Spinning winding device

A technology of a winding device and a spinning device, which is applied in the directions of drawing spinning, textile and papermaking, filament/thread forming, etc., can solve the problems of increased energy consumption, reduced efficiency of threading operations, and difficulty in making heating rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

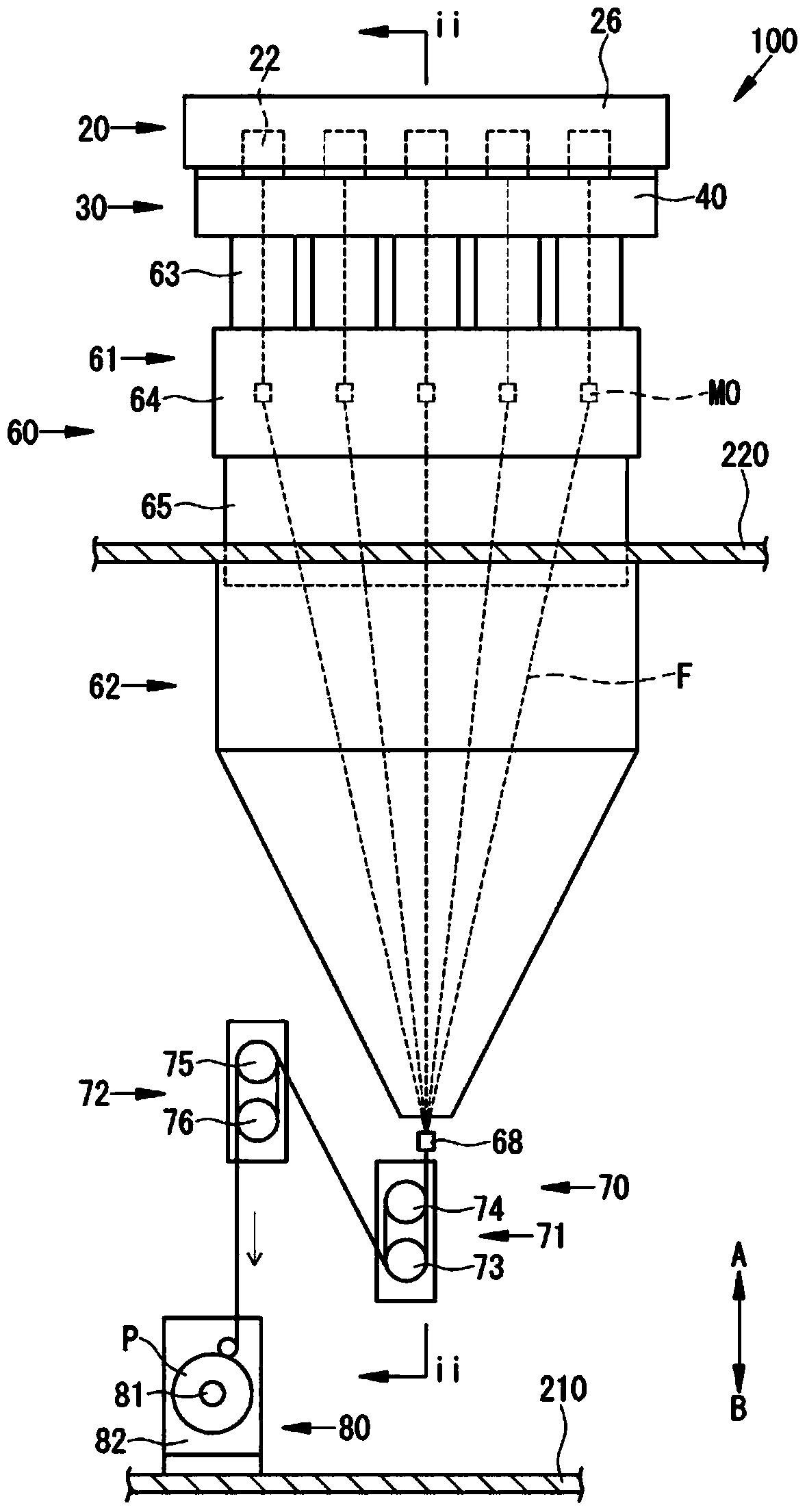

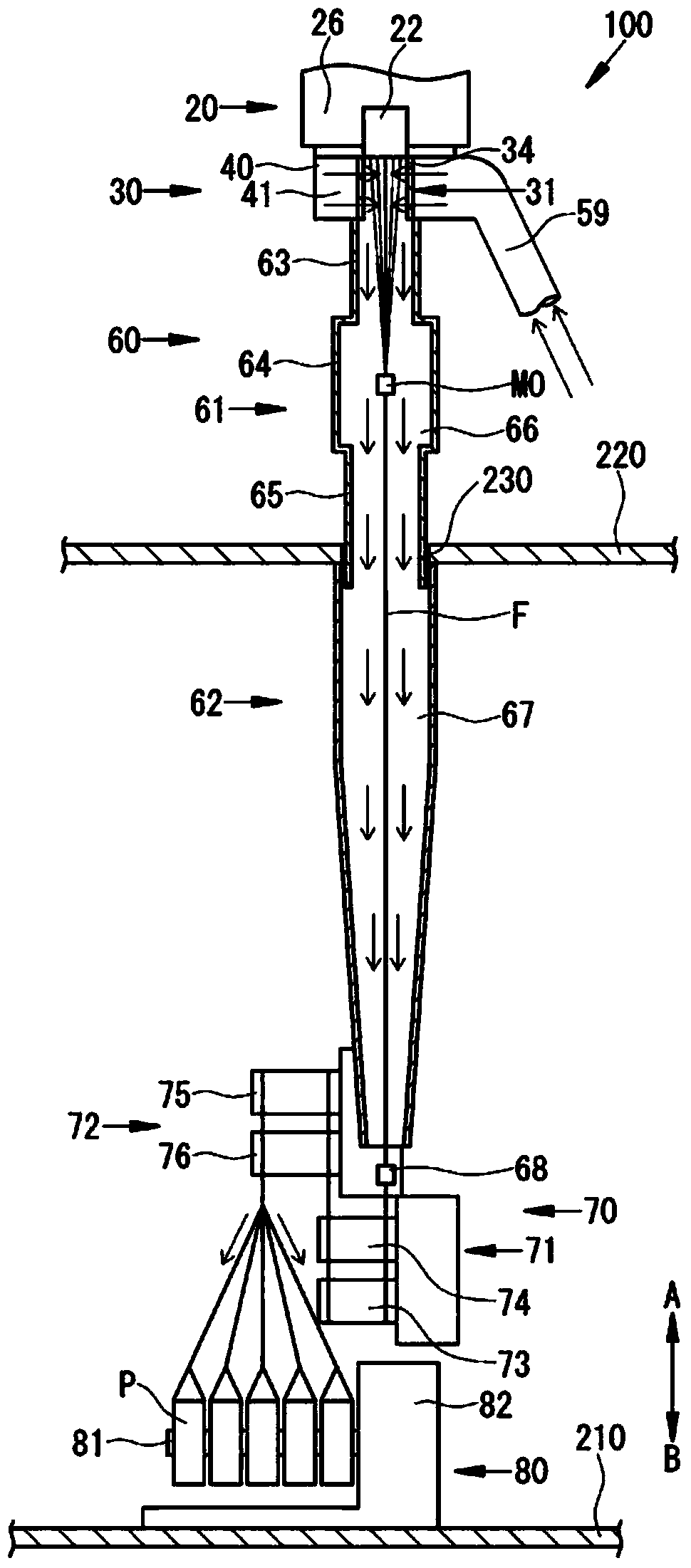

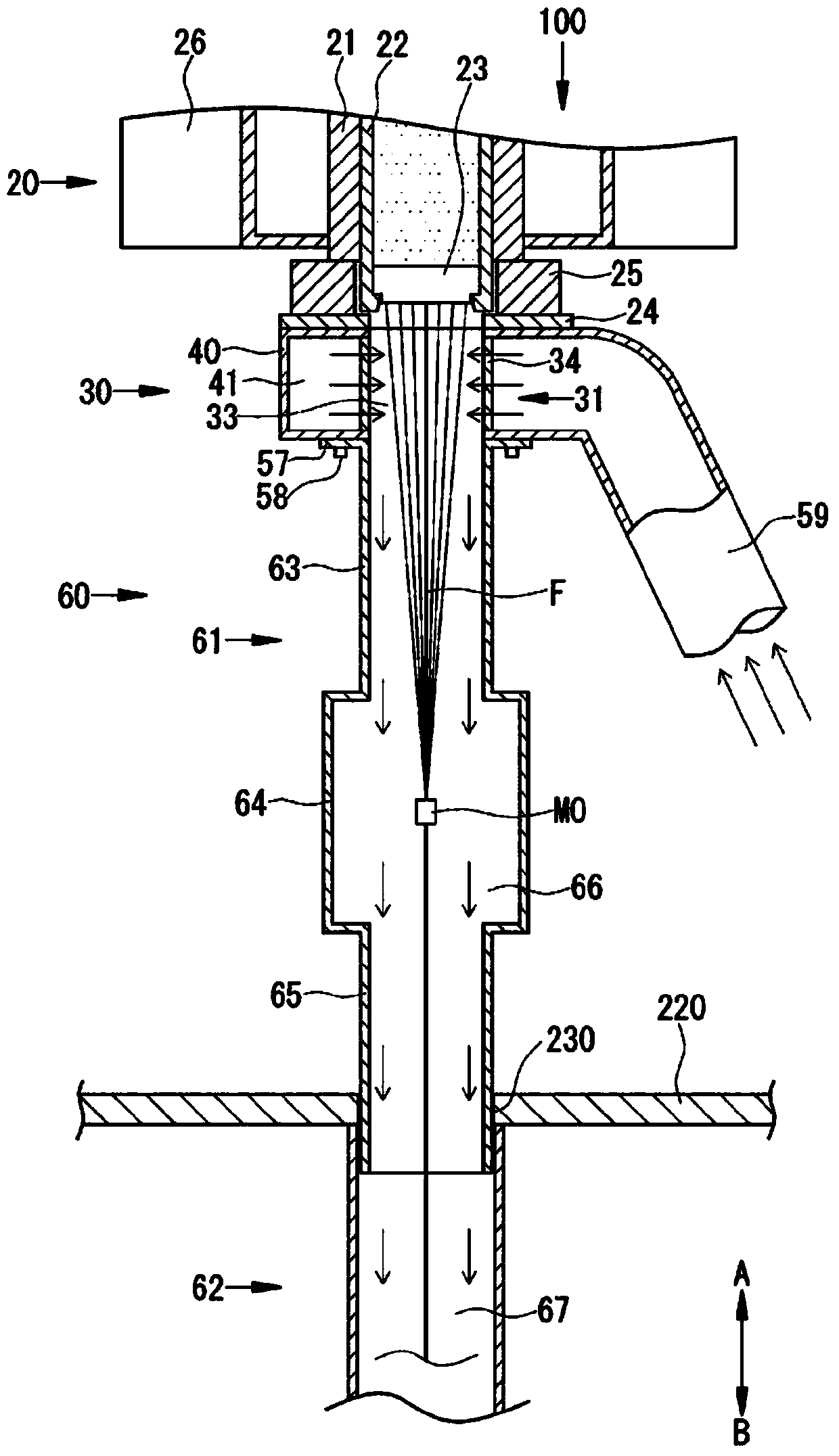

[0033] use Figure 1 to Figure 6 The spinning winding device 100 of the embodiment will be described. In the following description, the upward direction (arrow A) in each drawing is defined as upward, and the downward direction (arrow B) in the figure is defined as downward.

[0034] The spinning winding device 100 of this embodiment produces FDY (drawn yarn). Such as Figure 1 to Figure 3 As shown, the spinning winding device 100 mainly includes a spinning device 20 , a cooling device 30 , a heat preservation device 60 , a heating and stretching device 70 , and a winding device 80 . The spinning winding device 100 is arranged in a factory building, and the factory building has a first floor 210 and a second floor 220 provided above the first floor 210 . The spinning device 20 and the cooling device 30 are installed on the second floor 220 . The heating stretching device 70 and the winding device 80 are installed on the first floor 210 . The thermal insulation device 60 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com