Yarn heating apparatus

A heating device and silk thread technology, which is applied in the direction of artificial filament heat treatment, artificial filament physical therapy, and complete sets of equipment for the production of artificial threads, etc., can solve the problems of increased warm air volume, increased heater power consumption, etc., and achieve temperature suppression Effects of reducing, reducing power consumption, and suppressing temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] A preferred first embodiment of the present invention will be described below.

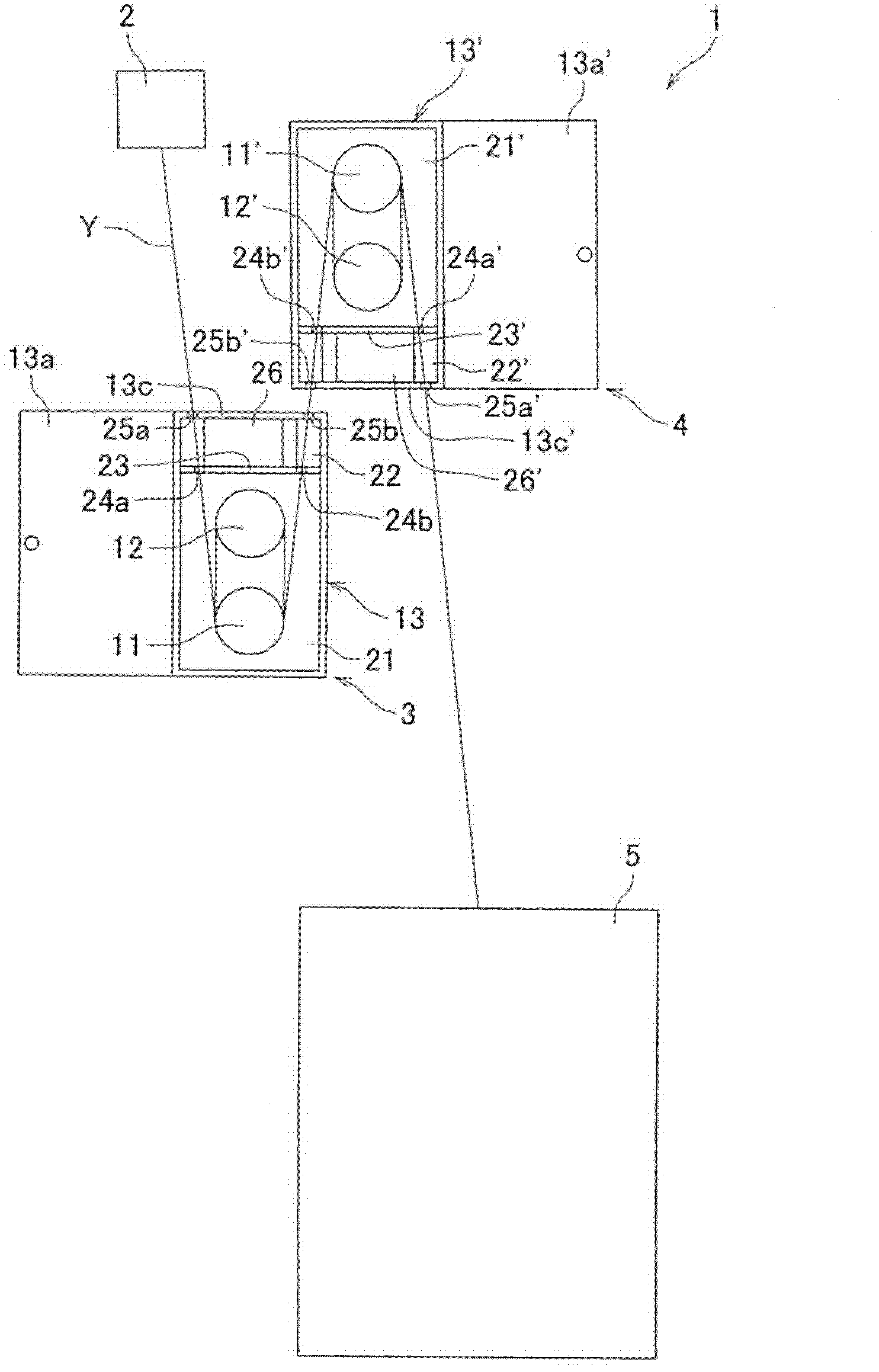

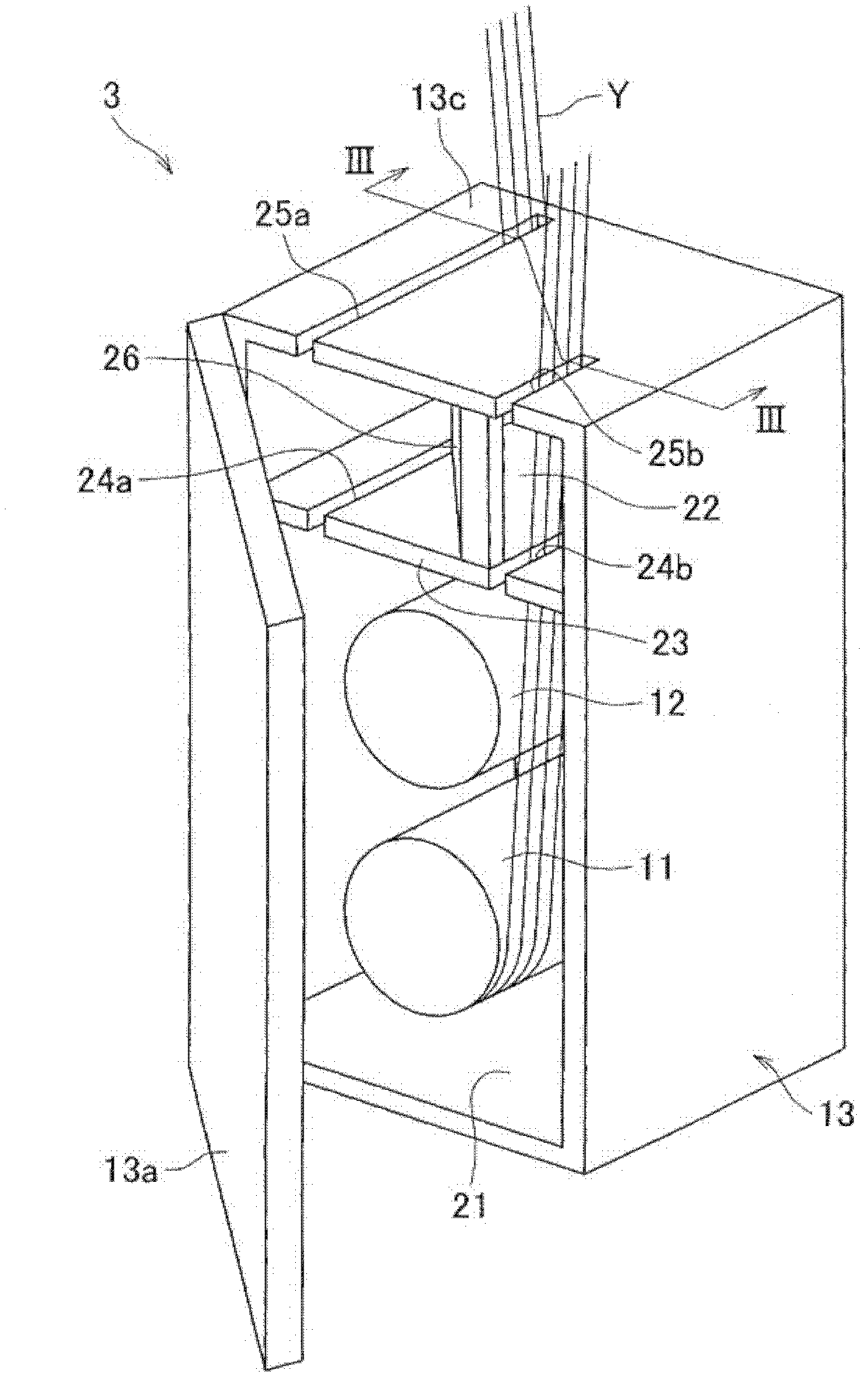

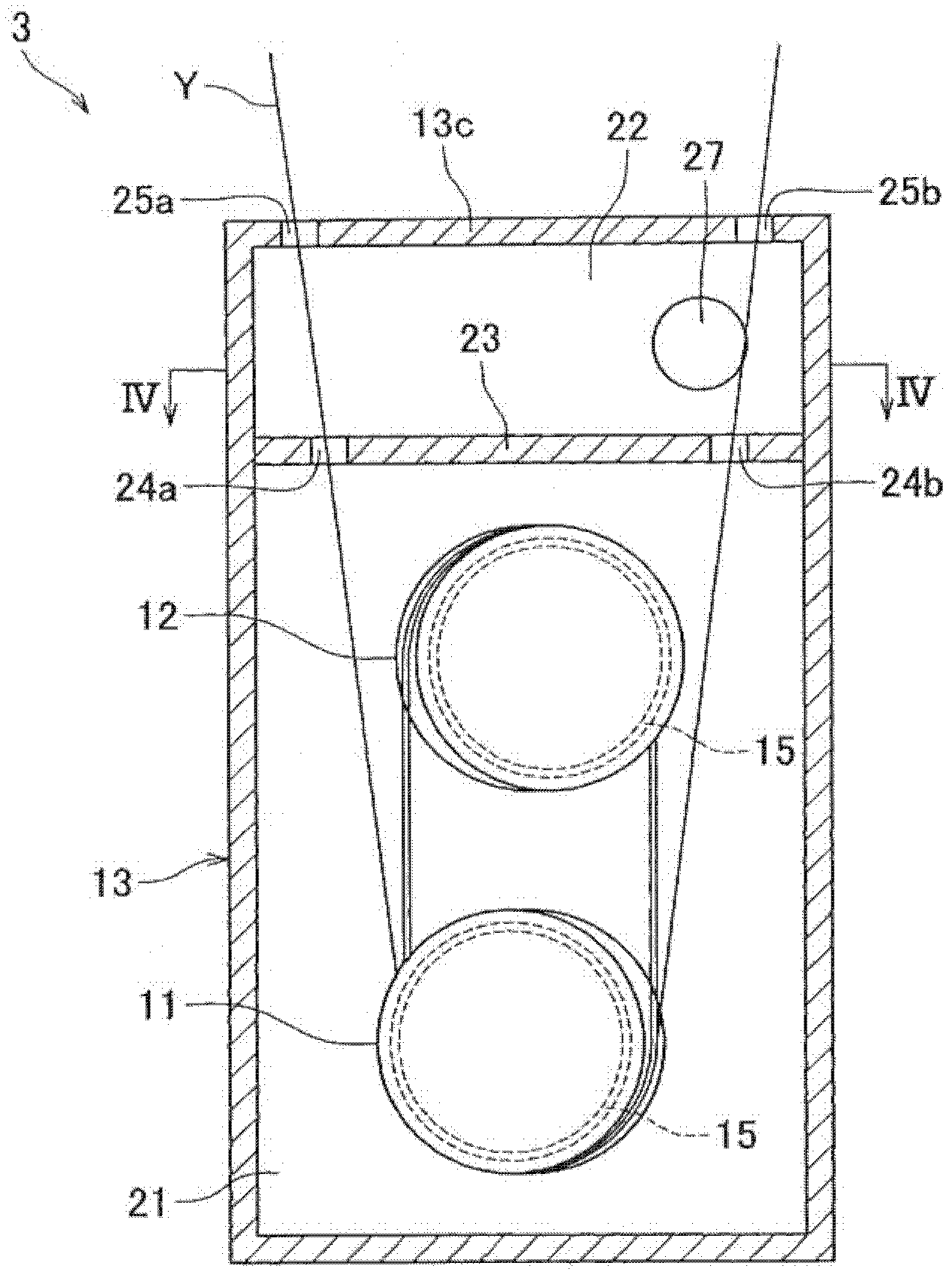

[0063] Such as figure 1 As shown, the yarn manufacturing apparatus 1 includes a spinning machine 2 , two roll units 3 and 4 (yarn heating devices), and a winder 5 . The spinning machine 2 makes a plurality of (for example, about 24 to 32) yarns Y along the figure 1 It is spun downward in a state where the drawing surfaces are aligned in the vertical direction. The roller units 3 , 4 heat and stretch the plurality of yarns Y spun from the spinning machine 2 . The winder 5 winds the plurality of yarns Y stretched by the roller units 3 and 4 onto a bobbin (not shown).

[0064] In addition, since the structure of the spinning machine 2 and the winding machine 5 in the above-mentioned structure of the yarn manufacturing apparatus 1 are the same as those of the prior art, detailed description thereof will be omitted, and the roll units 3 and 4 will be described in detail below.

[0065] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com