Polyphenylene sulfide short fiber and method for making the same

A technology of polyphenylene sulfide and manufacturing method, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, melt spinning method, etc., can solve the problems of filter cloth strength reduction, etc., to prolong product life, chemical resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

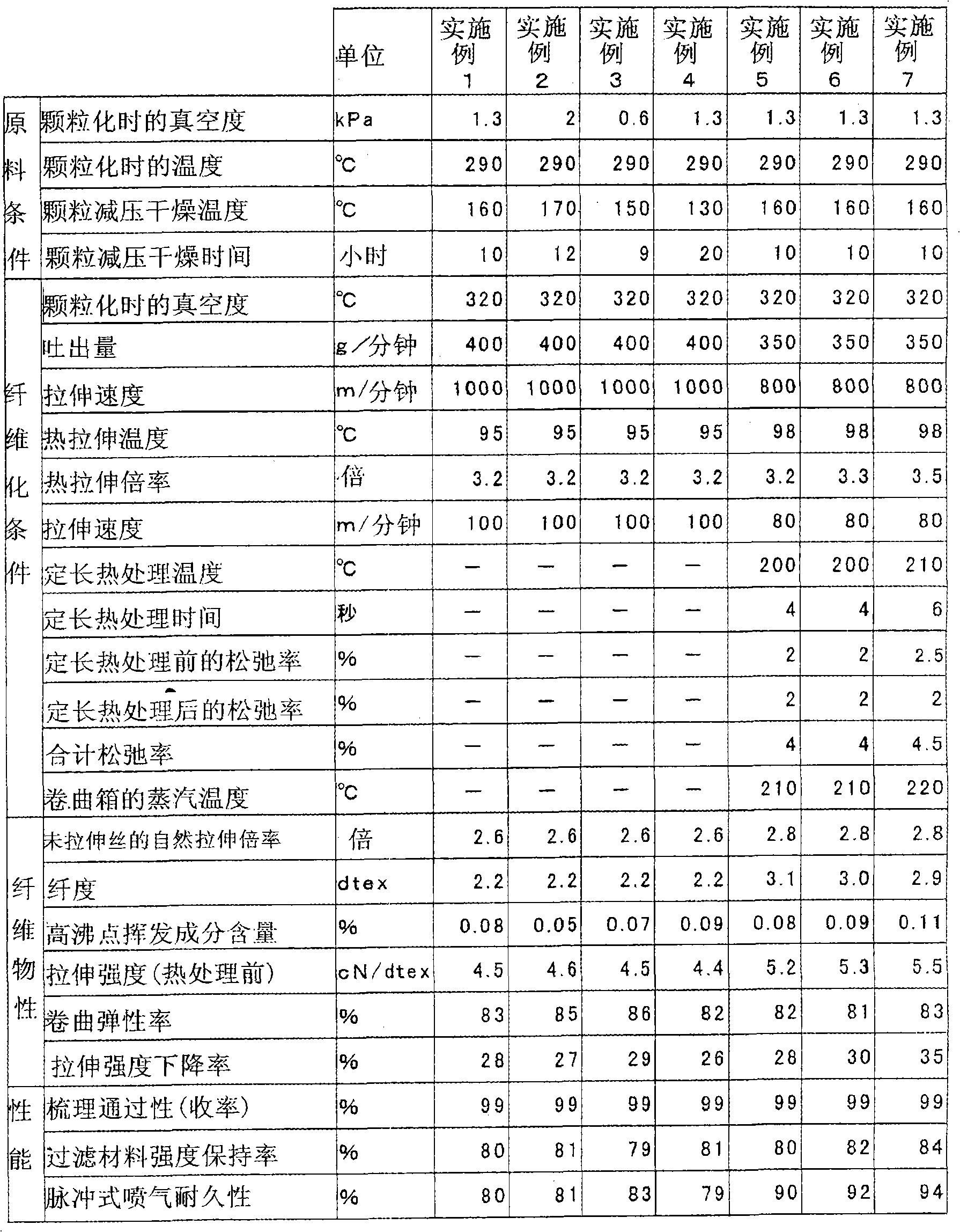

[0074] With a twin-shaft extruder with vents (TEX30 type manufactured by Nippon Steel Works), the vacuum degree was set to 1.3 kPa, the cylinder temperature was set to 290 ° C, and the screw rotation speed was 160 rpm. PPS powder E2280 (weight-average molecular weight: 49,500) produced by Li Co., Ltd. was melted, extruded from a circular hole (hole area: 15.9 mm 2 ), and cut into a length of 3 mm with a stranding machine to obtain pellets. The obtained particles were vacuum-dried at 160° C. and a vacuum degree of 1.3 kPa for 10 hours. It should be noted that the vacuum drying is carried out in batches, and the dried particles are 2 tons each time.

[0075] The vacuum-dried pellets were melt-spun at a spinning temperature of 320° C. and a discharge rate of 400 g / min using an extruder-type spinning machine, and pulled at a pulling speed of 1000 m / min to obtain undrawn yarns. The natural draw ratio of the obtained undrawn yarn was 2.6 times. Next, the obtained undrawn yarn was ...

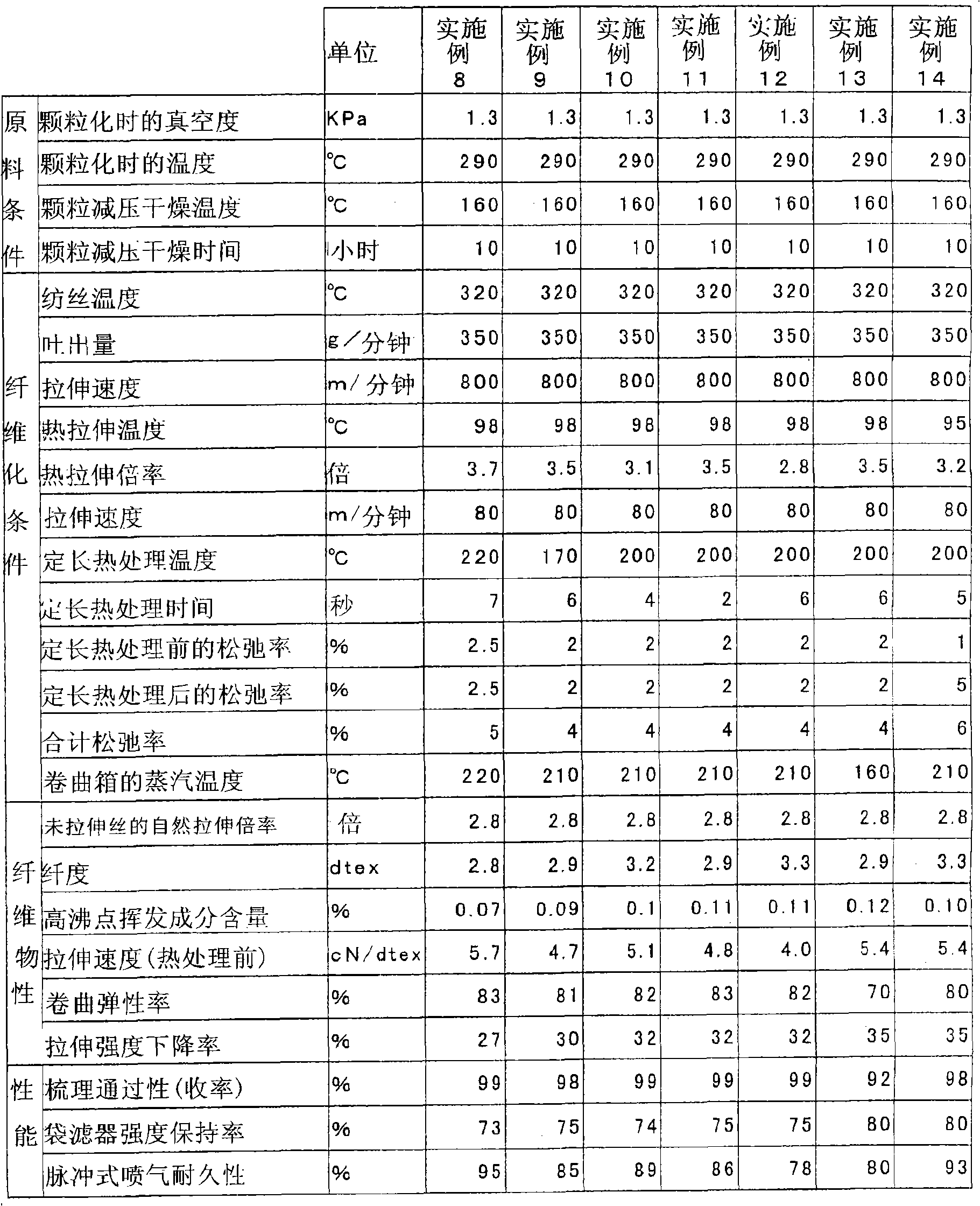

Embodiment 2~4、 comparative example 4、5

[0084] Except that the degree of vacuum when obtaining the particles or the reduced-pressure drying temperature and time of the particles were changed as described in Table 1, the same operation as in Example 1 was performed to obtain PPS short fibers and obtain a filter material at the same time. The measurement results of the fineness, tensile strength, crimp elastic modulus and the content of high boiling point volatile components in the obtained PPS short fibers and the measurement results of the pulse jet durability and filter material strength retention rate of the obtained filter material and The experimental conditions are shown in Table 3 together.

experiment example 5

[0086] With a twin-shaft extruder with vents (TEX30 type manufactured by Nippon Steel Works), the vacuum degree was set to 1.3 kPa, the cylinder temperature was set to 290 ° C, and the screw rotation speed was 160 rpm. The pPS powder E2280 (weight-average molecular weight: 49,500) manufactured by Rei Co., Ltd. is melted, and the circular hole (hole area: 15.9mm) 2 ) was extruded and cut into a length of 3 mm using a stranding machine to obtain pellets. The obtained particles were vacuum-dried at 160° C. and a vacuum degree of 1.3 kPa for 10 hours. It should be noted that the vacuum drying is carried out in batches, and the dried particles are 2 tons each time.

[0087] The vacuum-dried pellets were melt-spun at a spinning temperature of 320° C. and a discharge rate of 350 g / min using an extruder-type spinning machine, and pulled at a pulling speed of 800 m / min to obtain undrawn yarns. The natural draw ratio of the obtained undrawn yarn was 2.8 times. Next, the obtained undr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com