Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

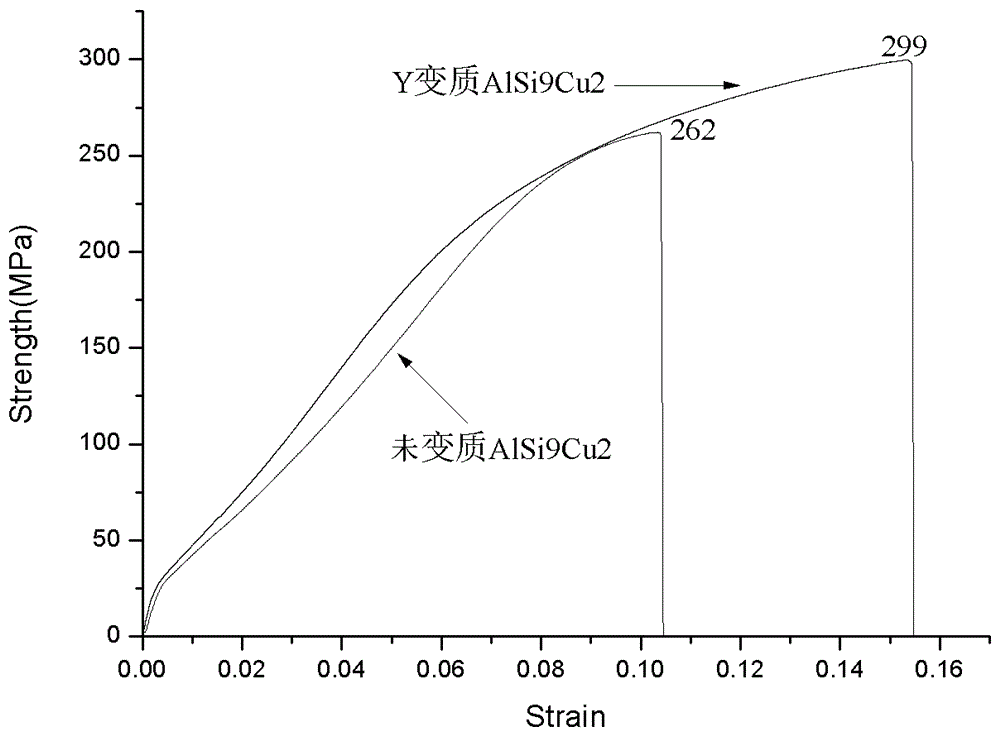

An alloy and rare earth technology, applied in the field of metamorphic cast aluminum-silicon alloys, can solve problems such as stomatal defects of AlSi9Cu2 alloys, and achieve the effects of easy composition control, improved as-cast performance, and large cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

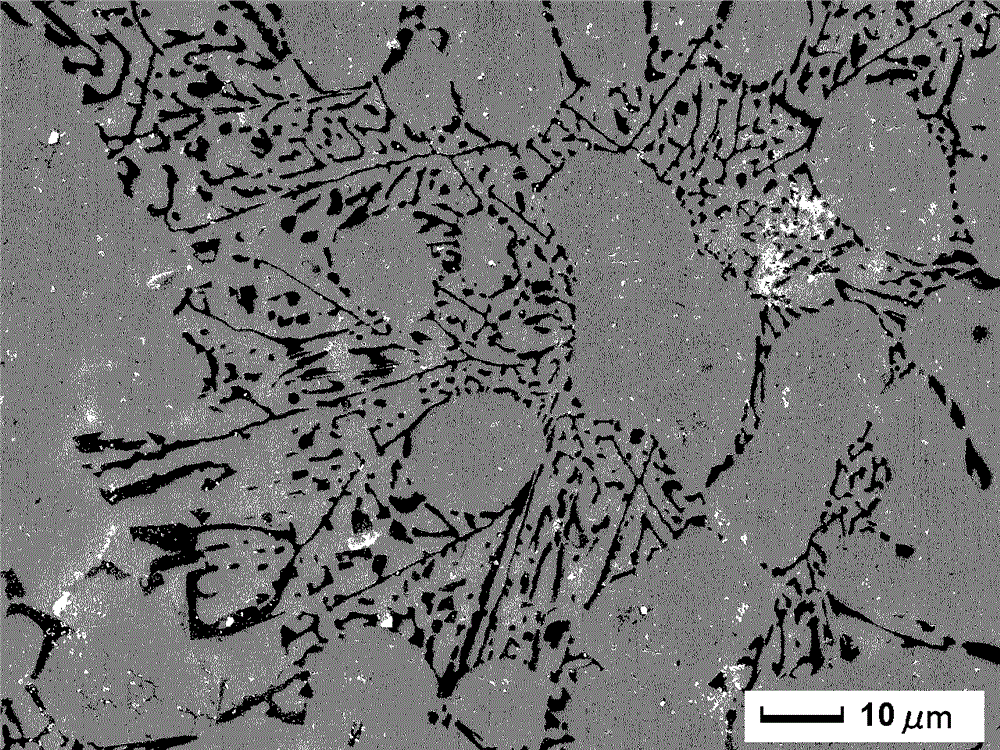

Image

Examples

Embodiment approach 1

[0017] The method for modifying AlSi9Cu2 alloy by rare earth Y in the present embodiment is realized through the following steps: 1. Weigh 51.5% to 57.5% of high-purity aluminum with a mass purity of 99.99%, and Al-20Si of 42.5% to 48.5% by weight percentage Master alloy, 1.5%~2.5% mass purity of 99.99% high-purity copper and 1.5%~2.5% Al-l0Y master alloy; 2. Clean and dry the high-purity aluminum and Al-20Si master alloy weighed in step 1 Then put it into a resistance furnace with a power of 10kW, heat it until it is completely melted, and control the temperature of the melt at 750°C~780°C; 3. Use a graphite bell jar with a temperature of 200°C to press the high-purity copper weighed in step 1 into the step 2. In the obtained melt, heat preservation and stand for 15-25min to obtain AlSi9Cu2 alloy melt, wherein the graphite bell jar is preheated at 200°C for 10-20min before use; 4. Add refining agent C to the AlSi9Cu2 alloy melt in step 3 2 Cl 6 After refining for 1 minute, a...

Embodiment approach 2

[0021] The method of the rare earth Y modified AlSi9Cu2 alloy of the present embodiment is realized through the following steps: 1. Weigh 52.5% of high-purity aluminum with a mass purity of 99.99%, 43.5% of Al-20Si master alloy, 2.0% of The mass purity is 99.99% high-purity copper and 2.0% Al-10Y master alloy; 2. After cleaning and drying the high-purity aluminum and Al-20Si master alloy taken in step 1, put it into a resistance furnace with a power of 10kW, and heat Until complete melting, the melt temperature is controlled at 780°C; 3. Use a graphite bell jar with a temperature of 200°C to press the high-purity copper weighed in step 1 into the melt obtained in step 2, and keep it for 20 minutes to obtain AlSi9Cu2 alloy Melt, wherein the graphite bell jar is preheated at 200 ° C for 15 minutes before use; 4. Add refining agent C to the AlSi9Cu2 alloy melt in step 3 2 Cl 6 After refining for 1 minute, add the Al-l0Y intermediate alloy weighed in step 1 to the AlSi9Cu2 alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com