Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

A technology of alloy and welding wire, which is applied in the field of aluminum-magnesium-scandium alloy welding wire and its preparation. The alloy provides welding compatibility and other issues to achieve the effect of ensuring the control accuracy of chemical composition, high comprehensive mechanical properties of joints, and low hot cracking sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

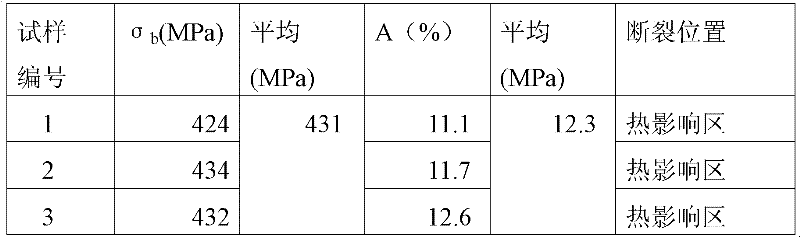

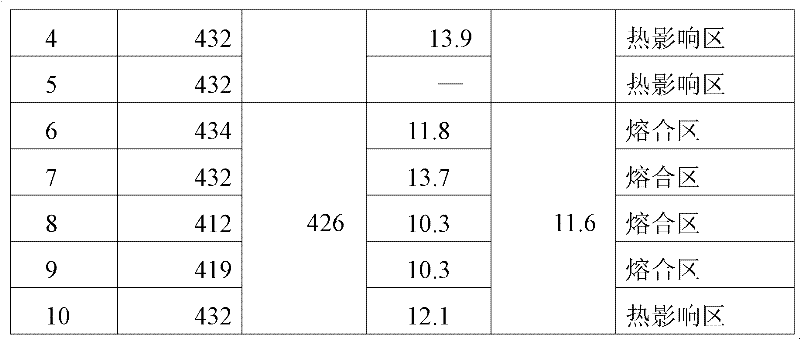

Examples

Embodiment 1

[0030] A welding wire for corrosion-resistant aluminum-magnesium-scandium alloy. The aluminum ingot is refined by smelting process according to the following formula, and then extruded and drawn into φ2mm and φ3mm welding wire. The formula of the welding wire is as follows:

[0031] Mg, its weight percentage is 4.5%;

[0032]Zr, its percentage by weight is 0.16%;

[0033] Sc, its weight percentage is 0.16%;

[0034] Mn, its weight percentage is 0.25%;

[0035] Ti, its weight percentage is 0.08%;

[0036] Cr, its weight percentage is 0.17%;

[0037] Ce, its weight percentage is 0.02%;

[0038] Y, its weight percentage is 0.02%;

[0039] The balance is Al;

[0040] The preparation of the above-mentioned corrosion-resistant aluminum-magnesium-scandium alloy matching welding wire can specifically adopt the following steps:

[0041] (1) Preparation of aluminum-based master alloy:

[0042] Al-10Mn alloy, wherein the weight percentage of Mn is 10%, and the balance is Al;

[...

Embodiment 2

[0060] A multi-element micro-alloyed scandium-containing aluminum-magnesium welding wire. According to the formula, aluminum ingots are refined by smelting process, and then extruded and drawn into φ2mm and φ3mm welding wires. The formula of the welding wire is as follows:

[0061] Mg, its weight percentage is 4.0%;

[0062] Zr, its percentage by weight is 0.13%;

[0063] Sc, its weight percentage is 0.14%;

[0064] Mn, its weight percentage is 0.28%;

[0065] Ti, its weight percentage is 0.07%;

[0066] Cr, its weight percentage is 0.16%;

[0067] Ce, its weight percentage is 0.02%;

[0068] Y, its weight percentage is 0.02%;

[0069] The balance is Al;

[0070] The preparation of the above-mentioned corrosion-resistant aluminum-magnesium-scandium alloy matching welding wire can specifically adopt the following steps:

[0071] (1) Preparation of aluminum-based master alloy:

[0072] Al-10Mn alloy, wherein the weight percentage of Mn is 10%, and the balance is Al;

[...

Embodiment 3

[0090] A multi-element micro-alloyed scandium-containing aluminum-magnesium welding wire. According to the formula, aluminum ingots are refined by smelting process, and then extruded and drawn into φ2mm and φ3mm welding wires. The formula of the welding wire is as follows:

[0091] Mg, its weight percentage is 4.0%;

[0092] Zr, its weight percentage is 0.14%;

[0093] Sc, its weight percentage is 0.14%;

[0094] Mn, its weight percentage is 0.3%;

[0095] Ti, its weight percentage is 0.09%;

[0096] Cr, its weight percentage is 0.15%;

[0097] Ce, its weight percentage is 0.02%;

[0098] Y, its weight percentage is 0.02%;

[0099] The balance is Al;

[0100] The preparation of the above-mentioned corrosion-resistant aluminum-magnesium-scandium alloy matching welding wire can specifically adopt the following steps:

[0101] (1) Preparation of aluminum-based master alloy:

[0102] Al-10Mn alloy, wherein the weight percentage of Mn is 10%, and the balance is Al;

[0103] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com