Two-wheel flexible spinning technology applicable to steel plate welding wheels with grooves

A technology of spinning technology and steel plate, which is applied in the field of wheel-type flexible spinning technology, can solve problems such as the difficulty of processing pulleys, and achieve the effects of improving processing efficiency, high economic benefits, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

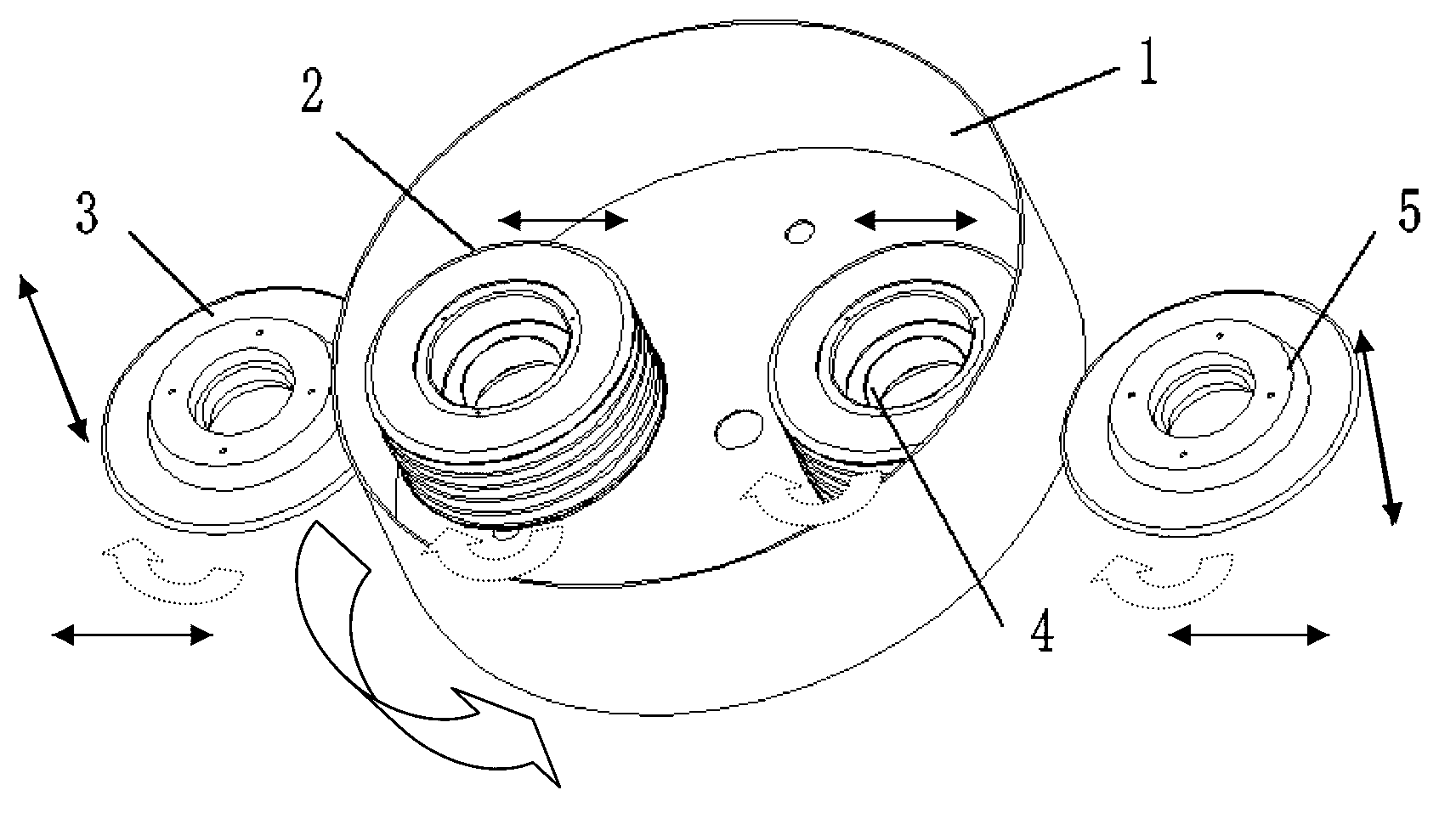

[0023] refer to figure 1 with figure 2 , a wheel-to-wheel flexible spinning process suitable for steel plate welding wheels with grooves, including the following steps:

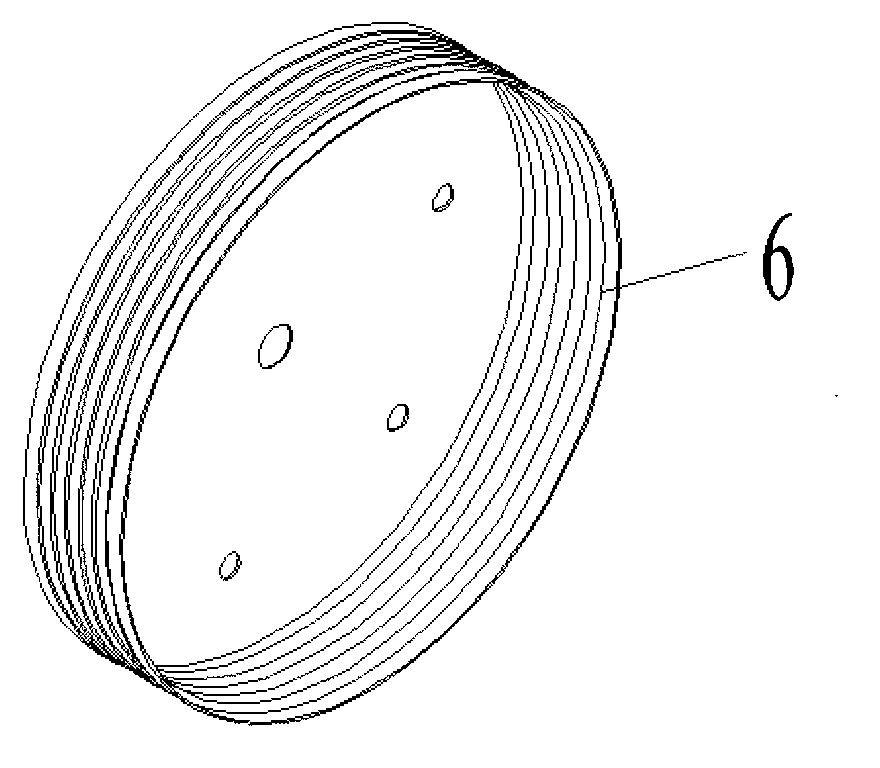

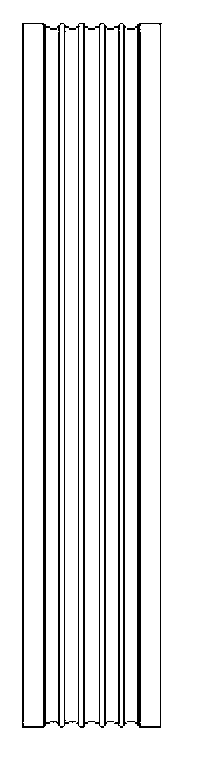

[0024] In the first step, under the condition that the blank rotates, two independent first core molds 2 and second core molds 4 having the same groove shape as the inner surface of the target workpiece 6 are symmetrically placed inside the cylindrical blank 1, The first mandrel 2 and the second mandrel 4 are in contact with the inner surface of the cylindrical blank 1, the height of the first groove of the first mandrel 2 and the second mandrel 4 is relative to the height of the cylindrical blank 1 and the target workpiece 6 The distance from the first groove of the to the bottom surface is the same;

[0025] In the second step, two independent first rotary wheels 3 and second rotary wheels 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com