Spun yarn taking-off apparatus

A traction equipment and spinning technology, applied in textiles and papermaking, conveying filamentous materials, and clustering of newly extruded filaments, etc., to achieve the effect of simple structure and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] Two embodiments of the spinning take-up device of the present invention will be described below.

[0157] The first embodiment is a spinning and drawing device 100 for POY that winds POY (partially drawn yarn), and the second embodiment is a spinning and drawing device 200 for FDY that winds FDY (fully drawn yarn).

[0158] In addition to the configuration of the spinning and drawing device 100 for POY, a device for drawing and spinning is added to the spinning and drawing device 200 for FDY.

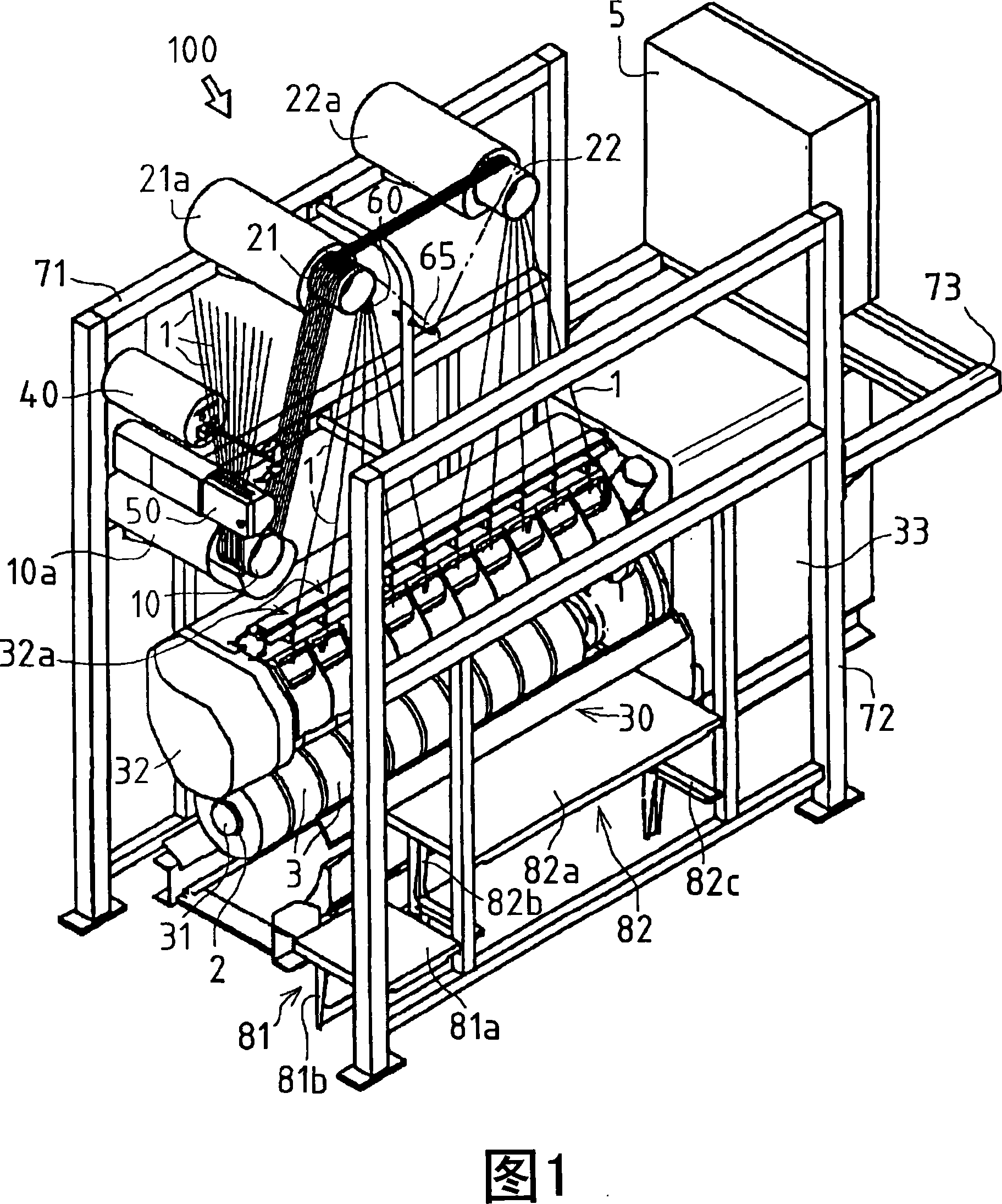

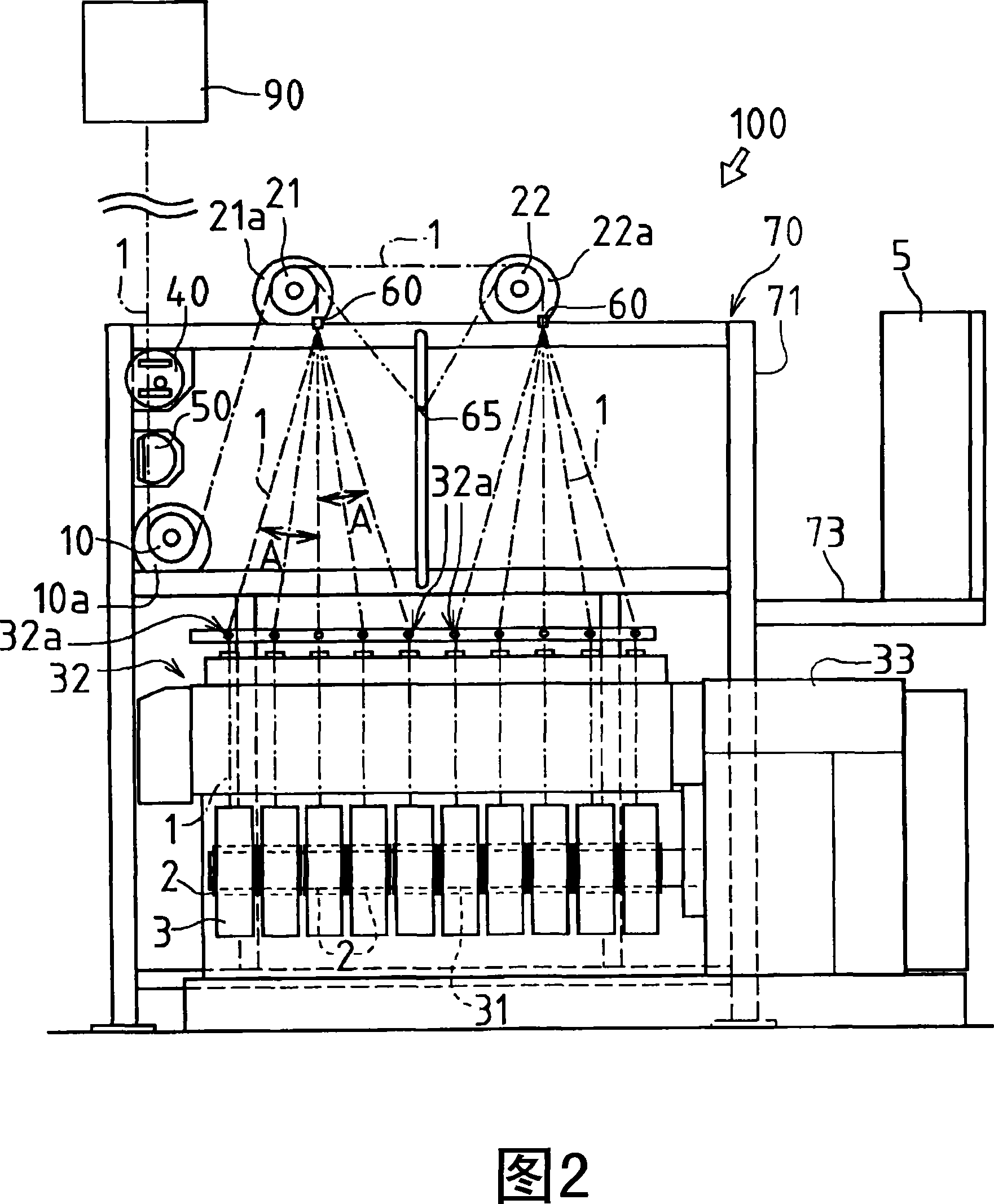

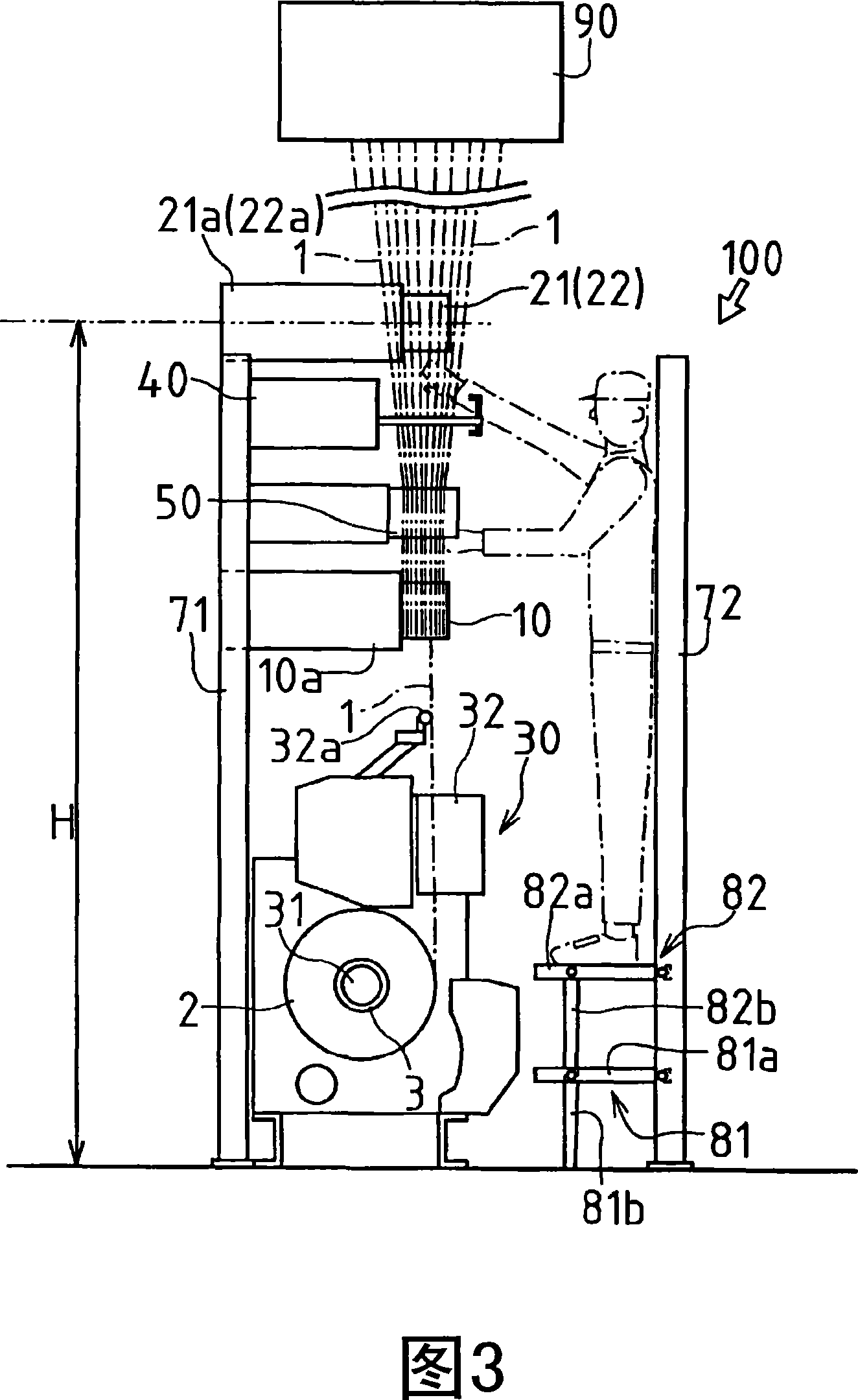

[0159] Next, the configuration of the POY spinning take-up device 100 will be described with reference to FIGS. 1 , 2 and 3 .

[0160] The spinning draw-up facility 100 for POY includes a winder 30 for winding a plurality of yarns supplied from a spinning head (molten resin discharge unit) 90 and multi-stage yarn supply rollers 10, 21, 22 (filament) 1; the yarn feeding rollers 10, 21, 22 are arranged between the spinning head 90 above and the winding machine 30 below, and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com