Method extracting high purity n-hexane by integrating rectification and extraction

A n-hexane, high-purity technology, applied in the field of chemical solvent preparation, can solve the problems of unsatisfactory separation accuracy, difficulty in obtaining n-hexane, high energy consumption, etc., and achieves easy separation, good thermal stability, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

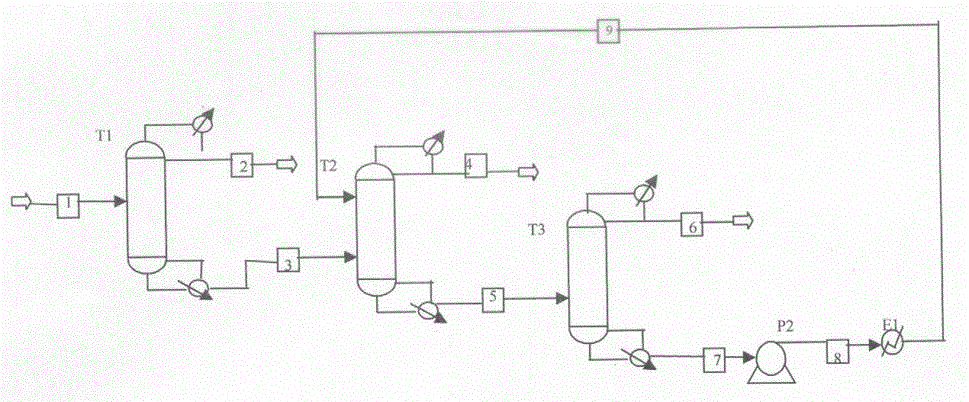

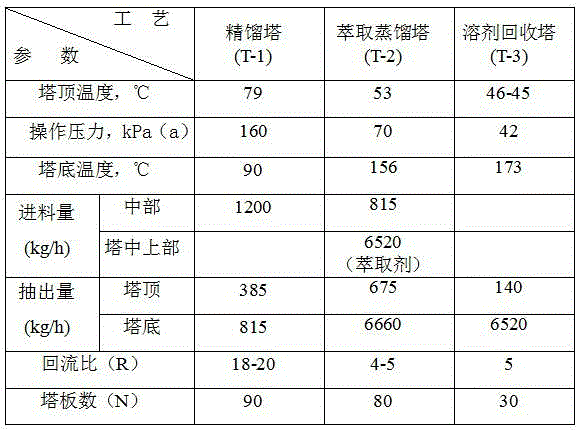

[0014] 1. Description of the process flow

[0015] according to figure 1 As shown, the raw material 1 of the raw material storage tank is continuously entered from the middle part of the continuous rectification tower T1, and the fraction 2 obtained from the top of the continuous rectification tower T1 is light components (light components below normal hexane, such as 3-methanol) base pentane), and feed liquid 3 from T1 continuous distillation column (control isohexane content less than 0.1%) into T2 extractive distillation column, use N-methylpyrrolidone as extraction solvent, and feed from the upper part of extractive distillation , the fraction 4 (n-hexane with a mass content of more than 99%) obtained from the top of the T2 tower is a qualified product, and the material 5 extracted from the bottom of the T2 extraction distillation tower is sent to the T3 extraction solvent recovery tower, and the top of the T3 tower is discharged 6 is a heavy distillate oil mainly com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com