Cobalt-base alloy for artificial tooth and preparation method of cobalt-base alloy

A technology of cobalt-based alloys and dentures, applied in the field of alloys, can solve problems such as biological safety that are rarely considered, and achieve the effects of excellent combination of strength and toughness, cold and hot processing performance, reduced oxygen content, excellent mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

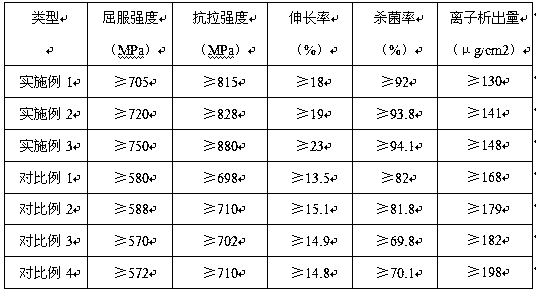

Examples

Embodiment 1

[0040] A cobalt-based alloy for dentures, characterized in that: by weight percentage, the chemical composition of the cobalt-based alloy is: Cr: 22.5%, Ni: 3%, W: 9%, Mo: 3%, Ta: 0.5%, Si: 0.1%, Mn: 0.1%, Ti: 0.1%, Cu: 1.0%, N: 0.1%, Sc+Y+La: 0.01%, and the balance is Co and unavoidable impurity elements. The specific manufacturing method is as follows:

[0041] (1) Ingredients: According to the composition design required by the cobalt-based alloy, the ingredients are first carried out, and the Co-Cr master alloy is selected. The Co:Cr mass ratio in the Co-Cr master alloy is 1.35-1.45:1; the Cr-Ni master alloy is selected. , the mass ratio of Cr:Ni is 1.05-1.1:1; the Co-Mo master alloy is selected, wherein the mass ratio of Co:Mo is 1.55-1.65:1, and other low-melting elements are in the form of simple metals with a purity of 99.99% and / or low Added in the form of melting point master alloy;

[0042] (2) Alloy smelting: Preheat the alloy ingot / powder in a crucible at 200-28...

Embodiment 2

[0049] A cobalt-based alloy for dentures, characterized in that: by weight percentage, the chemical composition of the cobalt-based alloy is: Cr: 23%, Ni: 3.5%, W: 9.5%, Mo: 3.5%, Ta: 1%, Si: 0.5%, Mn: 0.3%, Ti: 0.3%, Cu: 1.5%, N: 0.15%, Sc+Y+La: 0.05%, and the balance is Co and unavoidable impurity elements. The preparation method of cobalt-based alloy is:

[0050] (1) Ingredients: According to the composition design required by the cobalt-based alloy, the ingredients are first carried out, and the Co-Cr master alloy is selected. The Co:Cr mass ratio in the Co-Cr master alloy is 1.35-1.45:1; the Cr-Ni master alloy is selected. , the mass ratio of Cr:Ni is 1.05-1.1:1; the Co-Mo master alloy is selected, wherein the mass ratio of Co:Mo is 1.55-1.65:1, and other low-melting elements are in the form of simple metals with a purity of 99.99% and / or low Added in the form of melting point master alloy;

[0051] (2) Alloy smelting: Preheat the alloy ingot / powder in a crucible at 200...

Embodiment 3

[0058] A cobalt-based alloy for dentures, characterized in that: by weight percentage, the chemical composition of the cobalt-based alloy is: Cr: 24.5%, Ni: 4%, W: 10%, Mo: 4%, Ta: 1.5%, Si: 0.8%, Mn: 0.5%, Ti: 0.5%, Cu: 2.0%, N: 0.2%, Sc+Y+La 0.08%, the balance is Co and unavoidable impurity elements. The preparation method of cobalt-based alloy is:

[0059] (1) Ingredients: According to the composition design required by the cobalt-based alloy, the ingredients are first carried out, and the Co-Cr master alloy is selected. The Co:Cr mass ratio in the Co-Cr master alloy is 1.35-1.45:1; the Cr-Ni master alloy is selected. , the mass ratio of Cr:Ni is 1.05-1.1:1; the Co-Mo master alloy is selected, wherein the mass ratio of Co:Mo is 1.55-1.65:1, and other low-melting elements are in the form of simple metals with a purity of 99.99% and / or low Added in the form of melting point master alloy;

[0060] (2) Alloy smelting: Preheat the alloy ingot / powder in a crucible at 200-280°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com