Combined structure of corn husking roller

A combined structure and peeling roller technology, which is applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of low peeling rate, low corn ear damage rate, corn ear damage, etc., to reduce the broken rate of grains and improve Peeling efficiency, the effect of improving the peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

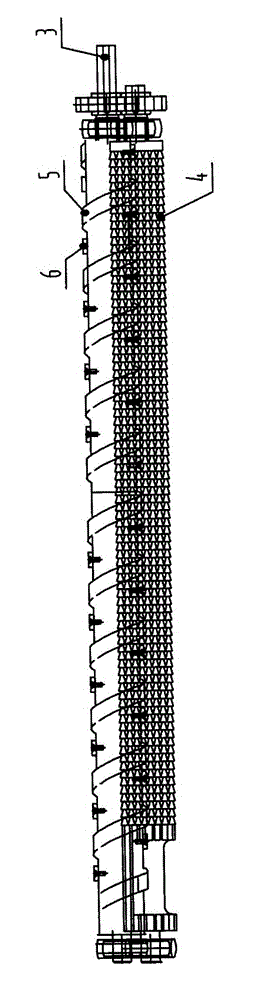

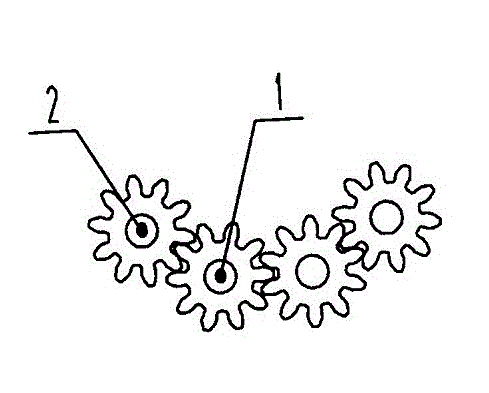

[0021] see figure 1 , figure 2 , among the figures, the combined structure of corn peeling rollers of the present invention includes active peeling rollers 1 and passive peeling rollers 2 arranged in parallel, and the active peeling rollers and passive peeling rollers have two respectively, two active peeling rollers and two passive peeling rollers The rollers are respectively located on the same level, and the two passive peeling rollers are respectively installed at the oblique upper positions on both sides of the two active peeling rollers. The roller body of the roller is a rubber roller body, and the roller body of the passive peeling roller is a composite roller body, and the composite roller body includes an iron roller body section and a rubber roller body section installed on the same mandrel.

[0022] The active peeling roller body is composed of multiple rubber roller bodies installed on the same mandrel, and the surface of each rubber roller body is staggered and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com