Patents

Literature

49results about How to "Reduce crack source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

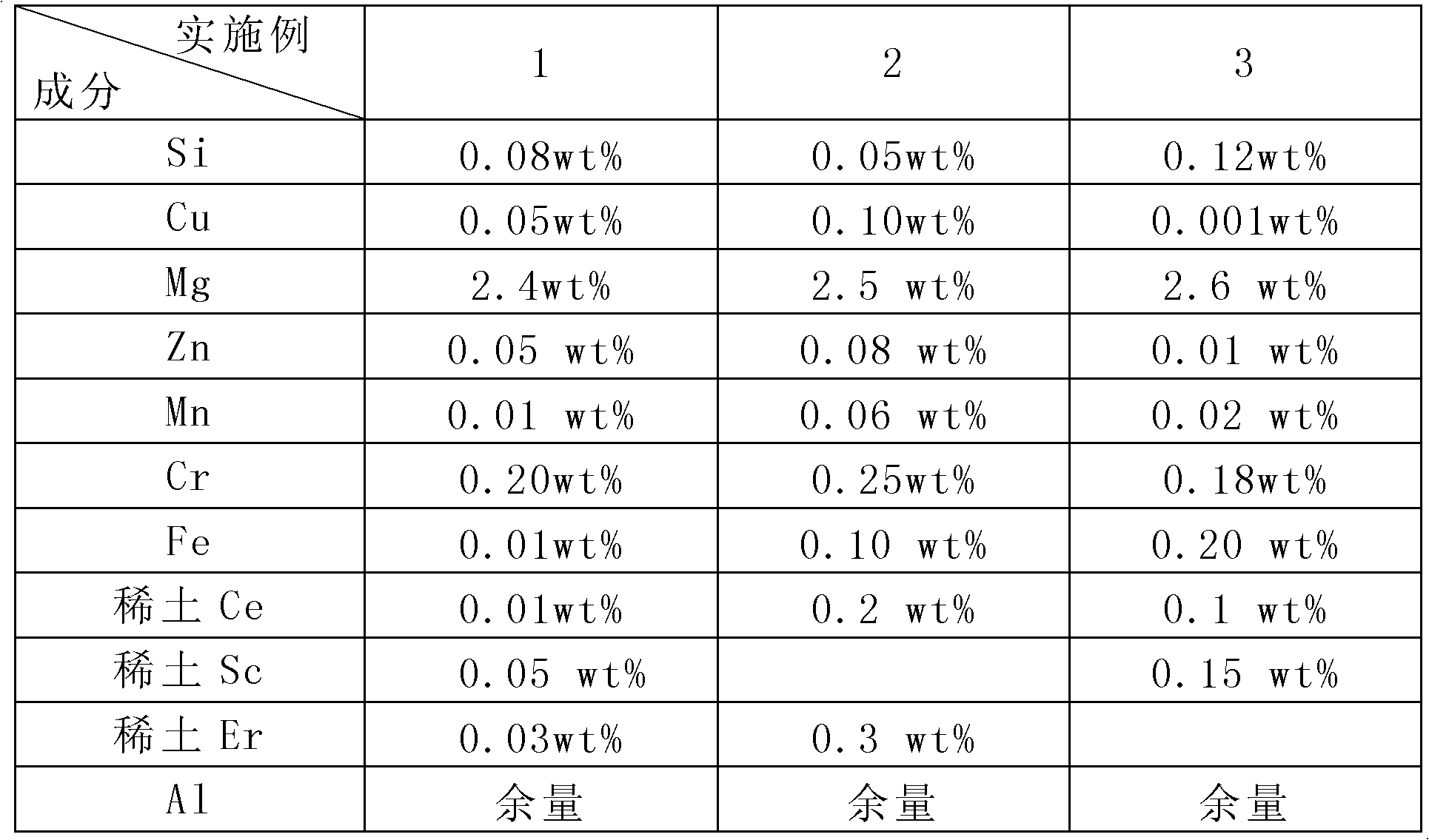

Aluminum alloy 5052 having high corrosion resistance and manufacturing method thereof

The invention provides an aluminum alloy 5052 having high corrosion resistance and a manufacturing method thereof, which belongs to the technical field of alloy materials and solves the problem of low corrosion resistance of the traditional aluminum alloy 5052 material. The aluminum alloy 5052 having high corrosion resistance comprises the following components in percentage by weight: no more than 0.20% of Si, no more than 0.20% of Cu, 2.4-2.6% of Mg, no more than 0.10% of Zn, no more than 0.10% of Mn, 0.18-0.30% of Cr, 0.01-0.40% of Fe, no more than 0.05% of single other element, no more than 0.15% of total other elements, 0.01-0.8% of rare earth elements and the balance of Al. The aluminum alloy 5052 having high corrosion resistance can improve the corrosion resistance and simultaneously maintain the stabilization of mechanical properties.

Owner:ZHEJIANG GKO ALUMINUM

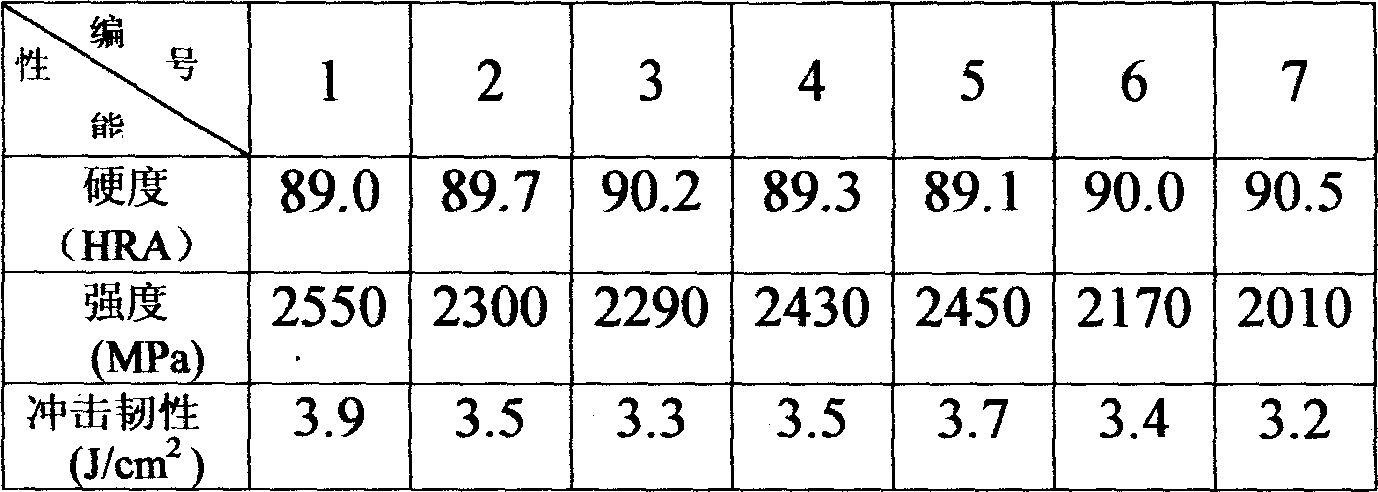

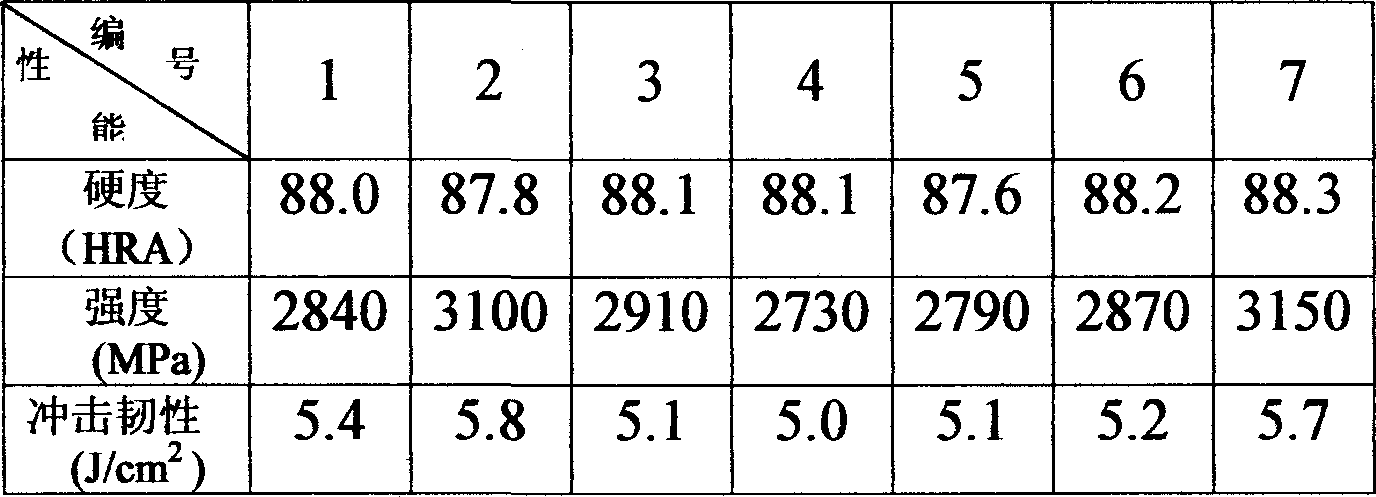

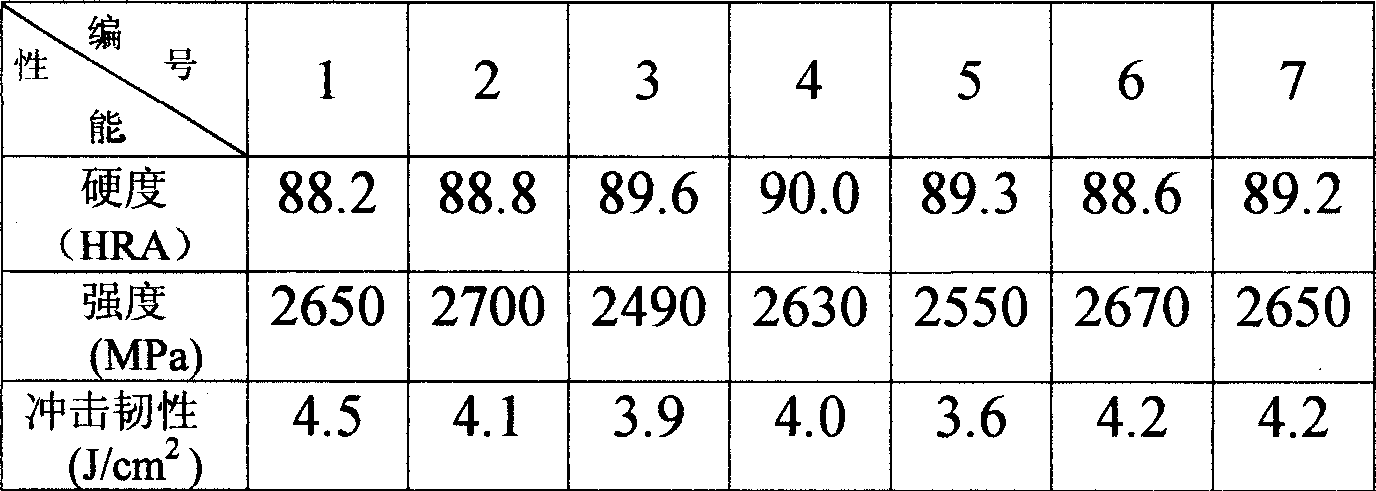

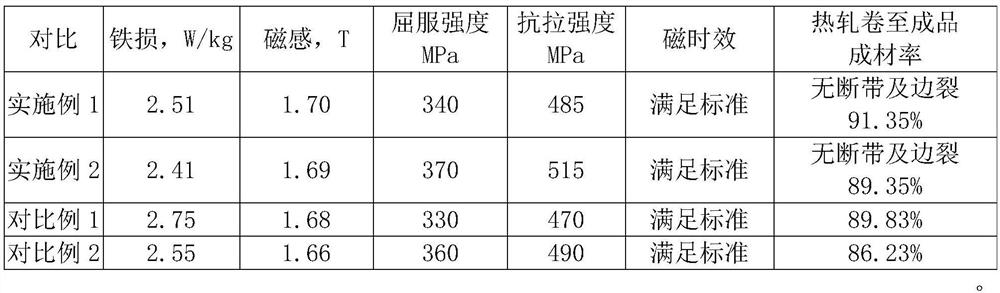

Process for preparing tungsten-cobalt hard alloy

The process of preparing hard W-Co alloy includes compounding material with WC powder and Co powder in 4-6 wt%, wet milling, drying, pelletizing after mixing with excipient, pressing to form, eliminating excipient, sintering and other steps. During compounding material, two kinds of WC powder, including great granularity component of 20-30 micron and fine granularity component of 1.2-1.8 micron in the weight ratio of 1.5-4.0, are used. The said process can compromise the wear resistance and toughness of hard alloy effectively to raise the comprehensive performance of alloy and expand the application range.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

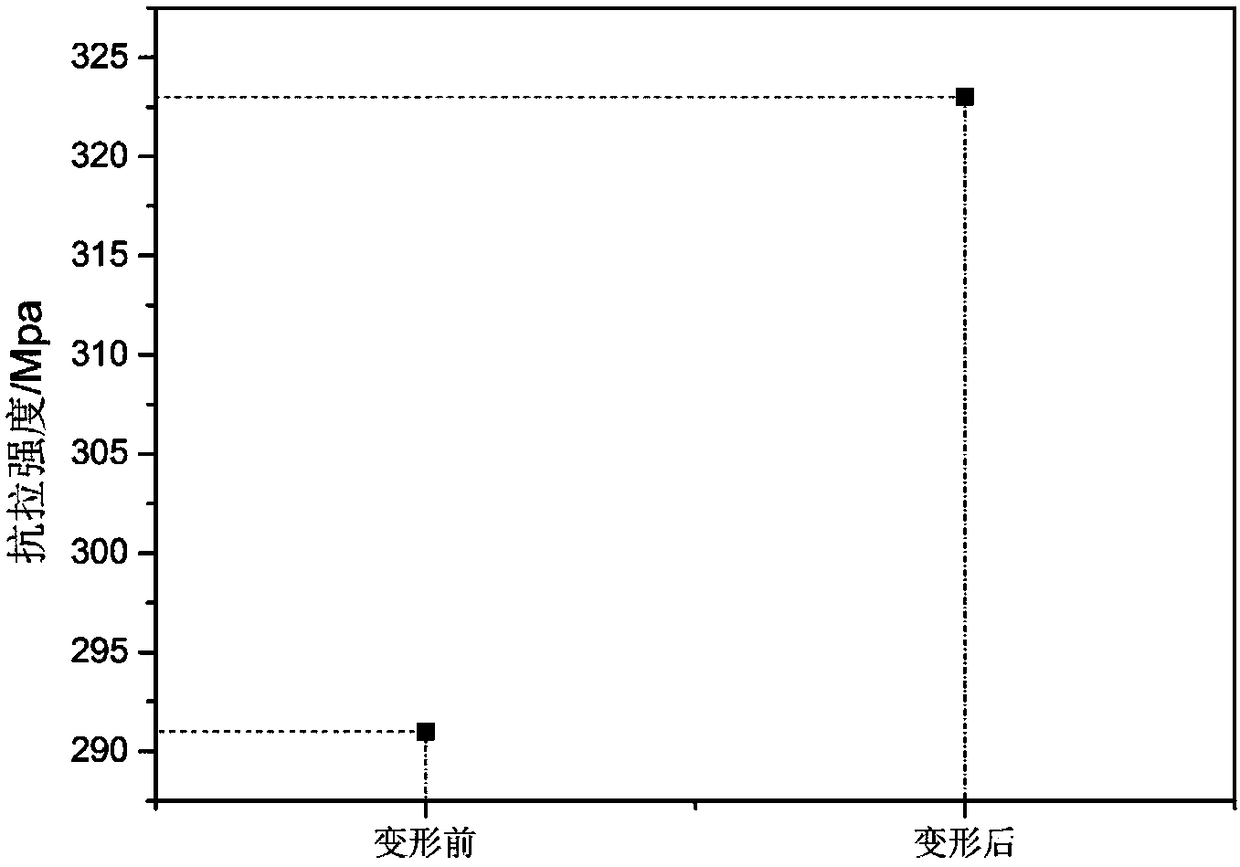

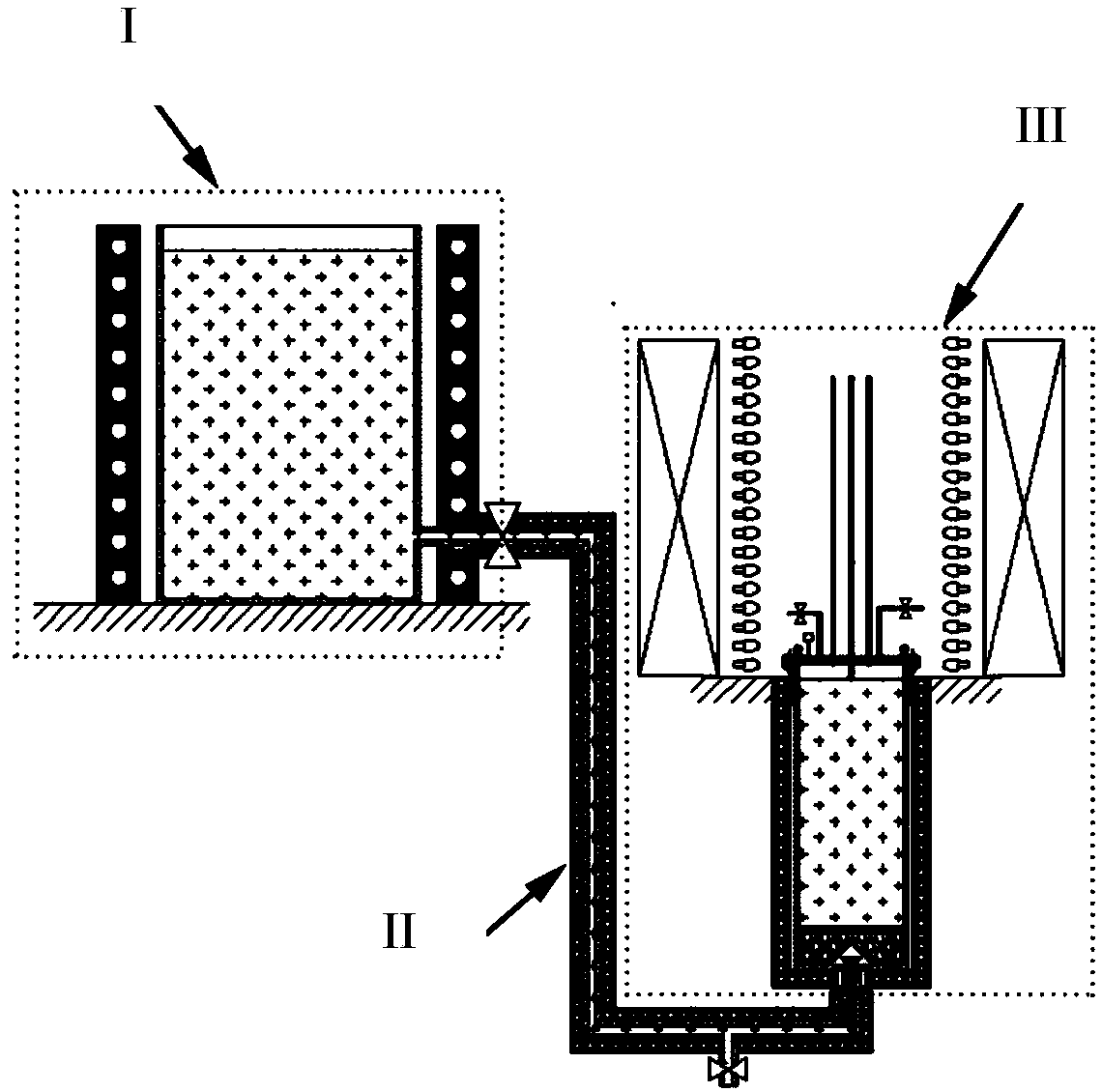

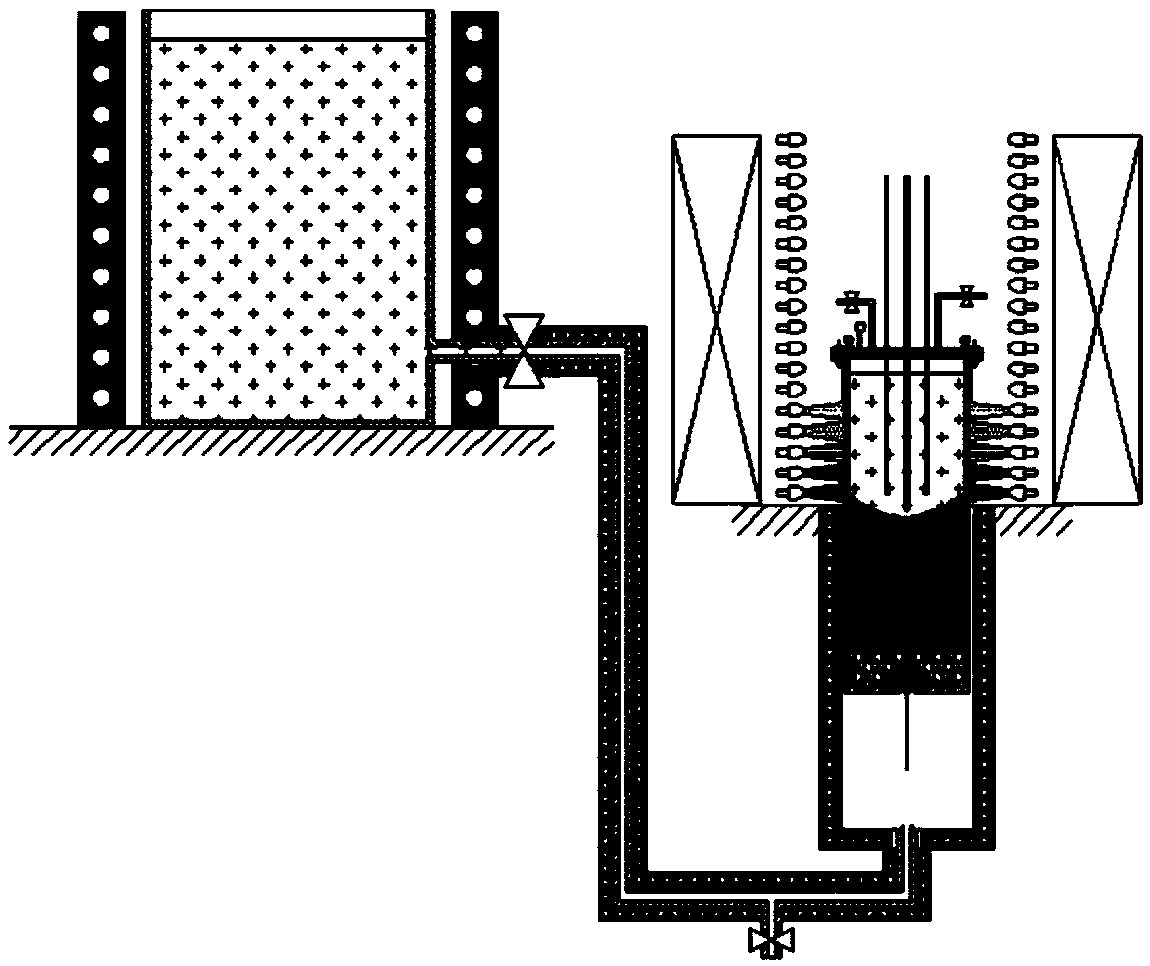

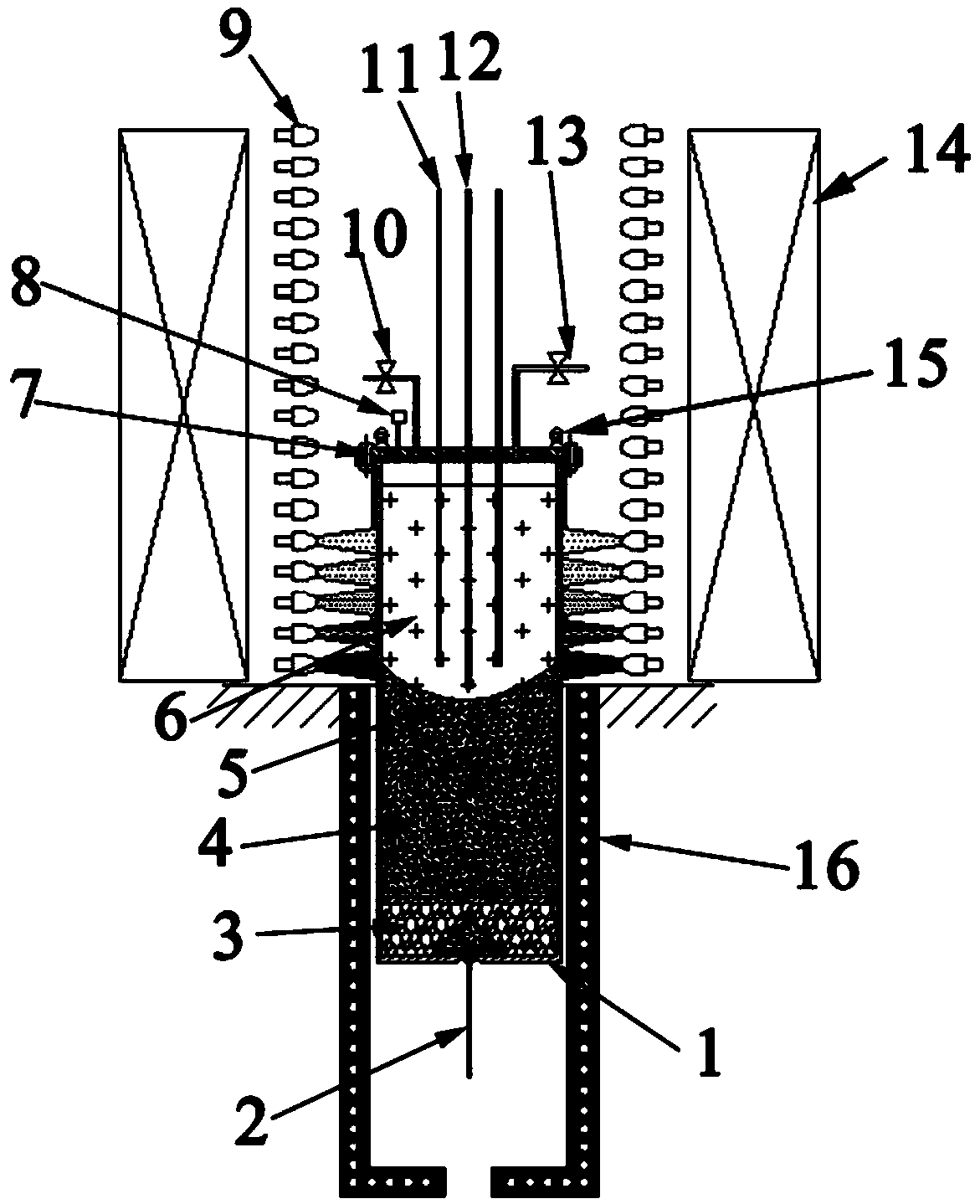

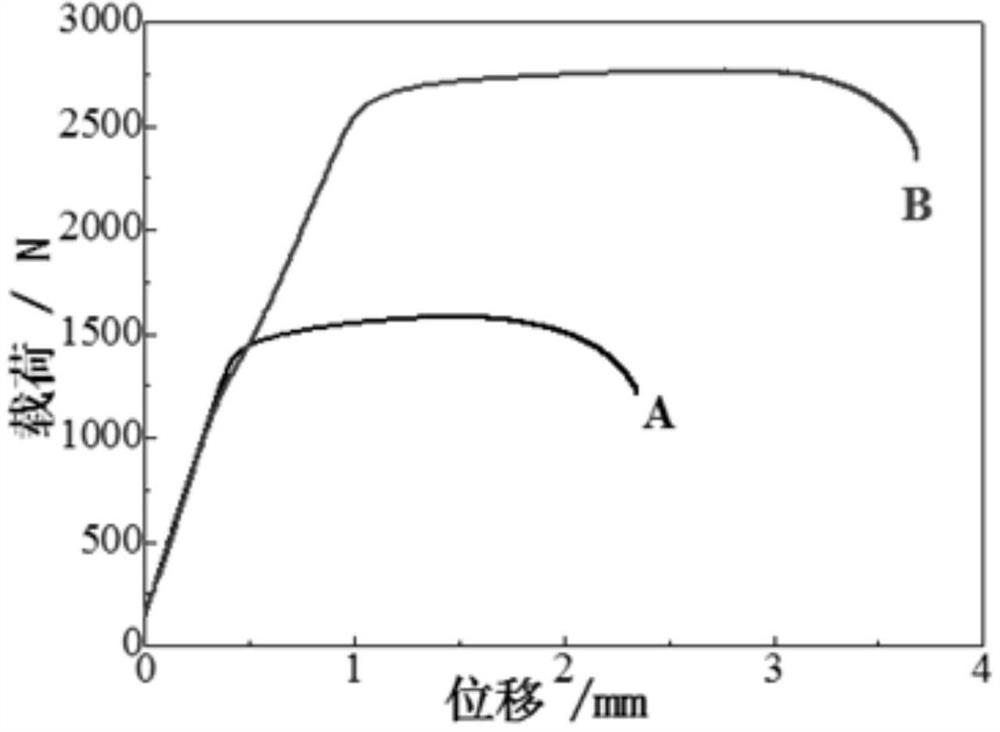

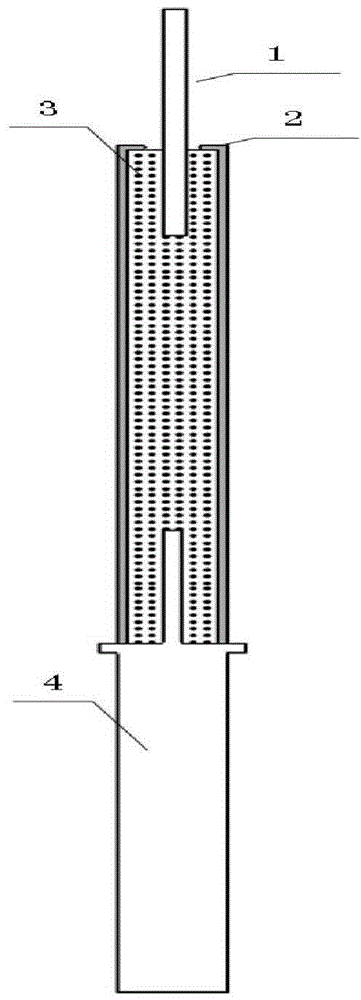

Method for manufacturing aluminum magnesium alloy structural parts through hammering reinforced arc added materials

InactiveCN108340047AReduce porosityReduce crack sourceAdditive manufacturing apparatusArc welding apparatusPorosityControl system

The invention discloses a method for manufacturing aluminum magnesium alloy structural parts through hammering reinforced arc added materials. The method comprises the following steps: 1) a substrateis cleaned; 2) an aluminum magnesium alloy structural part three-dimensional model is leaded into slicing software for slicing and path planning; and generated slicing files are leaded into a controlsystem; 3) process parameters comprising the welding speed, the wire feeding speed and the air flow are set; and the control system is used for layer-by-layer added material manufacturing of the aluminum magnesium alloy structural part according to the set process parameters and the slicing files; 4) after one layer of added material manufactured aluminum magnesium alloy structural parts are molded, the center of a hammer head is adjusted to overlap with the center of a welding bead; and hammering is performed according to a molding path; and 5) the steps 3) and 4) are repeated to finish wholearc added material manufacturing of the aluminum magnesium alloy structural parts and hammering strengthening. Air holes in hammered components are closed, so that the porosity is greatly reduced; and meanwhile, through deformation strengthening, the overall mechanical performances of the components are improved, and the mechanical performances are uniform.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

Prepn of hard W-Co alloy

The preparation process of hard W-Co alloy includes mixing WC powder and Co powder in 9-10 wt%, wet milling, drying, pelletizing after adding forming agent, pressing to form, elimiating forming agent, sintering and other steps. During compounding material, both coarse WC powder of particle size of 20-30 microns and fine powder of particle size of 1.2-1.8 microns in the weight ratio of 1.5-4 are used. The said preparation process can coordinate the wear resistance and toughness, raise the comprehensive performance of the alloy and expand the application range of the alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Process for preparing tungsten-cobalt hard alloy

The process of preparing hard W-Co alloy includes compounding material with WC powder and Co powder in 6-8 wt%, wet milling, drying, pelletizing after mixing with excipient, pressing to form, eliminating excipient, sintering and other steps. During compounding material, two kinds of WC powder, including great granularity component of 20-30 micron and fine granularity component of 1.2-1.8 micron in the weight ratio of 1.5-4.0, are used. The said process can compromise the wear resistance and toughness of hard alloy effectively to raise the comprehensive performance of alloy and expand the application range.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

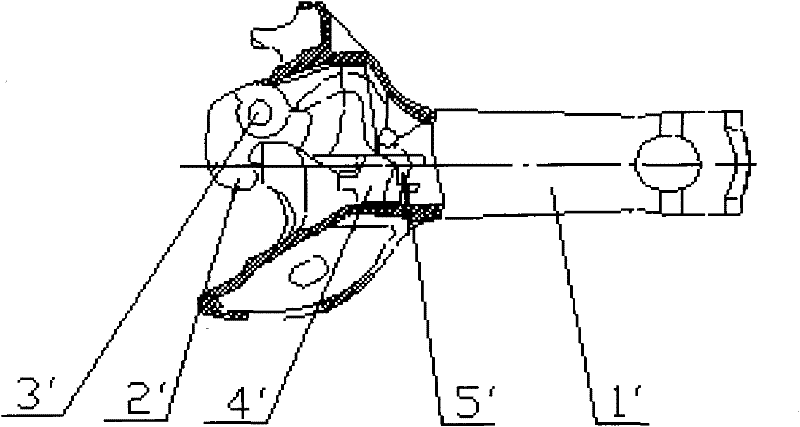

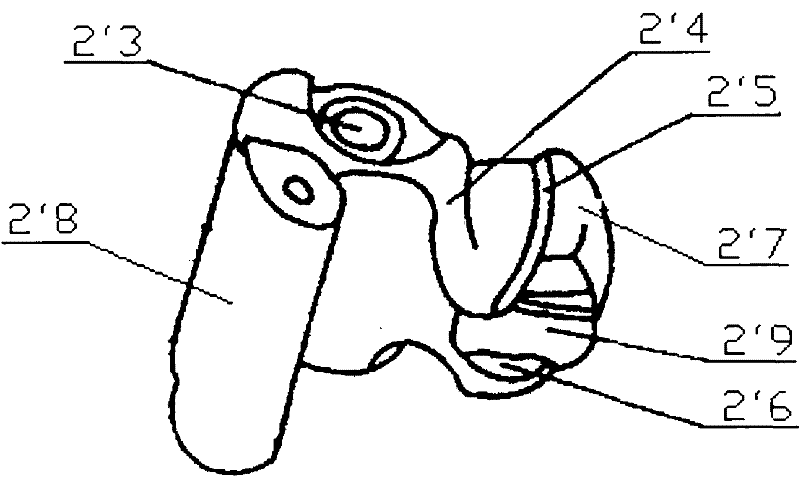

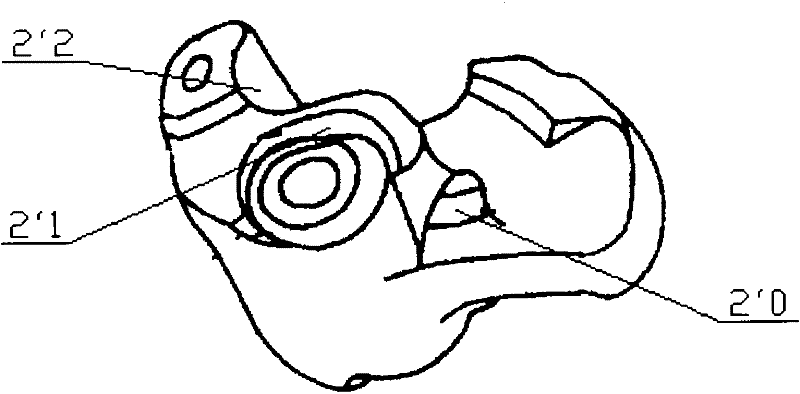

A hook and a railway vehicle including the hook

A coupler knuckle for railway vehicle has a draft surface (1) and a knuckle pivot pin hole (2). A bounce table (3) lies on the knuckle pivot pin hole (2), and a traction table (4) lies on the bounce table (3). A nose (5) of the coupler knuckle is provided in the lower part of the coupler knuckle. The bottom surface of the coupler knuckle's nose forms the coupler knuckle's face (6). There is a first groove (61) on the coupler knuckle's face (6). The coupler knuckle is a forging piece. The coupler knuckle has the advantage of high reliability, low cost and is easy to be transported.

Owner:CRRC QIQIHAR ROLLING CO LTD

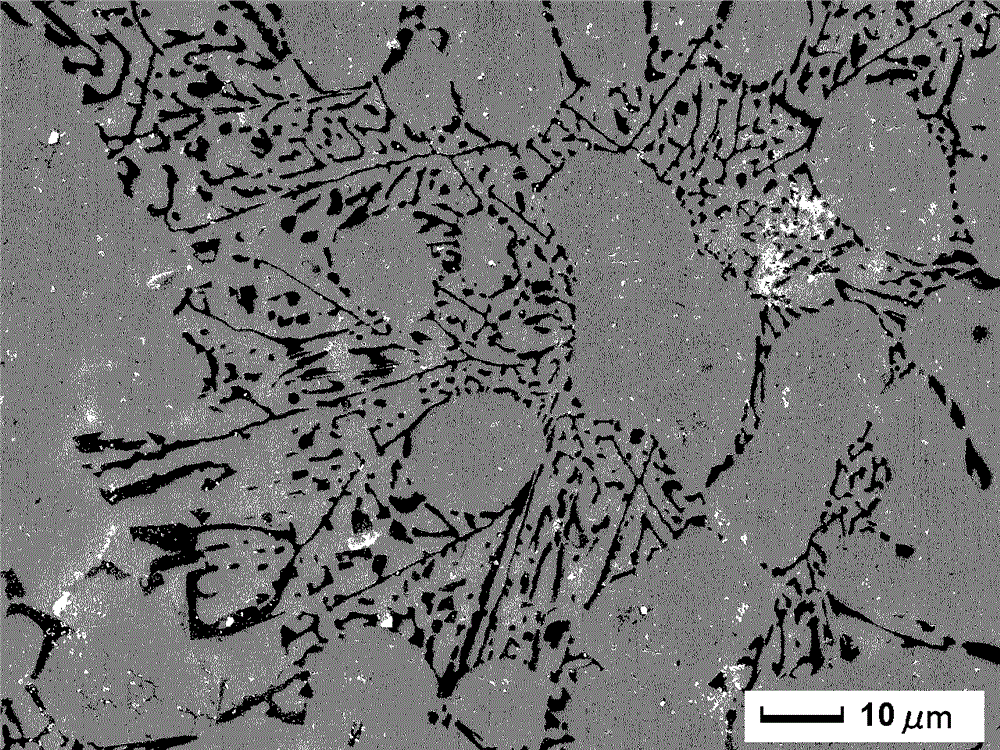

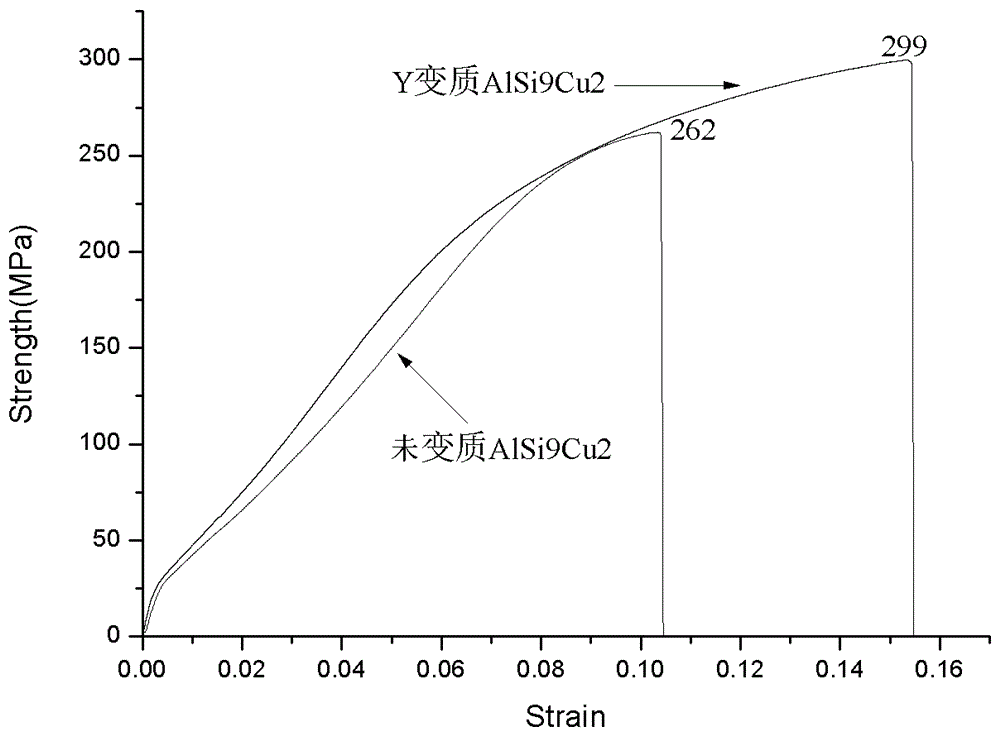

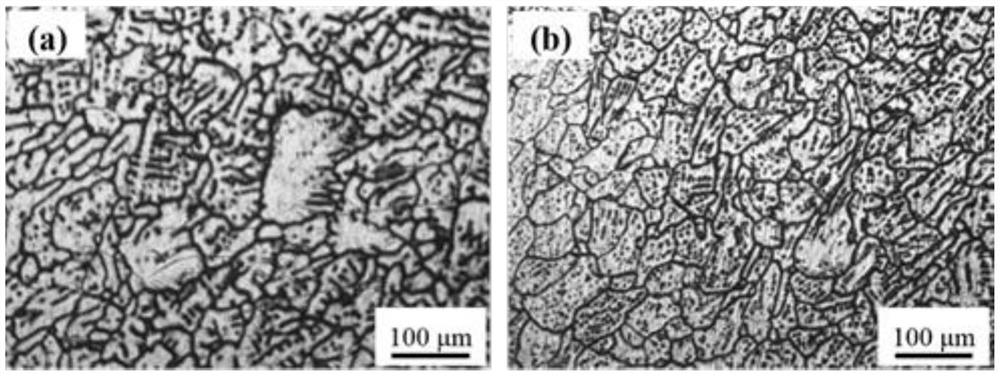

Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

The invention discloses a method for modifying an AlSi9Cu2 alloy by rare-earth Y, and relates to a method for modifying a cast aluminum-silicon alloy. By using the method for modifying the AlSi9Cu2 alloy by the rare-earth Y, the problem that a gas-hole defect exists in an AlSi9Cu2 cast alloy obtained by adopting a modifier Sr is solved. The method provided by the invention comprises the following steps of weighing to take high-purity aluminum, an Al-2OSi intermediate alloy, high-purity copper and an Al-10Y intermediate alloy raw material, fusing the high-purity aluminum and the Al-2OSi intermediate alloy, then pressing the high-purity copper into an obtained first mixture, smelting an obtained second mixture to obtain a fused mass, then adding the Al-10Y intermediate alloy into the fused mass, smelting an obtained third mixture, and pouring the smelted third mixture, so that the AlSi9Cu2 alloy is obtained subsequently. The method provided by the invention is simple, and is suitable for mass production. No gas holes exist in the obtained Y-modified AlSi9Cu2 alloy; the cast structure of the alloy is obviously thinned; the obdurability of the AlSi9Cu2 alloy is improved; and the compactability of a casting is increased.

Owner:镇江创智特种合金科技发展有限公司

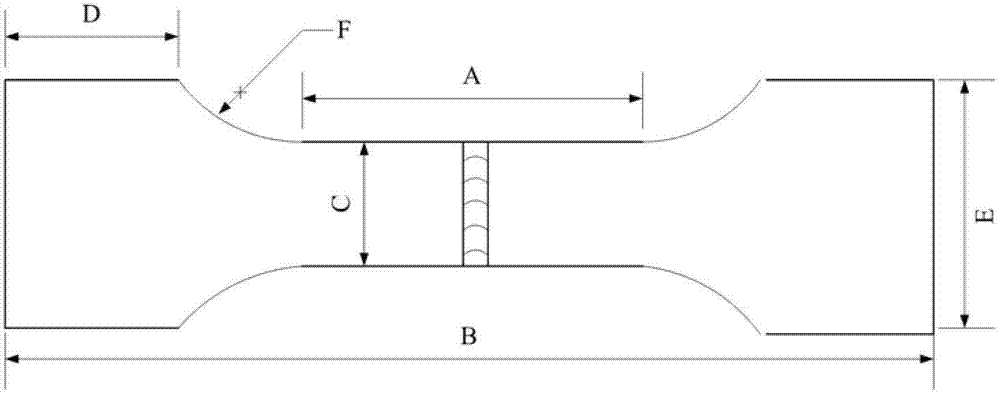

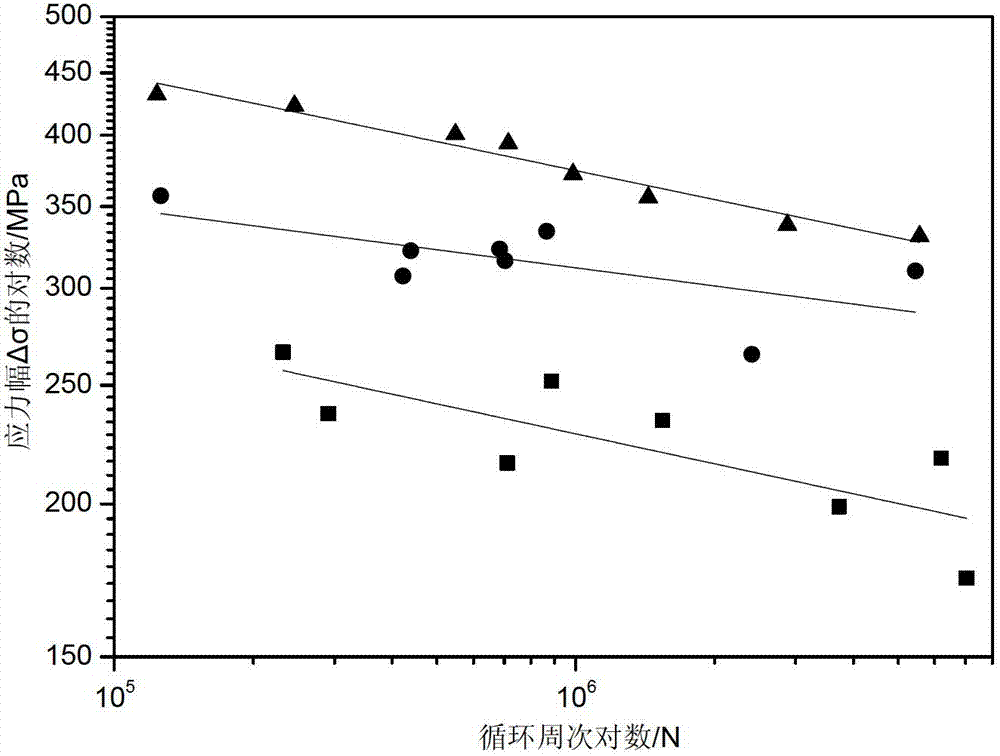

Pretreatment process for reducing defects of surface of ultrasonic impact test piece

The invention discloses a pretreatment process for reducing the defects of a surface of an ultrasonic impact test piece. The process comprises the following steps of carrying out degreasing and decontamination and then carrying out mechanical polishing. Through surface treatment, grease contaminations on the surface are removed, and residual slag and sharp parts on the surface of the test piece are polished off, so that higher surface quality is achieved. The surface conditions of the ultrasonic impact test piece are improved, and the sharpness of the surface is reduced, so that the crack initiation sources are reduced.

Owner:TIANJIN UNIV

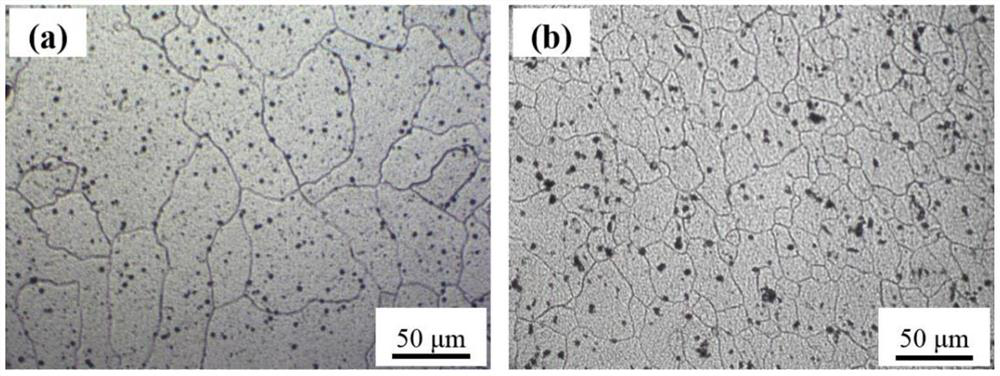

Preparation method of Mg-Zn-Ca series biomedical magnesium alloy

The invention relates to a preparation method of Mg-Zn-Ca series biomedical magnesium alloy, and belongs to the technical field of batch preparation of biomedical degradable magnesium alloy. The method comprises the steps of burdening, smelting and solidification system preparation, alloy smelting and purification, undercurrent transfer injection and forced filtration, precise solidification control and waste heat homogenization, near solidus homogenization treatment and plastic deformation treatment. The low-cost preparation technology has the greatest advantages that the preparation of a Mg-Zn-Ca series biomedical magnesium alloy ingot blank with the high thermal cracking tendency and the cross section area larger than 70000 mm <2> is met, homogeneous clean casting of industrial scale isachieved, and therefore the production efficiency can be greatly improved, the deformation degree is increased, and the performance is improved; and meanwhile, the cracking risk of a large cast ingotis greatly reduced, homogenization of a pasty area and a liquid phase area is achieved, the nucleation rate is increased, dendritic crystals are refined, and meanwhile specific gravity segregation and reverse segregation of Zn are effectively avoided.

Owner:GRIMAT ENG INST CO LTD

High-strength and corrosion-resisting alloy steel material and preparing technology thereof

InactiveCN108486484AImprove passivation corrosion resistanceEasy to weldProcess efficiency improvementRare-earth elementHigh intensity

The invention discloses a high-strength and corrosion-resisting alloy steel material and a preparing technology thereof. The raw materials and components include 0.21%-0.28% of C, 0.31%-0.43% of Si, 0.09%-0.13% of Mn, 0.21%-0.25% of B, 0.34%-0.42% of Ni, 0.09%-0.17% of Zr, 0.11%-0.15% of Cr, 0.11%-0.13% of Al, 0.07%-0.09% of P, 0.03%-0.04% of S, 0.07%-0.11% of Sb, 0.06%-0.09% of Ti, 0.001%-0.004%of Ca, 0.04%-0.07% of rare earth elements, smaller than or equal to 0.03% of O, smaller than or equal to 0.04% of N, and the balance Fe and inevitable impurities. The steel has good strength and tenacity and has high low-temperature tenacity, the preparing technology is simple, the production cost is relatively low, and the production requirement can be met.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

High strength heat resistant aluminum alloy wire

InactiveCN106057273AHigh strengthReduce crack sourceConductive materialMetal/alloy conductorsComing outRare earth

The invention discloses a high strength heat resistant aluminum alloy wire. The high strength heat resistant aluminum alloy wire is manufactured according to steps as follows, 100 parts of aluminum ingot are put in an aluminum melting furnace for melting; aluminum liquid after melting is injected to a holding furnace, when temperature of the aluminum liquid is kept at 740+ / -10 DEG C, silicon, iron, copper, rare earth, boron, titanium and beryllium are added to the aluminum liquid, and the mixed liquid is stirred to be in a uniform state; after casting, a casting blank is aligned and heated, temperature of the casting blank before rolling is controlled to be in a range of 520-540 DEG C; an aluminum alloy rod coming out of a rolling mill is rapidly cooled through water or dilute emulsion; before the aluminum rod enters a take-up frame, the surface of the aluminum rod is dried through compressed air, the aluminum rod is cleaned and dried, and the aluminum rod cools down naturally. The high strength heat resistant aluminum alloy wire is advantaged in that crack sources of the aluminum alloy are reduced, strength of the aluminum alloy is improved, and processing performance is improved.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

Stainless steel material for doors and windows

InactiveCN107058876AGood transverse yield strengthImprove plasticityAntifouling/underwater paintsPaints with biocidesRare-earth elementHigh intensity

The invention provides a stainless steel material for doors and windows. The material is prepared from a Fe element and modified chemical element impurities. The following modified chemical elements in percentage by mass are included: 0.05 to 0.11 percent of C, 0.5 to 1 percent of Mn, 0.21 to 0.24 percent of Si, 0.006 to 0.008 percent of P, 0.002 to 0.004 percent of S, 0.093 to 0.095 percent of Nb, 0.06 to 0.08 percent of V, 2.8 to 3.1 percent of Ti, 1.5 to 1.7 percent of Al, 0.001 to 0.006 percent of N, 0.0001 to 0.0002 percent of H, 0.05 to 0.07 percent of Cu, 7.4 to 15.2 percent of Cr, 8.1 to 11.3 percent of Ni, 0.23 to 0.25 percent of Mo, 0.21 to 0.23 percent of La, 0.04 to 0.08 percent of Sr, 0.05 to 0.1 percent of Th, 0.02 to 0.03 percent of Be, 0.05 to 0.08 percent of Zr, 0.0015 to 0.002 percent of B, and 0.06 to 0.09 percent of Re. According to the stainless steel material for doors and windows provided by the invention, the element contents in stainless steel are reasonably controlled, so that the obtained stainless steel is anti-corrosion and anti-erosion; and the rare earth element lanthanum is added, so that the high-strength anti-corrosion stainless steel for metal doors and windows are successfully obtained and has better transverse yield strength and high-ductility, the transverse tensile strength is larger than or equal to 450MPa, the transverse yield strength is larger than or equal to 240MPa, the transverse extension rate is larger than or equal to 30 percent, and the thickness-direction area reduction percentage is larger than or equal to 55 percent.

Owner:合肥市旺友门窗有限公司

Low-resistivity aluminum alloy rod

ActiveCN104805335AReduce crack sourceHigh strengthConductive materialFurnace typesRare-earth elementCerium

The invention discloses a low-resistivity aluminum alloy rod. The low-resistivity aluminum alloy rod consisting the following components in parts by weight: 100 parts of aluminum, 0.04 to 0.06 part of silicon, 1 to 1.3 parts of iron, 0.18 to 0.28 part of copper, 0.08 to 0.1 part of rare earth elements, 0.015 to 0.03 part of boron and 0.01 to 0.02 part of titanium; the rare earth elements consist of lanthanum, cerium and scandium. The low-resistivity aluminum alloy rod is manufactured through the following steps: mixing the lanthanum, the cerium and the scandium according to a weight ratio of 14: 6: 1 to form the rare earth elements; putting all the components into a smelting furnace, heating to smelt the components, carrying out heat preservation at 750 to 780 DEG C, sufficiently stirring over 30 minutes to be uniform, standing and carrying out heat preservation to obtain an alloy melt; casting to obtain an aluminum alloy cast ingot through an aluminum alloy melt, wherein the casting temperature is controlled at 690 to 700 DEG C; carrying out inductive heating, raising the temperature to 520 to 540 DEG C and then rolling, wherein the temperature is raised prior to rolling. A metallic structure of the low-resistivity aluminum alloy rod is better clearly; after production testing and follow-up wiredrawing, the tensile strength and the elongation rate of the low-resistivity aluminum alloy rod are remarkably improved and the resistivity is reduced by 6 to 10 percent.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Preparation method of high-strength stress-corrosion-resistant aluminum alloy profile

The invention relates to a preparation method of a high-strength stress-corrosion-resistant aluminum alloy profile. The preparation method comprises the following steps that a remelted refined aluminum ingot, cathode copper, a zinc ingot, a magnesium ingot, an aluminum-silicon intermediate alloy, an aluminum-manganese intermediate alloy, an aluminum-titanium intermediate alloy, an Al-10% Y intermediate alloy, an Al-5% Sc intermediate alloy and an Al-10% Sr intermediate alloy are smelted; then homogenization treatment is carried out, skin turning and saw cutting are carried out after cooling, and then heating treatment, extrusion forming treatment, solid solution quenching treatment, first-time stretching treatment, first-stage aging treatment, second-time stretching treatment, second-stage aging treatment and cooling are carried out to obtain the high-strength stress-corrosion-resistant aluminum alloy profile; and the speed of the second-time stretching treatment is slower than that of the first-time stretching treatment. The aluminum alloy profile treated by the method has the effects of improving the strength, plasticity and stress corrosion resistance, and the obtained aluminum alloy profile is high in surface quality and uniform and fine in structure.

Owner:JIANGSU UNIV OF TECH

Aluminum-plastic wood sectional material

InactiveCN107152213AImprove mechanical propertiesExtended service lifeWindow/door framesAnti-corrosive paintsLow-density polyethyleneFiber

The invention provides an aluminum-plastic wood profile, comprising a wood-plastic layer and an aluminum alloy layer; the wood-plastic layer is composed of the following raw materials in parts by weight: 10-30 parts of sarin resin, 5-15 parts of plant fiber powder, wood powder 40-50 parts, 20-40 parts of polyurethane foam powder, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1-3 parts of lubricant, 0-2 parts of antioxidant, ethylene-vinyl acetate copolymer 2-7 parts of mixture with ethylene-acrylic acid copolymer, 1-3 parts of cold resistance agent M711, 1-2 parts of light stabilizer GW-540, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1 part of lubricant ‑5 parts, 1‑3 parts of colorant, 3‑10 parts of bentonite, 20‑40 parts of low density polyethylene. In the present invention, the wood-plastic layer and the aluminum alloy layer are used in combination, and the advantages and disadvantages of the wood-plastic layer and the aluminum alloy layer are complemented. Weather resistance, wear resistance and other properties, in the natural environment, aluminum-plastic wood profiles have good mechanical properties, are not easy to age, and have a long service life.

Owner:合肥市旺友门窗有限公司

Alloy glass die material

The invention discloses an alloy glass die material. According to the formula, the die steel material is composed of iron, titanium, tungsten, aluminum, molybdenum, sulfur, phosphorus and rare earth elements. The alloy glass die material has the beneficial effects that the glass die material is beneficial to reduce using of precious metal elements, and the added rare earth elements are beneficial to decreasing crack origins formed due to the situation that large-scale massive primary molybdenum compound is instable at high temperature and is decomposed; the performance is stable, and meanwhile the service life of the glass die is prolonged.

Owner:TAICANG WANGMEI MOLD CO LTD

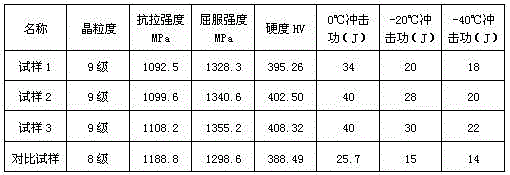

Micro-alloyed composite cored wire for wear-resistant steel

A micro-alloyed composite cored wire for wear-resistant steel, made of the following components by mass percentage: Ca12‑14%, Si45‑50%, Mg1.5‑2%, Ba1.5‑2%, Zr2‑3.5 %, Ce1.37‑2.6%, La0.75‑1.4%, Nd0.13‑0.6%, V0.2‑0.3%, Al0.01‑0.03%, Ti0.01‑0.03%, B0.002‑0.004% , and the balance is iron and unavoidable impurities. The present invention uses the micro-alloyed composite cored wire to replace the precious Ni element to smelt the wear-resistant steel. Compared with the existing technology, the addition of the composite cored wire improves the mechanical properties of the wear-resistant steel, so that the steel can obtain a higher Low relative mass wear amount and relative wear thickness refine grains and improve impact toughness and wear performance. The cerium, lanthanum, neodymium, calcium, magnesium, zirconium and other elements in the composite cored wire have a strong binding force with impurities such as oxygen and sulfur, which can purify the molten steel and reduce the source of cracks caused by the stress concentration of large inclusions , Improve the quality of steel. The invention improves the deficiencies in the production of the existing wear-resistant steel, and has good economic and social benefits.

Owner:HUBEI KMK WELDING MATERIALS

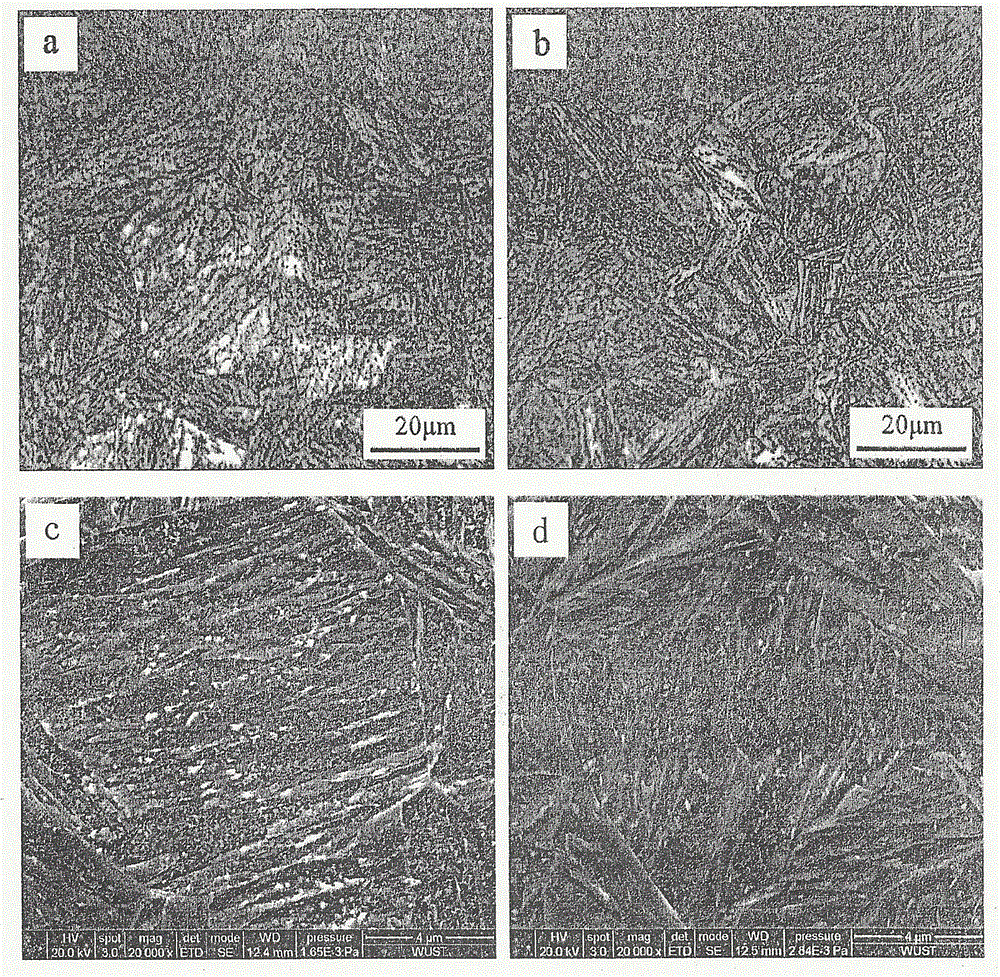

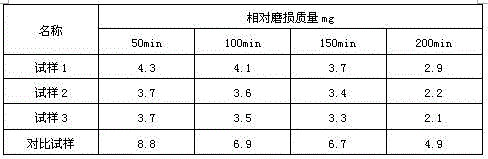

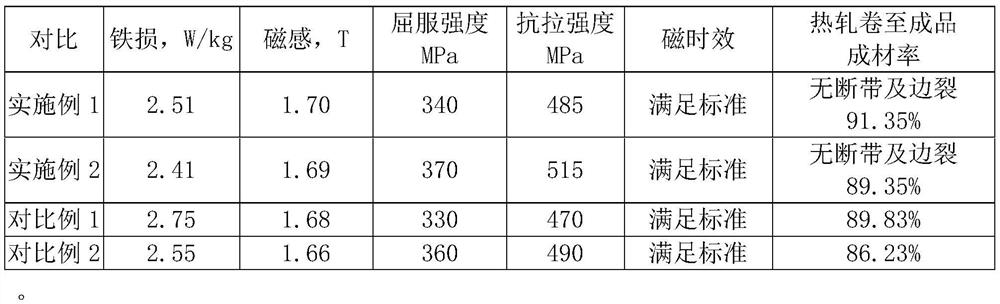

Method for producing non-oriented high silicon steel by cold continuous rolling method

ActiveCN113789471AImprove continuous rolling capacityImprove abilitiesProcess efficiency improvementAlloy elementDecarburization

The invention relates to a method for producing non-oriented high silicon steel by a cold continuous rolling method. The method comprises the following steps: after RH vacuum decarburization treatment, aluminum deoxidizing and partial aluminum alloying are carried out, and after alloying, net circulation is carried out on molten steel in a large tank for more than 3 times or more than 5 minutes; the standing time from smelting of qualified molten steel to continuous casting starting is longer than 20 minutes; the superheat degree is controlled to be 5-15 DEG C; electromagnetic stirring is adopted, and the proportion of equiaxed crystals is controlled to be 45% or above; 3) the charging temperature of a plate blank in the hot rolling process is higher than 750 DEG C; normalizing is carried out to enable the grain size to be in a range of 90-110 microns; and the temperature of a heating section of a continuous annealing furnace is set to be 950-1150 DEG C, the temperature of a soaking section is set to be 900-1050 DEG C, full-nitrogen dry atmosphere protection is adopted, and the grain size is controlled to be 120-170 microns. The thermo-history parameter control in the whole production process gives full play to the functions of designed microalloy elements, and changes the composition, size, form and distribution of precipitates.

Owner:ANGANG STEEL CO LTD

Prepn of hard W-Co alloy

The preparation process of hard W-Co alloy includes mixing WC powder and Co powder in 9-10 wt%, wet milling, drying, pelletizing after adding forming agent, pressing to form, elimiating forming agent, sintering and other steps. During compounding material, both coarse WC powder of particle size of 20-30 microns and fine powder of particle size of 1.2-1.8 microns in the weight ratio of 1.5-4 are used. The said preparation process can coordinate the wear resistance and toughness, raise the comprehensive performance of the alloy and expand the application range of the alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method of rolling niw alloy tapes for coated conductors

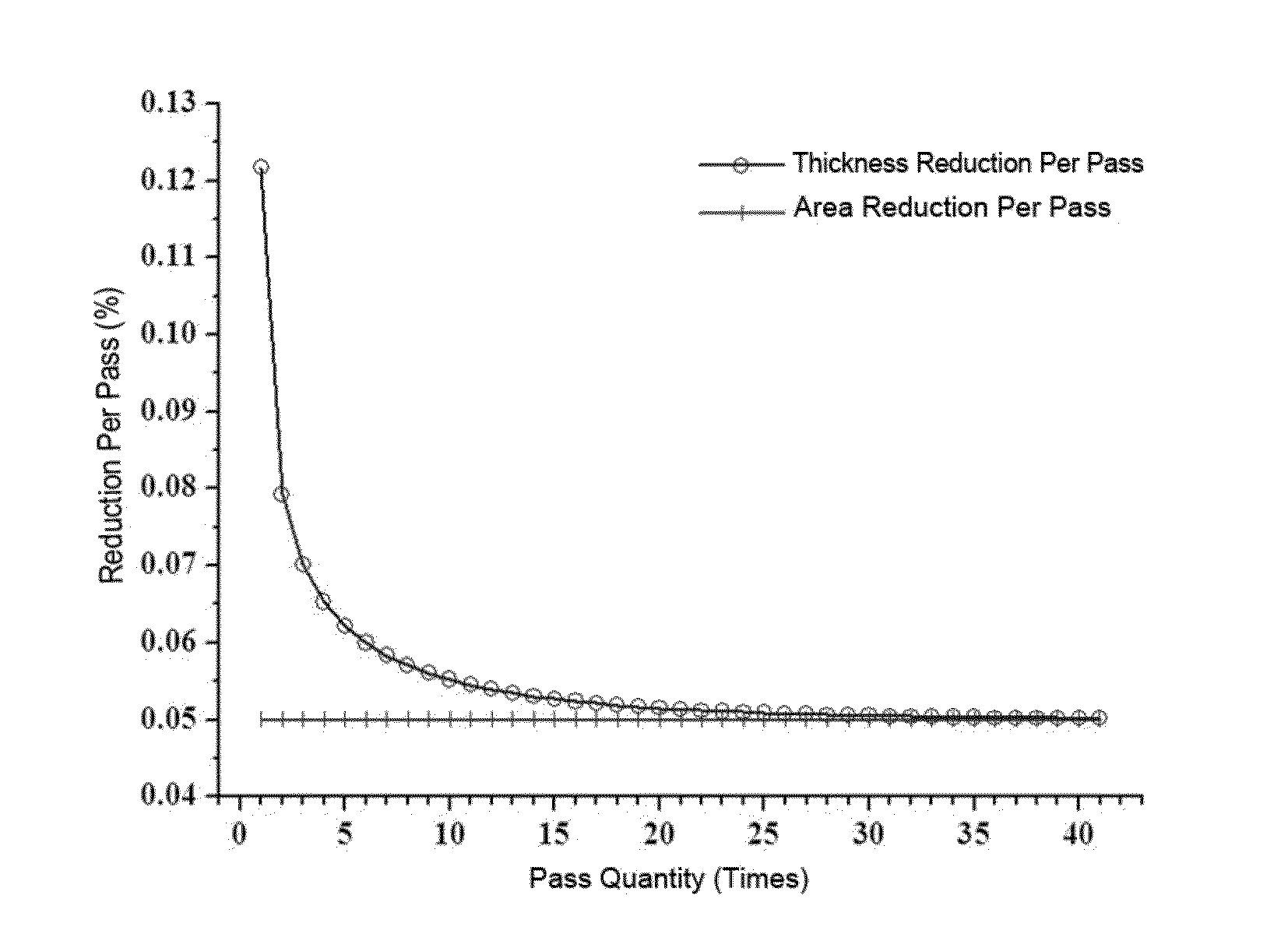

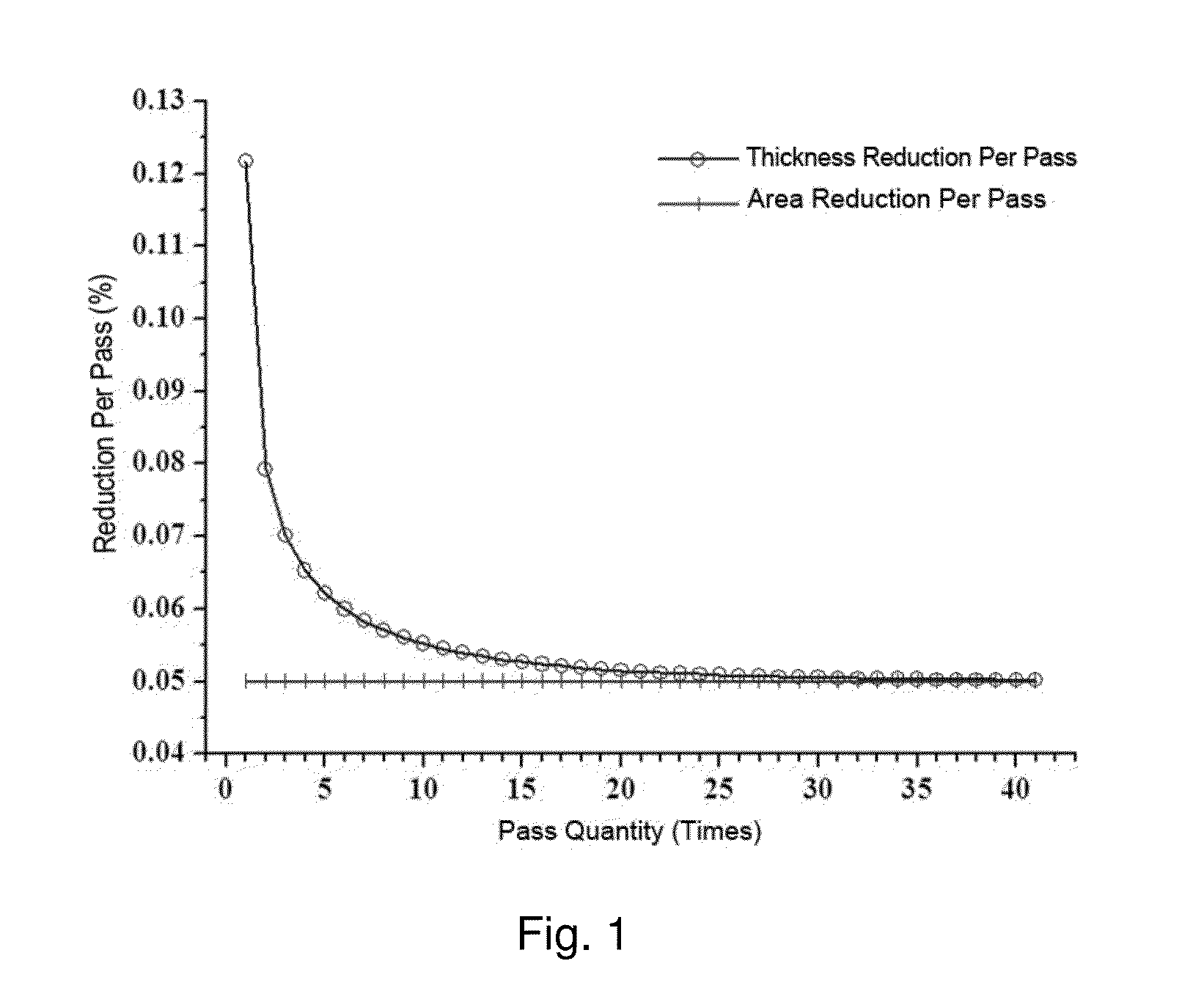

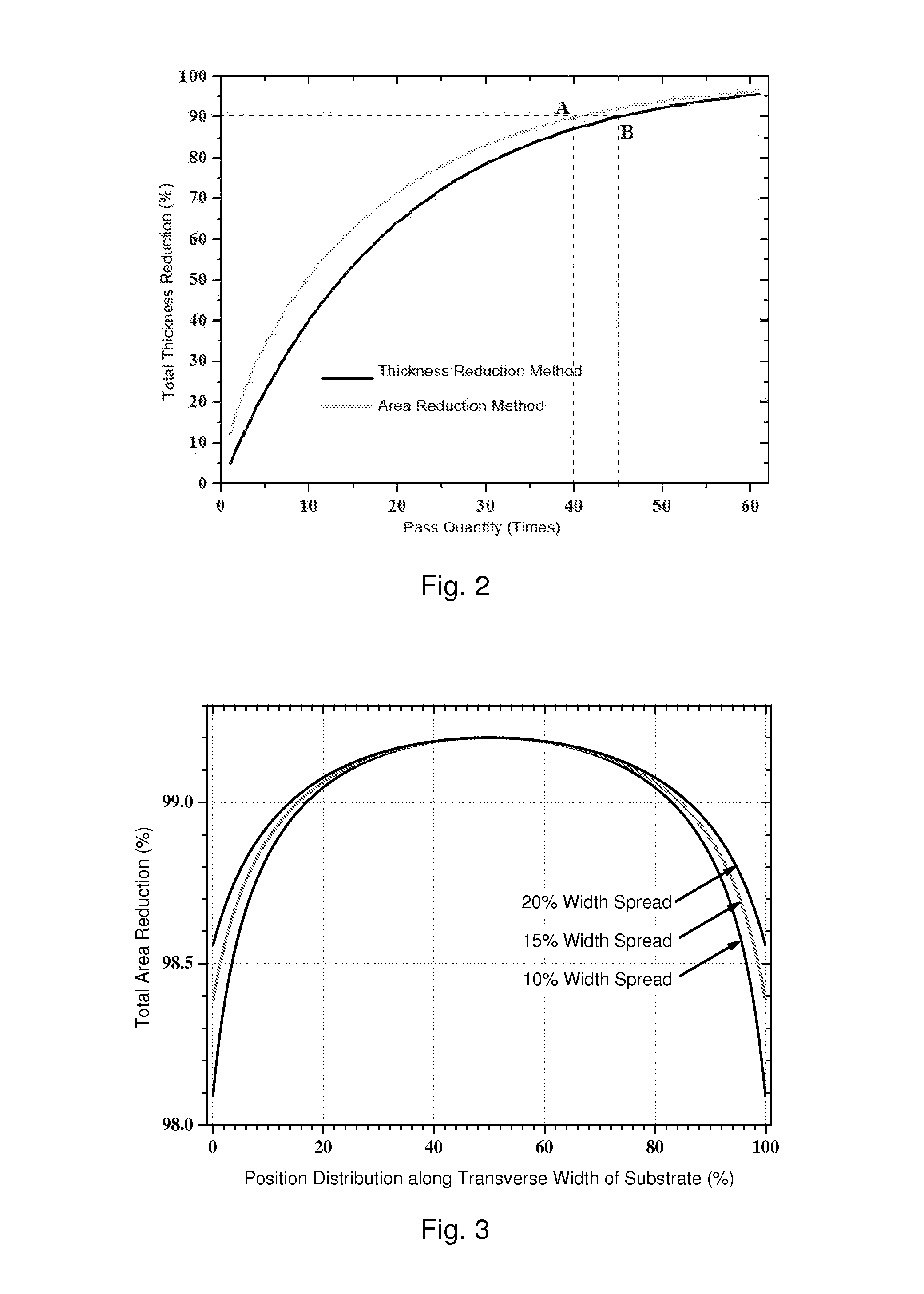

ActiveUS20150135791A1Increase productionReduce negative impactMetal rolling arrangementsElectrical conductorMetallic materials

A method of rolling NiW alloy tapes for coated conductors belongs to the technical field of metal materials rolling. According to the method, a cylindrical NiW alloy ingot with a diameter not less than 10 mm is used to be rolled back and forth along the axial direction as a rolling direction, wherein the content of W is 5˜7 at. %, and the axis of this ingot is perpendicular to the plane where the axes of working rollers are located. During rolling process, the cross sectional area reduction of the ingot is retained at 5% per pass. When the total cross sectional area reduction of the ingot is larger than 98% and the thickness of the tape is down to 60˜100 μm, the rolling is stopped, and thus the NiW alloy tape is obtained. The method has the advantages that the negative influence generated when the NiW alloy tape is produced from a cuboid initial NiW alloy ingot can be reduced as much as possible, the yield of the NiW alloy tapes is increased, as well as relatively ideal effects can be obtained in terms of the surface biaxial texture, the length and the axial quality.

Owner:BEIJING UNIV OF TECH

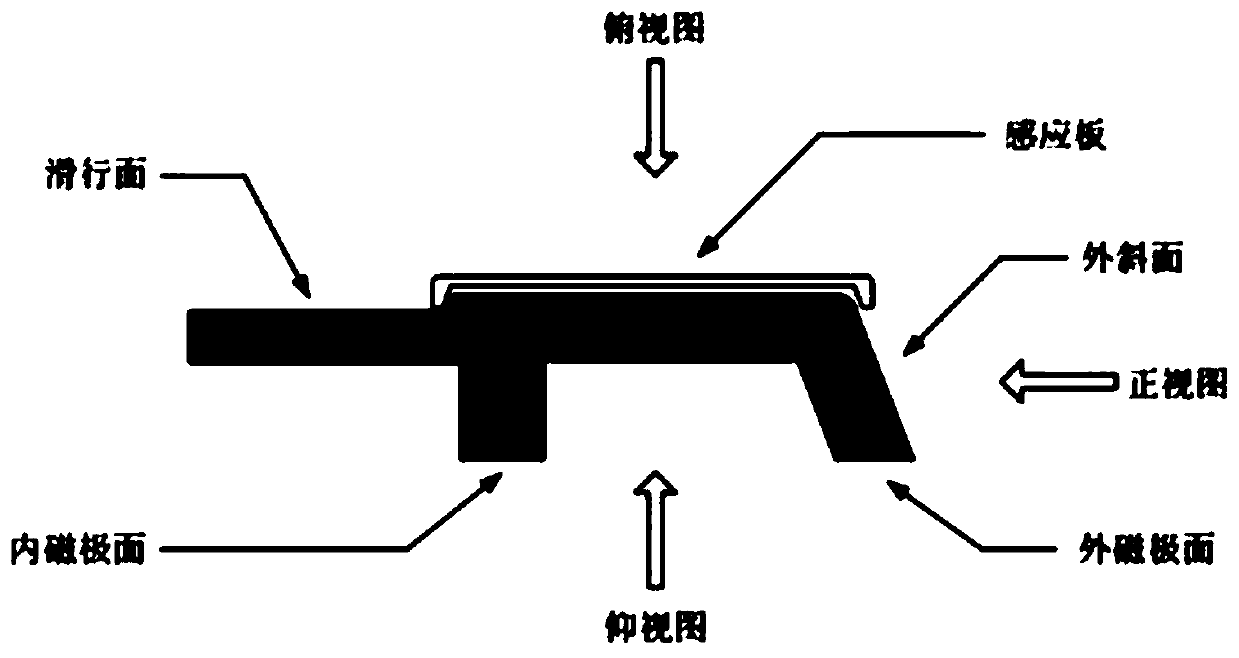

Aluminum alloy, induction plate for magnetic levitation rail transit and preparation method of induction plate

InactiveCN111394627AHigh strengthImprove conductivityMaterial strength using tensile/compressive forcesUltimate tensile strengthRail transit

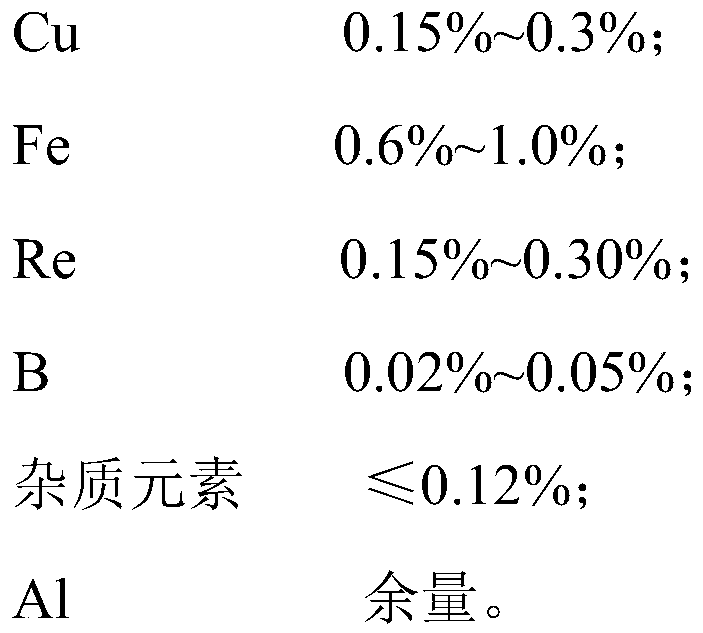

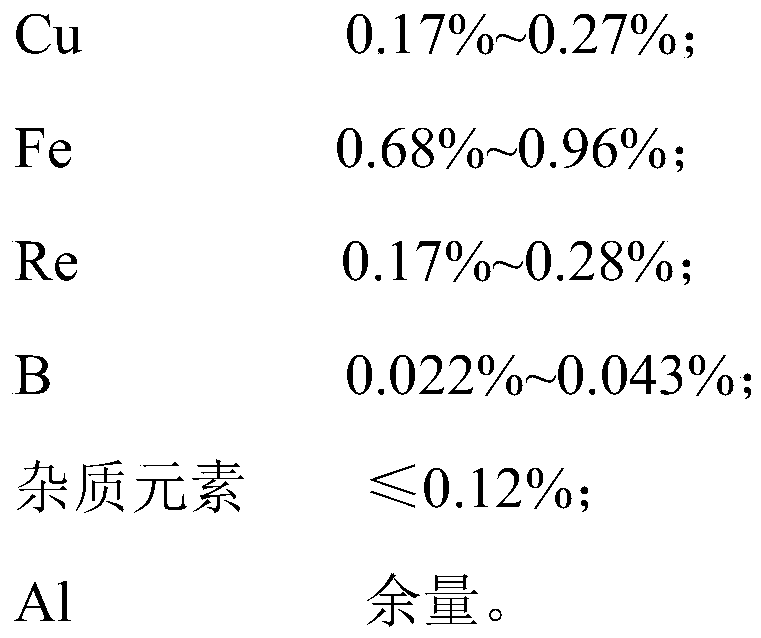

The invention provides an aluminum alloy. The aluminum alloy takes an Al element as a main material and mainly comprises 0.15 wt%-0.3 wt% of Cu, 0.6 wt%-1.0 wt% of Fe, 0.15 wt%-0.30 wt% of Re and 0.02wt%-0.05 wt% of B. The aluminum alloy has high strength and good conductivity at the same time. The induction plate for the magnetic levitation rail transit, which adopts the aluminum alloy as the raw material, has higher strength and good conductivity, so that the induction plate for the magnetic levitation rail transit can meet the performance requirements of a magnetic levitation rail transitsystem.

Owner:深圳市华加日西林实业有限公司

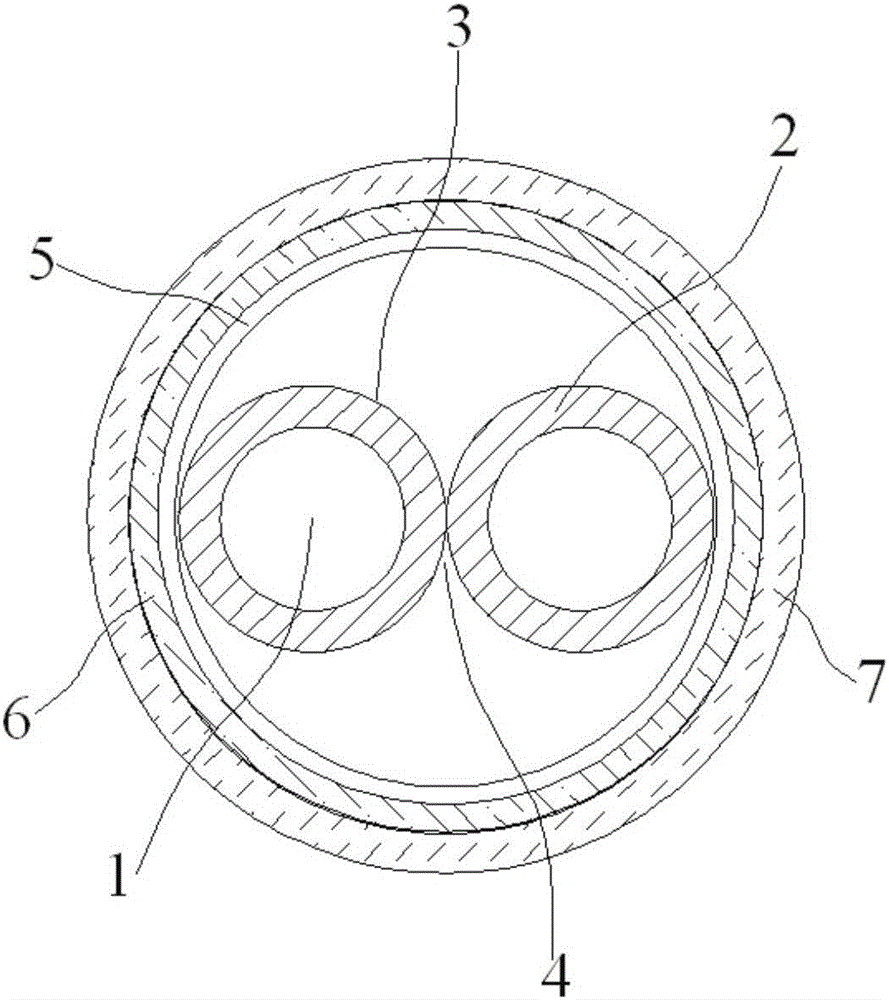

Overhead two-core user lead-in cable

InactiveCN105023647AReduce crack sourceImprove heat resistanceMetal/alloy conductorsCable/conductor manufactureRare-earth elementIndium

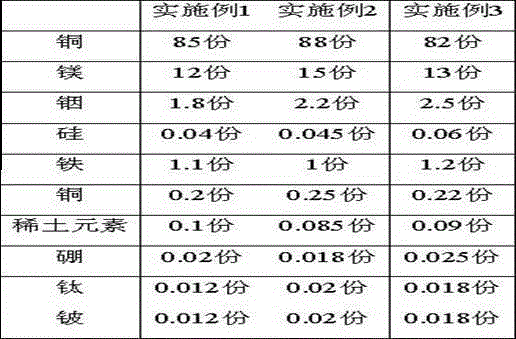

The invention discloses an overhead two-core user lead-in cable, and includes two copper-magnesium alloy conductors, outer surfaces of the copper-magnesium alloy conductors are wrapped by polyethylene layers to form leads, the two leads are intertwisted to form a stranded wire pair, An aluminum foil wraps an outer surface of the stranded wire pair, a polyvinyl chloride layer wraps an outer surface of the aluminum foil, a polyethylene sheath layer warps an outer surface of the polyvinyl chloride layer, and each copper-magnesium alloy conductor comprises the following components in parts by weight: 80-90 parts of copper, 10-15 parts of magnesium, 1.5-3 parts of indium, 0.04-0.06 part of silicon, 1-1.3 parts of iron, 0.18-0.28 part of copper, 0.08-0.1 part of rare earth elements, 0.015-0.03 part of boron, 0.01-0.02 part of titanium, and 0.01-0.02 part of beryllium. The rare earth elements consist of lanthanum, cerium and scandium which form the rare earth elements by mixing according to a proportion of 10:4:1 in parts by weight. The overhead two-core user lead-in cable provided by the invention has an obviously improved metal structure, passes a production test and has greatly improved tensile strength and elongation in subsequent wiredrawing.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Aluminum alloy material for rifle aiming device and preparation method of aluminum alloy material

InactiveCN107964612AImprove metallographic structureImprove heat resistanceSolution treatmentCrucible

The invention discloses an aluminum alloy material for a rifle aiming device and a preparation method of the aluminum alloy material. The aluminum alloy material comprises 0.4-0.6% of Si, 0.8-1.1% ofMg, 0.2-0.3% of Cu, 0.6-1.0% of Cr, 1.0-1.2% of Mn, 0.5-0.8% of La, 0-0.3% of Fe, 0-0.04% of Ti and the balance Al and impurities. The preparation method includes the steps that (1) all metal materials are obtained according to the weight; (2) all the materials are fed into a high-temperature smelting furnace, a refining flux is adopted, and deslagging and degassing are conducted; (3) a molten body is uniformly stirred; (4) metals on the lower portion of the molten body are slightly stirred through a stirring rod, and when the metals on the lower portion float to the upper portion of a crucible, semi-continuous casting is conducted to obtain a cast ingot; (5) the molten body is subjected to homogenization treatment; (6) the cast ingot is kept warm and subjected to thermal extrusion deformation, and online water penetration is conducted after demolding is finished so as to obtain an extruded material; and (7) the cast ingot is subjected to solution treatment and water quenching and thenartificial aging treatment and is air-cooled to the room temperature, and an aluminum alloy pipe material is obtained.

Owner:JIANGSU JIALV IND

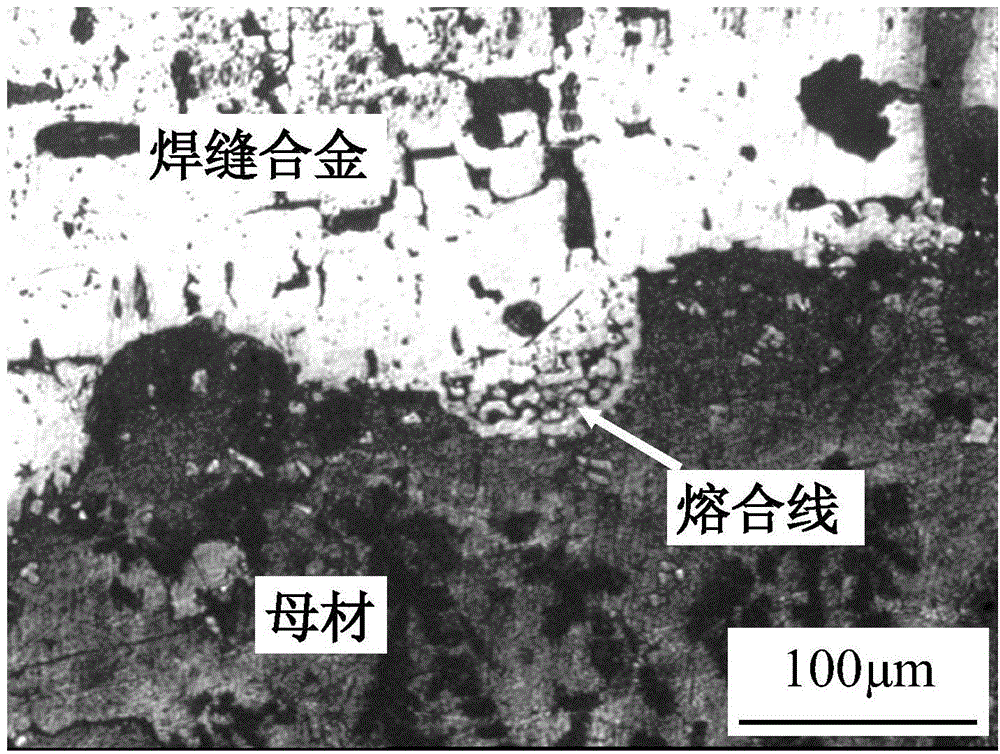

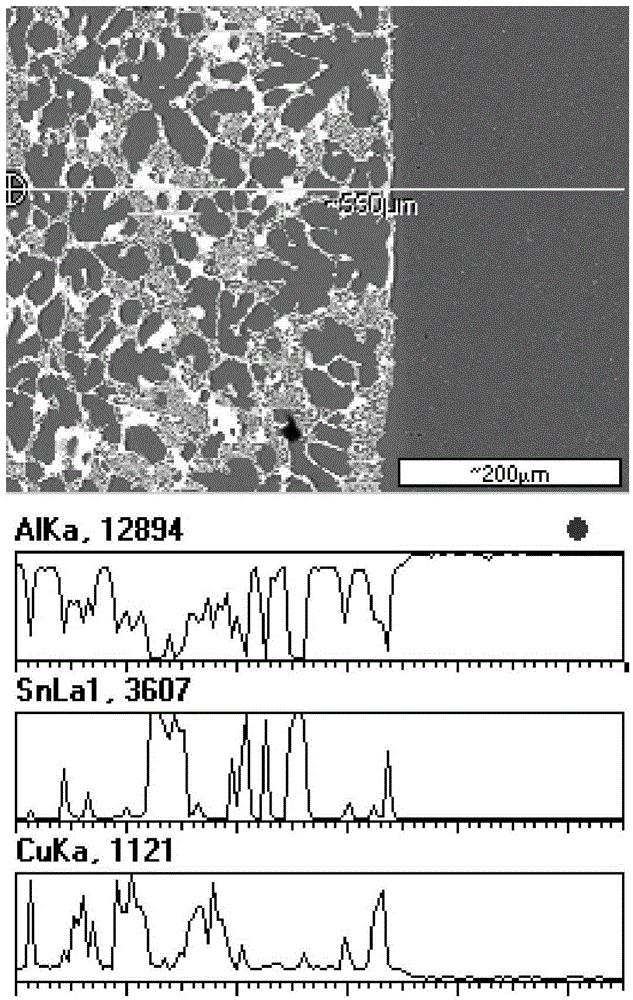

Self-propagating aluminum solder and welding rod

InactiveCN103537823BImprove purification effectImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaAl powderWelding defect

Owner:WUHAN UNIV

A method for producing non-oriented high silicon steel by cold rolling

ActiveCN113789471BImprove continuous rolling capacityImprove abilitiesProcess efficiency improvementFurnace temperatureNitrogen gas

The invention relates to a method for producing non-oriented high-silicon steel by cold tandem rolling. After RH vacuum decarburization treatment, aluminum deoxidation and partial aluminum alloying, the net circulation of molten steel in a large tank after alloying is more than 3 times or more than 5 minutes; the smelting is qualified The molten steel should be left to stand for more than 20 minutes before continuous casting; the superheating degree should be controlled at 5-15°C; electromagnetic stirring should be used to control the proportion of equiaxed crystals to more than 45%; 3) the furnace temperature of the slab in the hot rolling process should be greater than 750°C; Normalize to make the grain size within the range of 90-110μm; set the temperature in the heating section of the continuous annealing furnace to 950-1150°C, set the temperature in the soaking section to 900-1050°C, and protect the grain size with nitrogen dry atmosphere to control the grain size to 120-170μm . The thermal history parameter control in the whole production process can give full play to the function of the designed micro-alloying elements and change the composition, size, shape and distribution of precipitates.

Owner:ANGANG STEEL CO LTD

Aluminum alloy rod for shielding

ActiveCN104805336BReduce crack sourceHigh strengthNon-insulated conductorsInsulated cablesRare-earth elementCerium

The invention discloses an aluminum alloy rod for shielding. The aluminum alloy rod for shielding is composed of the following components in parts by weight: 100 parts of aluminum, 0.04-0.06 parts of silicon, 1-1.3 parts of iron, 0.18-0.28 parts of copper, rare earth 0.08-0.1 parts of elements, 0.015-0.03 parts of boron, 0.01-0.02 parts of titanium, and 0.01-0.02 parts of beryllium; the rare earth elements are composed of lanthanum, cerium and scandium, and the ratio of lanthanum, cerium and scandium to 14:6:1 The rare earth elements are formed by mixing in proportions by weight. The metal structure of the aluminum alloy rod for shielding of the present invention is significantly improved, and the tensile strength and elongation are greatly improved after production tests and subsequent wire drawing, and the macroscopic grain size can reach 6-8 levels.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

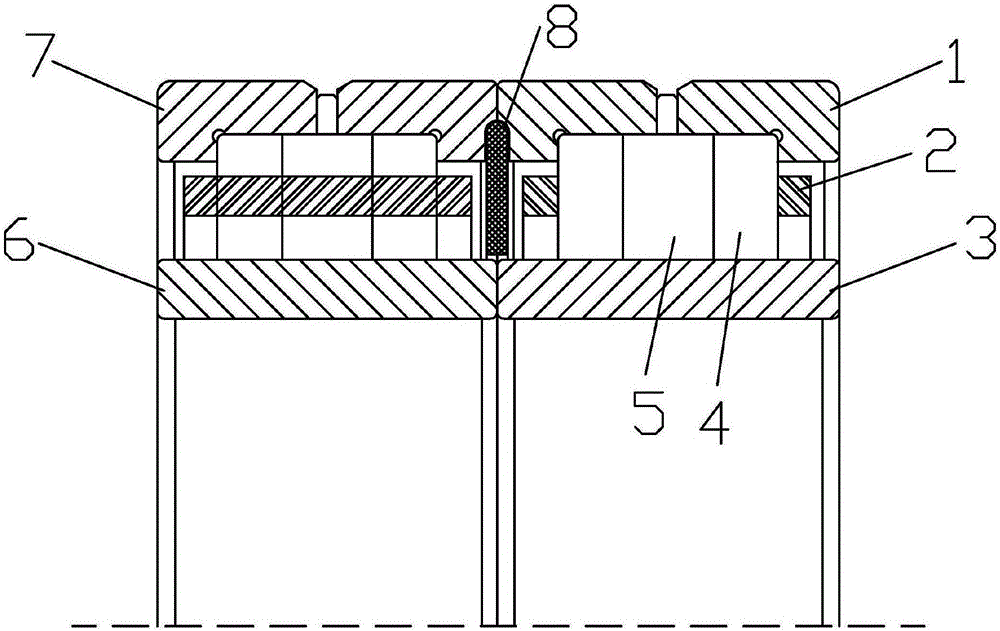

Cylindrical roller bearing

InactiveCN106195019AIncrease the lengthImprove carrying capacityShaftsBearing componentsEngineeringMechanical engineering

The invention discloses a cylindrical roller bearing. The cylindrical roller bearing comprises an outer ring, first cylindrical roller sets, a retainer, an inner ring and a check ring. The outer ring is composed of a first outer ring assembly and a second outer ring assembly which are arranged in parallel. An annular groove is formed between the first outer ring assembly and the second outer ring assembly. The bottom of the groove is of a semi-circular structure. The inner ring is composed of a first inner ring assembly and a second inner ring assembly which are arranged in parallel. The first cylindrical roller sets are arranged between the first outer ring assembly and the first inner ring assembly and between the second outer ring assembly and the second inner ring assembly. Each first cylindrical roller assembly comprises two first cylindrical rollers and a second cylindrical roller, wherein the second cylindrical roller is located between the two first cylindrical rollers, and the length of the second cylindrical roller is greater than that of each first cylindrical roller. The check ring is arranged in the groove. The check ring is of a circular ring structure.

Owner:WAFANGDIAN ZHENGDA METALLURGICAL MILL BEARING

Outer-wall external thermal-insulation anti-crack mortar prepared from superfine sand

The invention discloses an outer-wall external thermal-insulation anti-crack mortar prepared from superfine sand. The outer-wall external thermal-insulation anti-crack mortar consists of the following ingredients in parts by weight: 25-35 parts of cement, 62-72 parts of superfine sand with fineness modulus of 0.5-0.6, 1.0-3.0 parts of shrinkage reducing agent, 0.2-0.4 part of polymer modifier, 0.1-0.3 part of water-retaining agent, and 0.05-0.15 part of fiber. When the outer-wall external thermal-insulation anti-crack mortar is in use, all the ingredients are mixed with water added in a certain ratio as required on site and are stirred uniformly. Proven by experiments, the outer-wall external thermal-insulation anti-crack mortar has the advantage of solving the technical problems such as serious shrinkage and poor construction performance obstructing the use of the superfine sand with fineness modulus of 0.5-0.6 in the anti-crack mortar; and the anti-crack mortar with the ratio of compressive strength reaching 1.90, the bonding strength reaching 1.0MPa and long operational time reaching 2h is prepared and the anti-crack mortar meets the technical requirements of JG158-2004 ETIRS (external thermal insulation rendering systems made of mortar with mineral binder and nsing wxpanded polystyrene granule as aggregate) on the anti-crack mortar.

Owner:重庆钰居环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com