Equipment and method capable of achieving vacuum quantitative casting of molten metal

A quantitative pouring and metal melt technology, which is applied in the direction of supplying molten metal equipment, metal processing equipment, casting equipment, etc., can solve the problems of easy gas entrainment, melt adhesion, melt pollution, etc., and achieve the reduction of pores and Effects of inclusions, reduction of oxidation and hydrogen absorption, and improvement of casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

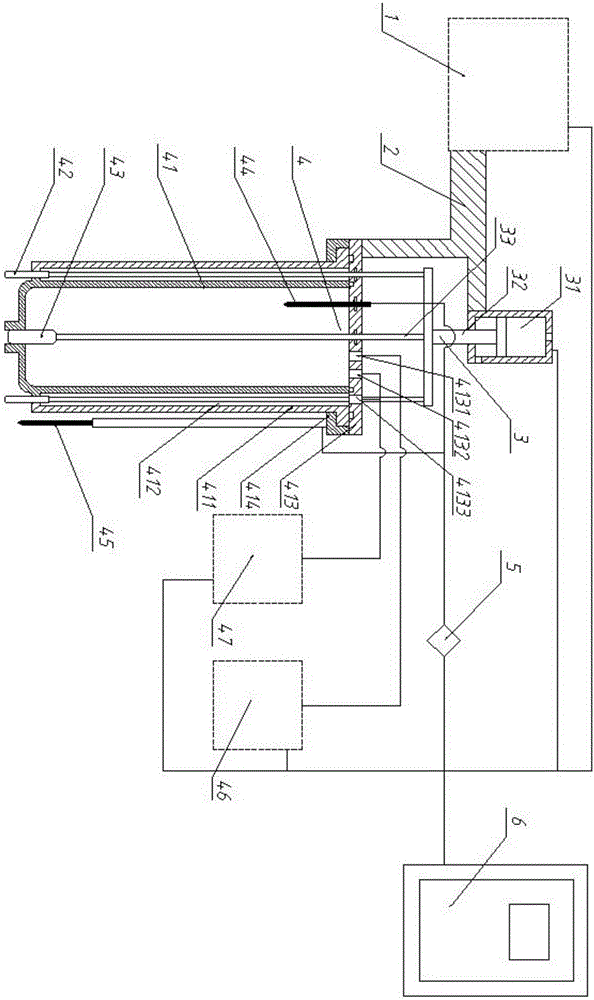

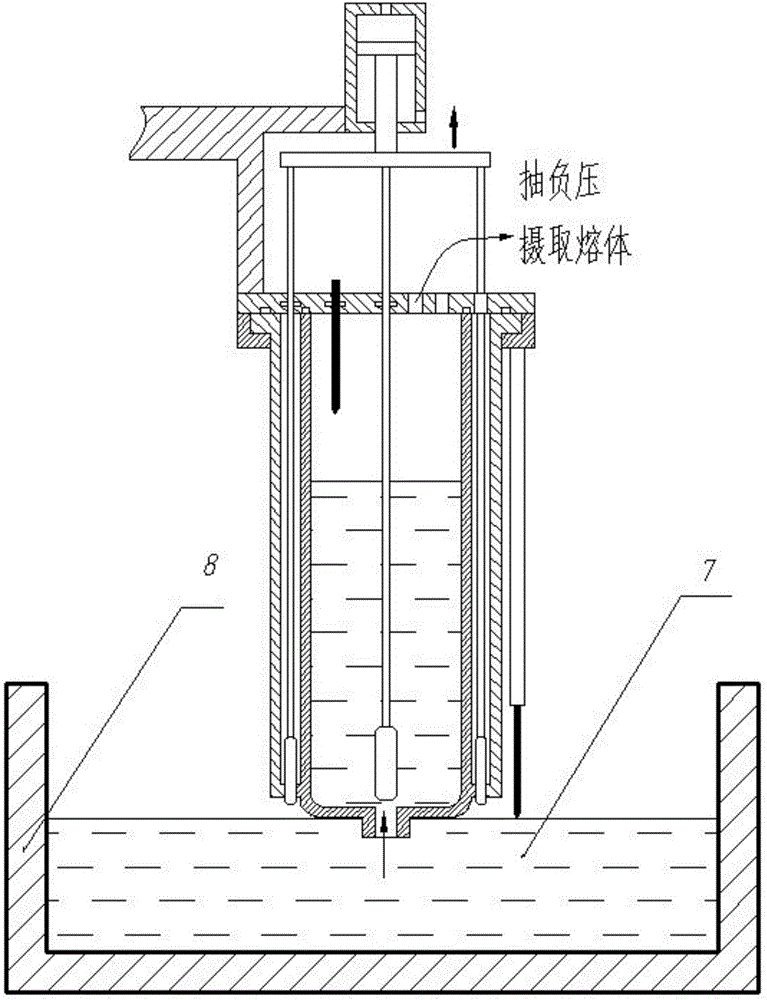

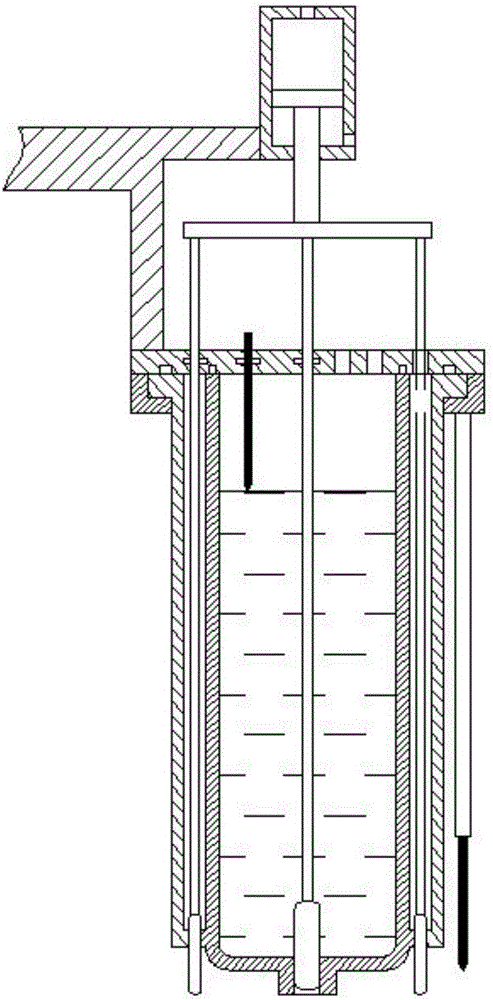

[0060] Attached below figure 1 to attach Figure 7 And embodiment the present invention is described further.

[0061] The alloy melt vacuum quantitative pouring equipment of the present invention includes a mechanical device 1 , a fixing device 2 , a cylinder and a transmission device 3 , a vacuum quantitative pouring device 4 , a feedback signal receiving device 5 , and a control system 6 . The vacuum quantitative pouring device 4 also includes a sealed container 41, an exhaust port closing plug 42, a liquid discharge port closing plug 43, an internal metal liquid level probe 44, an external metal liquid level probe 45, a vacuuming device 46, and an inert gas filling device 47. The fixing device 2 is a T-shaped beam, one end is fixed with a four-station cylinder 31, the other end is fixed with a vacuum quantitative pouring device 4, and the last end is fixed on the mechanical device 1, thus ensuring the four-station cylinder 31 and the vacuum quantitative pouring device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com