Low-pressure casting filling method and low-pressure casing filling equipment used by same

A low-pressure casting and filling technology, which is applied in the field of casting, can solve problems such as oxidation, and achieve the effects of simple process, great economic and social value, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A low-pressure casting equipment with simple structure, easy operation and good technical effect and a method for using the equipment to perform low-pressure casting operations.

[0036] 1) Equipment used in low pressure casting method

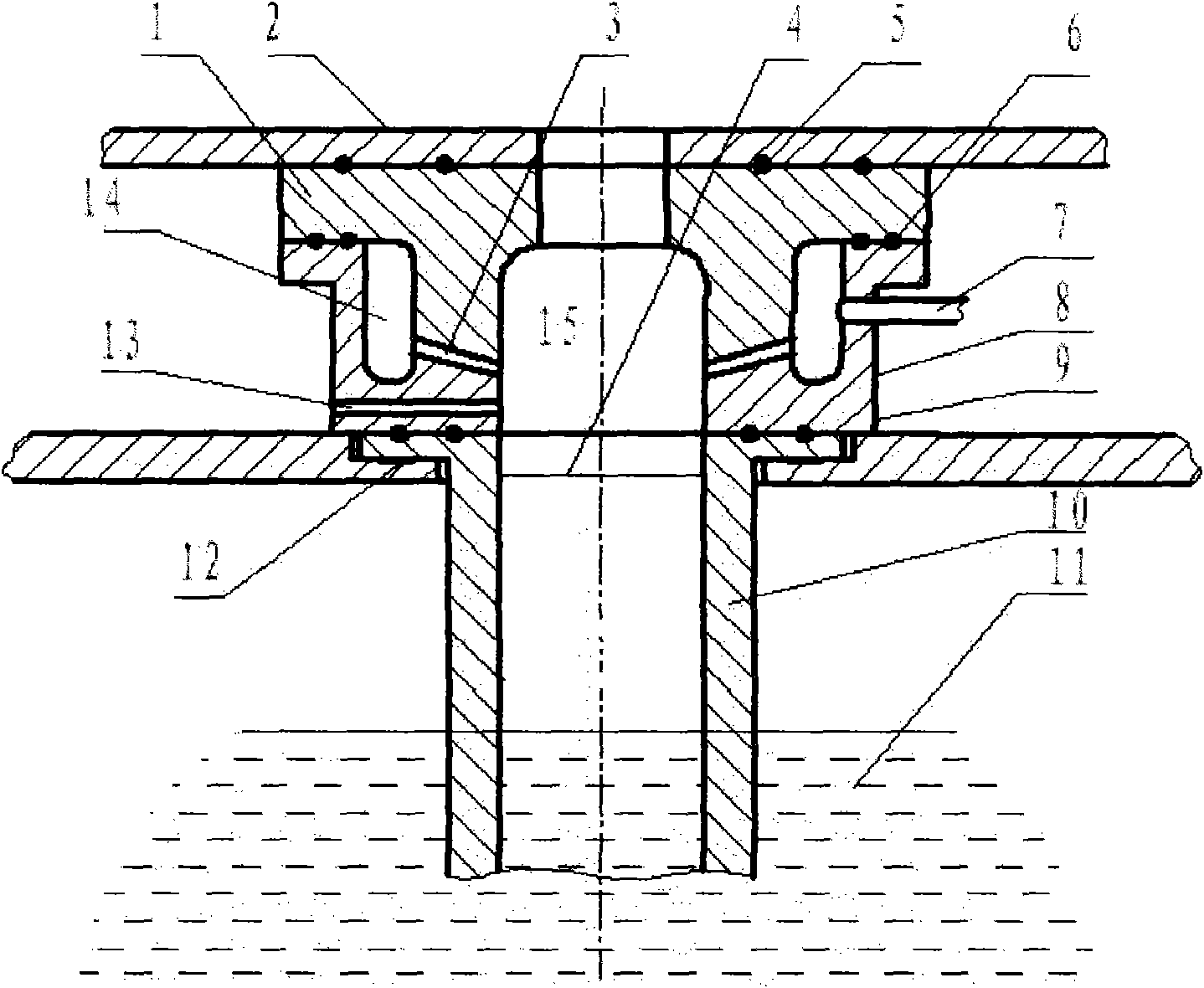

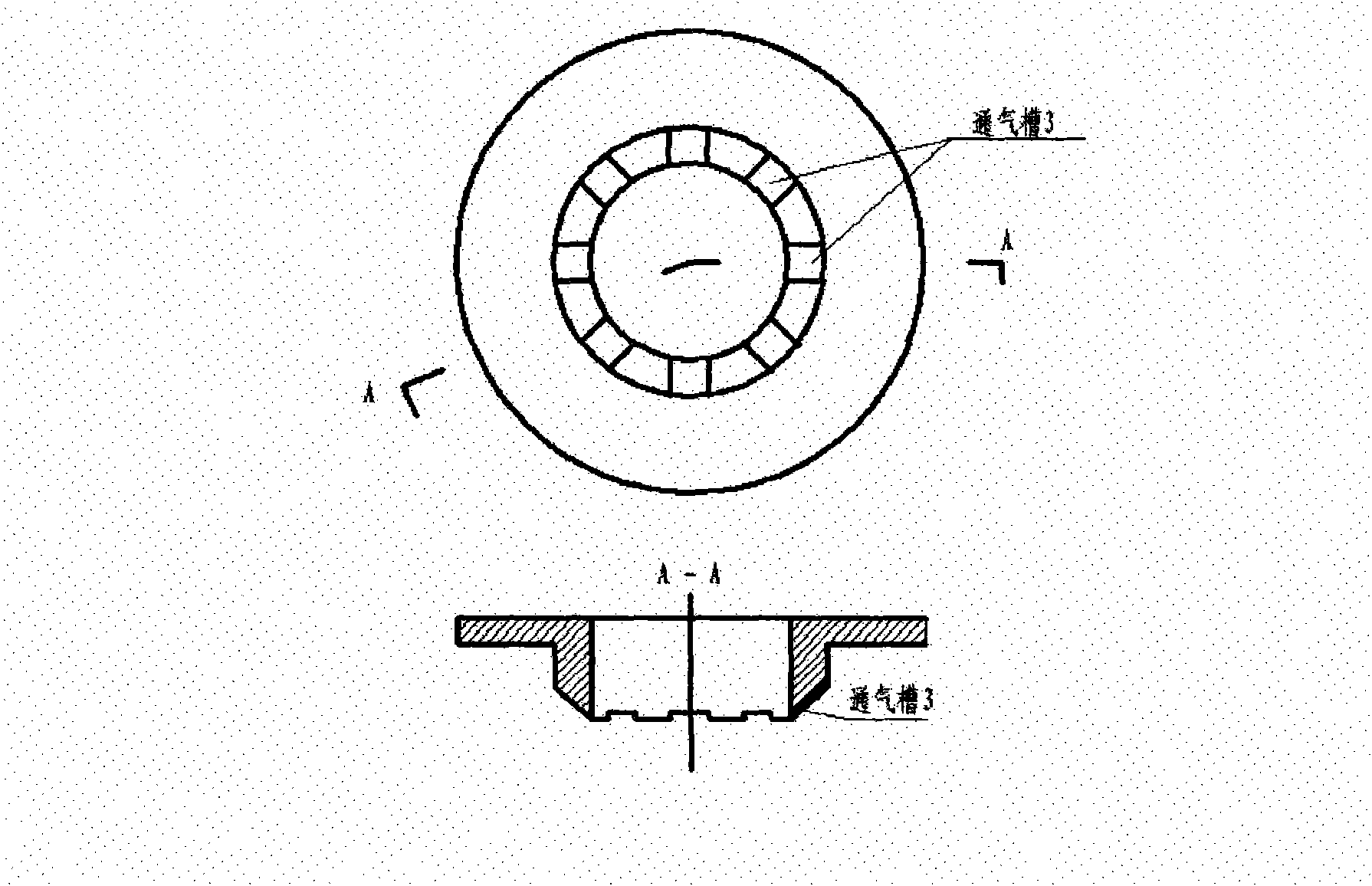

[0037] Magnesium alloy low-pressure casting filling equipment includes holding furnace, mold clamping and opening and closing devices, gas supply system, and control system; among them: a crucible containing magnesium alloy liquid is installed in the furnace hearth of the holding furnace, and there is a riser pipe on the upper part of the crucible 10. It is characterized by:

[0038] An adapter sleeve is provided between the riser pipe 10 and the casting port of the mold. The magnesium alloy liquid is introduced into the mold from the riser pipe 10 through the adapter sleeve. A protective gas interface is provided on the adapter sleeve to protect The gas enters the inner cavity of the adapter sleeve communicating with the upper mouth of the...

Embodiment 2

[0049] 1) Equipment used in low pressure casting method

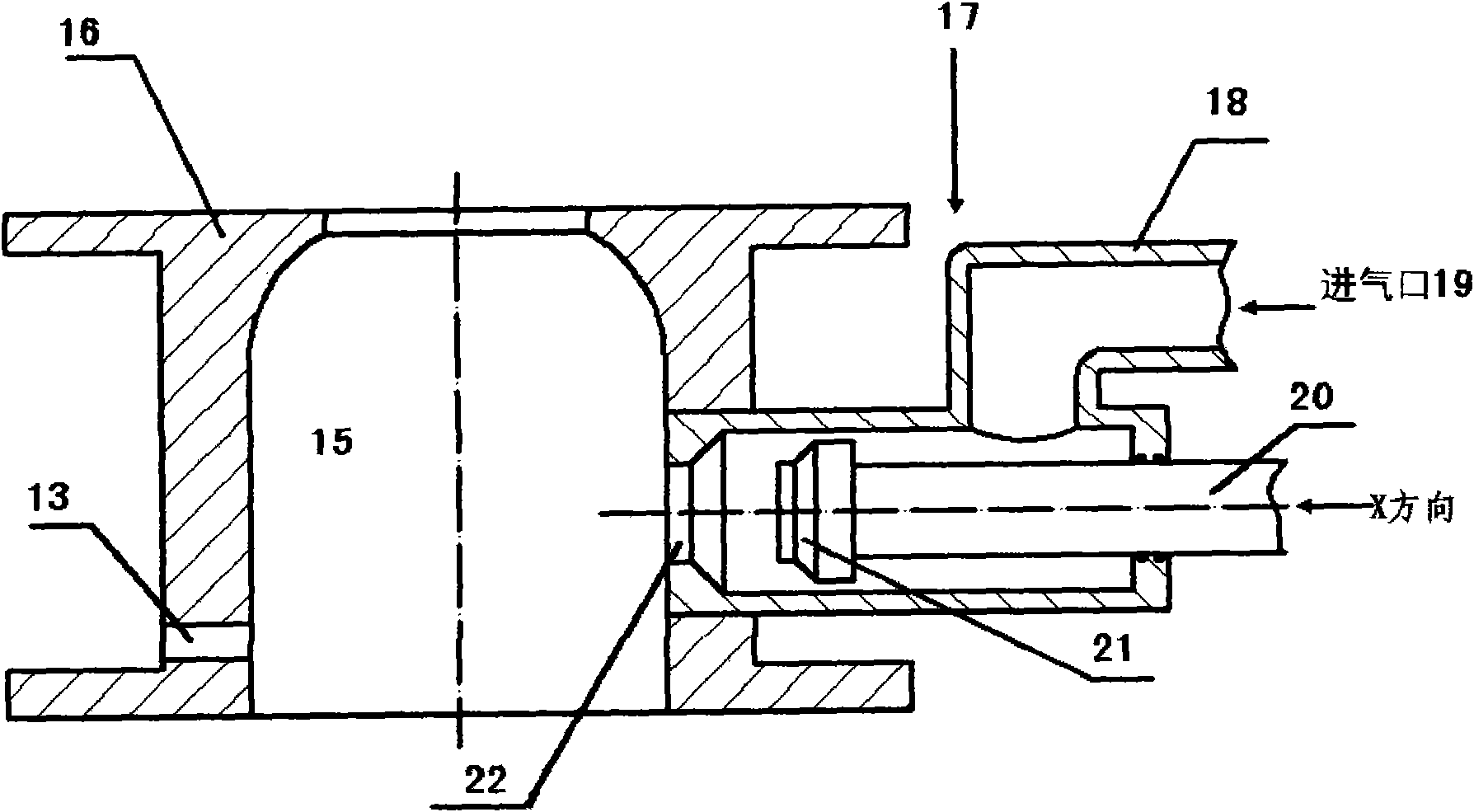

[0050] Magnesium alloy low-pressure casting mold filling equipment includes holding furnace, mold mounting and opening and closing devices, gas supply system, and control system; among them: a crucible containing magnesium alloy liquid is installed in the furnace hearth of the holding furnace, and there is a riser pipe on the upper part of the crucible 10. It is characterized by:

[0051] An adapter sleeve is provided between the riser pipe 10 and the casting port of the mold. The magnesium alloy liquid is introduced into the mold from the riser pipe 10 through the adapter sleeve. A protective gas interface is provided on the adapter sleeve to protect The gas enters the inner cavity of the adapter sleeve communicating with the upper mouth of the riser pipe 10 to protect the magnesium liquid suspended in the upper mouth of the riser pipe 10; the side wall of the adapter sleeve is provided with a magnesium liquid sensor mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com