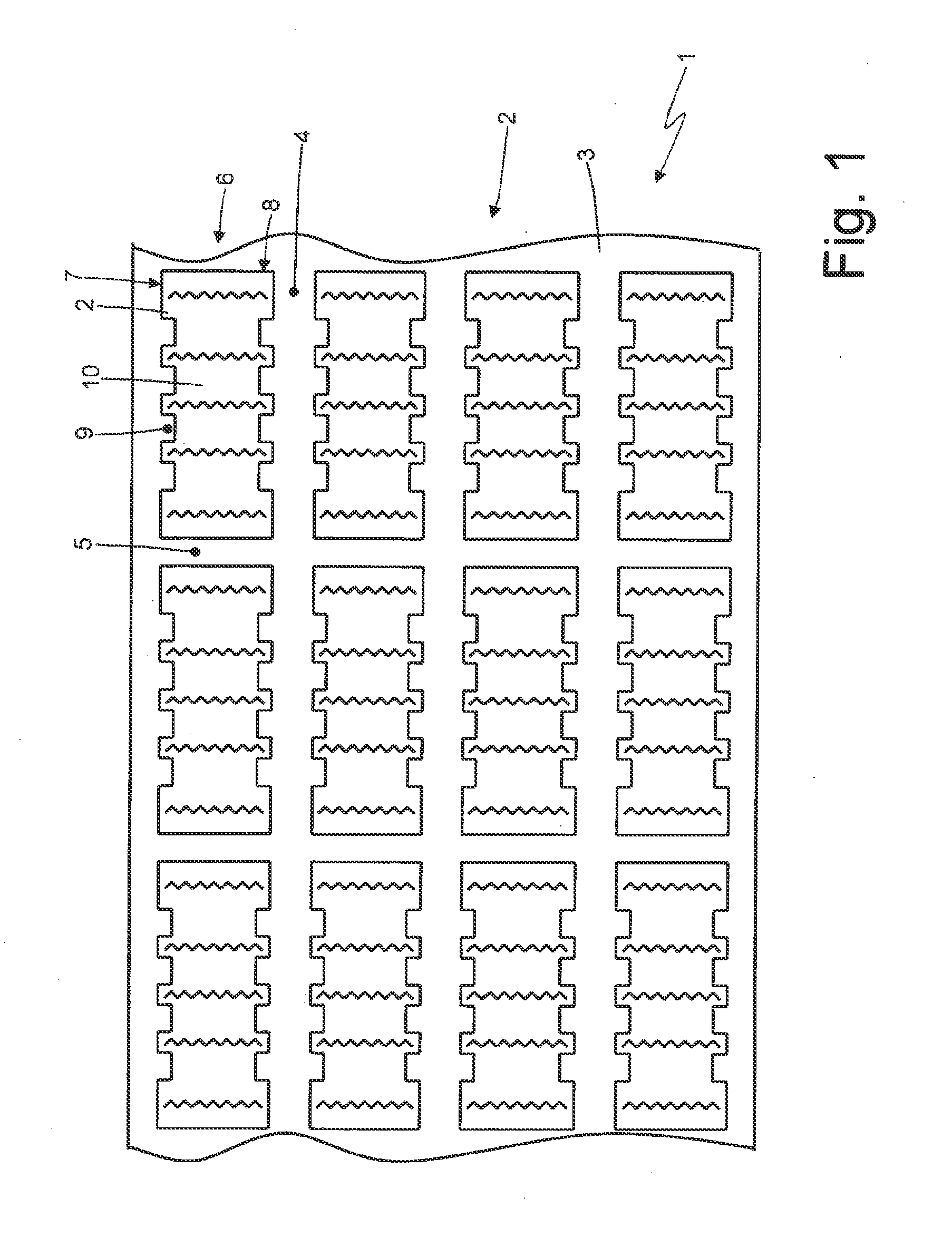

Winter tyre with improved traction on snow surfaces

ActiveUS20120273105A1Fine surfaceEasy and cheap to produceTyre tread bands/patternsNon-skid devicesSpin outTransverse groove

A winter tyre with improved traction on snow surfaces; the tyre has a tread with a raised pattern defined by a number of longitudinal and transverse grooves which form at least one longitudinal row of blocks projecting radially from a base surface of the tread. Each block has two longitudinal lateral surfaces bounding two corresponding longitudinal grooves, and two transverse lateral surfaces bounding two corresponding transverse grooves. At least one of the blocks has lateral channels, each of which is formed on the lateral surface of a corresponding block, extends from the base surface of the tread to a top surface of the block, and is designed to impede radial spin-out of snow trapped inside the lateral channel.

Owner:BRIDGESTONE CORP

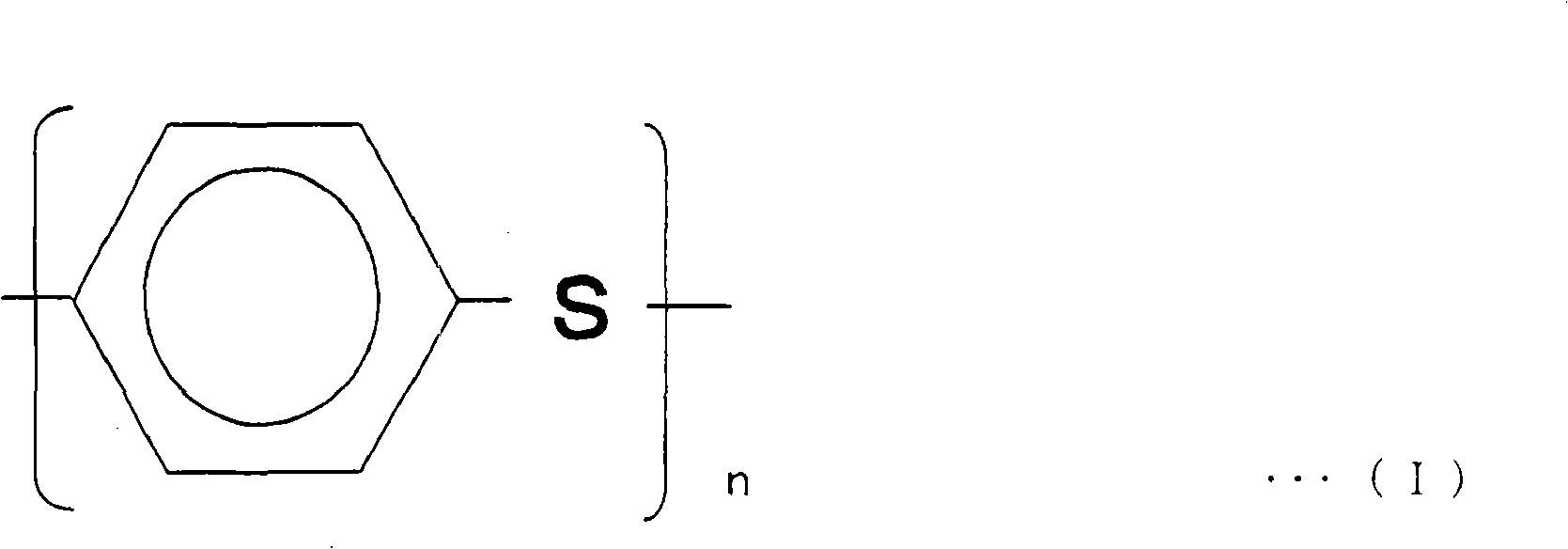

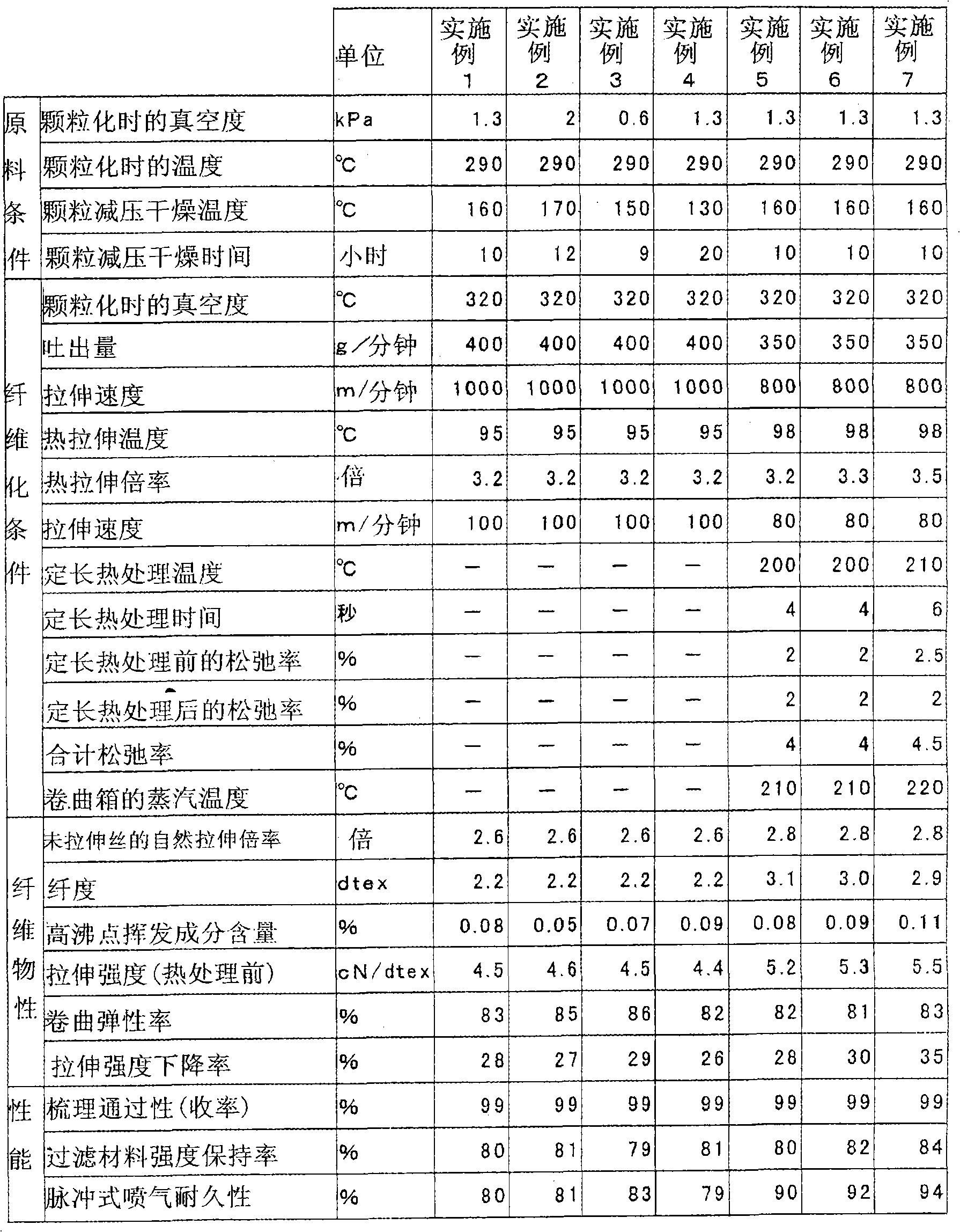

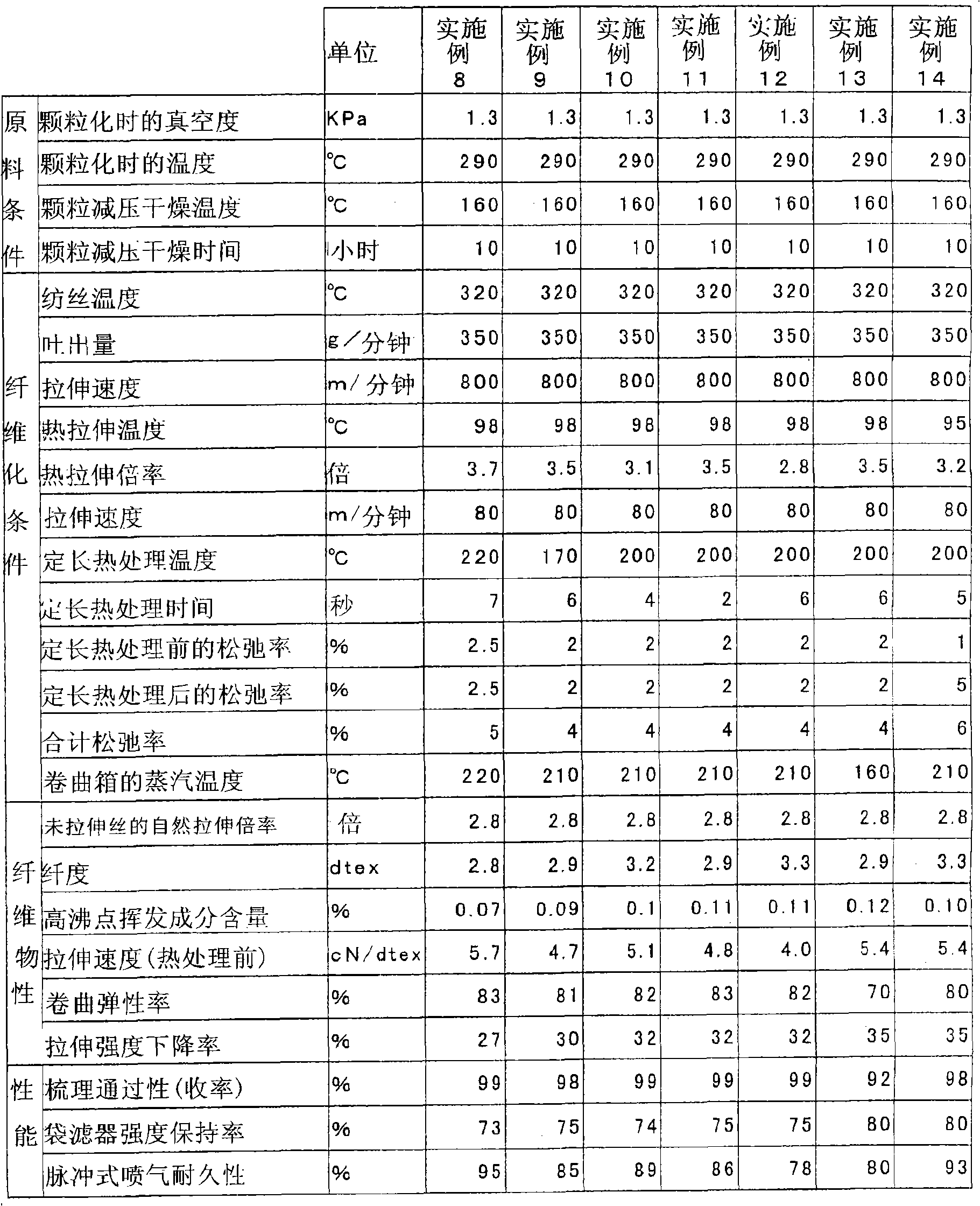

Polyphenylene sulfide short fiber and method for making the same

InactiveCN102618956AMechanical strength is not easy to reduceGood chemical resistanceArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberSpin out

The invention relates to polyphenylene sulfide short fiber and a method for making the same, with the tensile strength thereof beyond 5cN / dtex and bending modulus of elasticity over 75%. The polyphenylene sulfide short fiber can be obtained by the steps of: fusing polyphenylene sulfide powder under the conditions of decompression and at a temperature less than 350 DEG C; drying the granulated particles under a temperature ranging from 130 to 170 DEG C for fusing; spinning out from a spinning nozzle; and cutting it into regulated length after stretching; collecting the fused polyphenylene spun out from the spinning nozzle without stretching for thermal stretching of over 3 times while less than four times; conducting thermal treatment at a temperature over 180 DEG C for over 4 seconds; endowing crimp to it in a curving box filled with steam of over 180 DEG C and cutting it into regulated length; and conducting loosing treatment before and after the thermal processing with regulated length, thus to making the loosing rate thereof ranging from 1% to 6% during the period after thermal stretching and before curving.

Owner:TORAY IND INC

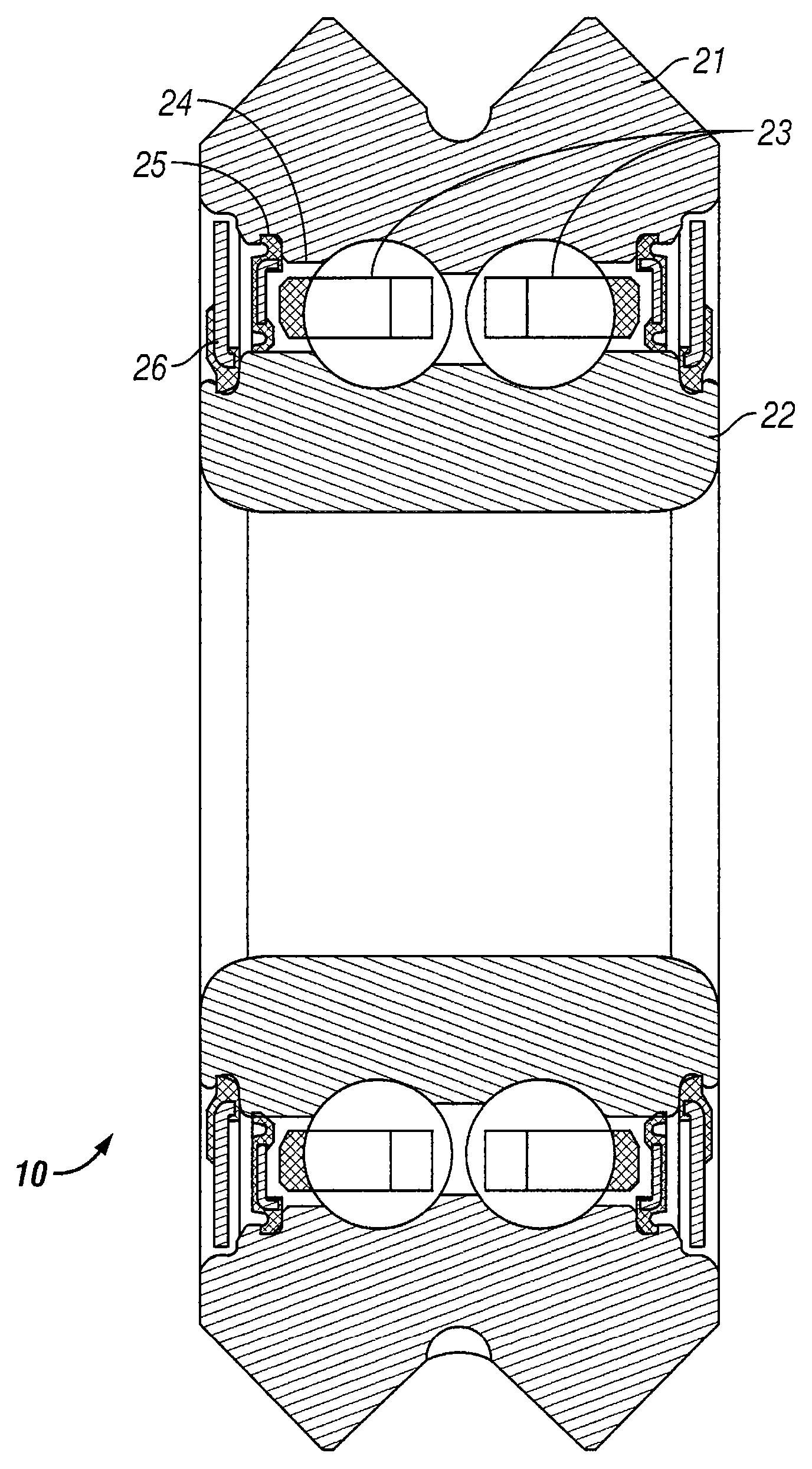

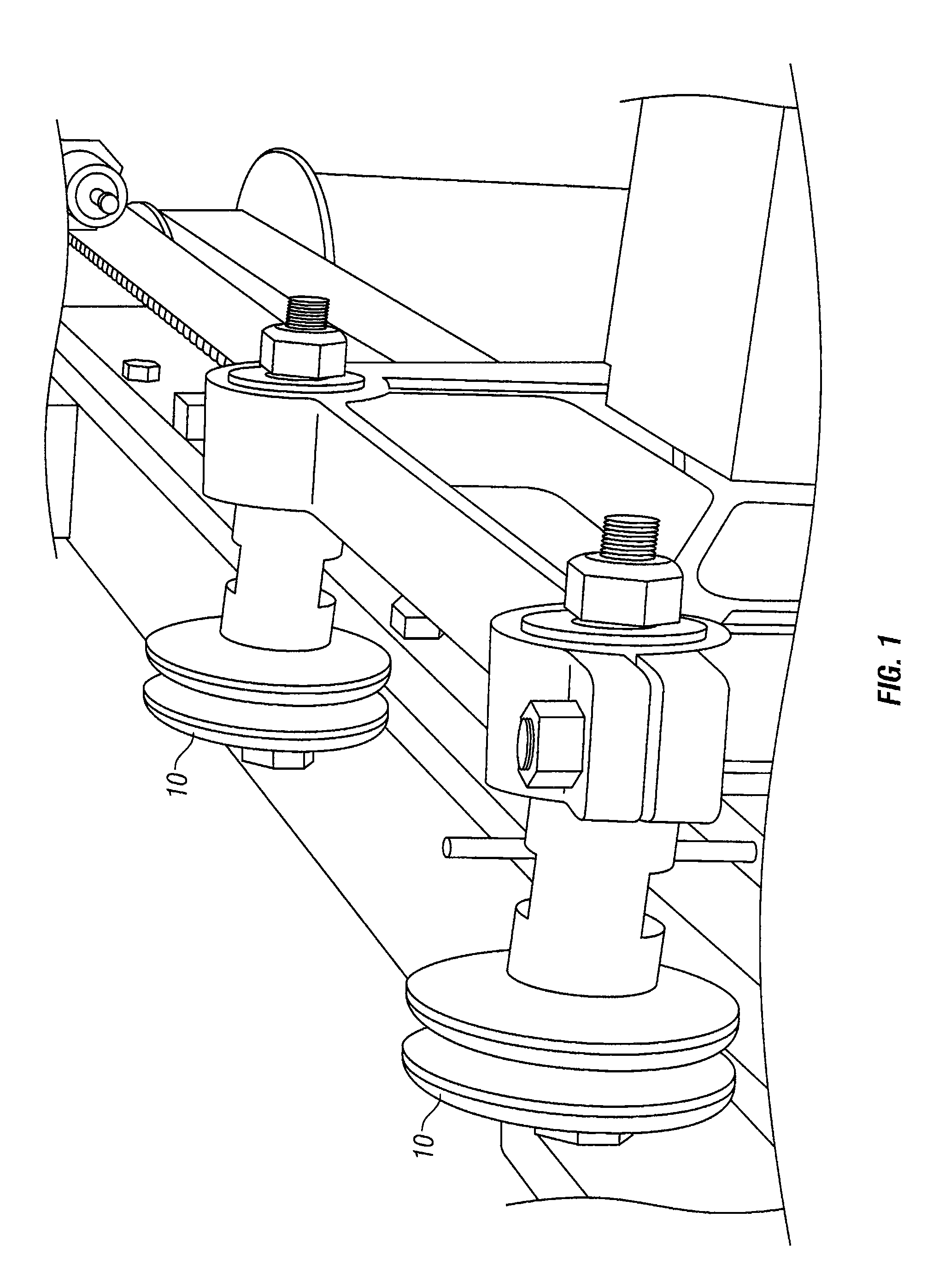

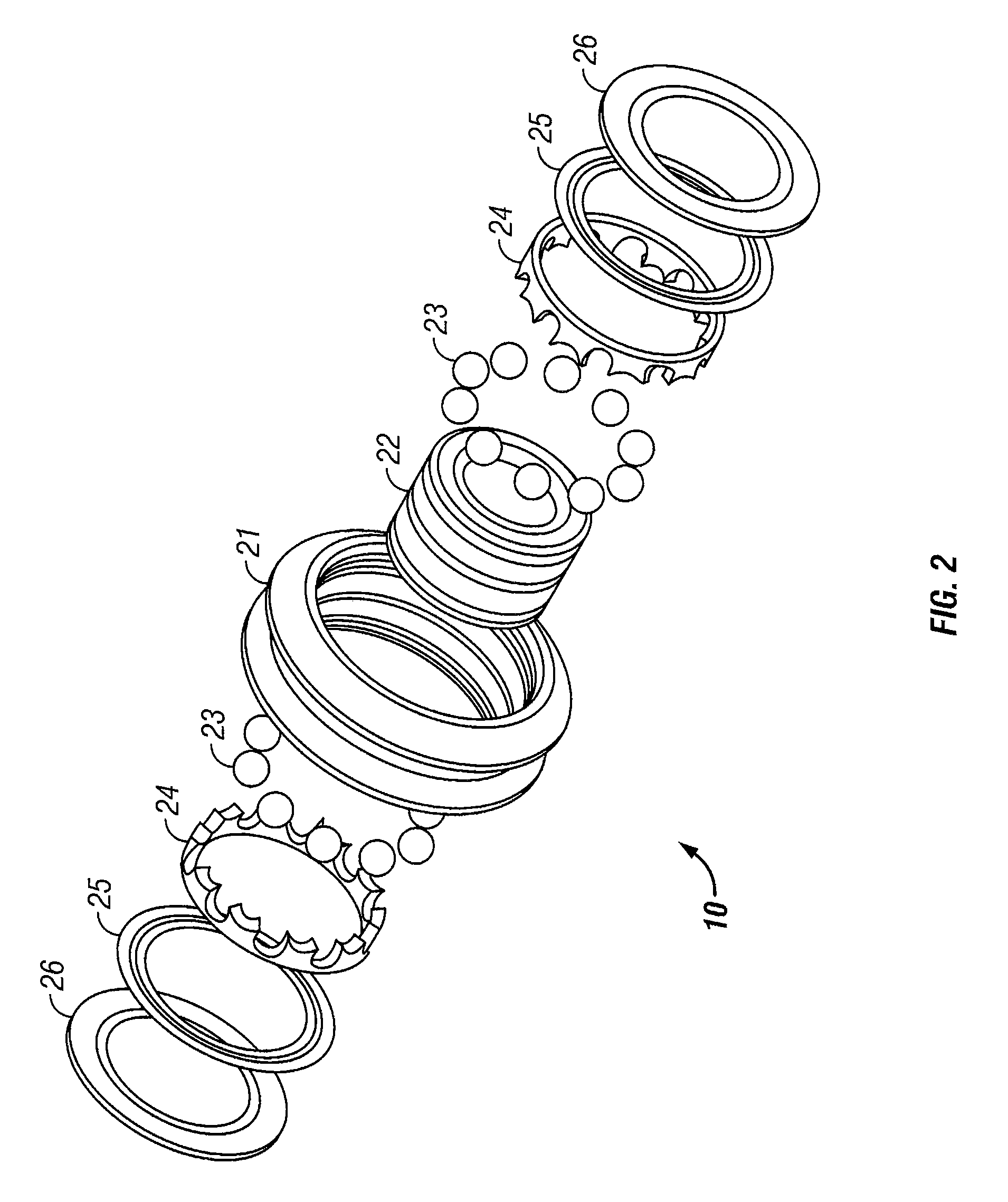

Guide wheel having a bearing for food and beverage applications

ActiveUS7588372B2Eliminate direct liquid pressure on sealImprove bearing lifeLinear bearingsBall bearingsSpin outDirect path

The invention provides a wheel design that incorporates both a shield and seal on both sides of the guide wheel to eliminate direct liquid pressure on the seal. By retaining the lubrication, bearing life is extended, dramatically reducing machine downtime. In the presently preferred embodiment, the combination of a guide wheel with two rubber spring return (RSR) seals in-bound of two shields, increases guide wheel life through the following: The shields prevent the direct force of a high pressure wash-down from reaching the seal directly. There is a non-direct path between the shield and the outer raceway of the guide wheel to allow any trapped liquid to seep back out of the guide wheel. Also, as the guide wheel rotates, any liquid between the shield and seal is spun-out by centrifugal force.

Owner:BISHOP WISECARVER CORP

Direct spinning method and system of colored terylene polyester melt mass

InactiveCN109371489AGood color consistencyGood mechanical propertiesMelt spinning methodsPigment addition to spinning solutionFiberMasterbatch

The invention provides a direct spinning method of colored terylene polyester melt mass. The method comprises the following steps: performing esterification reaction on pure terephthalic acid and glycol; feeding a product produced by the esterification reaction into a pre-condensating reaction kettle to perform pre-condensating reaction; feeding materials into a final polymerization kettle throughthe materials obtained by the pre-condensating reaction so as to perform final polymerization reaction; taking the melt mass of which the conveying quantity is 5 percent by volume to 10 percent by volume on a melt mass main pipeline arranged behind an outlet of the final polymerization kettle, and then enabling the melt mass to enter a dynamic mixer; adding colored masterbatch or colored powder in the dynamic mixer and then performing uniform mixing so as to generate colored melt mass; and then returning to the melt mass main pipeline, then feeding into a spinning box body and performing spinning. The method disclosed by the invention has the advantages that through an online addition way, the colored masterbatch or the colored powder is added into the melt mass, so that the melt mass which is uniformly mixed can be obtained, and the consistency of colors of fibers which are spin out is good. According to a method for reducing a temperature of the melt mass and a temperature of a spinning box body and simultaneously reducing the viscosity of the melt mass, destroy of the colored masterbatch or the colored powder on a fiber structure can be effectively reduced, and the produced fibers have the excellent mechanical performance and good handfeel.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

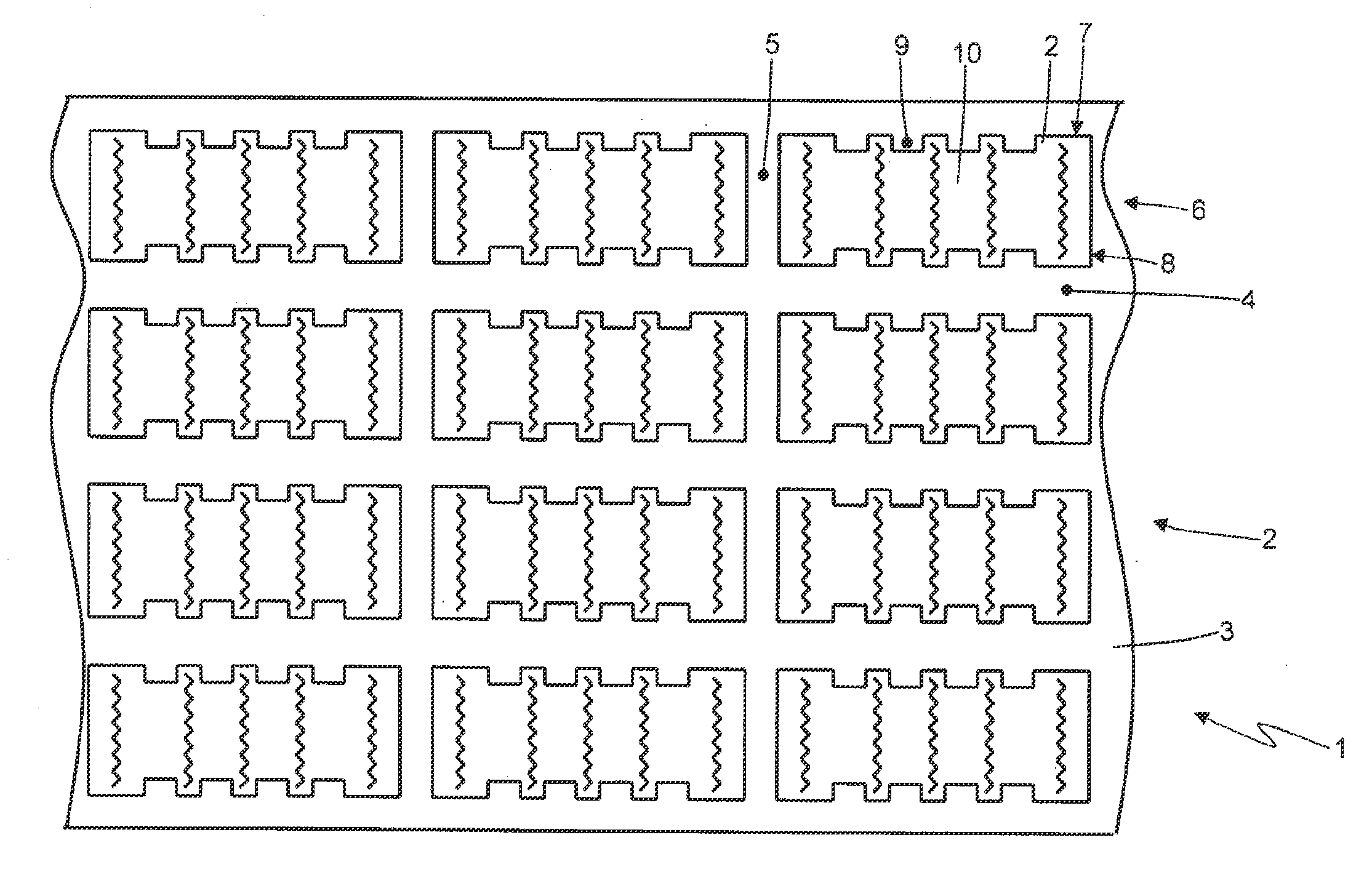

Take-up winding facility

ActiveCN101736425AThe quality variesGuaranteed qualityArtificial thread manufacturing machinesFilament handlingWinding machineSpin out

An object of the present invention is to provide a take-up winding facility which is miniaturized by reducing take-up winding device height and which is simplified by simplifying the layout of vicinity of a take-up winding machine. The present invention provides a take-up winding facility 100 configured to feed a plurality of filament yarns spun out by a spinning machine 10, from above to below to simultaneously wind the plurality of filament yarns 1 around respective plural bobbins 21 installed on a bobbin holder shaft 23 in one take-up winding machine 22, wherein a plurality of yarn feedingrollers (yarn feeding rollers 30, 31) are arranged immediately before the take-up winding machine 22, and the plurality of filament yarns 1 spun out by the spinning machine 10 are divided into a plurality of groups (filament yarn groups 2, 3) which are then fed to the respective plural yarn feeding rollers (yarn feeding rollers 30, 31) arranged immediately before the take-up winding machine 22, and the groups of filament yarns are distributively wound around respective bobbins 21 via the plurality of yarn feeding rollers (yarn feeding rollers 30, 31).

Owner:TMT MACHINERY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com