Preparing method of Nitorgen-doped carbon nano-material modified by metal cobalt

A nitrogen-doped carbon and nanomaterial technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as cumbersome steps, large differences in structure and performance between batches, and complicated operations. To achieve the effect of simple operation, stable structure and performance, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a metal cobalt-modified nitrogen-doped carbon nanomaterial, the steps of which are:

[0030] A. Add 4g EDTA as a carbon source to a 250mL beaker and add 50mL water;

[0031] B. Stir and adjust the pH value to 7.0 with 10% (m / m, the same below) ammonia solution, at which point the EDTA is completely dissolved;

[0032] C, and then 0.7g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 10 mL of water as a cobalt source and added to the EDTA solution;

[0033] D. After stirring, adjust the pH value to 7.0 with 10% (m / m, the same below) ammonia water again, and place the prepared solution in a rotary evaporator to spin out the water;

[0034] E. Put it in an electric blast drying oven with a temperature of 80°C for 18 hours until a pink granular solid is obtained;

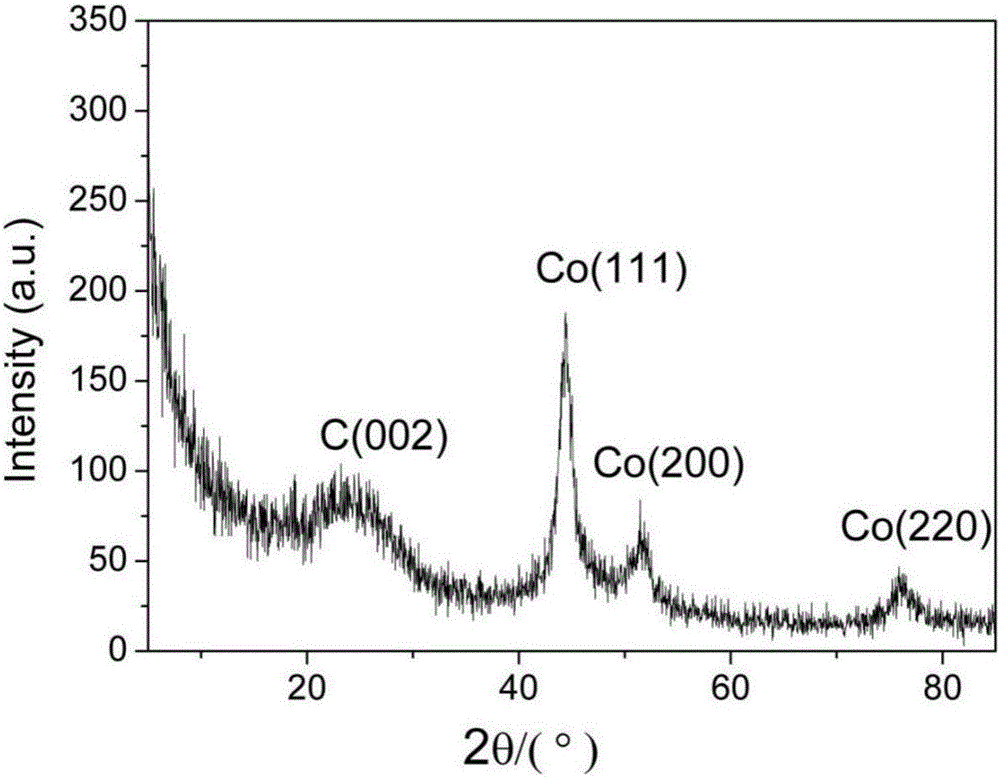

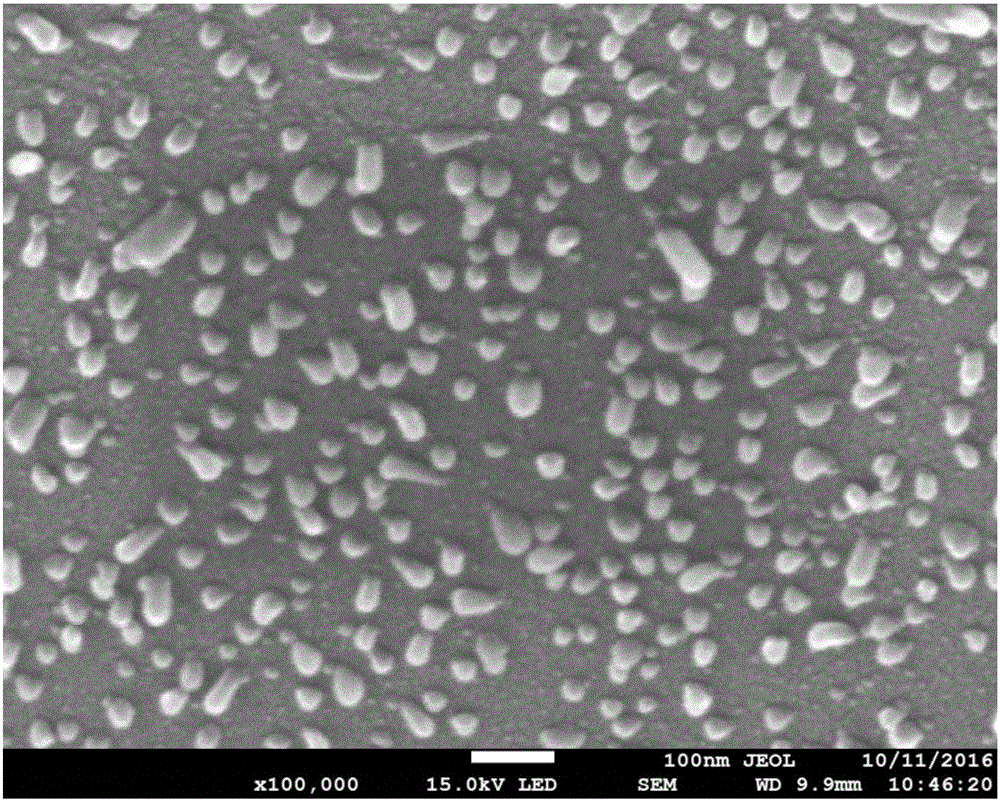

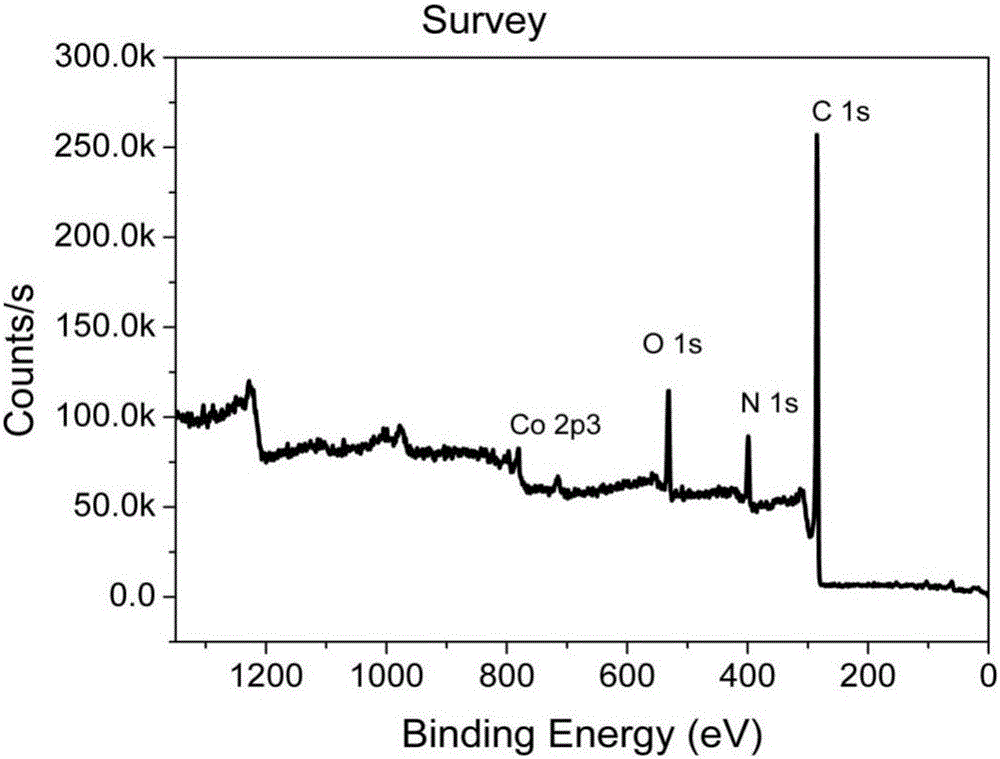

[0035] F. Grind the obtained pink granular solid into a fine powder, put it into a porcelain boat, place it in a vacuum tube type high-temperature sintering furnace for heating and roasting und...

Embodiment 2

[0040] A method for preparing a metal cobalt-modified nitrogen-doped carbon nanomaterial, the steps of which are:

[0041] Add 7g of EGTA as a carbon source into a 250mL beaker, add 80mL of water, stir and adjust the pH value to 7.5 with 7% triethylamine aqueous solution, at this time EGTA is completely dissolved, and then add 1.2g of Co(NO 3 ) 2 ·6H 2 O is used as a cobalt source and dissolved in 10mL of water, and then added to the EGTA solution. After stirring, the pH value is adjusted to 7.5 with 7% triethylamine aqueous solution again. The prepared solution is placed in a rotary evaporator to spin out the water, and then placed at It was placed in an electric blast drying oven at 85°C for 12 hours until a pink granular solid was obtained. The obtained pink granular solid was ground to a fine powder and put into a porcelain boat, and placed in a vacuum tube type high-temperature sintering furnace for heating and roasting under nitrogen protection at a flow rate of 35 mL / ...

Embodiment 3

[0046] A method for preparing a metal cobalt-modified nitrogen-doped carbon nanomaterial, the steps of which are:

[0047] Add 5g EGTA as a carbon source into a 250mL beaker, add 70mL water, stir and adjust the pH value to 7.2 with 9% ethylenediamine solution. At this time, EGTA is completely dissolved, and then 0.8g Co(NO 3 ) 2 ·6H 2 Add O as the cobalt source, add 10mL water to dissolve it, add it to the EGTA solution, adjust the pH value to 7.2 with 9% ethylenediamine solution after stirring, put the prepared solution in a rotary evaporator to spin out the water, and then place it at temperature It was placed in an electric blast drying oven at 82°C for 14 hours until a pink granular solid was obtained. The obtained pink granular solid was ground to a fine powder and put into a porcelain boat, and placed in a vacuum tube type high-temperature sintering furnace for heating and roasting under nitrogen protection at a flow rate of 40 mL / min. During the calcination process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com