Method and device for end forming of yarn in jet spinning machine

An open-air spinning machine and a technology for yarn spooling up, which is applied in the field of yarn spooling to achieve the effect of improving the quality of winding yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

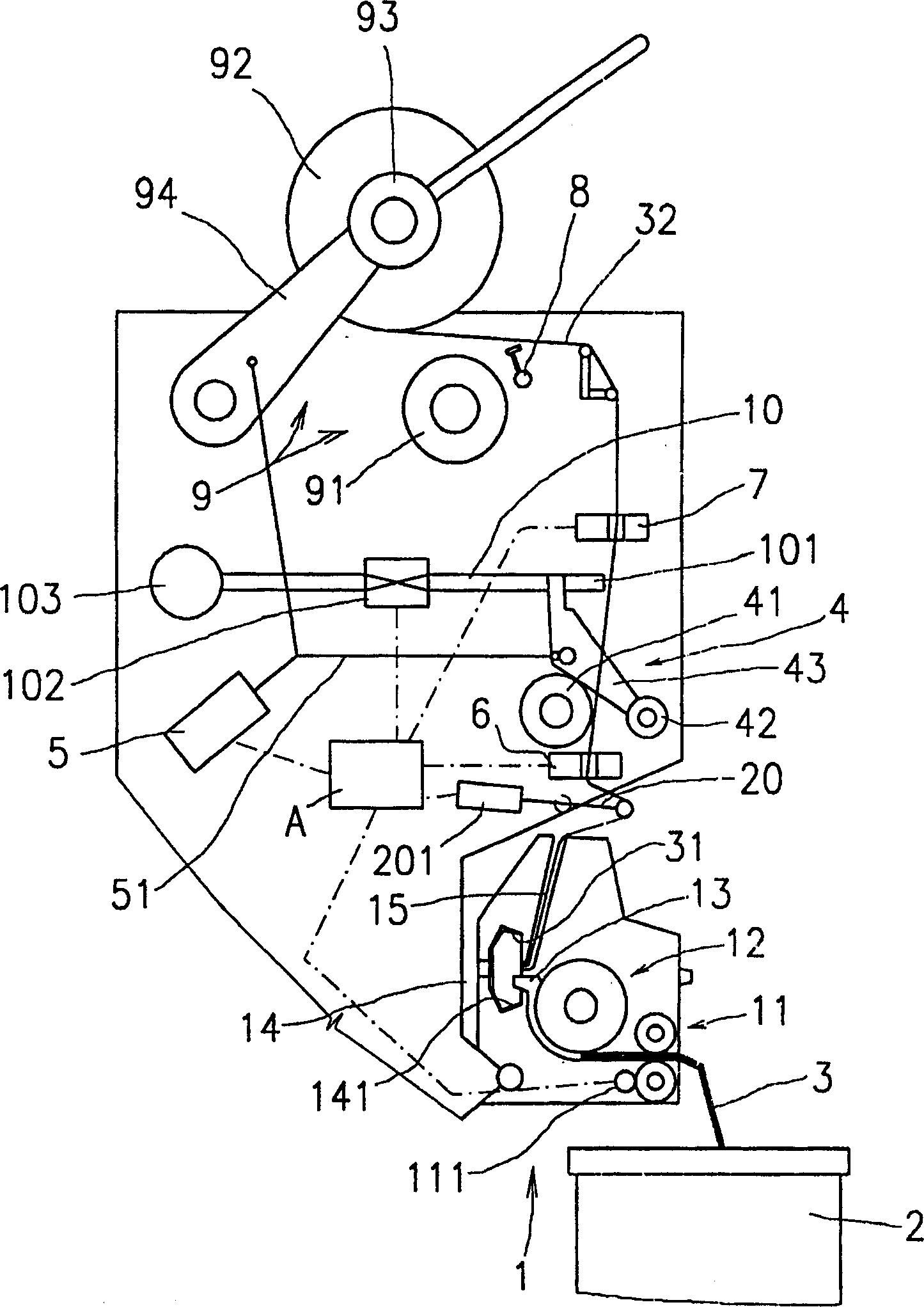

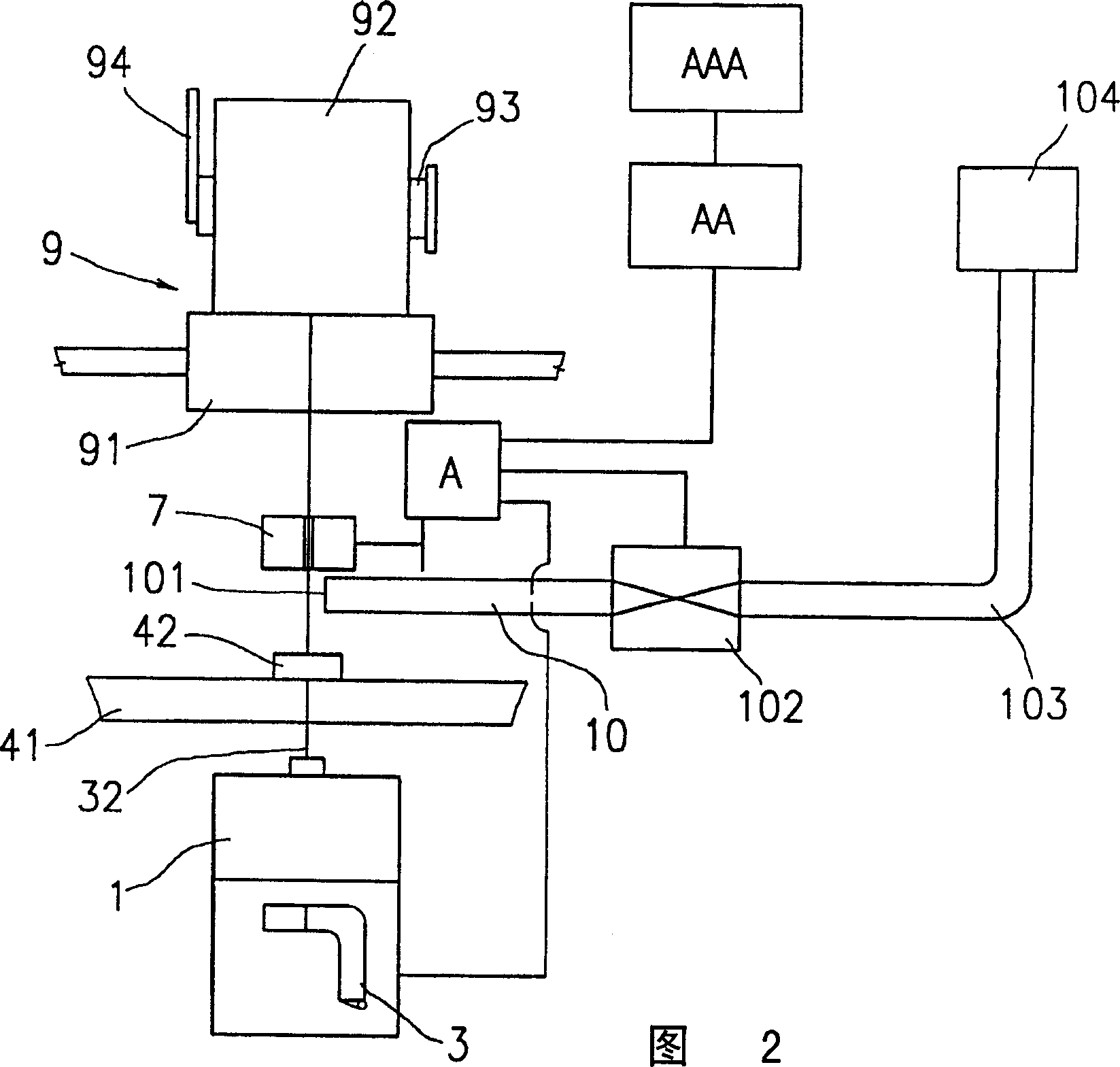

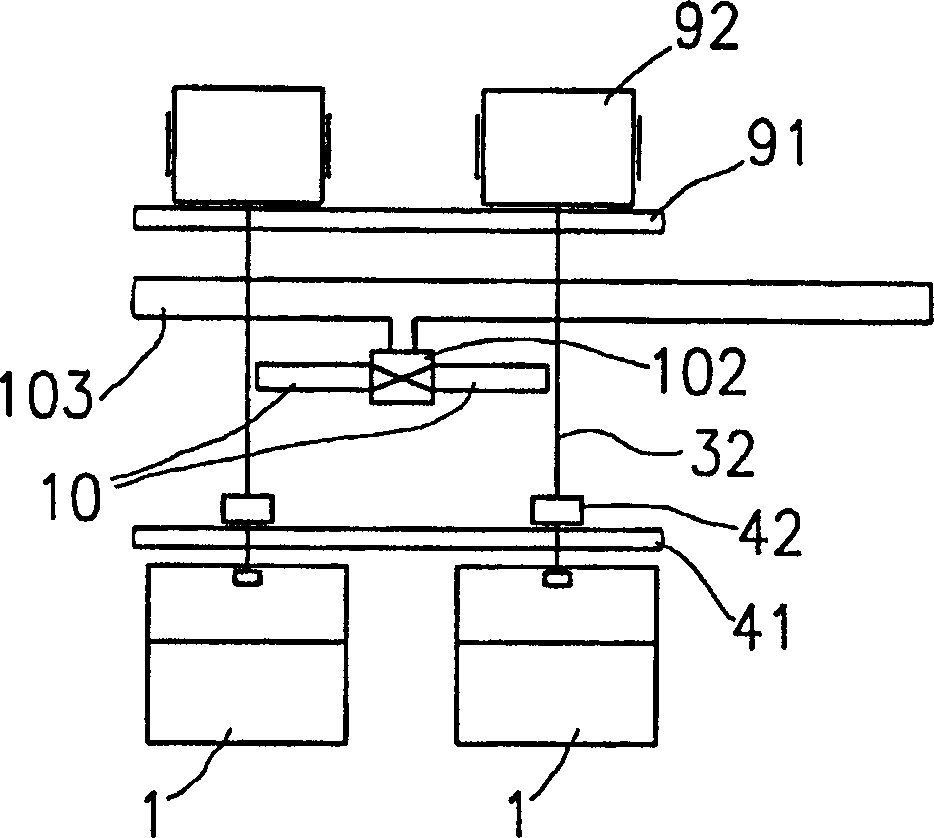

[0018] The air spinning machine includes a plurality of sequentially arranged working mechanisms, each of which is suitable for independently producing yarn from a sliver and winding the produced yarn on a bobbin. The device of the invention is illustrated on the basis of a semi-automatic spinning machine disclosed in patent CZ284295.

[0019] Each working part comprises spinning mechanism 1 and is positioned at below spinning mechanism 1 and the sliver tube 2 that sliver 3 is conveyed in the feeding device 11 of spinning mechanism 1, and feeding device 11 comprises and links to each other with control mechanism A Feed clutch 111. The feeding device 11 is followed by a single-strand withdrawal (singling-out) device 12 for single-strand withdrawal of single fibers from the sliver 3 . The conveying channel 13 of the single-strand extracted fiber entering the inner cavity of the spinning cup 14 is connected with the single-strand drawing device 12, and the widest part of the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com