Patents

Literature

72results about How to "Reduce oxidation inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

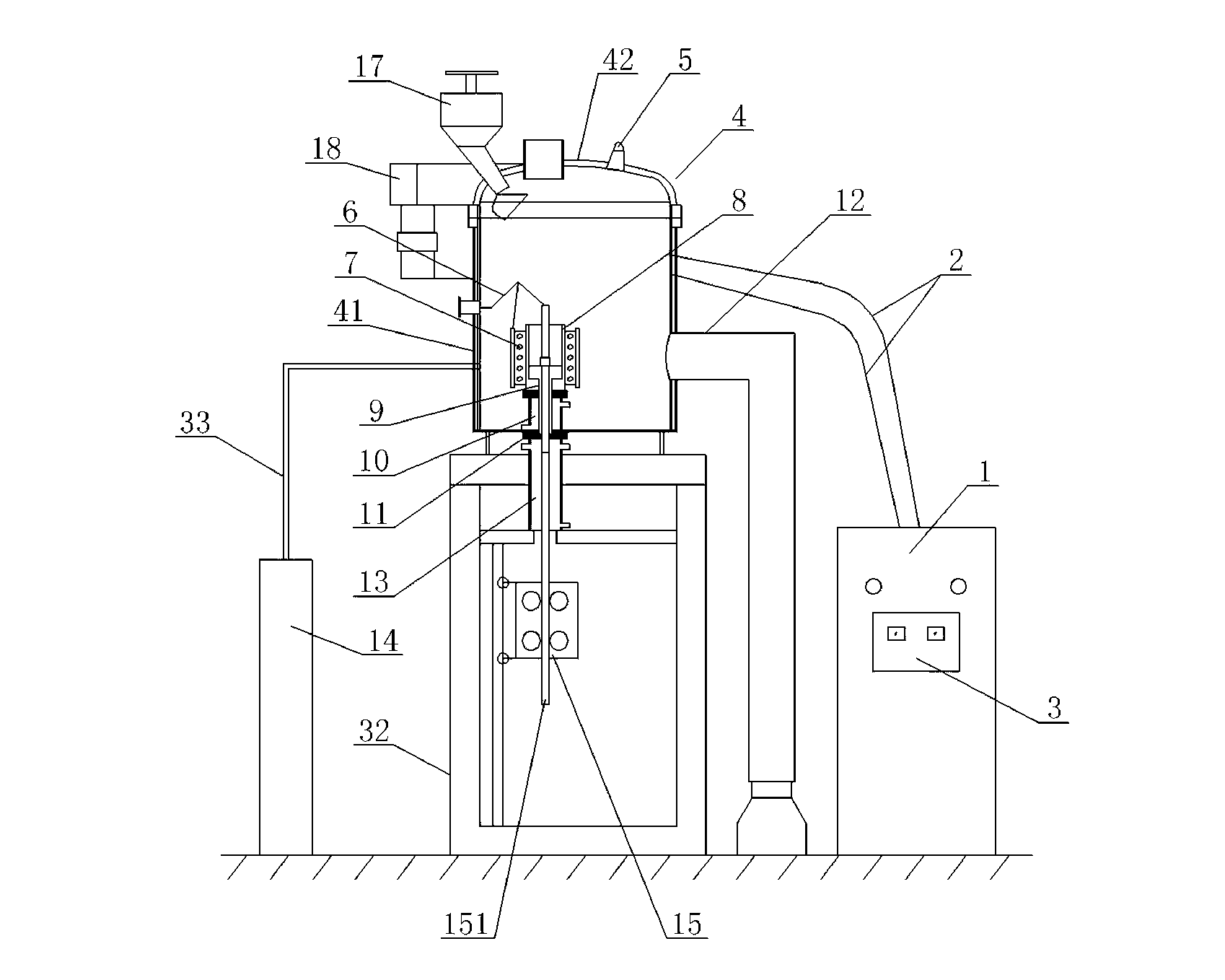

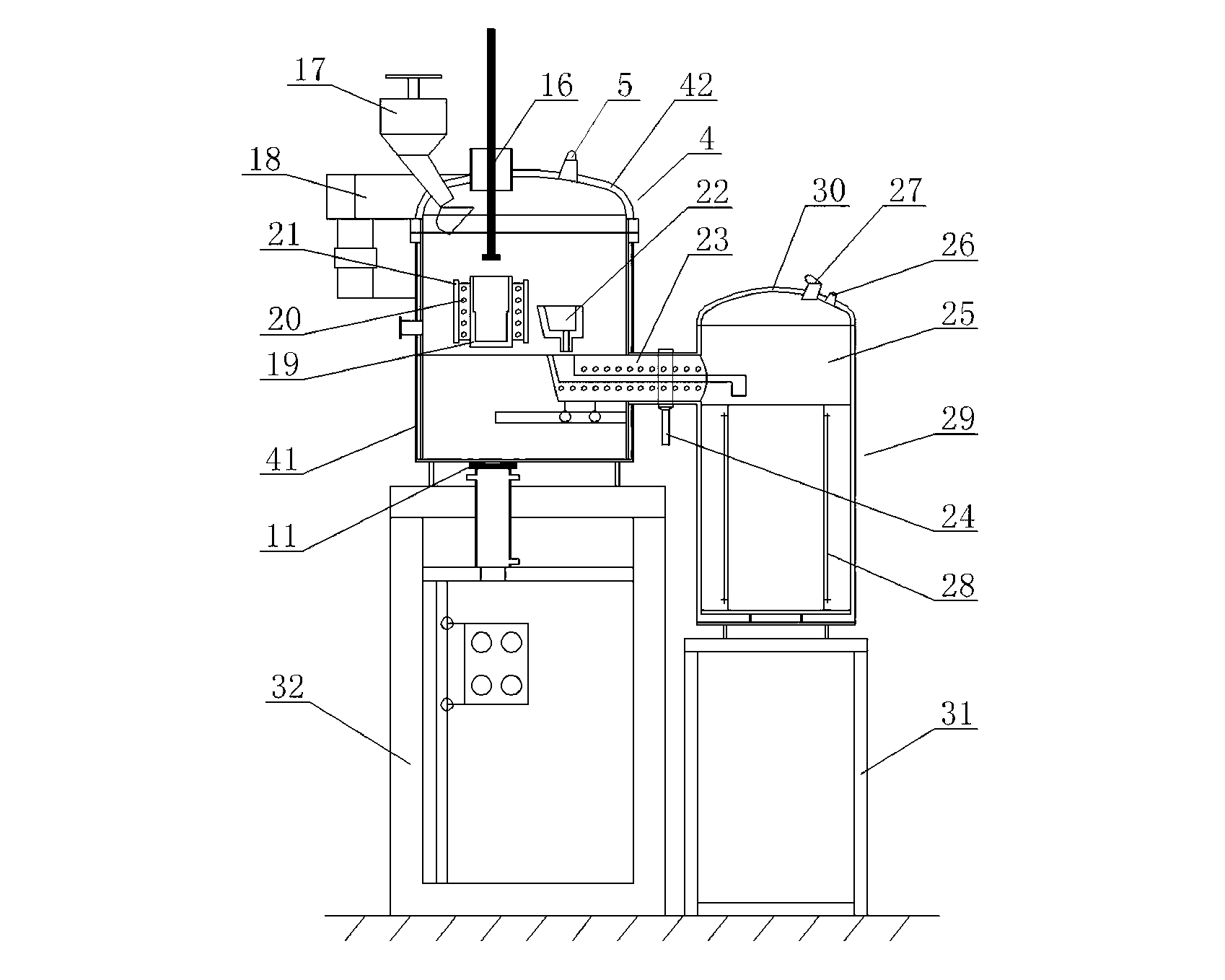

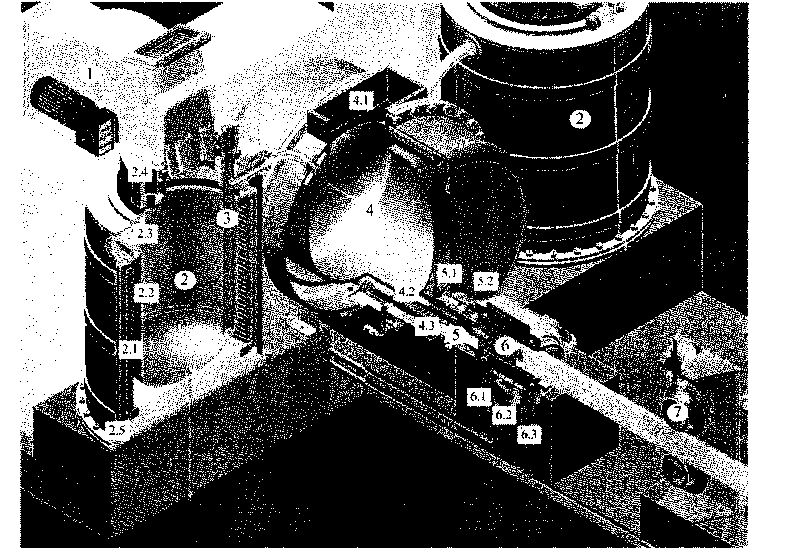

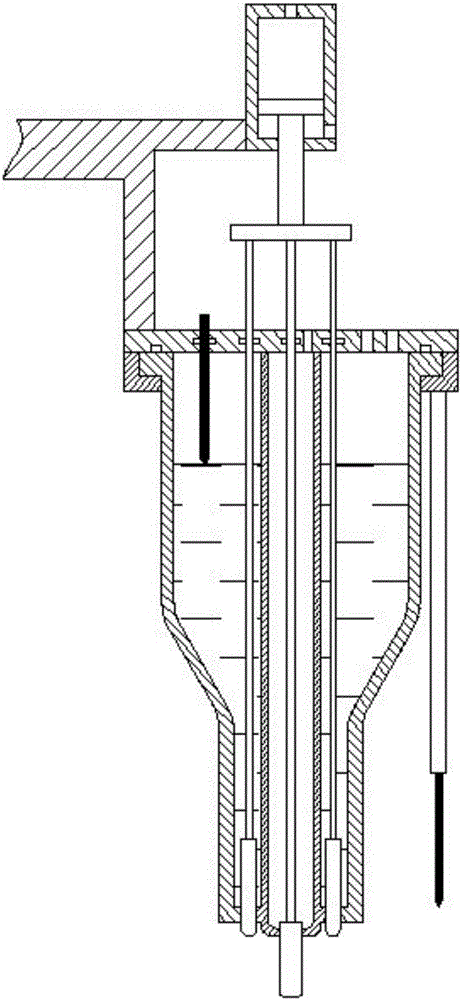

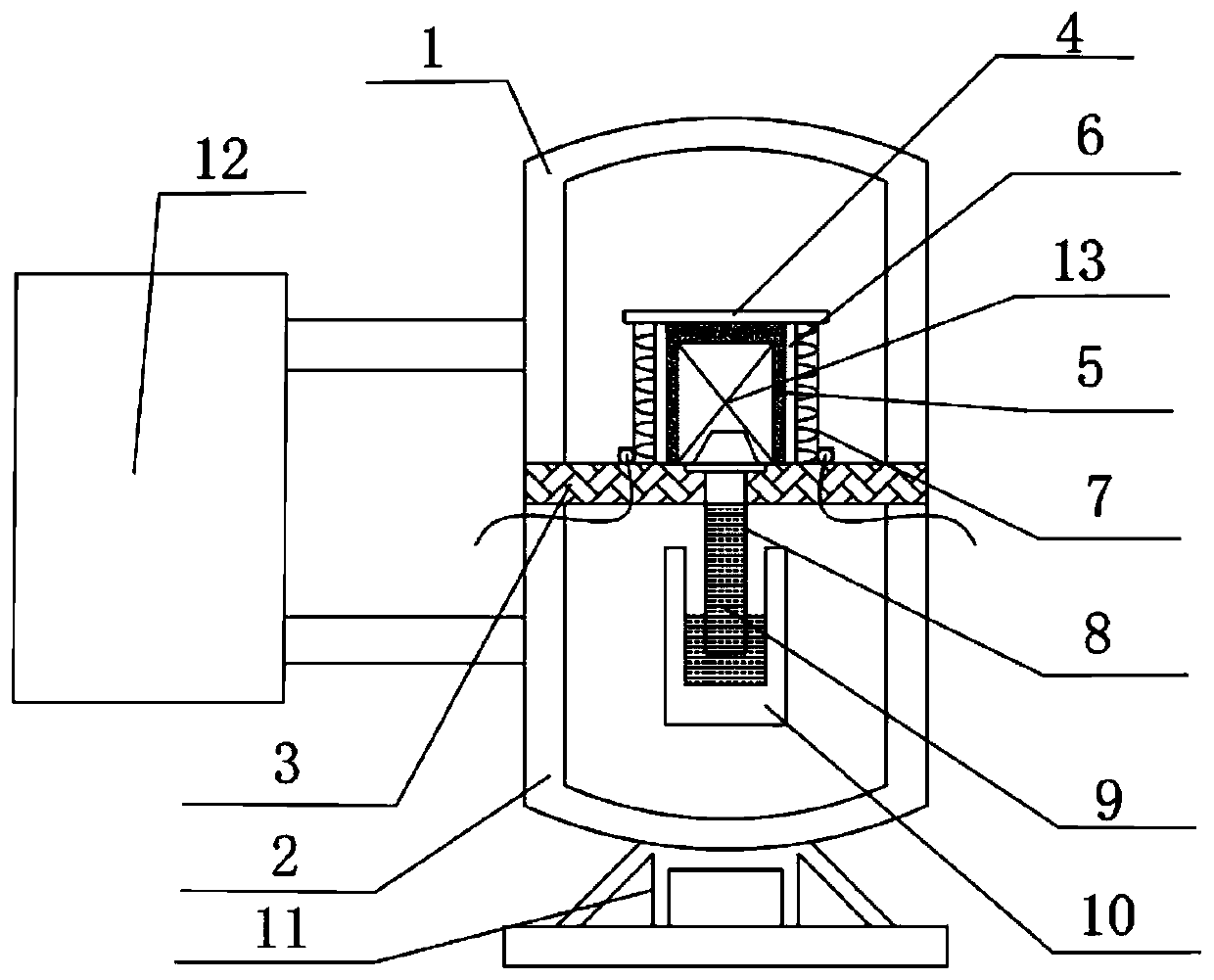

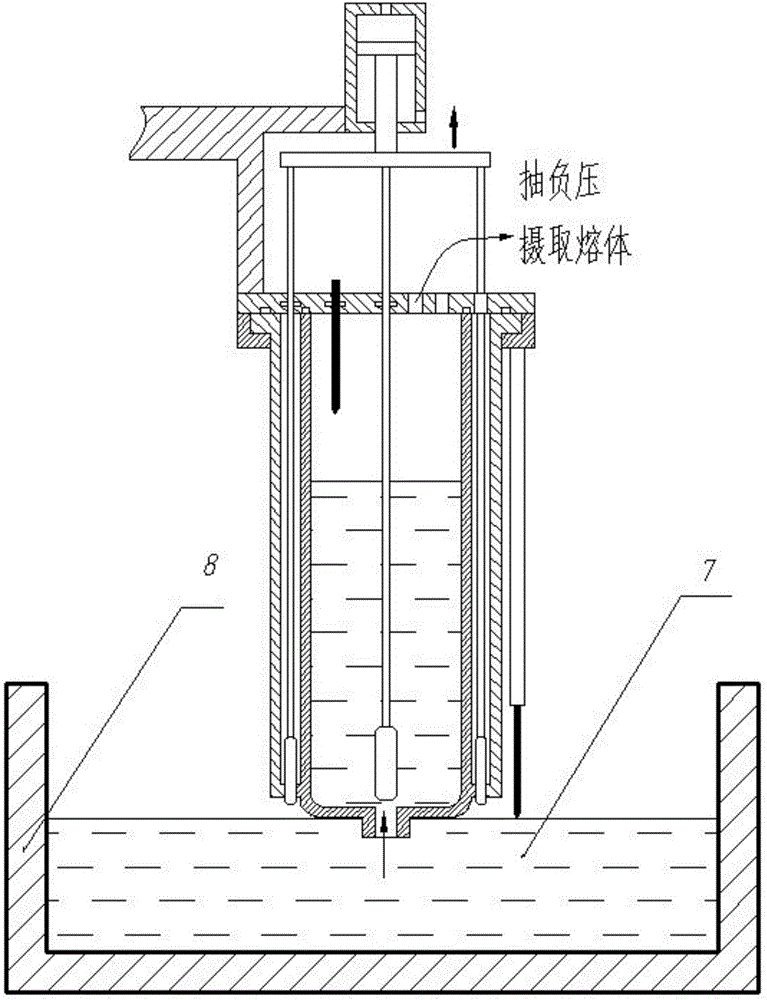

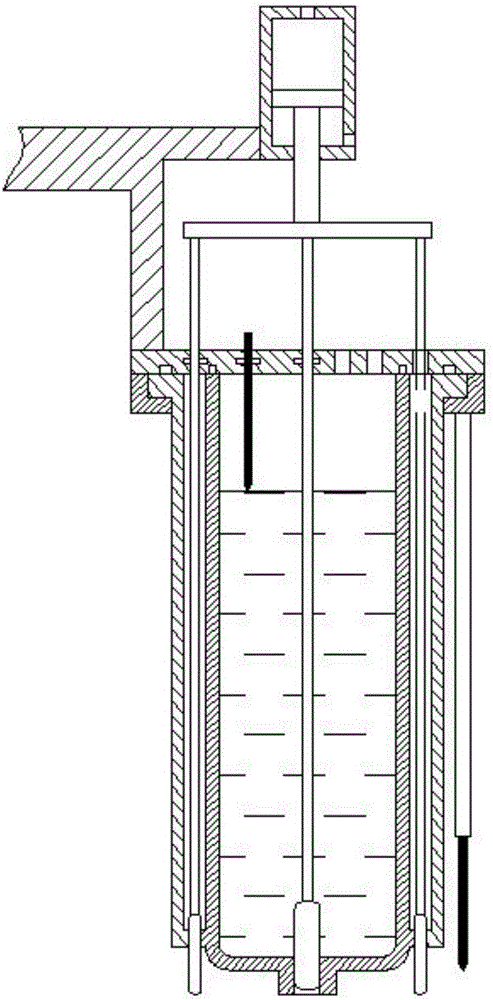

Multipurpose vacuum casting device

ActiveCN103170596AImprove liquidityAchieve oxidation inclusionsIncreasing energy efficiencyFailure rateVacuum pumping

A multipurpose vacuum casting device comprises a smelting furnace and a set of vacuum pumping system communicated with an inner cavity of the smelting furnace. The smelting furnace is provided with a casting pull-down continuous casting molding system which is formed together with the smelting furnace, a vacuum smelting system used for melting metal and a vacuum casting system used for ingot casting molding. Due to adoption of only one set of vacuum pumping system and one smelting furnace, a plurality of purposes such as vacuum induction heating smelting, vacuum casting, vacuum smelting and continuous casting under protection of inert gas can be achieved, the number of device components is greatly reduced, structure of a device is simplified, manufacture cost of the device is decreased to a large extent, production efficiency and casted blank quality are improved, operation is convenient and failure rate of the device is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

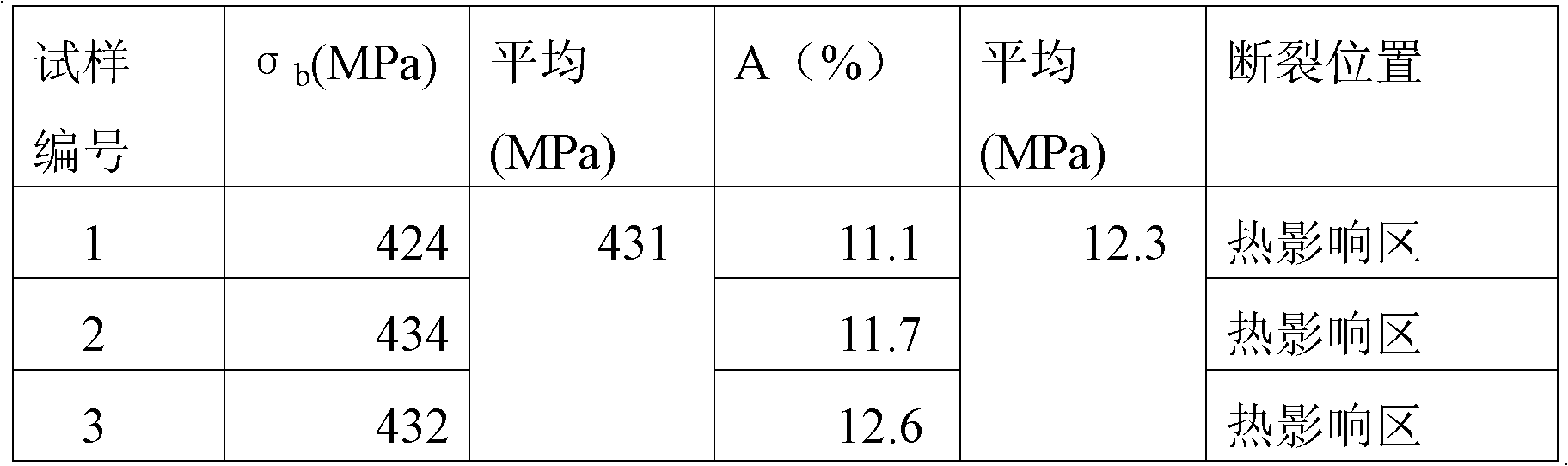

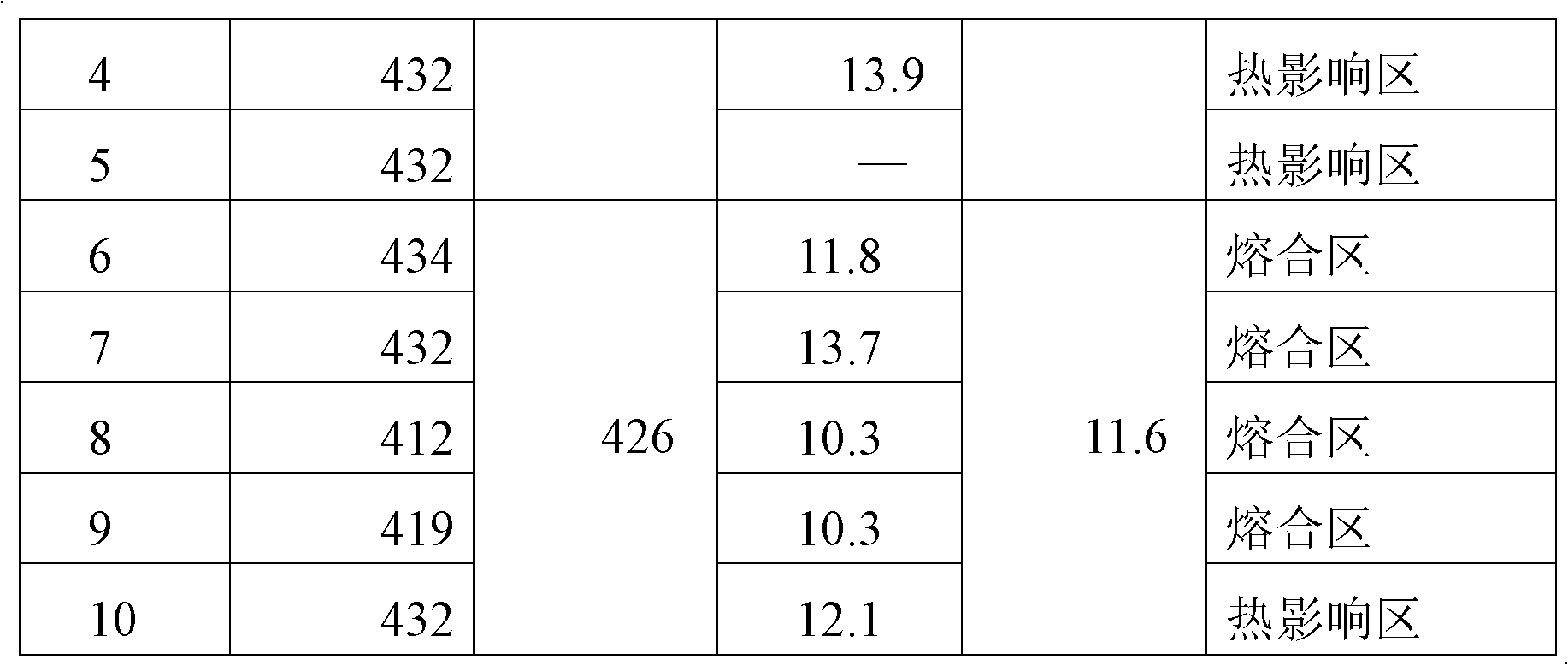

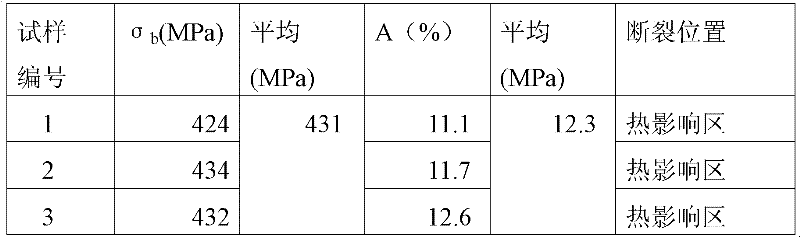

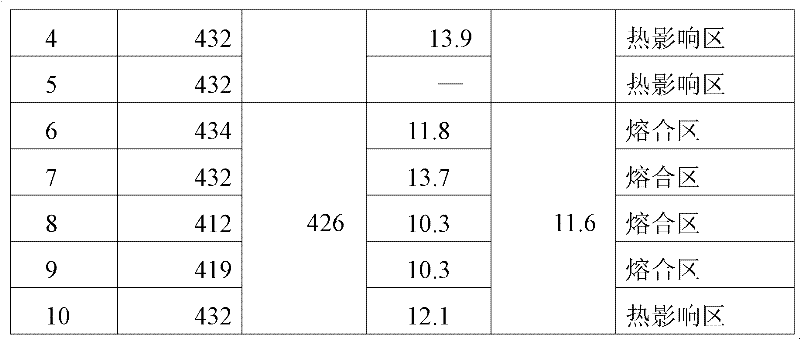

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122AImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

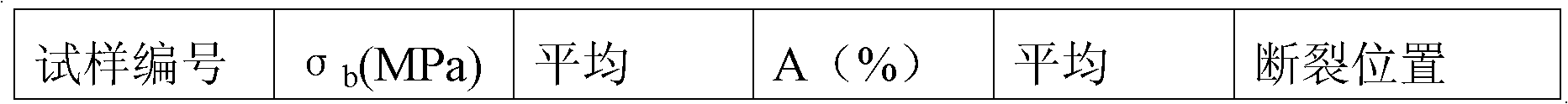

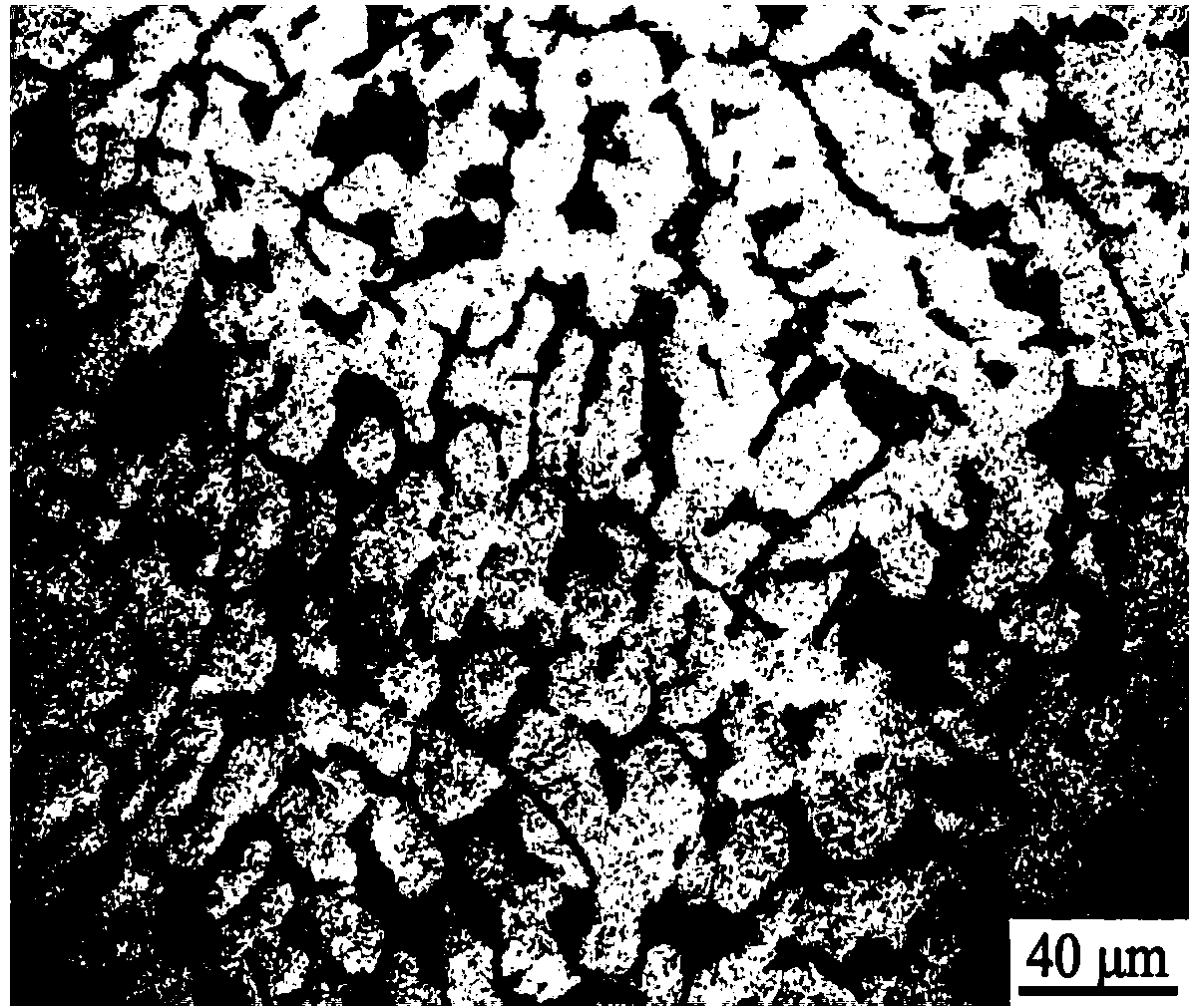

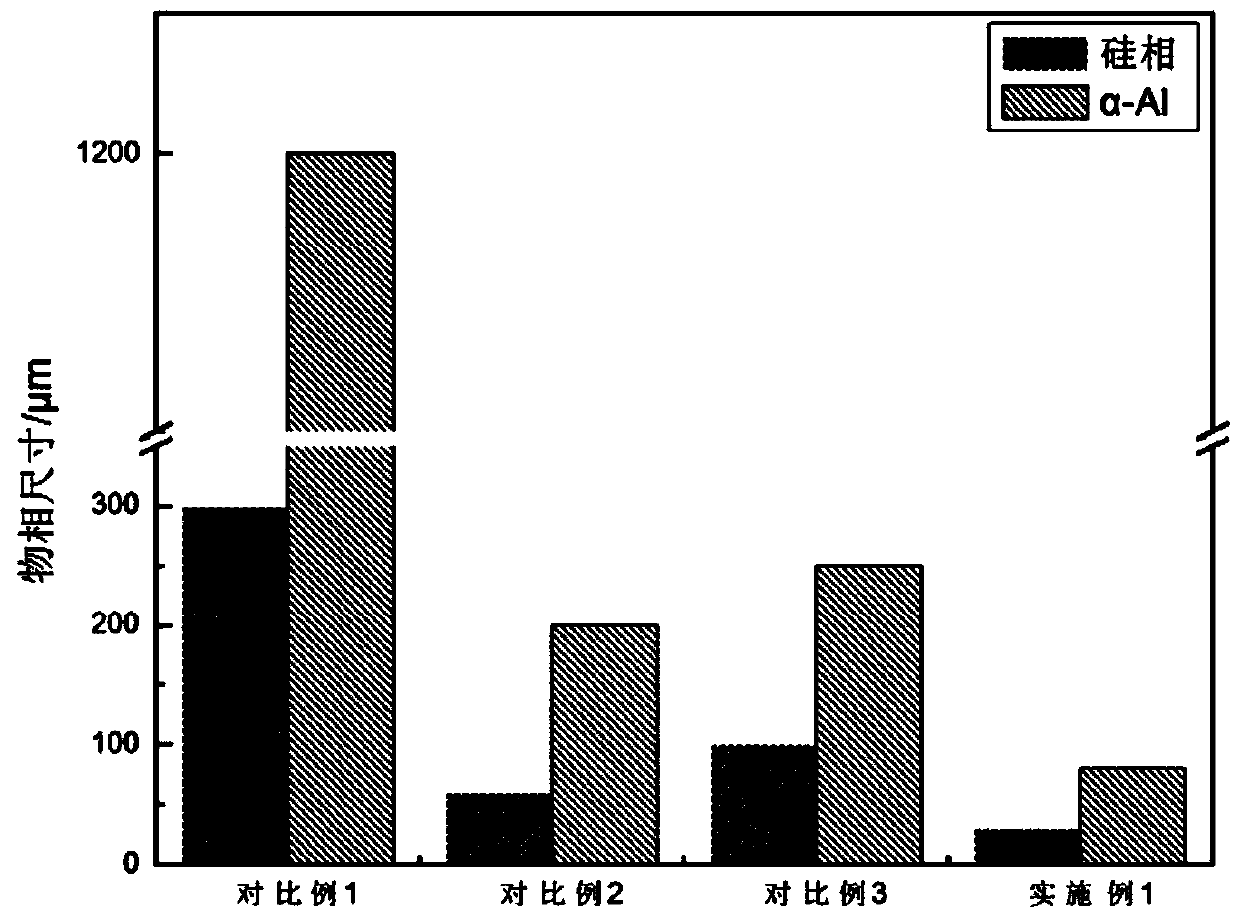

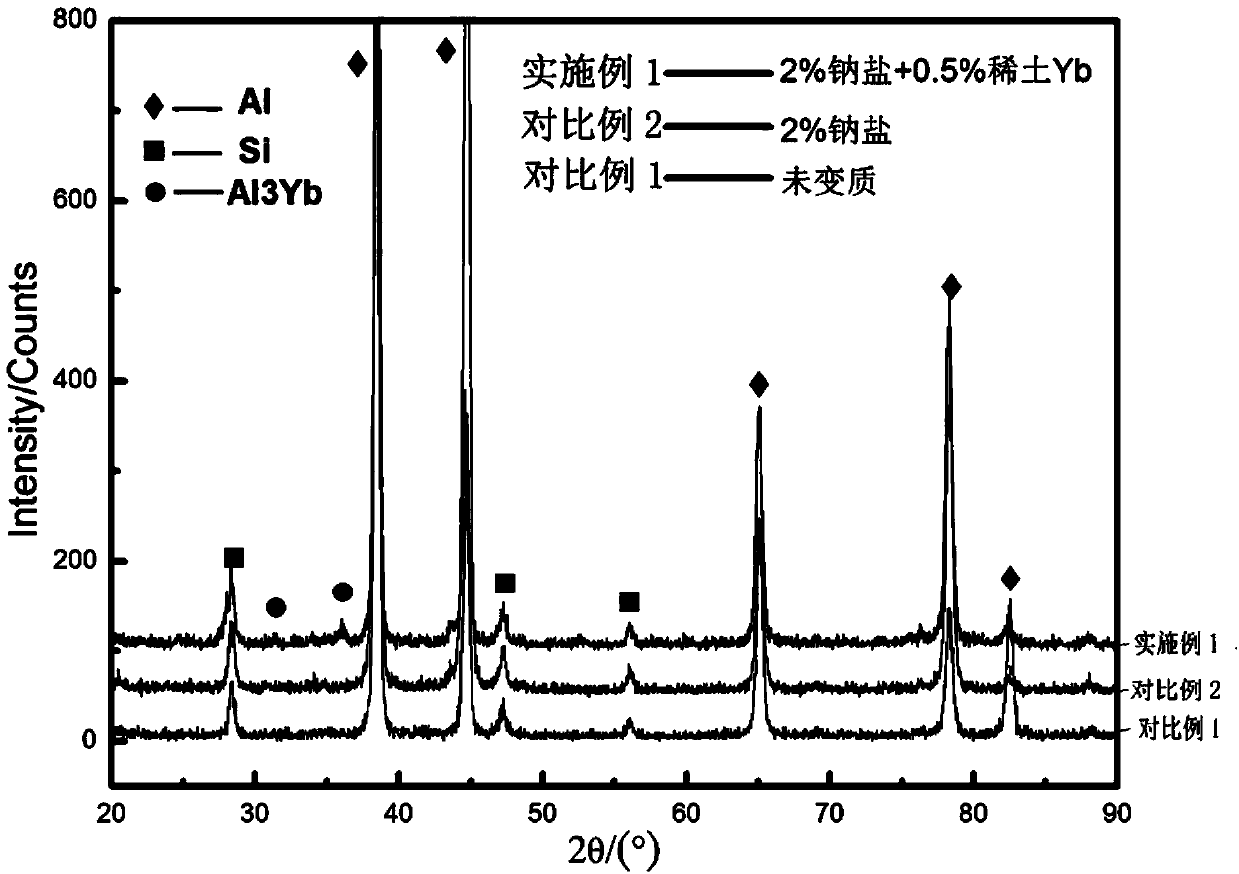

Composite metamorphic cast aluminum alloy and preparation method and application thereof

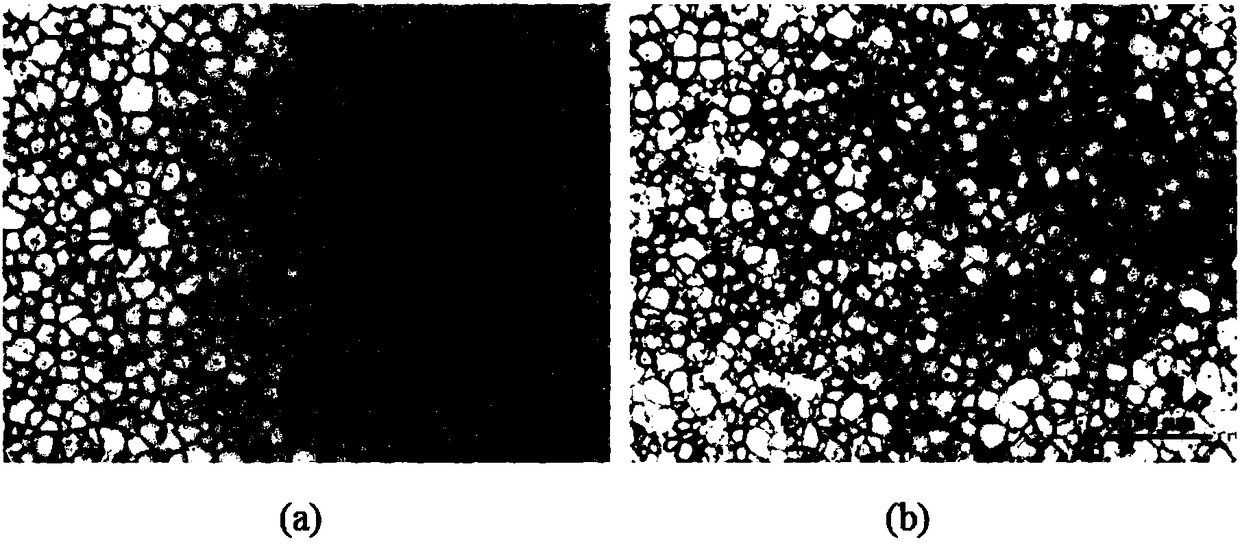

The invention provides a composite metamorphic cast aluminum alloy. The composite metamorphic cast aluminum alloy comprises, by weight, 8.0 % to 10.5 % of Si, 0.17 % to 0.3 % of Mg, 0.2 % to 0.5 % of Mn, 0.1 % to 1.0 % of Yb, 0.5 % to 3.0 % of sodium salt, less than 0.2 % of Fe, less than 0.1 % of Sn, less than 0.1 % of Cu and less than 0.05 % of Pb and the balance Al, wherein the Fe, the Sn, the Cu and the Pb are limited impurity elements. The invention further provides a preparation method and application of the composite metamorphic cast aluminum alloy. Due to metamorphism of the heavy rare earth element Yb and the alloying function, the casting-state structure of the alloy is significantly refined, strength and toughness of the alloy are improved, oxidation blending imported by the sodium salt metamorphism is reduced, and the compactness of a casting is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

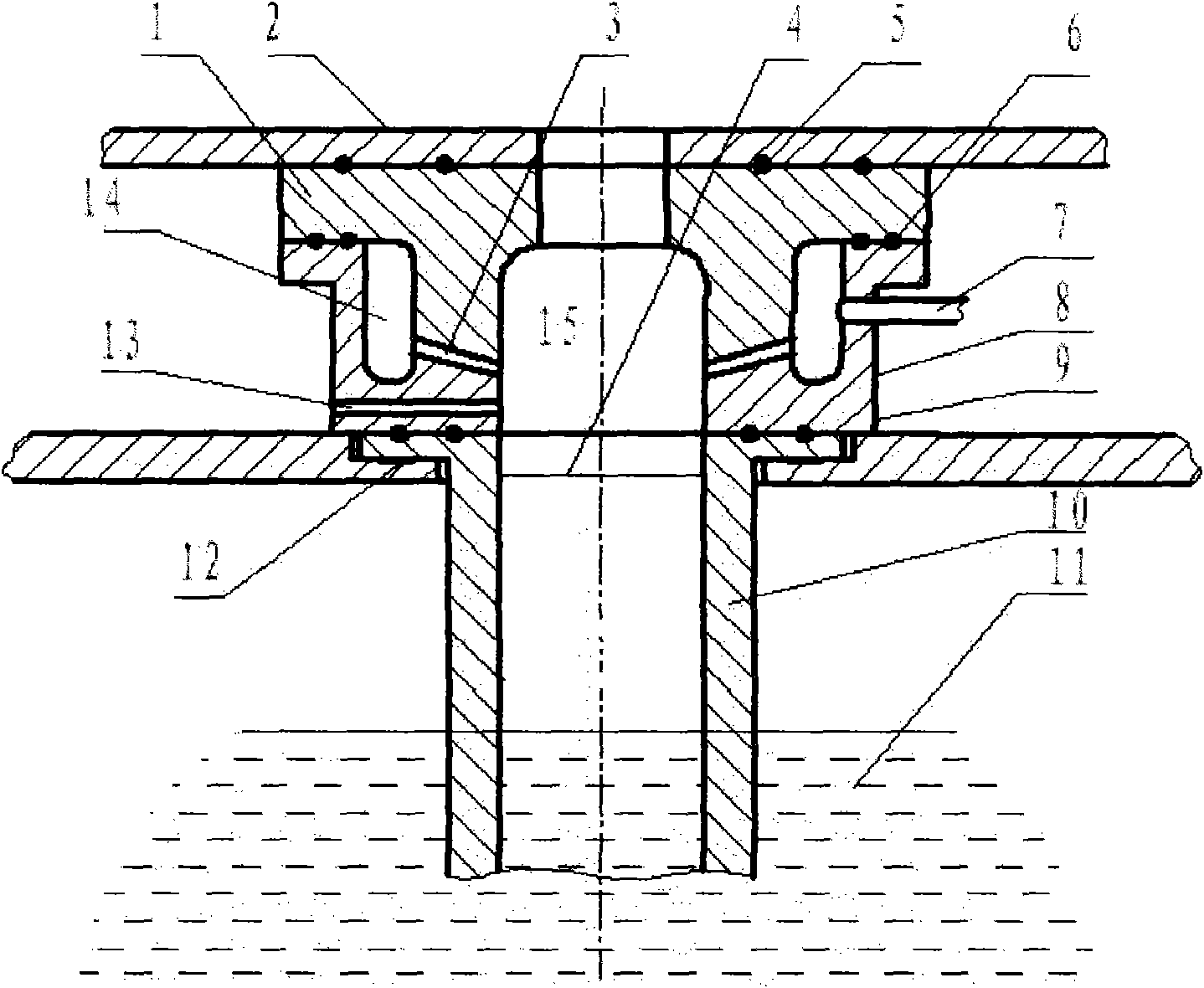

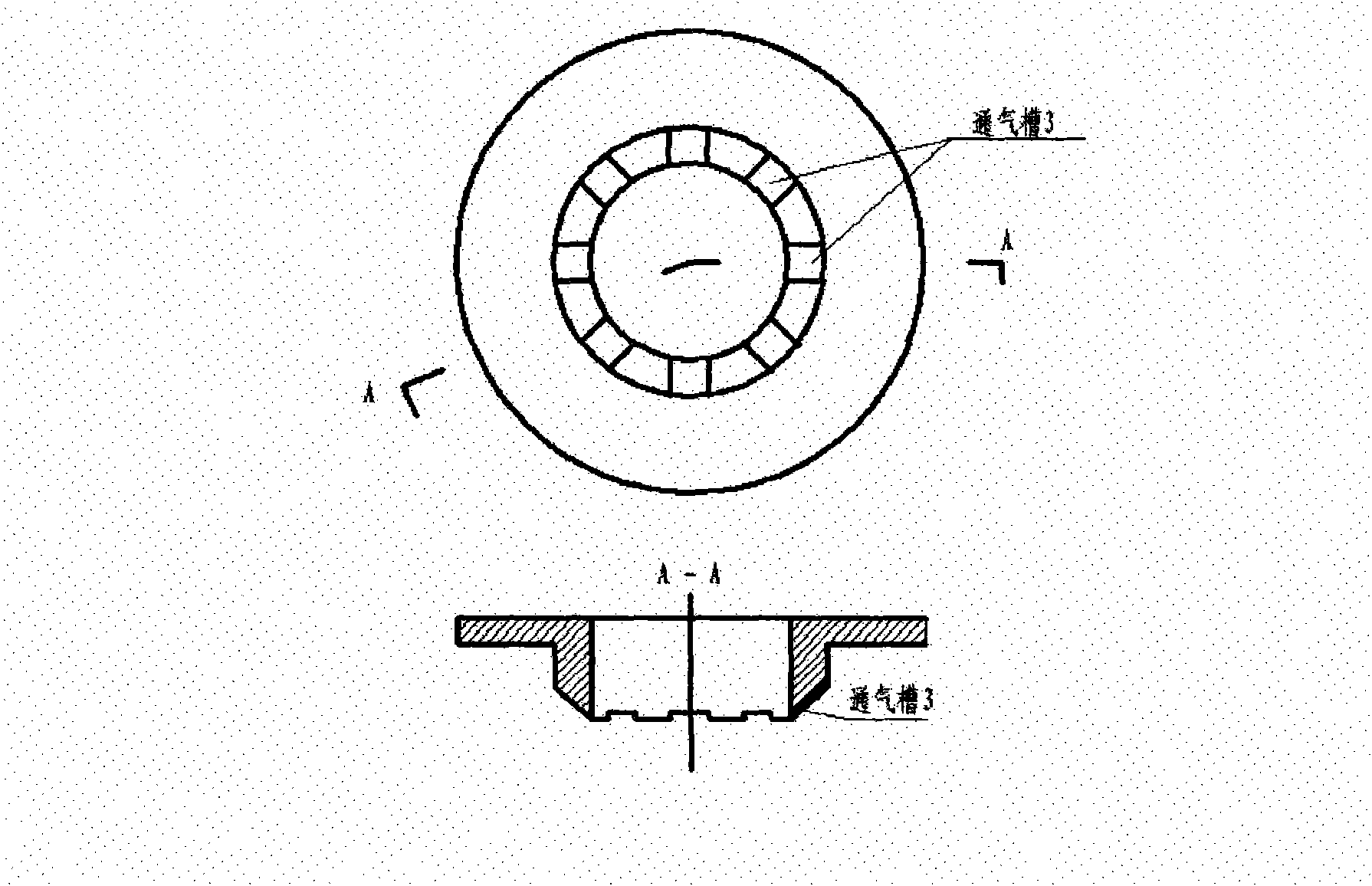

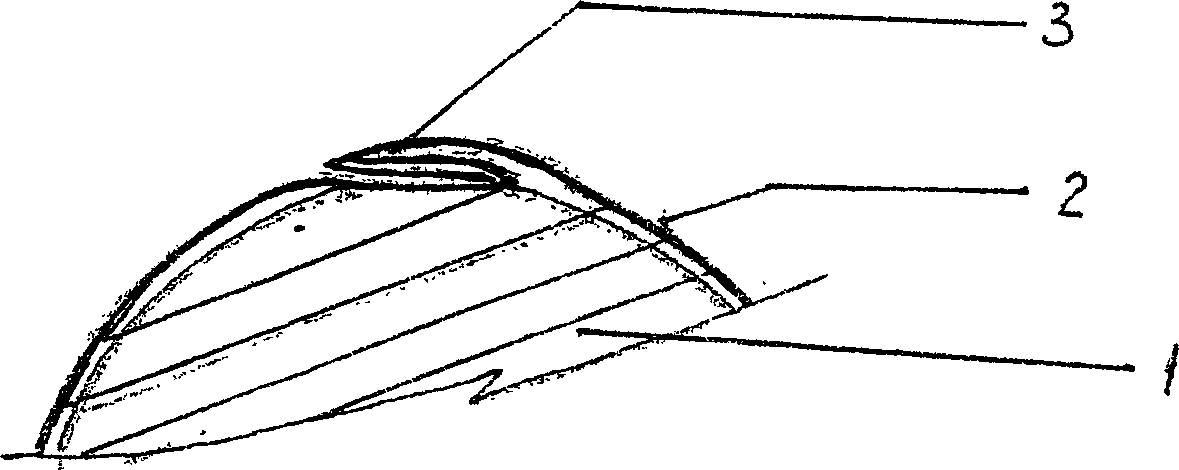

Low-pressure casting filling method and low-pressure casing filling equipment used by same

The invention relates to a low-pressure casting filling method comprising the steps of arranging a reducing sleeve arranged on an upper port of a riser tube (10), guiding magnesium alloy liquid from the riser tube (10) to a cast through the reducing sleeve; arranging a protective gas inlet on the reducing tube, and enabling the protective gas into the space above the magnesium alloy liquid in the riser tube (10) for protecting the magnesium alloy liquid in the riser tube (10) and reducing oxidation. The a low-pressure casting filling method uses a low-pressure casting filling device which includes the reducing sleeve composed of an upper part (1) of the reducing sleeve, a lower part of the reducing sleeve; wherein a magnesium alloy liquid sensor mounting hole (10) is arranged on a lower side wall of the lower part of the reducing sleeve; a plurality of subsize air suctions with enough section width are arranged on a joint face of the upper part (1) and the lower part (8) of the reducing sleeve, and the air suctions are slit structures with rectangular sections. The low-pressure casting filling method of the invention can obviously reduce the oxidation of the magnesium liquid in the riser tube and improve the quality of a magnesium alloy low-pressure casting member.

Owner:沈阳铸研科技有限公司

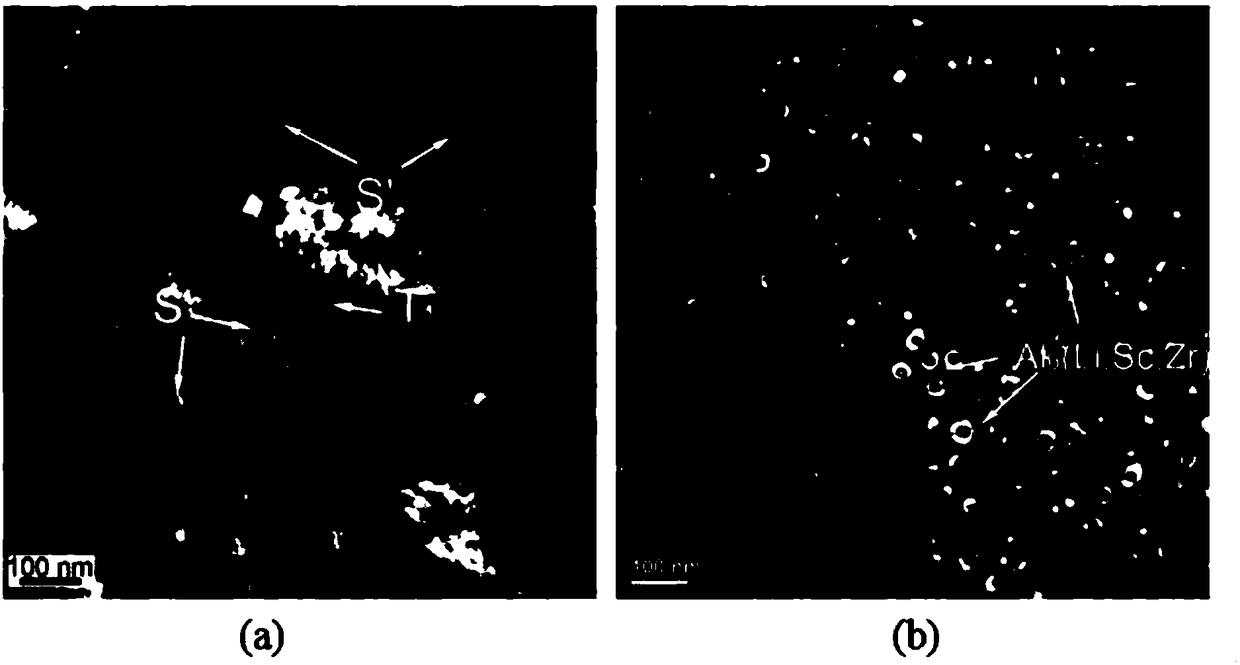

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

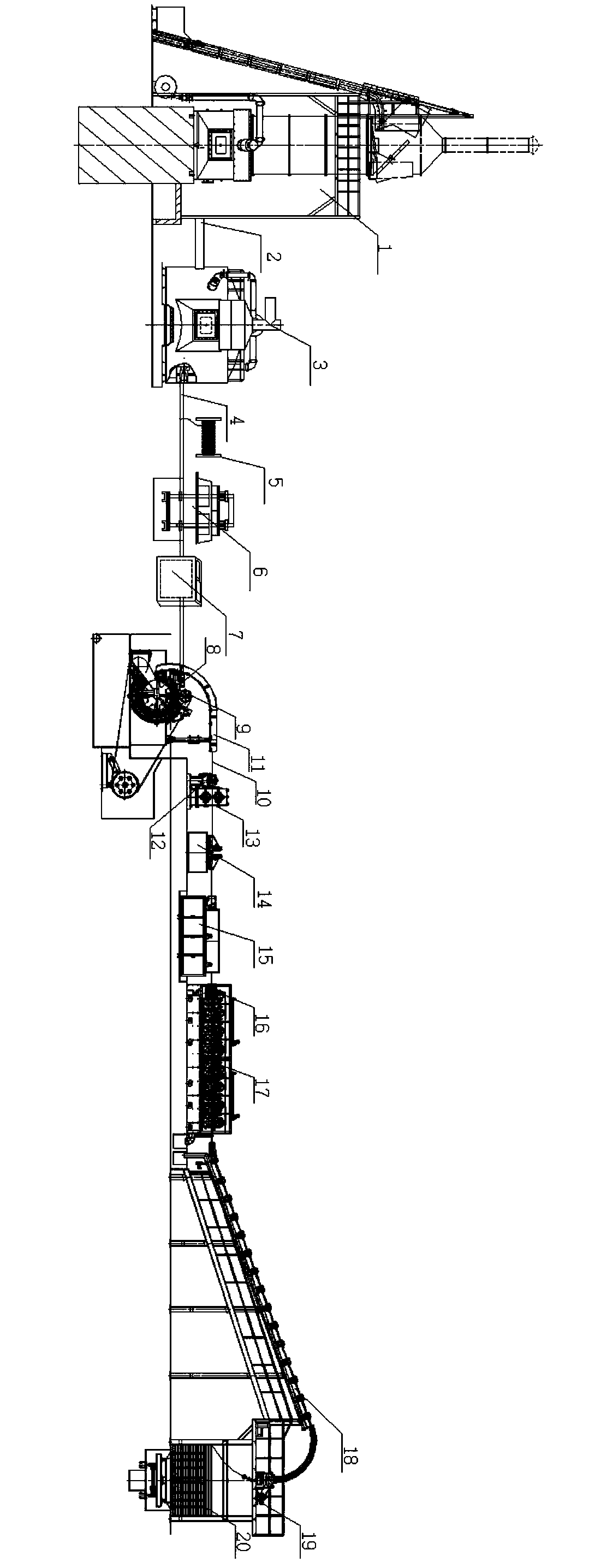

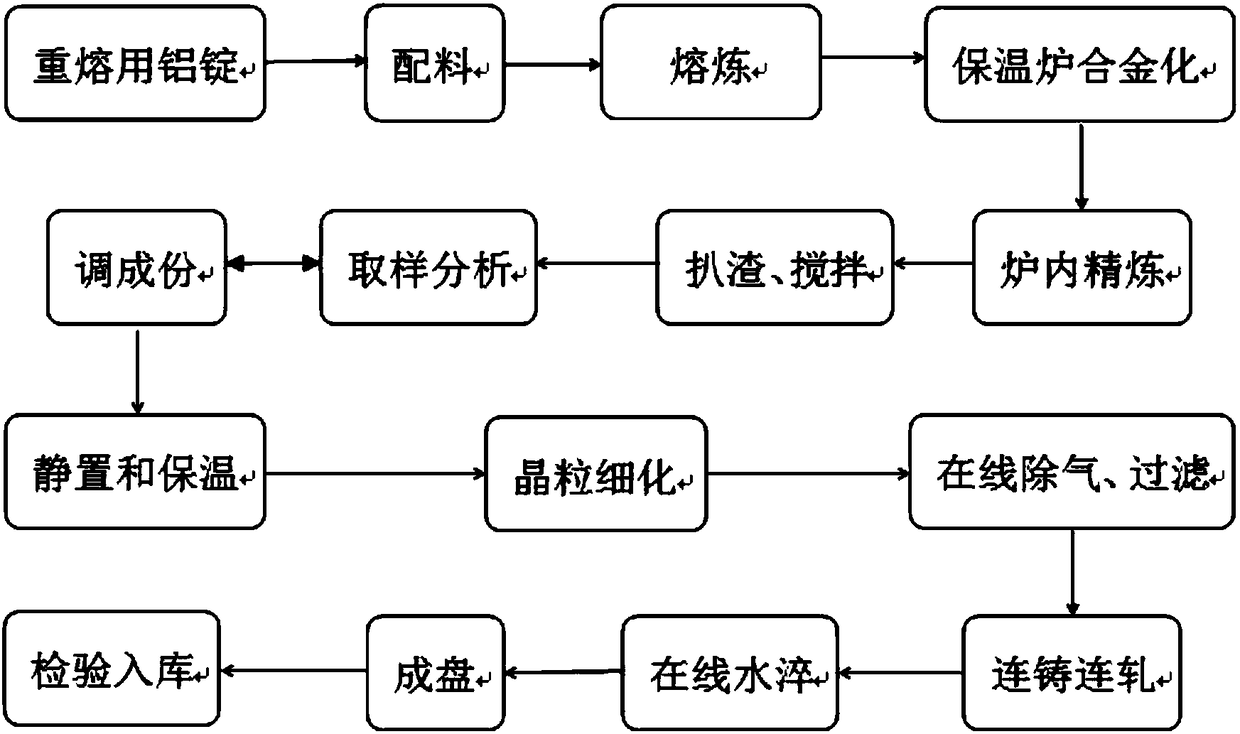

Continuous casting and continuous rolling production process for 5356 aluminum alloy welding rods

InactiveCN108300913AQuality assuranceControl contentMetal rolling arrangementsWire rodTemperature control

The invention relates to the technical field of aluminum alloy welding rods, in particular to a continuous casting and continuous rolling production process for 5356 aluminum alloy welding rods. The production process comprises the following steps: (1) smelting is performed; (2) continuous casting and continuous rolling are performed; a continuous casting cooling water constant-temperature technology, a roller temperature control technology and a continuous rolling emulsion constant-temperature technology are used for controlling the final rolling temperature within 340-460 DEG C; and water quenching is performed on the 5356 aluminum alloy welding rods of phi 9.5 mm by a cooling speed of higher than 100 DEG C / min; and (3) wire rods are cooled to 100 DEG C through an oilless guide rod waterquenching system by the cooling speed of higher than 100 DEG C / min; and under the effects of back traction and a continuous rod winding system, double frames collect the rods as coils for binding asdiscs. The 5356 aluminum alloy welding rods with low hydrogen-low oxide inclusion-bright surface-stable quality-uniform structure are produced by the continuous casting and continuous rolling production process through a controlled rolling and controlled cooling technology.

Owner:江苏和拓铝线有限公司

Casting method of spheroidal graphite cast iron valve

ActiveCN108531803AStable productionReduce manufacturing costFoundry mouldsFurnace typesElectricitySlag

The invention discloses a casting method of a spheroidal graphite cast iron valve, and relates to the spheroidal graphite cast iron valve. The method comprises the steps of model making, modeling, smelting, pouring, heat treatment and obtaining of a finished product valve casting. Alloy elements are not added, the spheroidal graphite cast iron valve with the supersize can be stably produced, a dedicated slag blocking device is arranged at the front end of a transverse sprue, when molten iron of the transverse sprue is introduced into the front end, the slag blocking effect is achieved, it is ensured that a mold cavity is rapidly and stably filled with the molten iron, oxide inclusions are reduced, a heat preservation top riser is adopted, and is placed on the top of the valve, and castingfeeding, slag discharging and exhausting are facilitated; a chilling block is arranged at the position, on the large and thick section and the portion with the large wall thickness difference, in thecasting, chromite sand is used around an even core and a shaft head in a shaft hole of the casting, the upper portion of an annular belt is paved with chromite sand, it is ensured that the casting canbe subject to directional sequential solidification, and meanwhile, the casting surface quality is ensured, and the method is particularly suitable for making a spheroidal graphite cast iron water and electricity butterfly valve with the supersize and the large section.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

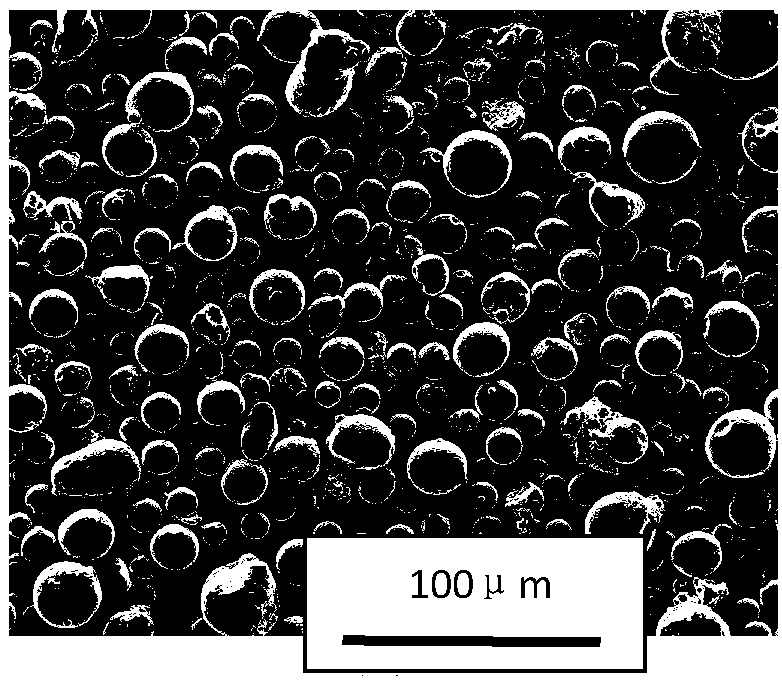

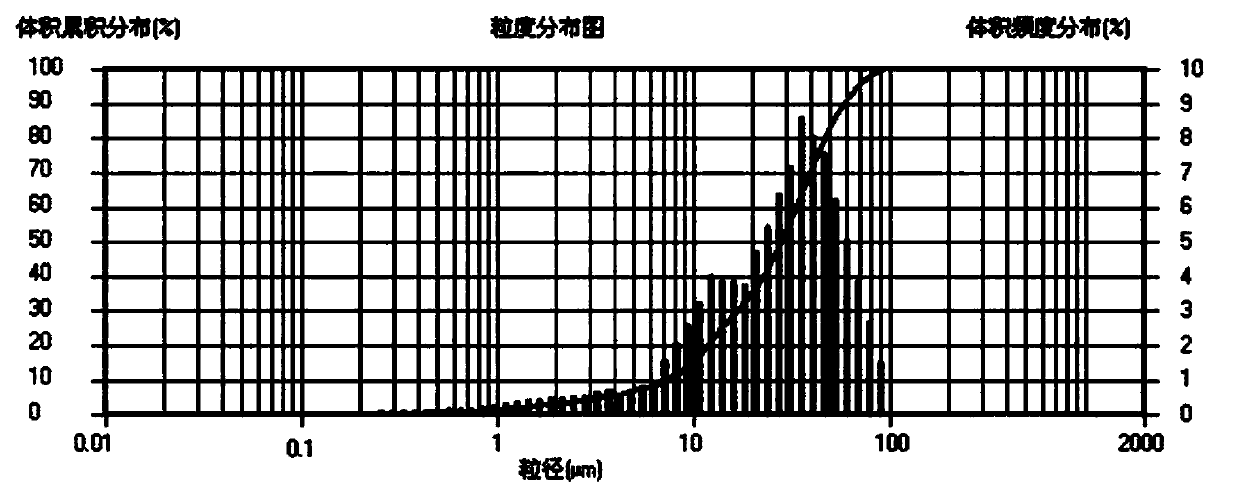

Ta-contained 3D printing cobalt chromium molybdenum alloy powder for dental department and preparation method thereof

ActiveCN107598151ASolve the broken porcelainSolve the problem of porcelain peelingAdditive manufacturing apparatusChemical compositionBond properties

The invention provides Ta-contained 3D printing cobalt chromium molybdenum alloy powder for the dental department and a preparation method thereof. The chemical components of the alloy power comprise,by weight, 26.0%-30.0% of Cr, 8.0%-10.0% of Mo, 0.5%-5.0% of Ta, 3.0%-8.0% of W and the balance Co. The preparation method of the Ta-contained 3D printing cobalt chromium molybdenum alloy powder comprises the three steps of mother alloy smelting, powder atomization, powder screening and drying treatment. According to the alloy powder, the particle size, the sphericility degree and the mechanicalproperty are ensured, and meanwhile, the gold-procelain bonding property, the thermal stability and the flowability are improved while the oxygen content is reduced, the problems of porcelain crackingand porcelain spalling of a cobalt chromium molybdenum alloy are effectively solved, and obtaining of dental rebuilt parts with the high quality is facilitated.

Owner:CHENGDU KENINGDA MATERIALS

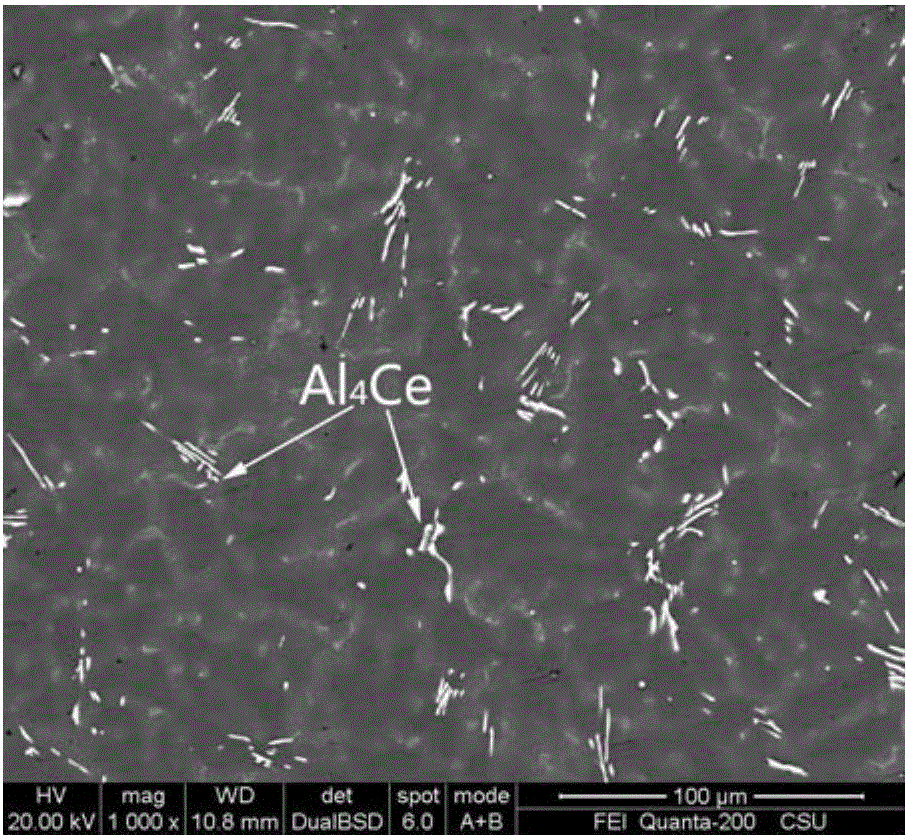

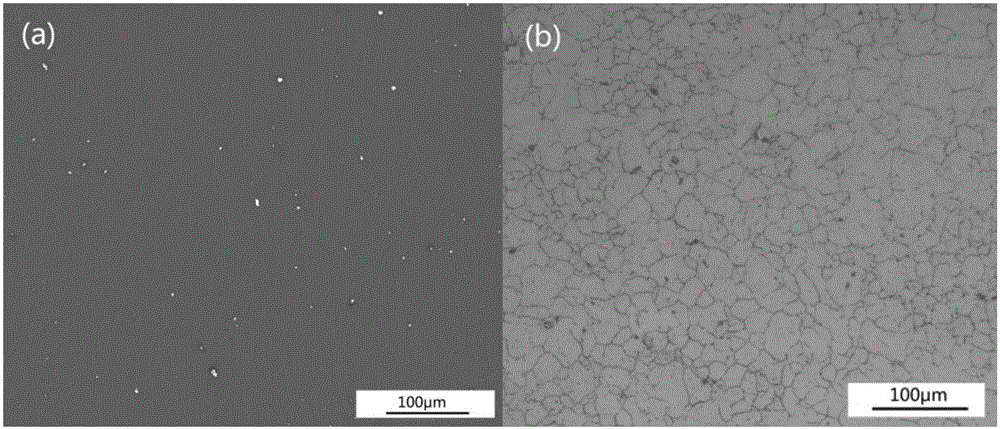

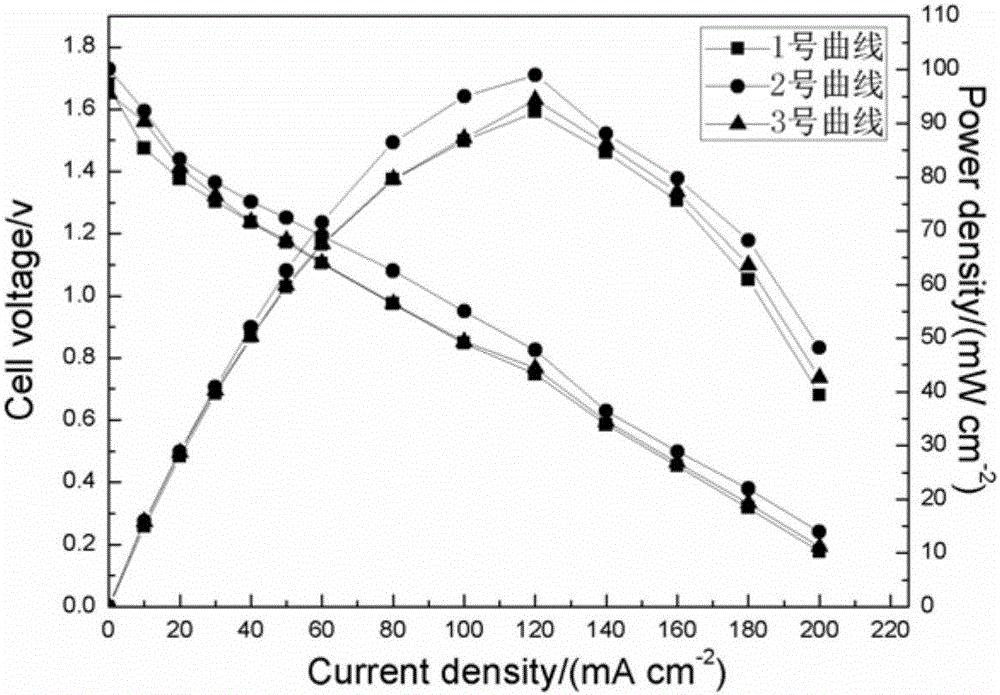

Mg alloy anode material and preparation method thereof

ActiveCN105925862AImprove electrochemical performanceUniform performanceChemical compositionElectrochemistry

The invention relates to a Mg alloy anode material and a preparation method thereof, and belongs to the technical field of development and preparation of novel anode materials for high-power chemical power sources. The Mg alloy anode material can be utilized as an anode material for a seawater battery or an air battery, and comprises the following chemical components in percentage by mass: 4-7% of Al, 0.5-1.5% of Sn, 0.05-0.5% of Ce, and the balance of Mg and impurities, wherein the total content of the impurities is lower than or equal to 0.01%. A Mg alloy plate being good in electrochemical property, relatively low in self-corrosion rate and high in anode efficiency is obtained by subjecting the Mg alloy anode material to such metal material machining processes as smelting, heat treatment, extrusion and rolling. The Mg alloy anode material provided by the invention has the advantages that the component design is reasonable, the preparation process is simple, the properties of the obtained product are good, and the large-scale industrialized application is facilitated.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

Covering flux of vitrous body of magnesium alloy and manufacturing method

This invention provided a Mg alloy glass covering flux and its production method. The mass percentage sphere of the flux chemical composition is: MgCl 45-65%, KCL10-22%, NaCl10-22%, CaCl2 2-10%, CaF3-10%, MgO2-8%, cryolite: 2-6%, glass agent 0.5-5%, among which, the glass agent is boric oxide / or sodium borate. The flux is in glass state under high temperature and no crack appears in the stirred solution in the Mg melt so that it increase the protection effect for over 3.5 hours.

Owner:SHANGHAI LIGHT ALLOY NET FORMING NAT ENG RES CENT

ZG022Cr22Ni5Mo3N material duplex stainless steel smelting process

The invention discloses a ZG022Cr22Ni5Mo3N material duplex stainless steel smelting process. A medium-frequency induction furnace smelting process and an AOD furnace refining process are performed insequence; nitrogen alloying can be realized through nitrogen blowing; carbon in steel can be removed to reach a requested target value; the contents of harmful elements such as sulfur, oxygen and hydrogen in the steel can be reduced to the greatest extent, so that the purity and the quality of molten steel are greatly improved; poured castings achieve excellent welding performance, fatigue resistance and mechanical performances; the metallographic structure is uniform; the two-phase ratio is near 50%; the corrosion resistance is excellent; and the hot tearing and cold tearing tendency is reduced at the same time, so that the service life of the castings is prolonged, the manufacturing cost is greatly reduced, and the purposes of energy conservation, consumption reduction and environmentalprotection are achieved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

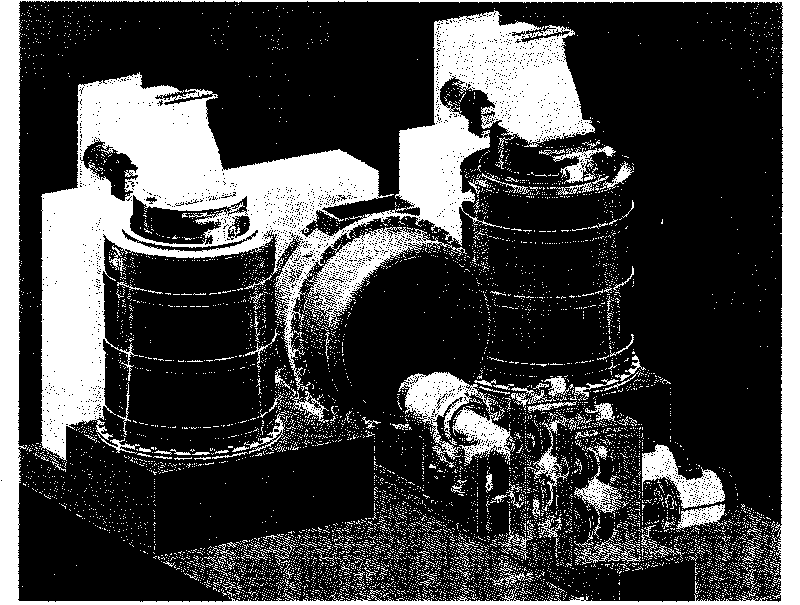

High-performance magnesium alloy parison continuous casting production line

The invention discloses a high-performance magnesium alloy parison continuous casting production line and relates to the technical fields of vacuum magnesium alloy metallurgy and material preparation. The production line is used for producing high-strength deformation magnesium alloy parison materials by whole-course vacuum protection. Equipment for the production line is provided with two vertical melting furnaces used for melting magnesium medium alloy or working alloy, wherein each melting furnace is divided into the two following parts in space: a hermetic melting chamber and a hermetic furnace body; and the pressure of the furnace body is lower than that of the melting chamber so as to form a vacuum barrier and double vacuum protection melting. Feeding cabins are arranged above furnace covers of the melting furnaces, and the opening and closing of doors of the cabins is matched with the conversion of pressure in the cabins so as to eradicate oxidization and burning of magnesium during feeding materials into hot furnaces. A heat insulation and homogenization furnace is arranged between the two melting furnaces to mix liquid coming from the melting furnaces and prepare magnesium alloy containing target components, and then the heat insulation and homogenization furnace stand still to preserve heat. An inoculation agent and leavening agent flowing addition mechanism is arranged on a gap bridge so as to effectively increase cores and prevent recession. Magnetic stirring is carried out in a crystallization process to control the pressing force and the traction speed of a tractor in real time. The equipment has compact structure, safe production and no pollution.

Owner:武汉镁里镁科技有限公司

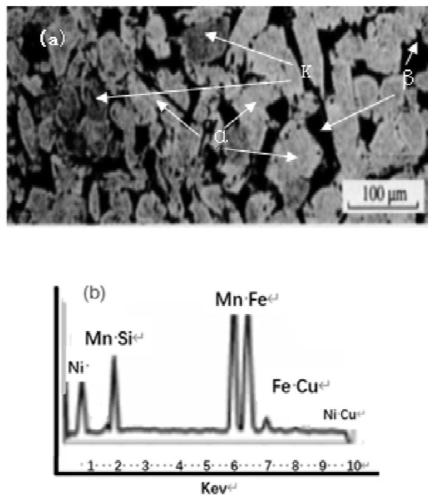

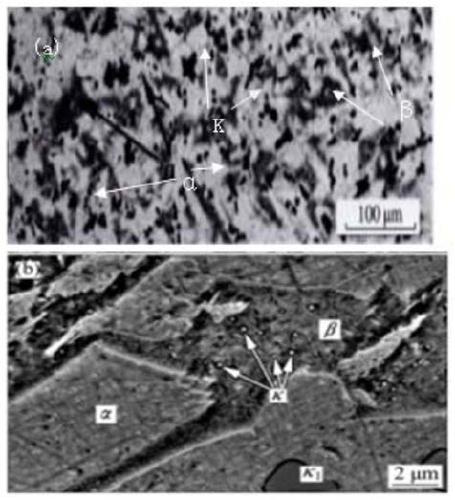

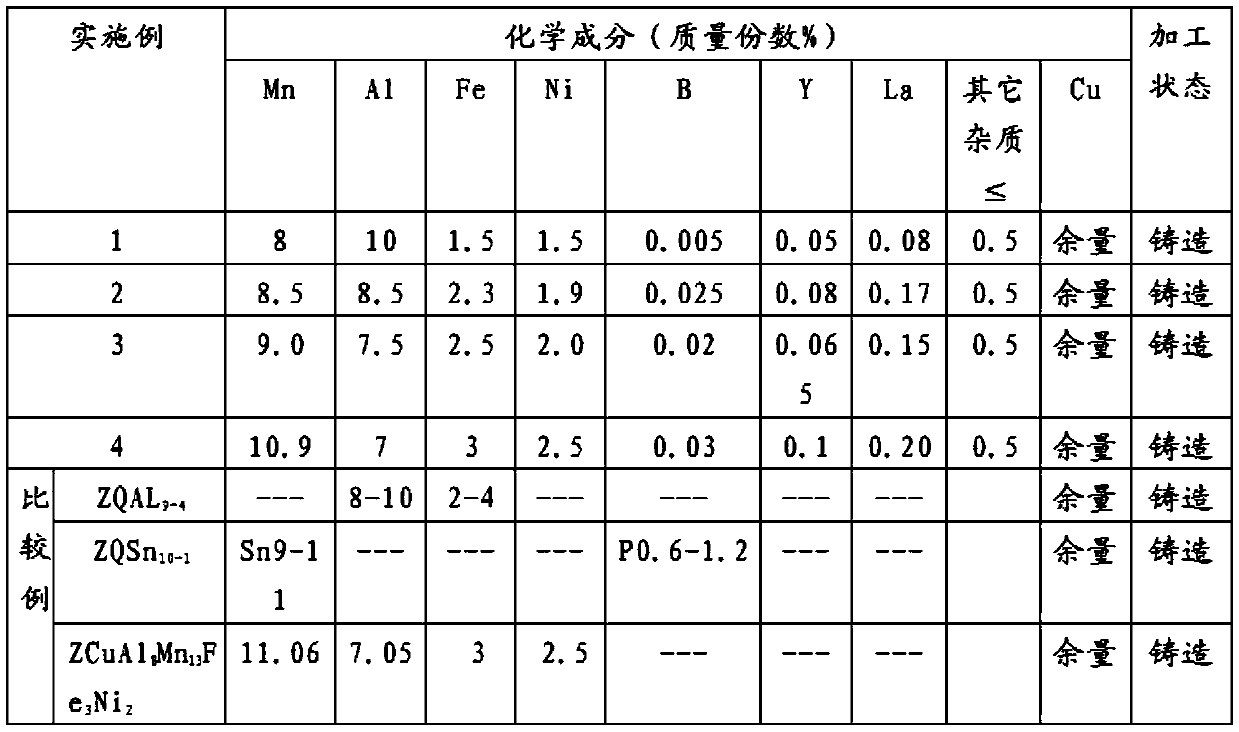

Wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy and preparation method thereof

The invention belongs to the field of alloy manufacturing, and particularly relates to a wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy and a preparation method thereof. The wear-resistant corrosion-resistant multi-element manganese aluminum bronze brazing alloy is prepared from the following components in parts by weight: 7-10% of Al; 8-11% of Mn; 1.5 to3.0% of Fe; 1.5 to 2.5% of Ni; 0.005-0.03% of B; 0.05 to 0.1 of Y; 0.08-0.20% of La, and the weight ratio of the three elements of B to Y to La is 1: 10: 15-1: 3: 6, and other impurities are less thanor equal to 0.5 percent. The balance is Cu. The wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy disclosed by the invention is composed of Al, Mn, Fe, Ni, B, Y, La and Cu, the casting temperature is equal to or lower than 1050 DEG C, and the mechanical property is good. The alloy material is used for cladding an inner wall of a cylinder in a hydraulic support, has bright surface, less deformation, hardness of more than HB240, good wear resistance and corrosion resistance, the operation up to now has always been 2 times of the life of the original material, and the alloy material is still normally used.

Owner:TIANJIN JINLONG WELDING MATERIAL

Covering agent for heat preservation of copper and copper alloy inside furnace

The invention pertains to copper alloy processing field. A heat preserving furnace of the existing continuous casting copper and copper alloy technique has the shortcomings of no covering agent or the existing covering agent with high cost and poor effect. In the invention, the metals covered on waste graphite electrodes and waste graphite crystallizers are removed, smashed into graphite powder with a granularity ranging from 3 to 750Mum to be taken as a covering agent, so as to form an excellent protective layer with a thickness ranging from 3 to 40mm on the surface of the molten metal surface in the heat preserving furnace. Compared with the existing rice bran covering agent, the covering agent does not cause environmental pollution, the temperature of the external surface of the heat preserving furnace is reduced by 30 to 50 DEG C, and the slag collecting cycle from the time that a new covering layer is formed to the time that slag has to be collected is extended by 500 to 800 percent, the total ash and slag is reduced by 40 to 80 percent, copper particles in the ash and slag is cut down by 60 to 110 percent, the cycle that the slag attached on furnace wall has to be destroyed is lengthened by 700 to 1400 percent, and the slag is easy to clean up, the service life of the continuous caster is prolonged by 30 to 150 percent. The covering agent of the invention is suitable for such non-Ni copper alloys as red copper, brass, Sn-P bronze for vertical continuous casting, up-drawing continuous casting and horizontal continuous casting, and optimized copper alloy of the invention is suitable for non-Ni copper alloy molten by waste copper for horizontal continuous casting.

Owner:JINTIAN COPPER GROUP CORP NINGBO +1

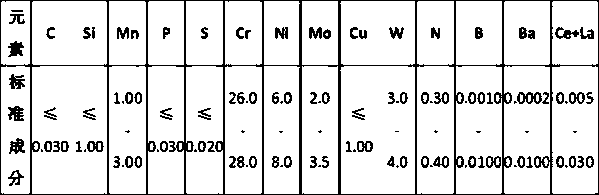

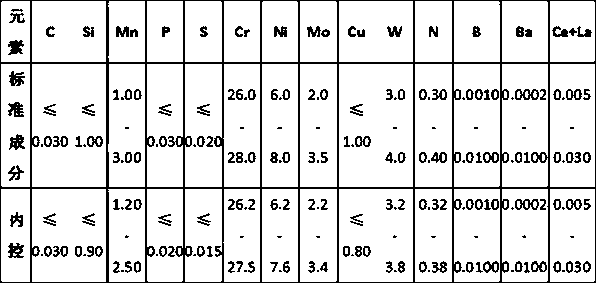

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

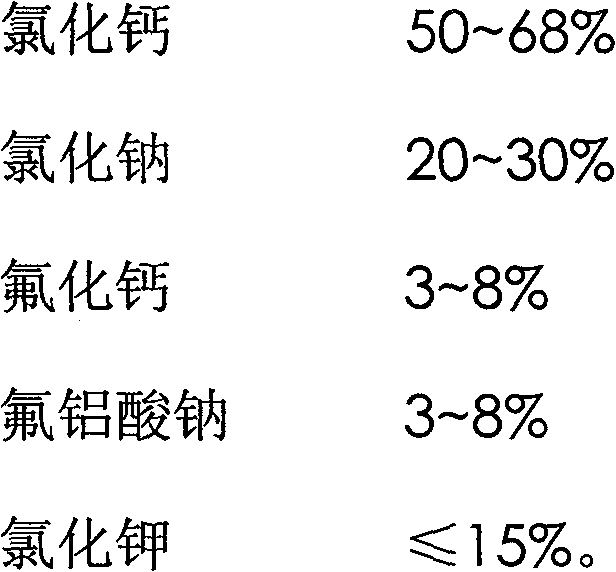

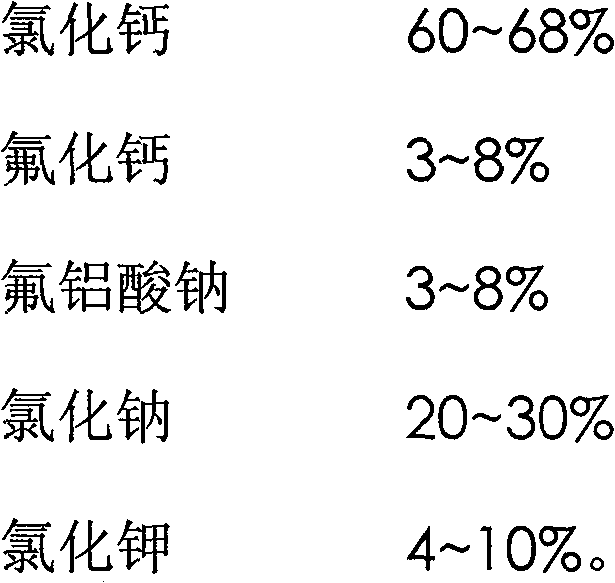

Covering agent for smelting copper alloy

The invention discloses a covering agent for smelting copper alloy, which is prepared by adopting the mixture of calcium chloride, potassium chloride, sodium chloride, sodium fluoaluminate and calcium fluoride; one layer of favourable protective layer with the thickness of 5-80 mm is formed on the surface of smelting furnace solution so as to effectively prevent oxygen in air outside a molten pool from entering and avoid oxidation burning loss of alloy elements in the smelting process, and the covering agent has the action of thermal insulation. The covering agent of the invention can ensure that copper alloy requiring vacuum smelting can be smelted under the atmospheric environment. The covering agent of the invention is suitable for smelting copper alloy, such as copper zirconium, copper chromium, copper magnesium, copper chromium zirconium and the like which contain oxidizable elements, and is suitable for ingot blank casting, vertical continuous casting, horizontal continuous casting, up-drawing continuous casting and the like.

Owner:SHENYANG NONFERROUS METALS PROCESSING CO LTD

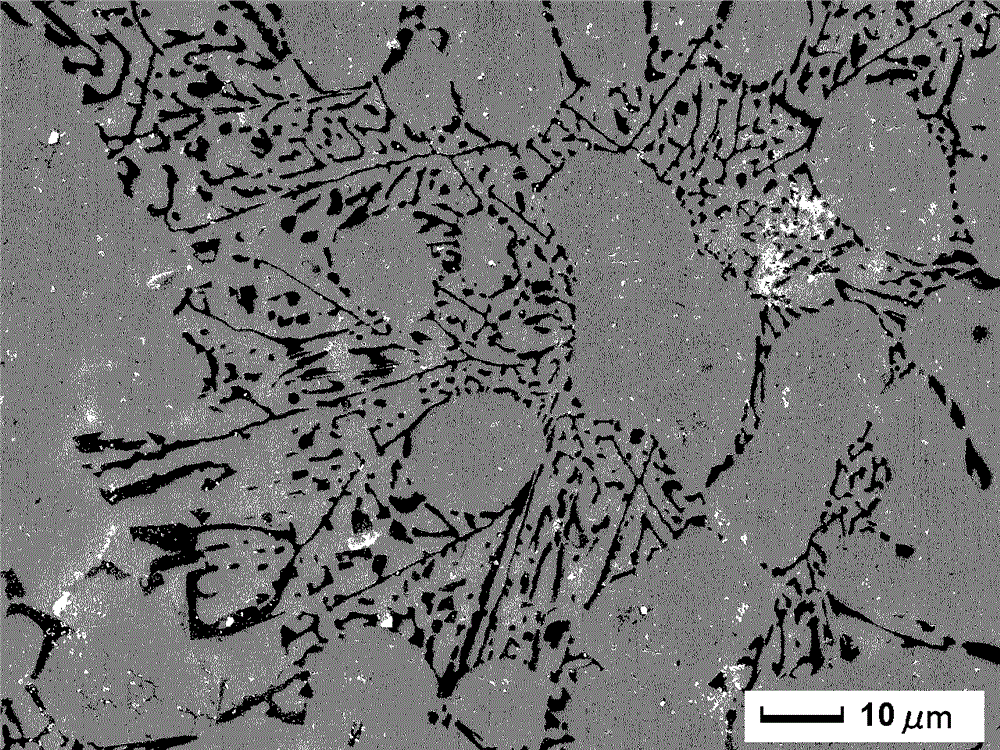

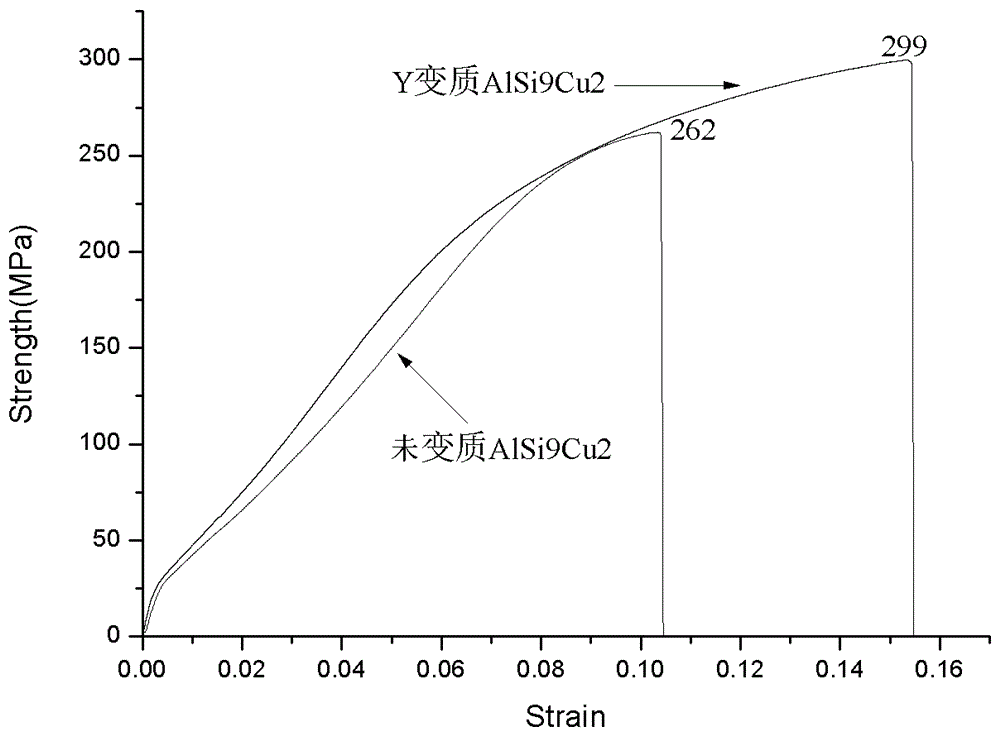

Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

The invention discloses a method for modifying an AlSi9Cu2 alloy by rare-earth Y, and relates to a method for modifying a cast aluminum-silicon alloy. By using the method for modifying the AlSi9Cu2 alloy by the rare-earth Y, the problem that a gas-hole defect exists in an AlSi9Cu2 cast alloy obtained by adopting a modifier Sr is solved. The method provided by the invention comprises the following steps of weighing to take high-purity aluminum, an Al-2OSi intermediate alloy, high-purity copper and an Al-10Y intermediate alloy raw material, fusing the high-purity aluminum and the Al-2OSi intermediate alloy, then pressing the high-purity copper into an obtained first mixture, smelting an obtained second mixture to obtain a fused mass, then adding the Al-10Y intermediate alloy into the fused mass, smelting an obtained third mixture, and pouring the smelted third mixture, so that the AlSi9Cu2 alloy is obtained subsequently. The method provided by the invention is simple, and is suitable for mass production. No gas holes exist in the obtained Y-modified AlSi9Cu2 alloy; the cast structure of the alloy is obviously thinned; the obdurability of the AlSi9Cu2 alloy is improved; and the compactability of a casting is increased.

Owner:镇江创智特种合金科技发展有限公司

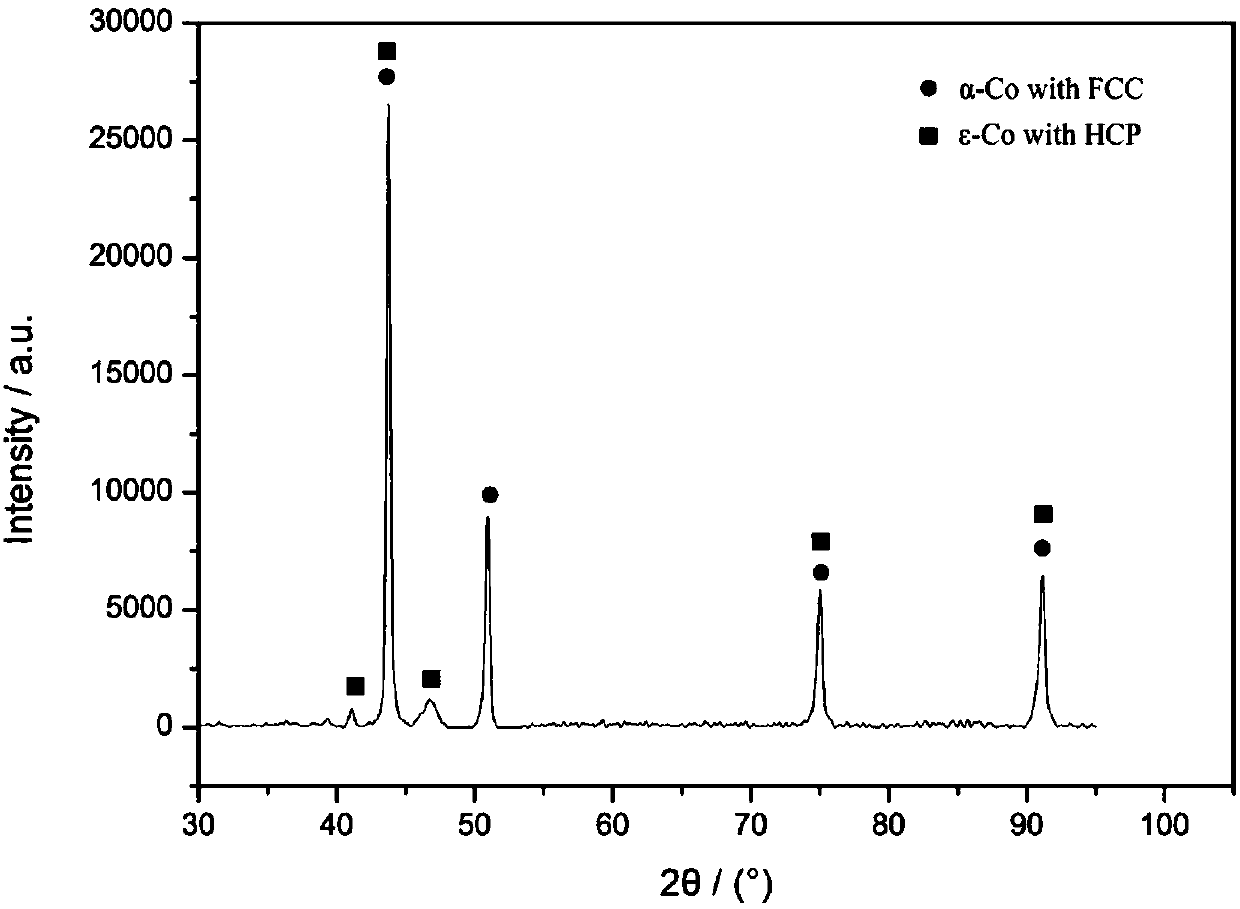

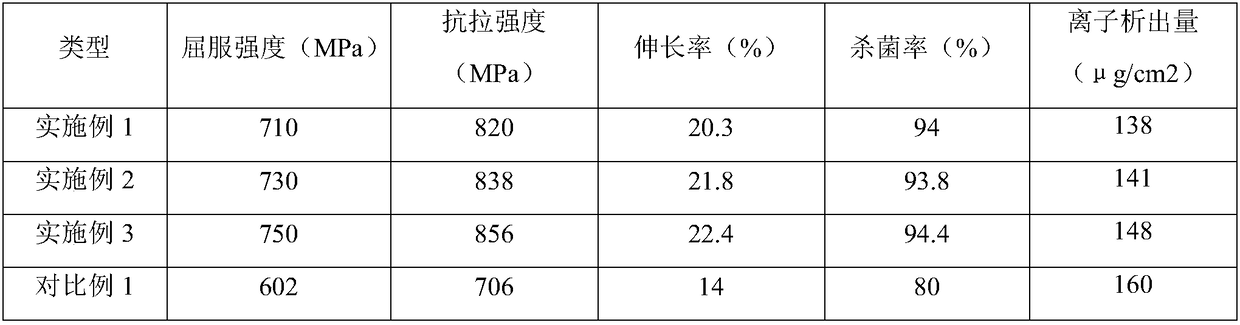

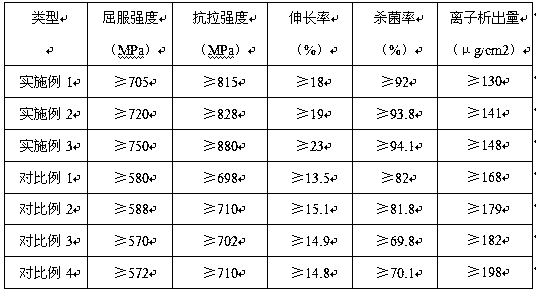

Cobalt base alloy for fixing human skeletons and preparation method thereof

The invention discloses a cobalt base alloy for fixing human skeletons. The cobalt base alloy is characterized by comprising the following chemical components in percentage by weight: 22.5-24.5% of Cr, 7-8% of Ni, 11-12% of W, 3-4% of Mo, 0.5-1.5% of Ta, 0.1-0.8% of Si, 0.1-0.5% of Mn, 0.1-0.5% of Nb, 1.0-2.0% of Cu, 0.1-0.2% of N, 0.01-0.08% of Sc+La+Ce, and the balance of Co and inevitable impurity elements. The yield strength of the cobalt base alloy is not less than 710 MPa, the tensile strength is not less than 820 MPa, the elongation is not less than 20%, and the sterilization rate is not less than 93.8%; and all the indexes are obviously higher than that of other products short of alloy elements, products not performing atomized pulverization and similar products not performing surface coating treatment.

Owner:王甲林

Engine cylinder cover aluminium alloy material smelt by utilizing aluminium scrap and preparation method thereof

The invention discloses an engine cylinder cover aluminium alloy material smelt by utilizing aluminium scrap, which is characterized by consisting of the following components in mass percentage: 7.2-8 of silicon, 0.55-0.6 of zinc, 0.1-0.15 of magnesium, 0.2-0.3 of titanium, 0.03-0.05 of scandium, 0.1-0.13 of cobalt, 0.06-0.07 of niobium, 1.5-2 of dolomite, 1-1.5 of sodium fluoride, 45-50 of aluminium scrap middle alloy powder and the balance of aluminium. The aluminium alloy material manufactured by the invention has the characteristics that the inside is compact and pore-free; pore and peeling defects do not exist; the abrasive resistance is good; the corrosion resistance is good; the swelling coefficient is small; the intensity is high; the high-thermal stability is good; weldability and forming property are good and the like. The aluminium alloy material can be used for manufacturing an engine cylinder cover.

Owner:WUHU HONGKUN AUTO PARTS

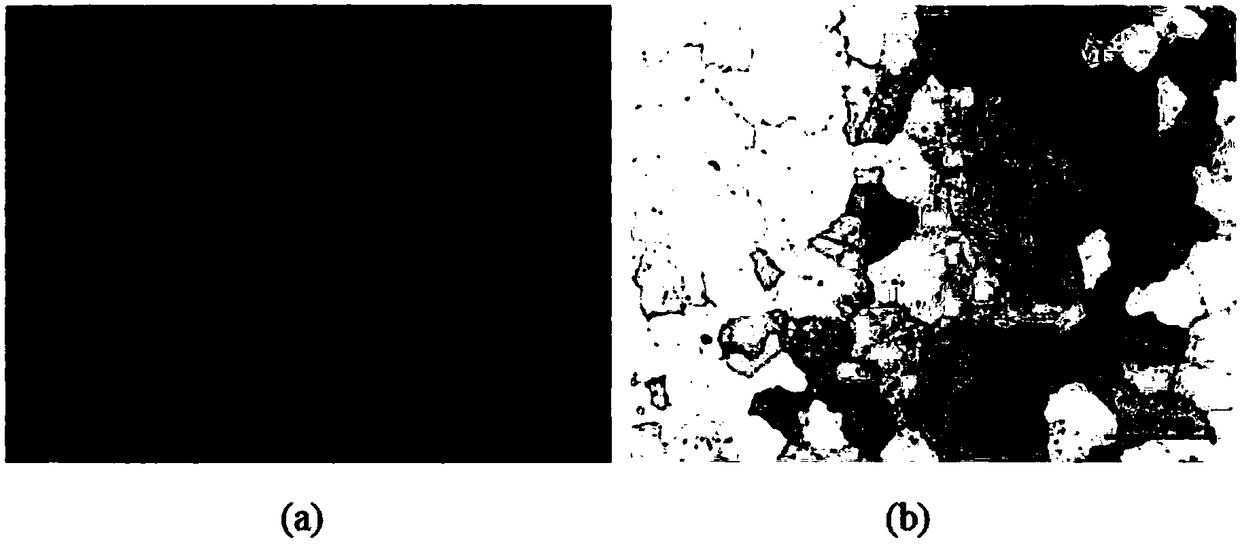

Method for preparing magnesium-gadolinium intermediate alloy by using high-intensity ultrasound

A method for preparing magnesium-gadolinium intermediate alloy by using high-intensity ultrasound comprises the following steps: 1) firstly placing pure magnesium ingot into a crucible, heating to be molten, coating rare earth gadolinium with aluminum-foil paper, adding in the pure magnesium melt, and preserving heat at a range of 736-740 DEG C for 36-40min to obtain alloy melt; 2) extending an ultrasound amplitude transformer into the alloy melt for carrying out intermittent type ultrasound treatment, wherein the ultrasound strength is 1.11kw / cm<2>-1.2 kw / cm<2>, the ultrasound time lasts 46-50min, applying time of the high-intensity ultrasound at each time lasts 51-60s, and the intermittence time lasts 51-60s; and 3) refining and purifying at temperature range of 736-740 DEG C, casting and sampling. The magnesium-gadolinium intermediate alloy prepared by using the method has the advantages of being stable in content, capable of effectively avoiding burning loss of the rare earth, and reducing oxidized inclusions, composition segregation and the like, and is simple in process, safe and reliable and convenient to operate.

Owner:NANCHANG UNIV

Ni-Zn high-strength cupronickel alloy and preparing method thereof

InactiveCN106086517AImprove performanceThe tensile strength corrosion degree meetsCupronickelColor intensity

The invention discloses Ni-Zn high-strength cupronickel alloy and a preparing method thereof. The Ni-Zn high-strength cupronickel alloy is prepared from, by weight, 20-40 parts of Ni, 30-35 parts of Zn, 20-30 parts of Mn, 12-18 parts of P, 4-7 parts of Fe, 5-15 parts of Al and the balance Cu. The performance of the cupronickel alloy is higher, tensile strength and corrosion resistance can better meet the requirement of artware, the specific color intensity and hardness of cupronickel alloy can be maintained for artware produced in the later stage, and environment friendliness is higher and daily use requirements of people are better met. The cupronickel alloy contains zinc which can be dissolved in copper nickel in a solid state to generate a solution strengthening effect, and corrosion resistance is also realized. The cupronickel alloy has high strength and corrosion resistance, high elasticity, attractive appearance and low price, and cost can be saved.

Owner:WUHU CHUJIANG ALLOY COPPER

Pressure casting method for multi-section uniform accelerated injection of liquid metal

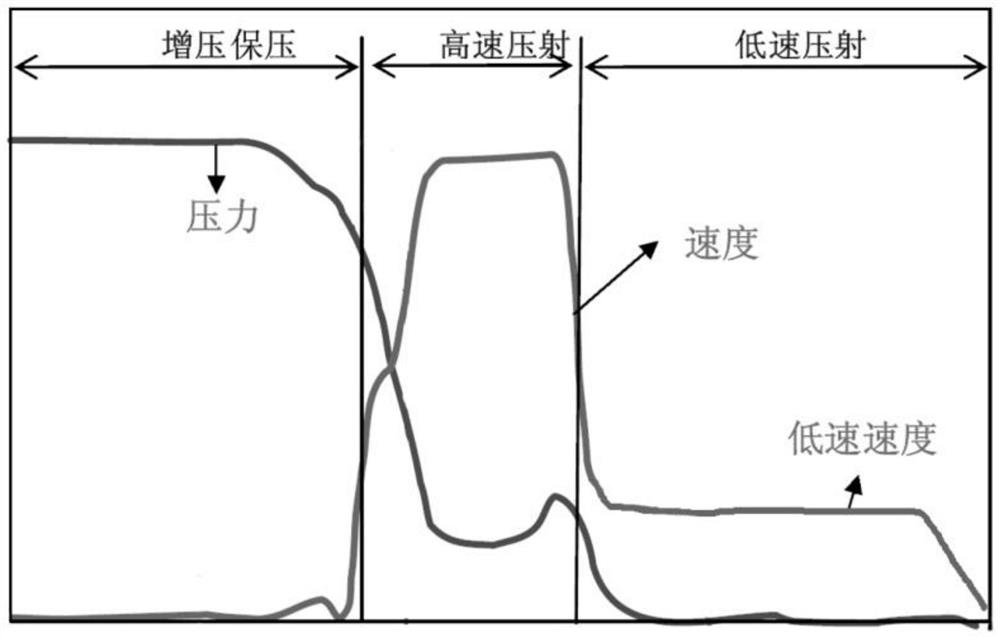

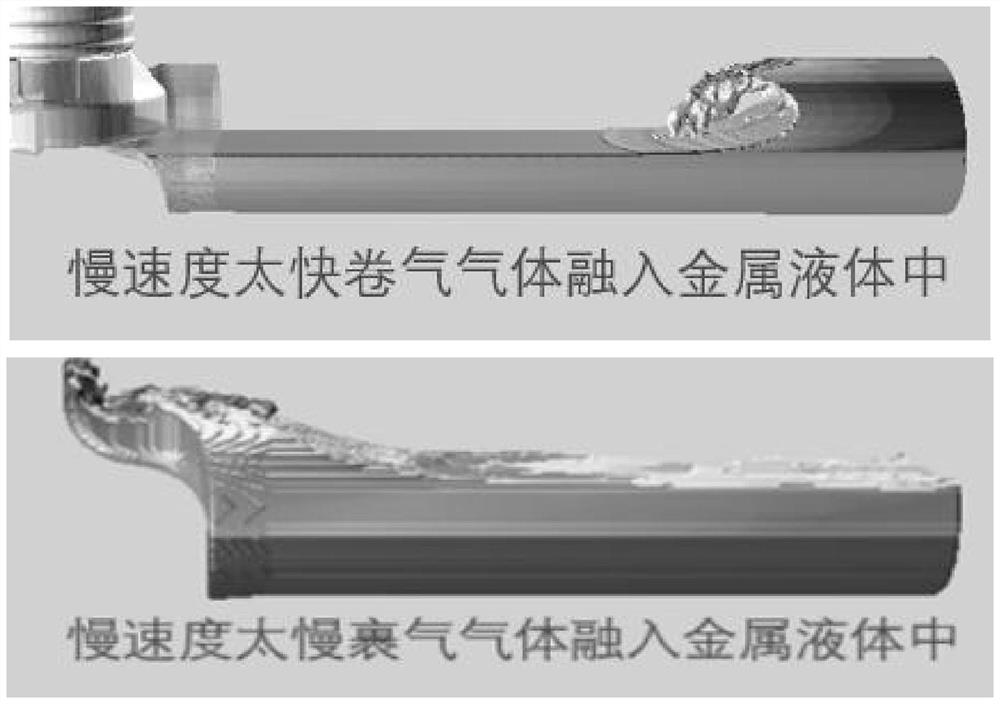

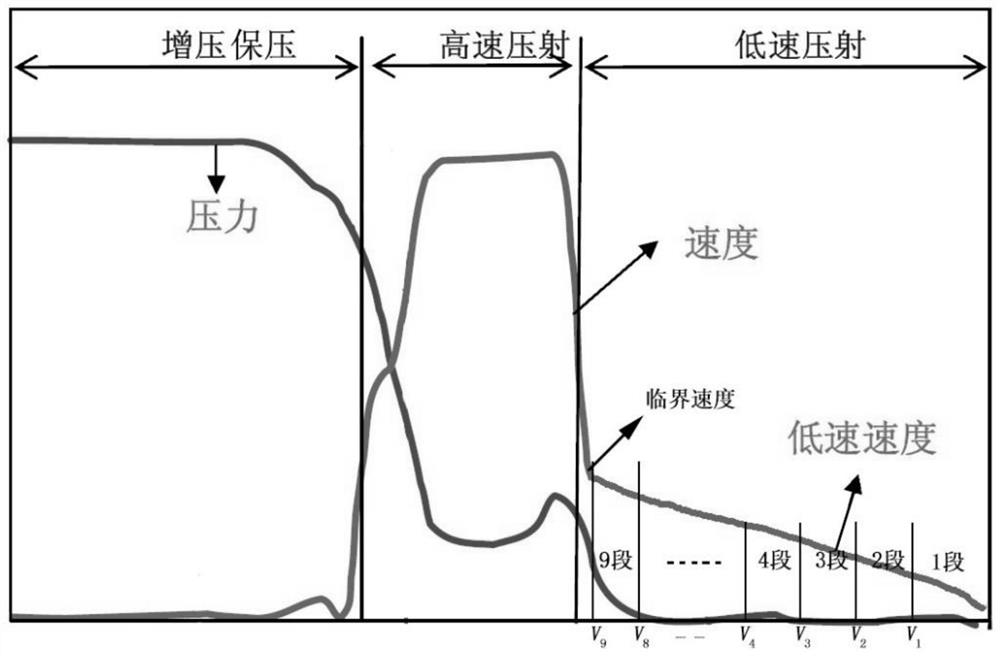

The invention discloses a pressure casting method for multi-stage uniform accelerated injection of liquid metal, which comprises three stages of low-speed injection, high-speed injection and pressurization and pressure maintaining, and comprises the following step: determining the initial injection speed, critical speed and critical acceleration of the liquid metal according to the parameters of apressure chamber and the fullness of molten metal after the low-speed injection stage and before the high-speed injection stage. A low-speed injection stage is divided into 3-9 acceleration stages, an injection punch performs uniform acceleration advancing according to the speeds of the 3-9 acceleration stages to reach the critical speed, so that liquid metal is prevented from splashing out of asprue gate to seal the sprue gate of a chamber, and thus, stable laminar flow motion of molten metal in the pressure chamber is achieved, turbulence and vortexes are avoided, air in the pressure chamber can be exhausted through a pouring gate system and a die; and the whole pressure chamber is filled with molten metal, so that the phenomena of air entrapment and oxide inclusion are avoided, air holes and oxide inclusion of castings are reduced, and the performance of the castings is improved.

Owner:厦门格耐尔科技有限公司

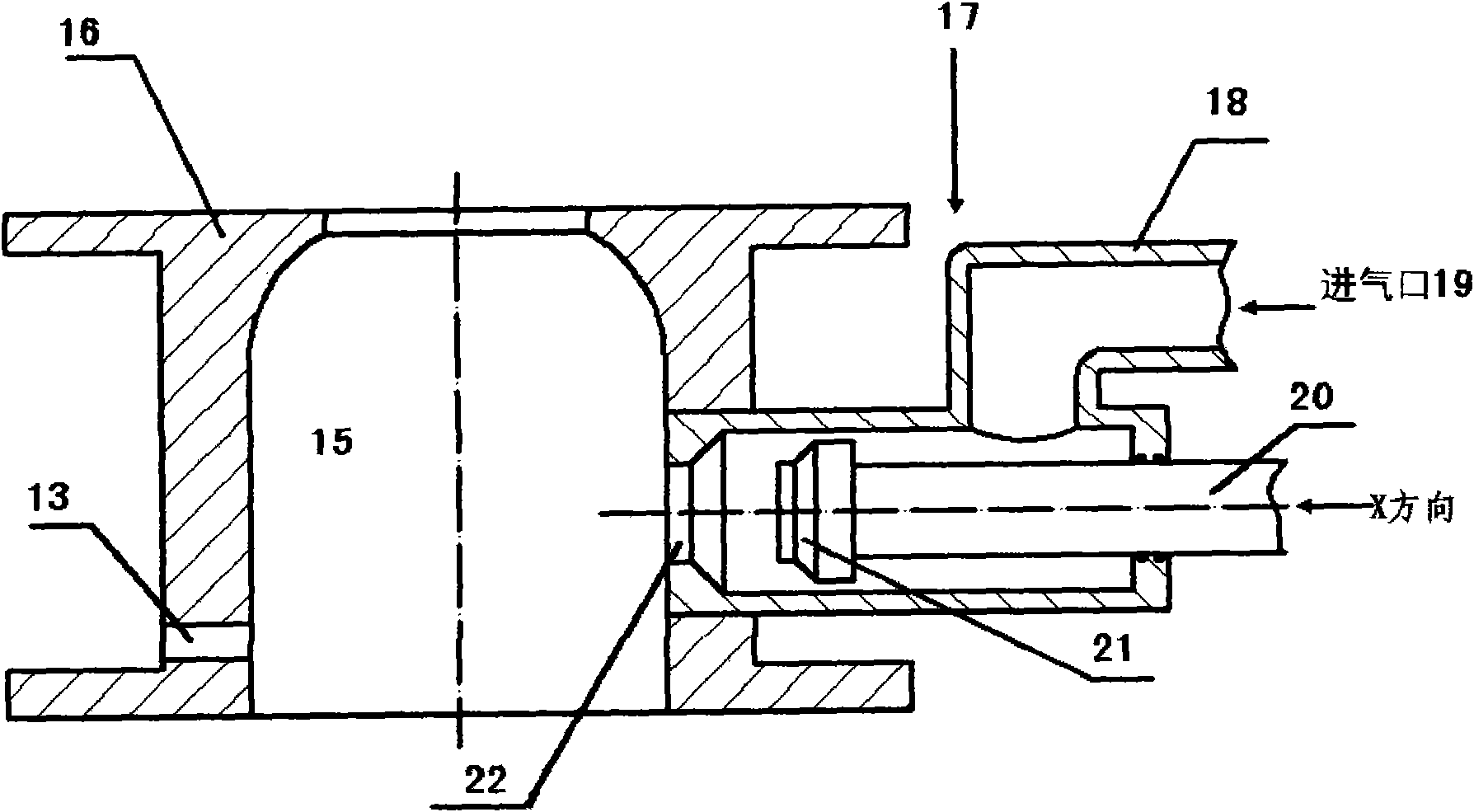

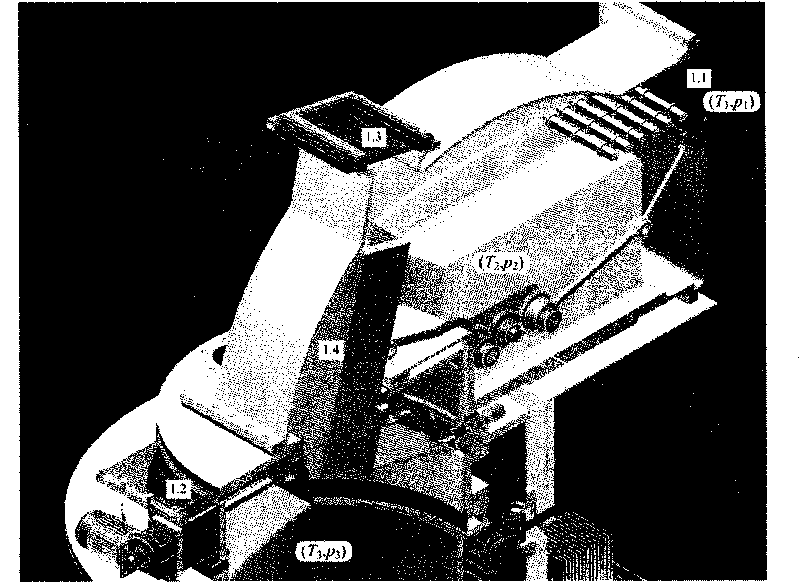

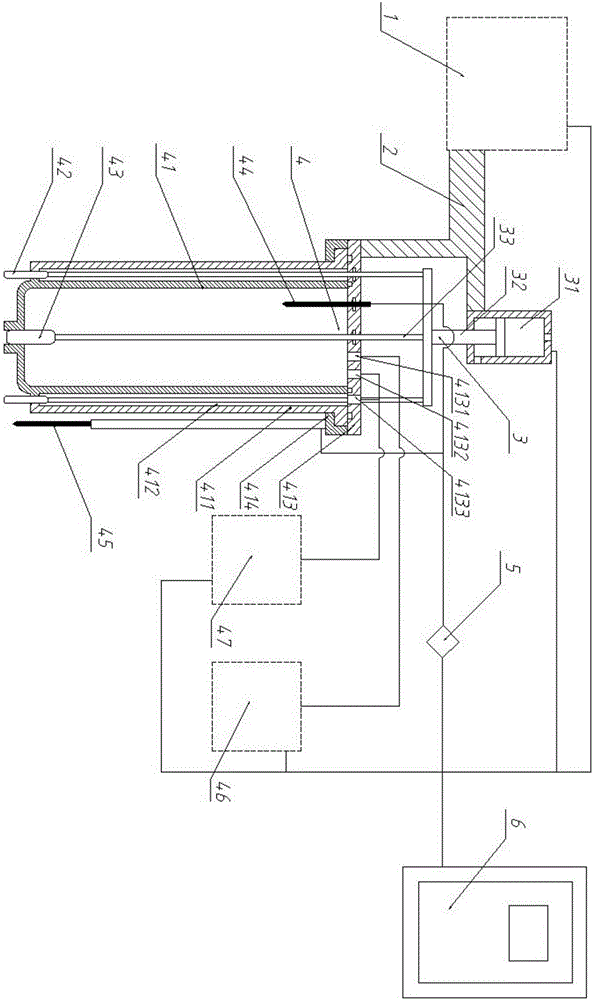

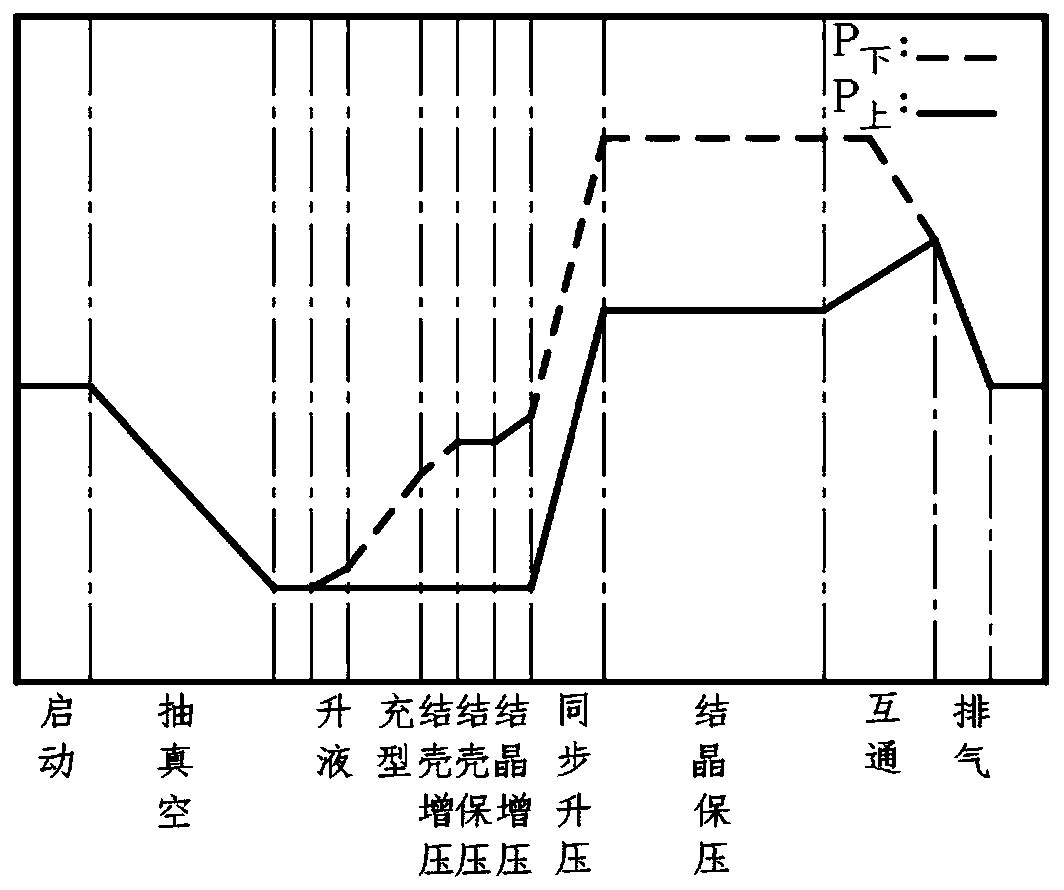

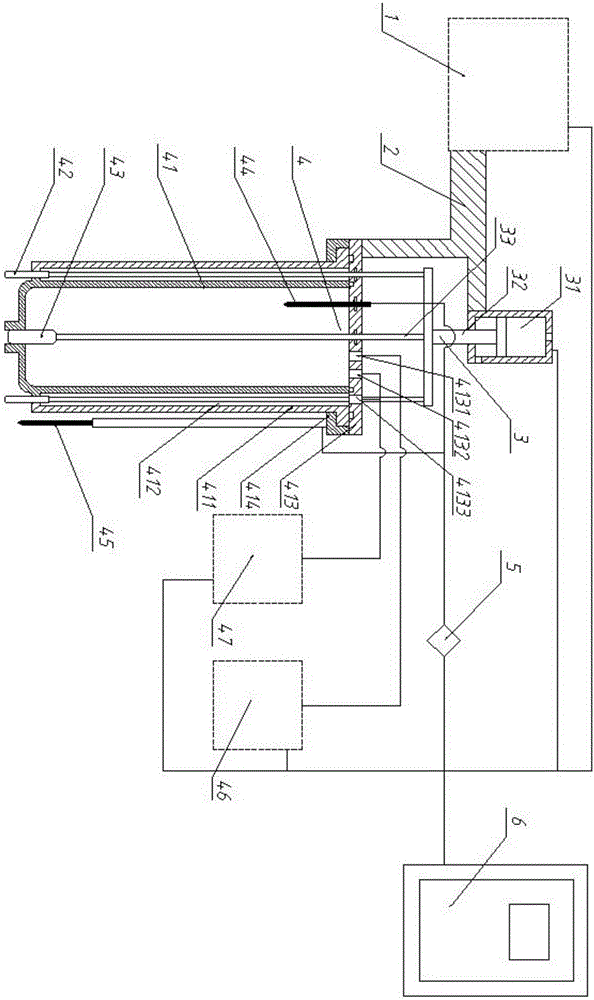

Alloy melt vacuum quantitative casting equipment and method adopting four-station mechanism control

ActiveCN106670442ASimple structureImprove reliabilityMolten metal supplying equipmentsReciprocating motionControl system

The invention discloses equipment capable of achieving vacuum quantitative casting of molten metal. The equipment comprises a T-shaped cross beam, a vacuum quantitative casting device, a drive and transmission device, a feedback signal receiving device and a control system; the drive and transmission device comprises a four-station drive mechanism which drives an exhaust opening closing plug and a liquid draining opening closing plug to perform reciprocating motion at the same time through a connecting part, and therefore the exhaust opening closing plug and the liquid draining opening closing plug can stay at the different positions, independent opening or closing of an exhaust opening and a liquid draining opening can be achieved, it is ensured that during casing of the molten metal, the oxidation and hydrogen absorption of the molten metal can be reduced, gas holes and oxide inclusion of a casting are reduced, and the casting quality is improved.

Owner:北京航大新材科技有限公司

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122BImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

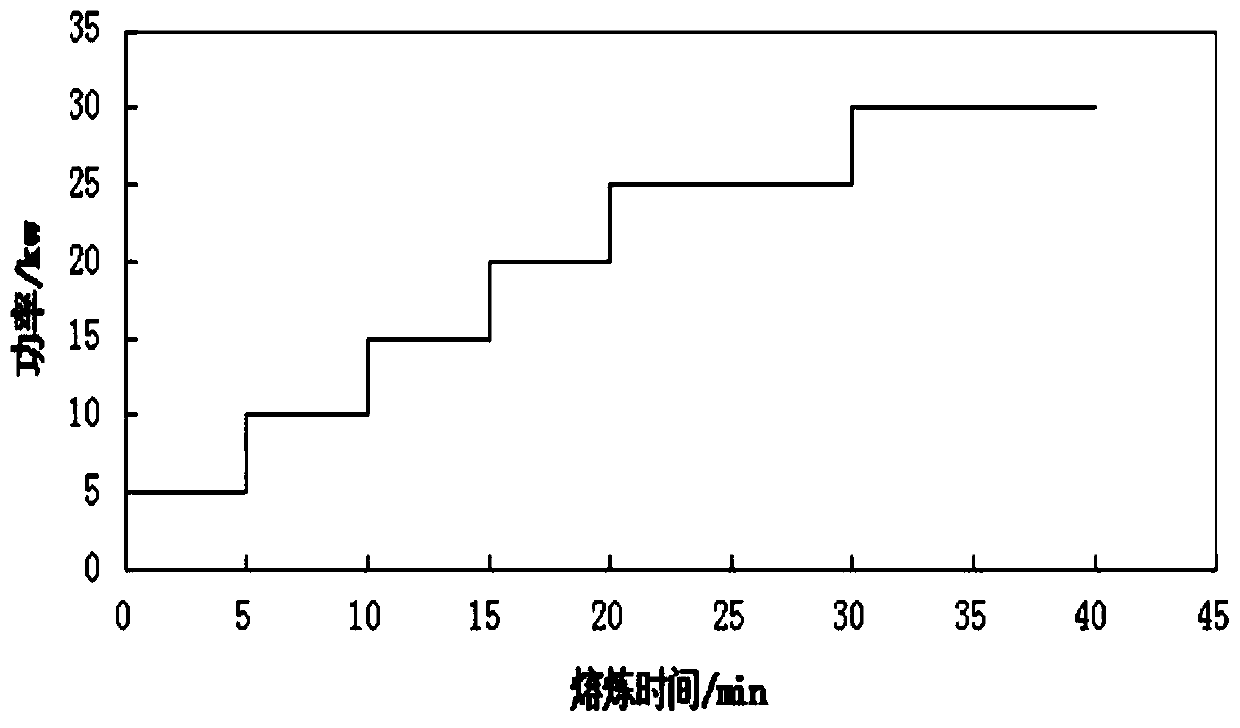

High-temperature alloy floating wall tile pressure-regulating precision casting method under action of external electromagnetic field

ActiveCN110421144AImprove metallurgical qualityReduce solidification segregationFoundry moulding apparatusWaxForced convection

The invention provides a high-temperature alloy floating wall tile pressure-regulating precision casting method under the action of an external electromagnetic field. The method comprises the following steps that printing is carried out by adopting a 3D printing technology to obtain a wax mould of a pouring system; the wax mold is atomized, polished and ground, and surface texture of the wax moldis removed; a multilayer shell is prepared on the wax mold; the shell is demolded; high-temperature alloy melt is poured into the shell by adopting vacuum counter-gravity pressure regulation to form acasting, an alternating electromagnetic field is added in the casting process of the casting, the electromagnetic volume force in the filling and solidification processes plays a stirring role on thehigh-temperature alloy melt, forced convection is generated to change the temperature field and the concentration field of the high-temperature alloy melt, and grains are refined. The high-temperature alloy floating wall tile pressure-regulating precision casting method is matched with a pressure regulating casting device, the alternating electromagnetic field is applied in the process of castingfilling and solidification, the effect of electromagnetic stirring forced convection is realized, the metallurgical quality of castings is improved, internal defects are reduced, and the density is improved.

Owner:SHANGHAI JIAO TONG UNIV

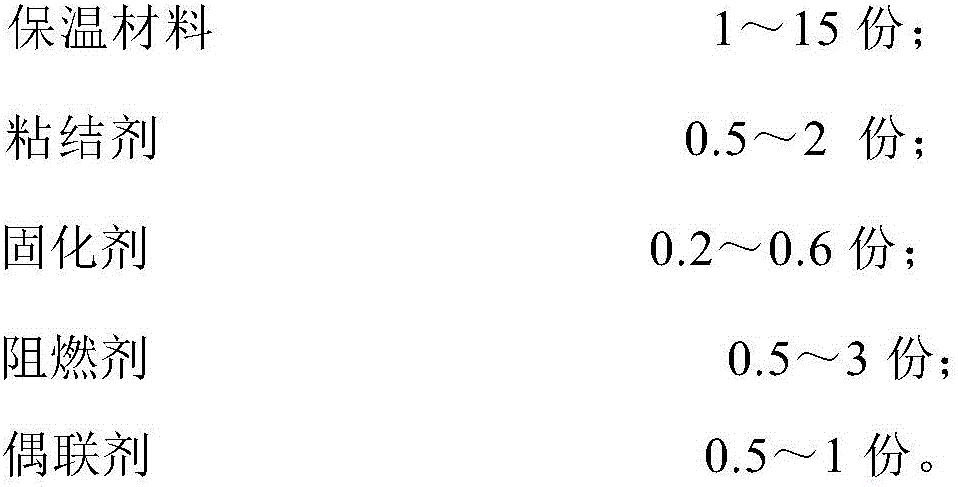

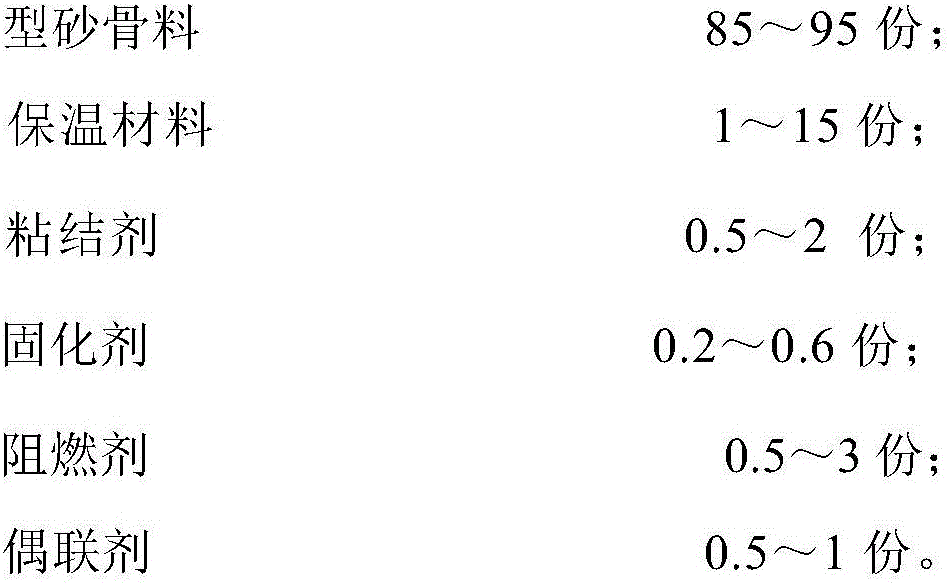

Flame-retardant insulated riser for magnesium alloy sand casting and preparation method of flame-retardant insulated riser

InactiveCN106116597AImprove feeding capacityProlong clotting timeFoundry mouldsFoundry coresThermal insulationCasting mold

The invention relates to a flame-retardant insulated riser for magnesium alloy sand casting and a preparation method of the flame-retardant insulated riser. The riser is prepared from components in parts by mass as follows: 85-95 parts of casting sand aggregate, 1-15 parts of a thermal insulation material, 0.5-2 parts of a binding agent, 0.2-0.6 parts of a curing agent, 0.5-3 parts of a flame retardant and 0.5-1 part of a coupling agent. According to the prepared riser, the problem that a conventional material for preparing the riser can react with a casting mold is solved, the setting time of molten metal in the riser is prolonged, and accordingly, defects of shrinkage cavities, shrinkage porosity and the like caused by insufficient feeding of a large and thick part of a casting are overcome.

Owner:SHANGHAI JIAO TONG UNIV

Cobalt-base alloy for artificial tooth and preparation method of cobalt-base alloy

The invention discloses a cobalt-base alloy for an artificial tooth. The cobalt-base alloy is characterized by comprising the following chemical components in percentage by weight: 22.5-24.5% of Cr, 3-4% of Ni, 9-10% of W, 3-4% of Mo, 0.5-1.5% of Ta, 0.1-0.8% of Si, 0.1-0.5% of Mn, 0.1-0.5% of Ti, 1.0-2.0% of Cu, 0.1-0.2% of N, 0.01-0.08% of Sc+Y+La and the balance of Co and inevitable impurity elements. The yield strength of the cobalt-base alloy is greater than or equal to 700MPa, the tension strength of the cobalt-base alloy is greater than or equal to 800MPa, the elongation rate of the cobalt-base alloy is greater than or equal to 18%, the sterilization rate of the cobalt-base alloy is greater than or equal to 92%, and the indexes are remarkably higher than those of other products without alloy elements, remarkably higher than products without flow energy grinded powder, and remarkably higher than similar products without surface coating treatment.

Owner:温州市赢创新材料技术有限公司

Preparation method for 5-series aluminum alloy welding wire containing rare-earth elements Nd and Ce

InactiveCN110227892AReduce porosityImprove toughnessFurnace typesWelding/cutting media/materialsRare-earth elementUltimate tensile strength

The invention provides a preparation method for a 5-series aluminum alloy welding wire containing rare-earth elements Nd and Ce, and belongs to the technical field of preparation for aluminum alloy welding wires. According to the method, an Al-Nd intermediate alloy and an Al-Ce intermediate alloy are machined into powders or chippings as adding raw materials, and an adding manner of mixing with arefining agent and then carrying out hot-pressing to form a blank is adopted, so that the preparation process is simplified and the cost is saved, oxide inclusions are reduced, and a second phase is uniformly separated out, so that the quality of an aluminum melt is further improved; and air pores of 5-series aluminum alloy are reduced, so that the problems of welding joint hot-cracking, low welding joint strength, low welding joint stability and the like occurring in a welding process are solved, meanwhile, the strength and toughness, the corrosion resistance, the hot workability and other comprehensive performance of the 5-series aluminum alloy welding wire are improved, and a wide market application prospect is achieved.

Owner:江苏港缆新材料科技有限公司

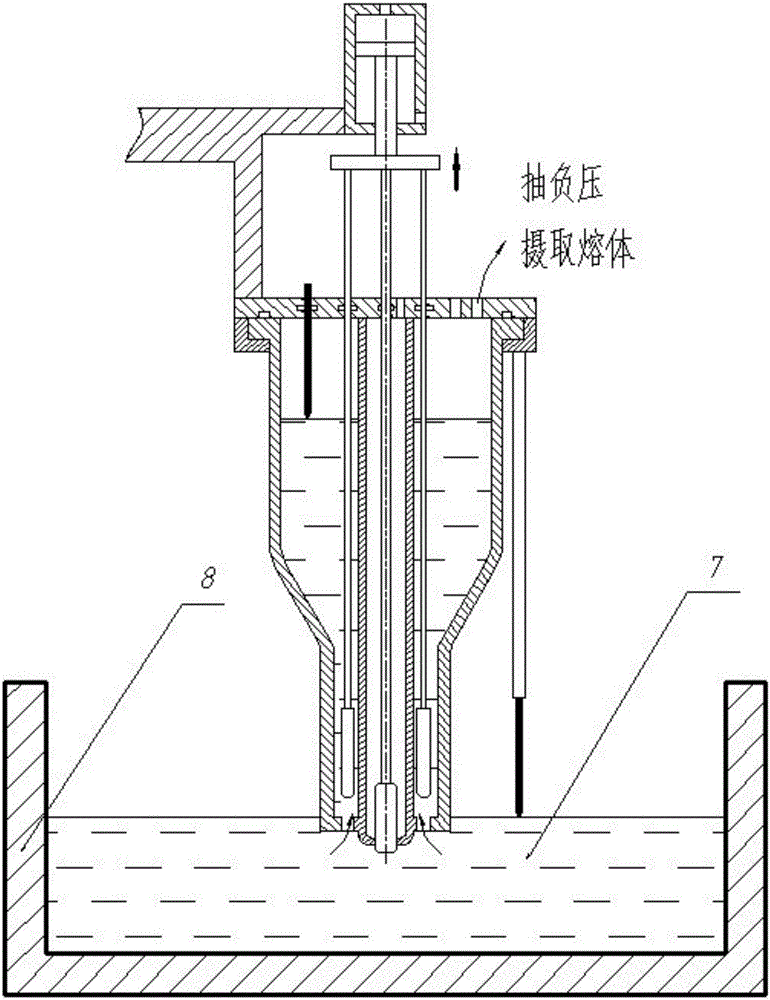

Equipment and method capable of achieving vacuum quantitative casting of molten metal

ActiveCN106670441AReduce oxidationReduce hydrogen absorptionMolten metal supplying equipmentsControl systemHydrogen absorption

The invention discloses equipment capable of achieving vacuum quantitative casting of molten metal. The equipment comprises a mechanical device, a vacuum quantitative casting device, an opening and closing device and a control system; the vacuum quantitative casting comprises a seal container with internal space, a gas filling mechanism, a vacuum mechanism and an exhaust opening; the exhaust opening comprises a liquid draining opening allowing molten metal to be drained, a pipeline allowing gas to pass through is further arranged in the internal space, and passes through the liquid draining opening, the pipeline is provided with a gas exhaust opening allowing gas not in contact with the molten metal to be exhausted, the opening and closing device achieves independent control over the liquid draining opening and the gas exhaust oponeing, that is, the opening and closing device can independently control opening and closing of the liquid draining opening and the gas exhaust opening, it is ensured that during casing of the molten metal, the oxidation and hydrogen absorption of the molten metal can be reduced, gas holes and oxide inclusion of a casting are reduced, and the casting quality is improved.

Owner:北京航大新材科技有限公司

Production method of high strength mixed rare earth metal filament core-spun wire

THe GBX-5 type wire covering machine made in China is modified. Thus, 13 sets of rolling wheels are reduced to 8 sets of rolling wheels. The wire of mixed rare earth RE-Ce45La32Nd8 is as the law material, and 08AI flexible strip steel as the covering material. The repeated sewing mode with two sides and two layers is adopted. Continuous processing through 8 sets of rolling wheels groups obtains the covered wire with diameter 2.5-5.5 mm. The speed of manufacturing wire can be adjusted at will. The invented method provides the features of reducing the encrusting matter of oxide in the steel, increasing recovery factor of rare earth and eliminating the deterioration of the covering layer caused by the oxide of the rare earth.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com