Take-up winding facility

A kind of equipment and spinning technology, which can be used in the production of complete sets of equipment for man-made threads, filament generation, textiles and papermaking, etc. It can solve the problems of complex equipment and achieve the effect of reducing height, improving efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

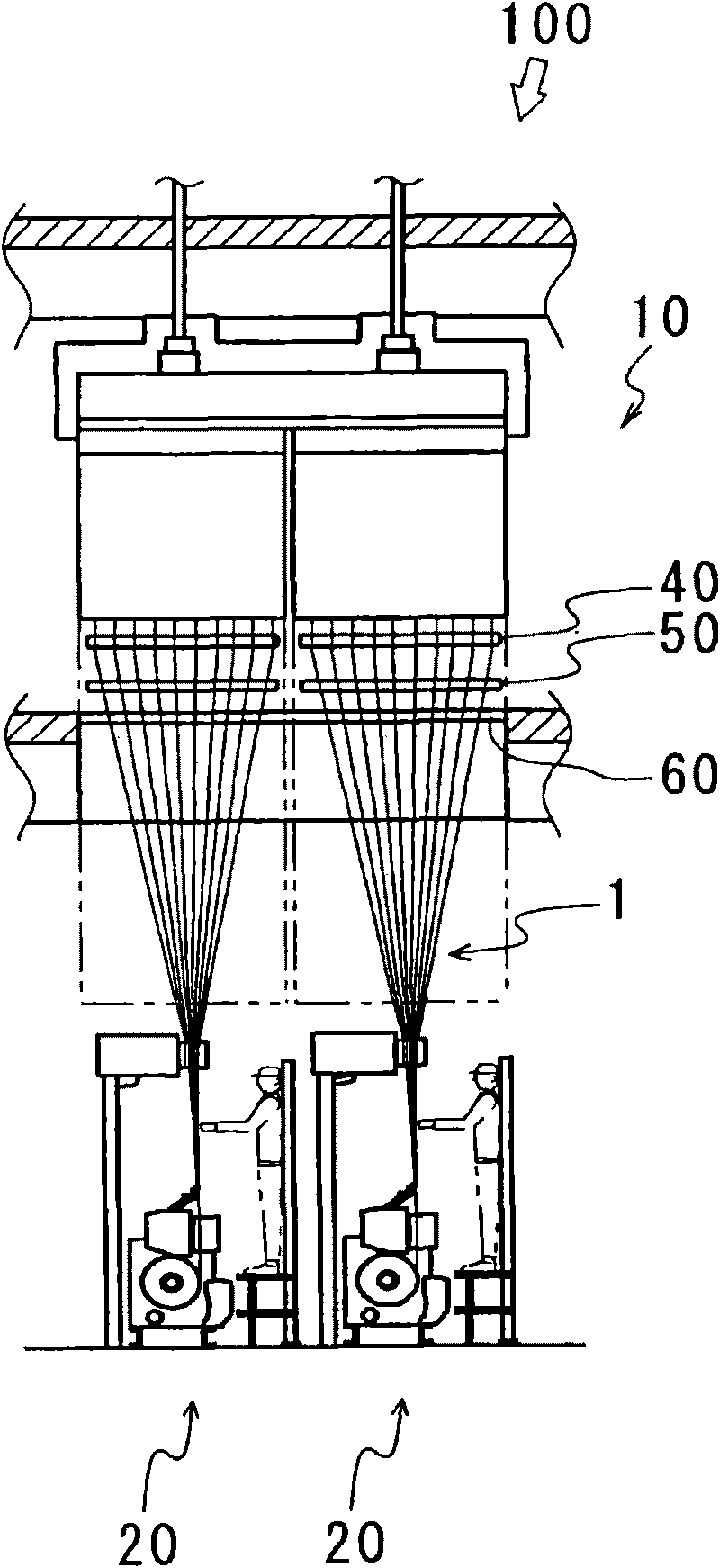

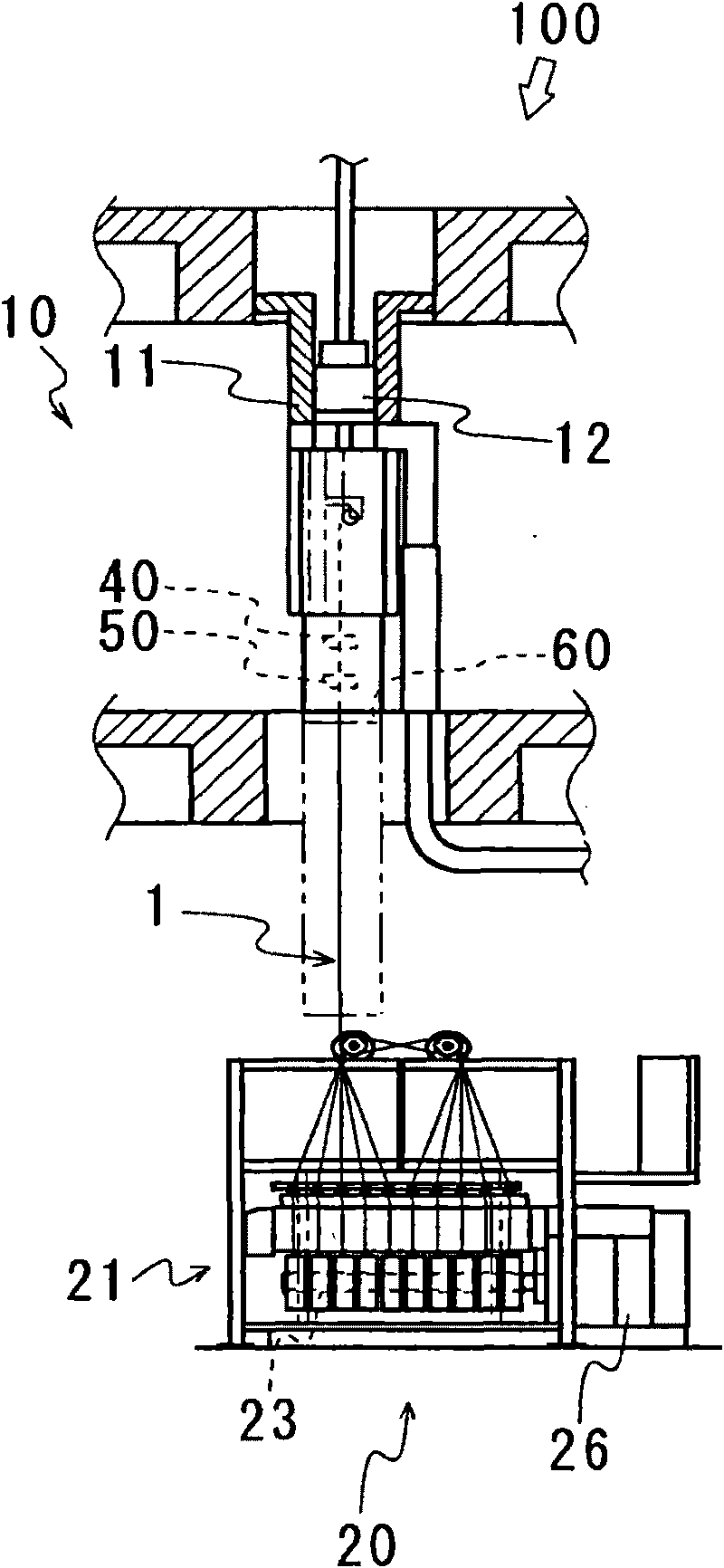

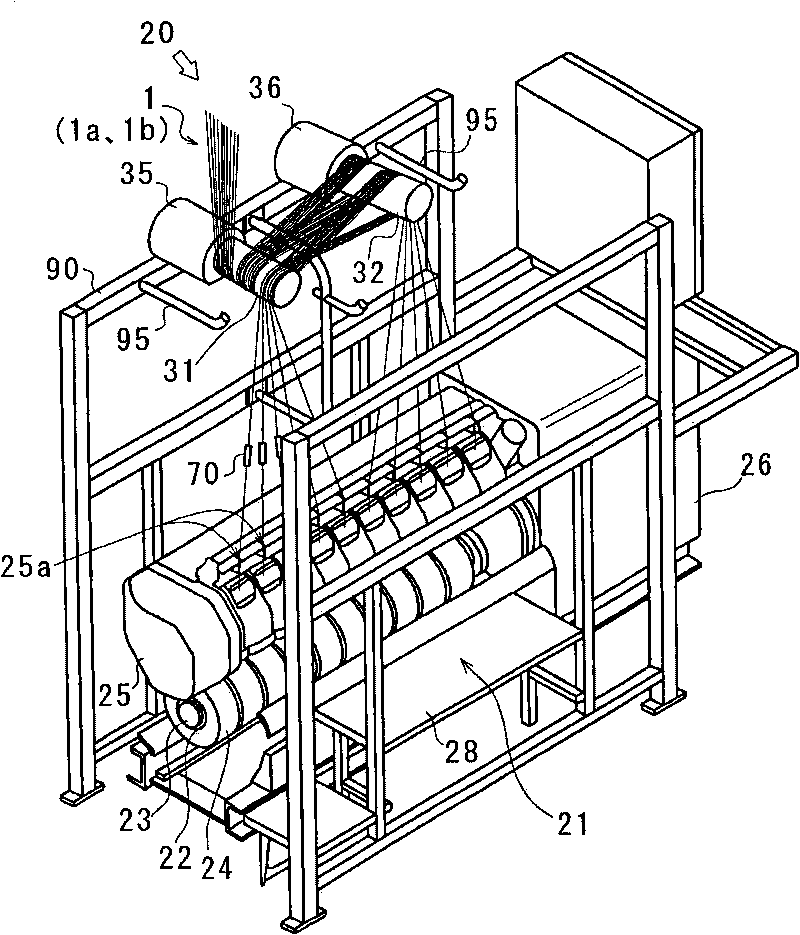

[0053] First, the overall structure of the spinning and winding apparatus 100 of the present invention will be described with reference to FIG. 1 . Figure 1A is a front view of the spin-winding apparatus 100, Figure 1B its side view. In addition, let the action direction of gravity be the up-down direction, let the axial direction of the bobbin holder shaft 23 provided in the winder 21 be the front-rear direction, and let the side of the bobbin holder shaft 23 connected to the drive device 26 be the rear side , and use the other side as the front side. In addition, the direction orthogonal to the vertical direction and the front-rear direction when the winder 21 is viewed from the front side is referred to as the left-right direction.

[0054] The spinning and winding apparatus 100 is mainly composed of a spinning machine 10 for spinning a plurality of yarns 1 and a spinning and winding device 20 for winding the yarns 1 spun from the spinning machine 10 .

[0055] The spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com