Patents

Literature

32results about How to "No entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

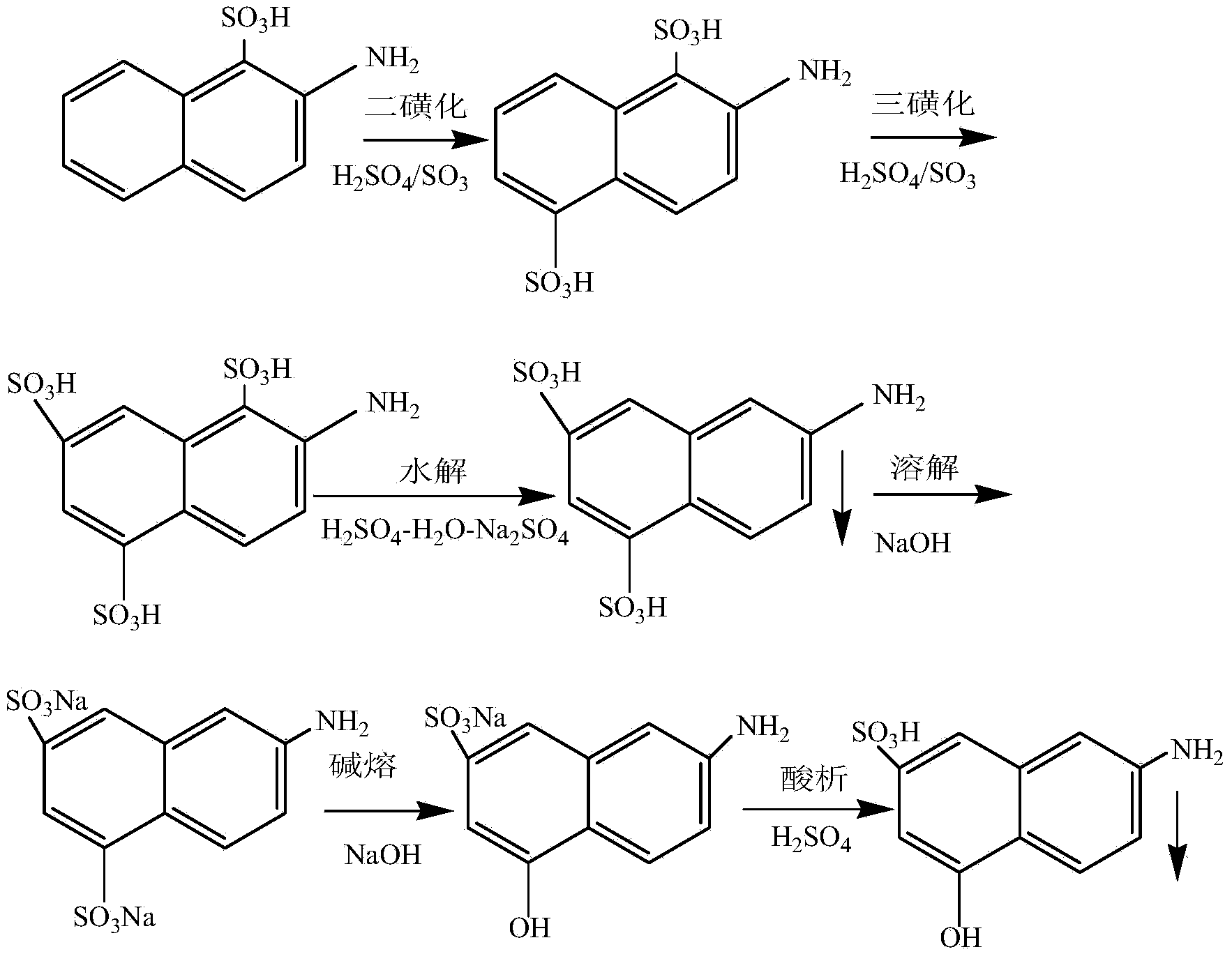

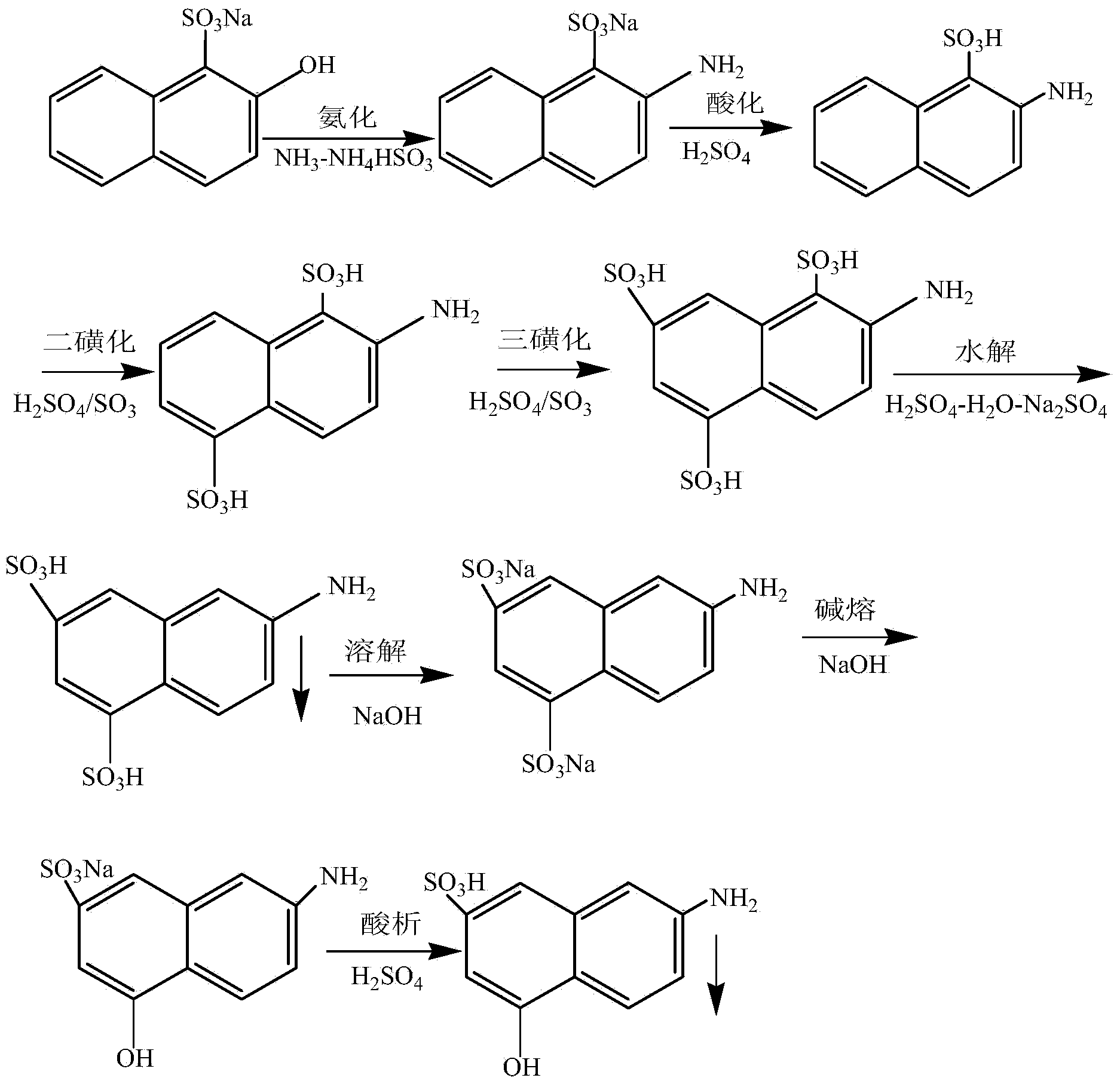

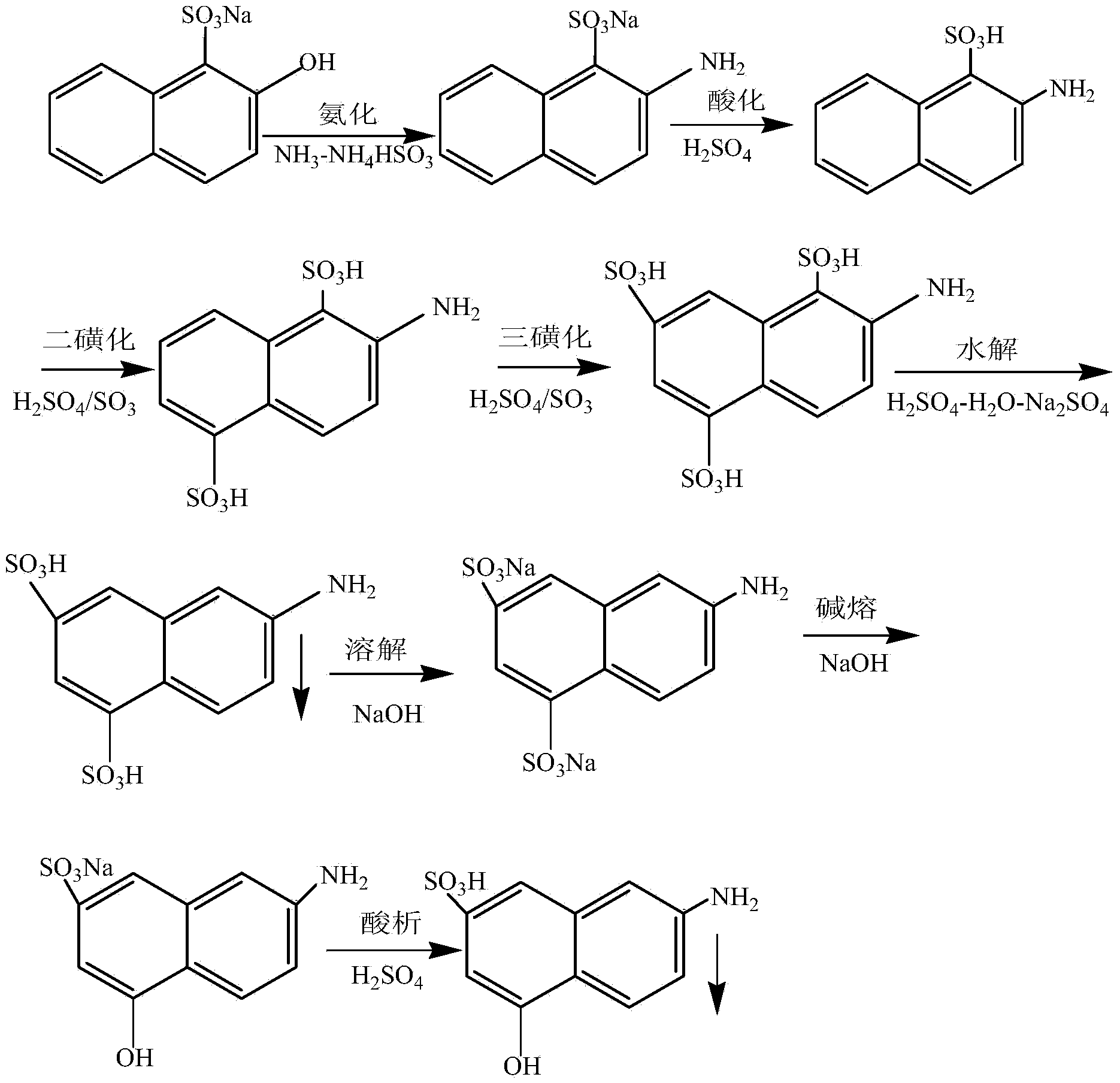

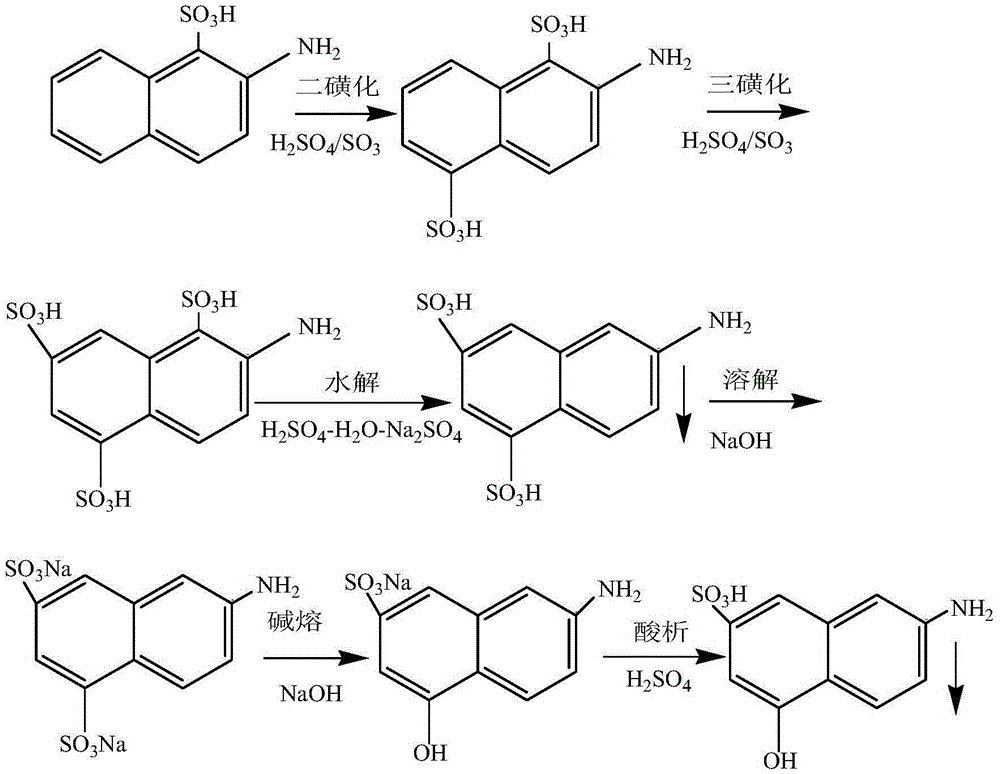

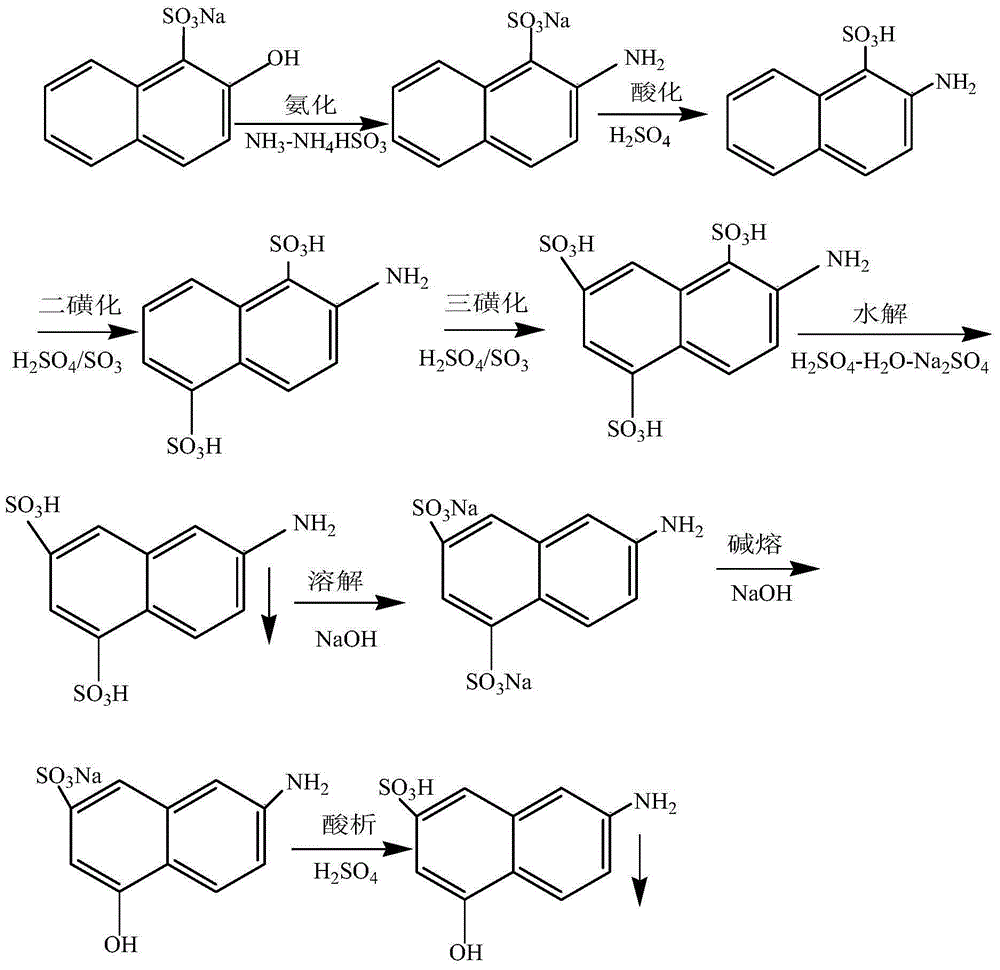

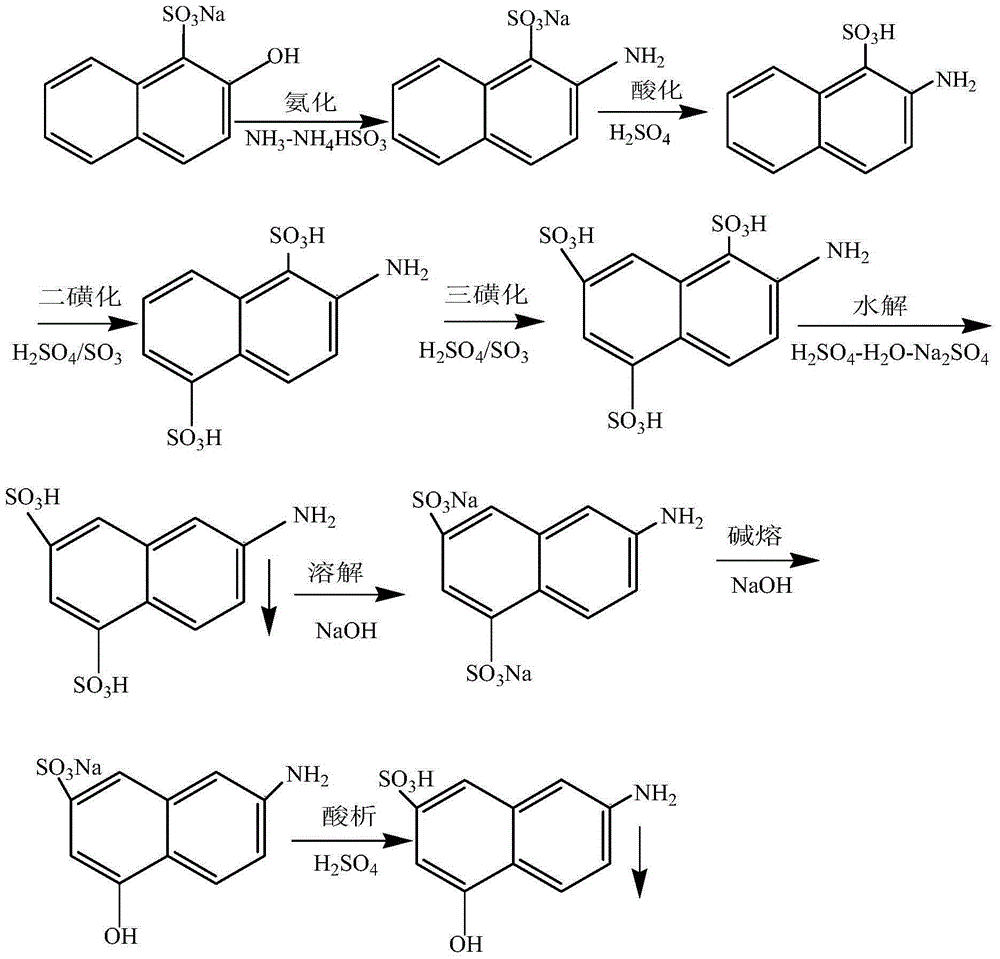

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

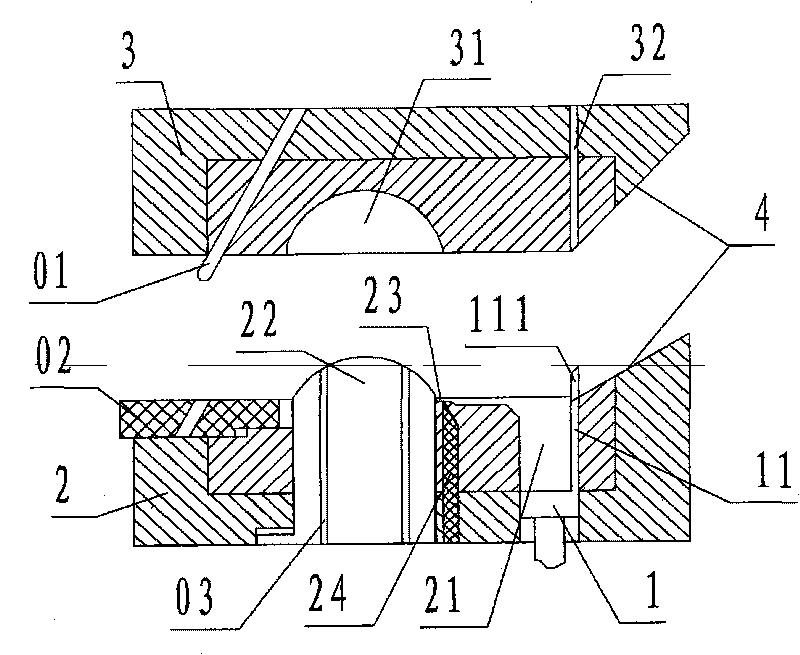

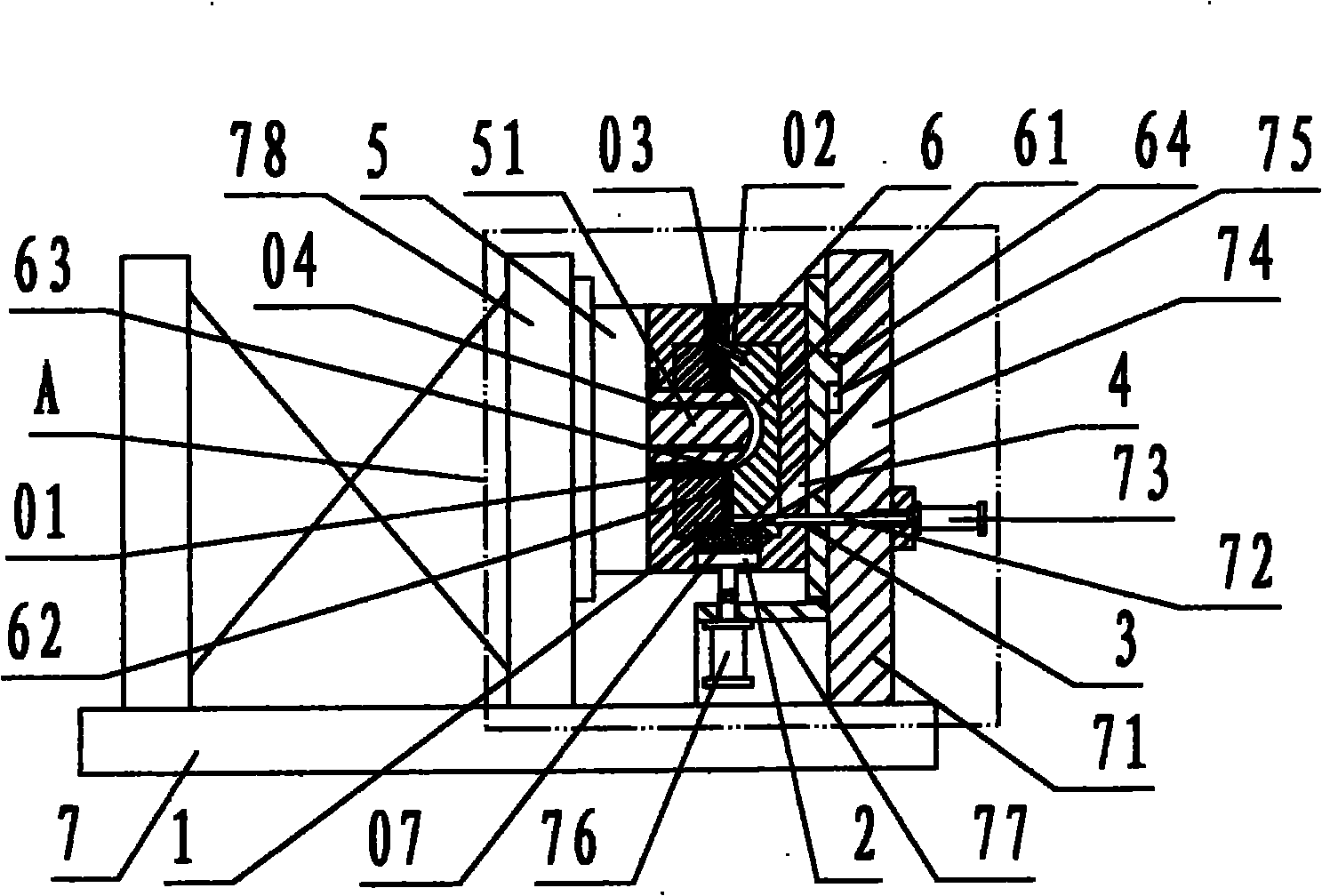

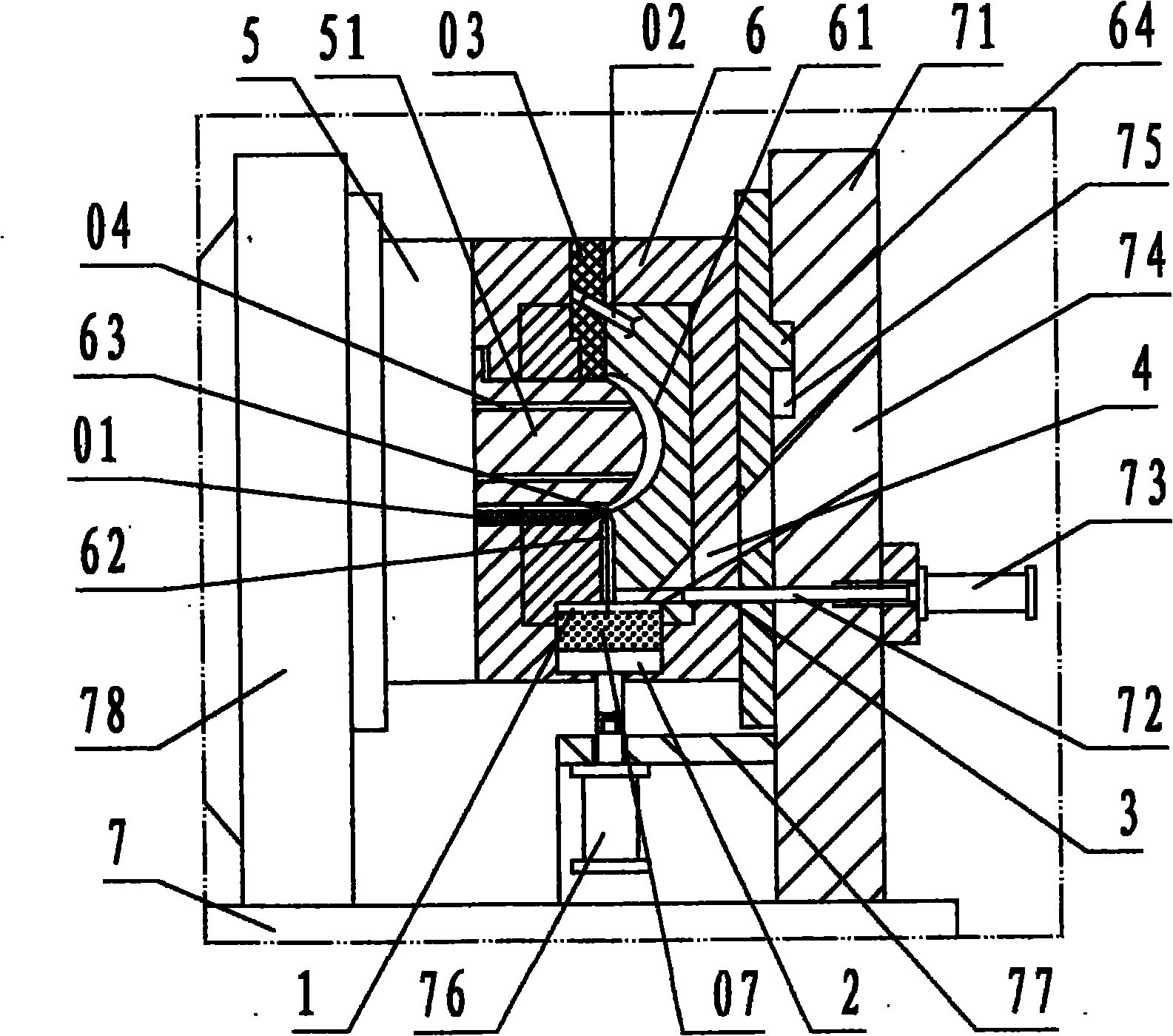

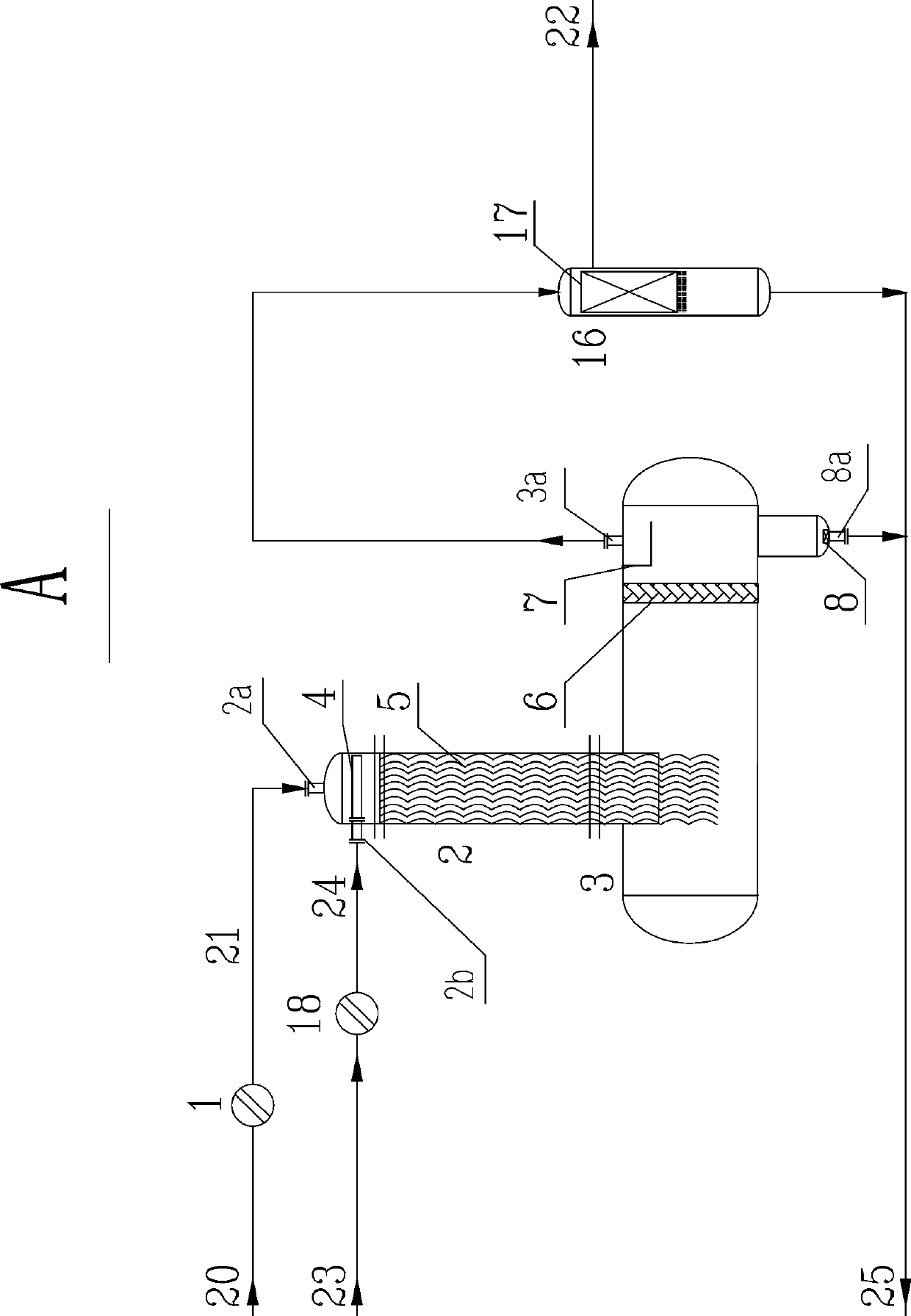

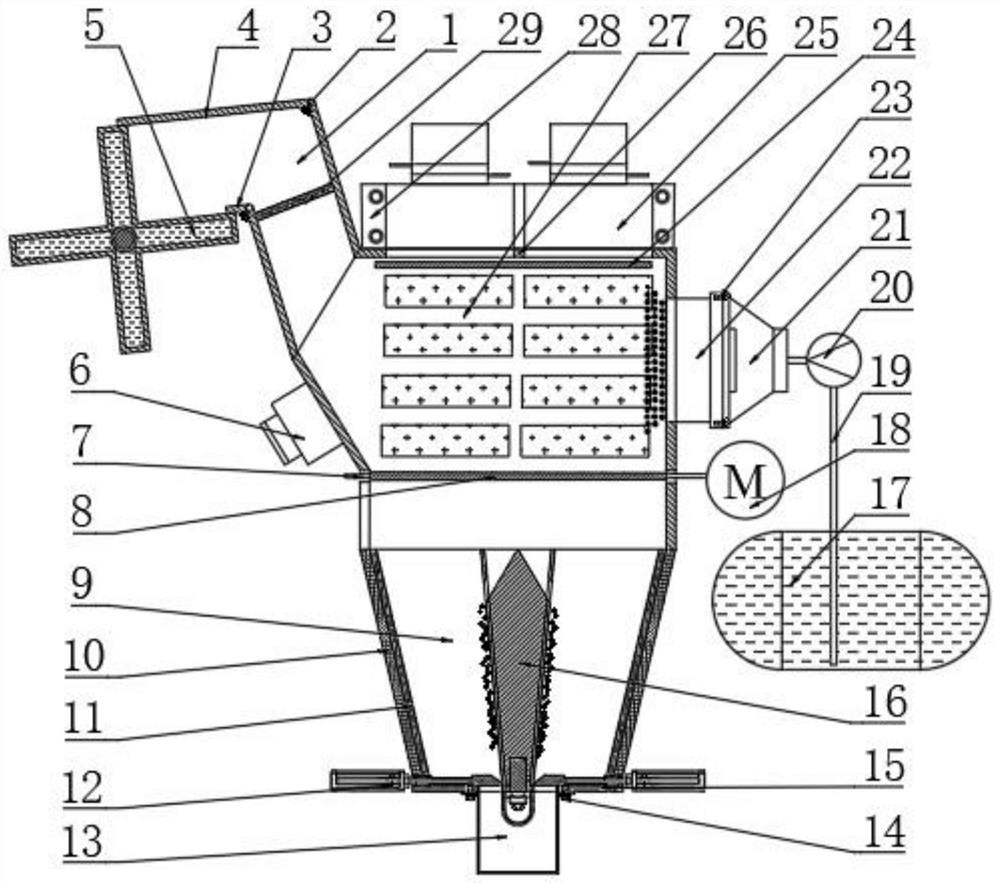

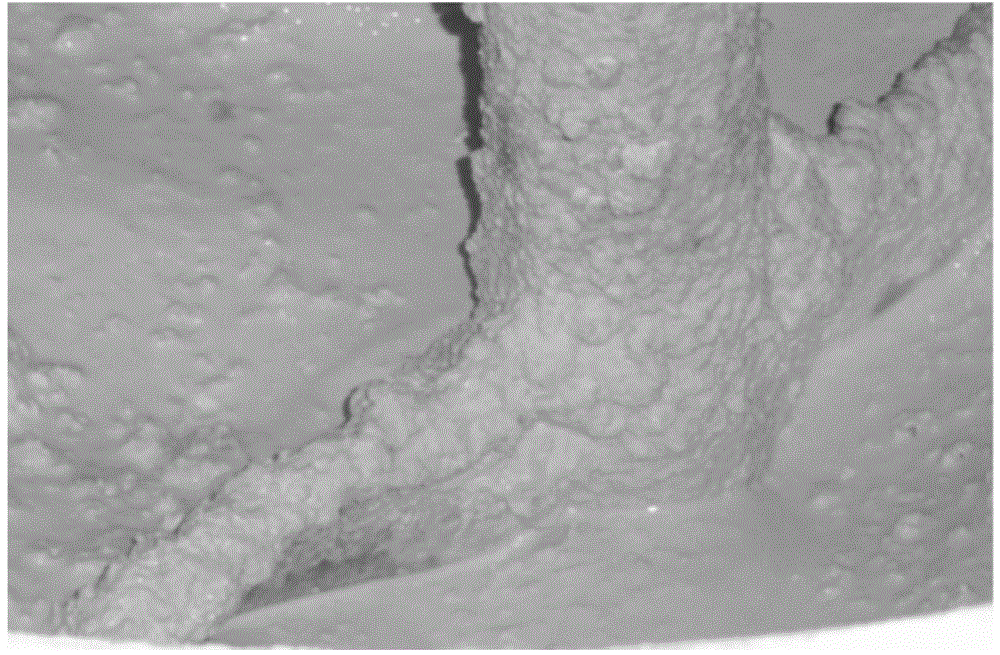

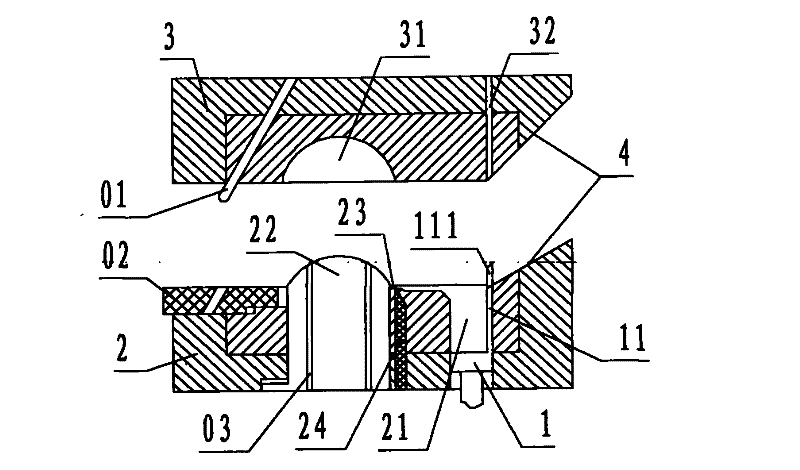

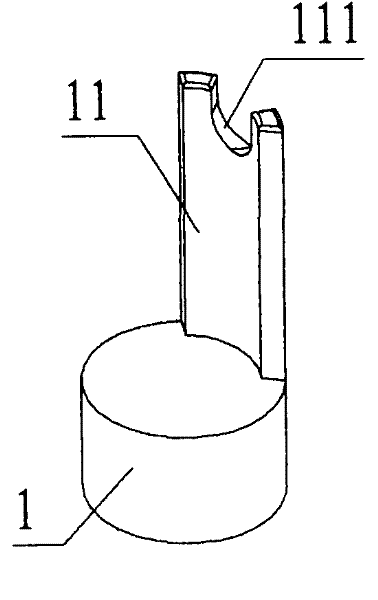

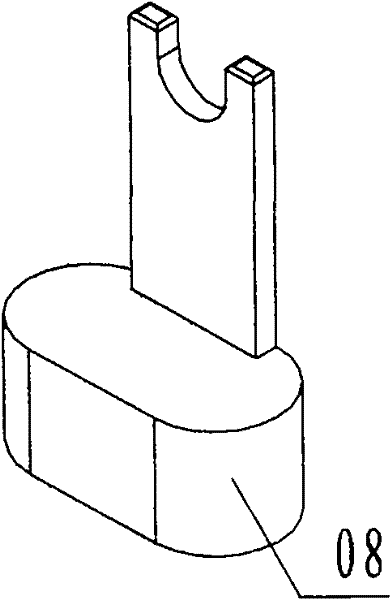

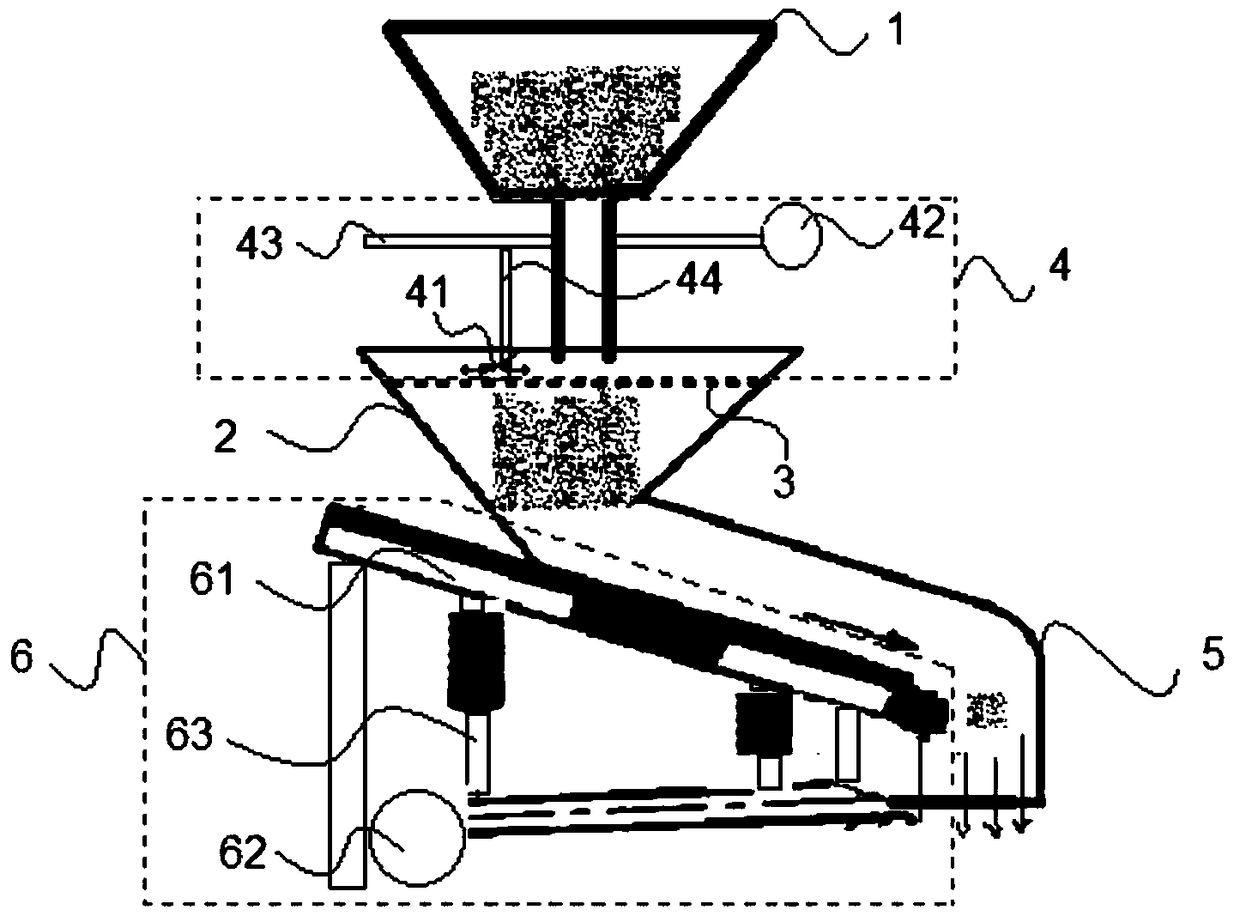

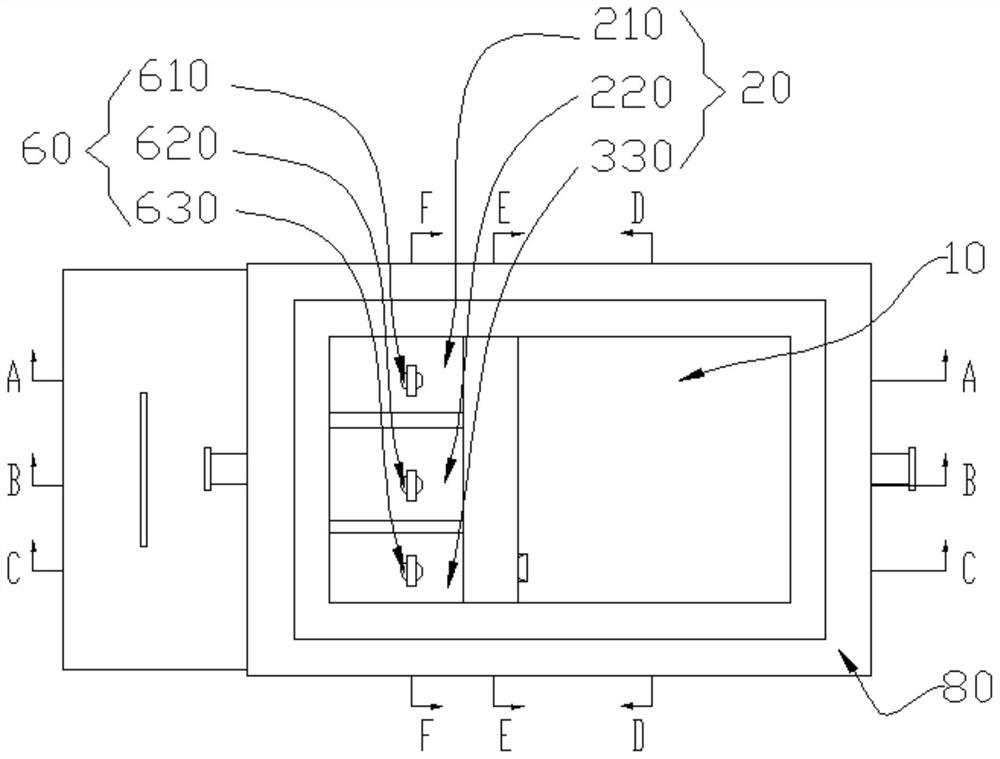

Alloy liquid extrusion casting forming device and process method thereof

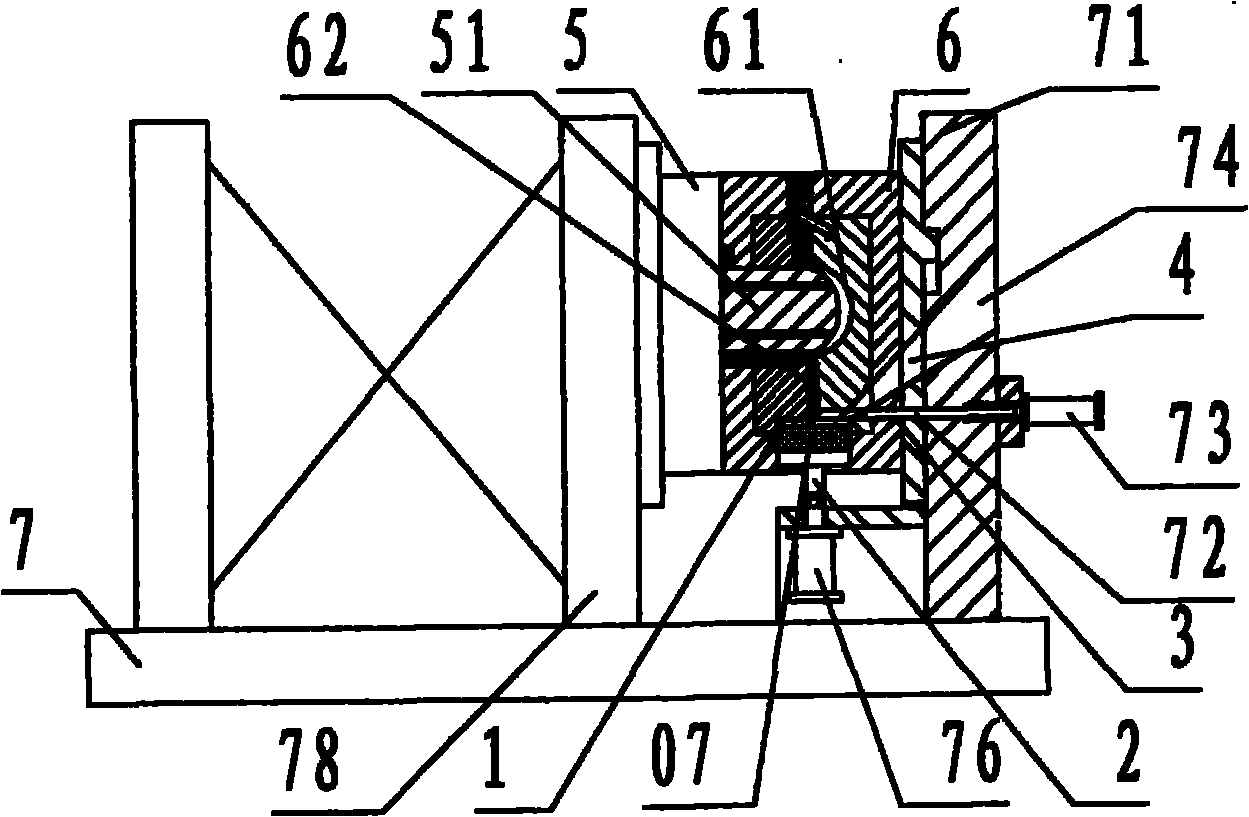

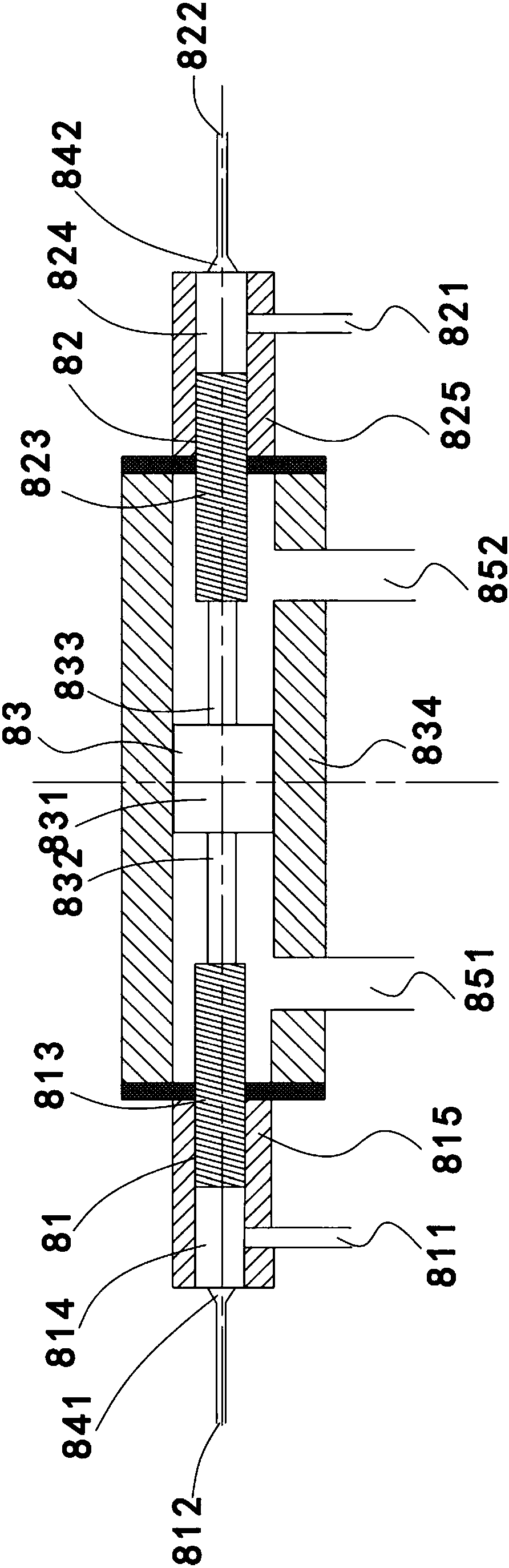

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

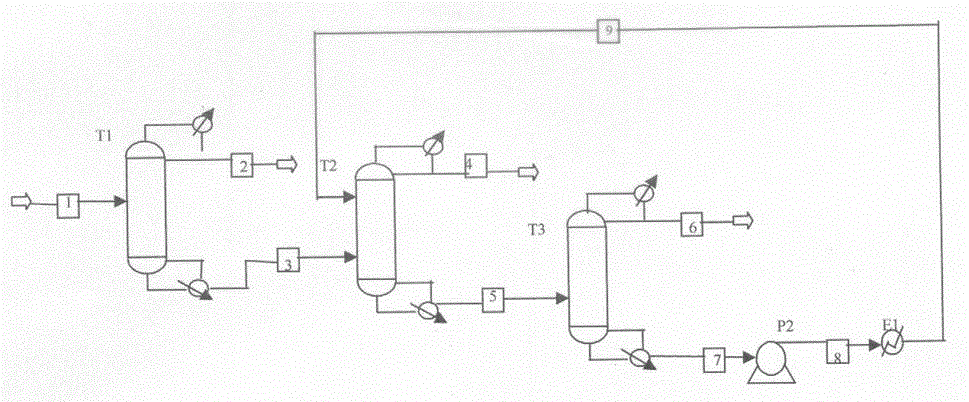

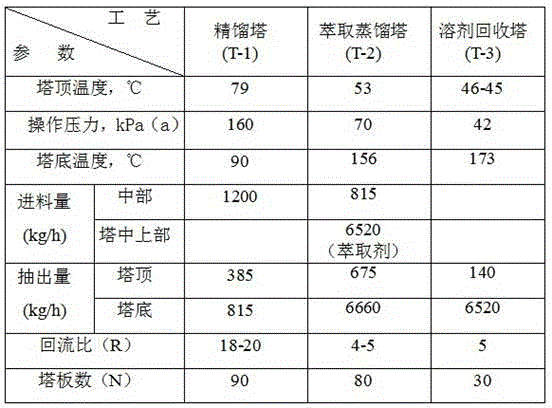

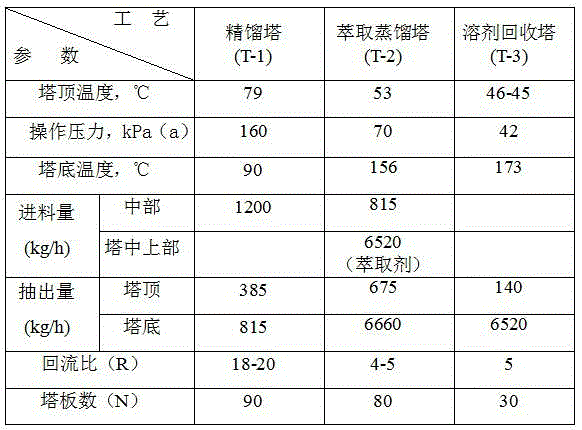

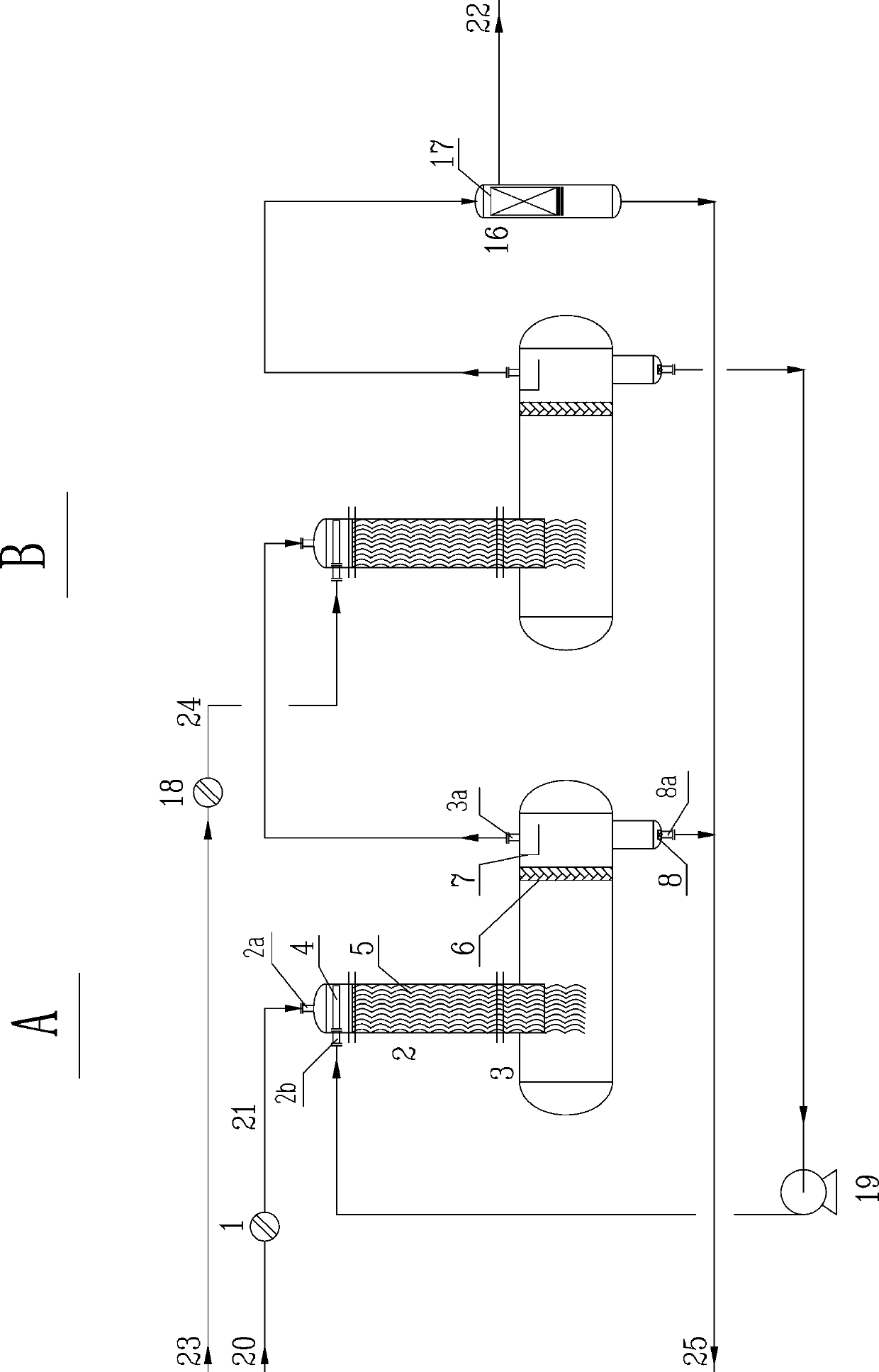

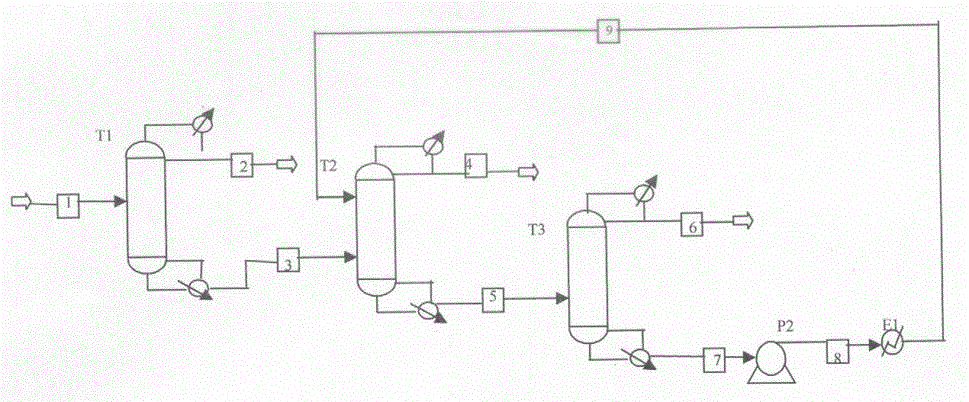

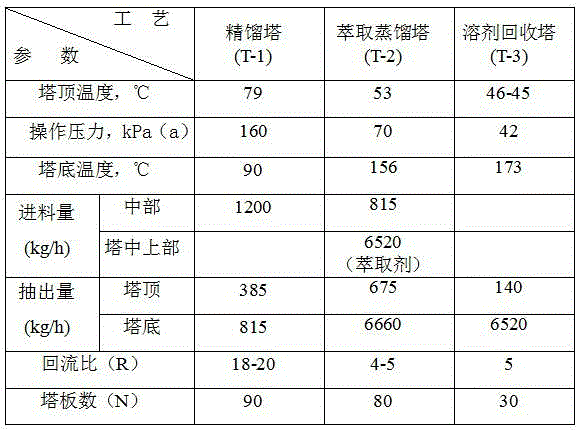

Method extracting high purity n-hexane by integrating rectification and extraction

InactiveCN102942434AWide variety of sourcesImprove thermal stabilityDistillation purification/separationExtractive distillationReactive distillation

The invention relates to a method extracting high purity n-hexane by integrating rectification and extraction. The method utilizes aromatic hydrocarbon raffinate oil as a raw material and adopts a three-tower technological process which combines continuous rectification and extractive distillation. Firstly, distillate lighter than n-hexane is removed in a rectifying tower, and n-hexane distillate which is around 80% in content is obtained at the bottom of the tower. The distillate at the bottom of the tower is adopted as the raw material of an extractive distillation tower, N-methyl pyrrolidone is adopted as an extracting solvent to be delivered into the extractive distillation tower, and the proportion of the N-methyl pyrrolidone and raw oil is 8:1, after extractive distillation, high purity n-hexane is extracted at the top of the tower by integrating rectification and extraction, and heavy components which are rich in methylcyclopentane and the extracting solvent are at the bottom of the tower. Materials at the bottom of the tower are delivered into a solvent recovery tower, distillate oil which is rich in methylcyclopentane is separated at the top of the tower, and N-methyl pyrrolidone solvent is at the bottom of the tower and sent back to the extractive distillation tower to be recycled. By means of the method, n-hexane content can achieve 99%, no extracting solvent is contained in products, solvent consumption is smaller than 0.1%, one-off yield of n-hexane is larger than 95%, and compared with traditional rectification, energy consumption can be saved over 50%.

Owner:广州赫尔普化工有限公司

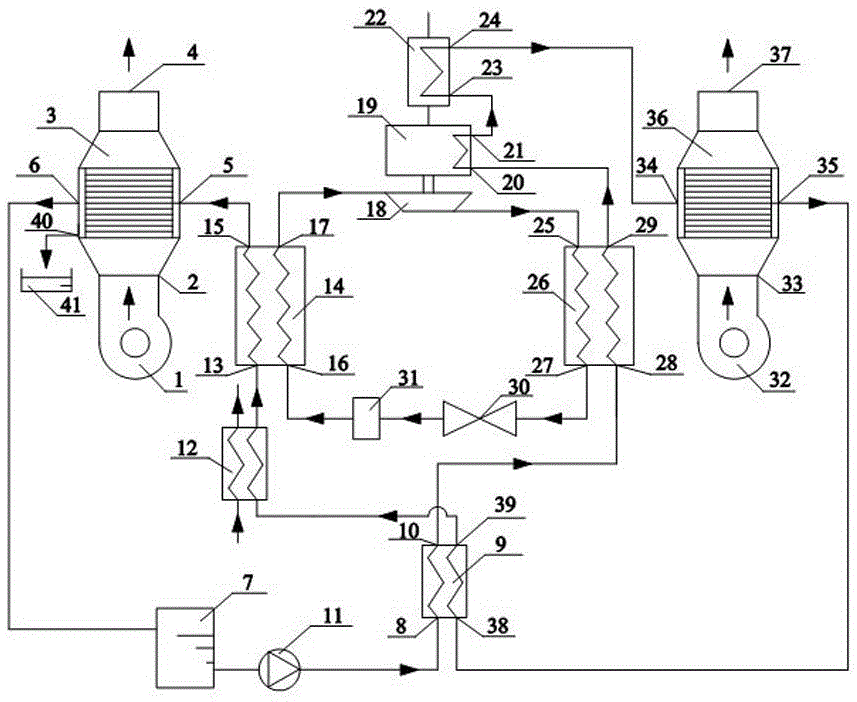

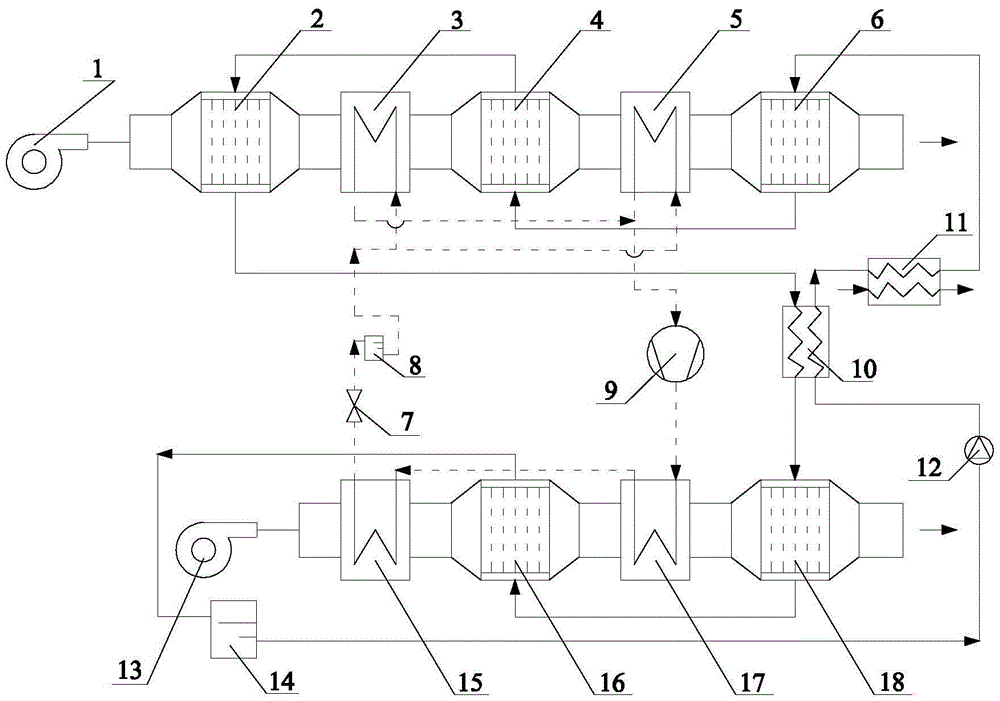

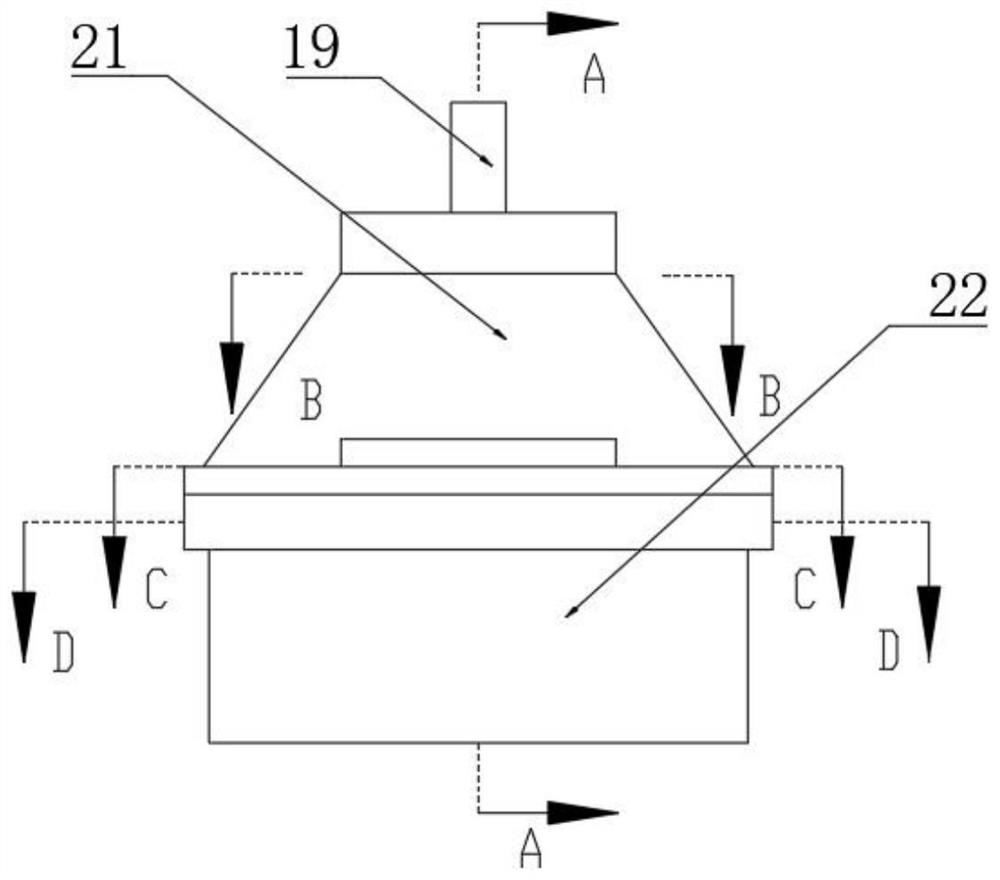

Hollow fiber membrane liquid dehumidifying device driven by gas heat pump

InactiveCN105627464AReduce partial pressureImprove dehumidification effectEnergy industryAir conditioning systemsWater vaporCooling capacity

The invention discloses a hollow fiber membrane liquid dehumidifying device driven by a gas heat pump. The hollow fiber membrane liquid dehumidifying device comprises an air inlet system, an exhaust system, a gas heat pump device, a dehumidifying solution circulating system, a gas engine waste heat recovery device, wherein the air inlet system is used for conveying air into a room, and the exhaust system is used for exhausting the air out of the room. According to the hollow fiber membrane liquid dehumidifying device driven by the gas heat pump, the gas heat pump is adopted for providing the required cooling capacity before air dehumidifying and the required heat before solution regeneration, the steam partial pressure difference between the two sides of a membrane assembly is increased, and good mass transfer efficiency is achieved; at the same time, the gas engine waste heat recovery device and a solution heat-regenerating device are adopted, so that energy consumption is reduced, and the energy utilization rate is increased; the gas heat pump has a good partial load characteristic so that gas combustion season peaks and valleys can be effectively balanced, the peak shaving problem of natural gas reserves is solved, the gas pipe network utilization rate is further increased, and the comprehensive gas supplying cost is further reduced; meanwhile, relieving of the tense power supply situation caused by summer power utilization is facilitated; natural gas is also a clean and efficient energy source, harmful emissions are basically avoided, and it is conducive to environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Alloy liquid extrusion casting and forming device and technical method thereof

Owner:中建投(绍兴)机械科技有限公司

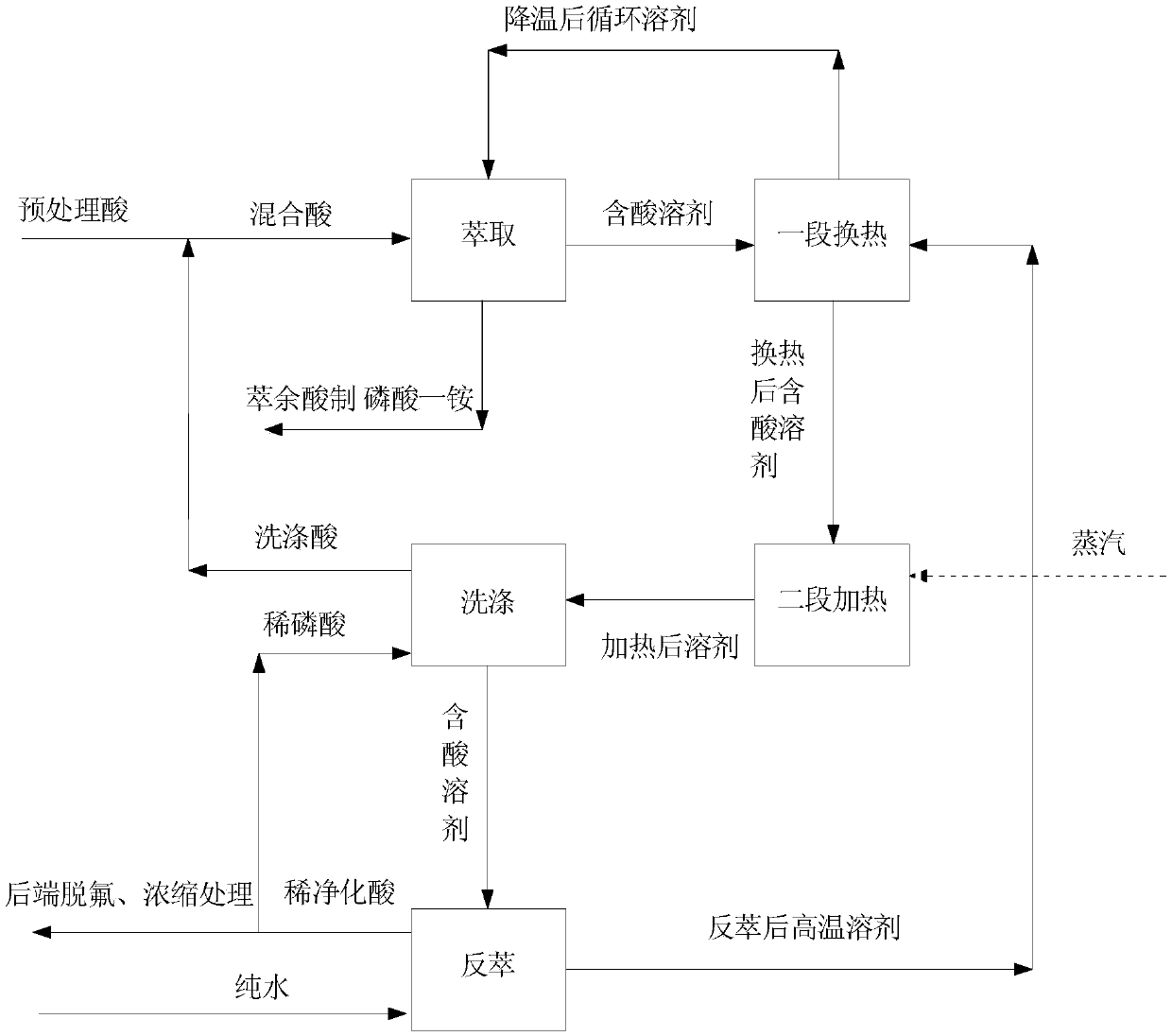

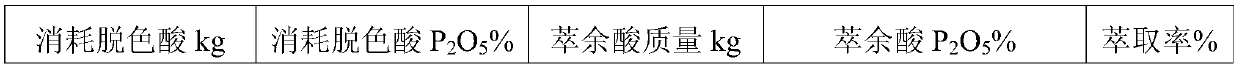

Method for purifying wet-process phosphoric acid by using centrifugal extractor

InactiveCN109650362ALow concentration requirementNo energy consumptionLiquid solutions solvent extractionPhosphorus compoundsPhosphoric acidPhase ratio

The invention discloses a method for purifying wet-process phosphoric acid by using a centrifugal extractor in the technical field of chemical production. The method mainly includes several phases ofpretreatment, extraction, washing, back extraction, desulphurization and condensation; and the main improving point is the extraction, washing and back extraction phases which adopt a centrifugal extractor. The centrifugal extractor can be used as extraction equipment which has low requirement for the phosphoric acid concentration of raw materials, only 30-40% is needed for the content of P2O5, requirements can be met by only performing simple treatment of ordinary semi-aqueous wet-process phosphoric acid without extra energy consumption, but the requirements in the prior art for the phosphoric acid concentration have to be controlled at 40-58%; extra control on the temperature of an extraction section is not needed, normal temperature reaction can be performed, the extraction rate of morethan 75% can be achieved when a phase ratio is 4 : 1, and compared with a rotating disc column, 6-8 : 1 has to be achieved; and through the centrifugal extractor, two phases can be fully mixed undera high-speed condition, so that high extraction efficiency and good split-phase effects can be realized, equivalent phase ratio with the rotating disc column can be achieved, and rapid split-phase andno entrainment can be realized.

Owner:CHANHEN ECO TECH CO LTD

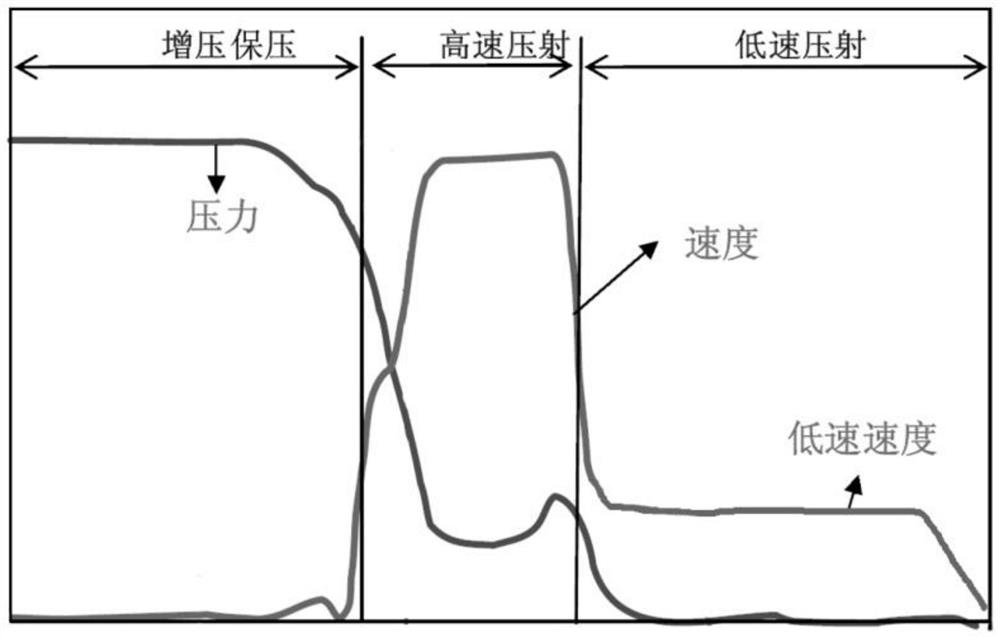

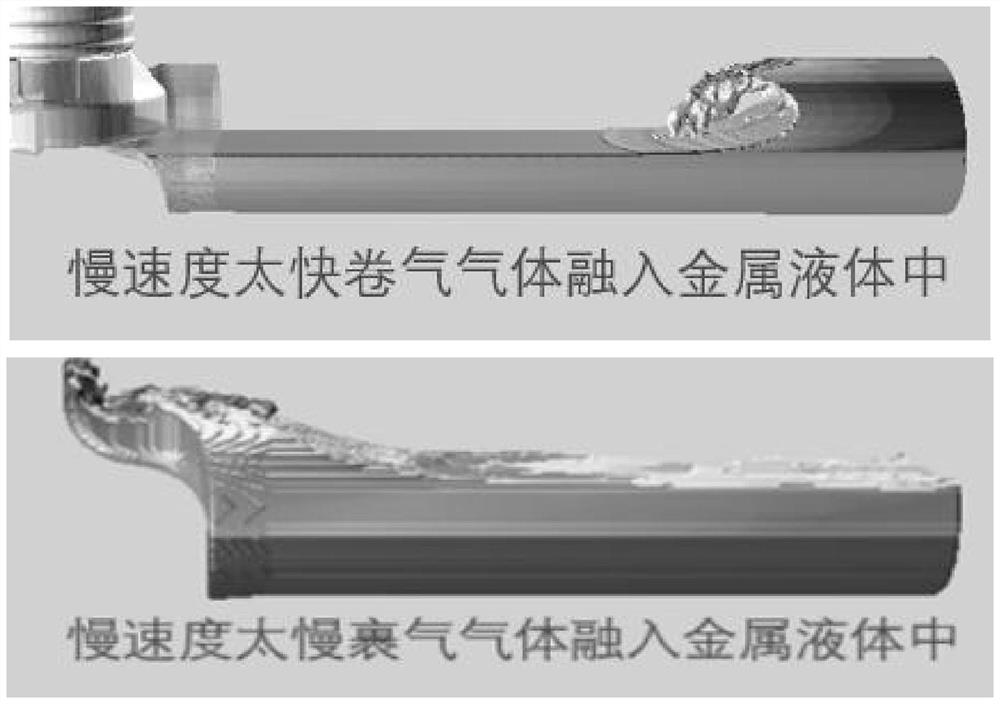

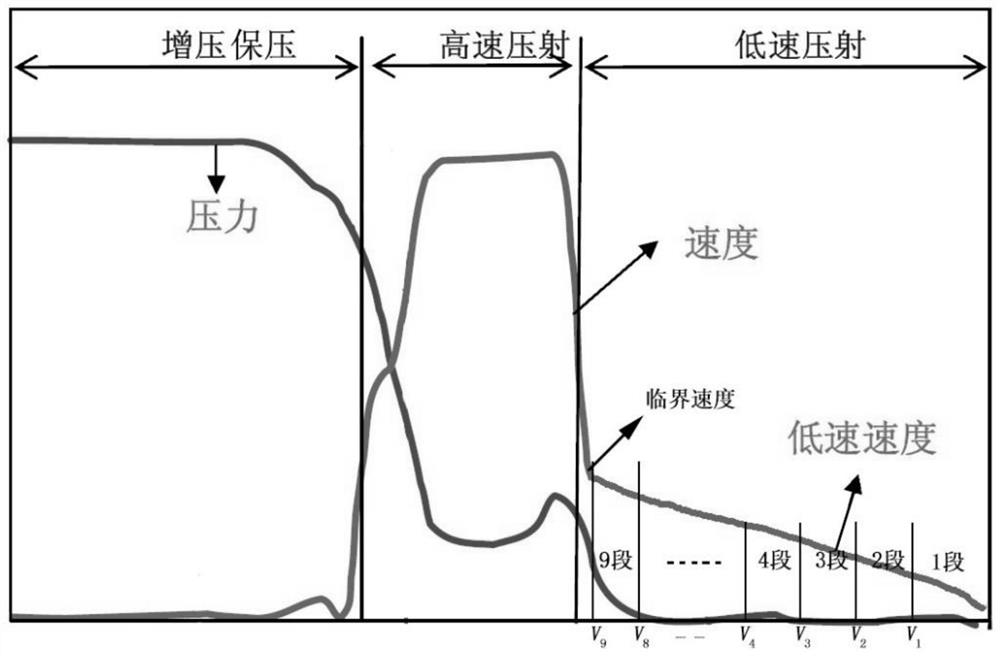

Pressure casting method for multi-section uniform accelerated injection of liquid metal

The invention discloses a pressure casting method for multi-stage uniform accelerated injection of liquid metal, which comprises three stages of low-speed injection, high-speed injection and pressurization and pressure maintaining, and comprises the following step: determining the initial injection speed, critical speed and critical acceleration of the liquid metal according to the parameters of apressure chamber and the fullness of molten metal after the low-speed injection stage and before the high-speed injection stage. A low-speed injection stage is divided into 3-9 acceleration stages, an injection punch performs uniform acceleration advancing according to the speeds of the 3-9 acceleration stages to reach the critical speed, so that liquid metal is prevented from splashing out of asprue gate to seal the sprue gate of a chamber, and thus, stable laminar flow motion of molten metal in the pressure chamber is achieved, turbulence and vortexes are avoided, air in the pressure chamber can be exhausted through a pouring gate system and a die; and the whole pressure chamber is filled with molten metal, so that the phenomena of air entrapment and oxide inclusion are avoided, air holes and oxide inclusion of castings are reduced, and the performance of the castings is improved.

Owner:厦门格耐尔科技有限公司

A fiber liquid film contactor amine washing desulphurization device and an amine washing desulphurization method

InactiveCN105505464AReduce hydrogen sulfide contentNo entrainmentGas treatmentDispersed particle separationFiberEngineering

The invention discloses a fiber liquid film contactor amine washing desulphurization device. The device comprises a first fiber liquid film mass-transfer contactor subassembly. The first fiber liquid film mass-transfer contactor subassembly comprises a fiber liquid film contactor, a settlement separating tank and a stream dividing pack. The vertical fiber liquid film contactor is mounted on one end of the horizontally disposed settlement separating tank through a flange. The device is advantageous in that when the hydrogen sulfide content of liquefied gas produced by an oil refinery is lower than 5000 mg / m3, the hydrogen sulfide content of the liquefied gas hydrogen sulfide in which is removed can be ensured to be lower than 1 mg / m3 by adopting amine washing with a primary fiber liquid film contactor and amine removing with a coalescer, and the liquefied gas after removal is free of entrainment of free amine liquids.

Owner:NINGBO ZHANGFU ENERGY TECH CO LTD

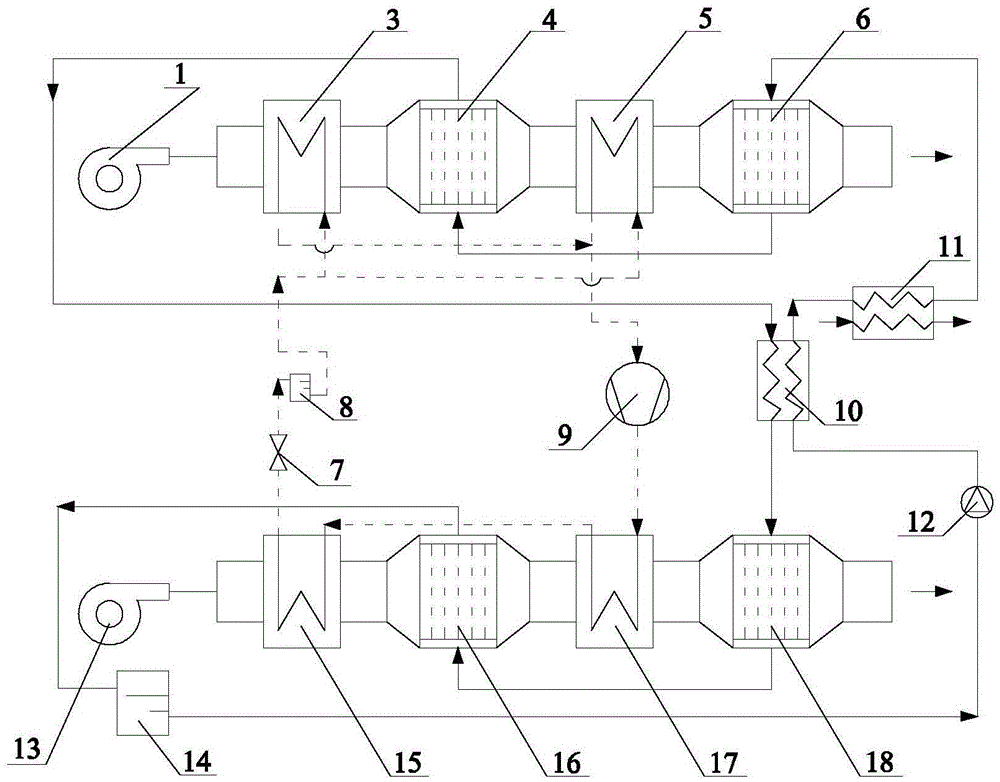

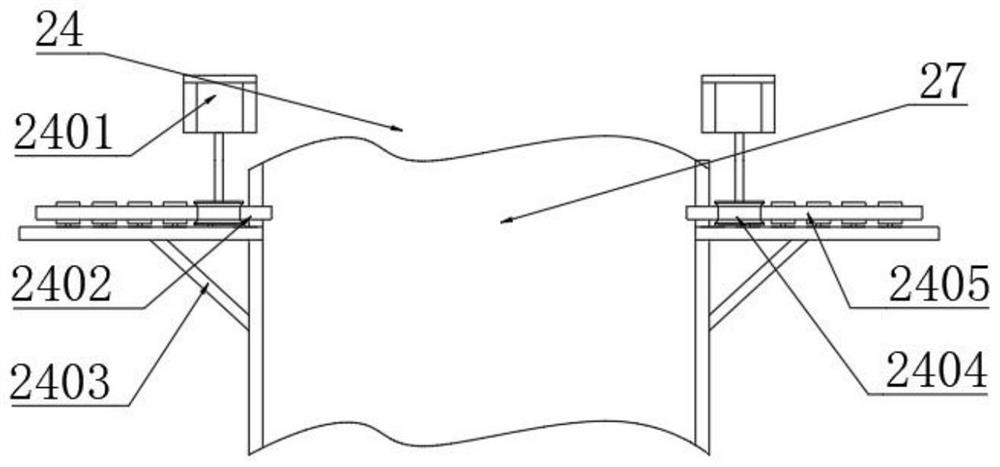

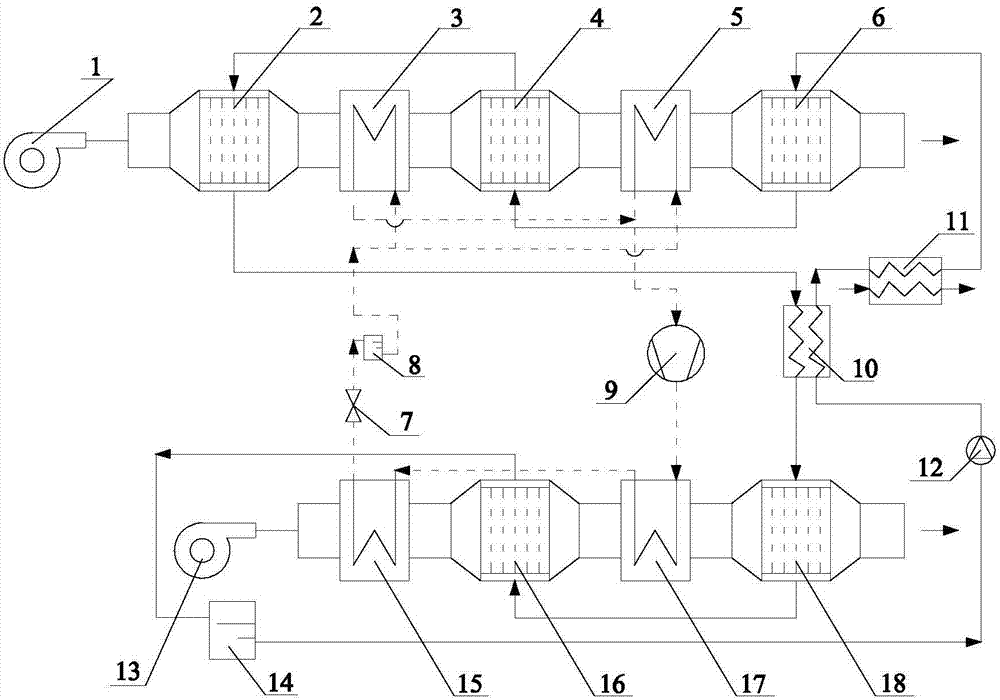

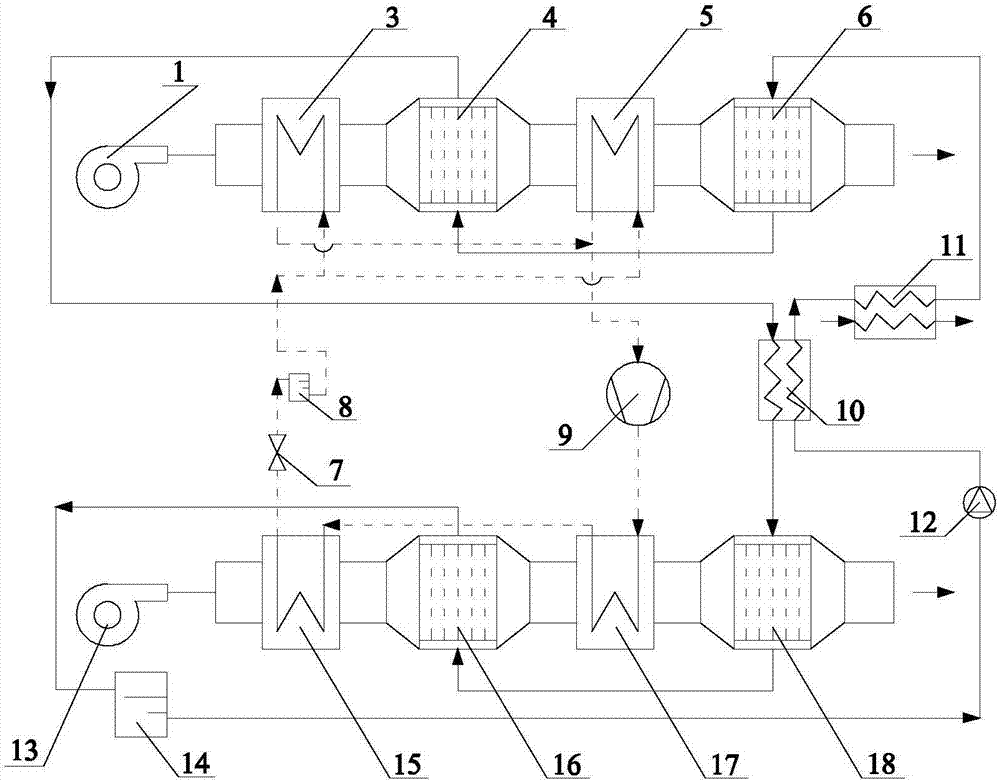

Multistage hollow fiber membrane liquid dehumidifying device applicable to hot and humid area

ActiveCN105571020ANo entrainmentAvoid pollutionLighting and heating apparatusAir conditioning systemsInlet channelEngineering

The invention discloses a multistage hollow fiber membrane liquid dehumidifying device applicable to a hot and humid area. The multistage hollow fiber membrane liquid dehumidifying device comprises an air inlet system used for conveying air into a room, an exhaust system used for exhausting the air out of the room, a heat pump system and a dehumidifying solution circulation system. The air inlet system comprises an air inlet channel, a fresh air fan and a plurality of hollow fiber membrane dehumidifying assemblies, wherein the fresh air fan and the hollow fiber membrane dehumidifying assemblies are sequentially arranged on the air inlet channel in the air intake direction. The exhaust system comprises an exhaust channel, an exhaust fan and a plurality of hollow fiber membrane regeneration assemblies, wherein the exhaust fan and the hollow fiber membrane regeneration assemblies are sequentially arranged on the exhaust channel in the air exhausting direction. The heat pump assembly comprises a compressor, an expansion valve, a refrigerant storage tank, a plurality of evaporators and a plurality of condensers. The multistage hollow fiber membrane liquid dehumidifying device avoids the gas and liquid entrainment phenomenon, has good mass transfer efficiency, solves the problem of corrosion of a dehumidifying saline solution to a metal heat exchanger by an existing method, reduces bacterium breeding, lowers the regeneration temperature of the solution and increases the energy utilization rate of a system.

Owner:SOUTH CHINA UNIV OF TECH

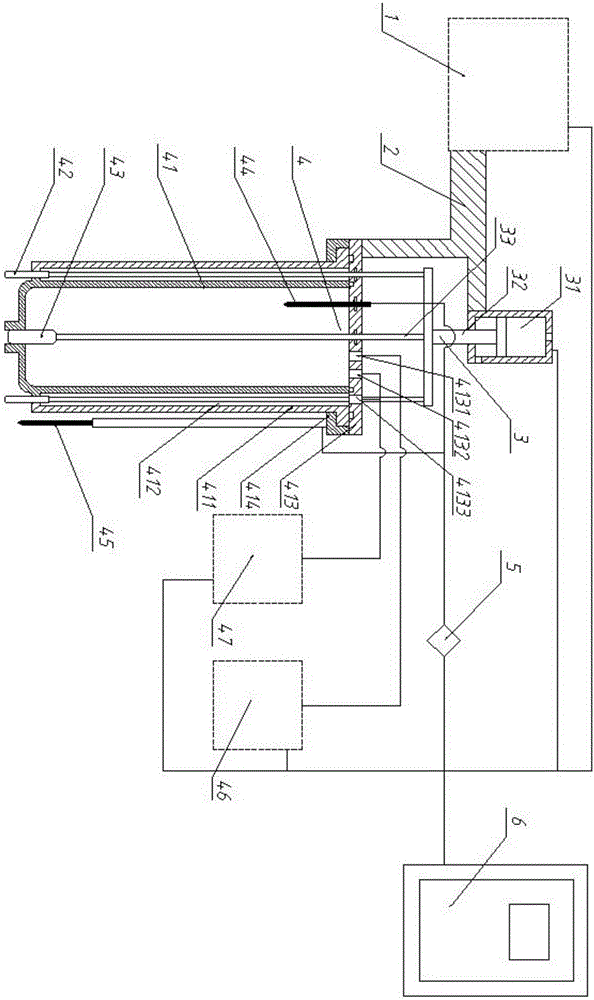

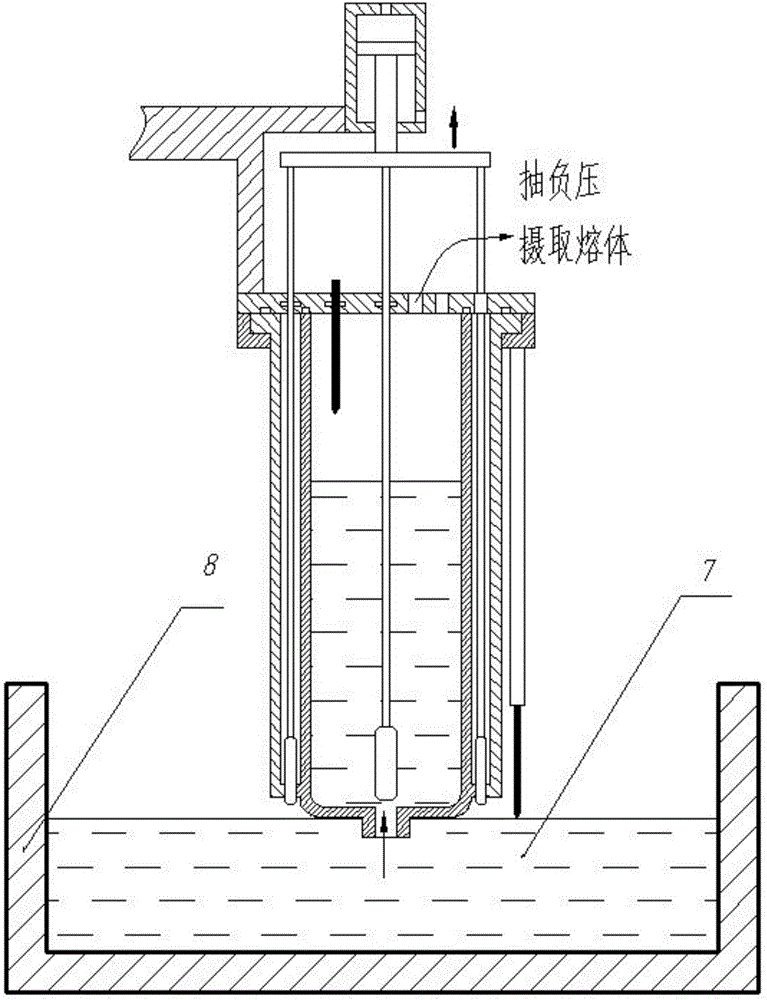

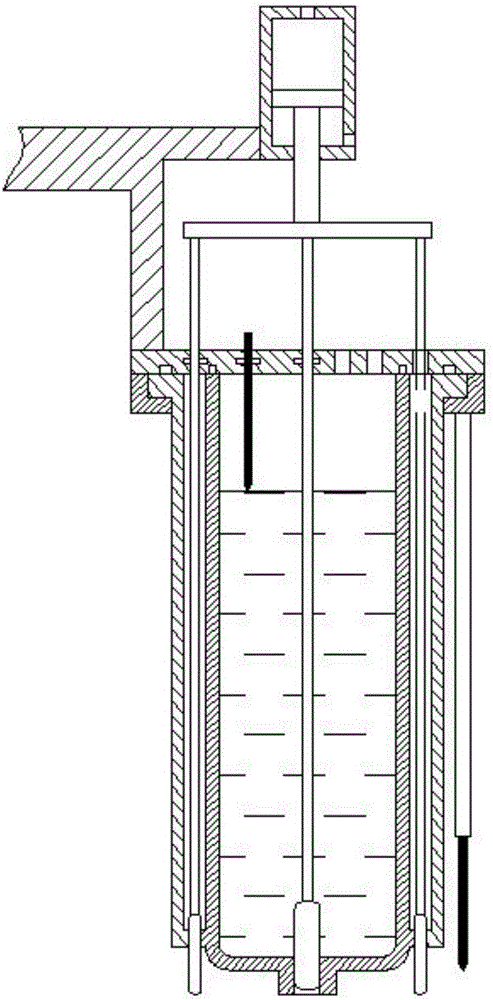

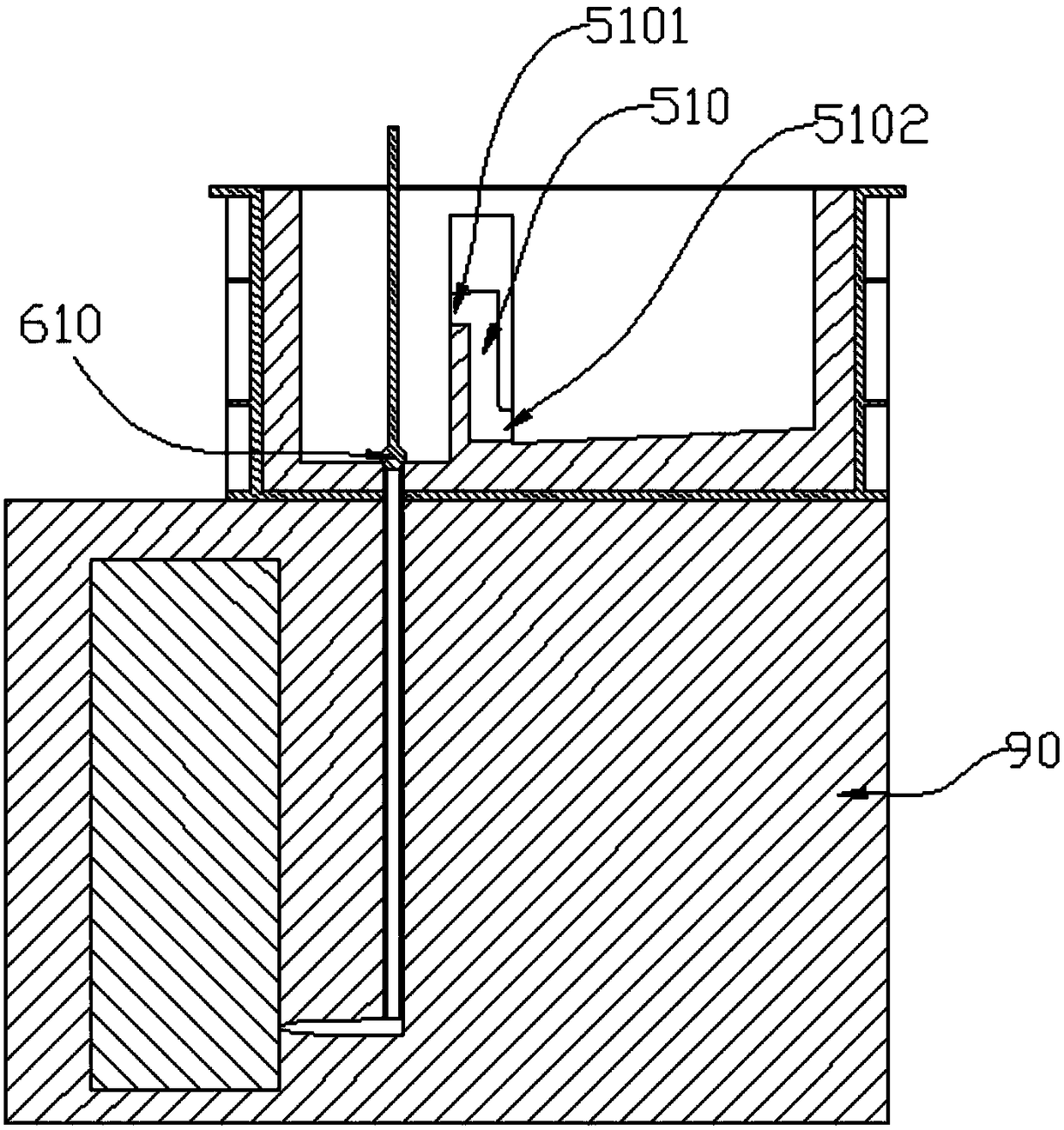

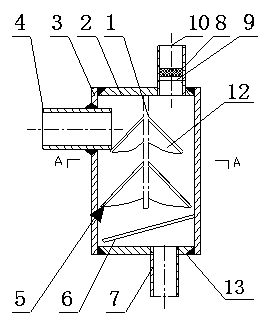

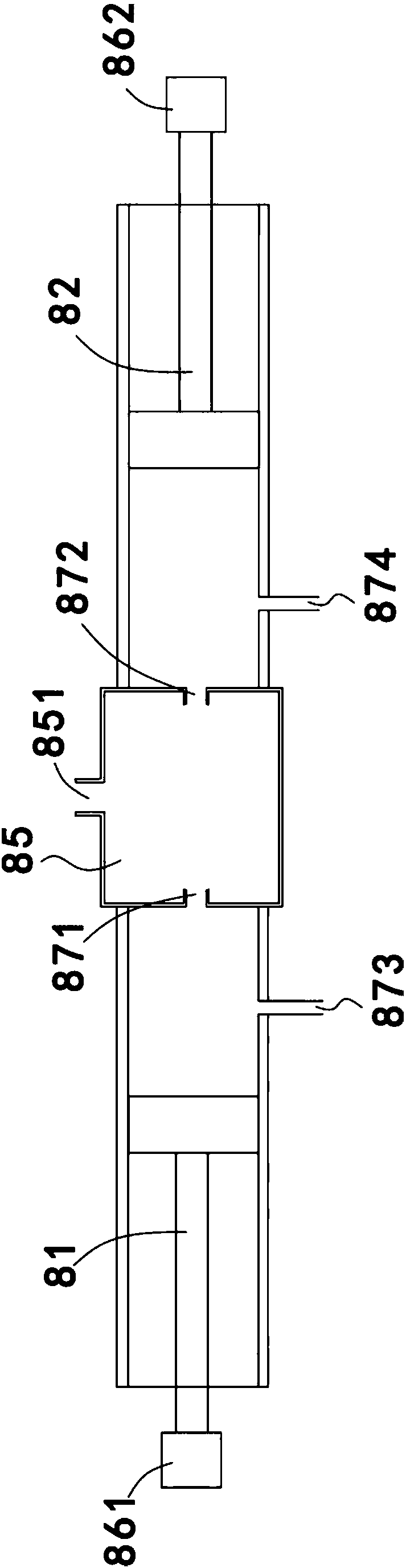

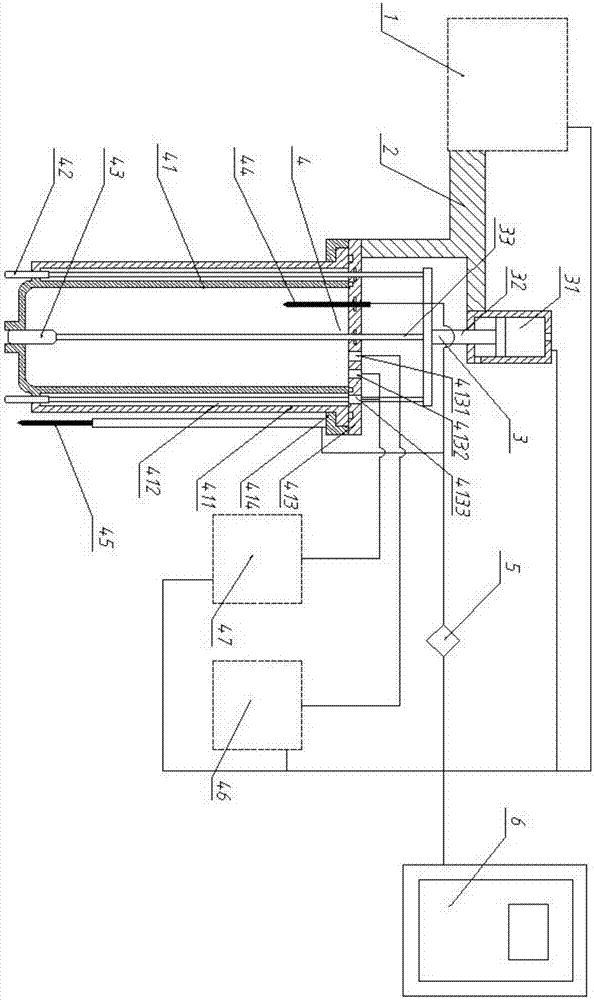

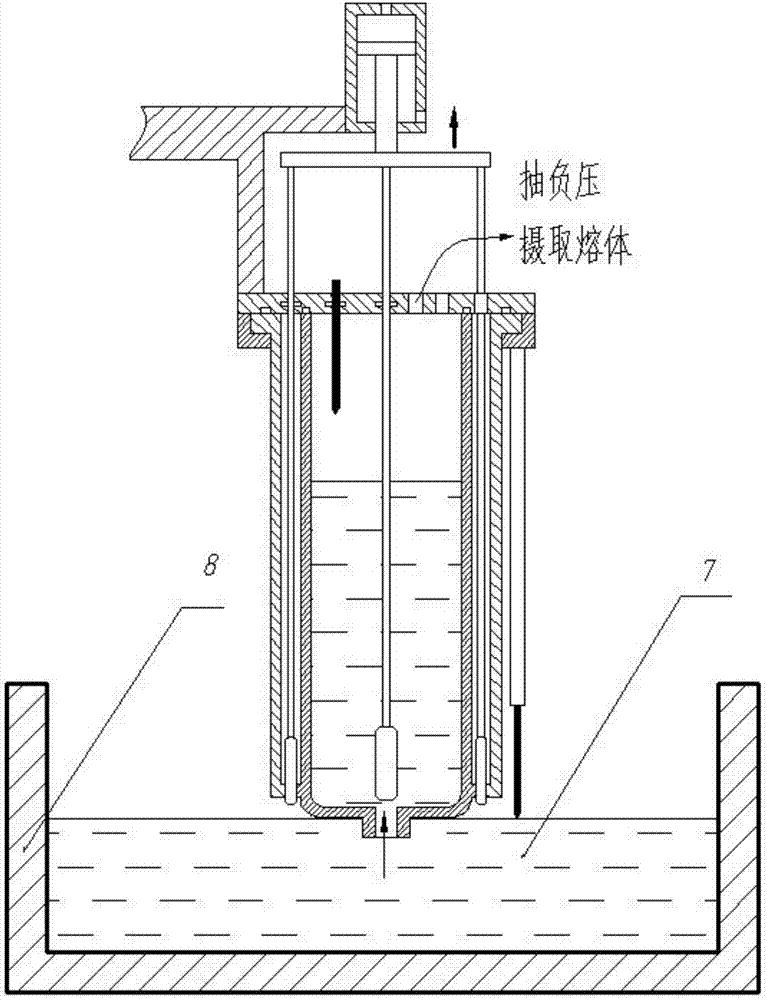

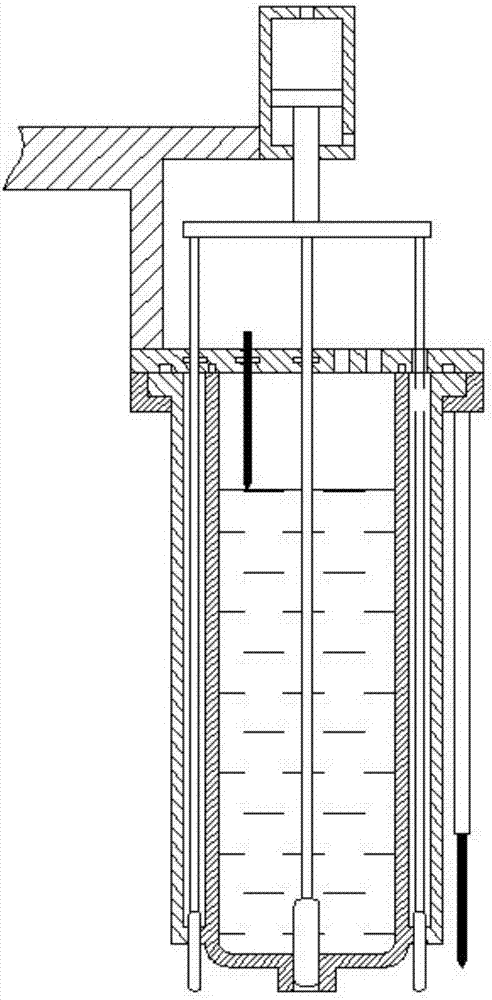

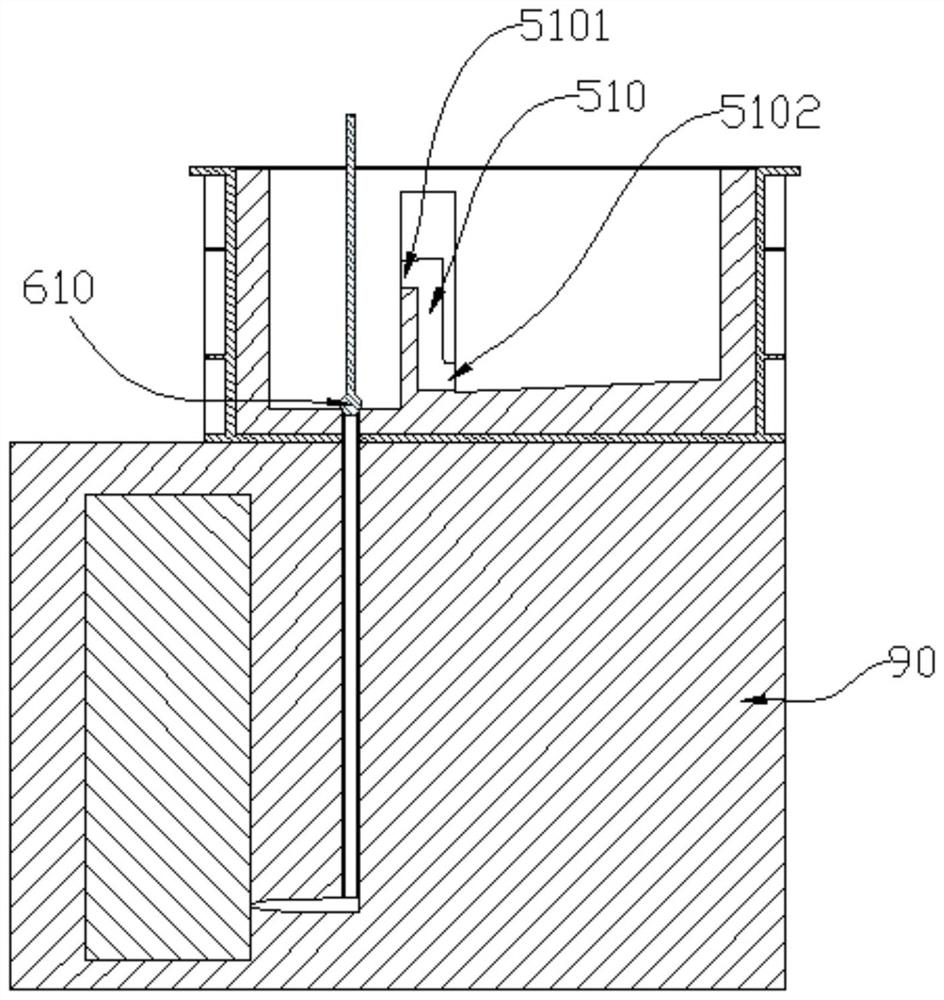

Equipment and method capable of achieving vacuum quantitative casting of molten metal

ActiveCN106670441AReduce oxidationReduce hydrogen absorptionMolten metal supplying equipmentsControl systemHydrogen absorption

The invention discloses equipment capable of achieving vacuum quantitative casting of molten metal. The equipment comprises a mechanical device, a vacuum quantitative casting device, an opening and closing device and a control system; the vacuum quantitative casting comprises a seal container with internal space, a gas filling mechanism, a vacuum mechanism and an exhaust opening; the exhaust opening comprises a liquid draining opening allowing molten metal to be drained, a pipeline allowing gas to pass through is further arranged in the internal space, and passes through the liquid draining opening, the pipeline is provided with a gas exhaust opening allowing gas not in contact with the molten metal to be exhausted, the opening and closing device achieves independent control over the liquid draining opening and the gas exhaust oponeing, that is, the opening and closing device can independently control opening and closing of the liquid draining opening and the gas exhaust opening, it is ensured that during casing of the molten metal, the oxidation and hydrogen absorption of the molten metal can be reduced, gas holes and oxide inclusion of a casting are reduced, and the casting quality is improved.

Owner:北京航大新材科技有限公司

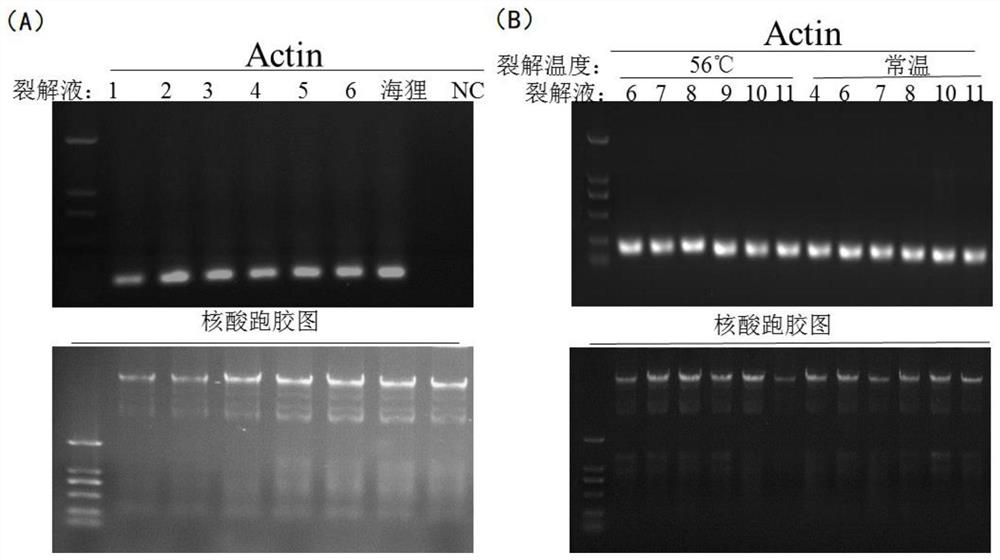

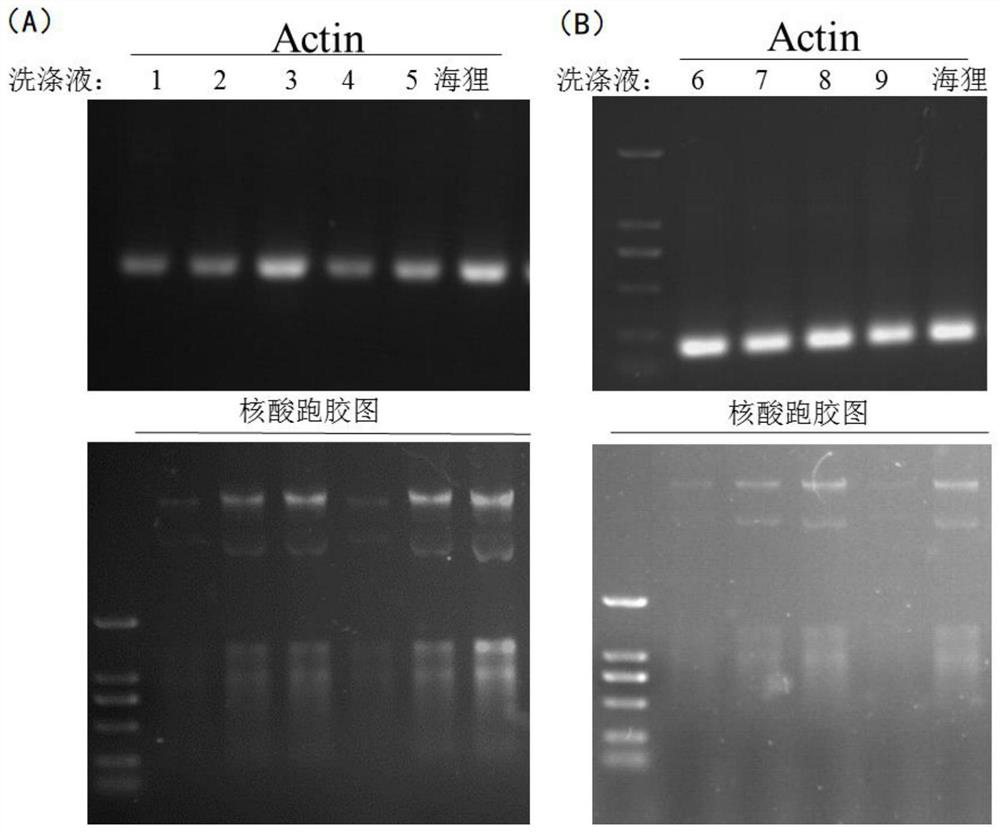

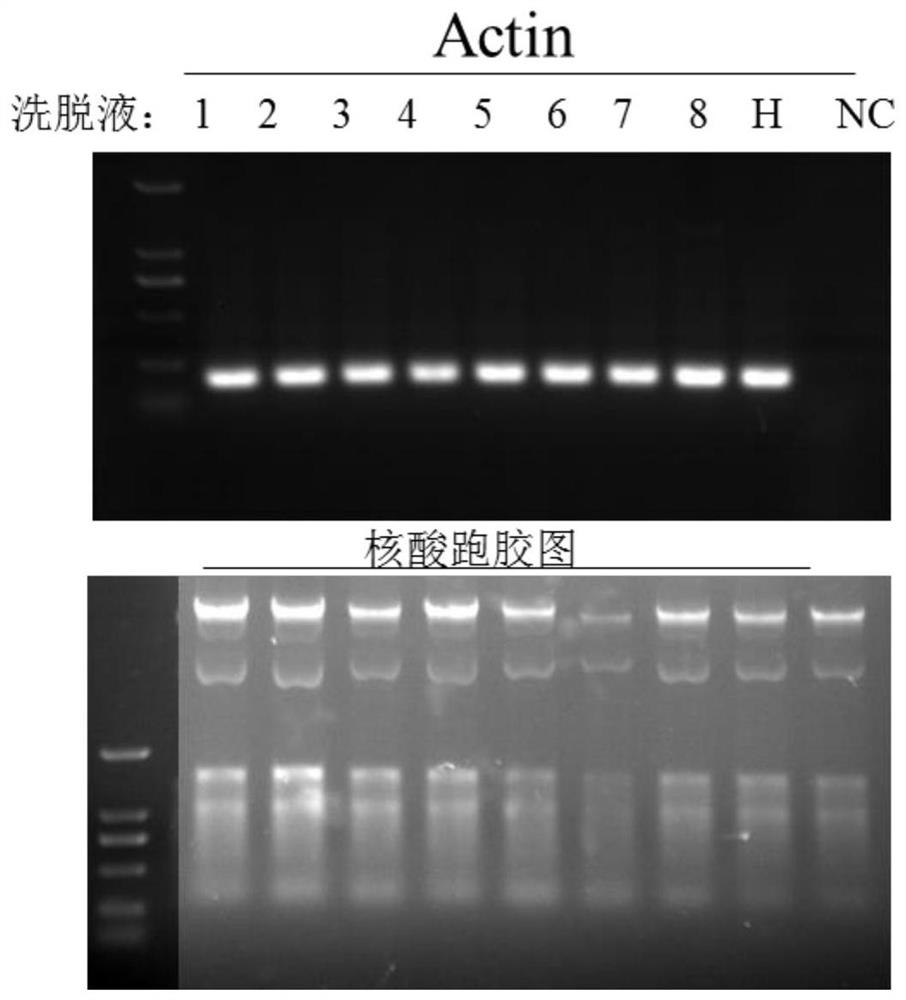

Genome magnetic bead extraction test kit and extraction method

InactiveCN111961663ANucleic acid concentration and purity are goodGood nucleic acid purityDNA preparationGuanidine isothiocyanateThiocyanic acid

The invention discloses a genome magnetic bead extraction test kit. The test kit comprises a lysis solution, proteinase K, isopropanol, hydroxyl magnetic beads, a washing solution and an eluent, wherein the formula of the lysis solution comprises 25 to 75 mM of Tris-HCL with a pH value of 7.5 to 8.5, 3 to 5 M of guanidine isothiocyanate, 5 to 15% of polidocanol and 5 to 15% of PEG8000; the washingsolution comprises a solution A and a solution B; the solution A comprises NaCl with a concentration of 120 to 130 mmol / l and absolute ethyl alcohol with a volume concentration of 80 to 90%; the solution B comprises Tris with a concentration of 25 to 35 mmol / l and absolute ethyl alcohol with a volume concentration of 80 to 90%; and the formula of the eluent comprises 9.5 to 10.5 mM of Tris-HCl and 0.8 to 1.2 mM of EDTA. The concentration of the nucleic acid extracted by the test kit is higher; nucleic acid agarose gel electrophoresis is free of the phenomenons of miscellaneous bands and bandtrailing; and the purity of extracted nucleic acid is better.

Owner:华芯生物科技(武汉)有限公司

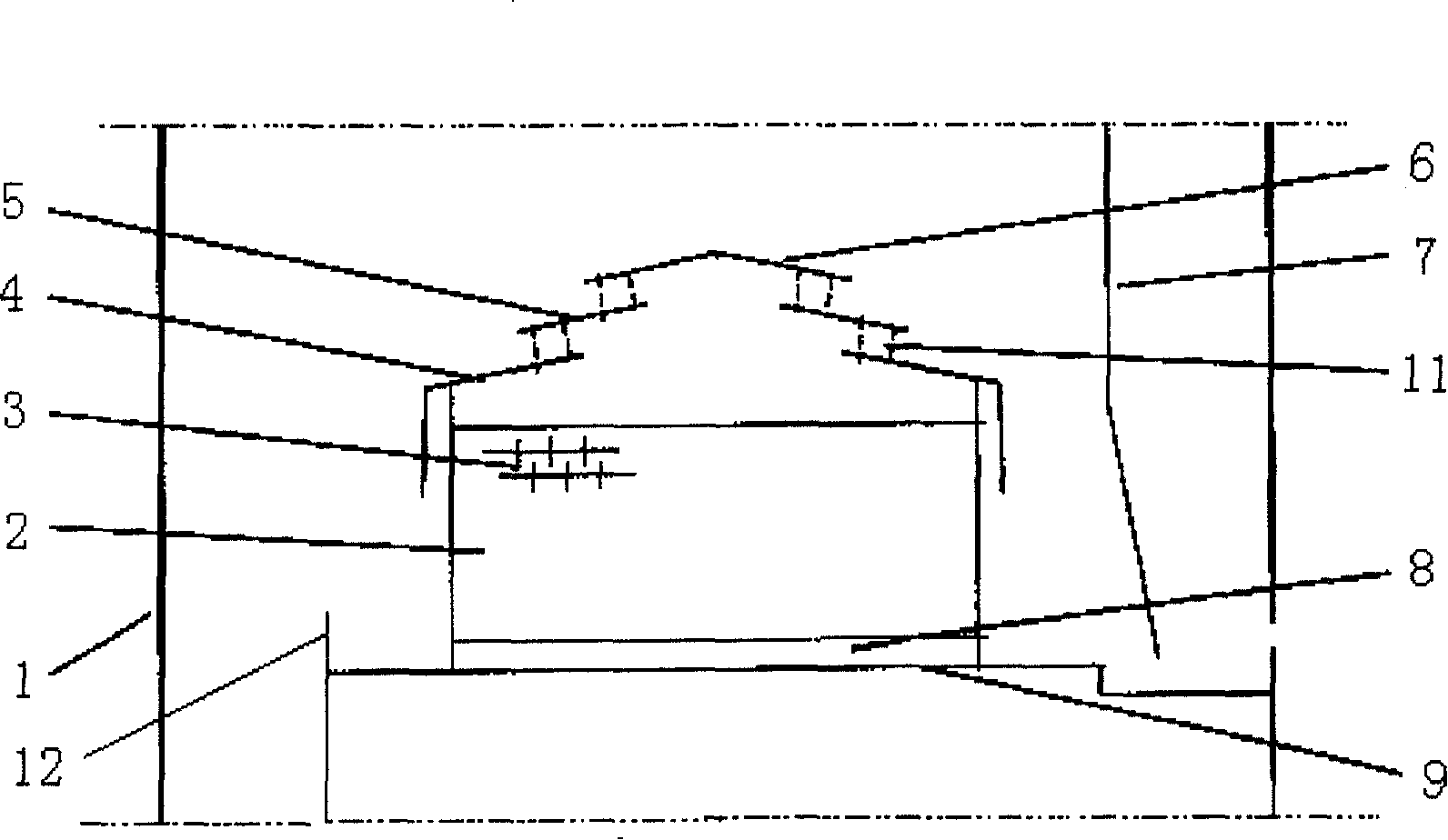

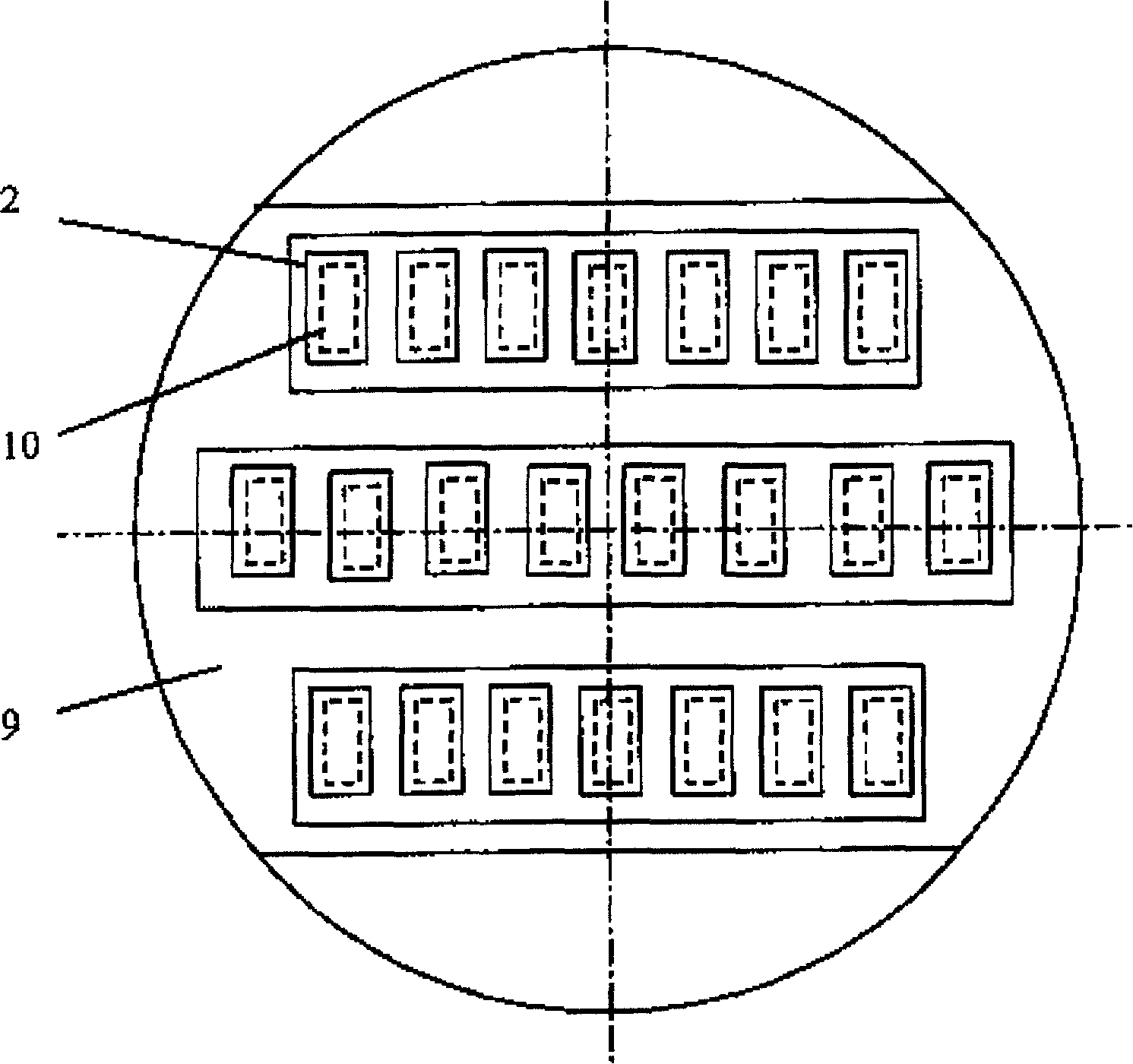

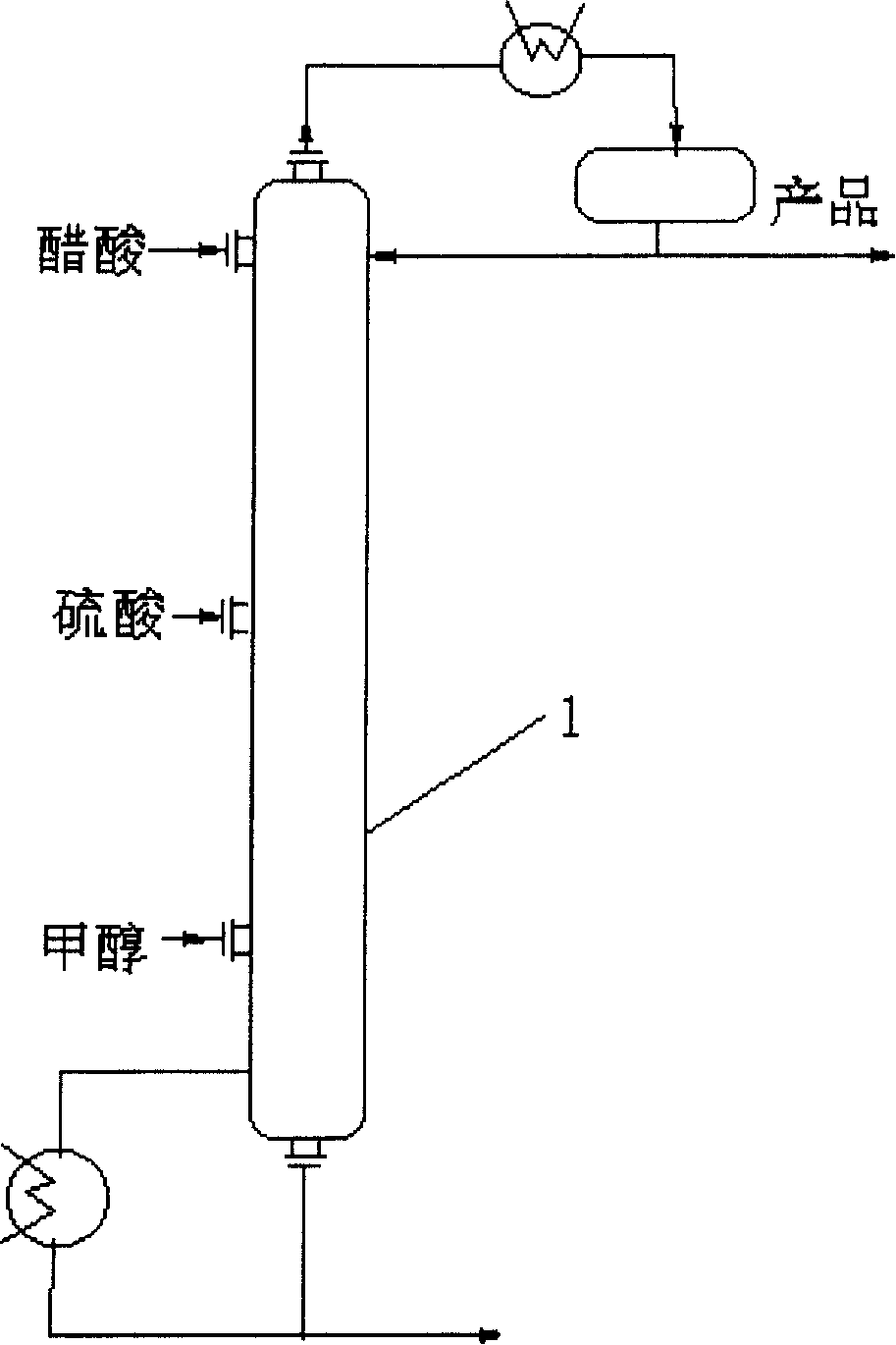

Method for preparing methyl acetate, and reaction rectification tower possessing spatial column plates of mass transfer

ActiveCN100389103CImprove production efficiencyNo entrainmentOrganic chemistryFractional distillationDistillationPhysical chemistry

This invention publishes a preparation method for methyl acetate and a reaction distillation column with combined trapezoid spray trays. It is unique that the height / spacing ratio of exit weir is 0.2~0.5:1 and the height of exit weir is 40~200mm. The reaction distillation column with combined trapezoid spray trays in this invention being adopted, liquid holdup on the trays would be significantly improved without obvious distillation entrainment, single-column yield would be significantly promoted and the purity of methyl acetate product on the top of the column can be over 99.3%.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

Technology for centrifugal extraction treatment of 1,4-dihydroxyanthraquinone industrial wastewater

InactiveCN110526437AProcess advantagesHigh degree of automationWater/sewage treatment by centrifugal separationTreatment involving filtrationFiltrationPhase ratio

The invention discloses a technology for centrifugal extraction treatment of 1,4-dihydroxyanthraquinone industrial wastewater. The pH value of the 1,4-dihydroxyanthraquinone industrial wastewater is adjusted to 0.8 to 1.3 through caustic soda, filtration is conducted to remove mechanical impurities, the 1,4-dihydroxyanthraquinone industrial wastewater is inputted into a heavy phase inlet of a centrifugal extractor at the normal temperature and pressure, meanwhile, a novel extraction agent is inputted into a light phase inlet of the centrifugal extractor, centrifugal extraction and separation are conducted, the oil-water phase ratio of the wastewater to the extraction agent is (1 to 5):(1), and the novel extraction agent is prepared from a complexing agent, a co-solvent, a diluent, and a demulsifier; after separation, raffinate phase extracted water is at a heavy phase outlet and is further treated for reaching the standard for discharging or reuse; and a extract phase loaded extractionagent is at a light phase outlet and sent to back extraction for regeneration. According to the technology for centrifugal extraction treatment of the 1,4-dihydroxyanthraquinone industrial wastewater, required investment is less, the floor area is small, the technological process is simple and reliable, the degree of automation is high, labor intensity is low, the production efficiency is high, and comprehensive treatment of the wastewater can be realized.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

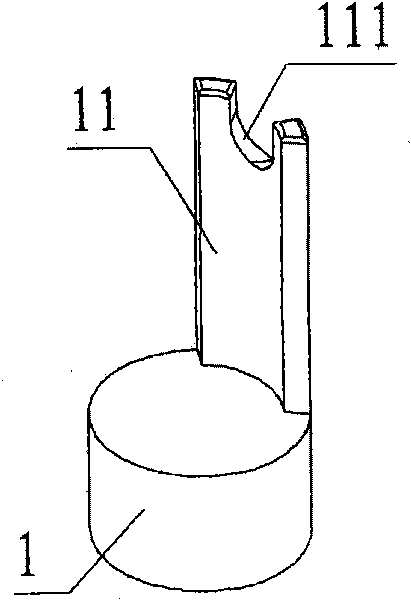

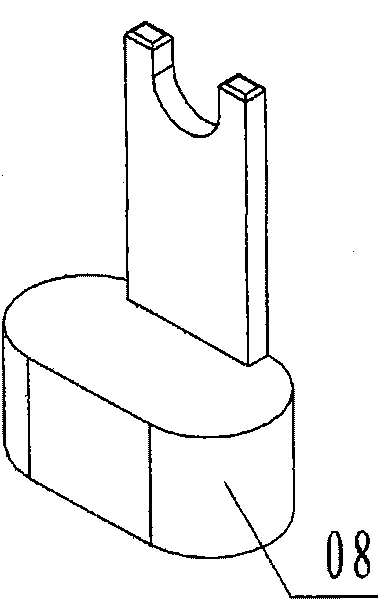

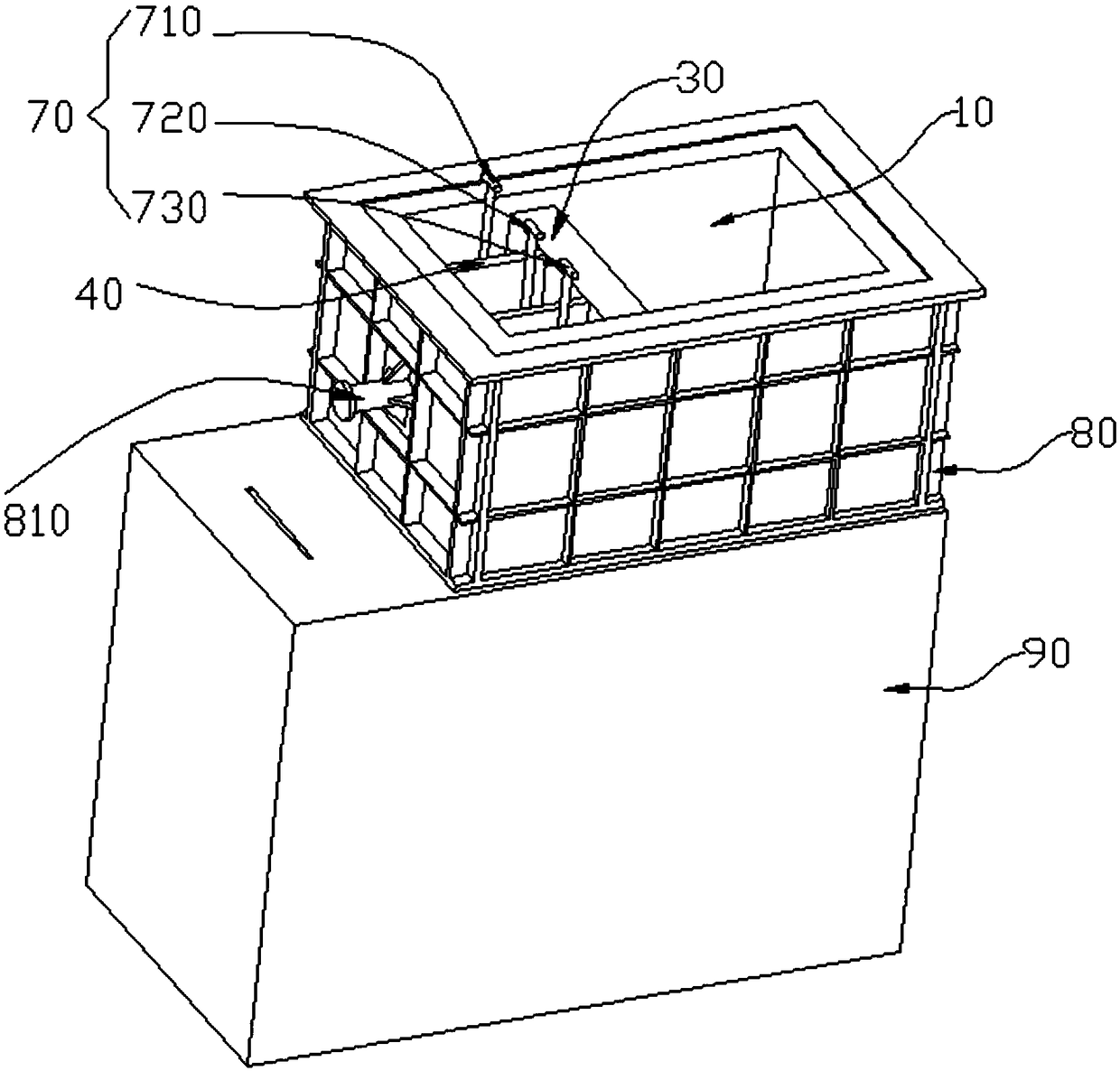

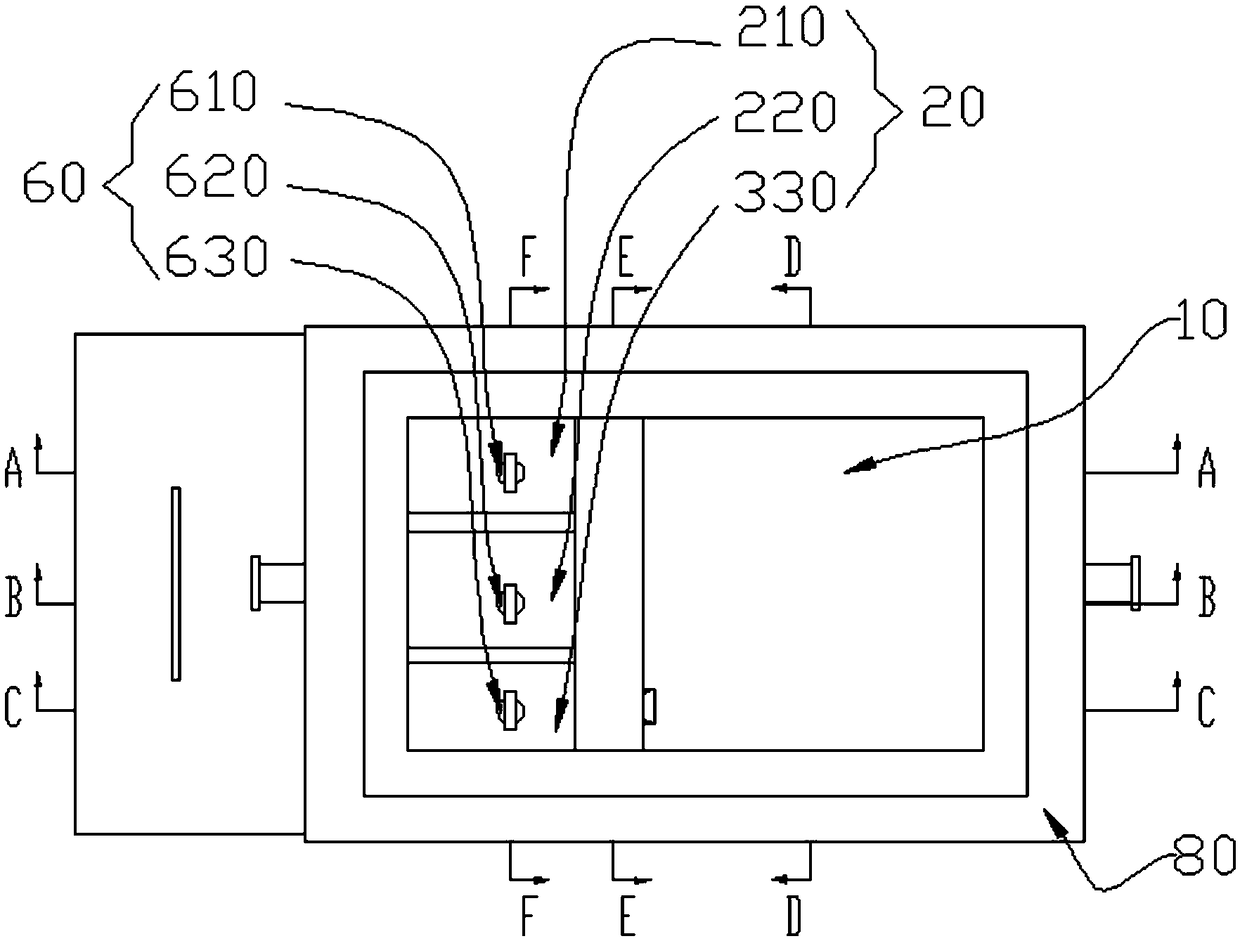

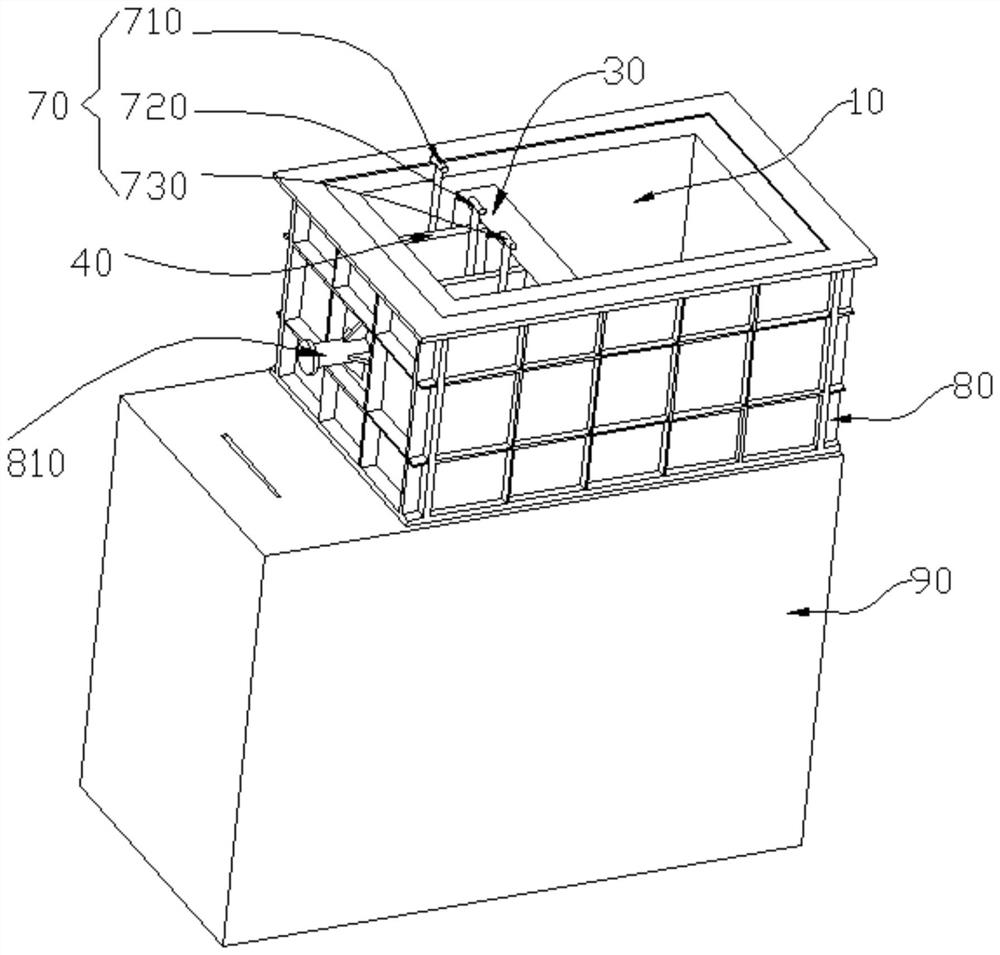

Pouring basin for stepped pouring system and application method of pouring basin

ActiveCN108907103ASolve the problem of pouring out of syncImprove the efficiency of injection into the liquid chamberFoundry mouldsFoundry coresMaterials science

The invention relates to a pouring basin for a stepped pouring system. The pouring basin comprises a basin body and water outlets. The basin body is internally provided with a stop body and divided into a liquid inlet cavity and a liquid outlet cavity. The liquid outlet cavity is internally provided with separation dams and divided into two or more liquid outlet cavity bodies, namely the first liquid outlet cavity body and the second liquid outlet cavity body. The stop body is internally provided with stepped connection channels which enable the liquid inlet cavity to communicate with the liquid outlet cavity. The first stepped connection channel is used for enabling the liquid inlet cavity to communicate with the first liquid outlet cavity body, and the second stepped connection channel is used for enabling the liquid inlet cavity to communicate with the second liquid outlet cavity body. The first water outlet is formed in the bottom of the first liquid outlet cavity body, and the second water outlet is formed in the bottom of the second liquid outlet cavity body. The lower portion of the first water outlet and the lower portion of the second water outlet communicate with corresponding sprues. The invention further relates to an application method of the pouring basin for the stepped pouring system. By means of the pouring basin, the problem that multiple pouring basins are not synchronous in pouring is solved; and the pouring basin is easy to operate and low in cost.

Owner:KOCEL EQUIP

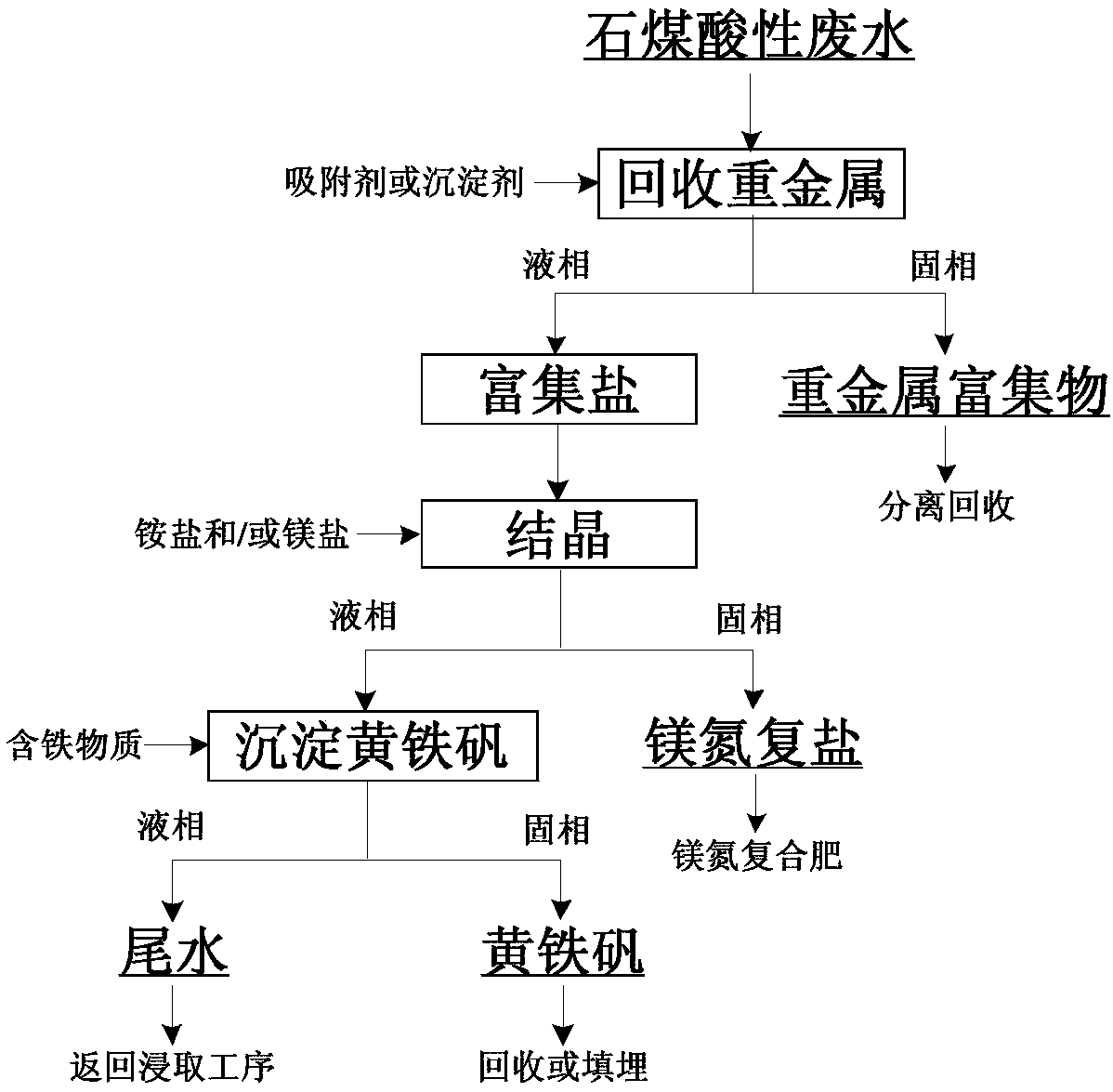

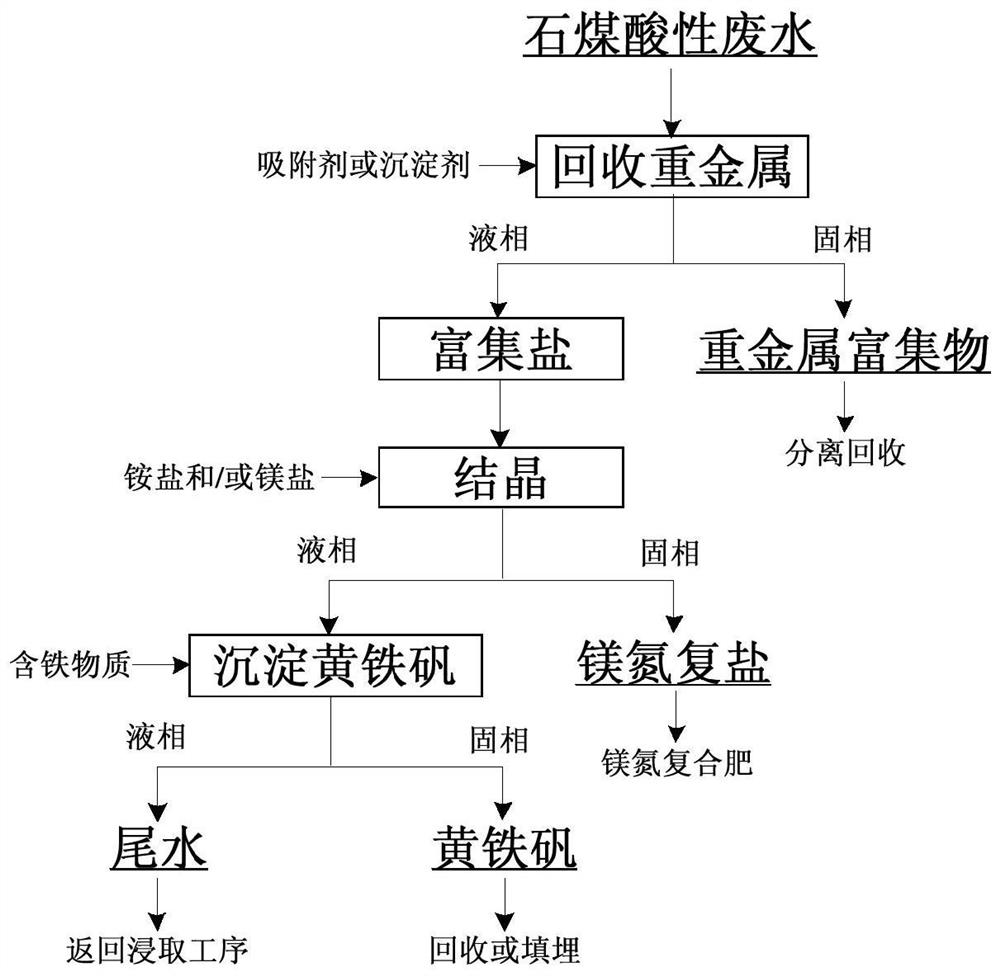

Stone coal acidic waste water resource utilization method

ActiveCN108675498AEfficient separationHigh purityMagnesium fertilisersWater/sewage treatmentAdditive ingredientSlag

The invention provides a stone coal acidic waste water resource utilization method. The method comprises the steps of heavy metal recovery, salt enrichment, magnesium nitrogen complex salt crystallization, ihleite precipitation, tail water circular treatment and the like. Stone coal acidic waste water is firstly separated to recover heavy metal ions; then, magnesium and nitrogen complex salt and ihleite are respectively obtained by a multi-step crystallization method; the efficient separation and recovery of different ingredients in waste water are realized; the problems of recovery incapability of valuable ingredients and generation of a large amount of waste slag by a traditional waste water neutralization deamination method are avoided; various kinds of products with high additional values are obtained; the product purity is high; no heavy metal is entrained; after the treatment, the waste water returns to a stone coal leaching working procedure; the zero discharge of the waste water is realized. The method has the advantages that the cost is low; the operation is simple; the clean and environment-friendly effects are achieved, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Rapid drying and collecting device for micro nano powder

ActiveCN113945070AFast dryingNot easy to reuniteDrying solid materials with heatSteam/vapor condensersMicro nanoMetallurgy

The invention provides a rapid drying and collecting device for micro nano powder, and belongs to the field of powder drying. The device comprises a micro-droplet spraying device for forming nano powder slurry into a droplet state, a rapid drying device for drying nano powder droplets to form nano powder, a dehumidification device for removing water vapor generated in the drying process of the nano powder, and a powder collecting device for collecting the nano powder. According to the device, the microwave technology, the ultrasonic technology and the electrostatic technology are organically combined, nano powder is rapidly collected under the action of an electrostatic field after being suspended and dried in a drying chamber, the device has the advantages of being high in drying speed, not prone to agglomeration, controllable in drying time and suitable for drying the nano powder with different particle sizes, and meanwhile the device is compact in structure, suitable for small-batch preparation of nano powder in scientific research laboratories, and meets the requirement of taking and using at any time.

Owner:WUXI HOPE LIGHT IND EQUIP TECH +1

An associated gas condensate recovery device

ActiveCN104028051BNo entrainmentPrevent taking awayCombination devicesGaseous fuelsCombustorEngineering

The invention provides an associated gas condensate recovery device which comprises a cylinder body, an upper end seal head welded on the upper end surface of the cylinder body, a lower end seal head welded on the lower end surface of the cylinder body, a transverse gas inlet pipe welded on the upper part of the outer wall of the cylinder body and penetrating the cylinder body, a longitudinal gas outlet pipe arranged on the upper end seal head and far away from the horizontal gas inlet pipe and penetrating the upper end seal head, a longitudinal draining pipe arranged on the bottom of the lower end seal head, and liquid dividing plates arranged in the cylinder body; the inner surface of the upper end seal head is provided with a vertical-direction baffle plate extending downwards along the longitudinal direction; multiple liquid dividing plates are successively arranged on the left side and the right side of the baffle plate from top to bottom and are inclined downwards; gaps are formed between the liquid dividing plates and the bottom of the cylinder body. Therefore, the device can greatly improve the gas-liquid separation rate of associated gas, and ensures the associated gas is not carried with liquids when entering a burner and can be fully burnt.

Owner:XIAN CHANGQING TECH ENG

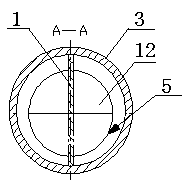

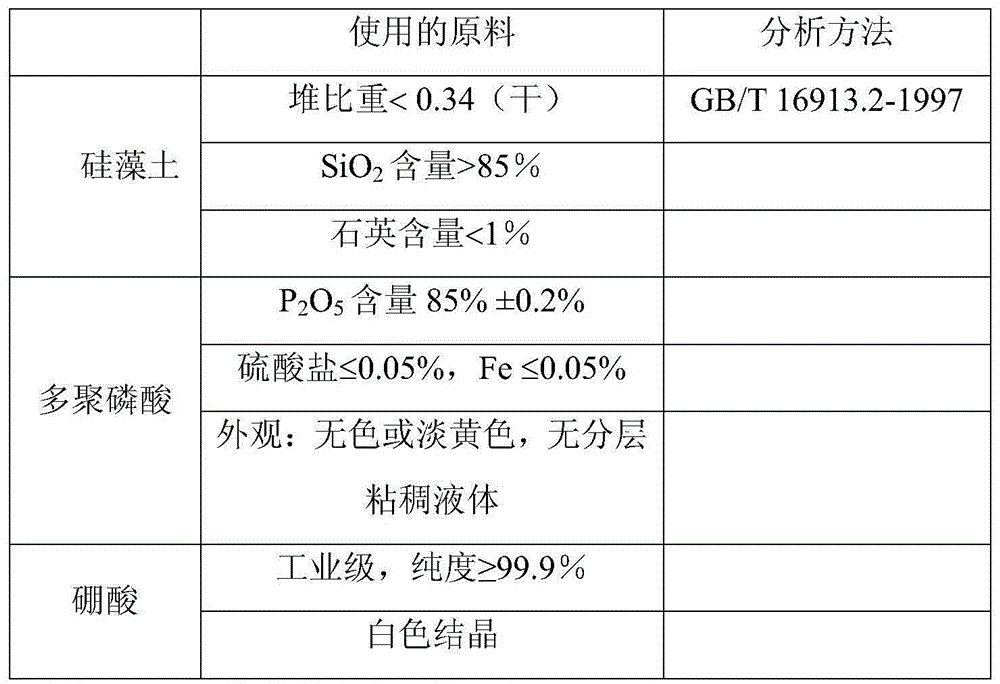

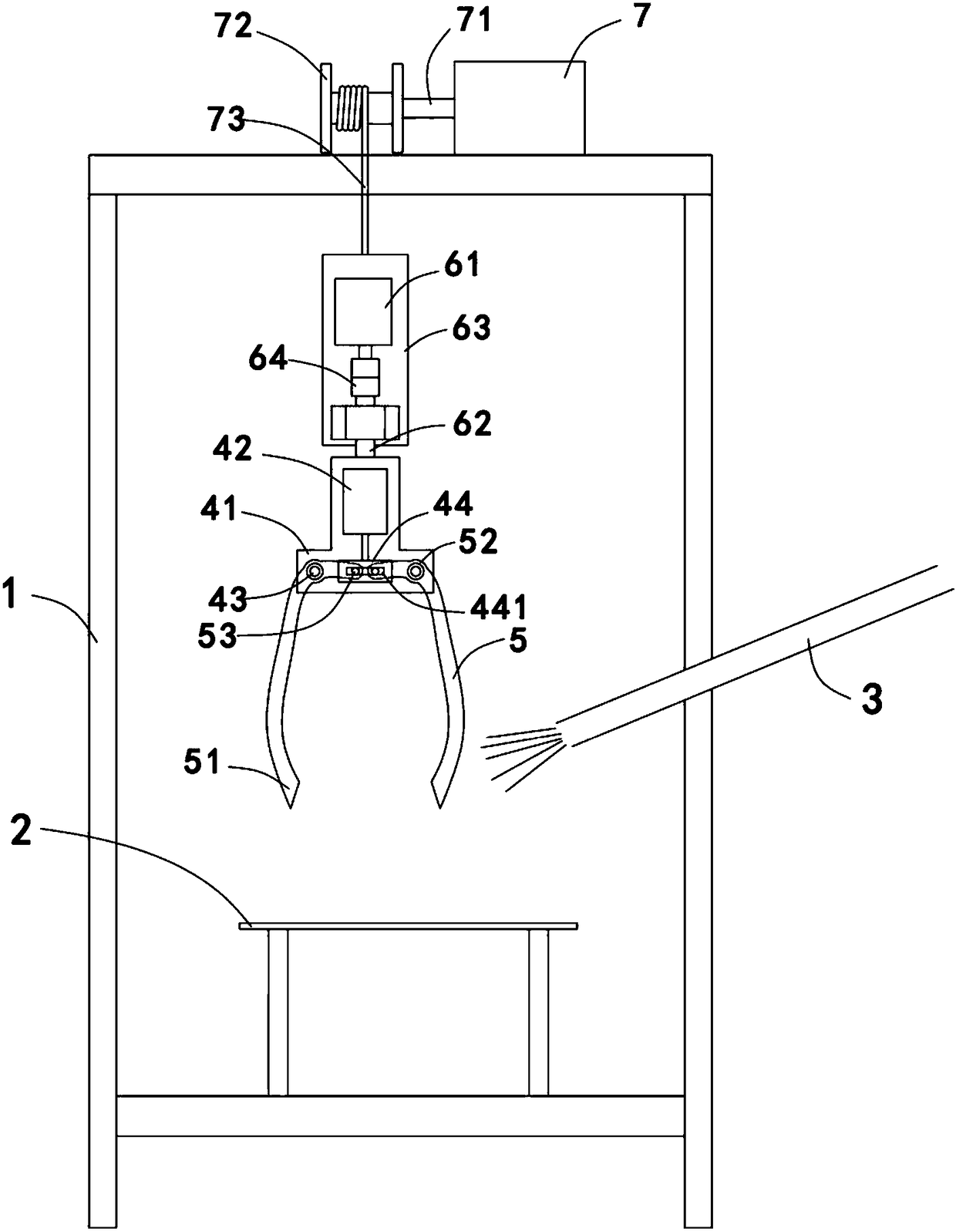

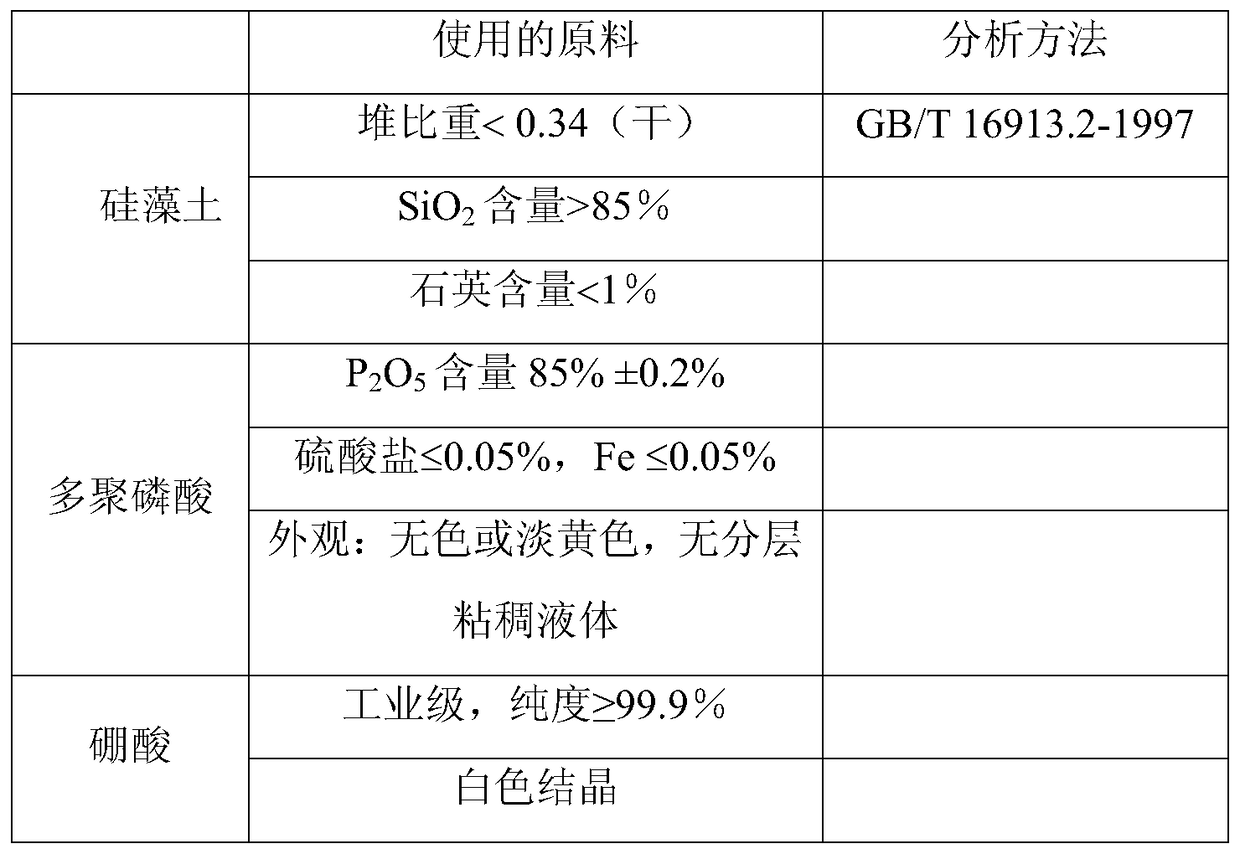

Preparation method of solid phosphoric acid catalyst, vibration type directional fine powder feeder applied to preparation method as well as application of feeder

ActiveCN105618092ANo entrainmentEnsure uniformity of dispersionPhysical/chemical process catalystsFeed devicesNiobiumPhosphoric acid

The invention relates to a preparation method of a solid phosphoric acid catalyst. The preparation method of the solid phosphoric acid catalyst comprises the steps of salt-forming reaction of niobium boron phosphate compound salt, forming of the solid phosphoric acid catalyst, and the like, so that the solid phosphoric acid catalyst is obtained. The invention further discloses a vibration type directional fine powder feeder and a feeding method of the feeder; the feeder and the feeding method are applied to the preparation method of the solid phosphoric acid catalyst. According to the preparation method of the solid phosphoric acid catalyst, the vibration type directional fine powder feeder applied to the preparation method as well as the application of the feeder, the production cost is reduced, and both the activity and the degradation in water of the solid phosphoric acid catalyst are improved, so that the solid phosphoric acid catalyst can be widely applied to large-scale industrial production.

Owner:RACHEM CHINA CO LTD

Alloy liquid extrusion casting forming device and process method thereof

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

A method for resource utilization of stone coal acid wastewater

ActiveCN108675498BEfficient separationHigh purityMagnesium fertilisersWater/sewage treatmentWater resourcesAmmonia

The invention provides a method for resource utilization of acidic waste water from stone coal. The method comprises the steps of heavy metal recovery, salt enrichment and crystalline magnesium nitrogen double salt, jarosite precipitation, tail water recycling treatment and the like. The stone coal acidic wastewater described in the present invention is firstly separated and recovered from heavy metal ions, and then the magnesium nitrogen double salt and jarosite are respectively obtained by a multi-step crystallization method, so as to realize the efficient separation and recovery of different components in the wastewater and avoid the neutralization and desorption of traditional wastewater. A large amount of waste residue and valuable components produced by the ammonia process cannot be recycled. A variety of high value-added products have been obtained with high purity and no heavy metal entrainment, and the wastewater is returned to the stone coal leaching process after treatment to achieve zero discharge of wastewater . The method of the invention has the advantages of low cost, simple operation, clean and environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A multi-stage hollow fiber membrane liquid dehumidification device suitable for hot and humid areas

ActiveCN105571020BNo entrainmentAvoid pollutionLighting and heating apparatusAir conditioning systemsInlet channelEngineering

The invention discloses a multistage hollow fiber membrane liquid dehumidifying device applicable to a hot and humid area. The multistage hollow fiber membrane liquid dehumidifying device comprises an air inlet system used for conveying air into a room, an exhaust system used for exhausting the air out of the room, a heat pump system and a dehumidifying solution circulation system. The air inlet system comprises an air inlet channel, a fresh air fan and a plurality of hollow fiber membrane dehumidifying assemblies, wherein the fresh air fan and the hollow fiber membrane dehumidifying assemblies are sequentially arranged on the air inlet channel in the air intake direction. The exhaust system comprises an exhaust channel, an exhaust fan and a plurality of hollow fiber membrane regeneration assemblies, wherein the exhaust fan and the hollow fiber membrane regeneration assemblies are sequentially arranged on the exhaust channel in the air exhausting direction. The heat pump assembly comprises a compressor, an expansion valve, a refrigerant storage tank, a plurality of evaporators and a plurality of condensers. The multistage hollow fiber membrane liquid dehumidifying device avoids the gas and liquid entrainment phenomenon, has good mass transfer efficiency, solves the problem of corrosion of a dehumidifying saline solution to a metal heat exchanger by an existing method, reduces bacterium breeding, lowers the regeneration temperature of the solution and increases the energy utilization rate of a system.

Owner:SOUTH CHINA UNIV OF TECH

Workpiece cleaning system

InactiveCN108393803AReduce labor costsImprove safety performanceBlast gunsAbrasive feedersPlunger pumpHigh pressure

Owner:江山澳特机械制造有限公司

A device and method capable of realizing vacuum quantitative pouring of metal melt

ActiveCN106670441BReduce oxidationReduce hydrogen absorptionMolten metal supplying equipmentsInterior spaceControl system

The invention discloses equipment capable of achieving vacuum quantitative casting of molten metal. The equipment comprises a mechanical device, a vacuum quantitative casting device, an opening and closing device and a control system; the vacuum quantitative casting comprises a seal container with internal space, a gas filling mechanism, a vacuum mechanism and an exhaust opening; the exhaust opening comprises a liquid draining opening allowing molten metal to be drained, a pipeline allowing gas to pass through is further arranged in the internal space, and passes through the liquid draining opening, the pipeline is provided with a gas exhaust opening allowing gas not in contact with the molten metal to be exhausted, the opening and closing device achieves independent control over the liquid draining opening and the gas exhaust oponeing, that is, the opening and closing device can independently control opening and closing of the liquid draining opening and the gas exhaust opening, it is ensured that during casing of the molten metal, the oxidation and hydrogen absorption of the molten metal can be reduced, gas holes and oxide inclusion of a casting are reduced, and the casting quality is improved.

Owner:北京航大新材科技有限公司

Method for preparing j-acid and method for comprehensive treatment and resource utilization of j-acid wastewater

ActiveCN103896438BLow costNo emulsificationMultistage water/sewage treatmentSulfonic acid preparationResource utilizationDiluent

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

Preparation method of solid phosphoric acid catalyst, vibration-type fine powder directional feeder used in the method and application thereof

ActiveCN105618092BNo entrainmentEnsure uniformity of dispersionPhysical/chemical process catalystsFeed devicesNiobiumPhosphoric acid

The invention relates to a preparation method of a solid phosphoric acid catalyst. The preparation method of the solid phosphoric acid catalyst comprises the steps of salt-forming reaction of niobium boron phosphate compound salt, forming of the solid phosphoric acid catalyst, and the like, so that the solid phosphoric acid catalyst is obtained. The invention further discloses a vibration type directional fine powder feeder and a feeding method of the feeder; the feeder and the feeding method are applied to the preparation method of the solid phosphoric acid catalyst. According to the preparation method of the solid phosphoric acid catalyst, the vibration type directional fine powder feeder applied to the preparation method as well as the application of the feeder, the production cost is reduced, and both the activity and the degradation in water of the solid phosphoric acid catalyst are improved, so that the solid phosphoric acid catalyst can be widely applied to large-scale industrial production.

Owner:RACHEM CHINA CO LTD

A sprue basin for step pouring system

ActiveCN108907103BSolve the problem of pouring out of syncImprove the efficiency of injection into the liquid chamberFoundry mouldsFoundry coresEngineeringHydrology

The invention relates to a pouring basin for a stepped pouring system. The pouring basin comprises a basin body and water outlets. The basin body is internally provided with a stop body and divided into a liquid inlet cavity and a liquid outlet cavity. The liquid outlet cavity is internally provided with separation dams and divided into two or more liquid outlet cavity bodies, namely the first liquid outlet cavity body and the second liquid outlet cavity body. The stop body is internally provided with stepped connection channels which enable the liquid inlet cavity to communicate with the liquid outlet cavity. The first stepped connection channel is used for enabling the liquid inlet cavity to communicate with the first liquid outlet cavity body, and the second stepped connection channel is used for enabling the liquid inlet cavity to communicate with the second liquid outlet cavity body. The first water outlet is formed in the bottom of the first liquid outlet cavity body, and the second water outlet is formed in the bottom of the second liquid outlet cavity body. The lower portion of the first water outlet and the lower portion of the second water outlet communicate with corresponding sprues. The invention further relates to an application method of the pouring basin for the stepped pouring system. By means of the pouring basin, the problem that multiple pouring basins are not synchronous in pouring is solved; and the pouring basin is easy to operate and low in cost.

Owner:KOCEL EQUIP

Method extracting high purity n-hexane by integrating rectification and extraction

InactiveCN102942434BWide variety of sourcesImprove thermal stabilityDistillation purification/separationExtractive distillationReactive distillation

The invention relates to a method extracting high purity n-hexane by integrating rectification and extraction. The method utilizes aromatic hydrocarbon raffinate oil as a raw material and adopts a three-tower technological process which combines continuous rectification and extractive distillation. Firstly, distillate lighter than n-hexane is removed in a rectifying tower, and n-hexane distillate which is around 80% in content is obtained at the bottom of the tower. The distillate at the bottom of the tower is adopted as the raw material of an extractive distillation tower, N-methyl pyrrolidone is adopted as an extracting solvent to be delivered into the extractive distillation tower, and the proportion of the N-methyl pyrrolidone and raw oil is 8:1, after extractive distillation, high purity n-hexane is extracted at the top of the tower by integrating rectification and extraction, and heavy components which are rich in methylcyclopentane and the extracting solvent are at the bottom of the tower. Materials at the bottom of the tower are delivered into a solvent recovery tower, distillate oil which is rich in methylcyclopentane is separated at the top of the tower, and N-methyl pyrrolidone solvent is at the bottom of the tower and sent back to the extractive distillation tower to be recycled. By means of the method, n-hexane content can achieve 99%, no extracting solvent is contained in products, solvent consumption is smaller than 0.1%, one-off yield of n-hexane is larger than 95%, and compared with traditional rectification, energy consumption can be saved over 50%.

Owner:广州赫尔普化工有限公司

Flash evaporator for gasifying liquid phase substances

The invention discloses a flash evaporator for gasifying liquid phase substances. The flash evaporator comprises an outer flash tank frame body and an outer demister frame body, wherein a flash tank gas phase outlet, a flash tank material inlet and a manhole are formed in the outer surface of the outer flash tank frame body; a downcomer is mounted in the outer flash tank frame body; a primary distributor is mounted under the downcomer; a distributor is mounted under the primary distributor; V-shaped weirs, a flash tank bed casting die, a flash tank bed and a flash tank bed supporting layer are mounted under the distributor; a concentrated solution gathering tank is mounted under the flash tank bed supporting layer, and a concentrated solution outlet of a flash tank is formed in a position under the flash tank bed supporting layer; a demister bed is mounted in the outer demister frame body; and a demister outlet and a demister inlet are formed in the outer surface of the outer demister frame body. The flash evaporator disclosed by the invention has the advantages that the flash efficiency of liquid phase materials is high; the flashed materials cannot have the phenomenon that materials and foams are mixed; and materials which are easy to crystallize cannot block the distributor and fillings.

Owner:HUBEI DONGFANG CHEM IND

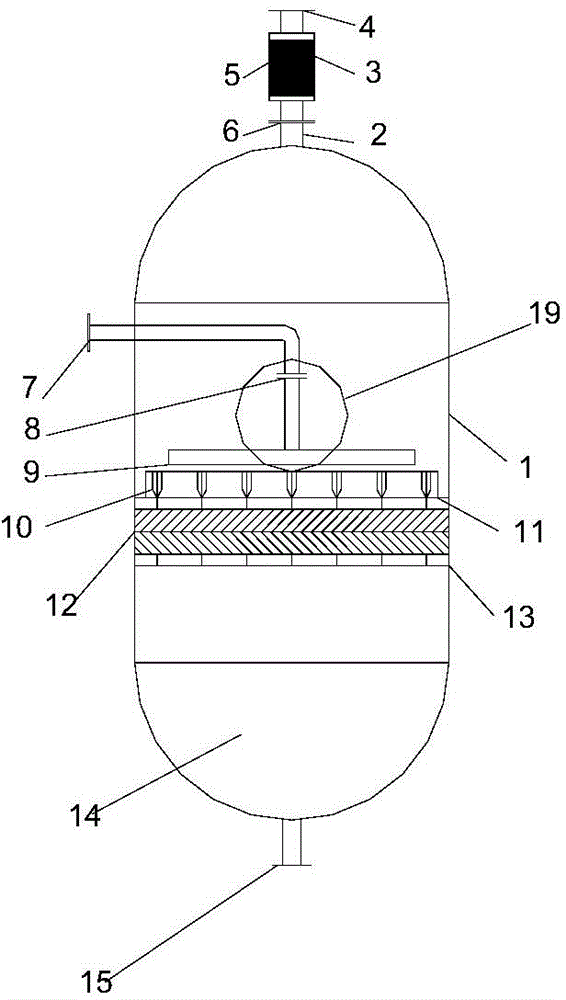

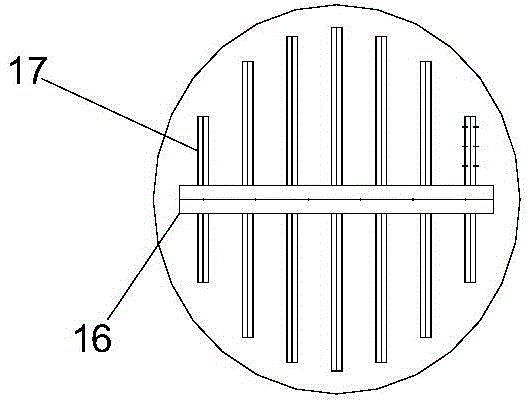

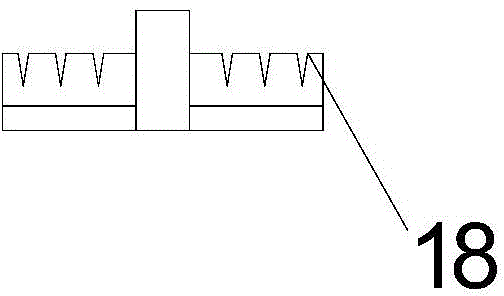

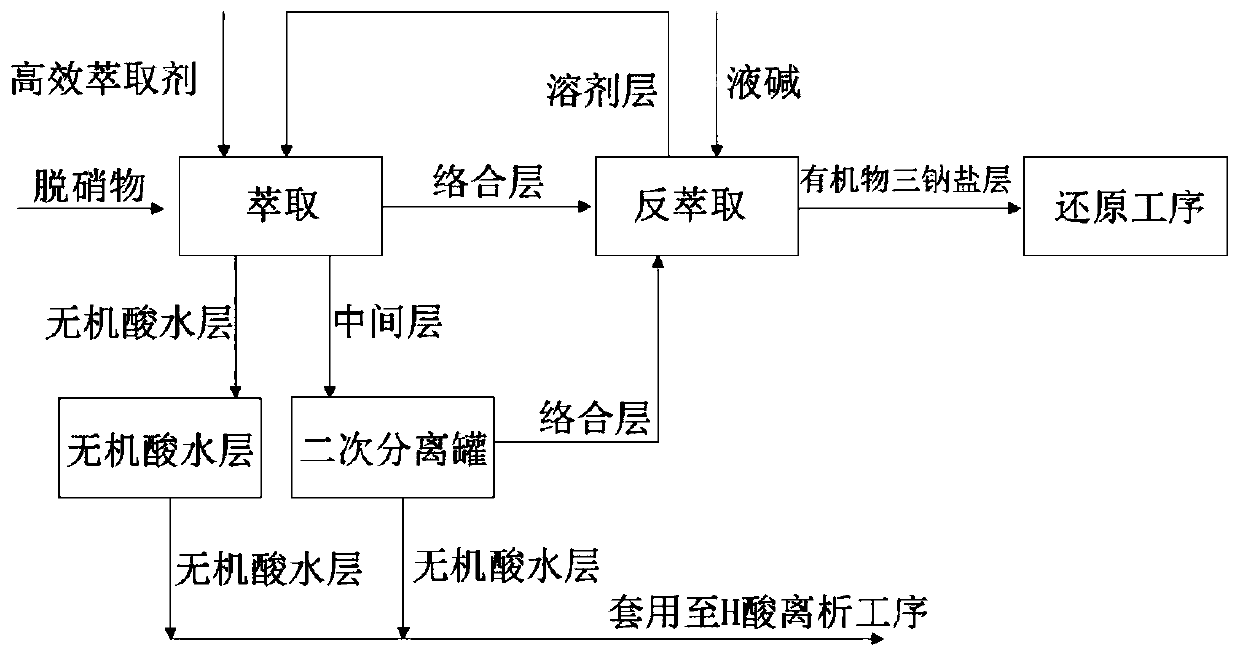

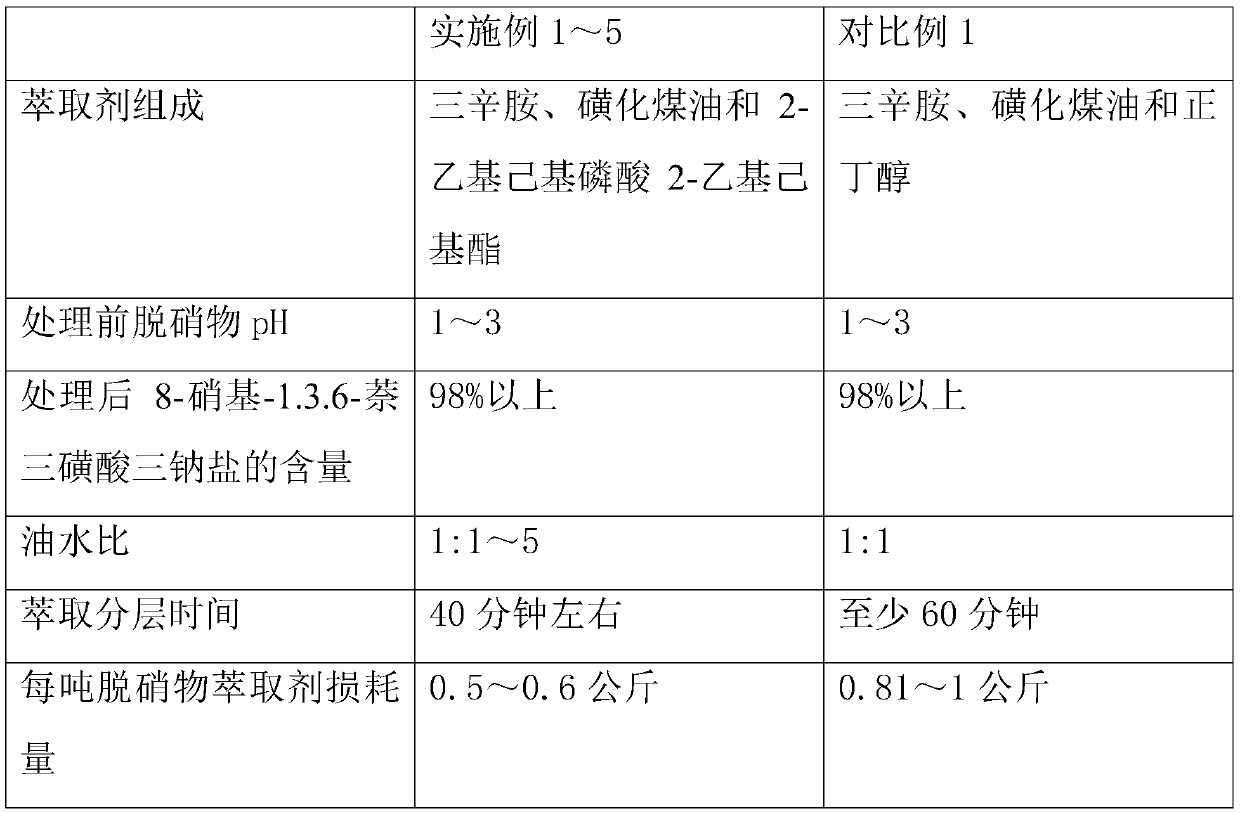

A kind of extraction method and extraction agent used in the denitrification process in H acid production process

ActiveCN108043067BReduce lossesPromote regenerationLiquid solutions solvent extractionKerosenePhosphate

An extraction method and an extractant for a denitration process in a H acid production process. First, an extractant is formulated. The extractant comprises a solvent, a diluent, and a cosolvent. The cosolvent is 2-ethylhexyl 2-ethylhexyl phosphate, the solvent is a tertiary amine solvent, and the diluent is one or more of sulfonated kerosene, benzene, or toluene. Subsequently, the extractant is used to extract a denitrate, and a complex layer and an inorganic acid / water layer are formed after extraction. The inorganic acid / water layer is separated and subsequently applied to an H acid segregation step, the complex layer is stripped, a stripping agent is added for stripping to form an organic substance / water phase having a pH of 7-9. The denitrate forms a trisodium salt, the solution is stratified by standing, an organic layer is separated, and a solvent layer is subsequently applied.

Owner:湖北丽康源化工有限公司

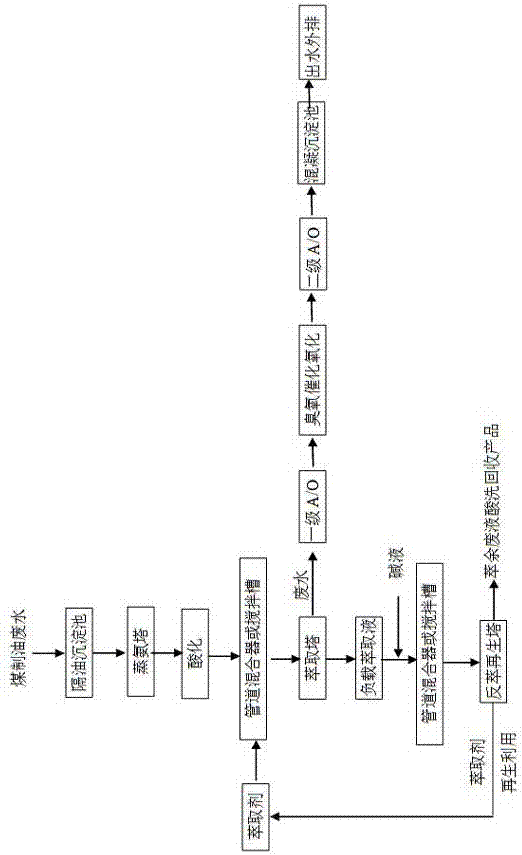

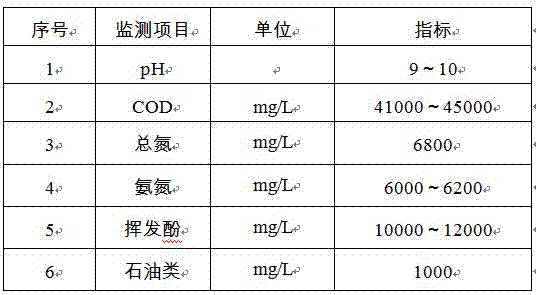

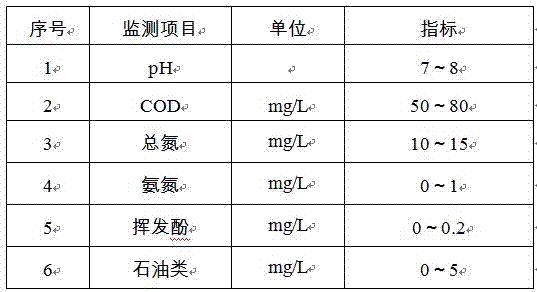

Coal-to-oil production wastewater treatment method

ActiveCN105254135BPromote regenerationNo emulsificationWater contaminantsMultistage water/sewage treatmentHigh concentrationEvaporation

The invention is a method for treating coal oil wastewater, and the specific method includes the steps of oil separation precipitation, ammonia steaming, extraction, back extraction, primary A / O, ozone catalytic oxidation, secondary A / O and the like. After removing slick oil and suspended solids through oil separation precipitation, the wastewater enters the ammonia distillation device to remove high-concentration ammonia nitrogen in the wastewater, then adjusts the pH value to 1-2 with inorganic acid, and extracts high-concentration phenolic organic matter in the wastewater with a specially selected extraction agent. The extract phase is back-extracted with lye, recycled after regeneration, and the product is recovered from the back-extraction solution. After the raffinate is neutralized, it enters the first-level A / O biochemical system to remove organic matter and ammonia nitrogen. The first-level A / O effluent enters the ozone catalytic oxidation device and then enters the second-level A / O biochemical system. The domesticated and cultivated microorganisms are used for biochemistry. The secondary A / O effluent is discharged up to standard after coagulation and sedimentation. The method of the invention is a combination method of physical chemistry and biochemistry, and the method is reasonable in design and strong in operability.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com